4

Performance of Barrier System Components

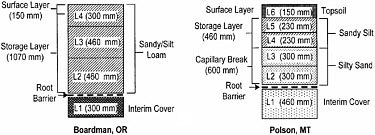

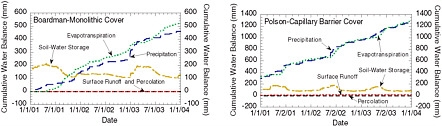

The performance of a barrier system component depends on two factors: (1) the performance of the component itself and (2) the way individual components interact as a system to contain contaminant transport. This chapter focuses on observations and predictions of the performance of individual barrier system components. Component interaction and overall barrier system performance are discussed in Chapter 5.

Problems that may arise with the performance of barrier system components in the short, medium, and long terms (see definitions in Box 1.2) are summarized in Table 4.1.

4.1

EARTHEN BARRIERS

Processed natural soils and mineral admixtures such as bentonite are extensively used as components of liners, covers, and vertical barrier walls in waste containment systems. At some sites the natural soil layer underlying a waste landfill or contaminated ground may be relied on to isolate and/or absorb contaminants in an engineered barrier system. If geological conditions and testing indicate that such layers are suitable in their initial state, they may still be subject to the same types of long-term performance concerns as earthen layers within liners and covers, including secondary structure development, incompatibility with the waste, and defects arising from induced deformations. Key performance concerns for earthen barriers, such as compacted clay liners, include the following:

-

Short term: the ability to achieve the specified hydraulic conductivity upon construction in the field and slope stability.

-

Medium and long term: increases in hydraulic conductivity with time caused by desiccation, shrink/swell, freeze/thaw, root penetration, thermal stresses, differential settlement, or chemical incompatibility; erosion of protective soil layers, development of secondary structures from cracking; and waste and slope stability.

Observations and predictions associated with these performance considerations are discussed below.

4.1.1

Hydraulic Conductivity

Field performance data on as-constructed compacted clay liners are summarized by Benson and Boutwell (1992), Daniel (1984, 1990), Cartwright and Krapac (1990), Elsbury et al. (1990), Gordon et al. (1990), Johnson et al. (1990), Reades et al. (1989), Trautwein and Williams (1990), King et al. (1993), Benson et al. (1999), Rowe et al. (2000), and Rowe (2005), among others. Reliable field permeability measurements generally require use of relatively large-scale tests, such as sealed double-ring infiltrometer tests or back calculation from lysimeter performance, to account for potential development of secondary structures within the compacted clay. An example of the measurement of the hydraulic conductivity of a compacted clay liner in the field using a sealed double-ring infiltrometer is given in Box 4.1. Available field performance data indicate that a target saturated hydraulic conductivity value (e.g., the prescriptive value of 1 × 10−9 m/s for Subtitle D low-permeability liner systems) can generally be achieved at the end of construction if the soil is compacted wet of the optimum moisture content and proper construction procedures are used.

Hydraulic conductivity data on compacted clay low-permeability soil layers for 85 cases from active landfill cells (8) and test pads (77) were reported by Benson et al. (1999). All of the compacted clay layers were intended to achieve a saturated hydraulic conductivity of less than 1 × 10−9 m/s. Although the test results indicated that the low-permeability soil layers for all 8 of the active landfill cells achieved a saturated hydraulic conductivity of less than 1 × 10−9 m/s (as measured by lysimeters), 22 of the 77 test pads tested did not achieve that goal, despite the fact that in all but 3 cases laboratory testing on thin-walled tube samples recovered from the test pad yielded a saturated hydraulic conductivity of less than 1 × 10−9 m/s.

TABLE 4.1 Performance Concerns for Barrier System Components

Relatively good agreement was achieved between hydraulic conductivities measured in the field using lysimeters (underdrains) and sealed double-ring infiltrometers, with geometric means of 9 × 10−11 m/s (8 cases) and 5 × 10−10 m/s (77 cases), respectively. However, the field-measured hydraulic conductivities did not correlate well with laboratory values of hydraulic conductivity measured on samples recovered from the test pad using thin-walled tubes when the soils were compacted dry of the optimum moisture content. This result reaffirms the need to compact clay liners wet of the optimum moisture content. Provided that this criteria is met and that there are no obvious visible secondary features (e.g., desiccation cracks), experience has shown that the hydraulic conductivity obtained in the laboratory on samples recovered with thin-walled tubes correlates well with values obtained in the field using lysimeters (e.g., Rowe et al., 2004).

Direct measurements of field hydraulic conductivity using sealed double-ring infiltrometers, as described in Box 4.1, are generally made only on test pads to establish compaction procedures and index properties (e.g., compaction moisture content and density) for quality control of the actual liner. Although the majority of field hydraulic conductivity measurements on compacted clay liners are made during or just after the completion of liner construction, some data are available on the hydraulic conductivity of a liner in the medium term. Box 4.2 describes the performance of a compacted clay liner test section subject to a constant hydraulic head of 0.3 m over a 14-year period. The performance of a liner in a waste containment environment may be influenced by the effects of increased temperatures, accompanying waste decomposition, and overburden pressures, as illustrated by the case history in Box 4.3.

4.1.2

Secondary Features

The difference between laboratory- and field-measured saturated hydraulic conductivity values for compacted earthen barriers can be attributed to macrostructure that often occurs when the soil is compacted at or dry of the optimum moisture content (Benson et al., 1999). Secondary features

|

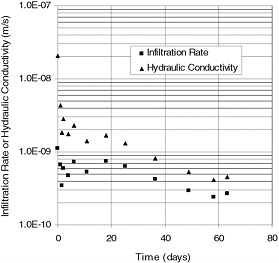

BOX 4.1 Case History on Measuring Field Performance of Compacted Clay Liner This case history illustrates the use of hydraulic conductivity measurements in the field to demonstrate the short-term performance of a compacted clay liner. The field data come from a test pad constructed to evaluate a compacted clay liner for a proposed hazardous waste landfill near Phoenix, Arizona (Gilbert, unpublished). The compacted clay liner was a soil-bentonite admixture, and the test method was a sealed double-ring infiltrometer (Daniel, 1989; ASTM D 3385-88). A 1.5-m square “ring” was placed on top of the liner and filled with water to a depth of 0.3 m. The infiltration rate (the volumetric rate of flow per unit area seeping into the top of the clay liner under a constant head) was measured by tracking the mass of water lost from the ring as a function of time. The infiltration rate in Figure 4.1 was calculated assuming that all of the water lost was infiltrated down into the clay liner. Tensiometers in the clay liner at depths of 0.15, 0.3, and 0.45 m were used to track the change in matric suction, and therefore pore water pressure, with depth and time as the water infiltrated the liner. When the measured matric suction is zero in a tensiometer, the hydraulic gradient can be estimated by assuming the pore water pressure is equal to zero at the elevation of the tip of the tensiometer. The infiltration rate, q, is related to the hydraulic conductivity as follows: q = ki, where k is the hydraulic conductivity and i is the hydraulic gradient. Hence, the hydraulic conductivity in Figure 4.1 is calculated by dividing the infiltration rate by the estimated gradient. The calculated or “measured” hydraulic conductivity changes with time for several reasons: (1) the soil swells during the test, so some of the flow lost from the inner ring goes into storage and does not infiltrate through the clay liner; (2) the depth of soil used to estimate the hydraulic conductivity increases with time and the soil displays variability with depth (such as layering); and (3) the hydraulic gradient changes rapidly with time and is more difficult to estimate at the beginning of the test. The reported value is typically taken from the last reading, a hydraulic conductivity between 2 × 10−10 and 3 × 10−10 m/s in this case. Note that this hydraulic conductivity does not necessarily correspond to saturated conditions because of the possible existence of entrapped air, but the measured value probably corresponds reasonably well to the field value since the test conditions are similar to those expected in the field except for the lack of overburden stress on the clay liner. In the field application the applied stress from waste in the actual landfill will tend to increase the degree of saturation and reduce the saturated hydraulic conductivity due to consolidation. The saturated hydraulic conductivity was measured in the laboratory on small-scale (64-mm-diameter), thin-walled tube samples taken from the clay liner at the end of construction. The laboratory measurements, which correspond to saturated conditions, ranged from 1 × 10−10 m/s to 7 × 10−10 m/s with a geometric mean of 3 × 10−10 m/s. Therefore, in this case, the hydraulic conductivity measured at the field scale (a 1.5-m square area), between 2 × 10−10 and 3 × 10−10 m/s, was both comparable to the laboratory measurements on small-scale samples under saturated conditions and less than the regulatory-specified maximum of 1 × 10−9 m/s.

