1

Introduction

STUDY ORIGIN

The prices of gasoline should serve as a wake-up call to all of us involved in public office, that we have got an energy security problem and a national security problem, and now is the time to deal with it in a forceful way.

—President George W. Bush, May 3, 2006

This report responds to a United States Air Force (hereinafter “the Air Force”) request to review all large nonfighter aircraft and develop a list of candidate aircraft that would benefit the most from engine efficiency improvement, to include re-engining and, in particular, reducing the fuel burden. Box 1-1 provides the study’s statement of task.

In February 2006, representatives from the Air Force and the Air Force Studies Board (AFSB) of the National Research Council (NRC) met to discuss the study parameters and finalize the above statement of task. During the course of this meeting and subsequent discussions, additional parameters for the study evolved, so that the task would include enhancement of aircraft performance and efficient completion of missions. For many military aircraft, the airframe lifetime encompasses a number of engine technology improvement cycles, and these aircraft could benefit accordingly from performance improvements such as shorter takeoff distance, increased range, lower exhaust gas temperature, higher altitude operation, and greater auxiliary electric power capability.

OVERVIEW OF AIR FORCE FUEL CONSUMPTION AND COST STRUCTURE

Reducing energy consumption is now a strategic goal of the Department of Defense (DoD):

The Department of Defense is now serious about developing a strategic approach to energy consumption and conservation. No longer will energy be considered a free commodity…. Both Defense Secretary Donald Rumsfeld and Deputy Defense Secretary Gordon England are initiating steps to galvanize new actions across the department…. The Secretary wants to ensure that the Defense Dept. is pursuing in-

|

BOX 1-1 Statement of Task The NRC will: Review all large, nonfighter aircraft and develop a list of candidates that would benefit most from engine efficiency improvements or re-engining. Assess and leverage all relevant past re-engining studies. Evaluate life-cycle cost-benefits for each candidate, including fuel savings, reliability, maintainability, logistics and sustainment support. Consider safety, environmental, and operational implications. Recommend affordable re-engining and/or engine life extension improvements. Determine whether multiplatform solutions are possible for reducing inventory footprint. Develop implementation strategies to include conventional as well as innovative acquisition, financing and support concepts. |

novative initiatives in the areas of fuel-efficient vehicles, advanced battery technology and hybrid power trains…. [Deputy Secretary] England is overseeing the issuance of a new department-wide guidance, focusing on concrete steps the Pentagon can implement to conserve energy. (Pudas, 2006, p. 42)

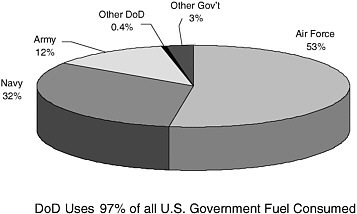

The above memorandum effectively institutionalizes energy conservation within DoD, and it is expected that the Air Force will follow with a set of guidelines for fuel conservation. As shown in Figure 1-1, in 2005 DoD consumed 97 percent of all fuel used by the U.S. government (Sega, 2006), or 5.6 billion gallons (DESC, 2005). Within DoD, the Air Force utilized the most fuel (53 percent), approximately 3.0 billion gallons (Sega, 2006; DESC, 2005).

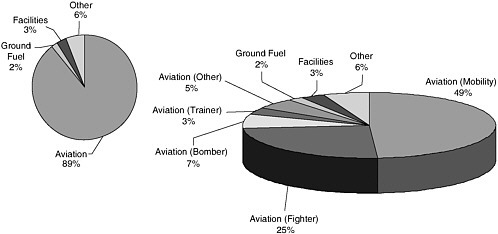

As shown in Figure 1-2, in 2005 aviation fuels accounted for 89 percent of all Air Force fuel, totaling approximately 2.7 billion gallons (Sega, 2006; DESC, 2005). Nonfighter aircraft accounted for approximately 64 percent of total Air Force aviation fuels (Sega, 2006), or approximately 1.7 billion gallons (DESC, 2005). Within the large nonfighter aircraft fleet, 10 aircraft families account for 90 percent of the total utilization of nonfighter fuel, as shown in Table 1-1. For this reason, the study reviewed each of these aircraft to determine whether there are engine improvements or, possibly, aerodynamic improvements that can be incorporated to reduce the overall fuel burden on the Air Force. The study also examined potential savings afforded by increased operational capabilities and maintenance measures that might lead to lower sustainment costs.

