Sustainable Biorefineries

CARINA MARIA ALLES AND ROBIN JENKINS

DuPont Engineering Research & Technology

Wilmington, Delaware

SUSTAINABLE BIOFUELS

Opportunities and Challenges

As the global demand for energy continues to rise, biofuels hold the promise of providing a renewable alternative to fossil fuels. High oil prices and the threat of negative climate change impacts have sparked a surge in research and business activities. National security concerns and the desire to increase farm incomes have prompted governments around the world to enact policies in favor of biofuels. Developing countries hope to increase access to inexpensive fuel in isolated areas. Biofuels are also seen as an option to reduce air pollution in urban areas. However, the current boom has sparked controversy as well. Opponents accuse biofuels of requiring more energy inputs and causing more greenhouse gas emissions than their fossil counterparts. Many concerns center on possible environmental degradation: erosion, deterioration of soil health, depletion of aquifers, and losses in biodiversity. Large-scale biofuels production is often regarded as a threat to food production and conservation efforts (Hill et al., 2006; Worldwatch Institute, 2006).

Sustainability assessments aimed at quantifying the economic, environmental, and societal impacts can help move the often heated debates over biofuels to a more factual level. Science-based methods like life cycle assessment (LCA), a

FIGURE 1 Fuel value chain. Source: DuPont.

holistic approach to quantify environmental impacts throughout the value chain of a product (ISO, 2006), have gained acceptance among decision makers.

Biofuels Sustainability in Well-to-Wheel Perspective

To assess the sustainability of (bio)fuels all stages of the fuel value chain have to be considered (Figure 1): feedstock production and supply, fuel production and distribution, and vehicle operation. An assessment of the entire value chain (i.e., well-to-wheel [WTW]) allows a fair comparison of different fuels, whereas a well-to-tank (WTT) or cradle-to-gate (CTG) (here: extraction of raw materials from the ground to fuel production) approach is adequate to compare different technologies to make the same fuel.

CASE STUDY: BIOREFINERY TECHNOLOGY DEVELOPMENT

The Integrated Corn-based Biorefinery

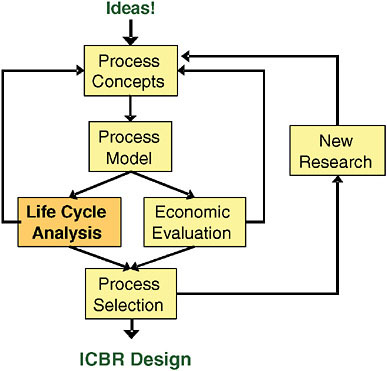

The DuPont integrated corn-based biorefinery (ICBR) process will use innovative technology to convert corn grain and stover into fermentable sugars for the parallel production of value-added chemicals and fuel ethanol (DOE, 2006). Current R&D efforts in the ICBR program focus on optimized process design for the conversion of lignocellulosic biomass to ethanol. From the beginning, economic evaluation and LCA have been used side by side to guide researchers to the most sustainable process alternative (Figure 2).

In the ICBR program, stakeholder engagement was critical to setting relevant sustainability goals. Stakeholder interests are represented by an external advisory panel of subject matter experts from government agencies, academia, industry, and nongovernmental organizations (NGOs), who helped prioritize topics, translate them into quantifiable metrics, and formulate specific targets for the environmental performance of the ICBR technology. The panel’s independent, critical review of life cycle methodology and results has been invaluable to the ICBR program.

FIGURE 2 Integration of LCA into process development. Source: DuPont.

ICBR Life Cycle Analysis

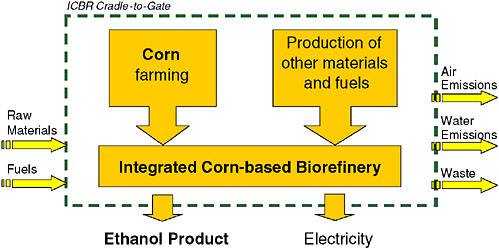

Life cycle assessment sheds light on relative or directional changes in sustainability resulting from ICBR technology choices. The LCA model follows all natural resources extracted from the environment and all material releases to the environment that cross the system boundaries shown as the dotted line in Figure 3. Many of these flows are then aggregated into impact assessments (e.g., fossil energy consumption, which includes petroleum, natural gas, coal, and lignite use) or greenhouse gas (GHG) emissions, where gases like anthropogenic CO2, CH4, and N2O are weighted by their global warming potential.

A process model of ethanol production from corn stover in an ICBR facility forms the core of the LCA model. The environmental impacts of material and energy inputs to the biorefinery are tracked back to ground, using LCA databases and publicly available information to describe upstream processes. Michigan State University provided a rigorous LCA model of corn farming, including agrochemicals manufacture and the production of fuels used in corn farming (Kim et al., unpublished manuscript). Most ICBR designs assume that nonfermentable

FIGURE 3 Cradle-to-gate LCA model of the ICBR. Source: DuPont.

biomass provides fuel for an onsite cogeneration facility, with the option to sell excess electricity to the local grid. The LCA credit for electricity sales covers the environmental burden of electricity generation all the way back to primary energy sources (Kim and Dale, 2005).

