5

Alternative Transportation Fuels

The U.S. transportation sector relies almost exclusively on oil. Because domestic sources are unable to supply sufficient oil to satisfy the demands of the transportation and petrochemical industry sectors, the United States currently imports about 56 percent of its petroleum supply. Volatile crude oil prices and tight global supplies, coupled with fears of oil production peaking in the next 10–20 years, further aggravate concerns over oil dependence. The other key issue is greenhouse gas emissions from the transportation sector, which contribute one-third of the country’s total emissions. These issues have motivated the search for alternative domestic sources of liquid fuels that also have significantly lower greenhouse gas emissions.

CONVERSION OF COAL AND BIOMASS TO LIQUID FUELS

Coal and biomass are in abundant supply in the United States, and they can be converted to liquid fuels for use in existing and future vehicles with internal-combustion and hybrid engines. Thus, they could be attractive candidates for providing non-oil-based liquid fuels to the U.S. transportation system. There are important questions, however, about the economic viability, carbon impact, and technology status of these options.

While coal liquefaction is potentially a major source of alternative liquid transportation fuels, the technology is capital intensive. Moreover, on a life-cycle

basis,1 coal liquefaction yields about twice the greenhouse gas emissions produced by petroleum-based gasoline when the carbon dioxide (CO2) is vented to the atmosphere. Capturing this CO2 and geologically storing it underground—a process frequently referred to as carbon capture and storage, or CCS—is therefore a requirement for production of coal-based liquid fuels in a carbon-constrained world. However, the viability of CCS, its costs, and its safety could pose a barrier to commercialization.

Biomass is a renewable resource that, if properly produced and converted, can yield biofuels with lower greenhouse gas emissions than petroleum-based gasoline yields. However, biomass production on fertile land already cleared might displace food, feed, or fiber production; moreover, if ecosystems were cleared to produce biomass for biofuels, the accompanying releases of greenhouse gases could negate for decades to centuries any greenhouse gas benefits from the biofuels (Fargione et al., 2008). Thus, there are questions about using biomass for fuel without seriously competing with other crops and without causing adverse environmental impacts.

This chapter assesses the potential for using coal and biomass to produce liquid fuels in the United States; provides consistent analyses of technologies for the production of alternative liquid transportation fuels; and discusses the potential for use of coal and biomass to substantially reduce U.S. dependence on conventional crude oil and also reduce greenhouse gas emissions in the transportation sector. Quantities in this chapter are expressed in the standard units commonly used by biomass producers. Greenhouse gas emissions, however, are expressed in tonnes of CO2 equivalent, as in other chapters in this report. Details of the analyses and numerical estimates presented in this chapter can be found in the America’s Energy Future panel report Liquid Transportation Fuels from Coal and Biomass: Technological Status, Costs, and Environmental Impacts (NAS-NAE-NRC, 2009).

FEEDSTOCK SUPPLY

Biomass Supply and Cost

While it is important that both the development of feedstocks for biofuels and the expansion of biofuel use in the transportation sector be achieved in a socially, economically, and environmentally sustainable manner, the social, economic, and environmental effects of domestic biofuels production have so far been mixed. In 2007, the United States consumed about 6.8 billion gallons of ethanol, made mostly from corn grain, and 491 million gallons of biodiesel, made mostly from soybean (EIA, 2008b), for a combined total of less than 3 percent of the U.S. transportation-fuel consumption. Diverting corn, soybean, or other food crops to biofuel production induces competition among food, feed, and fuel uses. Moreover, both for corn grain ethanol and soybean biodiesel, the use of fossil fuels and other inputs are substantial, and greenhouse gas reductions compared to petroleum-based gasoline emissions are small at best (Farrell et al., 2006; Hill et al., 2006). Thus, the committee judges that corn grain ethanol and soybean biodiesel are merely intermediates in the transition from oil to cellulosic biofuels or other biomass-based liquid hydrocarbon transportation fuels (for example, biobutanol and algal biofuels).

Assuming that technologies for conversion will be commercially viable, liquid fuels made from lignocellulosic biomass2 can offer major greenhouse gas reductions relative to petroleum-based fuels, as long as the biomass feedstock is a residual product of some forestry and farming operations or is grown on marginal lands that are not used for food and feed crop production. Therefore, the committee focused on the lignocellulosic resources available for producing biofuels, and it assessed the costs of different feedstocks of this type—corn stover, wheat and seed-grass straws, hay, dedicated fuel crops, woody biomass, animal manure, and municipal solid waste—delivered to a biorefinery for conversion. Societal needs were considered by examining recent analyses of trade-offs between land use for biofuel production and land use for growing food, feed, and fiber, as well as for ecosystem services.