In fact, because many nonfighter aircraft have been in service for a long time, the application of modern engine and aerodynamic technology could dramatically improve fuel efficiency.

However, all benefits must be balanced against the life-cycle costs of these new technologies over the remaining life of the aircraft. Incorporating engine improvements or re-engining an aircraft can impact all major aircraft systems. Moreover, the cost of implementation may also include reanalysis,

FIGURE 1-1 Fuel usage by DoD in 2005. SOURCE: Sega (2006).

redesign, or recertification of other major aircraft systems to include cockpit controls, bleed air systems, hydraulic systems, electrical systems, aircraft structure, as well as maintenance operations and technical publications. Offsetting these potentially high nonrecurring costs has been, and remains, a high hurdle to the incorporation of desired improvements.

To better understand when and how re-engining programs make economic sense, it is important to understand both how the Air Force consumes fuel and how it incurs cost. Although much of the material discussed below has been stated in other publications, it is worthwhile for the sake of context to restate some key facts.

FIGURE 1-2 Distribution of fuel usage within the Air Force in FY05. SOURCE: Sega (2006).

TABLE 1-1 Large Nonfighter Aircraft Candidates for Re-engining and Engine Modification

|

Fuel Use Rank |

Aircraft |

Number of Aircraft |

Number of Engines |

Engine Modela |

Fuel Consumed (million gal) |

Share (%) |

Cumulative Fuel Share (%) |

|

1 |

C-17 |

154 |

670 |

F117 (PW2040) |

427 |

25 |

25 |

|

2 |

KC-135R/T |

420 |

1,744 |

F108-100 (CFM56-2) |

335 |

20 |

45 |

|

3 |

C-5 |

111 |

612 |

TF39 |

225 |

13 |

58 |

|

4 |

KC-10 |

59 |

204 |

F103 (CF6-50) |

160 |

9 |

67 |

|

5 |

C-130H |

272 |

2,093 |

T56-15 |

113 |

7 |

74 |

|

6 |

B-52 |

114 (76 active) |

855 |

TF33-103 (JT3D) |

88 |

5 |

79 |

|

6 |

B-1 |

67 |

438 |

F101 |

85 |

5 |

84 |

|

8 |

KC-135D/E |

115 |

662 |

TF33-102 (JT3D) |

44 |

3 |

87 |

|

9 |

E-3 |

32 |

174 |

TF33-100 (JT3D) |

35 |

2 |

89 |

|

10 |

E-8 |

19 |

96 |

TF33-102C (JT3D) |

22 |

1 |

90 |

|

aTerm in parentheses is military designation. SOURCE: Adapted from Over (2006) and AFSAB (2006); fuel consumed is from DESC (2005). |

|||||||

Important factors that determine the total peacetime fuel burn of the Air Force large nonfighter aircraft fleet include fleet size, per-flying-hour fuel consumption, and the average annual usage rate in peacetime flying hours per aircraft per year. The annual fuel burn of each aircraft type is the product of these three factors.

The total Air Force fleet consists of approximately 5,986 aircraft and includes approximately 2,019 large nonfighter aircraft, which with the exception of bombers, are further categorized primarily as tankers, trainers, and transports.1,2 In addition, the Air Force fleet, as a whole, flies approximately 2 million accumulated flying hours per year.3,4

The overall cost structure of the Air Force can be divided into (1) fixed annual costs and (2) variable costs. The fixed annual costs are incurred each year regardless of whether and how the Air Force uses its aircraft and people.5 In contrast, variable costs are incurred only when the Air Force conducts missions for, or in direct support of, military operations. The estimated fixed costs account for approximately 95 percent of the Air Force’s annual budget.

