Appendix B

Water Purification: Hypothetical Case Study

This hypothetical case study on water purification explored the opportunities and challenges inherent in investment in a new enterprise that would capitalize on two distinct technologies: one to be sold for use by the family in the home and the other to be franchised or sold to water providers at the village or community level. At present, no company in Nigeria is engaged in these activities, although some companies are selling bottled spring water in the Nigerian market.

Workshop participants included representatives of the Federal Ministry of Agriculture and Water Resources, the Federal Institute of Industrial Research (FIIRO), the University of Lagos, and the University of Ibadan. The U.S. National Academies were represented by Ron Rivera, international coordinator, Potters for Peace of Managua, Nicaragua; Tralance Addy, president and CEO, WaterHealth International of California, United States; Wole Soboyejo, Princeton University and a member of the U.S. National Research Council committee for the project; and Michael Greene, project staff director at the National Research Council. The Nigerian Academy of Science was represented by Gabriel Ogunmola, president, and Njidda Gadzama, vice president. A complete list of participants appears at the end of this appendix.

TECHNOLOGY OF WATER PURIFICATION

Many effective technologies are available for home or community-scale water purification. Some are chemical-based, such as treatment with

chlorine. Some are thermal, such as boiling and solar heating. Others are mechanical, such as ceramic filtration. And some utilize radiation, such as ultraviolet (UV) treatment. Criteria for selection of the technology for the hypothetical case study included low cost, ease of assembly or manufacture, safety and simplicity in home operation, maintainability and sustainability, and worldwide experience with successful commercial exploitation. Some of the thermal methods are nearly free (the SODIS system requires only a blackened soft drink bottle and four hours on a sunny roof), although they may require extensive training so that users acquire the discipline necessary for health protection. Because there is no clearly preferred technology for efficiency and commercial opportunity, two distinct business models were studied. It is hoped, however, that a potential investor or entrepreneur will realize that the business models can be applied to a variety of technologies.

The two technological models described here are ultraviolet disinfection, as utilized in the business model of WaterHealth International (WHI) of California for sales in developing countries, and ceramic filtration, as promoted by Potters for Peace of Managua, Nicaragua. The business models are quite different.

The patented UV Waterworks (UVW) ultraviolet disinfection unit is at the core of the large systems sold by WaterHealth International to franchisees who use them to produce and sell potable water in containers to consumers at prices below those of bottled spring water. Other WHI products, such as community-scale water systems, are sold to governments or communities directly, and provide enough safe water to meet nearly all daily domestic needs, including hand and food washing and bathing. The operating costs for a system that can serve at least 3,000 people are less than $4 per person per year. Treated water is sold to recover the investment and maintenance costs of these systems at prices that are within the reach of the populations being served.

The Filtron ceramic filter technology is promoted by Potters for Peace and marketed by individual filter producers directly to households for operation by the end user. It provides safe drinking water for a family of six at a cost of about $7 for two years.

Ultraviolet Filtration

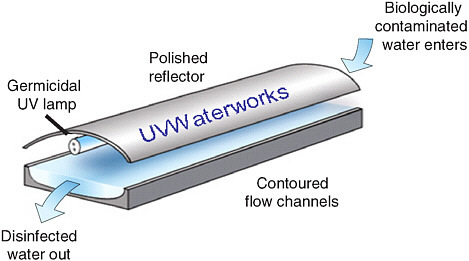

Figure B-1 is a schematic diagram of the UVW unit, which was invented by Ashok Gadgil of Lawrence Berkeley National Laboratory in California and licensed to WHI.

In the UVW system, the UV source is suspended above the water being treated rather than submerged in the water. Water passing through the system is irradiated at high intensity amplified by reflection. This

FIGURE B-1 UV Waterworks water filtration unit.

SOURCE: WaterHealth International, http://www.waterhealth.com.

configuration improves performance in challenging environments and overcomes operating barriers, such as corrosion, associated with conventional UV treatment technologies. The lower maintenance requirements enable the UVW system to be operated in areas where labor pools may lack technical knowledge or specialized education.