The committee estimated the amounts of cellulosic biomass that could be produced sustainably in the United States and result in fuels with significantly lower greenhouse gas emissions than petroleum produces. For the purpose of this study, the committee considered biomass to be produced in a sustainable manner if it met the following criteria: (1) croplands would not be diverted for biofuels (so that land would not be cleared elsewhere to grow the crops thus displaced); and (2) the growing and harvesting of cellulosic biomass would incur minimal adverse environmental impacts—such as erosion, excessive water use, and nutrient runoff—or even reduce them.

The committee estimated (1) that about 400 million dry tons (365 million dry tonnes) per year of biomass could potentially be made available for the production of liquid transportation fuels using technologies and management practices of 2008 and (2) that the cellulosic biomass supply could increase to about 550 million dry tons (500 million dry tonnes) each year by 2020 (Table 5.1). A key assumption in the committee’s analysis was that 18 million acres of land currently enrolled in the Conservation Reserve Program (CRP) would be used to grow perennial grasses or other perennial crops for biofuel production, and that the acreage would increase to 24 million acres by 2020 as knowledge increased with time. Other key assumptions were that (1) harvesting methods would be developed for efficient collection of forestry or agricultural residues; (2) improved

TABLE 5.1 Estimated Amount of Lignocellulosic Feedstock That Could Be Produced Annually for Biofuel Using Technologies Available in 2008 and in 2020

|

Feedstock Type |

Million Tons |

|

|

With Technologies Available in 2008 |

With Technologies Available by 2020 |

|

|

Corn stover |

76 |

112 |

|

Wheat and grass straw |

15 |

18 |

|

Hay |

15 |

18 |

|

Dedicated fuel crops |

104a |

164 |

|

Woody biomass |

110 |

124 |

|

Animal manure |

6 |

12 |

|

Municipal solid waste |

90 |

100 |

|

Total |

416 |

548 |

|

aCRP land has not been used for dedicated fuel crop production as of 2008. As an illustration, the committee assumed that two-thirds of the CRP land would be used for dedicated fuel production. |

||

TABLE 5.2 Estimate of Biomass Suppliers’ Willingness-to-Accept Price (in 2007 Dollars) per Dry Ton of Delivered Cellulosic Material

|

Biomass |

Willingness-to-Accept Price (dollars per ton) |

|

|

Estimated in 2008 |

Projected in 2020 |

|

|

Corn stover |

110 |

86 |

|

Switchgrass |

151 |

118 |

|

Miscanthus |

123 |

101 |

|

Prairie grasses |

127 |

101 |

|

Woody biomass |

85 |

72 |

|

Wheat straw |

70 |

55 |

management practices and harvesting technology would raise agricultural crop yield; (3) yield increases would continue at the historic rates seen for corn, wheat, and hay; and (4) all cellulosic biomass estimated to be available for energy production would be used to make liquid fuels. The last assumption allowed the committee to estimate the potential amount of such fuel that could be produced.

Although the committee estimated that 550 million dry tons of cellulosic feedstock could be harvested or produced sustainably in 2020, those estimates are not predictions of what would be available for fuel production in 2020. The actual supply of biomass could be greater if existing croplands were used more efficiently (Heggenstaller et al., 2008) or if genetic improvements to dedicated fuel crops resulted in higher yields. But the supply could be lower if producers decided not to harvest agricultural residues or grow dedicated fuel crops on their CRP land.

The committee also estimated the costs of biomass delivered to a conversion plant (Table 5.2). In this analysis, the price that the farmer or supplier would be willing to accept was assumed to include land-rental cost; other forgone net returns from not selling or using the cellulosic material for feed or bedding; and all other costs incurred in sustainably producing, harvesting, storing, and transporting the biomass to the processing plant. The cost or feedstock price is the long-run equilibrium price that would induce suppliers to deliver biomass to the conversion plant. Because an established market for cellulosic biomass does not exist, the analysis relied on estimates obtained from the literature. The committee’s estimates are higher than those of other published reports because transportation and land-rental costs are included.

