6

Other Considerations

This chapter discusses additional factors that may lead to increased fuel efficiency, including aerodynamic modifications, optimization of operations, maintenance practices, operational practices, and aircraft weight management. It also covers benefits other than increased fuel efficiency of re-engining the large nonfighter aircraft fleet.

AERODYNAMIC MODIFICATIONS

This section discusses three areas—winglets, laminar flow nacelles, and airframe modifications unique to the C-130—where aerodynamic modifications may increase fuel efficiency in the large non-fighter aircraft fleet.

Winglets

As presented by the Air Force Scientific Advisory Board (AFSAB), aerodynamic improvements from wing retrofits such as winglets may improve fuel efficiency by as much as 7 percent over current performance (AFSAB, 2006; Karagozian, 2006). While this option is not necessarily feasible for all the large aircraft in this study, the potential exists for winglets to aid a large portion of the Air Force and DoD fleet. Industry has designed and installed winglets on the 737-700/800, 737-300, and 757-200 aircraft, and they have been designed and are available for installation on the 737-900, 767-300ER, 757-200, and 737-500; a winglet for the 777-200ER is in product development (Inman, 2006).

Demonstrated benefits of blended winglets installed on commercial aircraft include lower block fuel, lower emissions, improved takeoff performance, which leads to better initial cruise altitudes, reduced engine maintenance costs, and increased payload range capability (Lombardo, 2003; Inman, 2006). While there is not a direct mapping from the commercial aircraft listed above, some large Air Force aircraft are similar enough that benefits of winglets can be predicted, and the benefits are expected to be great.

The block fuel improvement per aircraft at the design range is between 4.0 and 4.9 percent for the

737-300/700/800 and 757-200 and is estimated at 5.7 percent for the 767-300ER. The resulting potential annual fuel savings per aircraft is 100,000-110,000 gal for the 737-300 and 737-700, respectively; 130,000-150,000 gal for the 737-800 and 737-900, respectively; up to 300,000 gal for the 757-200; and up to 500,000 gal for the 767-300ER (Inman, 2006).

According to Inman, “With over 1,080 commercial aircraft currently flying with blended winglets, commercial airlines are currently saving 107,700,000 gallons per year…. Assuming APB’s projected delivery rate, by the end of 2010 blended winglets will have saved the commercial airlines approximately 2,000,000,000 gallons of fuel” (Inman, 2006).

Though this study is focused on fuel savings, blended winglets also reduce maintenance costs because the aircraft do not need as much thrust to achieve the same climb and cruise performance. In addition, blended winglets improve performance when operating in airfields that are at high altitudes and/or in hot environments and from airfields where operations are limited by obstacles or climb (Inman, 2006).

The uninstalled cost of blended winglets for the 737-700 and the 737-800 is $725,000 per kit. It is $850,000 per kit for the 757-200 and $1,500,000 per kit for the 767-300ER (Inman, 2006). Installation costs vary by aircraft but are not prohibitively high.

There is significant synergism between reductions in thrust-specific fuel consumption (TSFC) and aerodynamic improvements by means of increases in lift/drag (L/D) (Karagozian, 2006). The winglet modification increases L/D. This is shown in the Breguet range equation:

where TSFC is fuel flow rate/thrust, Wfuel is fuel weight, Wpl is payload weight, and Wo is operating empty weight (OEW).

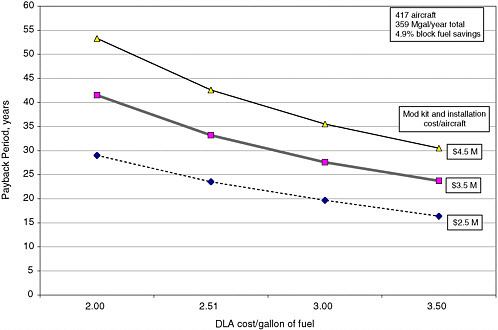

A 10 percent decrease in each of the three parameters—TSFC, L/D, and OEW—would result in a fuel savings of ~28 percent (Karagozian, 2006). While more specific analysis is required to determine which aircraft could be modified by adding winglets (including a structural analysis of the existing wing), it is possible to analytically determine the significance of installing winglets on some aircraft. The committee presents an example based on 417 KC-135R aircraft to make the point. The assumptions used in the example are as follows:

|

Kit cost: |

$1.5 million per aircraft |

|

Installation cost: |

$1.0 million, $2.0 million, and $3.0 million per aircraft |

|

Fuel used: |

359 million gallons (FY96-FY05 average) for the fleet |

|

Block fuel reduction: |

4.9 percent (by analogy to the 767-300ER) |

|

Fuel saved: |

17.59 million gal/yr |

The cost of modifying the KC-135R is not knowable until the wing loads and structure have been thoroughly studied. However, in 1981 there was a National Aeronautics and Space Administration (NASA) KC-135 winglet study (NASA, 1981a) accompanied by a flight test of winglets on a KC-135A in 1981 (NASA, 1981b). It was noted that parts of the wing probably needed to be strengthened. At this writing, the committee has insufficient knowledge of what wing modifications would be needed to make a precise calculation, so it parameterizes the modification cost to be $1 million, $2 million, and $3 million per aircraft. While this may or may not be an adequate representation of the modification cost, it illustrates the point. Another of the variables in this calculation is the cost per gallon of fuel. Figure 6-1 shows the relationship of payback period to cost of fuel per gallon for fuel saved and the modification cost per aircraft. The costs plotted here do not take into account NPV.