As the ICBR process development progressed the LCA model was continuously updated. Multiple scenario and sensitivity analyses helped identify favorable design options and optimized process parameter settings.

Comparison versus Benchmarks

Eventually ICBR technology will have to be competitive against other technologies to produce ethanol from corn. The LCA model has also been used to benchmark the environmental performance of the ICBR versus the incumbent technology (i.e., ethanol from corn grain) (Graboski, 2002) and potential alternative routes to produce ethanol from corn stover (Sheehan et al., 2004). Publicly available benchmark data were carefully reviewed when the environmental targets for the ICBR were defined. When necessary, critical assumptions and data sources were aligned to ensure a fair comparison.

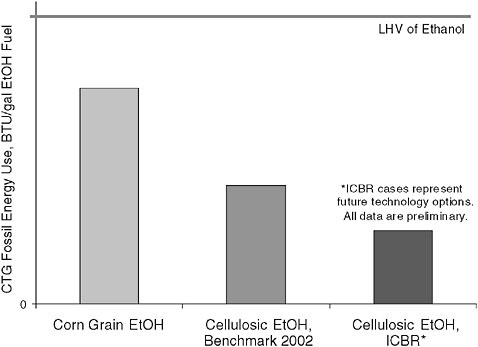

Results for cradle-to-gate fossil energy consumption, a metric commonly used to address the energy balance of biofuels, are shown in Figure 4. In all three scenarios the CTG fossil energy footprint to produce a gallon of bioethanol is well below the lower heat value (LHV) of the fuel (i.e., the energy ultimately delivered to a vehicle). The ICBR compares favorably against both benchmarks.

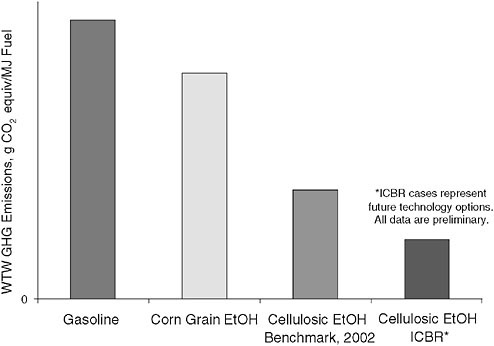

Greenhouse gas emissions have emerged as a priority metric in policy making. To benchmark biofuels against the incumbent fossil fuel, differences in the energy content of the fuels need to be considered. Figure 5 shows well-to-wheel greenhouse gas emissions normalized to an equal amount of fuel energy for U.S. gasoline and the three biofuel alternatives discussed above.

All three biofuels cause fewer GHG emissions along the fuel value chain than gasoline. Cellulosic ethanol offers significant advantages in GHG reductions, since corn stover has a smaller GHG footprint than corn grain (Kim et al., unpublished manuscript) and provides renewable fuel to the ethanol production facility, whereas conventional dry mills rely on natural gas or coal (Graboski, 2002). The ICBR ethanol presents the largest GHG reduction potential of all cases shown, thanks to advanced pretreatment and fermentation technologies and optimized process integration. A breakthrough in stover-to-ethanol technology could pave the way for ethanol from other lignocellulosic feedstocks, such as perennial grasses and agricultural or forestry residues.

FIGURE 4 Cradle-to-gate fossil energy use of selected biofuels. Source: DuPont.

FIGURE 5 Well-to-wheel greenhouse gas emissions of selected fuels. Source: DuPont.

ATTRIBUTES OF SUSTAINABLE BIOREFINERIES

Fundamental learnings from the in-depth analysis of a broad spectrum of ICBR technology options can be applied to biorefineries in general.

Feedstock Selection

The cradle-to-refinery-gate footprint of the primary biorefinery feedstock is a significant contributor to the overall footprint of a biofuel. Generally, lignocellulosic biomass has a lower environmental burden than food crops. In LCA terms, waste materials from industrial processes or municipal collection would come free of burden if using them in biorefinery processing would result in the avoidance of disposing of these materials. Similarly the footprint of processing chemicals used at the biorefinery needs to be considered, especially in the pretreatment of cellulosic feedstocks.

Biorefinery Process Efficiency

As a rule of thumb, cost-efficient measures to improve process efficiency will have a positive impact on both the economic and the environmental performance

of biorefineries. The common engineering goal to maximize product yield usually translates into reductions in feedstock footprint, waste generation, and energy consumption. Increasing the effective concentration of solids, intermediates, and products in aqueous process streams not only reduces the amount of water taken from the watershed but also reduces the burden on separation steps. Measures to lower the energy consumption within biorefinery battery limits (e.g., by heat integration or equipment design) have a positive impact on the overall biofuel energy balance, whether they reduce the need to bring supplemental fuel to the biorefinery or enable additional energy exports.

