6

Coal Utilization

This chapter addresses key issues associated with the utilization of coal in the United States. As noted in Chapter 1, although the committee’s task is broad and encompasses the entire coal fuel cycle, the congressional framers of this study requested that it focus primarily on the “upstream” aspects of the coal fuel cycle, recognizing that the research and development (R&D) aspects of coal utilization technologies have been extensively studied and assessed in prior reviews by the National Research Council and others. Accordingly, this chapter is not intended to provide a comprehensive review of R&D activities related to coal utilization. Rather, it presents a brief overview of coal use technologies and related issues and then concentrates on those factors associated with coal use that are likely to impose constraints on future demands for coal.

Of the many factors that influence the nation’s use of coal as an energy source, the analysis presented in Chapter 2 indicates overwhelmingly that the environmental impacts of coal use—especially carbon dioxide emissions associated with global climate change—pose the greatest potential constraint on future coal utilization. Furthermore, the uncertainty about future requirements to control these environmental impacts can itself act as a constraint on future coal utilization. Therefore, this chapter focuses primarily on these environmentally related issues, noting current R&D programs and describing priority R&D needs to minimize these impacts.

COAL UTILIZATION TECHNOLOGIES

Figure 1.7 portrayed the sustained growth in coal use for electric power generation over the past half-century, together with the decline in use of coal

as an energy source for industrial processes, transportation, and residential or commercial buildings. In 2005, the dominant use of coal in the United States (92 percent of the total) was for electric power generation (Table 6.1). Coke plants (2 percent) and other industrial uses (5 percent) account for most of the remainder, with a small amount of coal still used in residential and commercial buildings (EIA, 2006c).

Extensive discussions of the technologies used in each of these sectors, as well as the status and needs of ongoing R&D, can be found in other reports (e.g., NRC, 1994, 1995, 2000, 2002a, 2002b). Accordingly, this chapter presents only a brief overview of the major coal utilization technologies that influence the projections for future coal use in Chapter 2.

Electric Power Sector Technologies

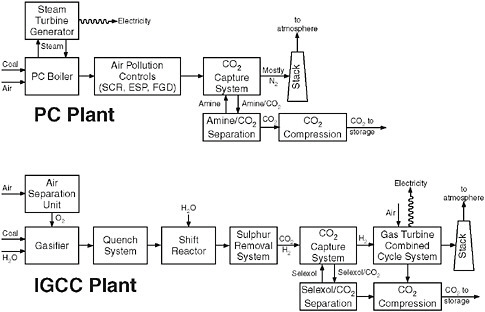

About 90 percent of the 313,000 megawatts (MW) of coal-fired generating capacity in the United States today is based on combustion of pulverized coal (PC). This process involves reducing the coal to a powder that is burned in a boiler to generate high-pressure, superheated steam that drives a turbine connected to an electric generator (Figure 6.1). The steam is then condensed back to a liquid and returned to the boiler to repeat the cycle. Although this process can use a variety of coal types, boilers capable of burning a more uniform quality of coal are generally less expensive than those designed for a broader range of coals. Consequently, it is common for many run-of-mine coals to be cleaned to reduce coal ash and (to a lesser extent) sulfur content, thereby providing a more uniform fuel supply with a higher heating value (see Chapter 4). Several of the newer coal-fired units constructed in recent years have employed atmospheric fluidized bed combustion (AFBC) technology offering greater flexibility in fuel quality.

The overall efficiency of PC power generation is affected by many factors, including the thermodynamic cycle design, steam temperature and pressure, coal particle size (coal grind), combustion air-to-fuel ratio, fuel mixing, air leakage into the system, cooling (condenser) water temperature, and the “parasitic” energy loads required to power auxiliary equipment such as grinding mills, pumps, fans, and environmental control systems. Since 1960, the average thermal

TABLE 6.1 Coal Use in the United States by End-Use Sector in 2005

|

End-Use Sector |

Coal Use (thousand short tons) |

|

Electric power sector |

1,037,485 |

|

Coke plants |

23,434 |

|

Other industrial processes |

60,340 |

|

Residential and commercial |

4,217 |

|

Total |

1,125,476 |

|

SOURCE: EIA (2006c). |

|

efficiency of PC plants in the United States has remained in the range of 33 to 34 percent (higher heating value [HHV]), with the newest plants having efficiencies between 35 and 37 percent. The most efficient coal plants are supercritical steam units that operate at higher temperature and pressure conditions than current sub-critical steam units and achieve net efficiencies in the range of 40 to 45 percent (IEAGHG, 2006). Although few supercritical units have been built in the United States, many of the 154 new PC projects proposed as of 2006 are expected to be supercritical units (NETL, 2007).

