Appendix E

Background Information on Lessons Learned from Previous Re-engining Programs

BACKGROUND

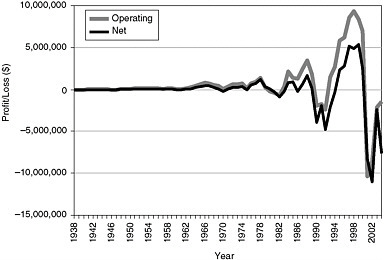

The air transport industry in the United States is capital intensive and has exceedingly low profit margins in comparison to traditional industries. In a recent year the airlines lost more money collectively than they had made cumulatively (and collectively) since their inception (see Figure E-1). The data in

FIGURE E-1 Airline profit history. SOURCE: Airline Transport Association annual data.

Table 2-1 reflect the activity of U.S. passenger and cargo airlines as defined by the U.S. Department of Transportation under Chapter 411 of Title 49 of the U.S. Code.1

Throughout most of its history, the industry worked under economic and regulatory constraints intended to provide a safe and economically viable national transportation system for the traveling public. The industry experienced a degree of economic deregulation in 1978, the intent of which was to allow market forces to drive the industry to the appropriate size and economic viability. Since the industry has never been fully deregulated from an economic standpoint, the intent of that legislative action was never fully realized. Following deregulation, a number of airlines, including some of the best-known international airlines, sought economic protections under Chapter 11, merged with other air carriers, or went out of business under Chapter 7 provisions.

In the early years (1930s) of the formation of the air transport industry in the United States, aircraft and engines were experiencing exponential growth as a result of technology development. Airlines were established and went out of business with great frequency. The regulatory agency—the Civil Aviation Association—was in its early development and concentrated its efforts on establishing regulations for the certification of personnel and equipment to meet safety and standardization requirements. At that time no incentives existed for airlines to conduct re-engining or engine performance improvement studies because improved aircraft and engines were entering the marketplace continually.

In the 1940-1950 decade, the air transport industry flew aircraft developed before World War II, and since all aviation materials were committed to the war effort, little activity was dedicated to improving performance or re-engining, except for engine modifications required to maintain airworthiness.

In the next two decades, 1950-1970, the airline industry initially adapted aircraft and designs primarily developed for military applications. The last models of piston-powered aircraft stretched the limits of altitude, range, and power for the technology of the time. Individual airlines resisted, then embraced, turbojet-powered aircraft as a means to go farther, faster, and higher in order to gain their share of the transportation market. Once again, the development of structural, aerodynamic, power plant, and systems technologies regularly led to new airliners with better performance. Traditional thinking was to operate an aircraft type until a newer aircraft reached the market that provided significantly better cost or revenue generation or until the growth in maintenance cost dictated replacement (generally every 15-17 years or less). Once again, not much was known about re-engining, and engine modifications were undertaken predominately to maintain airworthiness standards.

During the 1970s and the first part of the 1980s, the airlines were in the midst of the feast-or-famine days of deregulation. For the first time ever, major air carriers were gathering the assets of other carriers as those carriers ceased to exist, in order to meet the capacity demand unleashed by relatively unrestrained growth. Significant efforts were devoted to aircraft and engine technology modifications to achieve standardization within the hodge-podge of airline fleets that was coming into being. Immediately prior to and during this period, aircraft were commonly “overbuilt” with respect to structure to overcome the limiting factors of design technology and tools and to meet the overriding requirement for long-term structural strength.

Engineering tools and technology combined during the later 1980s through 2000 to provide aircraft and engines that were optimally designed to meet the range and payload requirements of their intended use. Excess structure was eliminated, and new materials and techniques were employed to ensure that an aircraft would meet certification and service life expectations while having the lowest practical empty weight in order to reduce fuel consumption. Computer-aided design and manufacturing techniques al-

|

1 |

More information on Chapter 411 may be found at http://www.law.cornell.edu/uscode/uscode49/usc_sup_01_49_10_VII_20_A_30_ii_40_411.html. Last accessed on January 22, 2007. |

lowed engineers to optimize aerodynamics and manufacturing techniques to minimize weight and drag. At the same time, aircraft and engine development and certification costs increased significantly. Not only because of economic constraints but also because these optimizations have for the most part already been carried out, there are unlikely to be future opportunities to improve fuel efficiency to justify re-engining a new generation of aircraft. Engine modifications will probably continue to be required for reasons of airworthiness, and it is possible that engine modifications or upgrades may provide an opportunity to maintain or improve performance and to realize fuel savings.