Industrial Ecology of Biorefineries

Typically the biofuel is not the only material output of a biorefinery. If more outputs find their ways into beneficial uses, then the economic and environmental burdens of the biorefinery operation can be allocated among a wider range of coproducts, effectively reducing both the production cost and the cradle-to-gate footprint of the biofuel. For example, lignin and other nonfermentable components of biomass feedstocks need not be disposed as wastes, but can be used as fuels to generate thermal or electrical energy onsite or offsite. Other potential coproducts include animal feed, fertilizer, and intermediates for specialty chemicals.

The colocation of biorefineries with other facilities processing agricultural and forestry feedstocks, livestock feedlots, or power plants in industrial parks will facilitate the beneficial exchange of material and energy flows to a great extent.

REFLECTIONS: SUSTAINABILIY IN TECHNOLOGY DEVELOPMENT

In the development of sustainable fuels, materials, and services for the future, researchers are challenged to find innovative technical solutions without losing sight of the economic, societal, and environmental impacts of their work. The ICBR program demonstrates how the early integration of sustainability analysis into the creative process of technology development enables a holistic approach to research guidance, where economic and environmental metrics are used alongside product performance standards to define and monitor success.

ACKNOWLEDGMENTS

Sustainability analysis in the ICBR program (DOE 1435-04-03-CA-70224) was a team effort, involving partners from Michigan State University, the National Renewable Energy Laboratory, Diversa Corporation, and DuPont. Interactions with researchers and leadership have been very rewarding. The program also benefited immensely from the perspectives of external stakeholders, in particular, members of the ICBR LCA advisory panel.

REFERENCES

DOE (U.S. Department of Energy). 2006. Biomass program—Integrated corn-based bio-refinery. Online. Available at <http://www1.eere.energy.gov/biomass/pdfs/corn-based_biorefinery.pdf>. Accessed July 2007.

Graboski, M. S. 2002. Fossil energy use in the manufacture of corn ethanol. National Corn Growers Association. Online. Available at <http://www.ncga.com/ethanol/pdfs/energy_balance_report_final_R1.PDF>. Accessed July 2007.

Hill, J., E. Nelson, D. Tilman, S. Polasky, and D. Tiffany. 2006. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol fuels. Proceedings of the National Academy of Sciences 103:11206-11210.

ISO (International Organization for Standardization). 2006. Environmental management—Life cycle assessment—Principles and framework. ISO 14040 Ed. 2. Geneva, Switzerland.

Kim, S., and B. Dale. 2005. Life cycle inventory information of the United States electricity system. International Journal of Life Cycle Assessment 10:294-304.

Kim, S., B. Dale, and R. Jenkins. Life Cycle Assessment of Corn Grain and Corn Stover. Unpublished manuscript.

Sheehan, J., A. Aden, K. Paustian, K. Killian, J. Brenner, M. Walsh, and R. Nelson. 2004. The energy and environmental aspects of using corn stover for fuel ethanol. Journal of Industrial Ecology 7(3-4):117-146.

Worldwatch Institute. 2006. Biofuels for transportation: Global potential and implications for sustainable agriculture and energy in the 21st century. Online. Available at <http://www.worldwatch.org/node/4078>. Accessed July 2007.

ADDITIONAL READING

Argonne National Laboratory: Transportation Technology R&D Center. 2007. GREET is “gold standard” for well-to-wheel analyses of vehicle/fuel systems. Online. Available at <http://www.transportation.anl.gov/software/GREET/publications.html>. Accessed July 2007.

DOE (U.S. Department of Energy). 2007. Ethanol. Online. Available at <http://www1.eere.energy.gov/biomass/ethanol.html>. Accessed July 2007. Note: Contains many further links on biofuels.

Ecole Polytechnique Federale de Lausanne (EPFL). 2007. Roundtable on sustainable biofuels announces first draft principles for stakeholder discussion. Online. Available at <http://EnergyCenter.epfl.ch/Biofuels>. Accessed July 2007. Note: Global stakeholder discussion, access via website; website also contains further links on emerging biofuels policy standards worldwide.

EPA (U.S. Environmental Protection Agency). 2007. Life-cycle assessment (LCA). Online. Available at <http://www.epa.gov/ORD/NRMRL/lcaccess/>. Accessed July 2007. Note: Contains useful background information and many further links on LCA, including “LCA 101.”

Farrell, A. E., R. J. Plevin, B. T. Turner, A. D. Jones, M. O’Hare, and D. M. Kammen. 2006. Ethanol can contribute to energy and environmental goals. Science 27(311):506-508. Note: Contains a meta-study of recent ethanol LCAs.

National Resources Defense Council. 2004. Growing energy: How biofuels can help end America’s oil dependence. Online. Available at <http://www.nrdc.org/air/transportation/biofuels/contents.asp>. Accessed July 2007.

National Resources Defense Council. 2007. Getting biofuels right: Eight steps for reaping real environmental benefits from biofuels. Online. Available at <http://www.nrdc.org/air/transportation/biofuels/contents.asp>. Accessed July 2007.

Shapouri, H. 2004. The 2001 net energy balance of corn ethanol. Paper presented at the Corn Utilization and Technology Conference, Indianapolis, IN, June. Online. Available at <http://www.usda.gov/oce/reports/energy/index.htm>. Accessed July 2007. Note: This USDA website also contains reports on the economics of bioethanol.