A number of proposed projects use technologies based on coal gasification rather than coal combustion. Integrated gasification combined cycle (IGCC) systems generate electricity by first converting coal or other feedstock into a clean gaseous fuel that is then combusted in a gas turbine to generate electricity (Figure 6.1). The exhaust from the hot gas turbine is used to generate steam that drives a second turbine to generate additional electricity. Like PC plants, the overall thermal efficiency of an IGCC system depends on many factors, including the

FIGURE 6.1 Schematic showing power plant designs, based on current technologies, for a pulverized coal (PC) combustion plant with post-combustion CO2 capture, and an integrated gasification combined cycle (IGCC) plant with pre-combustion CO2 capture. The PC plant also has emission controls for NOx (SCR = selective catalytic reduction system), particulate matter (ESP=electrostatic precipitator), and SO2 (FGD = flue gas desulfurization system); the IGCC plant has emission controls for NOx, particulates and SO2 (via quench and sulfur removal systems). SOURCE: Rubin et al. (2007).

gasifier type, coal type, oxidant type, and level of plant integration. The range of efficiencies for current IGCC systems is comparable to that for current PC plants, with significant future improvements expected as gas turbine technology develops (NRC, 2000). Another advantage cited for the IGCC process is its ability to achieve lower levels of air pollutant emissions than PC systems, although modern technology permits emissions from both types of plants to be controlled to very low levels for all regulated air pollutants (EPRI, 2006a). Both PC and IGCC plants also can achieve high levels of CO2 removal, should that be required in the future (see below).

The gasification process is an established commercial technology that is widely used in the petroleum and petrochemical industries to convert carbon-containing feedstocks (such as coal, petroleum coke, residual oil, and biomass) to a mixture of carbon monoxide and hydrogen, referred to as synthesis gas (or syngas). For IGCC applications, the syngas is burned in a combined cycle power plant to generate electricity. More than 160 gasification plants are currently in operation worldwide, producing syngas sufficient to power the equivalent of about 20,000 MW of electrical power (IPCC, 2005). Since 1995, four coal-fueled IGCC power plants, each with an output of approximately 250 MW, have been built as part of government-sponsored demonstration programs—two in Europe and two in the United States. Although the cost of these plants was significantly higher than that of an equivalent PC plant, the experience gained from their operation, as well as from the design, construction, and operation of other industrial IGCC plants, is expected to significantly reduce future costs.

A key attraction of IGCC technology is that the incremental cost of capturing CO2 emissions (in addition to regulated air pollutants) is lower than that for a comparably sized PC plant based on current commercial CO2 capture technology. Thus, while an IGCC plant without CO2 capture is currently more costly than a PC plant, an IGCC plant is typically less costly if CO2 capture is added to coal-based power plants using bituminous coal (IPCC, 2005). However, many other factors—especially coal type—also affect the relative costs of IGCC and PC power plants. For low-rank coals (subbituminous coal and lignite), preliminary studies indicate that the current cost of an IGCC plant with CO2 capture increases to levels comparable to or higher than the cost of a PC plant with CO2 capture using the same coals (IPCC, 2005; EPRI, 2006b; Rubin, 2007). While there is still uncertainty about the actual cost of power plants with CO2 capture, the potential for future constraints on greenhouse gas emissions is an increasingly important consideration when comparing the merits of investments in different power generation technologies. Although the properties, availability, and cost of different coal types is an important factor, the potential long-term impact of CO2 capture and storage on the demand for different types of coal (in conjunction with other environmental control requirements) is unknown (and unknowable) at this time.

Industrial Sector Technologies

Coal utilization technologies in the U.S. industrial sector today fall into two main categories—coke plants that produce high-purity carbon for use in steel making, and combustion technologies that use coal to provide heat and power for industrial process operations (Table 6.1). In addition, a small amount of coal is currently used to produce substitute natural gas and high-value products such as chemicals and liquid fuels. These latter applications are projected to grow significantly over the next several decades in some of the scenarios discussed in Chapter 2.