FIGURE 6-1 Winglet modification payback period vs. modification cost and cost of fuel. DLA, Defense Logistics Agency. SOURCE: Committee generated.

As can be seen in Figure 6-1, the more expensive the fuel the more cost-effective the modification can be, assuming that the Air Force can negotiate a reasonable cost for the winglet kit and modification. In this example, using $2.5 million as the modification cost per aircraft and the current cost of fuel ($2.51/gal), the payback period is 23.5 years. At $3.00/gal, the payback period is 19.7 yr, and at $3.50/gal, the payback period is 16.41 yr. If the modification cost plus the cost of the kit were $4.5 million per aircraft, the payback period would be correspondingly longer, as shown in Figure 6-1. In this specific example, at a replacement rate of 24 new aircraft per year, it would take the Air Force more than 17 yr to replace the 417 aircraft, and at 12 new aircraft per year, the time to replace would be 34.8 yr. Straightforward calculations such as these, along with an analysis of the wing itself, permit the decision maker to make an informed choice.

This simple example is not meant to minimize or oversimplify the engineering and cost analysis that goes into a decision like this. While there is a potential to save fuel—and, thereby, money—the costs of modifying an aircraft, particularly aircraft that are more than 40 years old, may be substantial. The only way to understand the potential benefit is to do the analysis, including the engineering analysis.

Finally, it may be that a greater good argument prevails and that the decision is made on more than

economic grounds, in which case the controlling variable is saving fuel, not at any cost but at a reasonable cost.

Finding 6-1. A deeper study of the use of winglets on Air Force nonfighter aircraft is warranted and will be carried out at a later date.

Finding 6-2. The Air Force has no control over the cost of fuel. Money has to be spent to save fuel. The expected remaining life of a fleet of aircraft relative to the payback period determines if such a modification would be cost-effective.

Recommendation 6-1. Operational suitability must be taken into account during both flight and ground operations. Once the engineering and operational suitability analyses have been done and the cost of modification (to include loss of aircraft availability) has been determined, the cost-effectiveness calculation is straightforward and must be considered for each type of aircraft as a function of remaining life. Because the Air Force has some control over how long it keeps a given fleet of aircraft, it can exert some leverage with respect to the modification cost per aircraft.

Laminar Flow Nacelles

Another opportunity for increasing L/D is through the use of laminar flow nacelles. The elimination of most of the turbulent skin friction drag on the nacelle reduces aircraft drag by approximately 1 percent.

The laminar flow technology for nacelles relies principally on shaping the outer nacelle profile so as to provide a long run of stable laminar flow over most of the length. Nacelles are short enough so that this can be readily accomplished. Further, the maximum outside diameter of the nacelle is not affected. The nacelle surface must be smooth and clean for this technology to work—no steps or gaps, however small. A number of studies also consider the use of suction, in addition to shaping, to make the laminarization more robust. This technology has been around for some time but has not so far been adopted into commercial aircraft operation.

Boeing is incorporating laminar flow nacelles into its 787 aircraft. This is done by having a smooth, continuous, single-color painted surface on the nacelle. Paint edges due to multiple colors would be enough to trip the boundary layer and must be avoided. This technology could best be incorporated into nonfighter aircraft by shaping alone, with smooth external surfaces (no suction). The nacelle surfaces would need to be cleaned frequently and monitored for surface defects.

Since there is no commercial experience with this technology, it is hard to estimate costs. Installation might require modifying the engine mount to accommodate the altered external shape of the nacelle, modestly increasing the maintenance cost. But the possibility of a 1 percent reduction in drag would justify consideration of this technology in re-engining.

Recommendation 6-2. Laminar flow nacelles should be considered as an option when re-engining aircraft that have pod-mounted nacelles.

Airframe Modifications for Fuel Savings Unique to the C-130

Several modifications could result in fuel savings. The first is trimming the ailerons to redistribute wing loading in cruise condition (the original purpose was to reduce the bending moment at the wing

root and provide an improvement in wing spar life). An unanticipated side benefit was found to be a significant reduction in drag at cruise. For example, with a –8 degree up-rigging of the ailerons, the drag reduction in cruise would reduce fuel consumption about 1.3 percent.

The addition of aerodynamic strakes at the rear of the aircraft has also been shown to reduce drag. In this case the improvement in fuel consumption was about 3.2 percent, but together the two modifications should improve fuel consumption about 4.5 percent for a modest investment. Lockheed also suggested that significant drag reductions might be possible through careful attention to and reconfiguration of the defensive measures and avionics devices that have been added to the aircraft in recent years. It gave as an example an antimissile device installed external to the airframe, significantly increasing drag (O’Banion, 2006).

Finding 6-3. Relatively simple and inexpensive devices can significantly reduce drag, with concomitant improvements in fuel consumption.

Finding 6-4. Airframe modifications for devices such as weapons racks, sensors, and electronic countermeasure (ECM) systems can increase fuel consumption if the potential for increased drag is not considered prior to installation.

