1

Secondary Waste Generation at Chemical Agent Disposal Facilities

INTRODUCTION

Under the direction of the U.S. Army’s Chemical Materials Agency (CMA), the nation is engaged in the destruction of its obsolete stockpile of chemical weapons. These materials are considered hazardous waste. The agents and munitions are destroyed using a combination of mechanical, chemical, and thermal processing. The progress made in destroying the stockpile agents and munitions comes with a challenge, however—disposal of secondary wastes from these destruction processes in a safe manner and in compliance with all applicable laws. The laws governing the disposal of these hazardous wastes are dictated primarily by the federal Resource Conservation and Recovery Act (RCRA) but are managed by state regulatory agencies, which sometimes stipulate different levels of performance.

At the Army’s request, the National Research Council (NRC) previously examined process technologies and associated requirements to optimize health, safety, and operations at chemical disposal facilities, 1 including issues related to the continuing operability of these facilities (NRC, 2006). An important and growing part of the ongoing operations at the chemical agent disposal facilities is managing the secondary wastes, which can amount to between 2 and 5 pounds per pound of chemical agent destroyed, excluding closure waste.2

In June 2006 the CMA asked the NRC to evaluate its practices for managing secondary waste at its chemical agent disposal facilities. This study focuses on the growing volume of secondary waste at each chemical agent disposal facility and the regulatory requirements and best practices for managing these wastes.

Statement of Task

The full statement of task for this study is as follows:

The NRC will conduct an examination of the environmental, regulatory and permit requirements that chemical agent disposal facilities (CDFs) are subject to, on a federal and state basis, concerning the treatment, storage, and/or handling and shipping of secondary wastes (chemical agent and non-agent related).

The NRC will compare the requirements for CDFs with those to which similar facilities in industry that treat, store, and/or handle and ship secondary wastes are subject, with particular emphasis on industrial best practices.

|

1 |

The NRC’s Board on Army Science and Technology has produced many reports on chemical demilitarization over more than a decade. The board’s reports on the Army Stockpile Disposal Program can be found at http://www7.nationalacademies.org/bast/Chemical_Stockpile_Demilitarization_Reports.html. The board’s reports on the Non-Stockpile Chemical Materiel Project can be found at http://www7.nationalacademies.org/bast/Non_Stockpile_Chemical_Demilitarization_Reports.html. The board’s reports on the Assembled Chemical Weapons Alternatives Program can be found at http://www7.nationalacademies.org/bast/Alternative_Technologies _for_Chemical_Weapon_Demilitarization_Reports.html. |

|

2 |

This ratio is a committee estimate based on the 31,496 tons of original chemical agent to be destroyed and the estimated quantities of secondary waste discussed in Chapter 3 of this report. |

The comparison with industry practices includes, but is not limited to the following areas:

-

the degree of characterization necessary for secondary waste (chemical agent and non-agent) produced during the stockpile disposal and/or storage operations, which is treated on-site or handled and shipped off-site for further treatment or disposal;

-

the number and types of trial burns/compliance tests for chemical stockpile incineration-based disposal facilities and the neutralization-based disposal facility on both a site-by-site basis and programmatically recognizing that the Resource Conservation and Recovery Act has provisions for using prior data;

-

feed-rate restrictions to which chemical agent disposal facilities are subject for post trial burns;

-

the extent and number of health risk assessments deemed necessary;

-

criteria being considered for shipment of agent contaminated wastes for final treatment/disposal;

-

facility closure requirements; and

-

the comparison will address site-specific situations concerning CDFs as well as program-wide considerations of the Chemical Materials Agency with regard to stockpile disposal operations.

The membership of the Committee on Review of Chemical Agent Secondary Waste Disposal and Regulatory Requirements included experts in environmental chemistry, hazardous waste management, transportation safety, risk analysis, toxicology, civil engineering, environmental law, chemical process engineering, industrial process technology, environmental management, chemistry, and chemical engineering. Biographical sketches for committee members are presented in Appendix A.

During the course of the study, presentations and written information on secondary waste practices and regulatory requirements were received from a multitude of organizations that included individual Army facilities, Army contractors, industrial facilities, regulatory authorities, and other organizations involved with waste management.

The committee met in Washington, D.C. (August 2006); Tooele, Utah (September 2006); Washington, D.C. (December 2006); Irvine, California (January 2007); and Washington, D.C. (February 2007). In addition to these full committee meetings, small teams of four to six people from the committee also conducted fact-finding site visits to chemical agent disposal facilities in Anniston, Alabama (October 2006); Umatilla, Oregon (November 2006); and Newport, Indiana (November 2006). Visits and discussions on hazardous waste practices also took place at the Clean Harbors Aragonite hazardous waste incineration facility (Aragonite, Utah) and at the Chemical Waste Management of the Northwest, Inc., landfill (Arlington, Oregon). Additional details on the committee’s meetings and activities are included in Appendix B.

Representatives from the committee also met with state regulatory officials in Alabama, Indiana, Oregon, and Utah during the site visits. Their discussions centered on state regulatory requirements impacting local facilities and any perceived secondary waste issues for the chemical agent disposal facilities. Committee members also met with representatives from the Confederated Tribes of the Umatilla Indian Reservation, representatives from three local Citizens Advisory Commissions (CACs) in Newport, Tooele, and Umatilla, and other public officials (Anniston) to gauge local public perception of secondary waste practices, regulatory requirements, and any associated issues that might emerge at the disposal facilities.