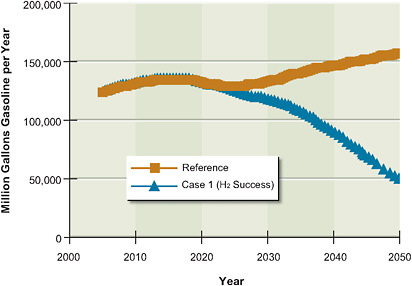

The geographic distribution of biomass supply is an important factor in the

FIGURE 5.1 The number of sites in the United States that can supply the indicated daily amounts of biomass from within a 40-mile radius of each site.

development of the U.S. biofuels industry. For illustrative purposes, the committee estimated the quantities that could, for example, be available within a 40-mile radius (about a 50-mile driving distance) of fuels-conversion plants across the United States (Figure 5.1). With the exception of transport of woody material (primarily pulpwood), 40–50 miles has historically been the maximum distance considered economically feasible for biomass transport. An estimated 290 sites could supply from 1,500 up to 10,000 dry tons per day (from 0.5 million to 3.7 million dry tons per year) of biomass to conversion plants within a 40-mile radius. Notably, the wide geographic variation in potential biomass availability for processing plants affects their sizes. This variation suggests the potential to optimize each individual conversion plant to decrease costs and maximize environmental benefits and supply within a given region. Increasing the distance of delivery could result in larger conversion plants with lower fuel costs.

To help realize the committee’s projected sustainable biomass supply, incentives could be provided to farmers and developers for using a systems approach to address biofuel production; soil, water, and air quality; carbon sequestration; wild2

life habitat; and rural development in a comprehensive manner. Such incentives might encourage farmers, foresters, biomass aggregators, and biorefinery operators to work together to enhance technology development and ensure that best management practices were used for every combination of landscape and potential feedstock.

Findings: Biomass Supply and Cost

An estimated annual supply of 400 million dry tons of cellulosic biomass could be produced sustainably with technologies and management practices already available in 2008. The amount of biomass deliverable to conversion facilities could probably be increased to about 550 million dry tons by 2020. The committee judges that this quantity of biomass can be produced from dedicated energy crops, agricultural and forestry residues, and municipal solid wastes with minimal effects on U.S. food, feed, and fiber production and minimal adverse environmental effects.

Biomass availability could limit the size of a conversion facility and thereby influence the cost of fuel products from any facility that uses biomass irrespective of the conversion approach. Biomass is bulky and difficult to transport. The density of biomass growth will vary considerably from region to region in the United States, and the biomass supply available within 40 miles of a conversion plant will vary from less than 1,000 tons per day to 10,000 tons per day. Longer transportation distances could increase supply but would increase transportation costs and could magnify other logistical issues. The development of technologies that increase the density of biomass in the field, such as field-scale pyrolysis, could facilitate transportation of biomass to larger-scale regional conversion facilities.

Improvements in agricultural practices and in plant species and cultivars will be required to increase the sustainable production of cellulosic biomass and to achieve the full potential of biomass-based fuels. A sustained research and development (R&D) effort to increase productivity, improve stress tolerance, manage diseases and weeds, and improve the efficiency of nutrient use will help to improve biomass yields. Focused R&D programs supported by the federal government could provide the technical bases for improving agricultural practices and biomass growth to achieve the desired increase in sustainable production of cellulosic biomass. Attention could be directed toward plant breeding, agronomy, ecology, weed

and pest science, disease management, hydrology, soil physics, agricultural engineering, economics, regional planning, field-to-wheel biofuel systems analysis, and related public policy.

Incentives and best agricultural practices will probably be needed to encourage sustainable production of biomass for production of biofuels. Producers need to grow biofuel feedstocks on degraded agricultural land to avoid direct and indirect competition with the food supply; they also need to minimize land-use practices that result in substantial net greenhouse gas emissions. For example, continuation of CRP payments for CRP lands when they are used to produce perennial grass and wood crops for biomass feedstock in an environmentally sustainable manner might be an incentive. A framework could be developed, with input from agronomists, ecologists, soil scientists, environmental scientists, and producers, to assess the effects of cellulosic-feedstock production on various environmental characteristics and natural resources. Such a framework would provide guidance to farmers on sustainable production of cellulosic feedstock and contribute to improvements in energy security and in the environmental sustainability of agriculture.

Coal Supply

Deployment of coal-to-liquid fuel technologies would require large quantities of coal and thus an expansion of the coal-mining industry. For example, because a plant producing 50,000 barrels per day (bbl/d) of liquid transportation fuels uses approximately 7 million tons of coal per annum, 100 such plants—producing 5 million bbl/d of liquid transportation fuels—would require about 700 million tons of coal per year, or a 70 percent increase in the nation’s coal consumption. That would require major increases in coal-mining and transportation infrastructure, both in bringing coal from the mines to the plants and in bringing fuel from the plants to the market. These issues would represent major challenges, but they could be overcome. Thus, a key question is whether sufficient coal is available in the United States to support such increased consumption while also supplying other coal users, such as coal-fired electric power plants. In evaluating domestic coal resources, the National Research Council concluded:

Despite significant uncertainties in existing reserve estimates, it is clear that there is sufficient coal at current rates of production to meet anticipated needs through 2030. Further into the future, there is probably sufficient coal to meet the nation’s needs for more than 100 years at current rates of consumption. [However, a] combination of increased rates of production with more detailed reserve analyses that take into account location, quality,

recoverability, and transportation issues may substantially reduce the number of years of supply. Future policy will continue to be developed in the absence of accurate estimates until more detailed reserve analyses—which take into account the full suite of geographical, geological, economic, legal, and environmental characteristics—are completed. (NRC, 2007)

Recently, the Energy Information Administration estimated the proven U.S. coal reserves to be about 260 billion tons (EIA, 2009). A key conclusion of these two studies is that coal reserves in the United States are probably sufficient to meet the nation’s needs for more than 100 years at current rates of consumption—and possibly even with increased rates of consumption. The primary issue is likely not to be reserves per se, however, but rather the increased mining of coal and the opening of many new mines. Increased mining would have numerous potential environmental impacts—and, possibly, heightened public opposition—which would need to be addressed in acceptable ways. Meanwhile, the cost of coal, which currently is low relative to the cost of biomass, would undoubtedly increase.

Finding: Coal Supply

Despite the vast coal resource in the United States, it is not a forgone conclusion that adequate coal will be mined and available to meet the needs of a growing coal-to-fuels industry and the needs of the power industry. The potential for a rapid expansion of the U.S. coal-supply industry would have to be analyzed by the U.S. coal industry, the U.S. Environmental Protection Agency, the U.S. Department of Energy, and the U.S. Department of Transportation so that the critical barriers to growth, environmental effects, and their effects on coal costs could be delineated. The analysis could include several scenarios, one of which would assume that the United States will move rapidly toward increasing use of coal-based liquid fuels for transportation to improve energy security. An improved understanding of the immediate and long-term environmental effects of increased mining, transportation, and use of coal would be an important goal of the analysis.

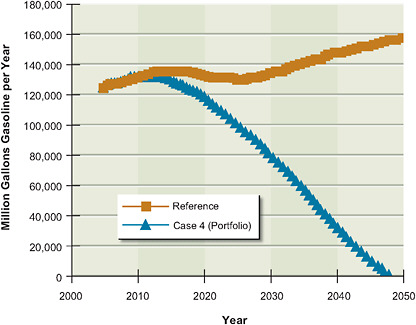

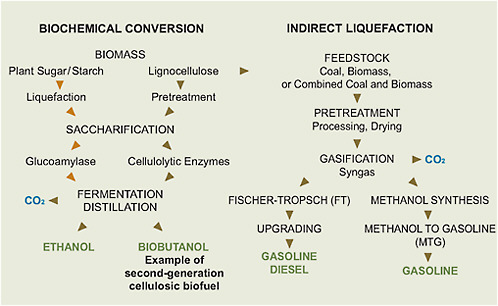

CONVERSION TECHNOLOGIES

Two key technologies, biochemical conversion and indirect liquefaction, are used for the conversion of biomass and coal into fuels, as illustrated in Figure 5.2.

FIGURE 5.2 Steps involved in the biochemical conversion of biomass and the thermochemical conversion (indirect route only) of coal, biomass, or combined coal and biomass into liquid transportation fuels.

Biochemical conversion typically uses enzymes to transform starch (from grains) or lignocelluloses into sugars (saccharification), which are then converted into ethanol by microorganisms (fermentation). Thermochemical conversion includes indirect liquefaction, which uses heat and steam to convert biomass or coal into carbon monoxide and hydrogen (synthesis gas). The synthesis gas can then be catalytically converted into liquid fuels such as diesel and gasoline. The CO2 from the fermentation process in biochemical conversion or from the offgas streams of the thermochemical processes can be captured and geologically stored. Direct liquefaction of coal (not shown in Figure 5.2), which involves adding hydrogen to slurried coal at high temperatures and pressures in the presence of suitable catalysts, represents another route from coal to liquid fuels, but it is less developed than is indirect liquefaction.

Biochemical Conversion

The biochemical conversion of starch (from grains) to ethanol, as depicted on the left side of Figure 5.2, has been commercially deployed. But while this pro-

cess is important for stimulating public awareness and enhancing the industrial infrastructure for fuel ethanol, the committee considers grain-based ethanol to be a transition to cellulosic ethanol and other so-called advanced biofuels, because grain-based ethanol does not meet the sustainability criteria discussed above. The biomass supplies likely to be available by 2020 could technically be converted into ethanol by biochemical conversion, thereby displacing a significant proportion of petroleum-based gasoline and reducing greenhouse gas emissions, but the conversion technology has to be demonstrated first and developed into a commercially deployable state.