Recommendation 6-3. The Air Force should conduct a detailed study to evaluate the potential for fuel savings from aileron up-rigging and strake modifications on the C-130. Aileron up-rigging may also be of benefit on other aircraft in the fleet, and a computational fluid dynamics study should be initiated to evaluate the potential for this modification.

Recommendation 6-4. Airframe modifications for devices such as weapons racks, sensors, and ECM systems should be evaluated with respect to their potential for increasing drag and fuel consumption. The fastest and cheapest way may not be the best way when all factors are considered.

OPTIMIZATION OF OPERATIONS

Commercial airlines have been able to reap significant cost savings by optimizing their planning and operations. For example, United Parcel Service management credits an optimization-based planning system for its aircraft network with having identified operational changes that had saved more than $87 million as of 2003, and it is anticipating additional savings of $189 million through 2014 (Armacost et al., 2004). Likewise, fractional aircraft operators, despite the probabilistic nature of business passenger demand, reap significant benefits by optimizing their operations. Indeed, the stochastic nature of business passenger demand is in many ways similar to that of military operations during a conflict, thus pointing to the applicability of optimization to the real-time replanning that is characteristic of wartime operations.

For monthly planning and real-time replanning, decisions are typically made by the planners and operators without advanced decision support. However, they do have access to comprehensive data systems. This situation is similar to the situation that existed at commercial airlines in the early 1990s. Based on the significant financial impact of schedule irregularities caused by weather—snowstorms, hurricanes, etc.—airlines have partnered with information technology firms to develop state-of-the-art decision support systems that assist their controllers in making tactical decisions about operations. Most of the concepts behind these systems are an outgrowth of academic research done in the late 1980s

and early 1990s at the Massachusetts Institute of Technology (Clarke, 1997), the Georgia Institute of Technology (Lettovsky, 1997), and the University of Texas at Austin (Bard et al., 2001).

In the last decade, airlines have come to appreciate the value of centralized decision making across multiple disciplines that pertain to their operations. By moving to a centralized operations center, each operational department within the airline is better able to understand and appreciate the impact of its decisions on downstream decisions and dependent activities. The development of the airline operations control center and the introduction of real-time decision support systems have enabled airlines to minimize flight cancellations and delays and ultimately improve operating profits (Clarke et al., 2000). For example, Continental Airlines was awarded the 2002 Franz Edelman Award for Achievement in Operations Research for the implementation of CrewSolver (developed by Caleb Technologies), which was reported to have saved $40 million in recovery costs in 2002, most of it attributable to its post-September 11 performance (Yu et al., 2003).

For more operational/tactical planning and execution, Air Mobility Command (AMC) has a division known as the Tanker Airlift Control Center (TACC). Here, much of the work is done manually (Nielsen, 2002). Some optimization work was done in the late 1980s and early 1990s using a system developed by Oak Ridge National Laboratories (ORNL), called Airlift Deployment Analysis System (ADANS) (Harrison et al., 1991). It used some optimization methods (mostly heuristic) and reported success in its work in support of the first Gulf War (ORNL, 2006). Components of ADANS were built into the Consolidated Air Mobility Planning System (CAMPS), which is currently in use at TACC. The planners, however, do not use the planning functions of CAMPS; instead, they use the system to manage data but make decisions based on experience and intuition (Nielsen, 2002).

A recent Broad Agency Announcement from the Air Force Research Laboratory (AFRL) seems to be a move in the right direction. It calls for the development of optimization methods that could be included in future versions of the AMC decision/data tools, such as CAMPS and the Global Decision Support System. However, recent work by Koepke on real-time execution and replanning (Koepke, 2004) has not been implemented.

Finding 6-5a. The commercial airline industry has reaped significant benefits from the introduction of optimization in both its planning processes and its daily operations.

Finding 6-5b. While the Air Force has implemented some optimization in its planning processes, it appears that the commercial airline industry has done so to a greater extent, especially in its daily operations, resulting in significant cost savings.

Conclusion 6-1. Optimization of Air Force operations could reduce the fuel consumption of non-fighter operations and should therefore be aggressively pursued.

Recommendation 6-5. The Air Force should study optimization and, where it has already done so, accelerate the implementation of optimization in all aspects of its operations, especially as it relates to maintenance and overhaul and to the scheduling of its cargo, passenger, and tanker fleets.

MAINTENANCE PRACTICES

There are several fundamental ideas that are critical to the understanding of the maintenance process. First, maintenance is a restorative process that at best returns the deteriorated equipment to its original design specifications. It cannot improve on the inherent capability, which is designed into the equip-

ment. However, the maintenance process can identify design deficiencies. It can also be a good time to incorporate design changes to correct flaws and shortcomings. It is important to recognize that once the design is modified the maintenance process must be reviewed to see if it is still applicable and effective. Second, today maintenance is less about turning a wrench than about gathering information on the equipment and how it operates. Too often, however, this information is not collected, not understood, or not taken advantage of to correct deficiencies and improve the maintenance process.

Maintenance evolved primarily from practical hands-on experience. If something failed, you either repaired or redesigned it. It depended in the earlier stages mostly on the knowledge of the maintainer and his or her skills. It tended to be reactive rather than proactive. Analysis of the maintenance skills and processes lagged behind analysis of the design process. Now, however, with the growing complexity of the new equipment and the burgeoning cost of operating it, maintenance has become more dependent on data and less dependent on the skills of craftsmen. It is being driven by information systems that better analyze trend data and by better information about the inherent operating characteristics of the equipment through better sensor technology and real-time diagnosis.