FIGURE 4.1 Field data from sealed double-ring infiltrometer test on a compacted clay liner. |

|

BOX 4.2 Case History on Field Performance of a Compacted Clay Liner This case history documents the monitoring of an instrumented earthen liner for changes in hydraulic conductivity over 14 years. In 1987 a heavily instrumented earthen liner was constructed by the Illinois State Geological Survey in Champaign, Illinois. The liner had dimensions of 7.3 m × 14.6 m × 0.9 m and was impounded with 0.3 m of water for 14 years. Two years after construction a hydraulic conductivity of 3–4 × 10−10 m/s was measured using large- and small-ring infiltrometers (Cartwright and Krapac, 1990). The liner was originally compacted to a mean gravimetric water content of 11.6 ± 1.2 percent, a dry density of 1.83 ± 0.071 kg/m3, and a saturation of 64.0 ± 9.6 percent (Frank et al., 2005). After 14 years of ponding, the water content remained relatively constant (10.6 ± 1.0 percent during excavation), even though water infiltration into the liner was documented. The essentially constant water content was attributed to insufficient hydraulic pressure to saturate the unsaturated portions of the liner. In contrast, the mean dry density of the liner increased approximately 10 percent by the conclusion of the test, and the saturation increased to 80.0 ± 6.3 percent. Tracer studies and modeling performed at the conclusion of the test indicated that the advective transport of tracers through the liner was negligible, with model results yielding k ≤ 1 × 10−9 m/s (Willingham et al., 2004). |

|

BOX 4.3 Case History on Long-Term Field Hydraulic Conductivity Changes Resulting from Consolidation and Heating This case history illustrates how the hydraulic conductivity of a clay layer in a bottom liner system in a municipal solid waste landfill can decrease over time because of consolidation but also increase over time (to a lesser extent) because of increased liner temperature. The Keele Valley Landfill, located in Maple, Canada, covers 99 hectares. The barrier system typically consists of a 1.5-m-thick compacted clay liner overlain by a 0.3-m-thick sand protection layer and a leachate collection system (described in Box 4.4). The landfill capacity is approximately 33 million m3, and the maximum depth of waste at closure was about 65 m. Between the first acceptance of waste in 1984 and closure in December 2002, the landfill received 28 million tonnes of municipal solid waste. The landfill has been extensively monitored and studied (Rowe, 2005). The hydraulic conductivity of the compacted clay liner was monitored by means of several lysimeters below the liner. Consolidation was an important factor affecting changes in the hydraulic conductivity k with time. For example, at 1 lysimeter the waste thickness increased from 1 m in November 1984 to 33 m in April 1987, then remained relatively constant. The annual average k of the liner dropped from 4 × 10−10 m/s in 1984 to 3.1 × 10−11 m/s in 1991. Two consolidation-related factors could have affected flow to the lysimeter during this period. First, expulsion of water from voids during consolidation is not explicitly considered in calculating k, so the inferred k value will be higher than the actual value until consolidation is complete. This effect was greatest from 1984 to 1987 when the waste thickness increased. Second, the decrease in void ratio of the soil due to consolidation will result in a decrease in k with time. Both effects occurred relatively quickly in the liner since consolidation was fast (95 percent consolidation in less than a year for a given load increment), but the decrease in void ratio was the dominant factor (Rowe, 2005). Hydraulic conductivity of the compacted clay liner was also influenced by temperature. The temperature above the compacted clay liner was monitored at four locations over a 21-year period (Barone et al., 2000; Rowe, 2005). At one location the average annual temperature above the liner increased from 14°C in 1991 to 35°C in 1995, after which time the temperature remained constant (see Box 5.3 for the relationship between temperature and the performance of the overlying leachate collection system). Over the same period, the average annual hydraulic conductivity at this location increased from 3 × 10−11 m/s to 5 × 10−11 m/s. This increase matches what would be expected from theoretical consideration of the effect of temperature on the viscosity and density of the leachate. Since both the temperature and the hydraulic conductivity have stabilized, no significant effect of clay-leachate interaction over the subsequent 8 years is likely (Rowe et al., 2004). |

such as cracks and voids can degrade the performance of both compacted earthen barriers and natural clay layers, where secondary features such as fissures are known to have a significant impact on performance (e.g., Keller et al., 1986; Rowe et al., 2000). Stress relief from differential settlement in soil covers can create secondary zones of high permeability, even in the absence of detectable cracking. The development of secondary features in a clay barrier as a result of desiccation, freeze/thaw damage, or tensile strains can cause significant increases in hydraulic conductivity. This effect is a particular concern for cover systems and for clay liners that are left uncovered during and after construction. Field data on air desiccation and freeze/thaw damage have been reported by Montgomery and Parsons (1990), Benson and Othman (1993), Corser and Cranston (1991), Benson and Khire (1995, 1997), Melchior (1997), Albrecht and Benson (2002), and Albright et al. (2006).

Desiccation of compacted clay liners in cover systems has been reported to result from both drying and freezing (Benson and Khire, 1997; Benson, 1999; Albrecht and Benson, 2002; Albright et al., 2006). Test pits excavated in compacted clay liners 6 months and 3 years after construction showed

extensive cracking in a profile with a single compacted clay liner.

Desiccation of compacted clay liners in bottom barrier systems is also possible if the liners are left uncovered (or covered only by a geomembrane) for weeks or months after construction (Corser and Cranston, 1991). Heat generated in the waste may also cause desiccation over the long term. The potential for desiccation depends on the temperature gradient, the water retention curve of the soil below the clay liner, and the location of the water table (Rowe, 2005). For example, a test plot of a barrier system with a geomembrane overlying a compacted clay liner was subjected to a constant temperature of 40°C above the liner system and an overburden stress of approximately 40 kPa for 2.5 years (August et al., 1997). The compacted clay liner was underlain by a fine-grained soil in one section and a coarse-grained soil in another section. The water content of the section over the fine-grained soil remained relatively constant with maximum changes of less than 1 percent, whereas the water content of the section over the coarse-grained soil decreased up to 7 percent under thermal gradients as low as 5°C/m. Additional studies of desiccation of clay liners in composite liner systems caused by the heat from decomposing waste are reported by Rowe (2005).

4.1.3

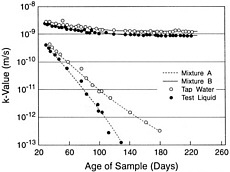

Chemical Compatibility

The long-term performance of earthen barriers with respect to advective flow depends directly on the hydraulic conductivity of the soil barrier materials after saturation by the liquid being contained, which for liner systems is typically leachate rather than water. It is important to know, therefore, whether or not the barrier soil and permeating liquid are compatible so that permeation with the liquid causes no significant increase in hydraulic conductivity relative to that based on permeation with water (Fernandez and Quigley, 1985, 1988; Bowders et al., 1986; Bowders and Daniel, 1987; Shackelford, 1994; Shackelford et al., 2000; Rowe et al., 2004; Lee et al., 2005). Chemical incompatibility may create adverse effects both by increasing the saturated hydraulic conductivity of the soil and by creating secondary features that increase the mass saturated hydraulic conductivity (e.g., by inducing cracking due to shrinkage or embrittlement of the clay). An adverse interaction due to chemical incompatibility is a particularly important consideration when clay soils are used for waste containment, since an adverse interaction may result in an increase in saturated hydraulic conductivity and potentially unacceptable release rates of contaminants into the surrounding environment. The importance of compatibility testing is highlighted in the industry standard ASTM D 7100.

Most, if not all, of the available data on chemical compatibility of compacted clay liners or other earthen barriers are based on the results of laboratory tests, performed either as part of the design process for the waste containment facility or as research studies. Field data on chemical compatibility are not readily available for several reasons, including (1) less control inherent in field tests, especially when dealing with potentially harmful liquids; (2) lack of evidence of chemical incompatibility in waste containment facilities that are performing satisfactorily; and (3) years or even decades may be required before there is any evidence of chemical incompatibility processes that lead to volume change and cracking (Shackelford, 2005).

