Corn-Based Materials

SANJAY V. MALHOTRA AND VINEET KUMAR

National Cancer Institute

Frederick, Maryland

ANTHONY EAST AND MICHAEL JAFFE

New Jersey Institute of Technology

Newark, New Jersey

The United States produces 44 percent of the world’s corn. The largest crop grown in the United States, corn occupies some 70 million acres. This versatile, natural, biodegradable, and renewable resource has many commercial applications. As a raw material, it is replacing petroleum in many industrial applications, from plastic containers to clean-burning ethanol. One current goal is to produce 5 billion gallons of ethanol from corn annually. Corn components can also be found in thousands of other products, ranging from foods, drugs, cosmetics, and cleansers to adhesives and shoe polish. For example, corn oil is used in emollient creams and toothpaste, and corn syrup is used as a texturing and carrying agent in cosmetics.

The development of biodegradable polymers is a high priority from the standpoint of environmental preservation; biodegradable polymers from corn chemistry have a number of advantages over other synthetic materials. Polymers derived from starch (a component of corn) or other carbohydrates made from entirely renewable resources have been used in the manufacture of quality plastics, packaging materials, and fabrics (Koch and Röper, 1988), as well a variety of biomedical materials (e.g., bioMEMs, biochips, bioscaffolds, etc.). This article focuses on new technologies arising from corn-based chemistry and their applications in the polymer industry and biomedicine, cosmetics and drug-delivery systems, and pharmaceuticals.

STARCH-BASED, BIODEGRADABLE POLYMERS

Starch, a major component of corn, is a linear polysaccaride made up of repeating glucose groups with glycosidic linkages in the 1-4 carbon positions with chain lengths of 500 to 2,000 glucose units. There are two major polymer molecules in starch—amylose and amylopectin. Amylose, which has alpha linkage, is both flexible and digestible.

As the starch content of a polymer increases, it becomes increasingly biodegradable and leaves fewer intractable residues. Biodegradation of starch-based polymers is the result of enzymatic attack on glycosidic linkages between the sugar groups, which leads to decreases in chain length and the “splitting out” of lower molecular-weight sugar units (monosaccharides, disaccharides, and oligosaccharides) that can be readily used in biochemical pathways.

Biodegradable starch-based polymers are being investigated for potential use in several biomedical applications. For example, new processing techniques and reinforcement with various fillers have led to the development of materials with mechanical properties comparable to those of bone (Reis et al., 1997a). These polymers may be suitable for bone-replacement implants (Reis and Cunha, 1995), bone cements (Reis et al., 1997b), drug-delivery systems (Malafaya et al., 2001), and tissue-engineering scaffolds (Gomes et al., 2001).

Thermoplastic-Starch Products

When biodegradable thermoplastic-starch plastics, which have a starch (amylose) content of more than 70 percent, are combined with specific plasticizing solvents, they produce thermoplastic materials with good performance properties and inherent biodegradability. The hydrophilic nature of high-starch content plastics, which readily disintegrate on contact with water, can be overcome by blending and chemically modifying the material by acetylation, esterification, or etherification. Starch-based polymers are often plasticized, destructured, and/or blended with other high-performance polymers (e.g., aliphatic polyesters and polyvinyl alcohols) to provide useful mechanical properties for different packaging applications.

Starch-Aliphatic Polyester Blends

Blends of biodegradable, synthetic, aliphatic polyesters and starch are often used to produce high-quality sheeting and films for packaging. Approximately 50 percent of synthetic polyester (which costs approximately $4.00/kg) could be replaced with natural polymers, such as starch (approximately $1.50/kg). In addition, polyesters can be modified by incorporating different functional groups (e.g., hydroxy, amine, carbonyl, etc.) that are capable of reacting with natural starch polymers.