Unfortunately, quite often this new knowledge is not well transmitted to the people who touch the equipment and whose hands-on experience prevails over available diagnostic and analytical tools. This conflict often clouds longer-term solutions and allows deterioration beyond the obvious. Performance deterioration that occurs over longer periods of time may not get the same attention if the failure is not obvious.

Consequently, over the years some of the more obvious deficiencies, such as mechanical failures or structural problems, are cured at the expense of the more subtle deterioration caused by aerodynamic anomalies or small and not so obvious deteriorations of seals, clearances, etc. The human eye is still the primary driver of the restorative process. The closer the maintainer is to the equipment, the more effective the maintenance.

There certainly are more and more tools available, but they have not changed the maintenance process nearly as much as they have improved equipment reliability. Maintenance has lagged both culturally (in terms of the acceptance of change) and technically (in terms of the use of information technology to identify systemic trends).

However all is not hopelessly slow, and change is indeed taking place. On-wing condition and failures are being bound together in a holistic approach, whereby maintenance shops and maintenance on the line and away from the shops and the actual operating events are being slowly tied together. As the maintenance process evolves, it becomes easier to track more subtle deterioration such as fuel burn and aerodynamic degradation and not just pending mechanical failures.

To maintain engines at their optimal efficiency, new strategies of maintenance must be undertaken. Of note, however, none of these strategies will produce optimal results by themselves; they are intrinsically tied together.

The first consideration in any policy regarding engine maintenance is that fuel savings and good fuel consumption are generally not the primary focus of maintenance but are the result of building an engine to a standard as close to the optimal design limits as possible. Engines built to higher standards tend to be more efficient and may have higher maintenance costs up front; however, these costs are spread over the life of the equipment. This is not an insignificant issue in determining build standards. Too often the cognizant authority will build engines to a low-cost standard from a shop visit standpoint, saving short-term costs. This may not be the most economical build from the standpoint of life-cycle costs (LCCs). It is critical that the objectives of the shop and the objectives of total cost are aligned. Engine shops have a great deal of flexibility to exercise economic judgments, which may have longer term consequences to transfer cost to other areas. There are numerous examples where shortsighted build standards lead to

short time on the wing, high fuel consumption, etc. It is critical that the build standards are developed with the objective of minimizing LCC, not just obtaining parochial benefits.

The second consideration for fuel efficiency is that the engine is only one part of an integrated airplane system. Thus to create a high standard in the shops but install these engines on only deteriorated airframes negates some of the benefits. Thus, the maintenance policy regarding fuel consumption must be developed for the aircraft as well as the engine.

The third element of the strategy is to gain a comprehensive knowledge of the condition of the equipment. This involves information systems that track not only operational data but also data on shop and build. Necessary information elements include aircraft fuel burn, engine build standards, and work performed in the shop and on the line. This information, too, must be viewable from a holistic not just a parochial perspective such as the engine shop or on the line. This requirement for data that will allow understanding fuel consumption and its dynamics means there must be an organizational structure and data systems in place that can track both on- and off-aircraft information and determine build standards and other actions involving the aircraft. These systems must be in a position to affect the outcome of maintenance. Rarely is there a global or comprehensive information network that captures all the relevant data or an integrated organizational structure that can analyze the available data.

This then leads into a discussion of strategies for maintenance and some understanding of what it takes to both manage the mechanical condition of the equipment and optimize its performance.

On-Wing Programs

On-wing programs require (1) an understanding of the various conditions of the aircraft that can cause mechanical malfunction and operational deterioration; (2) a history of the maintenance that was done; and (3), most importantly, a set of measures and procedures for efficient operation of the equipment.

The following discussion includes some of the strategies that might be able to assure better fuel burn of the air and engine system.

Mechanical Condition of the Aircraft

A program must be developed that takes into account some of the systems that if not operating properly can adversely impact fuel burn. Some engine instrumentation, such as instruments measuring engine pressure ratio, requires accurate air data. Often pneumatic leaks can cause a misleading reading in aircraft not being flown correctly. Leaks are common on older aircraft, and slight anomalies in engine indications can cause significant power differences between engines. This, in turn, causes deviations from optimal operating conditions and often leads to excessive trimming and, in some cases, subtle flight control deflections, which can adversely impact fuel burn. Instrumentation, especially with air-driven instruments, is one of the primary causes of excessive fuel burn.

Aircraft Pressurization System

Good maintenance here can prevent unnecessary fuel burn. Making sure that the aircraft is not leaking is very important, and programs to assure that the aircraft is properly sealed will yield significant benefits:

-

Seals. While aerodynamic cleanliness often keeps maintainers busy with little payback, there are some areas where paying attention can and does have significant benefits in fuel savings. Making

-

sure that seals between the lower and upper wing are in good condition, especially on the leading edges, is one such area.

-

Flight controls. It is imperative that flight controls are properly rigged. Floating spoilers, flaps that are not properly seated, ailerons not properly rigged—all can have a very large impact on fuel burn. Large surfaces such as rudders are especially critical, and not only if they are out of rig but also if the engines are not producing symmetrical thrust, they can cause excessive fuel burn.