The Air Force cost base is dominated by fixed costs because the Air Force flies its aircraft an average of 358 flying hours per aircraft per year. By contrast, a typical commercial airline flies its aircraft an average of 3,000 hours per aircraft per year. The reason for the striking difference between the Air Force and commercial practice is very straightforward. In commercial practice, an idle airplane means lost revenue and no return on investment. By contrast, the military must prepare for wars that it hopes

never come. This means that the military must be equipped with the right kinds and numbers of equipment to prevail in wartime. At other times, these assets are largely idle, with the use rate being held to the minimum necessary to maintain an adequate level of training for personnel.

For example, the committee estimated if the fuel consumption of the entire non-fighter aircraft fleet could be reduced by 25 percent, based on 2005 fuel usage, that would equal a reduction in fuel consumption of approximately 0.5 billion gallons of fuel per year. At the Defense Logistics Agency delivered fuel price of $2.53 per gallon, this represents just under $1.14 billion per year, or approximately 1 percent of the Air Force’s total annual budget (Harrison, 2006).

The committee concluded that while re-engining can lead to reductions in Air Force fuel consumption, it is unlikely to pay for itself for most weapons systems at today’s fuel prices.6 Exceptions to this are cited in the text.

LESSONS LEARNED FROM PREVIOUS RE-ENGINING PROGRAMS

Commercial Re-engining Programs

In recent history only one aircraft re-engining exercise was conducted by major airlines of the U.S. air transport industry. DC-8-60 series aircraft were re-engined by one major passenger airline and one major freight carrier. The experience of the passenger airline that conducted a conversion of JT3D-3 to CFM56-2 engines on DC-8-61 aircraft indicated that the standard net present value (NPV) calculation of the cost/benefit aspects directly tied to the program was relatively accurate. The program met all of its expected financial and operational goals to the point that the trip costs for the newly re-engined DC-8-71 were the best of all fleets except for the 767, which was the latest technology aircraft in delivery to the airline. The DC-8-61/JT3D-3 combination proved to be an ideal candidate for re-engining because the DC-8-61 airframe had the structural capability required to allow the use of the larger engine, and the CFM56-2 turbofan engine provided substantial efficiency, performance, and noise reduction improvements over the first generation of turbojet JT3D-3 engines.

Military Re-engining Programs

Similar to the experience of the passenger airline program to convert JT3D-3 to CFM56-2 engines on DC-8-61 aircraft, the KC-135 re-engining program indicated that performance improvements were accurate. However, the standard NPV calculation of the cost/benefit aspects directly tied to initial program justification could not be substantiated. Significant changes in quantities of aircraft and extensions of the modification program reduced the benefits that had been projected. That being said, and although force structure and operational utilization are not within the scope of this study, the data clearly indicate a dramatic increase in mission utilization for KC-135 tanker aircraft with the new CFM56-2 (F108) engines. Re-engining programs are much more involved than adding new engines on the wing.

Complexity of Re-engining Aircraft

There is a general lack of understanding of the magnitude and complexity of any re-engine program. A re-engine program affects just about every system on an aircraft (electrical, hydraulic, pneumatic,

|

6 |

Allowing for force structure trade-offs could lead to substantially different results and conclusions. This is addressed briefly in Chapter 6, in the section “Other Considerations.” |

aerodynamic flight controls, avionics, and structural). In addition to modifications to the aircraft, a significant effort is required to revise required technical manuals (performance, aircrew, maintenance, training, and repair) as well as to update support equipment, initial spares, maintenance concepts, and engineering substantiation analyses. Appendix D contains a sample work breakdown structure. Even if the selected engine is used in a commercial in-production aircraft, the engine accessories will have to be modified to meet military mission requirements. Even engines of the same thrust range will require a significant analysis and certification effort, whether it is a certification to civilian or military standards. Because a re-engine program impacts so many aircraft systems, obsolete and line replaceable units having short mean time between failures are also replaced with newer alternatives and add to the cost and planning burden for the modification.