The community water system can provide safe potable water for 3,000 people. WHI claims third-party laboratories have validated that the UVW technology, operating at a flow rate of four gallons per minute, eliminates at least 99.9999 percent of the bacteria and viruses that cause water-borne disease. WHI applies the technology to a wide spectrum of uses, from homes, schools, and hospitals in developing countries to residences that rely on well water. Very little maintenance is required—the lamps must be changed once a year, and the filters must be periodically backwashed and replaced. UVW technology is also designed to be fail-safe. If any type of malfunction occurs, such as a power outage or a drop in radiation dosage, an automatic valve closes the entry port to the device, ensuring that contaminated water cannot flow through the system without being disinfected. WHI’s systems can be powered by solar or wind energy or a generator. In an emergency, they can be run for two weeks at a time with a car battery.

Ceramic Filtration

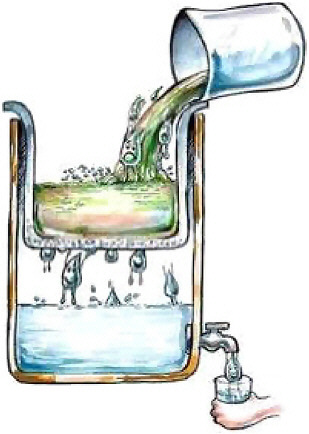

Figure B-2 is a schematic drawing of the colloidal silver-enhanced earthenware ceramic water filter first developed in 1981 by Fernando Mazariegos of the Central American Institute for Research and Industrial Technology (ICAITI) in Guatemala. The goal was to develop a low-cost filter, producible at the community level, that would both clarify turbid water and make the water safe from bacterial contamination. The technology is now promoted worldwide by Potters for Peace, which offers technical assistance to small companies that wish to produce and market these filters. There is no license fee.

The filter is primarily intended for household use, ideally as part of a water delivery network that provides intensive educational efforts aimed at improving water hygiene overall. The most economical model consists of a porous clay filter unit perched inside a lidded 5-gallon, spigoted receptacle of plastic or clay.

FIGURE B-2 Colloidal silver-enhanced earthenware ceramic water filter.

SOURCE: Drawing provided by SANITEC, Cuba.

The clay for the filter is mixed with an equal volume of sieved sawdust, rice husks, or peanut husks, mixed with water, and then pressed into an aluminum mold with a truck jack and fired in a kiln. The sawdust burns out, leaving 0.06–0.2 micron pores that will eliminate all bacteria and parasites. The filter is then painted inside and outside with colloidal silver, similar to that used in the newer refrigerators, which oxidizes the bacteria and inhibits regrowth, thereby acting as a germicide. The unit must be brushed periodically on a clean surface to remove particles of turbidity. Users of this equipment must be trained in hygienic practices to avoid recontamination of the water.

The unit has a flow rate of about 2 liters of water per hour, which will provide drinking water for a family of five to six persons. Another model processes 6 liters per hour. Potters for Peace claims the filter has been successfully laboratory tested in over 10 countries on four continents, and it has been proven effective in eliminating coliform bacteria, parasites, amoebae, and Vibrio cholera from water.

APPLICATION EXPERIENCE

Ultraviolet Filtration

WaterHealth’s systems are distributed using different business models in different countries, but always by means of local sales agents. One of WHI’s earliest commercial successes was in the Philippines. In 1997 WHI established a subsidiary in Manila to offer franchises that would use the UVW technology to provide lower-cost alternatives to bottled water. The subsidiary enables local “mom and pop” store proprietors to own and operate WaterHealth-branded “water stores” that would benefit from WaterHealth’s expertise—such as on where to open their stores, how much foot traffic versus deliveries they should expect, and how to manage finances—as well as technical services. Water is sold from storefronts in sanitary containers.

Today, over 3,000 water stores are vying for business in Manila’s thriving market. The WHI franchisee pays about $8,000 for a turnkey operation plus franchise fees. All franchisees are trained to operate their stores in compliance with the highest sanitary and quality standards. The Philippine government regulates water stores, and in order to maintain a “Grade A” facility, as required by WHI, a WHI water store must occupy at least 20–30 square meters of storefront. Access to municipal or well water and electricity is also necessary.

