4

Coal Mining and Processing

Although the United States has the vast coal resource described in the previous chapter, perhaps as much as 4 trillion tons, the key issue for policy makers is the amount of coal that is economically recoverable. This is not a fixed quantity, but depends on the geological resource, the market price, and the cost of mining. The particular characteristics of the coal mining industry create unique challenges as it endeavors to provide coal to the market at a competitive price, continually improve miner safety and health, and meet environmental and community requirements. This chapter provides a brief description of the characteristics of the coal industry in the United States, presents an overview of coal extraction and processing methods, and discusses the major issues associated with coal mining and processing. A summary of current research activities supported by state and federal agencies provides the context for recommendations for essential future research.

COAL MINING INDUSTRY IN THE UNITED STATES

The U.S. coal industry serves a vital role in the nation’s economy by producing fuel for more than half of its electricity. Despite the industry’s importance, industry financial data for 2005—the strongest year for the coal industry in recent years—shows that it is a relatively small industry with revenues totaling $20 billion to $25 billion and net income between $1 billion and $2 billion. To put that in perspective, the entire industry taken collectively would rank as about the one-hundredth largest company (in terms of either revenue or net income) on the 2005 “Fortune 500” list, and it is less than 10 percent the size of Wal-Mart.

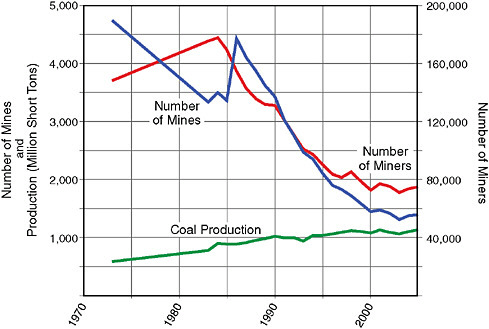

The U.S. coal industry has undergone a remarkable transformation over the last three decades. During this time, coal production has doubled, while the number of active miners has been halved and the number of mines has dropped by a factor of three (Figure 4.1). This has resulted in the concentration of production in a smaller number of larger mines. The 100 largest mines in the country produced 805 million tons of coal in 2004 (72.5 percent of total U.S. production), while employing about 45 percent of the mining workforce (an average of 310 miners per mine) (EIA, 2005d; NMA, 2006a). The remaining approximately 1,300 mines produced 27.5 percent of the nation’s coal while employing 55 percent of the workforce (about 30 miners per mine). Nearly 70 percent of U.S. coal mines, many of which are comparatively small operations, are in Kentucky, West Virginia, and Pennsylvania.

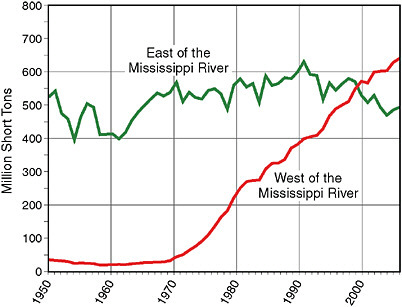

Since the 1970s, there has been a continuous increase in the proportion of coal produced by the western states. At present, states west of the Mississippi account for more than 55 percent of total tons produced (Figure 4.2). Wyoming alone accounts for almost 36 percent of national coal production tonnage (Table 4.1).

Considerable data are compiled on the basis of the union or non-union status of mines throughout the coal industry by the Energy Information Administration (EIA). At present, some 27.5 percent of the total coal mining workforce consists

FIGURE 4.1 Number of coal mines, production tonnage, and miner employment in the U.S. coal industry. Note that the left axis scale represents two parameters, production tonnage and number of mines. SOURCE: Based on data in NMA (2006b).

FIGURE 4.2 Domestic coal production during the last half century across the United States. SOURCE: EIA (2006a).

of union members, working at 147 mines (EIA, 2005d). The United Mine Workers of America (UMWA) represents the largest number of workers (16.3 percent of the workforce) and the largest number of mines (131) of any of the unions. The average number of workers at a union mine is 140.

COAL MINING AND PROCESSING METHODS

A modern coal mine is a highly mechanized industrial plant that has to meet strict standards of engineering design and operation. The size, power, strength, monitoring and control features, and automation of mining equipment dwarf

TABLE 4.1 U.S. Top Coal Producing States in 2005

|

State |

Production in 2005 (thousands short tons) |

Percentage of Total U.S. Production Tonnage |

|

Wyoming |

404,319 |

36 |

|

West Virginia |

153,650 |

14 |

|

Kentucky |

119,734 |

10 |

|

Pennsylvania |

67,494 |

6 |

|

Remaining coal-producing states |

386,301 |

34 |

|

U.S. Total |

1,131,498 |

100 |

|

SOURCE: EIA (2006b). |

||

those of even a few decades ago. Coal mines require substantial capital investment in both permanent structures and depreciable mining equipment, exceeding $75 per annual ton of capacity in large underground coal mines and $30 or more per annual ton for large surface coal mines.

The overall coal mining process consists of several sequential stages: (1) exploration of a potentially economic coal seam to assess minable reserves, environmental issues, marketable reserves, potential markets, and permitting risks; (2) analysis and selection of a mining plan; (3) securing the markets; (4) developing the mine; (5) extracting the coal; (6) processing the coal if necessary; and (7) decommissioning the mine and releasing the property for post-mining use. The two essential requirements that must be fulfilled before a prospective coal mine can enter the development stage are confirmation that there are sufficient minable reserves of adequate quality with no unacceptable environmental or permitting risks, and confirmation of an assured or contracted market for a substantial fraction of the coal that will be mined.