Program Schedule and Cost

Aircraft, engines, and weapons systems are designed as an integrated system to provide optimum performance and characteristics for planned missions. It is highly probable that unexpected costs and/ or operational implications are likely to accrue from any change to the engines no matter how much planning and analysis have been committed to the development of such a program. These risks can be mitigated by the involvement of all of the organizations, including engineering, maintenance, material, flight operations, technical publications, training, and finance, affected by the program. This multiorganizational approach will help to forestall program surprises but is an impediment to rapid action in the face of high-priority economic, operational, or regulatory action demands.

For various reasons, the Air Force was unable to take advantage of optimum schedules or quantities for the acquisition and installation during the KC-135 re-engine program. Yearly purchases were less than best economic quantity, and schedule stretchouts increased total program costs. Multiple changes to production quantities and schedules further increased costs. These, in turn, led to increased acquisition costs, a longer payback period, and fewer modified aircraft.

Potential for Future Re-engining Programs

Commercial Re-engining

Airline experience has demonstrated that it is unlikely that next-generation commercial aircraft will lend themselves to re-engining campaigns in the near term, because the engines and airframes are so highly optimized to meet service requirements, the benefits of engine technology is not improving sufficiently to justify significant expense, and the structural and certification constraints impose a significant cost burden that will be difficult to overcome. In addition, commercial users routinely modify their engines to take advantage of new technology, making a new engine less beneficial than it would otherwise be.

Military Re-engining

Conceptually the potential for re-engining large, nontactical military aircraft remains attractive because of the low utilization and consequently longer service life of those weapons systems, the probability of major advancements in engine technology during that extended service life, and because mission suitability generally transcends financial justification as the primary analysis criterion.

In this study, the life-cycle cost (LCC) of incorporating a new engine is based on the best estimates of fuel savings, maintenance cost savings, nonrecurring engineering costs, certification cost, and cost of incorporation of the improvement. However, the life-cycle cost analyses do not take into account many of the enhanced operational capabilities for tactical aircraft resulting from technology improvements. For example, performance improvements such as those that might allow aircraft to operate on shorter runways are not quantified in the economic portion of this study because they are beyond its scope.

FORCE STRUCTURE FOR FUTURE STUDY

The study did not attempt to evaluate the financial and fuel savings that might be achieved by re-shaping the force to take best advantage of the new capabilities of re-engined aircraft. Re-engining some aircraft might cause compounding effects beyond gains in fuel efficiency for the aircraft themselves. Those effects might lead to much larger reductions in fuel consumption for the Air Force as a whole. For example, tankers fly in support of other aircraft, particularly fighters and bombers, and the fuel consumption of the tanker fleet is related to the scale and usage of the fighter and bomber fleets. If re-engining could enable operational improvements to the bomber fleet, those operational improvements might have various downstream effects. For example, the reduced fuel burn would reduce the amount of fuel the bombers would have to upload from tankers, perhaps allowing a smaller tanker fleet. Further deliberations on Air Force force structure adjustments are beyond the scope of this study. However, force structure modifications might offer the Air Force an important mechanism for reducing fuel consumption and for making the economic case for re-engining. Any such changes might alter the findings, conclusions, and recommendations of this and previous studies. A follow-on study could reevaluate re-engining options for large nonfighter aircraft by pointing out explicitly how re-engining would allow the Air Force to alter its current and planned force structure to reduce overall fuel consumption and save money, while preserving the ability to execute the full range of missions required of it.