The franchisees recover their costs after a period ranging from 10 months to two years. The water store franchise model establishes a commercial model and entrepreneurial opportunities for those who would

like to own and operate their own businesses, while at the same time giving something back to their communities. Today, roughly 50 WHI franchisee water stores are in operation in the Manila area, in addition to several water co-ops that were installed with WHI technology via the Rotary Club there.

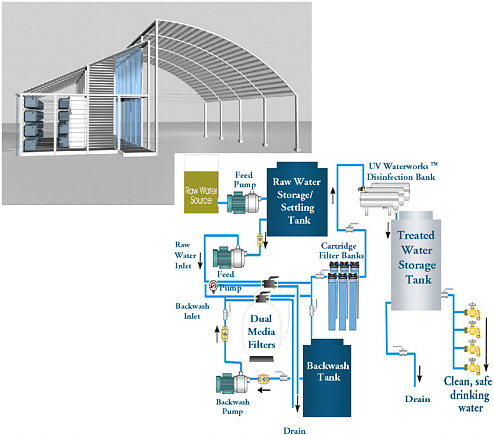

In other countries, WHI is establishing an alternative model, the community water system (CWS), to serve small villages in areas once thought to be unreachable by piped water. Figure B-3 shows a rendering of the prefab CWS structure soon to be built in India, as well as a diagram of the configuration of equipment inside.

The CWS shown in Figure B-3 is designed to provide a community of up to 3,000 people with up to 20 liters of safe water per person per day. Systems are modular and scalable—that is, they can be configured easily to serve larger or smaller populations.

In India and Mexico, WaterHealth markets the CWS as a “microutility” to governments and village organizations, which recover the investment in the community water systems through the sale of treated water to villagers. For the purchaser, it is a turnkey operation, including treated water storage and the pipes to bring the water from up to 2 kilometers away to the village for treatment if necessary. WHI hopes to integrate rainwater-harvesting capabilities into future installation designs.

In India, WHI created WaterHealth India, which seeks local affiliates in each state. In Andhra Pradesh, WHI sells equipment to the Naandi Foundation, which markets the units, with a service contract, to its own local franchises, entrepreneurs, and village organizations. The village organizations typically sell coupons to families to redeem for water; end users may opt to pay extra for home delivery in special containers. Part of each community water system is an educational program, usually conducted by a nongovernmental organization (NGO) under contract, that encompasses health and hygiene issues and encourages people to use clean water.

The cost of this turnkey program is about $50,000, or about $17 per person, which is lower than alternatives of similar capacity, such as bore wells that normally provide no disinfection, filtration, safe storage, or education on health and hygiene. By comparison, municipal facilities cost around $100–$250 per person to build, and the costs of bore wells are similar. After a community fully adopts a CWS, it should be able to generate $24,000 a year acting as a small utility.

WaterHealth International, as a U.S. firm, is sometimes able to take advantage of the U.S. Export-Import Bank to loan money to the local subsidiary to buy U.S.-made equipment. In India, WHI has arranged with an Indian bank for the loans to finance the installation of a large number of community water systems.

FIGURE B-3 Prefabricated community water system structure to be built in India.

SOURCE: WaterHealth International, http://www.waterhealth.com.

Ceramic Filtration

Potters for Peace (PFP) was formed in 1986. In October 1998, when Central America was struck by Hurricane Mitch and, as part of the relief effort, the Red Cross was importing clean water in large quantities, Potters for Peace sought a way to produce the water locally, using low-cost existing technologies. It chose a model that had been developed at ICAITI in Guatemala in 1981. As noted earlier, it sells for about $7, and is usually replaced after two years. It removes 98 percent of impurities and infectious organisms. Potters trained by PFP began by selling the filters to NGOs, which then distributed them in the villages. But this model was not sustainable because the NGOs tended to donate the filters to house-

holds, which thus were not motivated or trained to use and maintain them. Meanwhile, the donations undercut the market for commercial sales.