GENERAL FINDINGS

Analysis

The technical requirements to determine the cost/benefit of engine modification, upgrade, or re-engining are much the same for the commercial and military fleets. Basic engineering, maintenance, materials, and operational considerations are the drivers of such studies.

Airline experience includes relatively frequent modifications to existing engines in order to maintain airworthiness, to comply with environmental requirements (noise/emissions), to retain or improve performance (generally with respect to temperature), to reduce recurring maintenance costs, and to provide standardization and commonality between different engines within an airline’s fleet. Although airlines generally handle their airframe and engine maintenance programs as totally independent activities, aircraft utilization of about 3,000 hours per year generally provides ample opportunity to modify engines.

Both the capital investment and the operational costs to accomplish engine maintenance are relatively high. For this reason, airlines that choose to do in-house engine maintenance generally plan for an uninterrupted flow of engines through their facilities. In addition, the Federal Aviation Administration (FAA) publishes engine-oriented airworthiness directives (ADs) when needed to address potential safety issues. These ADs stipulate maintenance and/or engineering action on the part of the airlines that must be accomplished in a timely manner. These operational and safety concerns frequently result in the recall of an engine for maintenance before its scheduled time. Such a proactive effort can result in a separation of the induction programs for airframe and engine maintenance. This allows the airlines to accomplish engine modifications, whether mandated or self-initiated, relatively quickly.

Airline technical organizations work with their internal finance organizations to develop a business plan for review of potential engine modification, upgrade, or re-engining. Generally, an original equipment manufacturer (OEM) or other outside entity is employed to assist in the verification/justification process. Developing a cost/benefit analysis involves determining the following parameters:

-

The fully burdened cost of the various alternatives, including these:

-

Engine kit costs

-

Accessory costs

-

Airframe modification costs

-

Operating inventory costs

-

Man-hour costs for program engineering and maintenance

-

Certification costs

-

Technical manual/documentation costs

-

Maintenance costs related to inspections and shop visits

-

-

The indirect costs of the engine alternatives, including these:

-

Weight empty impact

-

Out-of-service time costs

-

Costs of training for flight crew, maintenance crew, and station crew

-

Costs of training out-of-service personnel

-

The service life remaining to verify financial return on investment, including these:

-

Structural life verification

-

Maintenance cost escalation

-

Aircraft systems life/cost verification

-

-

The benefits of various engine alternatives:

-

Maintenance shop visit cost reduction

-

Fuel consumption savings (trip cost impact)

-

Performance improvement, where applicable, in takeoff distance, time to climb, cruise altitude, landing distance, range, payload, and reduced thrust opportunities

-

LESSONS LEARNED FROM COMMERCIAL RE-ENGINING PROGRAMS

Re-engining Experience

In recent history only one aircraft series, the DC-8-60 series, was re-engined by major airlines of the U.S. air transport industry. The experience of one passenger airline that conducted a conversion of JT3D-3 engines on a DC-8-61 aircraft to CFM56-2 engines reported that standard net present value (NPV) calculations of cost/benefit directly tied to the program were relatively accurate. The program met all of its expected financial and operational goals to the point that the trip costs for the newly re-engined DC-8-61 were the best of all the airline’s fleets (six different types of aircraft) except for the 767 aircraft that was then in delivery to the airline. The DC-8/JT3 combination was an ideal candidate for re-engining because the DC-8 had significant structural reserves and the CFM56 turbofan engine had better efficiency and performance than the first-generation turbojet JT3D engine.

Unplanned Costs

Unplanned costs extraneous to the re-engine program resulted from the growth of costs for regulatory, marketing, and flight operations. Due to an increase in FAA ADs, aircraft downtime provided the opportunity to campaign the aircraft to complete the AD requirements in an accelerated manner rather than to suffer the detrimental effects of accumulated and nonproductive, repetitive access and inspection activities. In addition, completing the projects as quickly as possible averted a potential adverse psychological impact on safety and reliability.

Marketing took the opportunity to modify aircraft interiors in order to make them more attractive to airline passengers. It is seldom possible to verify cost/benefit analyses of such activities.

Flight operations took the advantage of aircraft downtime to standardize the various cockpit configurations that resulted from first-time-ever purchases of aircraft from other airlines. Although this project was not rigorously scrutinized from a cost/benefit standpoint, it made consummate sense from the standpoints of standardization and labor/management relationships.

These projects were not considered in developing the business case but became priorities that arose during the time between program justification and implementation. These costs were later justified independently and added to the overall program man-hours, materials, and operating inventory and out-of-service costs.