-

Good housekeeping. Simple actions such as keeping the leading edges clean and free of excessive dents and making sure the pitot static line is free of bugs and obstructions can have large benefits. Occasional washing of the aircraft, weighing of the aircraft, and, of course, engine wash all lead to better operations and in some cases significantly reduced fuel burn.

-

Engine wash. Engine water wash has been used successfully by commercial airlines for many years routinely to restore exhaust gas temperature margins and, in some cases, improve engine performance, including fuel burn. It is a standard practice that has proved to be effective and is recommended by the engine manufacturers as well. This is a very economical process that has great benefits for very little effort. If no such wash program exists, the committee recommends that one be introduced for the entire Air Force engine inventory.

Engine Maintenance Programs

Once the engine is in the shop, restoring its proper operating parameters is the goal. However this generally focuses most on what caused the engine to be removed, what can bring it back into specification, and its obvious faults and failures. Consequently, programs need to be put in place where there is sufficient knowledge about the condition of the engine, relationship of fuel burn deterioration versus time, and the modification levels available to assure good operating parameters.

As mentioned above, the key to engine maintenance in the shop is in-depth systems for gathering and analyzing the data that identify those deficiencies, the frequency of occurrence, and their relationship to other repair requirements so that a build standard can be developed not only to repair obvious failures but also to restore efficiency. A competent engineering staff that can dictate restoration requirements and a rigorous data system that provides the necessary information before and after repair are critical to this effort.

SFC and fuel burn information are critical data inputs for repair. In addition, certain parts of the engine that have a greater impact on fuel burn—e.g., compressors—may be applicable. Finally, ensuring that engine externals, such as bleeds, perform to specification may further benefit fuel consumption.

Information, Data Requirements, and Organizational Structure

Historically, engine data tended to be controlled vertically in functional areas. Too often, the shop and the line did not cross-feed information. Also too often, the expertise that resided in the shop did not have access to line operations personnel to advise them. This is not peculiar to the military, but it is exacerbated by the different contractors, locations, and the like that characterize the military. In the commercial sector there is a much closer tie to operations on the part of both line and shops. Since military aircraft are not designed for the same missions as commercial aircraft, the information challenges are much more critical.

Napoleon’s army marched on its stomach but the maintenance army marches on information. To fully benefit from the maintenance actions and processes it is essential that information systems are

available that give holistic views of aircraft fuel consumption, engine SFC, component reliability, maintenance schedules, reliability, maintenance actions, and histories of faults and failures of the various systems and components that make up the power plant–aircraft interface and that have an impact on fuel consumption.

While this study does not formally address information system requirements, those requirements must nonetheless be recognized as an essential element in achieving progress with fuel consumption. Lastly, the maintenance entity must be organized along the flow of information to assure that there is top-down and bottom-up access to all the knowledge that is needed to maintain the equipment. This knowledge cannot be isolated to functional areas. At the end of the information trail, there must be an organizational function that makes decisions across all the disciplines in a holistic fashion to ensure the greatest efficiency.

Finding 6-6. The creation of an integrated maintenance database, drawing from the military and civilian sectors in cases where common engine variants are used by both, is critical to achieving operational fuel efficiency. The commercial sector is a particularly good source of operating data because it experiences much higher utilization rates. The military can often gain insight, at no cost, on future problems and remedies.

Recommendation 6-6. The Air Force should undertake a review of maintenance requirements and how they affect fuel efficiency and/or fuel conservation. Additionally, it should have in place an organizational structure that will have the focus and authority to establish maintenance requirements across all operations. Additionally, the Air Force should undertake a comprehensive review of information systems to assure that repair histories and reliability information are being utilized in a holistic manner and being transmitted to the appropriate organizations—that is, those that have oversight responsibility for efficient operations and the ability to implement the required actions. Critical to this recommendation is the establishment of fleet manager programs to oversee the entire maintenance operation, both line and shop, and the development of a comprehensive information system to monitor the effectiveness of maintenance actions and fleet performance. The ability of an integrated database to inform a cognizant organization that has a say about the outcome of maintenance, whether in the field or in the shop, is a critical factor in achieving operational fuel efficiency. Lastly, the maintenance entity must be organized along the flow of information to assure that there is top-down and bottom-up access to all the information that is required to maintain the equipment.

OPERATIONAL PRACTICES

Operational practices affect fuel consumption. For example, aircraft configuration during taxi can affect fuel consumption. So can the use of an auxiliary power unit (APU) for power rather than ground power, chosen flight routes, training policies, etc.

Examples of actions the Air Force could take to reduce fuel consumption include the following:

-

Ensure flight planning is based on both operational requirements and optimal fuel burn requirements.

-

Use ground power where possible. Start tracking APU usage hours. Standard commercial practice is to assign an aircraft a parking spot upon landing and, if ground power is available at that location, not start the APU. Standard Air Force practice is to start APUs upon landing.

-

Taxi with as few engines as possible. Ensure that engine start and warm-up procedures, as well as shutdown and cooldown procedures, are in effect. Standard commercial practice is to start

-

engines when ready for takeoff. Standard Air Force practice on many aircraft, like the KC-135, is to start engines 30 min before takeoff.

-

Use available technology to analyze wind patterns and allow pilots to save fuel by flying at preferred altitudes and speeds, leveraging tailwinds and avoiding headwinds when possible.