Presently, the filter companies set up by PFP produce about 1,000 filters per month, sold mainly to NGOs in Nicaragua. PFP charges the local organizations for training on a sliding scale, depending on economic and social criteria. PFP’s income is supplemented by consulting fees from donors and clients as it helps small companies in other countries produce and sell water filters. The cost of the product around the world depends mainly on the cost of labor plus fuel or electricity, and the price varies between $5 (in Nepal) and $25, or even $100, for designer models that have the same water-purifying effectiveness but feature elegant containers designed for a more affluent clientele.

The cost of a factory that employs two to four people is generally about $10,000, and this cost can be recovered in as little as nine months. Often the producer partners with an NGO and receives the benefit of financial and marketing assistance. Potters for Peace offers the plans of the press and other equipment at no charge, or it will refer the client to mechanics who will build a press to order at a cost of $800 for a portable system able to produce about 50 clay filtering elements a day. Today, 100,000 Filtrons are in use throughout the world, serving about 500,000 people.

WATER PURIFICATION IN NIGERIA

In most countries, municipal water is the responsibility of the government and is subsidized for the consumer. The maintenance of pipes, pumps, and other infrastructure is generally a problem everywhere. In Nigeria, the problem is particularly acute, and it is widely believed that no community, rich or poor, in Nigeria receives safe, drinkable water from the government. Even those who rely on deep bore wells cannot rely on safe water, and so bottled spring water is widely used. The World Bank has sponsored several water projects, but most of these have been urban; rural areas are overlooked.

As a result of this situation, some Nigerians have never had clean water, and others drink only bottled water. Water is sold on the street in containers ranging from sachets in plastic sacks to bottles of mineral water. Many social programs exist to provide water, but the social agenda has not been linked with a business model to provide sustainability.

Nigeria has 320 million cubic meters of water of which 86 percent is surface water. Forty percent of the population, mostly in rural areas, has access only to surface water. The water table ranges from 300 meters in

sedimentary areas to 70 meters in basement areas. Water can be found above 70 meters, but the salinity levels are high.

The Federal Ministry of Agriculture and Water Resources is responsible for Nigeria’s water policy. The ministry has links with the United Nations Development Programme and the International Atomic Energy Agency for resource surveys and isotopic analysis. Amadeo Bello University has a mass spectrometer for contamination studies, and reference labs can be found in Lagos, Enugu, and Taiguna. The ministry provides assistance digging deep bore holes, and it provides hand pumps, bicycle-powered pumps, rain-harvesting technologies, and in-service training on maintenance and use. It advises consumers to use water from deep wells, with charcoal and sand filters, for domestic water. The government requires a minimum distance between wells and septic tanks, but the requirement is hard to enforce. Shallow wells are often contaminated by informal backyard cemeteries.

Water sellers often get their water from wells. Some is boiled or treated with ultraviolet radiation. Some facilities are inspected, but the water is not tested. Commercial bottlers sometimes get water from industrial steam as well as from natural springs. But even bottled water may be contaminated by users after purchase, for example, by adding locally made ice. Street water sells for 5 naira for a 500-milliliter bag and 40–60 naira for a bottle. In Nigeria, safe water is more expensive than petrol.

It is said that no one in Nigeria drinks piped water. In many rural populations, there has never been an alternative to drinking contaminated and sometimes turbid water. Some potential users argue that the resistance to waterborne diseases people have developed will be lost if clean water is provided. But children under five have no resistance, and many people suffer from diarrhea as a result of drinking impure water.

Education will play a critical role in the adoption of the technology and safe water-handling practices in the communities served. When people understand the high costs associated with drinking unhealthy water, including ill health or death (especially of infants and young children), loss of working hours, and hospital fees, they will realize the economic benefit of paying a small fee for treated water. The fees can support profitable companies and make the system sustainable.

The government of Nigeria has embarked on a costly program of urban water purification using mass spectrometry for separation as well as filtration and chlorination. It plans to repair the existing corroded pipes. Impurities in water include chemical and biological contaminants and volatile organics from plastic pipes, which are thought to cause infertility and a decline in the birthrate. Commonly diagnosed waterborne diseases include diarrheal disease, dracunculiasis (guinea worm), onchocerciases (river blindness), and typhoid.