Coal Mining

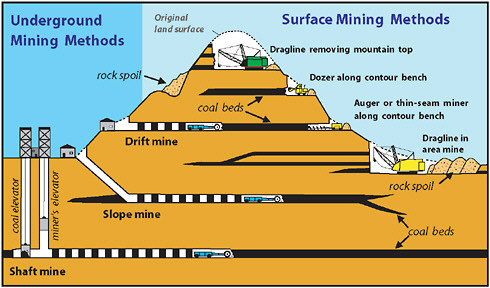

Coal seams can be mined by surface or underground methods (Figure 4.3), with the choice of mining method dictated by both technical and economic factors. The most important technical factors are the thickness of the coal seam, the depth of the coal seam, the inclination of the seam, and the surface topography.

FIGURE 4.3 Schematic depiction of the range of different surface and underground types of coal mining, illustrating types of access to coal deposits and mining terminology. SOURCE: KGS (2006).

Each of these technical factors can set limiting conditions when considering the economic recoverability for a given coal, mining method, and market. The important economic parameters are the relative costs of mining coal by surface and underground methods including costs associated with any site-specific land use constraints, the cost of removing the material above the coal seam in the surface method, and the price of coal. The price for any particular coal is related directly to coal quality (Box 4.1 and Table 4.2). Because more than 90 percent of the coal mined in the United States is used in power plants to generate electricity using steam turbines, the price for steam coal is dependent primarily on its heating value and sulfur content.

Relatively shallow coal deposits are generally extracted by surface mining, and deeper deposits are extracted by underground mining (more detailed descriptions of surface and underground mining processes can be found in Appendix E). There are also situations in which a seam is mined by surface methods first, and then if adequate reserves are still available, the mine is developed for underground extraction. Where remaining reserves are limited, other methods of mining—such as auger mining or highwall mining—may be used.

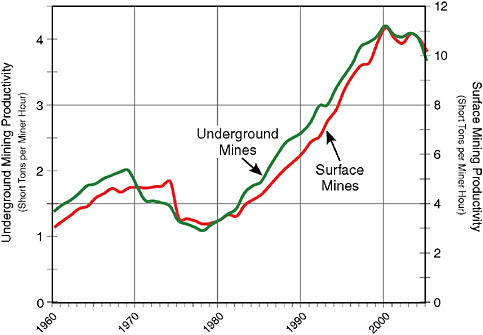

Surface mining has many advantages compared to underground mining. In general, coal recovery is very high (85 to 90+ percent), compared to 40 to 70 percent in underground mines. The productivity of surface mines is generally higher than that of underground mines (Figure 4.4), and health and safety statistics for surface mining are also generally better than those of underground mining. Surface-mined coal from the Powder River Basin is usually simply sized and screened in preparation for market, whereas underground-mined coal and surface-mined coal from the Interior and Appalachian basins often requires a greater amount of processing (see below) to improve its marketability. The cost per ton of mining coal by surface methods is generally lower than that by underground methods.

In the United States, in addition to a continuous growth in coal production since the 1960s, there has been a dramatic shift in production from underground mining to surface mining (Figure 1.6). In the Powder River Basin (PRB), where deposits of coal more than 100 feet thick occur close to the surface, individual surface mines can produce more than 90 million tons each year. Underground coal mining is more common east of the Mississippi River, particularly in Appalachia. Some of the largest underground coal mines, each producing around 10 million tons annually, are located in Pennsylvania and West Virginia. The largest underground mining complex in the United States produces about 20 million tons per year.

Bituminous coals in the eastern and central United States are mined by both surface and underground mining methods. Anthracite coal is mined exclusively in northeastern Pennsylvania, also by both underground and surface mining methods. Lignite and subbituminous coal production is centered in a small number of large mines (Table 4.3). Subbituminous coal and lignite comprise about 50

percent of U.S. coal production by tonnage, but because of their lower heating values, only about 40 percent by heating value. The distinction between tonnage and energy content is particularly important when considering possible shifts in coal supply and demand by producing and consuming regions. Subbituminous coals are produced almost exclusively in the PRB of Wyoming and Montana. EIA’s forecasts of increased coal production over the next three decades (see

|

BOX 4.1 Coal Rank and Quality Although the term coal refers to any readily combustible rock containing more than 50 percent by weight of organic matter, coals differ considerably in their physical and chemical characteristics (Table 4.2) and these differences have pronounced impacts on their value and use. Coals in the United States are classified by “rank,” a method of distinguishing coals on the basis of their fixed carbon content, volatile matter content, heating value, and agglomerating characteristics.1 Coal rank is defined as “the degree of metamorphism, or progressive alteration, in the natural series from lignite to anthracite. Higher-rank coal is classified according to the fixed carbon on a dry basis, lower-rank coal, according to Btu [heating value] on a moist basis” (AGI, 1997).2 Differences in sedimentary depositional environments and differences in the geological history of the coal strata result in differences in mineral matter content and composition, as well as differing concentrations of some of the important minor elements (e.g., sulfur, chlorine). These differing characteristics impact coal utilization in both the electricity generation and metallurgical markets. The term coal quality is used to distinguish the range of different commercial steam coals that are produced directly by mining or are produced by coal cleaning.3 Generally, coal quality for steam coals (i.e., coal used for electricity generation) refers to differences in heating value and sulfur content (Table 4.2), although other characteristics such as grindability or ash fusion characteristics are also specified in coal sale agreements. While not as obvious as the impact of sulfur content on environmental emissions, differences in the moisture content and heating values among different coal types affect CO2 emissions upon combustion, with higher-rank bituminous coals producing 7 to 14 percent lower emissions than subbituminous coals on a net calorific value basis (Winschel, 1990). |

|

TABLE 4.2 Typical Values for Characteristics of Major Commercial Steam Coals in the United States

|

||||||||||||||||||||||||||||||||||||||||||||||||

FIGURE 4.4 Productivity trends for surface and underground coal mines, illustrating the dramatic productivity increases over the past three decades. SOURCE: EIA (2006a).