While the present study benefits from many earlier engine improvement and re-engining studies conducted by the Air Force, subcontractors, and independent committees, it is unique in that it covers the entire fleet of nonfighter aircraft and utilizes consistent assumptions and analysis techniques.

ADDITIONAL CONTEXT

Previous Re-engining Studies

As shown in Table 1-2 and Appendix C, the Air Force has sponsored a number of evaluations over the past two decades regarding validation, improvement, or replacement of engines for existing nonfighter aircraft. Many of the studies were motivated by the aging of the fleet or technological advancement and tended to focus on specific aircraft models, including the B-52, KC-135, E-3, E-8, and C-130.They used a variety of calculations to arrive at the cost of fuel in their cost/benefit analyses.

Indeed, the results of past studies generally have shown that engine replacement for some models of aircraft, such as the KC-135, could not be justified by cost saving alone. To a great extent, the effectiveness of any weapon system depends on the suitability of its technology for the mission requirements. Because of significant advancements in electronics and avionics over the past two decades, all of these aircraft have benefited from technical systems upgrades, making them superior weapons systems for their assigned missions. The cost effectiveness of modification, upgrade, or replacement of existing power plants should therefore be periodically reviewed.

TABLE 1-2 Previous Studies on Re-engining Aircraft

|

Study |

Author |

Date |

|

Technology Options for Improved Air Vehicle Fuel Efficiency |

Air Force Scientific Advisory Board |

2006 |

|

B-52 Propulsion Capability Study |

ACSSW/PRSS New Engines |

2005 |

|

C-130 Enhanced Capabilities |

Snow Aviation International |

2005 |

|

AC-130U Alternate Engine Summary Report |

Macaulay Brown/UTC |

2005 |

|

Task Force on B-52H Re-engining (Revised and Updated) |

Defense Studies Board |

2004 |

|

TF33 Re-engine Fleet Look-Ahead |

Oklahoma City Air Logistics Center |

2004 |

|

The Air Force KC-767 Tanker Lease Proposal: Key Issues for Congress |

Congressional Research Service |

2003 |

|

B-52 Re-engine Study Report |

Boeing/Hannon Armstrong |

2003 |

|

B-1B Re-engining, Mission Flexibility (for Maj Gen Dan Leaf) |

Boeing |

2002 |

|

KC-135 Engine Modernization Program: LCC Analysis |

Boeing |

2000 |

|

TF33 Propulsion System Roadmapping Study |

Pratt & Whitney |

1998 |

|

Findings of the B-52H Re-engining Cost IPT |

SAF/Financial Management |

1997 |

|

Analysis of Aerial Tanker Re-engine Programs |

Congressional Budget Office |

1984 |

|

NOTE: For more information, see Appendix C. SOURCE: Committee generated. |

||

Air Force Scientific Advisory Board Study on Technology Options for Improved Air Vehicle Fuel Efficiency

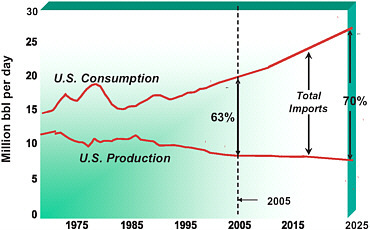

As shown in Figure 1-3, the AFSAB stated that the United States currently depends on foreign sources for 63 percent of its annual fuel utilization (AFSAB, 2006; Karagozian, 2006).

That dependency is projected to grow to 70 percent by 2025. The government used 1.7 percent of the total annual fuel consumption of the United States in FY03. As already stated in the discussions accompanying Figures 1-1 and 1-2, DoD was the largest fuel consumer, with 97 percent of government fuel usage attributed to DoD. Within DoD, the Air Force used 53 percent of the total fuel. Finally, as

FIGURE 1-3 Sources of crude oil consumed by the United States. SOURCE: AFSAB (2006) and Karagozian (2006).