The production of coke from coal is a centuries-old technology in which low-ash “metallurgical” coal is heated in an oven to drive off volatile matter, leaving a high-purity carbon product that is used in blast furnaces to produce iron for steel making. Modern coke plants consist of a battery of long, narrow, brick-lined rectangular ovens into which coal is fed. The volatile gases driven off by heating are collected, cleaned, and used as fuel. The hot coke product is pushed out of the oven into a rail car, quenched with water to cool it, and then shipped for use in steel making.

Most of the coal currently used at industrial facilities is burned in boilers to generate steam, just as is done in power plants. In many cases, electricity also is generated for on-site use, often in combined heat and power (CHP) systems (known also as co-generation) that yield high overall efficiencies, on the order of 80 percent or more. Industrial boilers are generally smaller than modern power plant boilers but use many of the same environmental control technologies found at larger facilities.

The recent rise in world oil prices, as well as domestic natural gas prices, has stimulated renewed interest in the production of gaseous and liquid fuels from coal. Coal liquefaction technology has long been used to produce high-quality transportation fuels, most notably in South Africa, which boasts the largest commercial facility in the world (the Sasol Group). Substitute natural gas (SNG1) also can be produced from coal, and one commercial plant has been operating in the United States since the 1980s (see Box 6.1). In both cases, coal gasification is a key technology. By adjusting the ratio of carbon monoxide and hydrogen in the syngas product, either gaseous or liquid products can be manufactured with the proper choice of catalysts and operating conditions (NRC, 1995, 2000, 2003a). However, the overall thermal efficiency of these processes is relatively low, on the order of 50 percent. Thus, total CO2 emissions for a coal-to-liquids plant, including CO2 from the conversion process and from combustion of the liquid fuel, are roughly twice that of diesel fuel produced from petroleum.

|

BOX 6.1 The Great Plains Synfuels Plant The Great Plains Synfuels Plant near Beulah, North Dakota, operated by the Dakota Gasification Company, may provide a hint of an important future use for coal in the United States—the production of synthetic liquid and gaseous fuels. The plant was built with government support over two decades ago during a time of high oil prices and natural gas shortages. Each day, it uses 18,000 tons of lignite to produce about 160 million standard cubic feet of methane gas. It also produces about the same amount of CO2, which is captured and piped 200 miles north to Saskatchewan, Canada, where it is used for enhanced oil recovery (EOR) in the Weyburn Field. An additional, roughly comparable amount of CO2 is discharged to the atmosphere. The plant also produces anhydrous ammonia and ammonium sulfate for agricultural use, as well as a variety of other minor products. With the high price of natural gas over the past several years, the plant has been profitable and is paying off its debt to the federal government. The Great Plains Synfuels Plant is a minemouth plant with an associated power plant. Water for the plant is pumped from the Missouri River, 20 miles to the north. The plant employs oxygen and steam-blown Lurgi gasifiers of the type used by Sasol in South Africa. Compared to natural gas from a conventional gas well, the Great Plains plant emits about twice as much CO2 to the atmosphere per British thermal unit (Btu) of methane produced, even after subtracting the CO2 captured and used for EOR (but including the carbon contained in the methane product). The CO2 emitted from a coal conversion plant can be reduced to a negligible quantity if hydrogen and electricity are the co-products (rather than methane or liquid fuels) and if all of the carbon dioxide is captured and sequestered (as is planned by the Department of Energy for the FutureGen plant; see p. 101-102). |

A number of studies have analyzed longer-term scenarios—to 2050 and beyond—in which coal to liquids, coal to substitute natural gas, and coal to hydrogen might begin to play increasingly important roles in the U.S. and global energy economies (e.g., IPCC, 2001; NRC, 2004a). There remains significant uncertainty, however, about these (or other) longer-term scenarios. In the time frame specified for the current study, to 2030, the scenarios reviewed in Chapter 2 suggest that power generation will remain the dominant use of coal. The remainder of this chapter focuses on issues associated with this use of coal.