-

Instill more scheduling discipline. Tankers frequently schedule a mission to refuel a given number of aircraft and end up refueling a different number. If scheduled refueling is canceled, the tanker is carrying extra fuel. Since aircraft in the area occasionally take advantage of a tanker’s availability, tankers often carry more than scheduled offload quantities of fuel.

-

Only fly the flying hours required to accomplish mission requirements. Air Force flight plans often call for fixed mission durations. Even if mission requirements are met using less than the scheduled flying time, aircraft often fly navigation or transition legs to use up the remaining flying hours. Change the headquarters and operational command cultures that grade units with metrics like flying all of the yearly flying hour allocation vs. meeting mission requirements and rewarding those units that meet mission requirements using fewer flying hours.

-

Review requirements that dictate reflying a functional check flight (FCF) for an aircraft coming out of program depot maintenance after the aircraft does not pass the FCF because a single system has failed. Conduct analysis to determine if some or most FCF refly can be eliminated by use of expanded ground or bench testing of failed systems.

-

Make sure pitot static tubes are clear and leading edges clean.

-

Ground ship equipment/supplies as much as possible.

-

Use ground power to heat and run electrical systems whenever possible.

Finding 6-6. Reduced maintenance costs and improved operational performance can have a significant impact on the benefits resulting from re-engining or engine upgrades. The preceding discussion notwithstanding, the Air Force is committed to quality and has adopted elements of six sigma, lean, and other quality principles in its practices and procedures. In addition, many of the companies that supply engines, parts, and components to the Air Force employ six sigma in their processes.

AIRCRAFT WEIGHT MANAGEMENT

The fuel consumption of an aircraft is primarily dependent on lift, drag, and weight. How closely, though, does the Air Force pay attention to the weight of the aircraft once it is put in service? Does the Air Force really know what the aircraft weighs? Does it really know what the cargo weighs? Does it really know how aircraft fuel consumption is affected by the weight of extra fuel carried onboard?

There are actions the Air Force could take in the near term that could positively affect fuel consumption, among them the following:

-

Establish a baseline of what is routinely carried on the aircraft (pallets, tools, etc.). Obtain fleet aircraft weight samples to determine the spread in actual weights, including by weighing some operational aircraft ready to go out on a mission and some empty aircraft. Weigh all the equipment that is put on aircraft such as repair kits, etc. Weigh all cargo; do not use estimated weights.

-

Revise operational practices to reduce unnecessary weight. For training flights, ensure aircraft are not carrying any equipment that is not part of the mission. Do not carry excess fuel since its weight increases fuel consumption. Review the need to carry remote station tools and equipment and make sure of their weight. Weigh all cargo until it becomes certain that the typical weights are accurate.

-

Revise maintenance practices to reduce unnecessary weight. Ensure aircraft are clean and not carrying lots of trash and dirt. Check insulation blankets for condensation, which can increase the weight of the blankets significantly—for example, the blankets for a 707 weigh more than 1,000 lb. Consider substituting lighter weight materials in floor panels, etc. (floors in KC-135s, for example, are made of plywood). Establish a maintenance weight program executive officer or equivalent.

The above are just a few examples (there are probably many more) of actions the Air Force could take in the near term to significantly reduce Air Force fuel consumption. One airline executive claims such actions saved his airline more than 100 million gallons of fuel last year against a 2004 baseline.

OTHER BENEFITS OF RE-ENGINING

Operational Benefits

The operational benefits and impacts of any given modification divide naturally into two categories:

-

Internal mission improvements, which result in directly calculable fuel savings on the same mission profile, and

-

Basing accessibility impacts, which can be translated into greater equivalent capability.

The operational benefits in the first category, “Internal mission improvements … same mission profile,” consist of shorter time to climb and an increase in cruising altitude. Reduced time to climb and increase in cruising altitude both translate directly into fuel savings (assuming the output demanded by the missions is constant). Savings from both were folded directly into the return on investments calculations.

It is less clear that the operational benefits from improved wartime basing can be reliably priced. Nevertheless, such operational benefits can be quite substantial, although the quantification is in terms of increased wartime capability rather than of dollars saved, as would be calculated in peacetime (see discussion above on force structure trades).

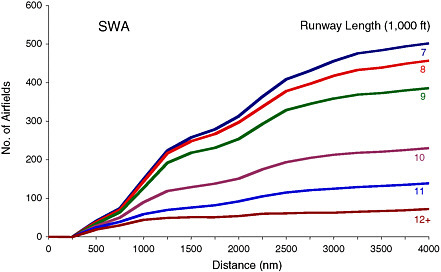

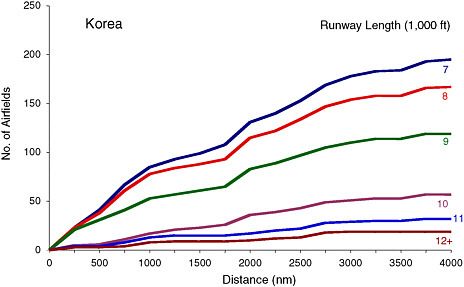

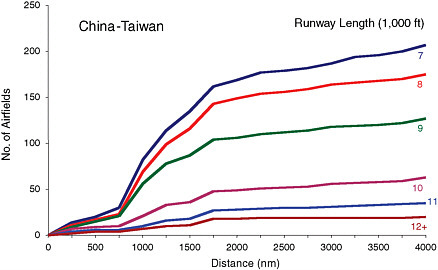

To illustrate the operational benefits from improved wartime basing, consider the distribution of bases and runways in three illustrative scenarios, which may be taken as typical of operations worldwide. Figures 6-2 to 6-4, provided by RAND, show availability of runways within a given distance of the designated point in nautical miles (nm) for these scenarios using the following rules:

-

At least one runway is operational.