TABLE 4.3 Coal Production by Rank for 2005

Chapter 2) rely heavily on increased production from this region for consumption east of the Mississippi River. Because it takes about 50 percent more subbituminous coal (on a tonnage basis) to replace a ton of bituminous coal in electricity generation,1 this has significant implications for transportation infrastructure and power plant design and capacity.

When used for electricity generation, coal from the PRB generally produces more CO2 per kilowatt-hour than the bituminous coal mined in the east. Combustion of subbituminous coal from the PRB produces about 226 pounds of CO2 for every million Btu (British thermal units) of heat generated (on a net calorific basis), compared with about 211 pounds for the bituminous coal mined in the East (Winschel, 1990). Another possible constraint on the use of coal from the southern PRB might be future air quality regulation of coarse particulates, although Environmental Protection Agency’s (EPA’s) proposal to exempt mining and agricultural operations in its update of particulate standards (EPA, 2006c) may remove or defer this potential constraint.

An increasingly important by-product of U.S. coal production is coal mine methane recovered during or prior to mining, in addition to coal bed methane produced independently of mining. Captured methane may be used as a fuel source at the mine or, where feasible, distributed in natural gas pipelines. In recent years, coal bed methane production has increased and now comprises about 8 percent of the U.S. natural gas supply. An ancillary benefit of recovering coal mine methane is reduced atmospheric methane emissions, because methane is a potent greenhouse gas.

Coal Processing

“Raw” or “run-of-mine” coal can be processed2 using physical separation methods to remove unwanted mineral matter to produce a “clean” coal. Processing adds value in several ways:

-

Removal of the mineral matter (or “ash”),3 which is largely noncombustible and may constitute up to 65 percent of the raw coal, increases the heating value of the coal on a mass basis.4 Although some combustible material is lost as part of the cleaning process, the removal of unwanted material reduces the mass and volume of coal for a given heating value thereby reducing shipping costs as well as minimizing coal handling and ash management costs for the end user.

-

Processing allows greater control over the “quality” of the coal—principally ash and moisture—which improves its consistency for end users, such as electricity generators or coke manufacturers. Improved and consistent quality increases the efficiency and availability of steam boilers and is particularly important for the quality of metallurgical coke.

-

Physical processing (see Appendix E) can, to some extent, reduce sulfur and trace element contents, particularly on a heating value basis. However, generally coal cleaning is not practiced primarily for this purpose except for the metallurgical coal market.

The decision whether or not to process a particular raw coal depends on the coal and its intended market. The subbituminous coal of the Powder River Basin is almost always shipped to market raw because it has inherently low ash content and poor “washability,”5 and the region has low water availability—a critical requirement for conventional coal beneficiation.

Most coal preparation plants are in the eastern states, with more than 80 percent of the plants and almost 80 percent of capacity located in West Virginia, Virginia, Pennsylvania, Ohio, and Kentucky (Fiscor, 2005; see Appendix E). The 11 coal preparation plants in the western states are located at bituminous

coal mines. Wyoming—the largest coal-producing state in the country—has no coal preparation plants, largely because the subbituminous Powder River Basin coal is low in ash. However, PRB coal has a high level of inherent moisture (~30 percent), which has stimulated some interest in thermal dewatering of the coal to increase its heating value and reduce its transportation costs (see Box 4.2).

MAJOR COAL MINING AND PROCESSING ISSUES

The conditions that will be encountered in future coal mines will undoubtedly be different from those of today—the more easily mined coal has already been extracted. As shallower coal is depleted and seams with greater amounts of overburden6 are mined, surface mining will become more expensive because stripping ratios7 will increase and multiple benches8 will be needed. This will increase the number of unit operations and the associated cost. In underground mining, the mines of the future will have to access seams that are deeper, thinner, or thicker, often with higher gas content and potentially with greater ground-control issues. Overlying or underlying seams may have been mined, or it may be necessary to mine multiple seams simultaneously to meet increased production requirements. These more difficult mining situations will have an effect on economic decisions related to mine profitability, on the health and safety of mine workers as they encounter more challenging or different mining requirements, on the technical ability to mine, and on the management of waste materials generated by mining.

Small mines (i.e., with annual production less than 2 million tons), which currently produce more than 25 percent of coal in the United States, play an important role in ensuring adequate coal supply because they have historically started and ceased production as demand and prices fluctuate. They also play a critical role in fully utilizing national coal resources, particularly those resources that may not be mined by larger operations.9 The population of small coal mines has been decreasing and is projected to continue to decline. However, small mines will continue to exist, and the technical and societal issues they will face in the future should be considered in agency plans.