Over the next decade or two, cellulosic ethanol could be the main product of the biochemical conversion of biomass into fuels. Further research and development could also lead to commercial technologies that convert sugars into other biofuels such as butanol and alkanes, which have higher energy densities and could be distributed by means of the existing infrastructure. Although the committee focused on cellulosic ethanol as the most deployable technology over the next 10 years, it sees a long-term transition to conversion of cellulosic biomass to higher-energy alcohols or hydrocarbons—so-called advanced biofuels—as having significant long-term potential.

The challenge in biochemical conversion of biomass into fuels is to first break down the resistant structure of a plant’s cell wall and then to break down the cellulose into five-carbon and six-carbon sugars fermentable by microorganisms; the effectiveness with which this sugar is generated is critical to economic biofuel production. The process for producing cellulosic ethanol, as shown in Figure 5.2, includes (1) preparation of the feedstock to achieve size reduction by grinding or other means; (2) pretreatment of the feedstock with steam, liquid hot water, or an acid or base to release cellulose from the lignin shield; (3) saccharification, by which cellulase hydrolyzes cellulose polymers into cellobiose (a disaccharide) and glucose (a monosaccharide), and hemicellulase breaks down hemicellulose into monosaccharides; (4) fermentation of the sugars into ethanol; and (5) distillation to separate the ethanol. The CO2 generated by the conversion process and the combustion of the fuel is mostly offset by the CO2 uptake during the growth of the biomass. The unconverted materials are burned in a boiler to generate steam for the distillation; some surplus electricity can thus be generated.

As of the end of 2008, no commercial-scale cellulosic ethanol plants were in operation. However, the U.S. Department of Energy (DOE) announced in February 2007 that it would invest up to $385 million for six biorefinery projects (two of them based on gasification) over 4 years to help bring cellulosic ethanol to

market (DOE, 2007). When fully operational, the total production of these six plants would be 8000 bbl/d. In addition, a number of companies are actively pursuing commercialization of cellulosic ethanol plants. The corresponding technologies will continue to evolve over the next 5–10 years as challenges are overcome and experience is gained in the first technology-demonstration and commercial-demonstration plants. As a result, the committee expects deployable and commercialized technology to be in place by 2020 if technology-demonstration plants continue to be built, despite the current economic crisis, and if they are rapidly followed by commercial-demonstration plants.

The committee developed a model, in collaboration with the Massachusetts Institute of Technology, that estimated costs and CO2 emissions for converting the biomass feedstocks just discussed into ethanol via biochemical pathways. The model included the effects of enzyme cost (10–40 cents per gallon [¢/gal]),3 feedstock composition, solids loading (18–25 percent), and plants size (40 and 100 million gallons per year, corresponding to daily feed rates of 1400 and 3500 dry tons, respectively). The analysis also included the effects of pretreatment, hydrolysis, and fermentation yields. Three scenarios (representing low, medium, and high levels of improvements) were developed, in the form of process-cost estimates, representing current technology for the biochemical conversion of cellulosic feedstocks, reasonable evolutionary advancement of the technology, and the most optimistic advancement of the technology. (See NAS-NAE-NRC, 2009, for details on the analyses and results.)

The committee judges that the reasonable-improvement scenario best represents where the technology will be for 2020 deployment, and that the major-improvement scenario shows the considerable potential likely to remain. Results of the modeling for the woody biomass poplar, as an illustration of how technology improvements and the size of the ethanol plant could affect costs, are given in Table 5.3. The current costs of production are estimated for a biorefinery with a production capacity of 40 million gallons of ethanol per year; the committee accounted for the costs of production by 2020 by assuming reasonable technological advancements between now and then for the same-size plant. The estimated cost of production in 2020 at a biorefinery with a production capacity of 100 million gallons of ethanol per year is also shown to illustrate the economy of scale.

Table 5.3 shows that the cost of biomass (listed as “raw material-dependent

TABLE 5.3 Comparison of Costs (in 2007 Dollars) for Three Scenarios That Represent Low, Medium, and High Levels of Improvements in Technology and Process Efficiency in a Biorefinery Using the Woody Biomass Poplar

|

|

Level of Improvement |

Cost at Higher Capacity and Medium Improvement |

||

|

Poplar Low |

Poplar Medium |

Poplar High |

||

|

Plant capacity (million gallons) |

40 |

40 |

40 |

100 |

|

Total capital ($ million) |

223 |

194 |

174 |

349 |

|

Total capital ($ per annual gallon) |

5.65 |

4.85 |

4.34 |

3.49 |

|

Total capital ($ per barrel per day) |

87,000 |

75,000 |

67,000 |

61,000 |

|

Biomass used (dry tons) |

593,000 |

514,000 |

461,000 |

1,286,000 |

|

Yield (gallons per ton) |

67 |

78 |

87 |

78 |

|

Ethanol operating cost ($ per gallon) |

1.95 |

1.40 |

0.90 |

1.30 |

|

Ethanol production cost ($ per gallon) |

2.70 |

2.00 |

1.50 |

1.82 |

|

Facility-dependent fraction of cost (percent) |

34 |

39 |

48 |

36 |

|

Raw material-dependent fraction of cost (percent) |

57 |

51 |

40 |

57 |

fraction of cost”) is a significant component of ethanol production costs. But with significant evolutionary improvement of the technology and scaling up of the operation, the process economics can be improved.

