1

Introduction

This report presents the findings of the National Research Council (NRC) Committee on the Continuing Operability of Chemical Agent Disposal Facilities and Equipment. Although focused on equipment/facilities obsolescence at chemical agent stockpile incineration facilities, the report takes a broader view of the problem in the context of the ability of the facilities to satisfactorily complete their site and programmatic missions. 1 How these systems are managed, repaired, replaced, and maintained is important to “continuing operability.”

BRIEF HISTORY OF CHEMICAL STOCKPILE DISPOSAL PROGRAM

The United States has stockpiled chemical agents and weapons for more than 50 years. The agents include the nerve agents GA, GB, and VX and the mustard blister agents H, HD, and HT. Following their manufacture, these agents were loaded into millions of individual munitions or stored in bulk containers. Almost all the agent and containment systems are over 40 years old and are deteriorating. In 1985 the U.S. Congress directed the Army to begin destroying the M55 rockets in the stockpile. The Army was subsequently mandated by Congress in 1992 to destroy the entire stockpile (Public Law 102-484). In 1997 the United States became a signatory to the Chemical Weapons Convention (CWC) following its ratification by Congress. This in turn required that the stockpile be totally destroyed by April 29, 2007. The provisions of the CWC provide for a five-year extension to the ten-year period following ratification during which declared chemical warfare items are to be destroyed. Application for a five-year extension to 2012 was approved in late 2006.

Since 1984, the NRC has provided scientific and technical guidance to the Army on important aspects of the stockpile disposal plans and programs with an overarching goal of safe and expeditious implementation of stockpile destruction. This guidance has taken the form of over 40 reports produced to date.

Box 1-1 shows a timeline with some historic program milestones. At the start of the disposal program, the chemical weapons stockpile was located at eight U.S. sites and on Johnston Island in the mid-Pacific. Table 1-1 shows the locations and the present status of disposal at the individual sites. Because of its remote location, the Johnston Atoll Chemical Agent Disposal System (JACADS) was used to demonstrate the baseline incineration system destruction technology developed by the Army. The stockpile consists of bulk storage tanks as well as rockets, mines, bombs, cartridges, and projectiles. The stockpile munitions are configured with bursters and propellant charges, but were not designed for disassembly. Although the Army had some limited experience with the destruction of chemical weapons in the past, the size and complexity of the entire original stockpile of over 30,000 tons of chemical agents along with the associated munitions and containers created a major new challenge. The destruction process involves disassembly that includes robotic separation of agent from munitions and bulk containers within an explosive containment structure, followed by incineration of the separated streams in three special types of furnaces: (1) the liquid agent incinerator (LIC); (2) the deactivation furnace system (DFS), for energetics and smaller metal parts; and (3) the metal parts furnace (MPF), for bulk metal and waste items. Associated systems for monitoring, treatment of all effluents, process control, and utilities have been designed and operated to protect the safety of the process as well as that of the workers, the community, and the environment. Because of the unique nature of the

|

1 |

Obsolescence is defined in the Merriam-Webster Online Dictionary as “the process of becoming obsolete or the condition of being nearly obsolete.” Obsolete is defined as “no longer in use or no longer useful.” See www.m-w.com/dictionary. Accessed July 12, 2006. |

|

BOX 1-1 Some Historic Milestones in the U.S. Chemical Weapons Program

|

stockpile, the facility design involved the integration of components, some standard and some unique, into a new prototype design that was built at JACADS.

JACADS operations were started in 1990, and although that facility performed well, lessons learned during JACADS operations were incorporated into the design of the second-generation plant at the Deseret Chemical Depot (DCD) in Tooele, Utah. Since the Army planned to continue to employ the basic design of its incineration system at the various sites, when major specialized equipment was ordered for the Tooele Chemical Agent Disposal Facility (TOCDF) in the 1980s, duplicates of major items were also procured for incineration facilities to be constructed subsequently.2 (At that time, the estimate for program completion was 2001.) This equipment included the large specialized furnaces, disassembly robotics, and the plant control systems. Such equipment was stored until the subsequent sites received approval for construction. Consequently, much of the major equipment in the present incineration facilities is of 1980s or earlier design and was delivered in the early 1990s. As TOCDF was built and operations begun in the mid-1990s, the Army learned that it had seriously underestimated the time required to obtain permits at sites in the continental United States and the program timeline started to extend considerably.