Numerous studies performed primarily to evaluate factors that potentially influence chemical compatibility of earthen soils used as barriers have provided some insight into expected behavior (e.g., Anderson and Jones, 1983; Fernandez and Quigley, 1985, 1988; Griffin and Roy, 1985; Mitchell and Madsen, 1987; Goldman et al., 1988; Shackelford, 1994; Stern and Shackelford, 1998). In general, the results indicate that qualitative predictions of chemical incompatibility can be made based primarily on three considerations: (1) the type and properties of the liquid, (2) the type and properties of the soil, and (3) the physical conditions imposed on the barrier soil.

The higher the concentration and/or the charge of ions in inorganic solutions, the greater the possibility for chemical incompatibility. In addition, decreasing pH tends to increase the potential for chemical incompatibility in two ways. First, as pH decreases, the concentration of ionic species in solution tends to increase. Second, solutions with pH less than about 2 can dissolve clay soils, resulting in the development of relatively large pores that cause increases in hydraulic conductivity (Shackelford, 1994). Very high pH (>12) solutions may also dissolve silica, although no examples of such solutions causing compatibility problems in compacted earthen liners have been published. Finally, high concentrations of hydrophilic organic compounds and pure-phase organic liquids (i.e., light and dense nonaqueous-phase liquids) can cause incompatibility due to clay shrinkage when the dielectric constant of the liquid is significantly lower than it is for water (e.g., Mitchell and Madsen, 1987; Shackelford, 1994). However, the specific threshold values at which chemical incompatibility becomes a potential issue for each of these parameters will also depend on the type and properties of the soil and the physical conditions imposed on the barrier soil.

The potential for incompatibility generally increases as the activity, defined as the plasticity index divided by the percent of clay-size particles (<2 µm), of the soil increases (Shackelford, 1994). The activity reflects both the mineralogy of the soil, with higher values for a plasticity index correlating with higher contents of high-activity clay minerals, such as sodium smectite, as well as the surface area effects, with greater surface areas reflected by higher contents of the smaller, clay-sized particles. Fortunately, available evidence suggests that many, if not most, natural clay soils used as compacted clay liners have relatively low plasticity index values. For example, of the 85 compacted clay liners

evaluated by Benson et al. (1999), 49 were constructed using clays of low plasticity (ASTM D 2487), with the remainder exhibiting moderate rather than high plasticity index values (maximum of 71 compared with >300 for bentonite). Consequently, waste containment barriers that contain significant bentonite contents, such as compacted sand-bentonite and soil-bentonite liners, soil-bentonite backfills for vertical cutoff walls, and geosynthetic clay liners (GCLs) may be particularly susceptible to chemical attack by invading liquids, resulting in chemical incompatibility and increased hydraulic conductivity.

Three factors relating to the physical conditions are particularly important: (1) the stresses imposed on the barrier soil (Fernandez and Quigley, 1991; Shackelford et al., 2000; Lee et al., 2005), (2) the initial level or degree of hydration of the barrier soil (e.g., Shan and Daniel, 1991; Daniel et al., 1993; Shackelford, 1994; Didier and Comeaga, 1997; Gleason et al., 1997; Kajita, 1997; Petrov and Rowe, 1997; Petrov et al., 1997a; Quaranta et al., 1997; Ruhl and Daniel, 1997; Stern and Shackelford, 1998; Lin and Benson, 2000; Shackelford et al., 2000; Vasko et al., 2001; Ashmawy et al., 2002; Shan and Lai, 2002), and (3) the hydraulic gradient of the liquid across the barrier (Shackelford, 1994). In general, the higher the effective stress in the soil, the less susceptible the soil is to adverse consequences of chemical attack. Thus, consolidation of barrier soils (e.g., from the weight of the overlying waste) not only tends to decrease the hydraulic conductivity of the barrier soil but also reduce the potential for chemical incompatibility.

A higher initial degree of water saturation of the barrier soil prior to permeation with a chemical solution, commonly referred to as prehydration, also has been reported to provide increased resistance to increases in hydraulic conductivity. However, prehydration by continuous permeation results in a different degree of resistance to chemical attack than prehydration by capillary wetting. In addition, most of the studies reporting a significant prehydration effect have involved barrier soils either comprised of or containing high-activity sodium bentonite. Recent studies also indicate that the prehydration effect is concentration dependent and tends to diminish as the concentration of chemical species in solution decreases (Lee and Shackelford, 2005a). Lastly, much of the data supporting the claim of increased chemical resistance with increased prehydration has been criticized on the basis that the data were derived from hydraulic conductivity tests that were terminated before chemical equilibrium between the effluent and influent had been achieved (Petrov et al., 1997b; Shackelford et al., 2000).

Finally, two-phase flow, the migration of mixtures containing two separate liquid phases in soil, requires special consideration. The interaction between the two liquid phases is particularly important when nonpolar hydrophobic organic liquids migrate through a barrier soil at an initially high degree of water saturation, such as a compacted clay liner. Due to surface and interfacial tension effects, the non-polar liquid (a non-wetting fluid) can displace the water (a wetting fluid) in the pore space of the soil only after a minimum pressure (known as the entry pressure) for the non-wetting fluid is reached. Although some studies have shown that permeation of compacted clay soils by hydrophobic organic liquids has resulted in significant increases in hydraulic conductivity (e.g., Fernandez and Quigley, 1985), the hydraulic gradients required to force these liquids through the soils typically have been quite large (>100). Thus, the relevance of these results to situations where much smaller hydraulic gradients are applicable is questionable (Shackelford, 1994).

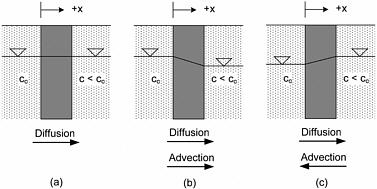

4.1.4

Chemical Transport

Chemicals migrate through earthen barriers primarily by two transport processes: advection and diffusion. A third process that causes spreading of the contaminant front due to variations in flow, referred to as mechanical dispersion, is typically insignificant in the case of thin, low-permeability earthen barriers and is consequently ignored. In addition to advection and diffusion, chemicals are subject to the myriad of physico-chemical processes (e.g., adsorption/desorption, precipitation/dissolution, acid/base, redox) and biological processes during migration that can ultimately affect the contaminant mass that flows through the barrier.

Temperature affects advective/diffusive transport as well as other physico-chemical and biological processes that contribute to contaminant mass transport. Hydraulic conductivity is expected to increase with temperature (see Section 4.1.2), which would increase advective transport. The free solution diffusion coefficient for species common in municipal solid waste (MSW) leachate (Rowe et al., 2004) and the soil diffusion coefficient for a clay soil beneath a landfill (Crooks and Quigley, 1984) increase with temperature, which would increase diffusive transport.

The advective mass flux of contaminants is essentially the product of the liquid flow or leakage rate and the contaminant concentration at a specified location and time. According to Darcy’s law, typical steady state leakage rates for an intact compacted low-permeability earthen barrier (e.g., a compacted soil layer with no secondary permeability features such as cracks or fissures) are shown in Table 4.2. These values do not take into account that both the gradient and the hydraulic conductivity may vary with time for reasons such as those discussed above.

The results of several field studies indicate that diffusion can be a significant, if not dominant, transport process for

TABLE 4.2 Representative Leakage Rates for Clay Liners

|

Hydraulic Conductivity (m/s) |

Steady State Leakage Ratea (lphd) |

|

1 × 10−9 |

100 to 10,000 |

|

1 × 10−10 |

10 to 1,000 |

|

1 × 10−11 |

1 to 100 |

|

aFor typical range of hydraulic gradients from 1/10 to 10. |

|

chemicals through intact clayey tills and low-permeability compacted clay liners (Goodall and Quigley, 1977; Crooks and Quigley, 1984; Johnson et al., 1989; Toupiol et al., 2002; Willingham et al., 2004). For example, the results of a tritium and bromide tracer test conducted over 13 years on a 0.3-m-thick compacted clay liner demonstrate that diffusion was the dominant transport mechanism and that there was no apparent preferential flow (Box 4.2; Toupiol et al., 2002; Willingham et al., 2004). As a result of these and other studies, minimizing advective mass flux transport has long been recognized as a necessary, but not sufficient, condition for minimizing chemical transport through low-permeability earthen barriers (Shackelford, 1988).

However, in contrast to these studies, Munro et al. (1997) found that advection and mechanical dispersion were more important than diffusion for a case involving migration of landfill leachate from an unlined landfill located directly on a fractured clayey till. This result underscores the importance of two considerations in terms of minimizing the extent of chemical release from waste disposal sites, namely the importance of a low-permeability engineered barrier system and the importance of disposal site location. Furthermore, in those cases where diffusion dominates advection, the total chemical transport is likely to be relatively small compared to those cases where advection dominates.