Organization of the Report

Chapter 1 provides a background overview of the issues surrounding management of secondary waste at chemical agent disposal facilities. The report focuses on the four operating facilities that are based on incineration as the primary destruction technology. It also covers the one other active facility, which uses neutralization (hydrolysis) as the primary destruction technology.3 Chapter 1 also briefly describes the chemical processes in these chemical agent disposal facilities and the types, sources, and volumes of secondary waste handled. Importantly, Chapter 1 also summarizes federal and state regulatory requirements for managing the hazardous waste from both the Army’s facilities and similar industrial facilities, as well as site-specific permits requirements. Key issues and comparisons central to this report are addressed in the two chapters that follow. Chapter 2 addresses trial burns and health risk assessment. It compares the experience of the Army’s chemical agent disposal facilities with that of industrial facilities practicing similar technologies. Chapter 3 characterizes the

secondary wastes at each site, describes and analyzes practices and permit requirements, and compares these with the situation and practices at industrial sites. Anticipated wastes and waste disposal issues associated with site closure at the end of chemical agent disposal operations are addressed in Chapter 4. Findings and recommendations are presented in Chapter 5.

Throughout the report, specific chemical agent disposal facilities are listed in the alphabetical order of the names of the states where they are located. This parallels the organization of state regulatory considerations throughout the report. The units still in operation began operation in the following order: Tooele, Utah; Anniston, Alabama; Umatilla, Oregon; Pine Bluff, Arkansas; and Newport, Indiana.

CHEMICAL STOCKPILE DISPOSAL PROGRAM

Overview

During the Cold War, the United States produced and stockpiled over 31,000 tons of unitary nerve agents (sarin (GB) and VX) and blister agents (sulfur mustard (H), distilled sulfur mustard (HD), and mixed mustard (HT)). The agents were loaded into individual munitions or stored in bulk containers. They are now obsolete and their use has been banned by the Chemical Weapons Convention (CWC), an international treaty that was ratified by the U.S. Congress in 1997. The Chemical Stockpile Disposal Program began over two decades ago. In 1985, Congress had mandated that the Army institute a sustained program to destroy some elements of the chemical weapons stockpile (Public Law 99-145), and in 1992 it extended this mandate to require the destruction of the entire stockpile (Public Law 102-484). The CWC requires that its signatory nations destroy their entire chemical weapons stockpiles by April 29, 2007. An extension to April 29, 2012, has been granted to the United States, Russia, and several other nations.

The U.S. Army, as the executive agent for the U.S. Department of Defense, selected incineration as the preferred method of stockpile destruction for the first U.S. chemical agent disposal facility. The Johnston Atoll Chemical Agent Disposal System (JACADS) was located on Johnston Island, southwest of Hawaii, operated throughout the 1990s, and has since been demolished. The first disposal facility in the continental United States is the still active Tooele Chemical Agent Disposal Facility (TOCDF) in Tooele, Utah, which began agent destruction operations in 1996. It was followed by incineration facilities at three additional sites: the Anniston Chemical Agent Disposal Facility (ANCDF) in Anniston, Alabama; the Pine Bluff Chemical Agent Disposal Facility (PBCDF) in Pine Bluff, Arkansas; and the Umatilla Chemical Agent Disposal Facility (UMCDF) in Umatilla, Oregon.

In response to public concerns, the Army also developed and implemented chemical neutralization technology as the method of destroying chemical agent at two sites where chemical agents were stored in bulk, and no explosives or propellants had to be destroyed. The sites that have used neutralization technology are the Aberdeen Chemical Agent Disposal Facility (ABCDF) in Aberdeen, Maryland, and the Newport Chemical Agent Disposal Facility (NECDF) in Newport, Indiana. Design and construction plans for neutralization facilities to destroy the stockpiled chemical agent and associated munitions located at Pueblo, Colorado, and Lexington, Kentucky, are currently being developed and are not covered in this report. JACADS and ABCDF have completed their agent destruction campaigns and are also not directly covered in this report.

Operating history and chemical agent disposal progress for each operating chemical agent disposal facility are summarized in Table 1-1. The composition of the chemical weapon stockpile at a particular site, the length of time the facility has been in operation, and the type of agent destruction process used, all influence the type and quantity of secondary waste generated at a facility.