Several products made of starch-based plastics are currently available commercially. These include films (e.g., shopping bags, bread bags, bait bags, over-wraps, and backing materials for “flushable” sanitary products) and mulch film. One commercial product, the “BioBag,” is produced from the Novamont resin (found in Italy), which has been around since 1994. The BioBag is made from corn starch combined with fully biodegradable plastics or polylactic acid.

Other products are produced from starch-based foams. A well-known example is water-soluble beads made from potato starch that can replace polystyrene-foam packaging beads. Starch-based beads, which are readily soluble and biodegradable, have created an early market for biodegradable plastics.

Starch and PBS/PBSA Polyester Blends

Polybutylene succinate (PBS), polybutylene succinate adipate (PBSA), and other polyesters can be blended with starch to improve the mechanical properties of materials. Starch and PBS or PBSA blends produce biodegradable plastic sheeting that can be thermo-formed into biscuit trays and other film products. The tensile strength of these blends is somewhat lower than that of polyester alone, but there is little significant further decrease in strength as the starch content increases, at least to a point. With a very high-starch content (>60 percent), however, sheeting can become brittle. To reduce brittleness and increase flexibility, plasticizers are often added.

Starch-Based Superabsorbent Polymers

Superabsorbent polymers (SAPs) are a unique group of materials that can absorb more than a hundred times their weight in liquid. In addition, SAPs do not easily release these fluids, even under pressure. SAPs were first developed in the 1970s by the U.S. Department of Agriculture in the form of starch/acrylonitrile/acrylamide-based polymers called “superslurpers.” These products were originally used in agricultural/horticultural markets as hydrogels to help retain moisture in soil during the growing and shipping of crops and other plants (Yamaguchi et al., 1987).

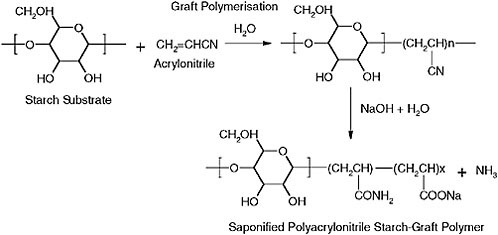

There are two primary types of SAPs—starch-graft polymers and polymers based on cross-linked polyacrylates. Starch-graft polymers are prepared by graft-polymerizing acrylonitrile onto a starch substrate (Smith, 1972; Yamaguchi et al., 1987).

Saponification of a starch-graft polymer with an alkali yields a final product with nitrile, amide, and carboxyl functionalities (Figure 1). The hydrophilic groups on the composite can be adjusted by controlling the amount of sodium hydroxide and reaction time during the saponification process. The collaborative absorbent effect of -CONH2, -COONa, and -COOH groups present in these poly-

FIGURE 1 Synthesis of a starch-graft polymer.

mers is superior to the absorbance capacity of other polymers containing a single -CONH2, -COONa, or -COOH group (Wu et al., 2003).

Cross-linking during polymerization yields a networked polymer that is not only insoluble in water but is able to absorb and retain water under low load. A typical cross-linking agent is trimethylolpropane triacrylate in concentrations of 0.05 mol percent relative to the monomer. Cross-linking is also possible with ethylene glycol diglycidyl ether, which reacts with carboxyl groups on the polymer molecules to cross-link them.

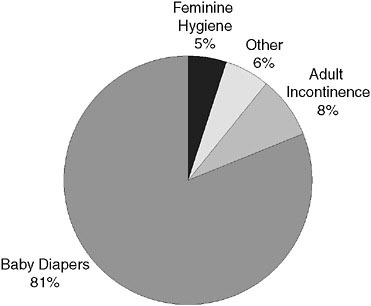

Global demand for SAPs totaled an estimated 1.05 million tons in 2003, and the demand is expected to increase an average of 3.6 percent per year from 2003 to 2008. Globally, baby diapers account for an estimated 81 percent of SAP demand (Figure 2) (http://nexant.ecnext.com/coms2/gi_0255-3047/Super-Absorbent-Polymers-SAP.html). Adult incontinence garments make up the next largest segment of the SAP market (8 percent), followed by other applications (6 percent) and feminine hygiene products (5 percent). The “other applications” category includes de-watering agents for sewage sludge, drying agents for china-clay slurries and pulverized-coal slurries (Farrar et al., 1995), and a wide range of other uses.