Recently, volatile organic compounds at various concentrations have appeared in a number of samples from 91 large (~ 110 m2) collection lysimeters (underdrains) located beneath both composite and compacted clay liners at 38 Wisconsin landfills that have been in operation for about 10 to 20 years (Shackelford, 2005; Klett et al., 2006). For example, concentrations greater than allowable maximum contaminant levels for toluene, tetrahydrofuran, dichloromethane, benzene, and ethylbenzene have been found in 90 of the 1,200 samples (~ 8 percent) from cells with liners containing geomembranes (Benson and Edil, 2004). These observations were not anticipated because the liners in Wisconsin have traditionally been thicker than those required by Resource Conservation and Recovery Act (RCRA) Subtitle D for MSW disposal facilities (Federal Register, 1991). That is, prior to 1996, Wisconsin required landfill cells to be lined with a minimum of 1.5 m of compacted clay, compared to 0.91 m required by RCRA Subtitle D. Subsequent to 1996, both Wisconsin and RCRA have required a composite liner consisting of a geomembrane liner overlying compacted clay, but Wisconsin requires 1.2 m clay compared to 0.62 m required by RCRA. The effects of natural attenuation processes such as dilution, adsorption, and degradation likely will render concentrations of these volatile organic compounds below detectable levels by the time the contaminants reach a regulatory compliance point, such as a perimeter monitoring well (Benson and Edil, 2004). The performance record is still relatively short (~ 10 to 20 years), so continued monitoring of these and other landfills will be required over the longer term before any final conclusions can be drawn regarding the performance of modern waste containment systems.

4.1.5

Mechanical Performance Issues

The ability of an earthen barrier to serve its intended function can be affected by cracking, erosion, and slope stability. Although attention often focuses on the resistance of barriers to advective flux of liquids and diffusive flux of chemicals, earthen barrier layers may also serve as intrusion barriers, provide protection for other layers in the barrier system, and resist advective flux of gases.

Gas control is a persistent problem at municipal landfills with earthen cover systems. Frequent maintenance (i.e., reworking the cover in areas where monitoring indicates gas emissions exceed regulatory standards) is commonplace at landfills that produce gas. This need for frequent maintenance can be attributed in part to cracking induced by subsidence of the waste and in part due to desiccation (e.g., from freeze/thaw). Observations of the susceptibility of earthen covers to gas emission suggests that they may also be poor infiltration barriers because cracks that let gas out are likely to indicate secondary structure development that degrades the hydraulic conductivity of a cover barrier layer.

Erosion of the uppermost earthen layer in a barrier system can also be a persistent problem at sites with covers that are steeper than the surrounding stable landforms. Establishment of healthy vegetative cover and provision of a mechanically resistant erosion control layer can mitigate soil cover erosion. However, until a stable ecosystem that mimics stable regional landforms develops on the cover, continued maintenance is likely to be required for vegetative cover layers. The longevity of mechanical erosion control layers depends upon the steepness of the cover, the severity of erosion-inducing forces (e.g., wind, water, freezing, thawing), and the character of the erosion-resistant material.

The integrity of earthen barriers can also be affected by displacements associated with slope instability. Earthen barrier layers in liner systems can be disrupted by foundation instability that develops as the waste is placed and the load on the foundation increases. Earthen barrier layers in cover systems are susceptible to veneer instability, wherein a planar failure surface develops along one of the interfaces in the system. Soil-geomembrane interfaces may be particularly susceptible to veneer failure due to the reduced strength of the interface compared to the soil. Failures at drainage layer interfaces are also common due to clogging or inadequate capacity of the drainage layer and the associated buildup of pore pressures within the drainage layer.

4.1.6

Summary

Documented observations of the hydraulic performance of compacted clay barriers for more than about 15 years do

not exist. However, the hydraulic conductivity of clay barriers is generally acknowledged to be susceptible to significant increase as a result of processes such as desiccation cracking, differential settlement, lateral spreading (induced tension), freezing and thawing, and root penetration. These processes are most significant in cover systems because bottom barrier performance is generally enhanced by increases in the confining pressure associated with waste disposal. Earthen barriers are also susceptible to a variety of mechanical performance problems, including erosion and cracking of earthen cover systems, disruption of base liner barrier layers due to foundation instability, and veneer failure of cover barrier layers due to low interface strength, clogging, or inadequate capacity of drainage layers.

Both laboratory research and field observations suggest that the following conclusions can be drawn about the performance of earthen barriers:

-

Clay layers, as components of barrier systems, are generally effective in the short and medium term unless poor construction and/or operational practices diminish layer integrity.

-

Unprotected clay layers in covers may develop secondary permeability that can lead to decreased effectiveness.

-

Temperature effects and postconstruction moisture changes in earthen barriers used in bottom liner systems have received insufficient attention.

-

Laboratory data indicate that there may be circumstances (e.g., when dealing with active clays) where there is cause for concern about chemical compatibility effects within clay liners, but corroborating field data are lacking.

4.2

GEOMEMBRANES

Short-term performance concerns for geomembrane barriers include defective material, physical damage caused by construction activities, and defective seams. Medium- and long-term performance concerns include geomembrane puncture due to increased overburden pressure and global stability and local slope stability failures, as well as loss of integrity caused by degradation. Global and local stability are addressed in Chapter 5. Geomembrane degradation is generally considered to be a long-term performance issue. However, as discussed below, under some conditions geomembrane degradation may develop in the medium term.

Modern manufacturing and construction quality assurance (CQA) processes have improved the as-manufactured quality of geomembranes. However, geomembranes can be easily damaged during installation, which emphasizes the importance of continuous observation of liner construction until a sufficient buffer layer of soil or waste shields the geomembrane from construction equipment and other potential sources of damage (see Box 5.2).

4.2.1

Chemical Transport

Chemical transport through geomembranes occurs via two mechanisms (Rowe, 1998; Katsumi et al., 2001): (1) advective transport of chemicals via leakage through holes or defects in the geomembranes and (2) molecular diffusion through the intact geomembrane. Equations for calculating the rate of leakage through geomembrane defects were proposed initially by Giroud and Bonaparte (1989) and refined subsequently by other investigators. Measurements of flow rates through geomembranes are sparse, although monitoring of leak detection systems provides information on likely leakage levels (Bonaparte et al., 2002) and the equations that should be used to predict leakage (Rowe, 2005). Chemical transport flow rates have usually been estimated from laboratory studies aimed at assessment of the prediction capabilities of proposed transport equations (e.g., Benson et al., 1995; Rowe et al., 2004), rather than evaluation of the performance of geomembranes used in liner systems (although Rowe, 2005, reports monitoring in a clay liner below a geomembrane over a 12-year period). In lieu of field measurements of leakage through geomembranes, the general practice has been to either estimate (in design) or measure (during CQA) the number of holes or defects that occur per unit area in a geomembrane and then estimate the resulting leakage rate using predictive equations. The amount of leakage through a geomembrane will depend on the particular situation but in general will be proportional to the number of holes or defects in wrinkles in the geomembrane. With good construction, the chemical transport of organic compounds (especially volatile organic compounds) will be controlled by diffusion through the barrier, rather than by the number of holes (Rowe, 2005).

Diffusion of volatile organic compounds occurs through geomembranes, in both the aqueous phase (e.g., Rowe et al., 1995; Rowe, 1998; Sangam and Rowe, 2001; Edil, 2003) and the gas (vapor) phases (e.g., Koerner, 2005). Shackelford (2005) compared the concentrations of dichloromethane in samples collected from lysimeters beneath both composite-lined cells (geomembrane overlying compacted clay) and clay-lined cells in Wisconsin landfills that had been in operation for periods ranging from about 10 to 20 years. The comparison indicated that the concentrations of dichloromethane collected in lysimeters beneath composite-lined cells were not substantially lower than those in samples collected beneath cells lined only with compacted clay. This result suggests that the geomembranes used in the composite liners have provided little, if any, resistance to diffusion of this volatile organic compound. Rowe (2007) showed that volatile organic compounds can diffuse (1) through high-density polyethylene (HDPE) geomembranes in as little as a few days to a few weeks, (2) through a 0.6-m-thick composite liner in 1 to 2 years (at 1 percent of the source concentration) or 4 years (at 10 percent of the source concentration), and (3) through a

1-m-thick composite liner in 4 to 6 years (at 1 percent of the source concentration) or 10 years (at 10 percent of the source concentration). Both theoretical modeling (Rowe, 2007) and laboratory tests (Sangam and Rowe, 2001) show that the geomembrane offers little resistance to diffusion of these contaminants. These results are consistent with the findings of Shackelford (2005).