Process Descriptions

Baseline Incineration System

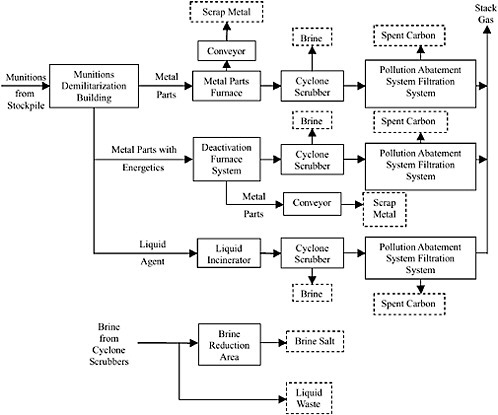

The baseline incineration systems for destroying chemical agent follow the process scheme shown in Figure 1-1. Agent contained in munitions (including rockets) and bulk containers is moved from the stockpile, where it is stored in igloos, to the munitions demilitarization building. The munitions are disassembled and the agent is drained from the munitions in this building. Energetics are also separated from the munitions at this point. Agent, metal parts, and energetics are then sent further for treatment and destruction. The liquid agent is sent to the liquid incinerator (LIC), where it is burned. Metal parts are treated in the metal parts furnace (MPF), where they are treated at high tempera-

TABLE 1-1 Chemical Agent Disposal Facility Start-up History and Progress

|

Location |

Process |

Start Date |

Agent Typea |

Share of Local Stockpile Destroyed (%)b |

|

TOCDFc |

Incineration |

August 1996 |

GB, H, HD, HT, VX |

59 |

|

ANCDFd |

Incineration |

August 2003 |

GB, HT, HD, VX |

27 |

|

UMCDFe |

Incineration |

September 2004 |

GB, HD, VX |

24 |

|

PBCDFf |

Incineration |

March 2005 |

GB, HD, HT, VXVX |

11 |

|

NECDFg |

Neutralization |

May 2005 |

VX |

43h |

|

aGB, a nerve agent known as sarin; H, HD, HT, blister or mustard agents; V X, an organophosphate nerve agent. bSite reported agent destruction progress as of February 2007. cTOCDF, Tooele Chemical Agency Disposal Facility. dANCDF, Anniston Chemical Agent Disposal Facility. eUMCDF, Umatilla Chemical Agent Disposal Facility. fPBCDF, Pine Bluff Chemical Agent Disposal Facility. gNECDF, Newport Chemical Agent Disposal Facility. hFurther treatment of the resultant hydrolysate is necessary to meet the requirements of the CWC (NRC, 1998). SOURCE: Agent destruction status as of February 28, 2007. Available at http://www.cma.army.mil/home.aspx#. Last accessed March 26, 2007. |

||||

ture to destroy any remaining agent and ensure that the metal parts meet the waste control limit (WCL) so that they can be shipped off-site. Energetics and metal parts with energetics are conveyed to the deactivation furnace system (DFS), where the energetics are destroyed and the metal parts are treated to meet the WCL. The metal from both the MPF and DFS is scrap metal and is a secondary waste. The gases from the three furnaces are treated in the pollution abatement system filtration system, where particulate and acid gases are removed in a cyclone scrubber and organic contaminants, primarily VOCs,4 are recovered by activated carbon adsorbers. The scrubber brine is either treated on-site and reduced to a solid in the brine reduction area before off-site disposal, or sent off-site as a brine solution if it meets the WCL. The off-gases, primarily carbon dioxide and water that are products of combustion, pass from the carbon filters to the stack, where they are discharged to the atmosphere. The activated carbon in adsorbers and filters requires periodic replacement. Depending on the source and degree of contamination, the waste carbon from this operation is either shipped off-site or stored on-site for future disposition.

Newport Neutralization Process

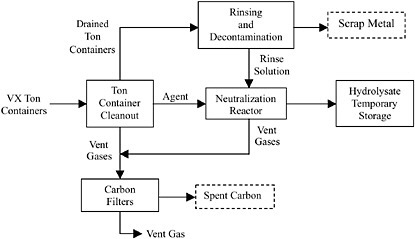

A process block flow diagram for the NECDF VX neutralization process is shown in Figure 1-2. The Newport stockpile of nerve agent VX is stored in bulk ton containers (TCs). These TCs are moved from the stockpile to the TC cleanout area, where the liquid agent is drained from the TC into a holding tank prior to treatment. The liquid is batch treated in the neutralization reactor, where it is mixed with an aqueous sodium hydroxide (NaOH) solution that hydrolyzes the VX into smaller organic molecules. The product of this neutralization, known as hydrolysate, is an aqueous mixture that may separate into two layers: an upper organic layer and a lower aqueous layer. The organic layer, which can make up from 0.5 percent to 5 percent by volume of the hydrolysate (IDEM, 2006), is tested to ensure that the VX has been destroyed and sent to temporary storage for further treatment to meet the requirements of the CWC (NRC, 1998). The vent gases from the process are sent through a series of high-efficiency particulate air filters and activated carbon adsorbers, which capture any remaining particulates and organic contaminants. The spent carbon is a waste that must be managed. The “empty” TCs are rinsed with a caustic decontamination solution to remove any residual liquid and thermally treated to meet the WCL, after which

they are sent to smelters as scrap. The liquid rinsate is returned to the neutralization reactor.

SECONDARY WASTE FROM CHEMICAL AGENT DISPOSAL FACILITIES

Types of Secondary Waste

The U.S. Army’s chemical agent disposal facilities, like many industrial facilities, produce wastes in the course of plant operations. For the purposes of this report, secondary waste is defined as any waste associated with the storage or destruction of chemical agent. Like other industrial waste, these wastes are either hazardous or nonhazardous. A particular waste is classified into one or the other of these categories by either laboratory analysis or “generator knowledge” of material source, use, and exposure (Box 1-1). The wastes discussed in this report are called “secondary wastes” to distinguish them from the chemical munitions that are

|

BOX 1-1 Definition of “Generator Knowledge” “Generator knowledge” is a hazardous waste evaluation method commonly accepted and defined by the EPA and individual states based on some or all of the following information:

SOURCE: EPA, 2005. |

being treated and disposed of, which are also wastes, but “primary” ones.