Ethanol has 66 percent as much energy as gasoline does. Ethanol is also hygroscopic and cannot be transported in existing fuel-infrastructure pipelines because of its affinity for water. It also is corrosive and can damage seals, gaskets, and other equipment and induce stress-corrosion cracking in high-stress areas. Ethanol is currently shipped by rail or barge. If ethanol is to be used in a fuel at concentrations higher than 20 percent ethanol (for example, in E85, which is a blend of 85 percent ethanol and 15 percent gasoline), the number of refueling stations will have to be increased. If ethanol is to replace a substantial volume of transportation gasoline, an expanded infrastructure will be required for its distribution. (The transport and distribution of synthetic diesel and gasoline produced from thermochemical conversion are less challenging because they are compatible with the existing infrastructure for petroleum-based fuels.)

Some key research, development, and demonstration challenges related to the ethanol-production process need to be overcome before the fuel’s widespread commercialization can be achieved. These challenges are as follows: (1) improve the effectiveness of pretreatment in removing and hydrolyzing the hemicellulose, separating the cellulose from the lignin, and loosening the cellulose structure; (2) reduce the production costs of the enzymes for converting the cellulose to sugars; (3) reduce operating costs by developing more effective enzymes and more efficient microorganisms for converting the sugar products of biomass-deconstruction into biofuels; (4) demonstrate the biochemical-conversion technology on a commercial scale; and (5) begin to optimize capital costs and operating costs. The size of the biorefineries will likely be limited by the supply of biomass available from the surrounding regions. Such limitations could result in potential loss of the economies of scale that characterize large plants.

Findings: Biochemical Conversion

Process improvements in cellulosic-ethanol technology are expected to reduce the plant-related costs associated with ethanol production by up to 40 percent over the next 25 years. Over the next decade, process improvements and cost reductions are expected to come from evolutionary developments in technology, from learning gained through commercial experience and increases in the scale of operation, and from research and engineering in advanced chemical and biochemical catalysts that will enable their deployment on a large scale. Federal support for R&D programs is important for resolving the major technical challenges facing ethanol production from cellulosic biomass: pretreatment, suitable enzymes, tolerance to toxic compounds and products, solids loading, engineering microorganisms, and novel separations for ethanol and other biofuels. Designing the R&D programs with a long-term perspective could address current problems at a fundamental level and contribute to visible industrial goals. Furthermore, R&D programs that are closely coupled with pilot and commercial-scale demonstrations of cellulosic-ethanol plants could help resolve issues that arise during demonstrations.

Biochemical conversion processes, as configured in cellulosic-ethanol plants, produce a stream of relatively pure CO2from the fermenter that can be dried, compressed, and made ready for geologic storage or used in enhanced oil recovery with little additional cost. Geologic storage of the CO2 from biochemical conversion of plant matter (such as cellulosic biomass) further reduces greenhouse gas life-cycle emissions from advanced biofuels, whose greenhouse gas life-cycle

emissions would become highly negative. Because geologic storage of CO2 from biochemical conversion of biomass to fuels could be important in reducing greenhouse gas emissions in the transportation sector, it could be evaluated and demonstrated in parallel with a program of geologic storage of CO2 from coal-based fuels.

Future improvements in cellulosic technology that entail invention of biocatalysts and related biological processes could produce fuels that supplement ethanol production in the next 15 years. In addition to ethanol, advanced biofuels (such as lipids, higher alcohols, hydrocarbons, and other products that are easier to separate than ethanol) should be investigated because they could have higher energy content and would be less hygroscopic than ethanol and therefore could fit more compatibly into the current petroleum infrastructure than ethanol can. Large-scale commercial application of advances in biosciences (genomics, molecular biology, and genetics) and in biotechnologies to convert biomass directly to produce lipids, higher alcohols, and hydrocarbons fuels (that can be directly integrated into the existing transportation infrastructure) poses many challenges. These challenges will need to be resolved by R&D and demonstration if major advances in the production of alternative liquid fuels from renewable resources are to be realized. Research support from the federal government could help focus advances in bioengineering and the expanding biotechnologies on the development of advanced biofuels.