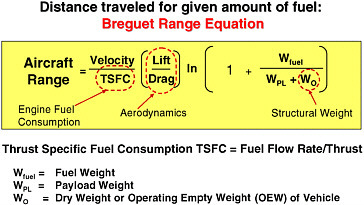

FIGURE 1-4 Fuel efficiency as defined by the Breguet range equation. SOURCE: AFSAB (2006) and Karagozian (2006).

shown in Figure 1-2, 89 percent of the total Air Force consumption was dedicated to aviation fuels, while nonfighter aircraft within the Air Force inventory consumed 72 percent of the aviation fuel.

The AFSAB study indicated the actual cost of fuel to the Air Force is $2.14 per gallon while the cost to deliver that fuel in mission applications varies significantly. For example, the cost to transport fuel for in-flight delivery via tanker is $24.23 per gallon, for a fully burdened cost of $26.37 per gallon (AFSAB, 2006; Karagozian, 2006).

When seeking technology alternatives for improved engine efficiency, the Breguet range equation, shown in Figure 1-4, provides a convenient method for assessing the effects of fuel consumption, aerodynamics and structural characteristics considerations on overall aircraft fuel efficiency.

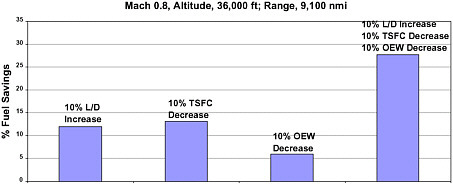

Figure 1-5 illustrates the relative cost/benefit of alternative means to achieve fuel efficiency, as determined by AFSAB. Table 1-3 provides the AFSAB’s view of additional cost/benefit relationships of various methods to enhance fuel efficiency.

FIGURE 1-5 Potential fuel savings for transports. SOURCE: AFSAB (2006) and Karagozian (2006).

TABLE 1-3 Factors Leading to Possible Fuel Savings

|

Solution |

Time Spana |

∆ Fuel Efficiency (%) |

∆ Fuel Efficiency/Cost |

|

Aerodynamic |

|

|

|

|

Wing retrofits, including winglets |

Near term |

5 |

High |

|

Major wing redesign |

Mid term |

10 |

Medium |

|

Active flow/separation control |

Mid term |

5 |

High |

|

Revolutionary configurations, including BWB, oblique wing, and hybrid airships |

Far term |

25 |

Medium |

|

Structural and material |

|

|

|

|

Integrated vehicle health monitoring |

Near term |

1 |

Medium |

|

Structural design and optimization and active wing control |

Mid term |

15 |

Medium |

|

Advanced design and analysis tools |

Far term |

10 |

High |

|

Operational |

|

|

|

|

Enhance tracking and reporting of Air Force fuel utilization |

Near term |

3 |

High |

|

Optimize aircraft operations including engine out taxi, APU usage, optimal route planning, and RVSM |