Many of the secondary wastes generated by the chemical agent disposal facilities are classified as hazardous by the federal and state regulatory agencies. This is because these wastes (1) exhibit a hazardous characteristic, (2) are listed as hazardous waste under the state regulatory program, (3) are derived from the treatment of a chemical warfare agent, or (4) are specified as hazardous in the state-issued facility permits. Hazardous wastes may therefore be either listed or characteristic, and some are both listed and characteristic. All hazardous and nonhazardous wastes generated at these facilities must be treated and disposed of in an environmentally safe manner, in accordance with the facility’s operating permits and applicable state and federal regulations. Treatment and disposal of secondary wastes is typically done locally, depending on the type of waste. Some hazardous waste can be treated on-site using thermal treatment, combustion, or decontamination technologies, while others must be shipped to off-site permitted treatment, storage, and disposal facilities (TSDFs).

Chemical agent disposal facilities generate the following major categories of secondary wastes over the lifetime of operations:

-

Spent activated carbon and spent particulate filter media from the pollution abatement system;

-

Brine solutions or brine salts resulting from evaporation of the brine;

-

Dunnage, consisting primarily of wooden pallets;

-

Scrap metal from munitions or TCs;

-

Plastics, particularly used demilitarization protective ensemble (DPE) suits and other personal protective equipment (PPE); and

-

Spent decontamination solution.

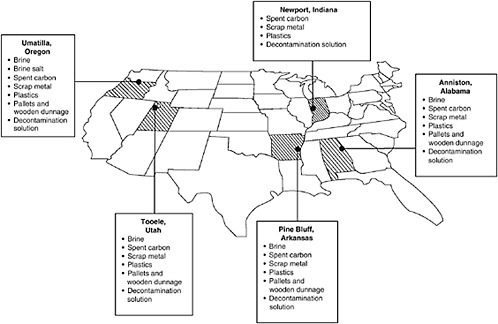

Figure 1-3 gives a pictorial overview of the main secondary waste streams generated across the five operating chemical agent disposal sites. Other common wastes generated at some or all sites but not covered in detail in this report include the following:

-

Cleaning materials;

-

Equipment parts from maintenance and repair activities, such as discarded pumps, piping, gaskets, and hoses;

-

Heated discharge conveyor ash and debris;

FIGURE 1-3 Major secondary waste distribution across chemical agent disposal facilities.

-

Incinerator slag and refractory; and

-

Laboratory waste.

These wastes are small in volume compared to the major secondary waste streams listed just above.

Chemical agent disposal facilities using incineration technology will have waste profiles somewhat different from facilities using neutralization technology. Table 1-2 gives a more detailed summary of both major and minor waste streams at chemical agent disposal facilities. The classification of these wastes and the acceptable treatment and disposal options, however, depend on state and federal regulations.

A separate category of waste, closure waste, results from the decontamination and destruction of the facility at the completion of disposal operations. These wastes, which are also classified as either hazardous or non-hazardous, are addressed in Chapter 4.

Sources of Secondary Waste

Direct chemical agent destruction operations as well as indirect or peripheral operations all result in secondary waste. Indirect or peripheral operations critical to chemical agent disposal facilities include laboratory operations, operations associated with protection of personnel or the environment, and operations associated with maintenance of the facility. The links between direct and indirect process operations and secondary waste streams are described next.

Pollution Abatement System Filtration System, Spent Activated Carbon

The pollution abatement system filtration system (PFS) treats all gases that emanate from the process or processing facilities. This includes gases flowing from the chemical processes and ventilation gases from the

TABLE 1-2 Site-Generated Waste Streams

forced air handling for all enclosed buildings on-site. Banks of activated carbon are used to capture and remove any trace-level residual semivolatile organics in the exhaust gases and air streams before release to the environment. The carbon beds are continuously monitored for organic breakthrough between individual trays of carbon, indicating when the trays need to be changed. This happens when the carbon is saturated to a specified practical limit, or is said to be “spent.” The beds containing spent carbon are emptied and refilled with fresh carbon. Spent activated carbon waste streams are generated at chemical agent disposal facilities using either the baseline incineration system or the neutralization process. The spent carbon may be considered hazardous or nonhazardous depending on the organic contaminants adsorbed, but they may also be classified as hazardous as a result of state regulation or site-specific permit conditions. In addition, prefilters, high-efficiency particulate air filters, and demister candles, all containing carbon, are also monitored and replaced as necessary. Spent carbon disposal options depend on contaminant type, contaminant level, and specific facility permit requirements. In at least two facilities, TOCDF and UMCDF, mustard agent containing mercury will be treated and will result in mercury-contaminated spent carbon in the PFS. Any such carbon will require special treatment and disposal techniques.5

PFS Scrubber Brine

Scrubber brine results from the treatment by the PFS of the process gases coming from the incinerators. Scrubber brine contains water, dissolved salts, suspended solids, and trace amounts of heavy metals. After use, scrubber brine is designated as spent brine and is transferred to storage tanks before off-site shipment to a permitted TSDF. A thermal evaporation system for concentrating the spent brine solution to solid brine salts is used at some sites, while other sites manage this waste as a brine solution. The use of a thermal evaporation brine reduction system may be required by individual site permits.