The need to expand the delivery infrastructure to meet a high volume of ethanol deployment could delay and limit the penetration of ethanol into the U.S. transportation-fuels market. Replacing a substantial proportion of transportation gasoline with ethanol will require a new infrastructure for ethanol’s transport and distribution. Although the cost of delivery is a small fraction of the overall ethanol fuel cost, the logistics and capital requirements for widespread expansion could present many hurdles if they are not well planned.

A comprehensive study could be conducted jointly by the DOE and the biofuels industry to identify the infrastructure system requirements of, the research and development needs in, and the challenges facing the expanding biofuels industry. Such a study would consider the long-term potential of truck or barge delivery versus the potential of pipeline delivery that is needed to accommodate increasing volumes of ethanol, in addition to the timing and role of advanced biofuels that are compatible with the existing gasoline infrastructure.

Thermochemical Conversion

Indirect liquefaction converts coal, biomass, or mixtures of coal and biomass to liquid fuels by first gasifying the feedstocks to produce syngas, then cleaning it and adjusting its H2-to-CO ratio (whereupon it is called synthesis gas) and catalytically converting the synthesis gas using Fischer-Tropsch (FT) technology into high cetane, clean diesel, and some naphtha (which can be upgraded to gasoline). The synthesis gas can also be converted into methanol using commercial technology, and methanol-to-gasoline (MTG) technology can then be used to produce high-octane gasoline from the methanol (Figure 5.2). These technologies can be integrated with those that compress the CO2 emitted during production and store it underground—for example, in deep saline aquifers. Unlike ethanol, the gasoline and diesel produced via FT and MTG are fully compatible with the existing infrastructure and vehicle fleet.

Gasification has been used commercially worldwide for nearly a century by the chemical, refining, and fertilizer industries and for more than 10 years by the electric power industry. More than 420 gasifiers are currently in use in some 140 facilities worldwide, with 19 plants operating in the United States. Application to coal-to-liquid-fuel systems, and to combined coal-and-biomass gasification, will lead to further improvements in the technology so that it might become more robust and efficient by 2020. Gasification of biomass alone has been commercially demonstrated but requires added operational experience to render it more robust.

FT technology was first commercialized by the South African firm Sasol in the mid-1950s. Sasol now produces more than 165,000 bbl/d of transportation fuels from coal, and it has built large plants based on conversion of natural gas into synthesis gas, which is then converted into diesel and gasoline by FT. As with several other ready-to-deploy technologies, FT will likely undergo significant process improvements by 2020. For example, more robust and efficient technology for producing liquid transportation fuels, and significant catalyst improvements for coal applications, can be expected.

In technologies based on methanol synthesis, synthesis gas is converted to methanol using available commercial technology; plants as large as 6000 tons per day are currently operating. The methanol can be used directly or upgraded into high-octane gasoline using the proprietary MTG catalytic process developed by ExxonMobil and commercialized in New Zealand in the late 1980s.4 Standard

MTG technology is considered by the committee to be commercially deployable today; a number of projects are in fact moving toward commercial deployment. Meanwhile, several variations on the technology, which could provide improvements, are ready for commercial demonstration.

While the technologies involved in thermochemical conversion of coal have all been commercialized and their operators have logged years of experience, geologic storage of CO2 has not been adequately developed and demonstrated. For power generation from coal, most of the costs for CCS are in the CO2 capture part of the process, and this technology has been demonstrated on a large scale. However, geologic storage of CO2 in the subsurface has not been developed and demonstrated, except for use in enhanced oil recovery, and so there is insufficient confidence in its efficiency and long-term efficacy for commercial application at required scales. This is an important consideration for coal-to-liquid-fuels technology, as its CO2 emissions are high because of the high carbon content of coal (about twice the carbon content of oil). Even with geologic storage of CO2, the well-to-wheel emissions from coal-to-liquid fuels are about the same as those of gasoline because, as for any hydrocarbon fuel, CO2 is released when the fuel is combusted in vehicles.

Inclusion of biomass in the feedstock with coal decreases the greenhouse gas life-cycle emissions because the biomass takes up atmospheric CO2 during its growth. Thus, it is possible to optimize the biomass-plus-coal indirect liquefaction process to produce liquid fuels that have somewhat lower life-cycle greenhouse gas emissions than does gasoline, and even to make carbon-neutral liquid fuels if geologic storage of CO2 is used. Although the notion of gasifying mixtures of coal and biomass to produce liquid fuels is relatively new and commercial experience is limited, several demonstration units are currently running in Europe. The committee judges that the technology for co-feeding biomass and coal is close to being ready for commercial deployment.