HYPOTHETICAL CASE STUDY

Participants in the Lagos workshop on water purification created a hypothetical enterprise to install water purification systems in Nigeria and the elements of a business plan.

The enterprise. Because the workshop considered two very dissimilar technologies, participants had to decide whether to imagine two distinct hypothetical companies or one. Filtron production is relatively quick to organize at low cost; a WaterHealth-type operation would take longer and would be costlier to assemble. The workshop decided to discuss them together as one company, recognizing that an investor can pick and choose the elements that suit real opportunities. The division that makes and markets ceramic filters might be called Filtron International.

Statement of purpose. Provide potable water and associated services affordable to everyone, specifically including those in rural areas and the urban poor. The water would be provided by direct sales, through ultraviolet filtration, or indirectly, through sales and service of home ceramic filters.

What is the product or service? For the Filtron, the product is a ceramic filter in a suitable containment vessel. For a small additional cost, a tester like those produced by the Hach Company of Colorado could be included to test for bacteria and other contaminants to assure the user that the unit is functioning properly.

For the UV procedure, the product is both equipment and potable water. Equipment is sold to franchisees, independent agents, local communities, or governments that produce safe water to be sold to the public. A maintenance contract on the unit is offered to the purchaser, and educational programs for the consumer may be offered to the communities. Treated water is marketed and sold in safe containers, perhaps bearing the company logo.

Who are the customers? The ultimate beneficiaries are any people who lack access to potable water, specifically including those in rural areas for whom municipal water service is not available and the urban and periurban poor who cannot afford well water or bottled water. Potable water or Filtron units also can be offered to middle-class customers in more elegant containers, and bottled water can be marketed through water stores or for home delivery. Branded water also may be sold in bottles in city traffic, with some security measures applied to discourage competitors with counterfeit (nonpurified) brands or contaminated containers.

In rural areas, operators of community water systems or water refilling stations may set up facilities beside a river or another traditional source so that families would have the option of buying safe water in portable, reusable containers. By selling other products and services, ranging from laundry soap to Internet access, entrepreneurs could turn the site into a small commercial hub.

The Filtron ceramic filter has been profitably marketed to NGOs and donor agencies in Central America, Cambodia, and other places for distribution in needy areas. Such marketing must be done with care, however, because NGOs often donate the filters to households at no cost and with minimum training and service, and they frequently fail for lack of maintenance. Such donations could seriously undercut the direct sales market.

What materials, technologies, and facilities would be used in the production, delivery, and service of the product? Filtron ceramic filters and UV radiation systems are manufactured in different facilities and can be discussed separately.

Ultraviolet disinfection. UVW-type units would initially be manufactured elsewhere and imported to Nigeria. It is possible that, after the development of a sufficient order pipeline, the units could be manufactured in Nigeria. The tank, containers, flow meter, pumps, PVC plastic casing, and spare parts can be made or sourced locally. Cone and filter paper cartridge filters can be acquired locally. Test equipment or laboratory services also can be arranged locally. At least 1.5 kilowatts of power is needed to operate a community water system. Depending on the water source, lower power requirements may apply to water store franchises that do not have to pipe water to their facilities. Solar cells and batteries for this purpose can be imported if desired, and in the future may be available locally.

Ceramic filters. The skills, tools, and materials needed to manufacture the Filtron filter are common to ceramics workshops everywhere. Clay is combined with sawdust, peanut shells, millet straw, or similar material in equal parts, resulting in 25 kilograms of clay to 6 kilograms sawdust. The mix is pressed into a mold, dried, and then fired in a kiln to 890 C. After tests on initial filtration rates, colloidal silver is painted on.

During the firing process, the sawdust burns off, leaving small twisted pores through the ceramic material too small to permit bacteria to pass. Colloidal silver provides additional antibacterial properties and prevents regrowth. The colloidal silver can be imported from Spain, Germany, or Mexico at a cost of $60 per liter, enough for 500 filters. It might be possible to manufacture colloidal silver in Nigeria, but the manufacture of Filtrons,

at about $0.12 worth of colloidal silver per filter, would hardly support a local industry alone.