Spent Decontamination Solution

Decontamination solutions are dilute aqueous solutions of caustic or sodium hypochlorite. These solutions are used to wash (decontaminate) work areas where agent has spilled. They are also used to decontaminate a worker in PPE prior to removing the suit for disposal. Spent decontamination solution (SDS) usually contains very small amounts of the chemical agent breakdown products resulting from hydrolysis of the agent present on the surface being decontaminated. SDS is collected and stored on-site for later disposal either off-site or on-site by incineration.

Metal Parts Furnace Scrap Metal

This scrap metal includes metal munitions casings after the chemical agent has been drained and the casings have been treated in the MPF. Drained bulk containers and metal munition casings and components are treated in the MPF to destroy agent residues. After treatment in the MPF, the metal parts are allowed to cool, vacuumed to remove loose paint flakes and ash residue, and stored temporarily in roll-off bins prior to shipment off-site. Munition bodies and empty TCs are carbon steel and may be recycled by smelting at either a commercial recycling facility or the Rock Island Arsenal,6 or disposed of at a hazardous waste landfill.

Furnace Ash and Debris

The DFS differs from the MPF in that it is equipped to process drained rockets, mortars, mines, and explosive components from projectiles. This processing leaves behind fiberglass ash and metal debris (aluminum and steel). The ash and debris are collected in bins, allowed to cool, and sampled and analyzed to verify that they are agent free. Once this determination has been made, the wastes are consolidated into larger roll-off bins. The ash and debris are transported to a hazardous waste landfill.

Wood Dunnage

Wood dunnage is the wood packing in and on which the munitions are stored in the munition storage igloos. The wood pallets and packing materials are monitored to verify that there is no agent contamination. This monitoring is done by analyzing the atmosphere in the igloos and in the transport vehicles between the storage area and the processing area. Once this verification occurs, the dunnage is characterized as a nonhazardous waste. This uncontaminated dunnage waste is accumulated in roll-off bins before shipment to an approved industrial waste landfill. Wood that might be contaminated with agent from leaking munitions is classified as hazardous and is disposed of on-site by incineration.

Liquid Incinerator Slag and Refractory

Slag is a molten, glasslike material that forms inside the LICs from the burning of SDS. When cooled to ambient temperature, it forms a solid. Refractory is a bricklike material used to line the inside of the LICs to provide insulation from the heat. As slag accumulates and the refractory gradually corrodes and is replaced, these waste materials are removed from the LIC. Slag and refractory are listed hazardous wastes in some states because they are derived from the chemical demilitarization process. These wastes typically are shipped to a hazardous waste landfill.

Maintenance, Lab, and Monitoring Wastes

A variety of small-volume wastes are generated by maintenance, analytical, and monitoring activities. These primarily consist of discarded glassware, wipe cloths, gloves, plastic, trash, and paint waste, as well as other monitoring materials. Most of these materials

|

6 |

Rock Island Arsenal is the largest government-owned weapons manufacturing arsenal in the United States. It is an active U.S. Army facility and manufactures ordnance and equipment. Some scrap metal is sent to Rock Island from chemical agent demilitarization facilities for smelting and recycling. More information can be found at http://www.ria.army.mil/sites/local/ and http://www.globalsecurity.org/military/facility/rock-island.htm. |

have hazardous components; they are also listed hazardous wastes in some states because they are derived from the demilitarization process. These wastes are generally transported off-site to appropriate permitted facilities suited to treatment and disposal of the particular type of waste.

Waste Demilitarization Protective Ensemble Suits

DPE suits are encapsulating, supplied-air PPE worn by personnel required to enter areas where chemical agent liquid or vapors are known to exist. Each suit is decontaminated and monitored for chemical agent vapor before being removed from the worker. Discarded DPE suits are characterized for chemical agent contamination based on generator knowledge and/or chemical agent vapor monitoring results. Waste DPE suits and similar plastic materials are sealed in containers and placed in storage on-site. These materials, depending on the type of waste and the level of contamination, are destroyed in the incinerators at baseline facilities or sent to off-site TSDFs.

Hydrolysate

NECDF is the only operating chemical agent disposal facility using neutralization technology. ABCDF also used neutralization technology to treat mustard agent but has now completed operations. The NECDF neutralization facility generates a dilute caustic process waste stream known as VX hydrolysate, in addition to generating many of the same secondary wastes found at baseline incineration facilities. Hydrolysate is a caustic wastewater containing breakdown products that come from the hydrolysis of the agent. This stream must undergo a second treatment step to meet the requirements of the CWC. Several disposal options for V X hydrolysate have been considered. This stream is not included in the quantities and waste inventory tables cited, but is reported and discussed separately in this report.