-

Runways made of gravel or sand are not considered.

-

Runways must be in fair or better condition.

-

A runway is deemed suitable if it can support a C-17 or KC-135R taking off at 50 percent of maximum fuel load.

-

Maximum on ground, instrument flight rules, and other criteria are not considered.

-

Runway strength requirements are moderate.

To properly interpret these charts to determine the operational benefits of improved wartime basing, it is important to understand the following:

-

Each 500 nm increment to and from a given location is worth about 2 hr flying time, which can be a significant fraction of the total mission duration (they range from 5 to 20 hr, depending on

FIGURE 6-4 Scenario 3—China-Taiwan. SOURCE: RAND.

-

the mission). Hence, each 500 nm increment in improved basing might provide the equivalent of 10-40 percent more on-station time, or less refueling needed for the same station time, or more refueling capability, etc.

-

Because of the double transit time, bases more than 1,000 nm from the operating location (Combat Air Patrol point, refueling track, etc.) get less useful very fast, and operations beyond 1,500 nm consume enormous resources compared to the same operations from, say, 500 nm away.

-

While it might at first appear that there are many bases to be had, that perception is quite incorrect. U.S. uses of suitable bases must be negotiated in the run-up to the conflict or, worse, during the conflict. Such negotiations are generally difficult. The more bases available that are operationally suitable, the easier such negotiations get.

-

Runway lengths tend to group themselves into three major categories: (1) long (>10,000 ft), typically needed by heavily loaded aircraft equipped with older, low-thrust (generally lower-bypass-ratio) engines, (2) medium (7,000-9,000 ft), suitable for moderately loaded and often even heavily loaded aircraft equipped with modern, higher thrust (generally higher-bypass-ratio) engines, and (3) short (<6,000 ft), suitable for aircraft that are generally designed for such operations (like C-17 and C-130 aircraft).

-

Modifications that result in significantly higher installed thrust for the aircraft often allow the aircraft to operate on medium-length runways under the same operational safety rules that previously required long runways.

-

The ratio of number of medium to long runways in the important range of 250 to 1,000 nm from typical operating locations ranges from ~3 to ~7.

Consider the case where a fleet of U.S. aircraft can use medium-length runways. If that same fleet could only use long runways, U.S. negotiators would have only 1/3 to 1/7 as many available with which to negotiate the bed down. Put another way, to secure the same number of long runways in the mix as available medium-length runways at ~500 nm, one can see from the above charts that the bed down planning horizon would have to expand out from ~1,000 to (in some cases, such as Korea) well over 2,500 nm, and while operations at the latter ranges are not impossible, they are difficult and absorb enormous resources. This is, to say the least, important.

Environmental Considerations and Implications

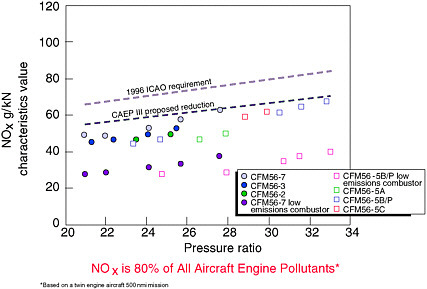

The impact of aircraft on environmental pollution (noise, emissions) is increasing. While nitrogen oxide (NOx) emissions from aircraft account for only about 3 percent of the total tonnage of the NOx emitted around the world and are therefore relatively small, they are forecast to become significant if nothing is done to regulate them. The commercial world has done this. Noise and emissions regulations of increasing stringency have been passed through the years. The Federal Acquisition Regulation (FAR) 36, Stage 3, regulation was passed in the United States in the late 1960s. It has since been updated and called Stage 4 (10 EPNdB cum tougher).

These strong U.S. regulations have been mirrored internationally by Annex 16 of the International Civil Aviation Organization (ICAO). Similar regulations for NOx and other pollutants have been passed by ICAO and are enforced internationally.

Carbon dioxide (CO2) is a harmful pollutant in terms of global warming. It affects the ozone levels in the atmosphere, global warming, and climate change (NRC, 2001). CO2 emissions are directly related to fuel consumption, so that any fuel efficiency improvements directly reduce global warming. Particulate, hydrocarbon, and sulfur emissions are also of some concern and should be taken into consideration.

Environmental factors need to be considered in the selection of engines. Aircraft noise and engine emissions bring increasing penalties when U.S. military aircraft are operated in some other countries. In the United States, environmental regulations are being waived for military operations, but this could change overnight, and the Air Force needs to be prepared for their reinstitution, especially on tanker and transport aircraft.