Polylactic Acid or Polylactide

Polylactide (PLA) is a biodegradable polymer based on renewable resources with a range of applications similar to polyethylene terephthalate (PET). Uhde Inventa-Fischer, a German-based company, has been developing a PLA process for the last 10 years (http://www.uhde-inventa-fischer.com), and Cargill in the

FIGURE 2 The market for superabsorbent polymers in 2003 (total 1.05 million tons).

United States and Teijin in Japan are investing in large-scale production facilities for the manufacture of PLA.

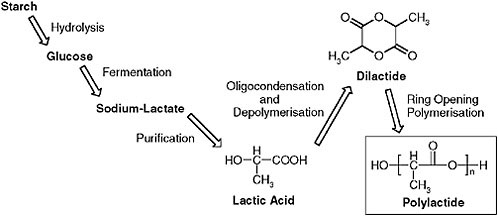

The feedstock for PLA processes is glucose, which can be produced from hydrolysis of starch. Glucose first undergoes fermentation to produce sodium lactate and some impurities, such as proteins, cellular mass, and so on. After a number of purification steps, sodium lactate is transformed into lactic acid, which is then concentrated to remove residual water. This is followed by thermal polymerization (self-condensation), which yields a low-molecular weight PLA prepolymer, which is then thermally depolymerised to yield a distillable cyclic dimer (dilactide, or simply lactide).

Ring-opening polymerization of the purified dilactide with a suitable catalyst, often a tin salt (e.g., stannous octoate), produces high-molecular weight PLA (Figure 3). The final polymer is then granulated and further processed for the desired application. Because of PLA’s good mechanical properties, it is used as packaging material (e.g., film, sheet, or bottles), textiles (e.g., filaments or fibers), engineering plastics, and medical polymers (e.g., surgical thread or implants).

1,4:3,6-Dianhydrohexitols-Based Polymers

Incorporating simple carbohydrates directly into polymer structures is difficult because both primary and secondary hydroxyl functionalities in carbo-

FIGURE 3 The Uhde Inventa-Fischer process of making polylactide from starch. Source: <www.udhe-inventa-fischer.com>.

hydrates interfere with the synthesis of well defined products. The problem can be circumvented by using 1,4:3,6-dianhydrohexitols.

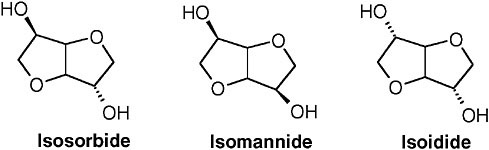

Dianhydrohexitols are well documented by-products of the starch industry obtained by dehydration of D-hexitols, which are made by a simple reduction of hexose sugars (Stross and Hemmer, 1991). About 650,000 tons of dianhydrohexitols are produced annually worldwide (Sheldon, 1993). These chiral biomass-derived products exist as three main isomers (isosorbide, isomannide, and isoidide), depending on the configuration of the two hydroxyl functions (derived from D-glucose, D-mannose, and L-fructose, respectively) (Figure 4). Isosorbide, which is produced from glucose via sorbitol, is the most widely available dianhydrohexitol.

FIGURE 4 The three main isomers of dianhydrohexitols.

Isosorbide

The Iowa Corn Promotion Board supports research on corn-derived products (notably isosorbide) in conjunction with the U.S. Department of Agriculture and U.S. Department of Energy and is partnering with the New Jersey Institute of Technology to identify and assess potential polymer applications for isosorbide. This biodegradable material is classified by the Food and Drug Administration as a “generally recognized as safe,” or GRAS, material.