Quality control is important, and the filtration rate and bacterial count must be monitored. The latter can be performed with the Hach presence/ absence test, using sachets that change color to reflect the presence of pathogens. The cost is about $0.50 per use.

The ceramic filters could be made from locally available clays, wood chips from local saw mills, and rice or peanut husks from local villages. The containers for the water also could be made locally, using local facilities for pottery and plastic manufacturing. Thus the capabilities exist within Nigeria to manufacture complete Filtron ceramic filters from locally available materials. This was demonstrated at the end of the workshop when Ron Rivera of Potters for Peace collaborated with Ishmael Bashir, a ceramist at the Lagos-based Federal Institute of Industrial Research (FIIRO), in making filters with an aluminum mold, using a kiln and ceramic processing materials that were available in Bashir’s lab. The real challenge is to combine this technical expertise with effective management that can manage and scale up the production, delivery, and service of the filters.

What are the advantages and challenges for this enterprise in Nigeria? The factors in favor of success are the large potential market, the 100 million people who do not have access to potable water, and the culture of business and entrepreneurship in Nigeria, which may lead many people to attempt to enter this business, including many water sellers who presently lack the technology to purify the water they sell. In the case of Filtron, all material and labor, except the colloidal silver, can be obtained locally.

The greatest challenges stem from the same factors as the advantages. The large potential market includes many people who have a history of consuming contaminated and turbid water and so do not see it as a cause of their health and infant mortality problems. In some areas, people may refuse to pay for water because they consider it a natural right, just as some Nigerians view the oil produced in their country. An educational campaign is needed to activate the market. The large number of potential entrepreneurs practically ensures that within a short time after a business appears to be successful, or even before, copies or similar products will appear on the market. The same technology should not be provided to potential competitors in the same area. To protect the market for Filtron, use of Hach tests should be encouraged by including test kits with the filter. Instructions for use of a Filtron should be displayed on the unit with waterproof paper or imprinted directly on the container to discourage imitators.

For UV-treated water, the difficulty will be greater, because the product will come into direct conflict with traditional water sellers, most of whom do not take care to purify adequately the water they sell—and they may be able to sell at a lower price. Some may begin to mimic the brand. Steps must be taken to brand the product clearly in a way that is hard to imitate, and to emphasize safety and reliability in all marketing activities.

The greatest challenge may be getting first-stage financing, especially for the UV system. The Filtron requires the facilities and skills of a ceramics company, and the candidates likely to enter this business are those already engaged in ceramics manufacture. The UV system enterprise will be engaged in selling and delivering water, and may find support from the government or from commercial banks.

Production Requirements

Ultraviolet filtration. The units can be assembled in a central location within the region. A thorough market assessment would be needed to predict the minimum order sizes in order to determine the size of the local business. Local agents or distributors would be identified in each region or state. Field sites or franchises should be selected for marketing advantages and access to a water source, whether surface water such as a river bank where people are accustomed to coming for water or ground water in a site where a bore well may be feasible.

The franchisee will have to acquire or build an attractive facility, stable and rainproof, near the water source or easy for customers to access. It must be about 20–30 square meters in size to accommodate production and the storage of clean water. Tanks for the storage of river or well water may also be required, along with at least 1.5 kilowatts in electrical power from the grid or solar power. A staff of two or three can operate the water store and serve customers; larger delivery areas may require additional delivery staff.

Maintenance service is perhaps more important than the choice of technology. In fact, the project can be considered turnkey only to the extent it includes maintenance and service. The service organization must be based locally; for example, WHI will not enter a market without first establishing the ability to provide adequate service. The franchisee must stock the essential spare parts, including UV disinfection units and other parts not available in the country. Once a month the unit must be opened and cleaned with a wet rag, water samples sent to the lab, and a new certificate issued, which should be prominently displayed. The UV bulb must be changed once a year. Experience has shown that poor people will pay for safe water, but they expect a demonstration that it is clean.