Quantities of Secondary Waste

CMA has estimated the types and quantities of secondary wastes projected to be in storage at the end of operations for each of the five chemical agent disposal facilities included in this study (Table 1-3). These quantities include wastes generated during operations but exclude wastes for which an on-site or off-site disposal option is currently available and is being used. Table 1-3 also does not include closure wastes. Several of the smaller individual waste streams cited earlier are combined in this summary for reporting purposes. The total estimated secondary waste stream inventory at the end of operations based on current practices is

TABLE 1-3 Projected Secondary Waste Inventories in Storage Across Sites at End of Operations According to Vapor Screening Levels (tons)a

|

|

Total Across All Sites |

|

|

Secondary Waste Stream |

Above VSLsb |

Below VSLs |

|

Spent carbon from filters |

1,112 |

869 |

|

Containerized combustible solids |

301 |

1,423 |

|

Containerized miscellaneous solids |

13 |

140 |

|

Containerized DPE/PPE/TAPc gear |

605 |

241 |

|

Metals |

177 |

76 |

|

Subtotal solids |

2,208 |

2,749 |

|

Spent decontamination solution |

318 |

0 |

|

Miscellaneous liquids |

63 |

13 |

|

Subtotal liquids |

381 |

13 |

|

Total |

2,589 |

2,762 |

|

aSite managements’ best estimates as of January 2007. bVSL, vapor screening limit, an internal control limit used to clear materials for off-site shipment, discussed in detail in Chapter 5. cTAP gear is protective clothing made mostly of butyl rubber. SOURCE: Personal communication between Raj Malhotra, CMA Deputy, Technical Support Directorate, and Billy Williams, NRC study director, December 11, 2006. |

||

projected to be over 5,000 tons (more than 10 million pounds), excluding neutralization hydrolysate. Spent activated carbon represents the largest of these streams and nearly 35 percent of the total nonclosure waste anticipated. The waste streams and special disposal issues at each of the five operating chemical agent disposal facilities are profiled in detail in Chapter 3.

REGULATORY FRAMEWORK AND CONSIDERATIONS

Overview of Federal Resource Conservation and Recovery Act Requirements

The generation, accumulation, treatment, storage, and disposal of hazardous wastes are regulated under RCRA and the Hazardous Solid Waste Amendments of 1984. Wastes derived from the management and destruction of chemical agents and munitions, i.e., “secondary wastes,” must be assessed under this authority and, if determined to be hazardous, must be managed under it.

The U.S. Environmental Protection Agency (EPA) authorizes states to regulate hazardous wastes within their borders under RCRA. A state must adopt a program that is no less stringent than the requirements adopted by the EPA (40 CFR 271). All of the states with operating chemical agent disposal facilities, namely, Alabama, Arkansas, Indiana, Oregon, and Utah, have obtained EPA authorization to implement and enforce state requirements for the management of hazardous waste.

Each of these states has adopted the basic EPA hazardous waste management program, including regulations for identification and listing of hazardous wastes; requirements applicable to generators and transporters of hazardous waste; requirements for facilities that treat, store, or dispose of hazardous waste; and restrictions for the land disposal of specific hazardous wastes.

Each state has a program for granting permits for the construction and operation of TSDFs. Permits stipulate the general RCRA requirements in the design, construction, and operation of a TSDF. They also establish appropriate site-specific conditions for all aspects of the hazardous waste management and destruction processes used. Secondary waste from the five chemical agent disposal facilities covered in this report are governed by the TSDF regulations and requirements established in the respective states in which these facilities are located. More recently, the Clean Air Act emission standards have been added to the operating permits for the four baseline incineration facilities, as discussed in additional detail in Chapter 2.

Waste Characteristics and Listing

There are two types of regulated hazardous waste: “characteristic” wastes and “listed” wastes. A solid waste is classified as a characteristic hazardous waste if it exhibits any of the following: ignitability, corrosivity, toxicity, or reactivity. A solid waste is a “listed” hazardous waste if it is specifically listed by the EPA or a state regulatory body based on certain criteria (40 CFR 261.11).

Phosgene is the only chemical agent that is a listed hazardous waste under the federal RCRA program. It is listed as an acute hazardous waste, commercial chemical, or manufacturing chemical intermediate (Hazardous Waste Code7 P095). Mustard agent is the only chemical agent included as a hazardous constituent under 40 CFR 261.11.8 Therefore, it can be considered for listing by the EPA or state regulatory authorities but is not currently a federally listed waste.

One of the critical differences between characteristic hazardous wastes and listed hazardous wastes is that, under RCRA regulations, any wastes derived from the treatment, storage, or disposal of a listed hazardous waste (e.g., treatment residues or secondary wastes from storage) are themselves regulated as listed hazardous waste. In addition, any mixture of a solid waste and a listed hazardous waste is then also designated as a listed hazardous waste. The listed hazardous waste designation applies regardless of the actual hazardous characteristics of the waste. Unlike listed hazardous wastes, wastes that exhibit one or more of the RCRA characteristics are not subject to the mixture

or derived-from rules, and once they no longer exhibit the characteristic, they are no longer hazardous wastes and may be managed under the less stringent rules for nonhazardous solid wastes.