The Army has scheduled the demilitarization operations at each site on the basis of destroying the highest-risk stockpile components first. Therefore, items containing GB were processed first, VX second, and mustard agent last. In between each agent campaign the disposal facility equipment is cleaned, scheduled maintenance is performed, and the agent monitoring capability is modified for the next agent. In each agent campaign the M55 rockets are processed first because of concerns about their long-term stability and their potential for creating the highest risk to the public in the event of a storage accident. Their destruction is then followed by that of other munitions and finally by destruction of bulk items.

A previous NRC committee assessed the degradation of the stockpile condition over time and its effects on stockpile disposal operations (NRC, 2004). Some of the concerns addressed in that report included:

-

degradation of agent leading to crystallization or gelling that impedes agent draining during processing;

-

corrosion problems leading to leakage; and

-

potential destabilization of M55 rocket propellant grains.

These and other aging problems are likely to continue and worsen over time, with potential impacts on both stockpile and processing safety. Thus, an incentive exists to dispose of the stockpile as soon as possible.

The schedule for the overall demilitarization of the nation’s stockpile has continued to slip considerably from initial Army projections for a variety of reasons, including permitting delays, budget constraints, and some operational problems. Therefore, the aging of the equipment, the unavailability of spare parts, and the loss of specialized expertise are among current concerns since these factors may impede the safe and effective operability of the disposal

TABLE 1-1 Stockpile Sites and Disposal Status as of January 2006

|

Site |

Percent of Original Stockpile |

Stockpile Components |

Disposal Status |

|

JACADS/Johnston Island |

6.6 |

All agents Munitions and bulk |

Prototype plant Destruction completed (in final environmental closure) |

|

ABCDF/Aberdeen, MD |

5.0 |

HD ton containers |

Neutralization plant Destruction completed Into closure operations |

|

TOCDF/Tooele, UT |

42.3 |

All agents Munitions and bulk |

2nd generation incineration plant 54.5% destroyed (all GB and VX) |

|

ANCDF/Anniston, AL |

7.1 |

All agents Munitions and bulk |

3rd generation incineration plant 18.7% destroyed (all GB) |

|

UMCDF/Umatilla, OR |

11.6 |

All agents Munitions and bulk |

3rd generation incineration plant 7.9% destroyed |

|

PBCDF/Pine Bluff, AR |

12.0 |

All agents Munitions and bulk |

3rd generation incineration plant 4.7% destroyed |

|

NECDF/Newport, IN |

3.9 |

VX ton containers |

Neutralization started Hydrolysate being stored pending disposal decision |

|

PCAPP/Pueblo, CO |

9.9 |

HD Munitions |

In design and site preparation |

|

BGCAPP/Blue Grass, KY |

1.6 |

All agents Munitions and bulk |

In design and site preparation |

|

SOURCE: Adapted from Chemical Stockpile Disposal (CSD) Facilities and Equipment Obsolescence Assessment. Briefing by Joseph Pecoraro, project manager for chemical stockpile disposal, CMA, to the committee, January 25, 2006. |

|||

facilities during the remainder of destruction operations and facility closure at each site.

FOCUS AND IMPLEMENTATION OF THIS CONTINUING OPERABILITY STUDY

Once a plant is operational, it is best to avoid unnecessary interruptions in operation, because operational transients stress the equipment. Prolonged outages also impact the performance of plant workers, so unnecessary shutdowns are counterproductive and probably increase both overall risk and costs. Although equipment that may show some signs of wear may still be able to operate satisfactorily, it is important that the capabilities and safety consciousness of facility workers and supervisors always remain at a high level. It is also essential that communications with regulatory and community groups continue to be effective so that any emerging issues or future changes in requirements can be identified and addressed in a timely manner.

In addressing issues that pertain to the safe continuing operability of a stockpile disposal facility, particular attention was paid to the operational experience at JACADS over the full life-cycle of that facility, and then at TOCDF, which is the oldest plant currently operating and where obsolescence problems are likely to be encountered first. Facilities at Anniston, Alabama (ANCDF); Umatilla, Oregon (UMCDF); and Pine Bluff, Arkansas (PBCDF) are all now operating and also have initiated programs to anticipate and manage problems associated with obsolescence.

In conducting this study the committee was aware that the Army’s standard procedures for addressing obsolescence of conventional Army equipment and munitions do not apply to an operational chemical stockpile processing facility, notwithstanding that the Army is destroying obsolete munitions (U.S. Army, 1999). Some simple cost reduction options for slowing or interrupting operations that might apply to a simpler system are not feasible in a complex stockpile incineration facility. For example, the facility refractory-lined furnaces and afterburners must be kept hot during short-term changes in processing operations to avoid ther-

mal damage from temperature transients, so there is no cost savings associated with slowing processing rates. Furthermore, plant personnel are highly trained and have acquired extensive experience in operations. A consequence of these conditions is that a facility cannot be realistically mothballed or decommissioned until after its mission is completed satisfactorily. Even at that point, some of the facility equipment and well-trained personnel will still be needed for closure activities to clean and remove all contaminated parts of the facility. Not only do delays in the program increase costs but they also prolong the risk to the public of exposure to the agents in the aging stockpile.