In principle, isosorbide can be incorporated directly into commercial polyesters, such as PET, which is widely used in a variety of food and beverage containers and has a current market of 4.4 billion pounds. Isosorbide, which has a rigid molecular structure, stiffens PET chains and raises the glass-rubber transition temperature (Tg) of PET resin to 85-90ºC, depending on the level of incorporation. At that Tg, bottles made from these modified resins can be filled with pasteurized food products while they are still hot or with products that are so viscous they require heating to reduce filling time. Normal, unmodified PET bottles simply become distorted when hot-filled in this way. Preliminary cost estimates show that isosorbide produced by processing of starch is competitive with the cost of petroleum-based building blocks currently used to make plastics (Adelman et al., 2003; Kricheldorf and Gomourachvili, 1997).

Besides modifying PET, isosorbide has many potential uses in the polymer industry and can potentially reduce the amount of petroleum necessary to make plastics. The synthesis of numerous polymers, such as polyethers (Chatti et al., 2006; Kricheldorf and Al Masri, 1995; Majdoub et al., 1994), polyesters (Kricheldorf et al., 2003; Thiem and Lueders, 1984), polyurethanes (Bachmann et al., 1998; Cognet-Georjon et al., 1995; Thiem and Lueders, 1986), and polycarbonates (Kricheldorf and Gomourachvili, 1997), is already being investigated.

A few of the potential applications of dianhydrohexitol-based polymeric products are listed below:

-

Isosorbide diglycidyl ether resins could replace bisphenol-A epoxies, which are used to line food and beverage cans. Bisphenol-A is a suspected xenestrogen, and replacing it with a naturally derived, biodegradable diol would have clear consumer advantages.

-

Isosorbide and dianhydroiditol polycarbonate resins could be used as molding plastics with high Tg, transparency, and UV-resistance to replace bis-A polycarbonates in CD blanks.

-

Chiral separation resins (amorphous, insoluble polyurethanes based on isosorbide) have great potential value in the pharmaceutical and fine-chemicals market for resolving enantiomeric molecules. These isosorbide-based materials exploit the basic chirality of anhydrosugar molecules.

-

Isosorbide/isoidide-ester copolymers of controlled stereochemistry could lead to high-performance fibers and engineering resins and the creation of new

-

classes of controlled-performance, cost-effective polyesters through the control of polymer chirality along the chain.

-

Potential applications of polyester resins from isosorbide with terephthalic and isophthalic acids and copolymers with monomers (e.g., L-lactide, caprolactone, etc.) range from environmentally friendly molding resins to drug-release and degradable-suture materials.

COSMETICS AND DRUG-DELIVERY APPLICATIONS

Dimethyl isosorbide (DMI) is a water-white liquid with excellent solvent properties that can be easily synthesized by methylation of isosorbide using dimethyl sulfate and aqueous alkali. DMI can be formulated with standard equipment and requires no special materials, such as flammables, in its production.

Used as a sustainable solvent in skin-care products and drug formulations, DMI facilitates the penetration of active ingredients through the epidermis, enabling targeted delivery of self-tanners, makeup removers, anti-acne treatments, and other transdermal products (http://www.bulkactives.com/dimethylisosobide.htm). DMI can transport water-soluble active agents into the skin without recrystallizing them and causing skin irritation. And, most important, it does not promote penetration of the ingredients into the bloodstream.

Materials made with DMI require a lower concentration of aggressive active agents, such as salicylic acid, vitamin C, lactic acid, hydrocortisone, and hyaluronic acid, thus reducing the formulation cost of finished products. Other advantages include longer shelf life (particularly for formulations susceptible to hydrolysis or trans-esterification); miscibility with most organic solvents and non-ionic surfactants; and compatibility with many product forms, including clear gels.

All of these properties make DMI a potential choice for transdermal or topical delivery of a variety of drugs. Preliminary studies indicate that DMI is practically nontoxic. Thus, when used internally, it is predicted that DMI will be metabolized to form isosorbide. DMI has already been used successfully for stable liquid formulation of aspirin (Luzzi and Joseph, 1980), which has been a long-standing problem because of the instability of aspirin in other solvents.