Scrap Metal Exclusion

EPA regulations on scrap metal are not straightforward. These regulations provide that all “excluded scrap metal”9 that is recycled is not a solid waste and, therefore, hazardous waste regulations would not apply (40 CFR 261.4(a)(13)). The regulations go on to state that all other scrap metal sent for recycling/reclamation is a solid waste and therefore is a hazardous waste if it exhibits a characteristic or has become contaminated with a listed waste (40 CFR 261.2(c)). However, a later section exempts from RCRA regulation all hazardous scrap metal if it is sent for recycling/reclamation (40 CFR 261.6(a)(3)(ii)). Therefore, under the federal and most state RCRA regulatory schemes, all scrap metal going to recycling, whether or not it exhibits a characteristic or has become contaminated with a listed waste, is exempt from the hazardous waste regulations. No waste characterization is necessary for material that meets the definition of scrap metal that will be recycled. Scrap metal that is to be disposed rather than recycled, however, is a solid waste and must be characterized and disposed of accordingly.

Maximum Achievable Control Technology Regulation

In October 2005, under authority of the Clean Air Act and RCRA, the EPA issued its final national emission standards for hazardous air pollutants from hazardous waste combustors. The standards require hazardous waste combustors to meet hazardous air pollutant emission standards reflecting the application of maximum achievable controllable technology (MACT). These standards are applicable to any hazardous waste incinerator, including the chemical agent disposal facilities. In some states, separate air permits are issued to hazardous waste incinerators, while in others the RCRA permit requirements are adopted or changed to implement the requirements of the new MACT emissions standards for controlling the following pollutants:

-

Dioxins and furans;

-

Mercury;

-

Semivolatile metals (cadmium and lead);

-

Low-volatility metals (arsenic, beryllium, and chromium);

-

Particulate matter, as a surrogate for nonmercury metal; and

-

Other hazardous air pollutants, including certain metals, hydrogen chloride, chlorine gas, and organic hazardous air pollutants.

Overview of State-Specific Regulatory Requirements

Each state has adopted its own waste characterization regulations. Alabama and Arkansas have generally adopted the federal scheme of regulation for hazardous waste characterization and listing. However, Indiana, Oregon, and Utah have issued additional regulations specifically addressing chemical agents or munitions. The discussion below addresses the general state-specific regulatory requirements for waste characterization and listing in the five affected states. However, each state can include in a permit additional requirements for the management and disposal of specific wastes. These additional requirements are discussed further in Chapter 3.

Alabama

The Alabama Department of Environmental Management (ADEM) has adopted hazardous waste regulations that mirror the federal RCRA program (Alabama Administrative Code Revised 335-14-2). ADEM has not specifically designated chemical agents or chemical munitions as listed hazardous wastes; therefore, under the Alabama RCRA regulatory program, secondary wastes from the treatment or management of chemical agents or munitions must be managed as RCRA hazardous waste only if they exhibit hazardous characteristics.

Arkansas

Similar to the situation in Alabama, the Arkansas Department of Environmental Quality (ADEQ) has promulgated hazardous waste regulations that basically reflect the federal RCRA program (ADEQ Regulation No. 23). ADEQ likewise has not specifically designated chemical agents or munitions as listed hazardous wastes; therefore, under the Arkansas RCRA regulatory

program, secondary wastes from the treatment or management of chemical agents or munitions must be managed as RCRA hazardous waste only if they exhibit hazardous characteristics.

Indiana

The Indiana Department of Environmental Management (IDEM) has also generally adopted the federal RCRA regulations concerning the identification and listing of hazardous waste (329 Indiana Administrative Code 2.1-6-1(b)). However, in addition to the federal list of hazardous wastes, the following wastes are listed hazardous wastes under the IDEM program and have been assigned the Indiana Hazardous Waste Code I001:

-

Nerve agents GA, GB, and VX;

-

Mustard agents H, HD, HT (60 percent mustard agent and 40 percent T, which is bis(2-chloro-ethylthioethyl) ether); and

-

Lewisite.

Oregon

The Oregon Department of Environmental Quality (ODEQ) has incorporated by reference the federal RCRA regulations for identification and listing of hazardous wastes (Oregon Administrative Rules 340-101-001). In addition to the federally listed acute hazardous wastes, ODEQ regulations include the following as state-specific listed hazardous wastes:

-

Blister agents (such as mustard agent) (Hazardous Waste Code P998) and

-

Nerve agents (such as GB and VX) (Hazardous Waste Code P999).

Oregon regulations also include the following as additional state-specific listed hazardous wastes from nonspecific sources:

-

Residues from demilitarization, treatment, and testing of blister agents (such as mustard agent) (Hazardous Waste Code F998)10 and

-

Residues from demilitarization, treatment, and testing of nerve agents (such as GB and VX) (Hazardous Waste Code F999).

Utah

The Utah Department of Environmental Quality (UDEQ) regulations generally restate the federal RCRA regulations concerning identification and listing of hazardous wastes (Utah Administrative Rules R315-2). Therefore, the UDEQ regulations incorporate by reference the list of acute hazardous wastes and then add the following state-specific listed wastes:

-

Nerve, military, and chemical agents (i.e., CX, GA, GB, GD, H, HD, HL, HN-1, HN-2, HN-3, HT, lewisite, T, and VX) (Hazardous Waste Code P999).