ENVIRONMENTAL IMPACTS OF COAL USE

Coal-based power plants emit air pollutants and create solid and liquid wastes that can adversely affect air quality, terrestrial and aquatic environments, water resources, human health, and climate. Environmental management technologies that are already widely available and in use can reduce most of these

impacts. However, no such measures are yet commercially deployed or have been demonstrated that can substantially reduce emissions of carbon dioxide from large coal-fired power plants, to ameliorate their contribution to global warming. Accordingly, the greatest difficulty in projecting future coal usage arises from uncertainty about the nature of future government action to limit CO2 emissions from power plants and the viability of large-scale applications of technology to capture and sequester CO2 emissions from power plants and other coal-based energy conversion facilities. Consequently, any projections of a substantial future expansion of coal use in the context of a meaningful CO2 reduction mandate depend on the development and widespread deployment of technology to reduce CO2 emissions from coal-based power plants.

Impacts on Air Quality

Atmospheric emissions of SO2, NOx, and particulate matter (PM) from coal combustion are significant sources of air pollution that have been linked to respiratory and other human health problems (e.g., NRC, 2005a; EPA, 2006a). However, as a result of a series of actions following the 1990 Clean Air Act Amendments, emissions of NOx and SO2 from coal-fired power plants in the United States are being substantially reduced even as U.S. coal consumption is increasing. As other requirements of the 1990 amendments are implemented, emissions of hazardous air pollutants such as mercury (EPA, 1997, 1998; NRC, 2002c) from coal-fired power plants are also expected to decline.

Projections of future coal use already reflect current government regulations aimed at reducing emissions of NOx, SO2, particulate matter, and mercury from coal-fired power plants. Both the technology needed to satisfy the regulatory requirements for NOx and SO2 emissions and the technology to eliminate more than 99 percent of PM emissions are currently in widespread commercial use (NESCAUM, 2005). The technology to significantly reduce mercury emissions in compliance with federal regulations is also expected to be commercially available by 2010 (STAPPA/ALAPCO, 2005; Feeley, 2006).

The present availability and continuing evolution of technology to respond to emissions of these pollutants make it unlikely within the 25-year time horizon of this study that current or future governmental requirements to control such emissions will materially affect future coal usage overall, although air quality considerations will continue to affect the siting of new coal-based facilities. Requirements to control air pollution from power plants are generally structured in one of two ways—as specific standards imposed on each individual electric generating unit in a regulated class; or as a “cap-and-trade” program (Box 6.2), which limits the aggregate emissions from all units in the regulated class but does not impose limits on individual units. Each approach can shift demand—either intentionally or unintentionally—to coals with differing characteristics (e.g., from bituminous to subbituminous coal or vice versa).

|

BOX 6.2 Cap-and-Trade Regulation of Coal-Fired Power Plant Emissions A cap-and-trade program requires each regulated unit to hold and use an emission credit, called an “allowance,” for each ton of the regulated pollutant that the unit emits. The total number of allowances created for each year (or other compliance period) equals the total number of tons of emissions allowed under the cap, ensuring that aggregate emissions cannot legally exceed the cap. Ideally, a cap-and-trade program leads each unit to choose the most cost-effective compliance strategy. For example, to comply with federal cap-and-trade programs to reduce power plant emissions of SO2, coal-fired power plants have a variety of strategies available:

The 2005 Clean Air Interstate Rule (CAIR) stipulates that beginning in 2009, each unit in the affected region of the country must hold two allowances for each ton of SO2 it emits (EPA, 2005), rather than the one allowance per ton currently required. This effectively halves the emissions cap for the CAIR region. |

In response to the 1990 Clean Air Act Amendments’ requirements to reduce sulfur dioxide emissions, most existing plants chose not to install scrubbers and instead relied on a less costly compliance approach that depended largely on a switch to less expensive, lower-sulfur fuel. This choice has been cited as a key reason why the rate of growth in the use of low-sulfur coal from the Powder River Basin has far outpaced the rate of growth for higher-sulfur coal from the eastern part of the United States. In the future, in order to comply with more stringent air quality requirements for fine particulate matter (which is formed when SO2 or NOx react with other substances in the atmosphere), the installation of flue gas desulfurization (FGD) systems at coal-fired power plants is projected to roughly double from its current level of about 30 percent of coal-fired capacity (EPA, 2005). Whether this will significantly affect the use of western low-sulfur coals as an air quality compliance strategy remains to be seen.