Miner Health and Safety

Although statistics show substantially improved health and safety conditions in mines in recent years—with continuous decreases in both the incidence and

|

BOX 4.2 Upgrading of Low-Rank Coals Combined reserves of subbituminous coal and lignite (known as “brown coal” in the international coal trade) make up approximately one-half of the world coal reserves and about one-half of the coal resources of the United States. These coals are rarely processed before shipment or use. However, the oxygen and moisture contents of low-rank coals are greater than those of bituminous coals. This reduces the heating value of the coal as mined, which increases the transportation cost on a heating value basis and reduces the thermal efficiency of the steam boilers that use these coals. Most lignite mined in the United States is used in minemouth plants. Subbituminous coals, however, are generally transported considerable distances, so their high moisture content and low heating value add to the effective transportation cost and environmental impact. One way to offset these disadvantages is to dry the coal before transportation or utilization. Numerous processes for drying low-rank coals to upgrade them have been proposed, demonstrated (e.g., Great River Energy Lignite Drying Process; Bullinger et al., 2006), and in a few cases, commercialized (e.g., K-Fuels Process; Kowalski, 2005). The characteristics of dried low-rank coal—it is friable, has a tendency to spontaneously heat, and readily reabsorbs moisture—constitute major obstacles that must be overcome to produce a saleable, transportable, dry coal product. |

the severity of diseases, disasters, fatal accidents, and nonfatal accidents—the health and safety of miners remain a major concern for government, industry, and labor. As the coal mine disasters in early 2006 demonstrated (MSTTC, 2006), the safe operation of mines remains a major challenge—there needs to be constant monitoring and control of health and safety threats as well as continuous safety training and improvements in operating practices.

Past experience has shown that changes in mining operations or practices (e.g., introduction of new equipment and systems, mining of virgin areas, infusion of new workers) all have the potential to create a more hazardous environment. Similarly, experience has shown that adequate engineering controls and a knowledgeable workforce are the prerequisites for a safer work environment. Continued health and safety research is needed to identify new hazards and hazard sources as well as to improve the engineering controls for existing hazards, particularly through the development of reliable monitoring and intelligent control systems. The likelihood of deeper mines in the future means that there has to be increased attention to methane control (including methane capture before, during, or after mining), dust control, ignition sources, fires, and explosions. Recent disasters have shown that there are major knowledge gaps and technology needs in the areas of escape and survival, and emergency preparedness and rescue, emphasizing the need for research to develop systematic and comprehensive

risk management protocols that can then be applied to individual mines (MSTTC, 2006). In addition, since powered haulage and machinery now have the dubious honor of surpassing ground-control incidents (e.g., roof falls) as the major source of accidents in mines, there is a clear need for better understanding of the hazards that are likely to be encountered as equipment sizes and operational conditions change. New technology for better geological characterization as part of mine planning, better monitoring sensors, and increased remote control and automation of mining equipment have the potential to decrease miners’ exposure to hazardous conditions. Mining of deeper seams, multiple seams, thicker seams, and seams underlying or overlying mined-out seams will all require a greater understanding of strata control aspects. The risks associated with mining coal seams adjacent to previously mined-out seams, with their actual or potential void spaces, emphasize the need for accurate, comprehensive, and readily available mine maps showing the distribution of older mine workings.

Exploration and Mining

Adequate information on the nature and characteristics of a coal seam prior to mining is vitally important for safe and efficient mine operations. Any unexpected anomalies in a coal seam and associated strata, such as sand channels, washouts, faults, and roof instability, can substantially impair mining productivity and create safety hazards. Research to devise improved techniques for imaging coal seams and associated strata, including coal quality parameters, prior to and during mining is needed for mine planning, permitting, and operations (NRC, 2002b). The Martin County coal impoundment failure (NRC, 2002a) and the Quecreek inundation (PDEP, 2002) illustrated the need for increased accuracy and reliability of the geological information used for mine and mine facilities planning.

At present, the drilling and blasting required for overburden fragmentation is the major limitation on increased surface mining productivity, and the development of improved rock fragmentation practices is an essential requirement for increased surface mine production. For underground mining, the increased use of longwall mining (see Appendix E) offers the greatest potential for higher productivity. While deeper reserves will be ideal for the increased application of longwalls, a number of limitations to the current production potential of longwalls, in particular the need for better roof support and improved coal haulage systems, must be overcome. Other areas in which the development of advanced technologies offers considerable potential for increased productivity are the continuous monitoring of produced coal and the development of improved remote control, automatic control, and autonomous systems.

Selective mining and blending are two practices that have been advocated to decrease the handling of unnecessary waste during mining and processing, and to increase the utilization of all coals for a range of purposes. While the bulk

mining methods of the present do not generally favor such practices, these areas need to be explored to determine whether they offer potential for increased mining productivity.

Even when exploration shows promise of an economically minable deposit, the elapsed time from first investment in planning until a mine enters full production, after passing through the permitting, construction, and marketing processes, can take anywhere from seven to fifteen years for a large operation. Although smaller operations in established coal mining districts may take less time, two to five years is normal even in these situations. This time delay can significantly impact the economic feasibility of opening a new mine and will have to be minimized if the higher production scenarios for the future are to be achieved.

Coal Processing

Research to improve coal processing has considerable potential to optimize the use of the nation’s coal resources by increasing production and productivity and improving environmental protection. The effect of improved marginal economics by increasing coal recovery can be significant—in one case, a study showed that a 1 percent increase in recovery of coal could increase profits by 25 percent.10 This could have the effect of making an uneconomic reserve available for production, thus extending the nation’s economic reserve base.