In summary, leakage through holes or defects as well as diffusion of volatile organic compounds can result in significant chemical mass transport through single geomembrane liners. As a result, the use of single geomembranes alone as liners for liquid containment is not advisable.

4.2.2

Geomembrane Defect Frequency

Geomembranes can develop leaks as a result of defective materials, physical damage caused by construction activities, and defective seams. Information on the short-term integrity of geomembrane barriers, immediately after installation, can be obtained using electrical leak detection surveys. These surveys are generally conducted after the leachate collection gravel is placed on top of the primary geomembrane and can be a powerful addition to CQA programs. A variety of factors can affect the results of an electrical leak detection survey, but if properly performed they are capable of detecting all but the smallest defects in a geomembrane liner (Hruby and Barrie, 2003). Average hole frequencies have been estimated for a large number of emplaced geomembranes, ranging from 0.7 to 11 holes per hectare for landfills (Rollin and Jacquelin, 1999; Nosko and Touze-Foltz, 2000; Hruby and Barrie, 2003; Forget et al., 2005) and up to 15 holes per hectare for leachate impoundments (Rollin and Jacquelin, 1999). Compiling 205 results from four published leak detection surveys, Rowe et al. (2004) found that (1) no holes were detected for 30 percent of the cases; and (2) less than five holes per hectare were detected for half of the surveys. In general, hole frequencies were higher in liners of MSW landfills than in liners of hazardous waste landfills, and hole frequencies were inversely proportional to the size of the facility. Furthermore, there was no correlation between the number of leaks and the geomembrane thickness, and leak densities were significantly lower (0.5 per hectare) for systems installed under strict CQA programs compared to those installed with no CQA (16 per hectare; Forget et al., 2005).

Although geomembrane leak frequency is important, so are the size and location of the defect. Geomembrane defects are often assumed to be relatively small holes caused by poor seaming, inadvertent puncture of the geomembrane, or thinning of the geomembrane during manufacture. Colucci and Lavagnolo (1995) reported that 50 percent of holes had an area of less than 1 cm2. While a hole in a geomembrane in intimate contact with the underlying clay may be relatively small, much greater leakage will be observed if that same hole is in a wrinkle (Rowe et al., 2004). Although defects are generally assumed to be on the geomembrane only, and not in the underlying low-permeability soil layer of a composite barrier, careless construction, waste placement, or compaction operations can cause relatively large through-going holes that can have a disproportionate effect on barrier effectiveness. Through-going holes may be particularly significant in composite liners that employ GCLs as the low-permeability soil layer because GCLs are thin (on the order of 6 mm) compared with typical compacted clay liners (on the order of 600 mm).

The primary medium-term concerns with respect to geomembrane integrity are geomembrane puncture by the overlying or underlying material (e.g., leachate collection gravel or rocks in the subgrade) and global or local stability failure. Once more than 1 or 2 m of material is placed on top of a geomembrane, there is no practical way to determine if the geomembrane has been punctured or torn. In landfill practice, cushion geotextiles are often used to protect geomembranes against puncture from the overlying leachate collection and removal system’s gravel. A cushion should not be used for subgrade puncture protection because it would negate the “intimate contact” between the geomembrane and underlying low-permeability layer required for composite liner effectiveness.

4.2.3

Impact, Tear, Burst, and Puncture Protection

Geomembranes are protected from puncture during construction and waste placement with a layer of soil cover, select waste, geosynthetics, or a combination of these materials. Several methods are used to design adequate puncture protection. The two primary approaches used in practice are (1) the “European” approach, which employs site-specific laboratory testing (ASTM D5514), and (2) the U.S. approach, which employs design charts and equations (Wilson-Fahmy et al., 1996; Narejo et al., 1996; Koerner et al., 1996). The European method is generally more restrictive than the U.S. method and results in a thicker cushion or a smaller allowable grain size of the leachate collection and removal system’s gravel. Although few field data exist to verify either approach, limited field tests of a geomembrane puncture seem to indicate that the U.S. approach provides adequate short-term protection against punctures (Richardson, 1996; Richardson and Johnson, 1998). However, the U.S. design method does not account for induced strains that could eventually lead to stress cracking (e.g., Tognon et al., 2000).

4.2.4

Geomembrane Durability

A key consideration in assessing the long-term performance of barrier systems is the durability and service life of the geomembrane component. The service life is the period of time that an engineered component of a barrier system performs in accordance with the design assumptions. Assessing the likely service life of geomembranes is difficult because of their relatively short history of use in

waste containment applications. A few field studies have provided some guidance. An HDPE geomembrane used in a contaminated soil containment facility for 7 years exhibited lower tensile resistance and elongation at rupture than the original material (Rollin et al., 1994). HDPE geomembrane samples from a 7-year-old leachate lagoon showed no substantial change in the internal structure of the geomembrane or its engineering/hydraulic containment properties (Hsuan et al., 1991). In contrast, an exposed HDPE geomembrane exhumed from a leachate lagoon liner after 14 years of operation was significantly degraded, severely cracked, and highly susceptible to stress cracking (Rowe et al., 1998, 2003). Geomembranes from the bottom of the same lagoon (covered by leachate rather than exposed to the elements) appeared to have been sufficiently protected to prevent significant degradation over the 14-year period. Tests on four different geomembranes from metal sludge impoundments after 20 to 31 years of service life indicated no significant change in the mechanical properties of interest (Tarnowski et al., 2005). These field performance evaluations are relatively positive; however, they do not assure the long-term effectiveness of geomembranes in landfill applications.

The potential for medium- and long-term degradation of HDPE geomembranes has been examined in the laboratory by several investigators (Hsuan and Koerner, 1998; Sangam and Rowe, 2002; Müller and Jakob, 2003; Tarnowski et al., 2005; Rowe, 2005). The primary geomembrane degradation mechanism is antioxidant depletion. Once the antioxidant used in modern HDPE geomembrane formulations is depleted, other geomembrane properties begin to degrade and the geomembrane becomes very susceptible to stress cracking and other damage. Given the relatively slow aging of geomembranes at room temperature, predictions of service life must be based on data from accelerated aging in laboratory tests. Even though no free oxygen is present at the base of a landfill, laboratory tests have shown that geomembranes can break down and reach the end of their service lives under highly reduced conditions (Rowe and Rimal, unpublished).

Typical laboratory tests to examine aging involve immersion of the geomembrane in a fluid (air, water, or leachate). The depletion of antioxidants is most rapid when the geomembrane is immersed in leachate and then in water and is slowest in air (Sangam and Rowe, 2002). Tests have been performed in which the geomembrane was placed on dry sand and covered with wet sand (Hsuan and Koerner, 1998) and also with geomembranes placed in simulated landfill liners with leachate-filled collection material above (Rowe, 2005). The latter tests show that the antioxidant depletion rate in a simulated liner is much slower than when immersed in leachate but substantially faster than when immersed in air.

Based on data on antioxidant depletion for a geomembrane in a simulated liner combined with published data for polyethylene pipe with a wall thickness comparable to a geomembrane (2.2 mm), Rowe (2005) inferred estimates of the likely range of the service life of HDPE geomembranes

TABLE 4.3 Estimated HDPE Geomembrane Service Life at Different Temperatures

|

Temperature (°C) |

Service Life (years)a |

|

20 |

565−900 |

|

30 |

205−315 |

|

35 |

130−190 |

|

40 |

80−120 |

|

50 |

35−50 |

|

60 |

15−20 |

|

aAll times have been rounded to nearest 5 years. SOURCE: Rowe (2005). |

|

in MSW landfills for a range of temperatures (Table 4.3). The estimated service life of geomembranes at a temperature of 20°C is 565 to 900 years, depending on the assumptions. While this is a large range, it suggests that geomembrane liners are likely to have a service life of more than 500 years at a temperature of 20°C (and longer at lower temperature). This is generally consistent with the findings of Tarnowski et al. (2005), who concluded that the service life of properly produced and installed HDPE geomembranes at least 2 mm thick could be more than 500 years. At a typical MSW landfill primary liner temperature of 35°C, the service life is on the order of 130 to 190 years (median 160 years). At temperatures of 50 to 60°C, the service lives are very short (15 to 50 years). These high (50 to 60°C) temperatures have been observed when there is a leachate mound in the waste (Rowe et al., 2004) but are not expected in modern solid waste landfills with operational leachate collection systems (Rowe, 2005). It should be noted that, while these temperatures are measured just above the liner, high temperatures can also be observed with depth. Even with a 1-m-thick primary composite liner, the temperature at 1 m may be only about 5°C lower than at the geomembrane (Rowe and Hoor, 2007). The depletion of antioxidants from geomembranes exposed to acid rock drainage has been reported by Gulec et al. (2004), and the data will assist in assessing the service life of HDPE geomembranes under these conditions.