Operational Contribution to Unplanned Costs

The most dramatic unplanned impact on the re-engine program resulted from concurrent changes in air traffic control procedures that kept all airline aircraft at cruise speed and cruise altitude until they were close to major airports. This was done for reasons of fuel conservation and traffic volume. The re-engining program produced aircraft with less cruise drag and higher residual thrust at idle throttle, making it more difficult for the flight crews to slow down and get down. Since the DC-8 does not have brakes to control in-flight speed, the pilots used the flaps (at limit flap speeds) to create the drag needed to slow down before descending. This use of the flaps generated significant uncalculated and unplanned structural loads. In addition, the thrust area that impacted the flaps in the landing configuration had higher residual level and was greater than that of the JT3 engine. A “thrust gate” had been provided on the flaps to reduce the area of impact of the JT3 engine, but the core of the engine impinged on significant wing surface around the thrust gates and on CFM56 fan thrust patterns. As a result of these unplanned loads, one of the aircraft suffered a flap retention failure that almost resulted in the loss of a flap. Corrective action involved an emphasis on proper flap use during transition and recurrent flight crew training periods, much less time between flap inspections, and the replacement of damaged parts. These actions affected costs.

LESSONS LEARNED FROM MILITARY RE-ENGINING PROGRAMS

Similar to the passenger airline re-engining program that replaced JT3D-3 with CFM56-2 engines on DC-8-61 aircraft, the KC-135 re-engining program turned out to have accurately predicated performance improvement. However, the standard NPV costs and benefits calculated in the course of initial program justification could not be substantiated. Significant changes in quantities of aircraft and in the duration of the modification program reduced the benefits that had been projected by the initial cost/ benefit analyses. That being said, and although force structure and operational utilization are not within the scope of this study, the data clearly indicate a dramatic increase in the mission utilization rate for KC-135 tanker aircraft with the new CFM56-2 (F108) engines. Re-engine programs involve much more than adding new engines on the wing.

Additional Capability

As part of the KC-135 re-engining program a new, heavier-duty main landing gear was added. This modification was not required because of the new engines, but was undertaken to exploit the increased thrust available and to allow the aircraft to completely fill their fuel tanks, which had not been possible for the power-limited KC-135 with J57 engines. There is often a natural inclination to take advantage of the analysis, test, and verification efforts of an existing modification program by adding new capability at the same time. This was and can be a cost-effective approach to increasing the capabilities of an aircraft, but the added costs and benefits of such modifications are not considered as part of a re-engining program.

Complexity of the Modification

There is a general lack of understanding of the magnitude and complexity of any re-engining program. A re-engining program affects just about every system on an aircraft (electrical, hydraulic, pneumatic, aerodynamic flight controls, avionics, and structural). In addition to the modifications to the

aircraft itself, a significant effort to revise the technical manuals (performance, aircrew, maintenance, training, and repair), as well as support equipment, initial spares, maintenance concepts, and engineering substantiation analyses, is required. Engine accessories have to be changed, even if the selected engine is a commercial in-production aircraft, to meet military mission requirements. Even engines of the same thrust range will require significant analysis and certification effort, whether to FAA or military standards. Because a re-engining program impacts so many aircraft systems, obsolete and line replaceable units having a low mean time between failures are also replaced with newer alternatives and become part of the modification.

Program Schedule and Cost

For various reasons the Air Force failed to take advantage of favorable schedules or prices for acquisition and installation during the KC-135 re-engining program. Schedule extensions and annual purchases that were less than the best economic quantity increased total program costs. Multiple changes to production quantities and schedules further increased costs. These changes resulted in increased acquisition cost, a longer payback period, and fewer modified aircraft.

Future Re-engining Potential

Aircraft and their engines and weapons systems are designed in an integrated fashion to provide optimum performance and characteristics for planned missions. Unexpected costs and/or operational implications are likely to result from any change to the engines regardless of how much planning and analysis was committed to the development of the program. These risks can be mitigated by the involvement of all of the organizations affected by the program (engineering, maintenance, material, flight operations, technical publications, training, finance, etc.). This multiorganizational approach will help to prevent program surprises but is an impediment to rapid action in the face of high-priority economic, operational, or regulatory needs.

Commercial Re-engining

It is unlikely that next-generation commercial aircraft will lend themselves to potential re-engining campaigns in the near term, because the engines and airframes are highly optimized to meet service requirements, engine technology is not improving sufficiently or fast enough to justify significant expense, and structural and certification constraints pose a significant cost burden that will be difficult to bear.

Military Re-engining

Conceptually, re-engining large, nontactical military aircraft remains an attractive option for three reasons: (1) the low utilization rate leads to much longer service life for the weapons systems, (2) the probability of major advances in engine technology increases along with the service life of the weapons systems, and (3) mission suitability generally transcends financial considerations as the primary analysis criterion.