Normal chemical industry practices for preventing obsolescence in process plants likewise apply only in part to stockpile processing plants because of their unique design and finite length of operation. Most chemical and manufacturing plants use well-developed technologies and are designed to operate efficiently and indefinitely with relatively common equipment—not just until a finite task is accomplished.

Thus, the Army’s objective for stockpile processing is to ensure the continuing capability to safely and expeditiously process the remaining stockpile items. The most rational approach for stockpile processing facilities would allow for some equipment obsolescence or degradation as the plants age, as long as this main programmatic objective is not compromised. Replacing equipment that is old but still functional usually involves a major interruption in plant operations, which in turn would increase overall program risk because of prolonged exposure to the stockpile. Such changes often require permit modification at the state level, which may cause further extensions in schedule.

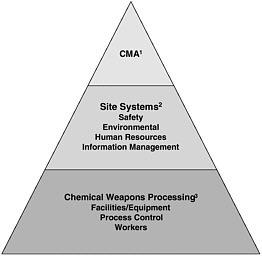

Figure 1-1 shows the conceptual framework that the committee used for evaluating issues of continuing operability. At the bottom of the pyramid are the elements of facility operations that are required for processing the chemical stockpile. These are the elements where obsolescence or loss of capabilities may create vulnerabilities that impact successful continuing operability. At each site, systems from the middle level of the pyramid are in place to ensure the safety of workers, the public, and the environment, as well as to meet regulatory requirements. These are the systems that can be employed to detect and correct or manage the impact of potential vulnerabilities. At the top of the pyramid is the programmatic management that not only will ensure that programwide standards are achieved but also will enhance the robustness of the program facilities against obsolescence through the sharing of knowledge and spare parts across sites.

This report will focus on the four presently operational incineration facilities. The neutralization plants at Aberdeen, Maryland (ABCDF) and Newport, Indiana (NECDF) are not directly included in the study since one has already completed operations and the other is awaiting resolution of issues around neutralization product disposal. The two remaining

FIGURE 1-1 Conceptual framework for achieving continuing operability.

1Manage programmatically across sites to facilitate mission completion.

2Ensure that site systems are in place to manage vulnerabilities.

3Identify vulnerabilities that may impact continuing operations.

sites at Blue Grass (Kentucky) and Pueblo (Colorado), which are under the Assembled Chemical Weapons Alternatives (ACWA) program, are still in the late stages of design. Although these plants were not specifically addressed in this study, some of the findings and recommendations may be helpful in addressing and avoiding some future obsolescence issues at the ACWA sites.

The report is based on a review of ongoing programs conducted by the Army and its site contractors to resolve potential problems related to facility obsolescence. Each site operates fairly independently under a site contractor with some Army oversight and with separate contractual obligations and incentives. The TOCDF site is managed by EG&G and the other incineration facility sites are managed by the Washington Demilitarization Corporation, a part of the Washington Group International, which is the contracting authority. The site contractors are encouraged to interact frequently and share information and spare parts. However, obsolescence issues and management vary by site.

At the committee’s first meeting in January 2006 at the Chemical Materials Agency (CMA) Headquarters at the Edgewood Area of Aberdeen Proving Ground in Aberdeen, Maryland, programmatic responses were given to a list of committee queries, and the objectives on which the statement of task is based were further clarified. The Edgewood

Area also is the location of the Chemical Demilitarization Training Facility (CDTF), where operational replicas of the robotic disassembly systems, the vestibule areas for toxic entry, and the control room are used for training purposes. The committee observed how these systems and areas were operated, discussed how general troubleshooting activities can be done in an uncontaminated environment, and interviewed CDTF training personnel. The committee also held meetings at Tooele, Utah, and Anniston, Alabama, where members spoke with groups of experts and workers, examined documents, and toured parts of the facilities. Committee subgroups also visited the facilities at Umatilla, Oregon, and Pine Bluff, Arkansas. A briefing was received on the two ACWA sites to indicate where committee input might be helpful. See Appendix A for a listing of committee meetings and site visits.

As the data-gathering part of this study was coming to an end, a further change in program management within the CMA organization was announced. The project manager for chemical stockpile disposal retired on May 30, 2006, and his responsibilities were combined with those of the project manager for alternative technologies and approaches to form a new organization led by a project manager for chemical stockpile elimination.