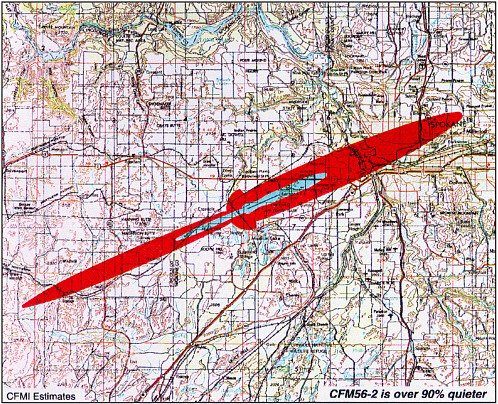

It is important therefore that any re-engining opportunities address environmental constraints. The CFM56 engine family meets the current NOx regulation, as shown in Figure 6-5. The dramatic noise reduction provided by the incorporation of the CFM56-2 (F108) on the KC-135 R is shown in Figures 6-6 and 6-7. The CFM56-2 powering the KC-135R airplane meets the FAR 36, Stage 3, regulations. A reduction in fuel consumption will also result in a reduction in CO2 emissions.

Recommendation 6-7. Any re-engineering decision of the Air Force should take into account the back-to-back evaluations on a platform—for example, the B-52H, E-8, and E-3—of the different engine options in terms of noise and pollution. In addition, platforms should be environmentally acceptable for a significant amount of time into the future.

FIGURE 6-7 Actual noise disturbance over Fairchild Air Force Base. SOURCE: CFM.

REFERENCES

Published

AFSAB (Air Force Scientific Advisory Board). 2006. Technology Options for Improved Air Vehicle Fuel Efficiency: Executive Summary and Annotated Brief. SAB-TR-06-04. Air Force Scientific Advisory Board, Washington, D.C., May.

Armacost, Andrew, Cynthia Barnhart, Keith Ware, and Alysia Wilson. 2004. UPS optimizes its air network. Interfaces (34) 1: 15-25.

Bard, Jonathan, Gang Yu, and Michael Argüello. 2001. Optimizing aircraft routings in response to groundings and delays. IIE Transactions 33(10):931-947.

Clarke, Michael. 1997. Development of heuristic procedures for flight rescheduling in the aftermath of irregular airline operations. Sc.D. thesis, Massachusetts Institute of Technology, Cambridge.

Clarke, Michael, Ladislav Lettovsky, and Barry Smith. 2000. The development of the airline operations control center. Handbook of Airline Operations. McGraw-Hill Publishing. New York, N.Y.

Harrison, Greg, F. Southworth, A. Sexton, M. Hilliard, R. Kraemer, D. Russell, M. Holcomb, T.S. Wood, H. Brenner, and J. Jacobi. 1991. Functional description of the airlift deployment analysis system (ADANS). ORNL-6560. May.

INFORMS. 2006. Warner Robins Air Logistics Center wins 2006 Franz Edelman Award for Achievement in Operations Research. INFORMS Press Release. Hanover, Md., and Miami, Fla., May 2.

Koepke, Corbin. 2004. Multi-mission optimized re-planning in Air Mobility Command’s Channel Route execution. S.M. thesis, Massachusetts Institute of Technology, Cambridge, Mass. November 10.

Lettovsky, Ladislav. 1997. Airline operations recovery: An optimization approach. Ph.D. thesis, Georgia Institute of Technology, Atlanta.

Lombardo, David. 2003. Elegant winglets save precious fuel. Aviation International News. June 16. Available online at http:// www.ainonline.com/publications/paris/paris_03/pd1wingletspg72.html. Last accessed on January 19, 2006.

NASA. 1981a. KC-135 Winglet Program Review. NASA Conference Publication 2211. September.

NASA. 1981b. KC-135 Winglets Flight Test Summary, January.

Nielsen, C. 2002. Large-scale network design using composite variables: An application to Air Mobility Command’s 30-day Channel Route Network. S.M. thesis, Massachusetts Institute of Technology, Cambridge, Mass.

NRC (National Research Council). 2001. Climate Change Science: An Analysis of Some Key Questions. Washington, D.C.: National Academy Press. Available online at http://books.nap.edu/books/0309075742/html/. Last accessed on January 25, 2007.

ORNL (Oak Ridge National Laboratory). 2006. The Air Mobility Command deployment analysis system (ADANS). Web site of the Data System Sciences and Engineering Group (DSSE) in the Computational Sciences and Engineering Division at the Oak Ridge National Labs (ORNL). Retrieved from http://computing.ornl.gov/cse_home/datasystems/adans.shtml on August 15, 2006.

Yu, Gang, Michael Argüello, Gao Song, Sandra McCowan, and Anna White. 2003. A new era for crew recovery at Continental Airlines. Interfaces (33)1: 5-22.

Unpublished

William Harrison, Director, National Aerospace Fuels Research Complex, Air Force Research Laboratory, “Alternate fuels overview,” Presentation to the committee on June 13, 2006.

Jay Inman, Vice President for Programs, Aviation Partners Boeing, “Blended winglets,” Presentation to the committee on June 14, 2006.

Ann Karagozian, Chair, Air Force Scientific Advisory Board. “Quick-look study on technology options for improved air vehicle fuel efficiency,” Presentation to the committee on May 23, 2006.

Jack O’Banion, Director of Air Mobility Requirements, Lockheed Martin Corporation, “C130 Re-engine discussion,” Presentation to the committee on May 23, 2006.