Impacts on Terrestrial and Aquatic Environments and Water Resources

Coal combustion and gasification processes generate ash and other solid residues, as well as liquid effluent. Solid residues retain trace elements that were originally present in the coal, and some of these elements (e.g., arsenic, cadmium, cobalt, copper, iron, lead, mercury, molybdenum, nickel, scandium, selenium, uranium, zinc) have the potential to impact human health and the environment. Leaching of ash and slag, and the water used for handling ashes as slurries, can create water pollution problems. The processes applied to control air pollution from coal combustion also create potentially harmful residues (e.g., the removal of SO2 from flue gases generates wastes containing sulfur compounds). Appropriate management of these residues can minimize their potential for negative effects (e.g., sludge can be dewatered by evaporation in lined ponds to reduce the potential for leakage into the soil). In addition, about 40 percent of coal combustion products produced annually are currently used for beneficial purposes, and this figure is expected to rise as a result of government and industry awareness initiatives (ACAA, 2005).

The use of water in “once-through” cooling systems in power plants can also harm aquatic life. When water is withdrawn from rivers and other water bodies for use in condensers, aquatic life can be harmed by impact against the cooling water intake structures, by being drawn into the condenser and subjected to high heat, or by higher temperatures in the water body where the cooling water is discharged.

Increases in coal combustion and gasification are likely to lead to an increase in solid residues, liquid effluents, and the use of water for condenser cooling and other plant functions. However, technologies and practices to manage the associated environmental issues currently exist and are continually being improved. Consequently, these issues are unlikely to pose a significant obstacle to increased coal use, although site-specific factors could be important in the viability and design of coal-based energy plants.

Impacts on Global Climate

Burning coal and other fossil fuels for energy releases carbon dioxide to the atmosphere, and atmospheric CO2 concentrations have increased by about one-third since 1750; substantially higher levels are projected for the coming decades (NAS, 2005). These increased levels have been linked to global climate change and an overall warming of the earth’s surface (NRC, 2001; IPCC, 2007).

In the United States, power plants account for about 40 percent of the nation’s CO2 emissions (EPA, 2006b). Strategies available to reduce these emissions include the following:

-

Reducing the demand for electricity, for example, by improving the efficiency with which machinery and appliances use electricity.

-

Generating electricity in plants that are more efficient. For example, a new supercritical pulverized coal plant requires less than 9,000 Btu (British thermal units) of coal energy input to generate 1 kWh of electricity (>38 percent efficiency) compared to the current average of more than 10,000 Btu/kWh of electricity (<34 percent efficiency).

-

Switching to a less carbon-intensive fossil fuel. For example, generating 1 million Btu of energy as heat from coal combustion releases about 200 pounds of CO2, whereas generating the same amount of energy as heat from natural gas releases about 120 pounds of CO2.

-

Combining fuel switching and more efficient generating plants. For example, a new natural gas-fired combined cycle (NGCC) power plant requires only about 6,800 Btu of energy input to generate 1 kWh of electricity (~50 percent efficiency). Hence, to generate 100 kWh of electricity, a NGCC plant would emit about 80 pounds of CO2 compared to the average coal plant that emits 200 pounds per 100 kWh, or a more efficient PC plant that emits 180 pounds per 100 kWh.

-

Generating electricity without using fossil fuels, for example, by using renewable resources or nuclear power.

-

Capturing and sequestering (storing) CO2 produced by fossil fuel combustion or gasification.

The technologies currently offered commercially to capture power plant CO2 emissions can achieve net emission reductions of 85 to 90 percent at new PC or IGCC power plants (IPCC, 2005). Such technologies are widely used in a variety of industrial processes, mainly in the petroleum and petrochemical industries, but are not yet deployed commercially in the electric power sector. Although post-combustion CO2 capture systems employing amine sorbents have demonstrated effective removal of CO2 from flue gas streams from gas-fired and coal-fired boilers, they have not yet been applied at the larger scales typical of modern power plants (e.g., plants that generate several hundred megawatts of electricity). The same is true for the “pre-combustion” capture technologies used commercially at gasification-based processes. Various types of oxyfuel combustion systems2 also are being developed to facilitate CO2 capture, but these have not yet been proven. A variety of advanced gas separation methods are being developed by national and international R&D efforts to selectively and more cost-effectively remove CO2 from flue gas and other gas streams. However, large-scale demonstrations of CO2 capture and sequestration at the 100 MW scale are needed before such systems can be implemented on a large scale.

FEDERAL COAL UTILIZATION R&D PROGRAMS

Federal R&D programs related to coal utilization are located primarily in the U.S. Department of Energy (DOE). A number of smaller programs at the U.S. Environmental Protection Agency (EPA) also are related to coal utilization.