-

There are large volumes of western bituminous coals with high ash content (>20 percent) that cannot be cleaned by conventional methods because there are insufficient water resources where the coal is mined to permit conventional wet coal processing. Also, a considerable amount of surface-mined subbituminous coal is lost because of out-of-seam dilution with mineral matter—an annual loss of as much as 10 million tons was reported for the Arch Coal Black Thunder Mine (which produces about 80 million tons per year).11 The development of dry coal beneficiation processes designed for these coals could greatly increase recoverable reserves.

-

Improved coal processing also offers the potential to minimize existing environmental problems and potential future issues. There is approximately 2 billion tons of waste fine coal in “gob” piles resulting from past processing techniques in eastern bituminous coal fields—Pennsylvania alone reports more than 250 million tons of waste coal (McGinty, 2004). Many of these piles are environmental liabilities being dealt with under the federal Abandoned Mine Land reclamation program, but a growing number are being viewed as potential opportunities for utilization. Pennsylvania has 14 sites at which circulating

-

fluidized bed boilers are operating on waste coal for electricity or process steam generation.

-

Improved coal processing also offers potential for responding to future environmental requirements. For example, the development of new or modified flotation processes permit fuel oil to be replaced as a froth flotation collector if it is prohibited because of disposal concerns.

There are two technical areas where the development of improved coal processing technologies offers the greatest potential to increase resource recovery (Peterson et al., 2001; NRC, 2002b; CAST, 2003):

-

The use of improved information technology, perhaps in conjunction with improved online analysis capabilities, to optimize the performance and efficiency of existing unit operations; and

-

The development and deployment of better materials with which to construct vessels, separation devices, and conduits.

Mining and the Environment

The primary needs for research in the broad environmental area are to support the regulation of existing and future mining operations and to mitigate the effects of past mining practices.

Existing Mine Operations. There is still an incomplete understanding of how strata behave after coal is extracted from both surface and underground mines, and the hydrologic consequences of mining are not fully understood. For surface mining, the properties of the altered subsurface—particularly the leaching and permeability characteristics—are likely to be different compared to those existing prior to mining. For underground mining, the collapse of strata above a coal seam into the mined void can propagate all the way to the surface, damaging buildings and disrupting the quantity and quality of surface and subsurface water flows.

Disposal of mine waste can be a significant problem, particularly where the coal has to be cleaned before shipment (e.g., see NRC, 1975; 1981; 2002a; 2006). There is a need for enhanced understanding of the physical and chemical behavior of spoil stored in valleys or waste—from coal combustion or coal preparation plants—that is disposed in surface or underground mines. Waste management is a major problem where land either is not available or is more valuable for other productive uses. Increased research to develop productive uses of mine waste offers considerable potential to reduce waste disposal issues.

Mine Decommissioning and Closure. Federal regulations for decommissioning and closure of mining operations are administered by the Mine Safety and Health Administration (MSHA), the Office of Surface Mining Reclamation and Enforcement (OSM), and the EPA—in some cases state and local governments

have additional requirements. The major decommissioning and closure activities are (1) sealing of all access to underground mine areas, (2) removal of all surface facilities, and (3) reclamation of surface mine areas (generally carried out concurrently with mining operations) and the surface areas of underground mines. Underground and surface coal mines present different challenges for decommissioning and closure. The critical factors in underground mining are the effects of subsidence and hydrology, both of which require continued monitoring and control. For surface mines, the critical factors relate to drainage and treatment of water and to erosion and sedimentation of the slopes, the waste and spoil banks, and the final pit. Continued use of the surface mine infrastructure (e.g., roads, buildings, utilities) depends to a large extent on the post-mining requirements described in the mining plan. A mining plan that is well integrated with a community master plan can result in optimum post-mining use of this infrastructure.

Abandoned Mined Lands. A range of environmental issues (e.g., subsidence, fires, acid mine drainage, waste disposal sites, derelict lands) associated with abandoned mined land (AML) continues to cause major concerns and threats to the health, safety, and general welfare of communities. This problem is particularly acute in the older coal mining districts of the eastern United States, specifically in the Appalachian hill country. Although mine closure today is a rigorously regulated process requiring detailed technical and financial analysis during the planning and operation stages for a mine—and ensuring financial and legal responsibility for post-mining closure—the nation continues to grapple with the effects of past mining practices. Additional research is required to develop and demonstrate more effective and sustainable solutions to the problems of acid mine drainage, mine fires, and the utilization of waste piles from AML sites.

COAL MINING AND PROCESSING R&D PROGRAMS

Coal mining research and development (R&D) are carried out by a range of organizations and entities—federal government agencies, state government agencies, equipment manufacturers, academic institutions, and industry. In general, the scope of and motivation for research are determined by the relevance and potential impact of the problems that need to be dealt with by these various stakeholders. Industry participants in mining research include individual companies and mining company associations.

Research Programs in Federal Agencies

While the federal government continues to have extensive involvement in the regulation of the coal mining industry, its support for mining research has decreased substantially over the past 10 years. At present, federal research is focused primarily on health and safety. Some research is being done on environmental issues, but support for research aimed at advanced mining technologies

and practices has progressively declined since the closure of the U.S. Bureau of Mines (USBM) in 1995 and is now essentially eliminated (see Appendix C).