PHARMACEUTICAL USES OF DIANHYDROHEXITOLS

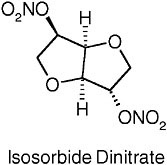

The mono- and dinitrate esters of isosorbide and isomannide, both active NO-releasing drugs, are widely used in the pharmaceutical industry as vasodilators. Figure 5 shows the configuration of isosorbide dinitrate (sold under the brand names Isordil® and Sorbitrate®), which is used as a vasodilator in various formulations that work by different routes for the management of angina pectoris and congestive heart failure (Bidoggia, 1987; Marten et al., 1984). Many pharmaceutical preparations of these compounds are trade products.

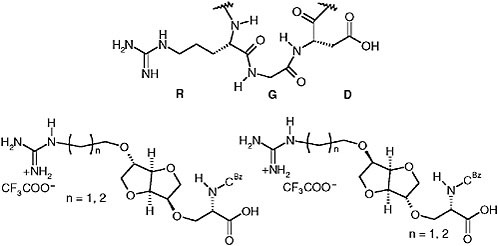

Isosorbide and isomannide have also been successfully used as templates for

FIGURE 5 Chemical structure of the isosorbide dinitrate molecule.

FIGURE 6 RGD-mimetics derived from isosorbide and isomannide.

RGD-mimetics1 (Figure 6) in the development of integrin antagonists 2(Osterkamp et al., 1999). Because RGD mimetics can inhibit cell attachment and consequently induce apoptosis, they might someday be used as drugs against angiogenesis, inflammation, and cancer mestastasis.

CONCLUSION

Corn is a versatile, natural, biodegradable and renewable resource that has many commercial applications. Corn-chemical and biotechnological processes have led to the development of a wide range of products, from polymers to biofuels and vitamins. In the past decade, numerous consumer products based on the results of research have demonstrated the potential of biorenewable sources being used instead of petroleum-based products. With continued work and technological advances, we may soon achieve this potential.

REFERENCES

Adelman, D. J., L. F. Charbonneau, and S. Ung, inventors. E. I. Du Pont de Nemours & Company, assignee. December 2, 2003. Process for Making Poly(ethylene-co-isosorbide) Terephthalate Polymer. U.S. Patent 6,656,577.

Bachmann, F., J. Reimer, M. Ruppenstein, and J. Thiem. 1998. Synthesis of a novel starch-derived AB-type polyurethane. Macromolecular Rapid Communications 19(1):21-26.

Bidoggia, H. 1987. Isosorbide-5-mononitrate and isosorbide dinitrate in the treatment of coronary heart disease: A multi-centre study. Current Medical Research and Opinion 10(9):601-611.

Chatti, S., M. Bortolussi, D. Bogdal, J. C. Blais, and A. Loupy. 2006. Synthesis and properties of new poly(ether-ester)s containing aliphatic diol based on isosorbide effects of the microwave-assisted polycondensation. European Polymer Journal 42(2):410-424.

Cognet-Georjon, E., F. Méchin, and J. P. Pascault. 1995. New polyurethanes based on diphenylmethane diisocyanate and 1,4:3,6-dianhydrosorbitol, 1: Model kinetic studies and characterization of the hard segment. Macromolecular Chemistry and Physics 196(11):3733-3751.

Farrar, D., P. Flesher, M. Skinner, and D. Marshall, inventors. Allied Colloids Limited, assignee. January 24, 1995. Water-Absorbing Polymers. U.S. Patent 5,384,343.

Gomes, M. E., A. S. Ribeiro, P. B. Malafaya, R. L. Reis, and A. M. Cunha. 2001. A new approach based on injection moulding to produce biodegradable starch-based polymeric scaffolds: Morphology, mechanical and degradation behaviour. Biomaterials 22(9):883-889.

Koch, H., and H. Röper. 1988. New industrial products from starch. Starch–Stärke 40(4):121-131.