Ceramic filters. Production of Filtron units requires a well-equipped ceramics facility, with a kiln of capacity 1.5 cubic meters. A 16–20 ton press, or alternatively a truck jack, a hammer mill, and a pug mill to extrude the clay, are needed as well. Plastic receptacles and faucets should be ordered locally.

Human Resources

Ultraviolet treatment. The company must conduct a thorough market assessment before mapping out staffing operations. Staff would likely include a chief executive officer, an operations director, a quality control officer, and technical staff to assemble the UV disinfection units. A staff person would be placed in charge of marketing, urban and rural, and this person would require transport. The maintenance service for the equipment could be contracted out to an experienced service company, but training would have to be provided. The quality control officer would work directly with the vendors. It is advisable to fill these positions through advertising and application.

For the water store franchise model, the franchisees could be recruited through advertisements and trade shows. Franchisees would sign a contract with the company that provides for purchase or lease of the equipment plus a franchise fee and monthly royalties. The franchise agreement should specify all details, including hand washing, dress code, hygiene, equipment maintenance, and water testing, if the latter is not included in a service contract. The quality control officer would independently test the water and inspect the equipment. A typical water store franchise would likely require three employees for filtering water, washing and refilling containers, and water delivery, depending on the area served and its demographics.

Ceramic filters. The ceramic filter factory would require at least two experienced potters, one skilled in kiln use and temperature control. Staff should be devoted to marketing and distributing the filters, and others to preparing written and oral materials for instruction for users. This business is usually grafted onto a working pottery facility, which should be prepared for a major expansion of sales and distribution of its low-price, life-saving product.

Legal and regulatory requirements. Presently, all surface and ground water is the property of the state. The authority to distribute water is exclusive to the state government, and it may be illegal to bring water into a home without permission and without paying certain taxes and

fees. Normally, the government does not implement the rule, but one homeowner in Ibadan, who is connected to the municipal water supply but has never received any water from its pipes, was threatened with prosecution for bringing water into his own home without permission. It should be clarified whether there is a right to sell water to homes. Currently, a bill is before the parliament to clarify a similar situation related to electricity.

Insurance requirements are also unclear, and may depend on the provisions of the financier.

An environmental impact assessment would have to be prepared. The use of UV and colloidal silver must be approved by the Ministry of Health, and a certificate for the use of UV will be required. The water product must be approved by the National Agency for Food, Drug Administration and Control (NAFDAC), and a NAFDAC number will be required, at a cost of about $1,000.

Marketing requirements. Marketing would likely take place at two different levels. The first would be general to make a compelling case, especially to poor people, for the purchase of water or a ceramic filter in order to upgrade their quality of life and avoid the negative consequences of poor health. The second would be to brand and identify the product. The role of science must be emphasized in order to distinguish the product from unapproved and inferior competitive products. (In this context, it is important to filter out turbidity in the water, as both models do, to distinguish the product from boiled and chlorinated water and so that people can see directly the effectiveness of the filtering process.) The government and NGOs should be enlisted for the first campaign. An endorsement from the Ministry of Health would be effective, if it can be persuaded to admit that municipal water is not adequate. The government should be urged to subsidize diarrhea prevention as it does HIV prevention. “Wash your hands, filter your water” would be a good slogan for a government campaign. NGOs could participate through the Internet and at health centers, especially maternity and pediatric wards, where NGO employees may be working. Radio might also be effective.

As noted earlier, people who have never had potable water may not want to pay, because either they do not see the need or they believe it is a natural right. It would help to ensure that the vendors are local people, and that the emphasis is on the product as not simply water but the process of purification. The low cost of treated water versus the avoidably high costs of consuming untreated water should be analyzed, and the results conveyed through social marketing and education campaigns.