The service life of cover geomembranes depends on the temperature and exposure conditions. Koerner and Koerner (2005) suggest that the service temperature of a soil-covered geomembrane used in a cover of a dry landfill will be approximately equal to the ambient temperature of the site. Thus, for cover geomembranes in a temperate climate, with a mean ambient temperature of less than 30°C, the service life should be on the order of several hundred years (Table 4.3). This logic does not apply to geomembranes exposed to solar radiation or to geomembranes made of materials other than HDPE (e.g., linear low-density polyethylene, flexible polypropylene). Tarnowski et al. (2005) report on the service life of exposed HDPE geomembranes estimated from testing on four different exposed geomembranes after 20 to 31 years of service life and on 2.5 mm HDPE geomembrane specimens stored in air for 13 years at 80°C. Based primarily on tests conducted on specimens recovered from the exposed

geomembranes from the four projects in Galing, Germany, Tarnowski et al. (2005) concluded that a service life of more than 50 years could be expected for the 2.5 mm HDPE geomembranes studied. Inadequate data are available for materials other than HDPE to assess their long-term performance as geomembrane liners or covers.

The values in Table 4.3 provide order-of-magnitude estimates of the geomembrane service life and also highlight the importance of liner temperature. However, as discussed by Rowe (2005), these estimates should be used with caution. Only the results for antioxidant depletion are based on actual tests on geomembranes typically used in landfill applications in a simulated liner configuration. Degradation of the polymer is based on tests for polyethylene pipe with water inside and air outside and is subject to a number of limitations (Viebke et al., 1994). Long-term testing to address these limitations is currently under way and the estimates of service life are likely to evolve as more data becomes available.

The calculated service lives (Table 4.3) all assume a constant temperature. However, the temperature of the liner is likely to vary with time, and this will influence both the antioxidant depletion time and the service life. The effect of time varying temperature on service life has been examined theoretically by Rowe (2005).

4.3

GEOSYNTHETIC CLAY LINERS

The primary performance concerns with GCLs are defective material and seam separation in the short term and desiccation, freezing, chemical incompatibility, and strength degradation in the medium and long terms.

Numerous laboratory measurements have established that the saturated hydraulic conductivity of GCLs permeated with water at nominal overburden pressure (on the order of 20 kPa) generally ranges from about 1 × 10−11 m/s to about 5 × 10−11 m/s (e.g., Daniel et al., 1997). With increasing overburden pressure, the saturated hydraulic conductivity of a GCL can be significantly lower.

Rowe (2005) concluded that the service life of a GCL used in a composite liner system should be on the order of thousands of years, provided that (1) the seams of the GCL do not separate; (2) the GCL does not desiccate; (3) the design hydraulic conductivity is based on considerations of chemical effects such as bentonite-leachate compatibility, groundwater and subgrade soil chemistry, and applied stress; (4) there is no significant loss or movement (thinning) of the bentonite in the GCL during placement or in service; and (5) the geosynthetic component of the GCL is not critical to the long-term performance of the bentonite component of the GCL (otherwise the service life of the GCL is controlled by that of the geosynthetic component). Predictions of GCL performance. must include consideration of local and global slope stability, strength degradation, and chemical transport.

4.3.1

Seam Separation

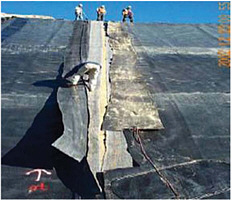

Seam separation is a relatively recently observed phenomenon. Separation of lapped seams beneath exposed geomembranes at a number of sites has been reported not only in areas of relatively steep (1.5H:1V to 2H:1V) side slopes but also on relatively flat slopes (Thiel and Richardson, 2005; Koerner and Koerner, 2005). In all cases, the GCL was installed with a state-of-the-practice CQA program using overlaps between 150 and 300 mm at the seams, and the separation occurred prior to placement of waste against the side slope. The observed separation between panels was typically between 0 and 300 mm and occurred from 2 months to 5 years after placement, although separation exceeding 1 m also was observed. For the cases reported, the GCL had a high initial (as manufactured) moisture content and no scrim reinforcement. Although research assessing the significance of various factors in causing shrinkage of GCL panels is ongoing, quick covering of the liner system clearly is desirable as a means for minimizing potential shrinkage. Figure 4.2 shows the GCL seam separation observed at a California landfill.

Postulated mechanisms for seam separation include necking of the GCL panel under gravity loads and shrinkage of GCLs manufactured at moisture contents greater than the in situ equilibrium moisture content (Thiel and Richardson, 2005). Exposure of the overlying geomembrane to large temperature extremes can result in moisture loss and shrinkage of GCLs on side slopes. At night the colder air temperature draws water vapor up to the bottom of the geomembrane, where it condenses, drains down the slope along the interface between the geomembrane and GCL, and is no longer available to rehydrate the GCL the following day. Free water has been found accumulating between the

FIGURE 4.2 GCL seam separation at a California landfill. SOURCE: County of Riverside (2004).

GCL and geomembrane at the toe of steep side slopes under these conditions (personal communication, J.P. Giroud, independent consultant, and Jeff Dobrowolski, Geosyntec Consultants, October 2004), which appears to support this shrinkage mechanism. Recent laboratory tests suggest that cyclical wetting and drying can explain a large percentage of the observed shrinkage (Thiel et al., 2006). However, no single mechanism can explain the magnitude and prevalence of panel separations in all cases.

4.3.2

Chemical Compatibility

Chemical compatibility of GCLs, including both cation exchange and pore fluid chemistry effects, has been investigated extensively in both the laboratory and the field. Chemical degradation of the hydraulic conductivity of GCLs is possible when relatively high concentrations of divalent cations such as calcium and magnesium in the natural pore water or soil cause cation exchange with the sodium in the bentonite. For example, in one field investigation of a cover, laboratory tests on exhumed samples and field percolation rates showed that the saturated hydraulic conductivity of the GCL increased by about 100 times due to cation exchange (Benson, 1999, 2001). In a study of the effects of cation concentration and valence, the saturated hydraulic conductivity was correlated to the volumetric swell of GCL bentonite (Jo et al., 2001). Although this investigation was limited to a single cation species, subsequent investigations showed similar correlations with multispecies inorganic chemical solutions as well as with waste leachate (Kolstad et al., 2004; Katsumi and Fukagawa, 2005).

Bentonite quality (e.g., percent sodium smectite, plasticity, cation exchange capacity) and microstructure also influence the chemical compatibility of GCLs. Lee and Shackelford (2005b) and Lee et al. (2005) investigated the effect of bentonite quality on the hydraulic behavior of GCLs permeated with inorganic salt solutions and demonstrated that the higher-quality bentonite GCLs (i.e., higher cation exchange capacity, higher plasticity, higher swell capacity in the presence of water, lower hydraulic conductivity) were more susceptible to chemical attack and increased hydraulic conductivity than the lower-quality bentonite GCLs. Sodium bentonite can be quite susceptible to an increase in hydraulic conductivity when permeated by solutions with a high salt content (Petrov and Rowe, 1997; Lee and Shackelford, 2005b; Lee et al., 2005), especially when the effective stress is low. Under these circumstances it may be more appropriate to use a modified bentonite. However, as noted below, there are many practical situations when the sodium bentonite commonly used in GCLs performs well.