Engineering and Technology Development. The now-defunct Mining Industry of the Future (IOF) program, administered by the Department of Energy’s (DOE’s) Office of Energy Efficiency and Renewable Energy, supported engineering and technology development with a focus on improving the energy efficiency, resource utilization, and competitiveness of the mining industry. Although not exclusively focused on extraction or on coal mining, many of the program outputs were applicable to the extraction phase of the coal fuel cycle. At present, coal extraction receives no support from the DOE-Office of Fossil Energy (FE) Coal R&D program, which is focused primarily on utilization aspects (see Chapter 6).

Relatively little is being done by the federal government to address coal preparation issues. The Mining IOF program funded some work that was relevant to minerals separation (as part of a much broader program and not exclusively coal related), but new funding for this program (never more than $5 million per year) has been terminated and the program is being closed out. DOE-FE had a solid fuels program, although it tended to fund more advanced work—such as chemical coal cleaning—than processes related to conventional coal preparation. However, there has been no administration request for funding for this area in recent years, and the program is essentially defunct. Some research programs addressing a variety of mineral separation issues (i.e., not exclusive to coal) have been funded at the federal level through small direct congressional appropriations.

There is a low level of support for fundamental research in the earth sciences and engineering disciplines (geosciences, material sciences, rock mechanics, etc.) by the National Science Foundation that has potential applications in the development of improved technologies for the coal industry.

Health and Safety. The National Institute for Occupational Safety and Health (NIOSH) Mining Program is the principal focus for mining health and safety research (NRC, 2007b), consolidated at the Pittsburgh and Spokane research centers. The NIOSH Mining Program has seven areas of health and safety research activity, addressing respiratory diseases, hearing loss, cumulative musculoskeletal injuries, traumatic injuries, disaster prevention, rock safety engineering, and surveillance and training. NIOSH and MSHA appear to work closely together to prioritize health and safety research, with NIOSH carrying out the R&D in response to the regulatory environment established by MSHA. The 2005 NIOSH budget for mine health and safety research ($30 million) represents a decrease of approximately $12 million in nominal dollars for health and safety research compared to 1994-1995 funding.

Reclamation and Rehabilitation of Abandoned Mined Lands. The Office of Surface Mining Reclamation and Enforcement was established in the Department of the Interior in 1977 following passage of the Surface Mining Control and Reclamation Act of 1977 (SMCRA), with the primary role of regulating surface

coal mining. Among the stated purposes of SMCRA were to support research, training programs, and the establishment of research and training centers in the states on various aspects of mineral production. Although the involvement of OSM with aspects of extraction research is minimal, OSM does have limited technical and applied science activities in support of its regulatory mission. In particular, OSM, in cooperation with the states, plays a major role with regard to the reclamation and rehabilitation of abandoned mined lands.

The environmental problems associated with active and abandoned mines and their abatement, particularly land reclamation and water quality maintenance, and the proper handling and disposal of the spoils and wastes from mining operations (e.g., mountain top coal mining, coal combustion residues), also receive regulatory attention from the U.S. Environmental Protection Agency. EPA is also involved in a program to promote the capture and utilization of coal bed methane. Overall, coal mining research in EPA is limited to support for its regulatory role.

Mining Regulation. The Mine Safety and Health Administration, in the Department of Labor, provides technical support and training services to its personnel and to personnel from the mining industry through its Pittsburgh Safety and Health Technology Center and the National Mine Health and Safety Academy. The direct involvement of MSHA in funding mining research is limited because of its primary regulatory role. However, MSHA undertakes field investigations, laboratory studies, and cooperative research activities on health and safety issues in support of its inspection and technical support functions. Further, MSHA evaluates new equipment and materials for use in mines at its Approval and Certification Center. It also supports state miner training activities through its state grants program.

State Government Research Programs

State government involvement in coal mining and processing research is primarily dependent on the importance of the mining industry to each particular state. The major coal-producing states—Wyoming, West Virginia, Kentucky, Pennsylvania, Texas, Virginia, and Illinois—have or have had agencies with specific responsibilities for health, safety, and environmental issues associated with coal mining. Further, mining industry organizations in these states work closely with state agencies to support research programs that address the specific needs of coal reserve estimation and coal mining operations. These state agencies also work with their corresponding federal agencies, particularly for the acquisition of federal grants to support industry’s needs. Some state governments have provided grants for coal processing research in academic departments (e.g., Virginia Polytechnic Institute and State University, University of Kentucky, Southern Illinois University) or at university-affiliated research centers (e.g., University of Kentucky’s Center for Applied Energy Research and West Virginia University’s National Center for Coal and Energy Research).

Product Engineering by Equipment Manufacturers

The mining industry is truly international—not only are mining operations carried out globally, but there is considerable capital, knowledge, and mined-materials flow across international boundaries to satisfy the global demand for mined and processed materials. The coal industries in different countries have much in common, particularly with regard to health, safety, and environmental issues. Because of these similarities, there is considerable exchange of research results—developments in one country are quickly incorporated into mining practices in other countries. This global interaction is particularly facilitated by mining equipment manufacturers. The consolidation of coal mining equipment manufacturers over the past three decades and the broad applicability of equipment across a range of mining situations have led manufacturers to work with mining clients and their own suppliers to develop evolutionary improvements to their products. In addition, equipment manufacturers invest substantial resources to improve the durability and reliability of mining equipment. For example, one leading mining equipment manufacturer indicated that its global engineering budget was approximately $40 million, with about 25 percent spent on engineering development activities that are related mostly to evolutionary advances and software development.