Near term |

5 |

High |

|

Increased use of simulators and distributed mission training |

Near term |

5 |

Medium |

|

Autonomous formation flight |

Mid term |

15 |

High |

|

Fuelsb |

|

|

|

|

Fischer-Tropsch fuel from coal |

Near term |

1 |

High |

|

Oil shale |

Mid term |

1 |

Medium |

|

Other hydrocarbons, including LNG, ethanol blends, and biodiesel |

Mid term |

1 |

High |

|

Hydrogen for fuel cells in APUs |

Mid term |

1 |

Medium |

|

Biomass, including black liquor fuels |

Far term |

1 |

High |

|

Hydrogren fuel for turbine engines |

Far term |

5 |

Medium |

|

NOTE: BWB, blended wing-body; APU, auxiliary power unit; RVSM, reduced vertical separation minima. a“Near term” is defined as the period from the present out to 5 years; “mid term” is 5 to 15 years in the future; and “far term” is implementable beyond 15 years in the future. For each solution, both the approximate benefit (ΔFE, or the change in the fuel efficiency metric) and the benefit-to-cost ratio (ΔFE divided by a rough estimate of cost) are listed. Each technological concept identified here has, approximately, a high or medium impact based on the benefit-to-cost ratio. The values and magnitudes of ΔFE and benefit-to-cost are not exact here (due in part to the brevity of this ‘quick look’ study) but should be regarded as rough approximations. If a potential technological (or other) solution had a low benefit-to-cost ratio, then it was not included in the list. Finally, it should be noted that the ΔFE metric here is likely NOT additive if multiple solutions are implemented. bWhile utilizing alternative fuels may not directly impact the fuel efficiency of a given vehicle to any significant extent, this fuel efficiency study views the development of alternatives to crude-oil-based fuels to be of critical importance to the Air Force, since these fuels can be produced domestically and are therefore a relatively secure supply. Hence the present study did explore, in a limited way, potential alternative fuels that could be used in air vehicles in particular. In this table, the ΔFE parameter should be viewed to be notional (and in fact may actually be zero or possibly even negative for a given fuel). The benefit in the benefit-to-cost ratio here derives from the potentially extraordinary benefits that would be associated with access to a more assured, domestically generated source of fuel. SOURCE: Adapted from AFSAB (2006) and Karagozian (2006). |

|||

Finally, the AFSAB study considered the viability of alternative fuels to reduce dependency on foreign oil imports. With the exception of the use of Fischer-Tropsch synthetic fuel, the alternatives provided in this analysis do not meet near-term fuel efficiency improvement requirements.

SUMMARY

Table 1-2 illustrates that the subject of modifying engines and re-engining aircraft for various reasons has been studied extensively. However, two factors distinguish this study from the previous studies: (1) the selection of candidate systems herein is based mainly on their ability to reduce the Air Force fuel burden and (2) consideration is given to the entire fleet of large nonfighter aircraft. The following chapters analyze in depth the methodology for selecting the candidate systems for modifying engines and re-engining aircraft; additional factors that may reduce aircraft fuel consumption; promising alternative fuels and engine developments that may one day impact fuel consumption; and innovative contracting and financing approaches that the Air Force may employ with industry to reduce engine development and sustainment costs.

REFERENCES

Published

AFSAB (Air Force Scientific Advisory Board). 2006. Technology Options for Improved Air Vehicle Fuel Efficiency: Executive Summary and Annotated Brief. SAB-TR-06-04. Air Force Scientific Advisory Board, Washington, D.C., May.

AFM (Air Force Magazine). 2006. The Air Force in Facts and Figures—2006 USAF Almanac. May. Available online at http://www.afa.org/magazine/may2006/0506structure.pdf. Last accessed on January 22, 2006.

DESC (Defense Energy Support Center). 2005. Fuel Used for Large Non-Fighter Aircraft for Calendar Year 2005.

Pudas, Terry. 2005. A strategic approach to energy in the Department of Defense. Defense Technology International. May/June. Available online at http://www.oft.osd.mil/energy/docs/A%20Strategic%20Approach%20To%20Energy-Pudas.pdf. Last accessed on January 22, 2006.

Sega, Ron. 2006. Air Force Energy Strategy. April 19. Available online at http://www.desc.dla.mil/DCM/Files/Dr%20Ronald%20Sega%20-%2019%20Apr%2006-V2.ppt. Last accessed on September 11, 2006.

Unpublished

William Harrison, Director, National Aerospace Fuels Research Complex, Air Force Research Laboratory, “Alternative fuels overview,” Presentation to the committee on June 13, 2006.

Ann Karagozian, Chair, Air Force Scientific Advisory Board, “Quick-look study on technology options for improved air vehicle fuel efficiency,” Presentation to the committee on May 23, 2006.

John Over, Director, 448th Combat Sustainment Wing, Tinker Air Force Base, “Re-engining and engine modernization from a sustainment perspective,” Presentation to the committee on May 23, 2006.