Kricheldorf, H. R., and M. Al Masri. 1995. New polymer synthesis. LXXXII. Syntheses of poly(ether-sulfone)s from silylated aliphatic diols including chiral monomers. Journal of Polymer Science Part A: Polymer Chemistry 33(15):2667-2671.

Kricheldorf, H. R., and Z. Gomourachvili. 1997. Poly-anhydrides 10: Aliphatic polyesters and poly(ester anhydrides) by polycondensation of silylated aliphatic diols. Macromolecular Chemistry and Physics 198(10):3149-3160.

Kricheldorf, H. R., S. Chatti, G. Schwartz, and R. P. Kruger. 2003. Macrocycles 27: Cyclic aliphatic polyesters of isosorbide. Journal of Polymer Science Part A: Polymer Chemistry 41(21):3414-3424.

Luzzi, L. A., and K. H. Ma Joseph, inventors. Research Corporation, assignee. October 14, 1980. Dimethyl Isosorbide in Liquid Formulation of Aspirin. U.S. Patent 4,228,162.

Majdoub, M., A. Loupy and G. Fleche. 1994. New polyethers and polyesters from isosorbide: Synthesis and characterization. European Polymer Journal 30(12):1431-1437.

Malafaya, P. B., C. Elvira, A. Gallardo, J. San Roman and R. L. Reis. 2001. Porous starch-based drug delivery systems processed by a microwave route. Journal of Biomaterials Science, Polymer Edition 12(11):1227-1241.

Marten, W., M. Weiss, and W. Haase. 1984. Treatment of coronary heart disease with isosorbide mononitrate (‘Elantan’ 20): A multi-centre study in hospital and general practice. Current Medical Research and Opinion 9(2):96-106.

Osterkamp, F., H. Wehlan, U. Koert, M. Wiesner, P. Raddatz and S. L. Goodman. 1999. Synthesis and biological evaluation of dianhydrohexitol integrin antagonists. Tetrahedron 55(35): 10713-10734.

Reis, R. L., and A. M. Cunha. 1995. Characterization of two biodegradable polymers of potential application within the biomedical field. Journal of Material Science: Materials in Medicine 6(12):786-792.

Reis, R. L., A. M. Cunha, and M. J. Bevis. 1997a. Structure, development and control of injection molded hydroxyapatite reinforced starch/EVOH composites. Advances in Polymer Technology 16(4):263-277.

Reis, R. L., S. C. Mendes, A. M. Cunha, and M. Bevis. 1997b. Processing and in vitro degradation of starch/EVOH thermo-plastic blends. Polymer International 43(4):347-352.

Sheldon, R. A. 1993. Chirotechnology: Industrial Synthesis of Optically Active Compounds. New York: Marcel Dekker.

Smith, T., inventor. Grain Processing Corporation, assignee. May 9, 1972. Water Absorbing Alkali Metal Carboxylate Salts of Starch-Polyacrylonitrile Graft Copolymers. U.S. Patent 3,661,815.

Stross, P., and R. Hemmer. 1991. 1,4:3,6-dianhydrohexitols. Advances in Carbohydrate Chemistry and Biochemistry 49:93-175.

Thiem, J., and H. Lueders. 1984. Synthesis and directed polycondensation of starch-derived anhydroalditol building units. Starch–Stärke 36:170-176.

Thiem, J., and H. Lueders. 1986. Synthesis and properties of polyurethanes derived from diaminodianhydroalditols. Makromolekulare Chemie 187:2775-2785.

Wu, J., Y. Wei, J. Lin, and S. Lin. 2003. Study on starch-graft-acrylamide/mineral powder superabsorbent composite. Polymer 44(21):6513-6520.

Yamaguchi, M., H. Watomoto, and M. Sakamoto. 1987. Super-absorbent polymers from starch-polyacrylonitrile graft copolymers by acid hydrolysis before saponification. Carbohydrate Polymers 7(1):71-82.