The UDEQ regulations also incorporate by reference the federal list of hazardous waste from nonspecific sources and then add the following state-specific listed wastes:

-

Residues from demilitarization, treatment, and testing of nerve, military, and chemical agents CX, GA, GB, GD, H, HD, HL, HN-1, HN-2, HN-3, HT, lewisite, T, and VX (Hazardous Waste Code F999).

Overview of Site-Specific Permits

Each chemical agent disposal facility has been issued a RCRA permit under the applicable state regulations. These permits establish the waste characterization requirements, the pertinent sampling/analysis methodologies, waste disposal methods, facility oper-

ating parameters, and closure requirements for each facility. In addition to reflecting the requirements found in each state’s law and regulations, permit provisions also establish specific operating parameters and waste characterization requirements that are not specifically addressed in the general state regulations. A facility must file a modification request to deviate from any of the provisions set forth in its permit. The individual facility permit requirements for specific secondary waste streams are discussed in Chapter 3.

Anniston

ADEM issued a permit (AL3210020027) to the U.S. Department of the Army, Anniston Army Depot; the U.S. Department of the Army, ANCDF Field Office (ANCDF site); and Westinghouse Government Environmental Services Company LLC to operate a hazardous waste storage and treatment facility.

Pine Bluff

The Arkansas Department of Pollution Control and Ecology issued a permit (Permit No. 29-H) to Pine Bluff Arsenal to operate a hazardous waste management facility at Pine Bluff Circle, Jefferson County, Arkansas.

Umatilla

The Oregon Environmental Quality Commission issued a permit (ORQ 000 009 431) to the U.S. Army, as represented by the Umatilla Chemical Depot and the Washington Demilitarization Company, LLC, to operate a hazardous waste treatment and storage chemical demilitarization facility located in Umatilla County in Hermiston, Oregon, off Interstate Hwy-84 at exit 177.

Tooele

The Utah Solid and Hazardous Waste Control Board issued a permit (UT 3213820894) to the Tooele Army Depot to operate a hazardous waste treatment and storage facility located approximately 3 miles south of Tooele, on State Highway 36, in Tooele County, Utah.

Newport

IDEM issued a permit (IN1210022272) to Newport Chemical Depot to operate a hazardous waste facility located in Newport, Indiana.

Comparison of Broad Regulatory Requirements for Chemical Agent Disposal Facilities and Industrial Facilities

Based on the information gathered by the committee, there is little difference in the overarching regulatory requirements at industrial TSDFs and U.S. Army chemical agent disposal facilities.

The transportation, treatment, storage, and disposal of hazardous wastes are regulated under RCRA, the Hazardous Solid Waste Amendments of 1984, and the regulations promulgated thereunder. Wastes derived from the management and destruction of chemical agents and munitions are assessed under this authority and, if determined to be hazardous wastes, must be managed under these regulations. The same regulations and authority apply to hazardous waste from industrial waste facilities. Specific hazardous wastes may be declared “listed hazardous wastes” by federal or state regulations.

In three of the states hosting chemical destruction facilities, the wastes that result from the disposal of agent-containing munitions have been declared listed hazardous wastes by the state. The regulation and management of listed hazardous wastes associated with disposal of agent are similar to the management of listed hazardous wastes from industrial processes.

There are some differences in the specific waste disposal management schemes at the five sites that were reviewed. Most of the differences between the five chemical destruction facilities are due to the different implementation strategies in place in the five different states, particularly permit parameters and requirements. Each state has a program for granting permits for the construction and operation of TSDFs. Permits implement the general RCRA requirements in the design, construction, and operation of a TSDF. They also establish appropriate site-specific conditions for almost every aspect of the hazardous waste management and destruction processes used.

Secondary waste from the five chemical agent disposal facilities covered in this report are governed by the regulations and requirements established in the respective states in which these facilities are located. The same is generally true for industrial facilities located in these states. However, the management of chemical warfare agents and munitions is not directly addressed in the federal or state RCRA programs (e.g., there are no land disposal restrictions established for the warfare agents). This may result in some differences in the

management and shipping criteria found in chemical destruction facility permits. The application of these individual state requirements to specific waste streams and a comparison to practices and requirements at similar facilities in industry are provided in Chapters 2 and 3.

REFERENCES

EPA (U.S. Environmental Protection Agency). 2005. RCRA Hazardous Waste Identification Training Module, 40 CFR Part 261, September. Washington, D.C.: U.S. Environmental Protection Agency.

IDEM (Indiana Department of Environmental Management). 2006. Hazardous Waste Management Permit, Newport Chemical Depot, June 21. Indianapolis, Ind.: Indiana Department of Environmental Management.

NRC (National Research Council). 1998. Using Supercritical Water Oxidation to Treat Hydrolysate from VX Neutralization. Washington, D.C.: National Academy Press.

NRC. 2006. Assessment of the Continuing Operability of Chemical Agent Disposal Facilities and Equipment. Washington, D.C.: The National Academies Press.

UDEQ (Utah Department of Environmental Quality). 2004. Tooele Chemical Agent Disposal Facility Resource Conservation and Recovery Act Hazardous Waste Permit. Salt Lake City, Utah: Utah Department of Environmental Quality.