The first marketing decision to be made is the market entry point. Should marketing begin with the highest-cost or lowest-cost product—

that is, with the urban water stores or the rural vendors, the middle-class designer model or the basic Filtron? Coca-Cola is famous for marketing first to the affluent to exploit aspirations. People of means will not be attracted by what appears to be a poor people’s product, even if the quality is good, so designer models would be suitable for that market. Meanwhile, the basic model can be sold to NGOs that serve the poor and might be enlisted in the educational campaign. But reliance should not be placed entirely on NGOs, because people may not continue to buy when the NGO leaves the area. Similarly, it is important to prevent the product being given away at no charge except in an emergency. It may be possible to offer basic Filtrons at 1,000 naira ($7) and designer models at 3,000 naira ($20).

The extent of marketing would be limited or expansive, depending on the targets and the development goals of those entering this business. If the goal is to sell a ceramic filter to every home in Nigeria or to dominate the market for bottled water in Lagos in 10 years, marketing would be organized differently than if the goal is to sell 1,000 Filtrons or open 50 water stores a year. Normally, a marketing agent receives a salary of about 35,000 naira, or about twice the average wage of a full-time employee. In Nigerian pharmaceutical firms with global ambitions, the successful marketing manager receives from 2 to 3 million naira a year plus car, health insurance, and housing allowance. In marketing, it is believed, you get what you pay for.

Financing. Both projects of this hypothetical company have been deemed “bankable” or worthy of financing by the chief executive of a bankers’ association. External banks, such as the U.S. Export-Import Bank, may provide credit, but they may require overseas purchasing, which is not appropriate for the Filtron component. Local banks would charge a higher interest rate, about 25 percent, and would require capital investment by the borrower. The amount of capitalization required by a bank would depend on the risk and time required to recover costs. That amount may be as high as 80 percent because little of the investment is for capital assets, but mainly to build the company. One possible strategy might be to raise money from the backers of the company to build an initial supply of Filtrons or UV units for demonstration and to meet initial demand, and then go to a bank with the business plan.

Partnerships. For the Filtron effort, a natural partner is the Federal Institute of Industrial Research, which operates an industrial ceramics laboratory capable of turning out about 40 filtering elements a day. FIIRO, in turn, could offer technical assistance to small ceramics companies interested in producing the filters.

The Ministry of Health could be a very effective partner for both marketing and helping to resolve the legal dilemma about the rights to sell water. The Ministry of Agriculture and Water Resources, which is directly responsible for water policy, should also be approached as a potential partner. Among NGOs, the Nigerian branch of the Red Cross may be persuaded to purchase Filtron units to be available in an emergency.

Implementation plan. In view of the importance of safe potable water to public health in Nigeria, it may be useful to form a stakeholders group to advise and assist any individual or company interested in pursuing this initiative. Useful members might include experts from academia, government, NGOs, and the private sector, including the Ministry of Health, the Federal Institute of Industrial Research, the International Center for Business Research, the National Agency for Science and Engineering Infrastructure, and the Nigerian Association of Small and Medium Enterprises. The Nigerian Academy of Science could serve as convener of the group, taking care to maintain objectivity and impartiality among the interested companies. The Academy might be well positioned to partner with a university or NGO to offer nationwide courses and other training activities in entrepreneurship and water purification technology. It could also urge the government to clarify the law about the right to provide potable water to households and to mount a campaign in favor of filtered water to combat diarrheal disease.

The Filtron could be demonstrated publicly at an early date. The ceramics laboratory of the Federal Institute of Industrial Research has the capability to produce a prototype Filtron within a day (provided the colloidal silver is available). If FIIRO finds it difficult to obtain colloidal silver, it might arrange with the suppliers to represent the manufacturer in Nigeria.

PARTICIPANTS, WATER PURIFICATION WORKSHOP

|

Tralance Addy |

WaterHealth International |

|

T. A. I. Akeju |

University of Lagos |

|

Ishmael Bashir |

Federal Institute of Industrial Research FIIRO |

|

Fola Esan |

University of Ibadan |

|

Njidda Gadzama |

Nigerian Academy of Science, University of Maiduguri |

|

Michael Greene |

U.S. National Academies |

|

A. Adio Moses |

Nigerian Academy of Science |

|

O. O. Ogbede |

Federal Ministry of Agriculture and Water Resources, Abuja, Nigeria |

|

G. B. Ogunmola |

Nigerian Academy of Science, University of Ibadan |