Some equipment manufacturers have worked in partnership with government agencies and mining companies to develop and demonstrate new concepts (e.g., three major equipment manufacturers are members of the Australian CRCMining program; see Box 4.3). For some equipment manufacturers, mining equipment is only one of many product lines. The applied engineering research and development work that they conduct is generally fundamental to their production and materials processes, and the research is often proprietary and not generally available to the wider industry.

Other Coal Mining and Processing Research

Cross-industry research under the aegis of coal companies or coal industry organizations, or with support from industry organizations, appears to be minimal. There are no longer organizations such as Bituminous Coal Research, Inc. (BCR) that used to work on coal mining and coal preparation issues. Instead, industry’s emphasis is on improvements to existing technologies—the remarkable increases of mining productivity since the mid-1970s (Figure 4.4) are a testimony to the development and adoption of evolutionary improvements in mining technology and practices. Several coal companies work in partnership with government agencies and academic institutions on coal mining research projects. The importance to researchers of access to operating mines and input from mining company experts is particularly worth noting.

|

BOX 4.3 Australian Government-Academia-Industry Research Models One model for cooperative government-academia-industry research is that of the Australian Coal Association Research Program (ACARP).1 ACARP, which began in 1992, is funded by a 5 cent per tonne tax paid by the Australian black coal industry that generates $A10 million-$A15 million annually. The funds are paid to Australian Coal Research Ltd. (ACR), a company established by the industry to manage all aspects of the program. Each year, ACARP’s industry-chaired committees select approximately 80 research projects for funding from about 300 proposals submitted under a competitive solicitation. The amount of leveraged matching funding for these projects from sources outside ACARP has been at an average ratio (external:ACARP) of more than 2.5:1 over the last three years. The research projects, which are conducted by university, industrial, and government-affiliated researchers, are monitored by industry representatives. The Australian government also supports the Cooperative Research Centre (CRC) for Mining (CRCMining),2 an incorporated entity created in 2003. CRCMining is projected to receive $A27 million in funding from the Australian government over seven years. This will be matched by about another $A100 million of funding from 12 industry and 4 university partners. CRCMining is one of about 60 CRCs in Australia, 8 of which are concerned with mining and energy. Each CRC is incorporated and operates under a formal agreement with the Australian government of up to seven year’s duration. Under this agreement, the government agrees to provide a certain level of funding each year to the CRC, and CRC participants agree to undertake certain activities and contribute specified personnel and resources. |

The National Mining Association (NMA) earlier outlined its vision and goals for the Mining IOF program (NMA, 1998). This recognized the importance of developing research priorities for new technologies and joint sponsorships of chosen projects, and resulted in an NMA-DOE partnership that supported several roadmaps as part of the Mining IOF program. Three specific roadmaps (Mining Industry Roadmap for Crosscutting Technologies, 1999; Mineral Processing Technology Roadmap, 2000; and Exploration and Mining Technology Roadmap, 2002) resulted in projects funded by DOE.

FINDINGS AND RECOMMENDATIONS—COAL MINING AND PROCESSING

The more difficult mining conditions that will be encountered in the future will require improved methods to protect the health and safety of mine work-

ers, careful environmental management of mined lands and waste products, and improved productivity and recovery to optimize use of the nation’s coal resource.

Improved Mine Worker Health and Safety

A range of factors increase health and safety risks to the coal mining workforce, including the introduction of new equipment and systems; the commencement of mining in virgin areas; the infusion of new workers; and the mining of multiple seams, seams that are thinner, thicker, or deeper than those customarily mined at present and new seams that underlie or overlie previously mined-out seams. All of these factors are likely to apply to some degree in future mines, irrespective of whether the higher production scenarios suggested in some forecasts eventuate. If they do materialize, then these risks are likely to become even more pronounced.

-

There are major knowledge gaps and technology needs in the areas of survival, escape, communications systems (both surface-to-underground and underground-to-underground), and emergency preparedness and rescue. Additional risk factors that are likely to apply in the deeper mines of the future are the potential hazards related to methane control, dust control, ignition sources, fires, and explosions.

-

Greater understanding and better prediction of strata behavior to prevent unanticipated12 roof collapse, particularly problems associated with roof and side fall during thick seam extraction, are essential for maintaining and improving worker safety.

-

Federal support for health and safety research significantly decreased about a decade ago, and has essentially remained constant since that time.

Recommendation: Health and safety research and development should be expanded to anticipate increased hazards in future coal mines. These R&D efforts should emphasize improved methane control, improved mine ventilation, improved roof control, reduced repetitive and traumatic injuries, reduced respiratory diseases, improved escape and rescue procedures, improved communications systems, and research to reduce explosions and fires. This should be coupled with improved training of the mining workforce in all aspects of mine safety. R&D should also be directed toward lowering the exposure of mine workers to hazardous conditions, particularly through expanded use of remote sensing and the automation of mining operations.

|

12 |

Roof collapse is anticipated during longwall mining after the coal has been removed (see Appendix E). |

Most mining health and safety research by the federal government is carried out by the Mining Program at the National Institute for Occupational Safety and Health. Technology-related activities in the Mine Safety and Health Administration are limited to technical support and training services for its personnel and those from the mining industry. With NIOSH carrying out the research needed to improve mine safety and to support MSHA’s regulatory role, these two agencies play a vital role in coal mine health and safety. The committee estimates that the enhanced health and safety program proposed here will require an additional $35 million to provide total annual R&D funding of approximately $60 million and recommends that NIOSH continue as the lead agency with enhanced coordination with MSHA and industry.