STATEMENT OF TASK

The statement of task that this report is intended to address is as follows:

At the request of the director of the Army’s Chemical Materials Agency, the NRC will establish an ad hoc committee to assess and evaluate current and proposed policies and approaches by the Army and its contractors to adequately anticipate and address equipment/facilities obsolescence at chemical demilitarization facilities. The assessment will examine the extent to which these policies and approaches are consistent with generally accepted practices in the chemical process industry. In conducting this assessment, the NRC will evaluate current and proposed activities involving:

-

anticipating equipment needs and upgrading facilities in a manner that does not compromise plant safety or environmental compliance, or have severe adverse effects on schedule

-

extending the operational life of equipment and facilities as necessary while not compromising worker health and safety or environmental compliance

-

strategies to overcome scarce availability of spare parts and/ or services for aging systems

-

prioritization plans for addressing obsolescence issues

-

maintaining plant reliability, availability, and maintainability while upgrading equipment and facilities

REPORT STRUCTURE

This report examines the various ways that obsolescence, resulting from significant schedule extensions beyond the originally planned facility life, may impact future stockpile disposal operations and how these potential problems are identified and managed by the Army and its site contractors. Chapter 2 examines the vulnerabilities relating to obsolescence at stockpile incineration disposal facilities. Chapter 3 addresses the site-related means being used to implement sound continuing operations management programs, and reviews several issues relating to specific sites. Chapter 4 specifically addresses continuing operability issues concerning the information management and technology systems used at chemical stockpile incineration facilities. Chapter 5 addresses higher-level program management systems that are employed by the CMA and the site contractor management teams to enhance continuing plant operability and safety through programwide cooperation.

The findings and recommendations that appear throughout the chapters of this report are numbered in accordance with the order of their appearance. They have been compiled in one location at the end of the Summary for this report. The committee ranked all of its recommendations into three tiers to indicate their prioritization, with Tier 1 being the highest. Although all the recommendations are important, the committee considers the Tier 1 recommendations to be critical to the life-cycle continuing operability of the chemical stockpile disposal program. A description of the three tier levels follows:

-

Tier 1: Recommendations critical to the life-cycle operability of the chemical stockpile disposal program;

-

Tier 2: Recommendations that are important initiatives supporting higher-level recommendations; and

-

Tier 3: Recommendations that are other desirable action items.

Table 1-2 shows the hierarchy according to tier level for related recommendations. Numerous other observations and suggestions are discussed throughout the general text of the report. The report also includes a detailed assessment of information management systems, including physical facilities, software, and system development processes.

REFERENCES

NRC (National Research Council). 1994. Recommendations for the Disposal of Chemical Agents and Munitions. Washington, D.C.: National Academy Press.

NRC. 2004. Effects of Degraded Agent and Munitions Anomalies on Chemical Stockpile Disposal Operations. Washington, D.C.: The National Academies Press.

U.S. Army. 1999. Diminishing Manufacturing Sources and Material Shortages, Army Materiel Command Pamphlet No. 5-23. Alexandria, Va.: Department of the Army Headquarters, United States Army Materiel Command.

TABLE I-2 Tier-Level Hierarchy for Related Recommendations

|

Recommendation Number and Topic Area by Tier Level |

||

|

Tier 1 |

Tier 2 |

Tier 3 |

|

6 (CMA oversight of control system improvements) |

|

|

|

9 (Safety programs) |

|

|

|

|

21 (Lessons-learned program) |

|

|

|

|

1 (Continuing operational security analyses) |

|

18 (CMA staffing) |

|

|

|

19 (Programmatic guidance) |

|

|

|

20 (Intersite obsolescence management) |

|

|

|

|

3 (Integrated spares management) |

|

|

|

|

2 (Control system spares contract) |

|

|

|

5 (Spare DFS kiln) |

|

|

8 (Development of consistent obsolescence management system) |

|

|

|

|

4 (Maintain skunk works) |

|

|

|

7 (Replace inapplicable DOD standards) |

|

|

|

23 (Key equipment planning for closure) |

|

|

10 (Knowledge management) |

|

|

|

11 (Personnel retention) |

|

|

|

12 (Information management) |

|

|

|

|

13 (Servers) |

|

|

|

14 (PCs) |

|

|

|

15 (Operating systems) |

|

|

|

16 (Data formats and archiving) |

|

|

|

17 (Ongoing information management surveys and assessments) |

|

22 (Continuous, predictable funding) |

|

|