DOE Coal Utilization R&D Programs

The DOE Office of Fossil Energy (DOE-FE) is responsible for pursuing research, development, and demonstration (RD&D) efforts to make coal power plants less expensive, cleaner, and more efficient. These efforts are administered through the National Energy Technology Laboratory (NETL) and are focused on developing cost-effective coal use technologies and environmental controls that have the potential to yield near-zero emissions (NETL, 2006a). The NETL RD&D programs include Gasification, Advanced Turbines, Carbon Sequestration, Innovations for Existing Plants (IEP), Fuel Cells, Fuels, and Advanced Research. Within the IEP program, NETL is supporting research on emissions control for mercury, advanced NOx, and particulate matter; utilization of coal by-products; and air and water quality.

NETL’s clean coal demonstration projects have the goal of demonstrating and deploying advanced clean coal technologies that, in DOE’s words, will “benefit the environment, enhance electricity reliability, bolster energy security, and help to ensure an affordable supply of electricity” (DOE, 2004). Among the projects are two government-industry partnership programs—the Clean Coal Power Initiative (CCPI) and the Power Plant Improvement Initiative (PPII). DOE provides up to 50 percent of the funding for each project, and the industrial partners involved contribute the remainder. The programs have somewhat different goals:

-

The CCPI program was designed to support the demonstration of a range of promising technologies with potential to efficiently and reliably generate electric power with minimum adverse impact on the environment. This 10-year program was established in 2001 to increase investments in clean coal technology.

-

The PPII program was a one-time program conducted in 2000 to implement commercial-scale demonstration of clean coal technologies at existing and new electric power generation facilities, with the objective of demonstrating higher efficiencies, lower emissions, improved economics, and enhanced system performance. Improving by-product utilization was also one of the areas of focus in the PPII program.

NETL’s Coal and Power Systems Program includes the Gasification Technologies Program and the FutureGen Project, as well as a component that sponsors

advanced research. Research projects are under way in gasification, advanced combustion, turbine and heat engine technologies, and carbon sequestration:

-

The Gasification Technologies Program emphasizes R&D on gas cleaning and conditioning. Activities include research on (1) a two-stage process for the removal of H2S, trace metals, HCl, and particulates; (2) membrane processes for control of H2S, mercury, and CO2; and (3) sorbents for NH3 control.

-

FutureGen is a planned 275 MW prototype plant that will use coal gasification and other advanced technologies to produce electricity, hydrogen, and other products, with near-zero emissions at high efficiency levels. The facility will serve as a large-scale engineering laboratory for testing new clean power, CCS, and coal-to-hydrogen technologies. The plant is expected to begin operating in the 2012 time frame.

-

One of DOE’s fastest-growing programs in recent years has been the Carbon Sequestration Program, which focuses on CO2 capture and storage technologies with high potential for reducing greenhouse gas emissions. The initial goal was to develop instrumentation and measurement protocols for direct sequestration in geological formations and for indirect sequestration in forests and soils. Other program goals are to begin demonstration of large-scale carbon storage options by 2008, and to develop—to the point of commercial deployment—systems for advanced indirect sequestration of greenhouse gases, also by 2008. Biological and chemical processes that convert CO2 to solid materials also are being investigated as means of sequestering CO2, and oceanic and terrestrial carbon sequestration has been studied (NRC, 2003b; DOE, 2007c). However, the principal focus of the DOE program is on geological sequestration, which is the only long-term storage option that has been demonstrated at a commercial scale—three large facilities are already in operation worldwide, and a number of smaller injection sites operate for research and development purposes (IPCC, 2005). In terms of capture technology, DOE’s target is to develop—to the point of commercial deployment—systems for direct capture and sequestration of greenhouse gases and pollutant emissions from fossil fuel conversion processes by 2015. The goal is for these systems to have near-zero emissions and approach a no-net-cost increase for energy services (DOE, 2007a).

-

DOE’s NETL also sponsors basic research through its Advanced Research Program. This program supports research in a variety of areas and strives to bridge the gap between basic research and the development of new systems capable of improving the supply and utilization of fossil energy resources.

DOE also manages several programs that focus on technologies to facilitate the production of hydrogen from coal for use in fuel cells and other systems. Two possible coal-based hydrogen production scenarios are considered in the program: (1) the production of hydrogen alone or in combination with electricity, and (2) the production of high-hydrogen-content liquid fuels that can be

transported through the existing infrastructure to sites where the fuels would be extracted and stored near the customer.