A number of GCL tests have focused on the effects of prehydration (e.g., Katsumi et al., 2004; Lee and Shackelford, 2005a; Thiel and Criley, 2005), confining pressure, cation exchange, and other factors on chemical compatibility. The hydraulic conductivity of a prehydrated and calendared (density has been increased to achieve a uniform thickness and void ratio) GCL appears resistant to degradation from permeation with CaCl2 solutions (Kolstad et al., 2004; Katsumi et al., 2006a). The effects of overburden pressure on the hydraulic conductivity of GCLs permeated by sodium and calcium solutions were found to be significant and depended on the type of chemicals (Katsumi and Fukagawa, 2005). The effect of prehydration is also affected by the applied head pushing the prehydration water into the GCL. However, prehydration by capillary action alone is relatively ineffective in improving chemical compatibility of GCLs in the presence of salts (Vasko et al., 2001). Thiel and Criley (2005) showed that the hydraulic conductivities of GCLs prehydrated and permeated with a variety of waste leachates and water under high effective confining stresses (>500 kPa) were independent of fluid chemistry.

The importance of performing hydraulic conductivity tests long enough to achieve chemical equilibrium between the effluent and influent has been demonstrated for both prehydrated GCLs (Shackelford et al., 2000; Lee and Shackelford, 2005a, 2005b) and nonprehydrated GCLs (Jo et al., 2004, 2005; Katsumi et al., 2006b). Unconservative (low) values of hydraulic conductivity may be measured if the test is terminated before complete chemical equilibrium has been established. For example, in a test for salt compatibility in which the influent contains no sodium cations, true chemical equilibrium is not established until the concentration of sodium in the effluent is zero or below the method detection limit for practical purposes. At this point, cation exchange with the chemical solution has essentially been completed. However, because the method detection limit for sodium is so low (e.g., 0.2 mg/l) and the process of cation exchange in sodium bentonites can be slow (Jo et al., 2005), establishment of true chemical equilibrium can require long test durations (>1 year), which generally increase with decreasing concentration of multivalent cations in the permeant liquid (Jo et al., 2005; Lee and Shackelford, 2005a, 2005b). Thus, measuring the chemical composition of the influent and effluent precisely may be impractical, and meeting method detection limit criteria may not be possible for most applications.

As a result, Jo et al. (2005) recommend that electrical conductivity be used as a measure of chemical composition for the influent and effluent as proposed by Shackelford et al. (1999) and that tests be terminated once the effluent-to-influent electrical conductivity ratio is within 1.0 ± 0.05. This would acknowledge that the long-term hydraulic conductivity may be as much as three times higher than the reported hydraulic conductivity. Alternatively, Jo et al. note that if tests are terminated when the electrical conductivity ratio is within 1.0 ± 0.1 (as per ASTM D 6766), the hydraulic conductivity could be as much as 10 times higher than the reported hydraulic conductivity for conditions similar to those examined by Jo et al. (2005).

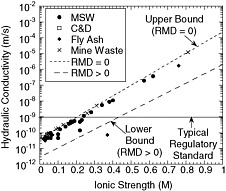

The hydraulic conductivity k of nonprehydrated GCLs

permeated with inorganic chemical solutions was correlated with two chemical parameters: (1) the ionic strength of the solution I, which is the sum of the product of the molar concentration and the square of the charge for all ionic species in solution, and (2) the ratio of the molar concentrations of monovalent cations MM to divalent cations MD in the solution, or RMD (= MM/MD0.5; Kolstad, 2000; Kolstad et al., 2004). The RMD is similar to the sodium adsorption ratio commonly used in the soil science literature. The resulting correlation between the k of GCLs and I and RMD of the permeant liquids is shown in Figure 4.3.

Two observations are apparent from the data plotted in Figure 4.3. First, the hydraulic conductivity increases with increasing ionic strength for a given value of RMD and also increases for a given ionic strength as the RMD decreases toward zero. These trends are consistent with expected behavior in the sense that an increase in concentrations and/or charge is expected to result in an increase in hydraulic conductivity (Shackelford, 1994). Second, the hydraulic conductivity of GCLs to chemical solutions with ionic strengths greater than about 0.2 to 0.4 M can be higher than the typical regulatory standard value of 1 × 10−9 m/s, and much higher in some cases (e.g., for mine waste, k = 1.2 × 10−5 at I = 0.81 M). Although the relationship shown in Figure 4.3 is relatively new, several independent assessments using different GCLs and different chemical solutions have shown good agreement between measured k values and the predicted k values based on Figure 4.3 (e.g., Lee and Shackelford, 2005a; Shackelford, 2005; Brown and Shackelford, 2007).

FIGURE 4.3 Correlation among hydraulic conductivity, ionic strength, and the ratio of monovalent-to-divalent cations (RMD) for nonprehydrated GCLs. NOTE: MSW = municipal solid waste; C&D = construction and demolition. SOURCE: Kolstad (2000).

4.3.3

Freeze/Thaw and Shrink/Swell

Freeze/thaw and shrink/swell are medium-term GCL performance concerns associated primarily with GCLs used in covers. The higher confining and overburden pressures applied to bottom-liner systems tend to mitigate these effects. Several studies have investigated resistance of GCLs in the laboratory after as many as 20 freeze/thaw cycles. Little if any change in hydraulic conductivity was measured, suggesting that freeze/thaw is not an important degradation process for GCL performance (Foose et al., 1996; Kraus et al., 1997; Della Porta et al., 2005; Rowe et al., 2006).

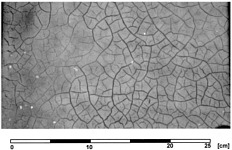

In contrast to freeze/thaw cycles, shrink/swell cycles can cause significant degradation of GCLs if (1) the wetting fluid contains multivalent cations, such as calcium or magnesium; (2) the dehydration during drying is severe enough for desiccation cracks to form in the bentonite layer; and (3) the overburden pressure is too low to prevent the formation of desiccation cracks. Under these circumstances, desiccation, combined with the chemical incompatibility effects of cation exchange discussed in the previous section, can cause increases of as much as three to five orders of magnitude in hydraulic conductivity. Desiccation is particularly important when combined with cation exchange because the multivalent cations reduce the ability of the bentonite to swell and heal the desiccation cracks (Lin and Benson, 2000; Sporer and Gartung, 2002a, 2002b). This mechanism of degradation is a particular concern for GCLs in cover systems where the potential for desiccation is greatest because of the combination of large fluctuations in temperature and low overburden pressures. For instance, Melchior (2002) showed the adverse effects of desiccation on five sodium-bentonite GCLs overlain by 0.45 m of cover soil. Both cation exchange and desiccation cracking were observed in exhumed samples (Figure 4.4) and the saturated hydraulic conductivities after exhumation were approximately five orders of magnitude

FIGURE 4.4 X-ray image showing desiccation cracks in the bottom layer of a GCL after 5 years in a landfill cover at HamburgGeorgswerder. SOURCE: Melchior (2002).

higher than when the GCLs were installed. Plant-root penetration through the GCL also was observed.

Meer and Benson (2007) exhumed GCL samples from four landfill covers and found similar increases in hydraulic conductivity caused by cation exchange and desiccation cracking. In one case, although the GCL was overlain by a geomembrane, it was still affected by cation exchange, apparently from pore water in the underlying subgrade. Other field investigations confirm that desiccation occurs in GCLs after cation exchange and results in severe degradation of GCLs (Aboveground Tank Update, 1992; James et al., 1997; Benson, 2002; Mackey and Olsta, 2004).

Degradation caused by wet/dry cycles can be prevented by avoiding contact between the GCL and pore fluids containing relatively high concentrations of multivalent cations. A number of laboratory studies have shown that wet/dry cycles do not significantly degrade the performance of sodium-bentonite GCLs, provided that the sodium is not exchanged for divalent cations (e.g., Shan and Daniel, 1991; Boardman and Daniel, 1996; Lin and Benson, 2000). In addition, Mansour (2001) showed that the saturated hydraulic conductivity of a needle-punch-reinforced sodium GCL buried under a moderate thickness (0.66 m) of vegetated cover soil was unchanged after 5 years of exposure to the semiarid climate of Bakersfield, California. The cover soil was rich in sodium, and there was little potential for cation exchange in the GCL. The conclusion drawn from these studies is that desiccation cracks in a sodium-bentonite GCL may heal upon rehydration as long as the pore fluid chemistry in the GCL does not change with wetting and drying cycles and there is sufficient overburden pressure.

In addition, if the extent of drying is not severe, wet/dry cycles may not significantly degrade the performance of sodium-bentonite GCLs. For example, a GCL covered by a thick (1-m) layer of silty sand in a landfill cover subjected to a humid climate exhibited no significant desiccation cracking or other notable defects over a 3-year period despite dry summertime conditions (Blümel et al., 2002). Mineralogical testing on exhumed GCL samples showed that the transition from sodium- to calcium-bentonite due to cation exchange was essentially completed during the 3-year observation period but that ion exchange did not cause any significant increase in permeation (as measured by a lysimeter beneath a GCL) since the dehydration during the drying cycles was not severe. Della Porta et al. (2005) reported that drying temperatures of 105°C degraded GCL performance more than drying temperatures of 60°C.