Improved Environmental Protection

Coal mining has environmental impacts on air, water, and land. Actions taken to meet federal and state environmental regulations already respond to and ameliorate many of these effects. However, there are gaps in the knowledge base related to a range of environmental issues that need to be addressed, and future changes in environmental requirements may drive the need for new coal mining and beneficiation technology.

-

As mining extracts coal from deeper and operationally more difficult seams by both surface and underground methods, it is likely that many existing environmental issues and concerns will be exacerbated. New concerns, particularly related to greater disturbance of hydrologic systems, ground subsidence, and waste management at mines and preparation plants, are likely to arise.

-

Inadequate understanding of post-mining strata behavior and the associated hydrologic consequences of mining in both surface and underground mines affects mine permitting, mine development, environmental mitigation, and post-mining land use, including use for waste management.

-

Research offers considerable potential to mitigate the effects of past mining practices, particularly acid mine drainage on abandoned mine lands.

-

The regulatory environment (framed by such statutes as the Clean Air and Clean Water Acts) and technical support programs administered by both state and federal agencies, and implemented by mining companies through their compliance practices, are inadequately supported by existing research programs.

Recommendation: Additional research is needed to mitigate the adverse environmental impacts associated with past, existing, and future coal mining and processing. Research activities should focus particularly on developing techniques to mitigate the alteration and collapse of strata overlying mined areas, to model the hydrological impacts of coal mining, to improve mine mapping and void detection, to improve the stability of

spoils on steep slopes, and to improve the construction and monitoring of impoundments.

Both the Office of Surface Mining Reclamation and Enforcement and the Environmental Protection Agency, although primarily regulatory agencies, fund limited R&D activities in support of their missions. The committee estimates that annual funding of approximately $70 million will be required to conduct the research necessary to adequately respond to the environmental impacts of past, existing, and future mining operations. The committee recommends that OSM should be the lead agency in this effort, and it should coordinate closely with related EPA and state research activities.

Improved Mine Productivity and Resource Optimization

The productivity of U.S. coal mines increased two- to three fold in the past three decades, largely due to evolutionary improvements, most notably the introduction of longwall mining in eastern underground mines and the development of large surface operations in the West. The sustained production and productivity increases that followed these changes resulted from incremental improvements in equipment and mining practices by mining companies and equipment manufacturers, and there has been little research and development on truly advanced mining technologies.

-

The development of advanced technologies, such as thin-seam underground mining technology or dry processing methods for western surface-mined coals, will present opportunities to recover a significant portion of potentially recoverable coal that currently is not extracted and may be permanently lost. In situ extraction or utilization methods, while they have not found broad application in the past, may become attractive as more easily mined reserves are exhausted. Many advanced mining technologies with the potential to reduce mine hazards, such as remote sensing, continuous monitoring at the mine face, remote control, and autonomous systems, also have the potential to increase production and productivity and improve resource recovery. Although the national coal resource is truly vast, the economically recoverable reserve base will depend on mining costs that in turn are determined by labor, environmental, and technological factors.

-

Small percentage increases in coal recovery through improved coal preparation processes and improved mining methods, perhaps including in situ extraction, have the potential to significantly expand economically recoverable reserves of both eastern and western coals. The development of these technologies, increasingly needed as coal reserve quality decreases over time, will help to maximize utilization of the nation’s coal resource.

-

The global transfer of coal mining and processing technology within the industry is facilitated by international equipment manufacturers, who work

-

closely with suppliers and the larger mining clients on evolutionary product developments. However, there is little evidence of the efficient transfer of technologies from outside the mining industry. This is at least partly due to the relatively small market that the coal mining industry represents to potential technology suppliers and the scarcity of coal mining research at academic institutions and national laboratories.

-

There is minimal federal support for the research and development of advanced mining technologies and practices that are necessary to optimize utilization of the nation’s coal resource.

Recommendation: There should be renewed support for advanced coal mining and processing research and development to optimize use of the nation’s coal resources by increasing the amount of coal that is economically minable through technological advances that accommodate health, safety, and environmental requirements. The focus of this R&D should be on increased integration of modern technology in the extraction and processing phases of coal production, with particular emphasis on emerging advances in materials, sensors, and controls; monitoring; and automated mining systems.

Although there is currently little federal funding for advanced mining technology to improve resource recovery, in the past the Department of Energy successfully partnered with the National Mining Association as part of the Mining Industry of the Future program. In addition, there are government-industry-academic cooperative models in other countries that are successful in directing and funding mining research (e.g., see Box 4.3). Research to develop advanced mining technologies requires not only cooperation among relevant federal agencies, but also participation by academic institutions as well as funding, guidance, and technology transfer by industry. The committee estimates that advanced coal mining and processing R&D will require a total of approximately $60 million per year and recommends that this funding should comprise $30 million in federal support, with cost sharing from non-federal sources. The DOE Office of Fossil Energy should be the lead federal agency and should coordinate with the National Science Foundation, OSM, NIOSH, academic institutions, and the coal industry to ensure that all research activities carefully consider the environmental, reclamation, and health and safety aspects of coal mining.