Currently absent from the portfolio of DOE-sponsored projects are any full-scale demonstration projects of integrated CO2 capture and storage at a modern coal-based power plant. The largest planned project is the 275 MW FutureGen plant noted above, which is classified as a research project rather than a demonstration project. Nonetheless, FutureGen will provide valuable information on the design and operation of IGCC plants with carbon capture and sequestration (CCS). In addition, DOE also recently announced its intention to support seven large-scale demonstrations of CO2 sequestration in Phase III of its Carbon Sequestration Regional Partnerships program. As of February 2007, there were no plans for full-scale demonstrations of other CCS technologies, particularly post-combustion capture systems applicable to the current and future fleet of PC power plants in the United States. Nor are there any planned U.S. demonstrations of oxyfuel combustion systems for CO2 capture at PC plants, although such projects are underway in other countries.3 In recognition of the need for additional full-scale demonstrations of CCS, the Coal Utilization Research Council (CURC) and the Electric Power Research Institute (EPRI) recently called for a $6.7 billion program of technology demonstrations, including demonstrations of CO2 capture at both combustion- and gasification-based facilities, plus a $900 million initiative for three demonstration projects and expanded R&D for CO2 sequestration (Burke and Carter, 2006).

While preliminary studies indicate that there are many geological formations in the United States that are potentially capable of storing large quantities of CO2 (DOE, 2006), more detailed assessments are needed to identify suitable storage sites, quantify their capacities to store CO2, assess and quantify carbon dioxide migration and leakage rates at the storage sites, understand the environmental impacts of storage, and make the sites available (see Box 6.3). To a large degree, these important research areas can and are being addressed by participants in the current DOE Carbon Sequestration Program, including the seven regional partnerships in different parts of the country.

EPA R&D Programs Associated with Coal Utilization

Although primarily focused on regulation, the U.S. Environmental Protection Agency (EPA) does support limited research through the Office of Research and Development. While it does not have a program specifically focused on coal utilization, a number of EPA activities are directly or indirectly related to coal use, for example:

|

BOX 6.3 Geological Sequestration of CO2—Resources, Reserves, and Characterization Geologic sequestration of CO2 will require specific geologic strata in which the CO2 can be placed and where it will remain permanently. As such, these geologic units are “resources,” but in a different sense than mineral or energy resources. Sequestration resources have the ability to host CO2 at some time in the future, whereas mineral and energy resources are currently hosts to their desired elements. The primary targets for geologic sequestration of CO2 are petroleum reservoirs, saline reservoirs, and deep, unminable coal seams. The first two are widely distributed in sedimentary basins and have the potential to provide storage for large quantities of CO2. Coal seams are more limited in their ability to sequester CO2 on a worldwide basis, but individual coal seams may be an attractive storage target because in some settings coal may sequester a greater mass of CO2 per unit volume than the other reservoirs, and there is also the potential of recovering methane from coal during the sequestration process. Recently, researchers have found it useful to characterize the geologic sequestration process by the types of trapping mechanisms that can occur in the subsurface—structural and stratigraphic trapping, residual gas trapping, dissolution trapping, mineral trapping, hydrodynamic trapping, and coal adsorption (Bradshaw et al., 2005). Reliable estimates of the amount of geologic storage of CO2 that can be located in any region depend on the ability to determine accurate capacity estimates for the “reservoirs” in the various types of storage sites. Current estimates for world storage capacity range over four orders of magnitude, indicating that these estimates are less than satisfactory. Many of the estimates used overly simplistic methods and were based only on the total surface area of a sedimentary basin, using an assumed average thickness of reservoir rock and an average porosity (Bradshaw et al., 2005). |

-

The Particulate Matter (PM) Research Program is focused primarily on understanding how fine particles are emitted into the atmosphere, how they are formed in the atmosphere from gaseous pollutants, and how they are transported. Research is also under way to better understand the attributes of particles that cause adverse health effects, to identify those who may be most susceptible to these effects, and understand how people are exposed to PM air pollution.