Other examples of good and bad field performance of GCLs in covers has been discussed by Henken-Mellies et al. (2002), Sporer (2002), Heerten and Maubeuge (1997), Sivakumar Babu et al. (2002), and the potential for cracking and desiccation of GCLs in bottom composite liners due to heat generated by the waste has been discussed by Southen and Rowe (2002, 2004, 2005), and Rowe (2005).

4.3.4

Chemical Transport

Chemical transport parameters, including sorption effects, for GCLs exposed to volatile organic compounds have been reported by Lake and Rowe (2004, 2005a) and Rowe et al. (2004, 2006). Diffusion and sorption factors were such that volatile organic compound migration could be reduced but not controlled to the same level as with a compacted clay liner, unless the GCL was underlain with a suitable thickness of a soil attenuation layer. This effect results primarily because of the relative thinness of GCLs (typically 6 mm) compared to compacted clay liners (typically 0.6 to 0.9 m). Under diffusion-dominated conditions, such as can occur in low-permeability earthen barriers, the steady state diffusive mass flux is estimated by the product of the diffusion coefficient for the chemical species within the porous material (soil) and the concentration gradient, or the difference in concentration across the barrier divided by the barrier thickness. Thus, for the same concentration difference, the concentration gradient for a GCL will be much higher than that for a compacted clay liner. If, in addition, the effective diffusion coefficients for a given chemical species are similar between the GCL and a compacted clay liner (not unexpected since the GCL is usually composed of a natural clay mineral), the diffusive mass flux across the GCL may be expected to be greater than that across the compacted clay liner. In addition, the sorptive capacity of the GCL may be lower than that of the compacted clay liner because the GCL has a lower total mass of sorbent (clay) than the thicker compacted clay liner.

The results of studies aimed at measuring the diffusion coefficients of simple salt ions (e.g., Na+, K+, Cl−) diffusing through GCLs under transient and steady state conditions have been reported by Lake and Rowe (2000), Malusis et al. (2001), and Malusis and Shackelford (2002a). Of particular note is the observation that GCLs can act as semipermeable membranes that restrict the migration of aqueous chemical species (Malusis et al., 2001; Malusis and Shackelford, 2002b). The membrane efficiency coefficient ranges from 0 percent in soils that exhibit no membrane behavior to 100 percent in ideal membranes that restrict the migration of all solutes. In general, the membrane efficiency of natural clay soils that exhibit semipermeable membrane behavior tends to be more prevalent in clay soils with a significant portion of high-swelling clay, such as the sodium bentonite in GCLs (Shackelford et al., 2003). For example, membrane efficiencies ranging from 8 to 69 percent have been reported for a GCL subjected to electrolyte solution with KCL concentrations ranging from 3.9 to 47 mM (Malusis and Shackelford, 2002b). Other factors that affect the existence and extent of semipermeable membrane behavior in clay soils include the stress conditions on the soil and the concentrations and valences of the cations in the pore water (Shackelford et al., 2003). Membrane behavior tends to be most significant for solutions with relatively low concentrations of monovalent cations. However, such dilute solutions can still significantly

exceed regulatory limits (e.g., maximum contaminant levels) for individual contaminant species (e.g., cadmium, zinc, lead; Malusis et al., 2003; Shackelford et al., 2003).

When GCLs exhibit semipermeable membrane behavior, the diffusion of aqueous chemical species (both inorganic and organic) through the GCL will decrease as the membrane efficiency of the GCL increases, so at 100 percent membrane efficiency diffusion of the chemical species is effectively prevented. Thus, GCLs that act as semipermeable membranes perform better as barriers than those that do not. The potential existence of membrane behavior in GCLs adds an order of complexity to the analysis of chemical transport through GCLs that may not be warranted in practical applications, particularly since ignoring the existence of membrane behavior will result in conservative (higher) estimates of contaminant mass flux (Malusis and Shackelford, 2004). However, failure to recognize and account for the existence of membrane behavior also can affect the accuracy of predictions of contaminant mass flux through GCLs, as well as the accuracy of the measurement of transport parameters, which may be important in predicting long-term impacts.

In summary, laboratory and field observations of GCL performance under a variety of conditions suggest that although GCLs alone are not an effective barrier to diffusive transport, they can be effective replacements for low-permeability soil layers as operational barriers to advective transport, provided the integrity of the GCL is maintained during installation and operation. Further, although desiccation may be of concern to GCL integrity, particularly when coupled with cation exchange, it can be mitigated effectively by providing sufficient overburden pressure (e.g., in liner systems). Finally, the adverse effects of chemical incompatibility can be mitigated to some extent or delayed by prewetting the bentonite in the GCL or by permeating the GCL under sufficient overburden pressure.

4.4

DRAINAGE LAYERS

Modern engineered resistive barrier systems generally contain both a low-permeability barrier layer and an overlying high-permeability granular and/or geosynthetic drainage layer. The rate of leakage through a barrier layer increases as the hydraulic head on the barrier layer increases. For example, the rate of leakage through a 1-m-thick compacted clay liner with a hydraulic conductivity of 1 × 10−9 m/s would increase by about 300 percent if the head on the liner increases from 0.3 to 3 m (i.e., assuming a 1-m-thick clay liner with zero head at the base).

The effectiveness of the barrier system depends not only on the ability of the resistive low-permeable barrier layer to restrict flow but also on the ability of the drainage layer to limit the hydraulic head on the barrier by providing a path for effluent flows of liquid away from the barrier. Inadequate drainage layer capacity is a primary short-term performance concern as leachate flows are generally highest immediately after construction. Medium- and long-term performance concerns include the potential for reduction of capacity from clogging of the drainage layer or overlying filter due to soil infiltration, biological growth, and mineral precipitation. Geosynthetic drainage layers, which are relatively thin, are also susceptible to a reduction in flow capacity caused by penetration of adjacent geosynthetic or soil materials or by compression of the layer itself.

4.4.1

Field Performance

Measurements of field performance of drainage layers in leachate collection or cover systems are much less common than for barrier layers. Most of the available information is indirect, such as indications of leachate mounding or a significant reduction in pumping rates over time in a leachate collection system. The most significant concern with field performance of drainage layers over time is the buildup in head on the underlying barrier layer.

Clogging of leachate collection systems has been observed in landfills with a wide range of collection systems, ranging from French drains (gravel drains at spacing of 50 to 200 m leading to a collection sump) to continuous sand and gravel layers and in systems both with and without geotextile filters (see Table 4.4 and Rowe, 2005). Clogging typically involves a combination of biological clogging, mineral precipitation, and an accumulation into the clog material of fines, as discussed in detail by Rowe (2005). Several field examples of clogging have been reported. For example, field exhumations found that the upper portion of the sand protection layer over a compacted clay liner became clogged within 4 years and thus did not contribute to the hydraulic performance of the collection system (Reades et al., 1989; Barone et al., 1993). Koerner and Koerner (1995) reported clogging of a sand layer where, after 10 years, the hydraulic conductivity dropped three orders of magnitude from 4 × 10−4 m/s to 2 × 10−7 m/s and leachate was flowing through the waste rather than through the sand. Koerner et al. (1994) and Koerner and Koerner (1995) reported excessive clogging in two cases where the geotextile was wrapped around either the perforated pipe or the gravel in a drainage trench and some clogging in a third case. A detailed description of a case history where clogging occurred in a leachate collection system is provided in Box 4.4.

Field evidence of leachate collection system performance commonly exhibits deposits of both biofilm and inorganic mineral precipitate on the surface of granular materials. These deposits reduce the drainable porosity and hydraulic conductivity of the drainage material. Clogs of minerals precipitate have been reported to contain over 50 percent calcite, 16 to 21 percent silica, 8 percent iron, and 5 percent manganese (e.g., Brune et al., 1991; Fleming et al., 1999). Calcite (CaCO3) was also the dominant mineral in clog scale obtained from a leachate collection pipe in a Florida landfill that received incinerator ash and municipal solid

TABLE 4.4 Observations from Exhumation of Leachate Collection Systems

waste (Maliva et al., 2000) and in clog scale obtained from a leachate collection pipe in the United Kingdom (Manning, 2000).