-

The EPA has undertaken a range of research related to mercury emissions, including the development of protocols for verifying continuous air emission monitors used to measure total and chemically speciated mercury in source emissions, and the compilation of speciated (elemental, oxidized, and particulate) mercury emissions data from coal-fired utility units to estimate mercury emissions nationwide.

|

Reliable estimates of CO2 storage capacity are required by national, regional, and local governments, as well as by the emerging sequestration industry. Estimation of CO2 storage capacity requires a detailed knowledge of the characteristics of the potential reservoir (Bradshaw et al., 2005, 2006; Brennan and Burruss, 2006). Although there are no currently accepted guidelines for classifying CO2 storage “resources” and “reserves,” a classification system for CO2 storage capacity has been proposed by Frailey et al. (2006). Bradshaw et al. (2005) identified four gaps that require additional research into standards for measurement of CO2 storage capacity:

The DOE’s Office of Fossil Energy is the lead federal entity for development of carbon sequestration technology in the United States. The program, administered by DOE’s National Energy Technology Laboratory, is extensive—$67 million was enacted in FY 2006 and nearly $74 million was requested for FY 2007. This program included support for a high-level overview of potential geologic sequestration sites in the United States and Canada (DOE, 2007c). A large number of state agencies, universities, and private companies are involved in the program through seven regional partnerships as well through a variety of other projects funded by the program. |

EPA also has regulatory responsibility for waste disposal that involves underground injection of hazardous and nonhazardous wastes. Injection of CO2 for geological sequestration currently falls within the purview of the EPA Underground Injection Control (UIC) program, whose primary purpose is the protection of drinking water supplies. CO2 injection for enhanced oil recovery (EOR) is currently permitted under the UIC, and EPA has recently formulated draft guidance to permit pilot geological sequestration projects involving injections into deep saline formations. However, the regulatory structure and requirements applicable to future large-scale CCS programs are yet to be developed, although such issues are receiving considerable attention from a variety of interest groups in the United States and elsewhere (NETL, 2006b).

FINDINGS AND RECOMMENDATION—COAL UTILIZATION

The dominant use of coal in the United States today is for electric power generation based on the combustion of pulverized coal. As a result of regulatory programs over the past two decades, substantial progress has been made toward the control of emissions of air pollutants and other wastes that can harm human health (EPA, 2007). Federal R&D programs concerned with coal use are focused on developing more cost-effective technologies to enable coal-based power plants to meet environmental constraints.

Emissions of CO2 from coal-based power plants are not currently subject to regulation or controls. However, low-emission coal-based power plants equipped with technologies for the capture and geological sequestration of CO2 are projected to be developed to the point of commercial readiness by 2015 as part of DOE’s Carbon Sequestration Program. Currently, however, there are no full-scale demonstration projects of CO2 capture and storage at a large, modern coal-based power plant.

The following principal findings have resulted from this brief review of coal utilization issues:

-

Potential regulatory requirements to further reduce emissions of NOx, SO2, mercury, and particulate matter in the future are not expected to significantly limit the overall use of coal in the next several decades. However, future emission control requirements for these regulated air pollutants could result in changed preferences for particular types of coal, depending on the nature of future regulations.

-

Decisions to invest or not invest in coal-based power plants will strongly influence future coal use, and this will depend in large part on both the timing and the magnitude of any future constraints on CO2 emissions, as well as on the demonstrated commercial readiness of technologies to significantly reduce CO2 emissions from coal-based power plants and other energy conversion processes.

-

Detailed assessments are needed to identify and characterize potential geological formations in the United States that are capable of sequestering large quantities of CO2; to quantify their storage capacities; to assess migration and leakage rates; and to understand the economic, legal, and environmental impacts of storage on both near-term and long-term time scales. Such geologic sequestration sites should be considered “resources,” and categorized and described in the same way that conventional mineral or energy resources are assessed.

Recommendation: The U.S. Geological Survey (USGS) should play a lead role in identifying, characterizing, and cataloguing the CO2sequestration capacity of potential geologic sequestration resources.

The USGS has expertise in coordinating nationwide assessments of oil and gas, minerals, and coal, and a history of developing consensus in resource and reserve terminology. It would be appropriate for the USGS to have the same lead role in a national assessment of the nation’s geologic carbon sequestration resource that it currently has with regards to coal and petroleum resources. The committee estimates that approximately $10 million per year for five years will be required for this activity.4 There should be close cooperation and coordination among the USGS, the Carbon Sequestration Program managed by DOE-FE, and the states involved in the Carbon Sequestration Regional Partnerships.