Gasifiers for biomass alone, designed around limited biomass availability, operate on a smaller scale than those for coal and thus will be more costly because of the diseconomies of scale of small plants. However, the fuels produced from such plants can have greenhouse gas life-cycle emissions that are close to zero without geologic storage of CO2, and they can have highly negative carbon emissions if geologic storage of CO2 is employed. The committee judges that standalone biomass gasification technology is probably 5–8 years away from commercial scale-up.

Working with the Princeton Environmental Institute, the committee analyzed the costs and CO2 balances for thermochemical conversion of coal and biomass.

In these analyses, the viability of CCS was assumed to have been demonstrated by 2015 so that integrated coal-to-liquid fuel plants could start up by 2020. This assumption is ambitious, and focused and aggressive government action will be needed to make it happen. Four technologies, with and without CCS, were evaluated:

-

A 50,000 bbl/d plant converting coal into diesel and naphtha using FT and then upgrading the naphtha to gasoline.

-

A 50,000 bbl/d plant converting coal into gasoline using MTG.

-

A 4,000 bbl/d plant converting biomass into diesel and naphtha using FT and then upgrading the naphtha to gasoline. The capacity of the plant is limited by the biomass supply of 4,000 dry tons per day.

-

A 10,000 bbl/d plant converting biomass and coal into gasoline and diesel at a 40:60 ratio by feedstock energy (about 4,000 tons per day of biomass) using FT or MTG.

Some key results of the analysis are given in Table 5.4, and the complete results are contained in the report Liquid Transportation Fuels from Coal and Biomass: Technological Status, Costs, and Environmental Impacts (NAS-NAE-NRC, 2009). Details of models can be found in Kreutz et al. (2008) and Larson et al. (2008).

Table 5.4 shows that a large-scale coal plant with a 50,000 bbl/d capacity could produce fuels at a cost of about $50–70/bbl of crude oil (or about $60–80/bbl of gasoline equivalent). However, without CCS, the plant’s CO2 emissions would be double those of petroleum-based gasoline on a life-cycle or well-to-wheels basis. Results with MTG are comparable. But even with CCS, both the FT and the MTG process produce low-cost fuels, and the CO2 emissions are similar to those of petroleum gasoline.

The engineering cost of CCS is about $10–15 per tonne of CO2 avoided. The coal-to-liquid plant configurations produce a concentrated stream of CO2 as an integral part of the process, so CO2 capture can be readily and more cheaply achievable than that, for example, in integrated gasification combined-cycle or pulverized-coal plants. The FT and MTG options without CCS are relevant if reduced CO2 emissions are not desired and if energy supply and diversity of supply are the overriding societal issues. However, in a carbon-constrained world, there will be a drive to produce fuels with zero net CO2 emissions. A plant that used combined coal and biomass as a feedstock with CCS could produce

TABLE 5.4 Fuel Costs and CO2 Emissions for Thermochemical Conversion of Coal and Biomass

|

|

Coal-to-Liquid FT |

Coal-to-Liquid FT |

Coal-to-Liquid MTG |

Coal-and-Biomass-to-Liquid FT |

Biomass-to-Liquid FT |

|

Without CCS |

With CCS |

With CCS |

With CCS |

With CCS |

|

|

Inputs: |

|

|

|

|

|

|

Coal (tons per day as received) |

26,700 |

26,700 |

23,200 |

3,030 |

0 |

|

Biomass (dry tons per day) |

0 |

0 |

0 |

3,950 |

3,950 |

|

Biomass (mass %) |

0 |

0 |

0 |

57 |

100 |

|

Biomass energy (%, low heating value) |

0 |

0 |

0 |

42 |

100 |

|

Outputs: |

|

|

|

|

|

|

Gasoline (bbl/d) |

21,290 |

21,290 |

50,000 |

4,260 |

|

|

Diesel (bbl/d) |

28,700 |

28,700 |

0 |

5,750 |

|

|

Total liquid fuels (bbl/d) |

50,000 |

50,000 |

50,000 |

10,000 |

4,410 |

|

Economic metrics: |

|

|

|

|

|

|

Specific total plant cost ($/bbl per day) |

97,600 |

98,900 |

80,400 |

134,000 |

147,000 |

|

Total liquid fuels cost ($/gal of gasoline equivalent) |

1.50 |

1.64 |

1.57 |

2.52 |

3.32 |

|

Break-even oil price ($/bbl) |

56 |

68 |

51 |

103 |

139 |

|

Emissions relative to petroleum-derived fuels |

2.18 |

1.03 |

1.17 |

−0.02 |

−1.35 |

|

Cost of avoided CO2 ($/tonne)a |

— |

11 |

10 |

15 |

20 |

|

Note: CCS = carbon capture and storage; FT = Fischer-Tropsch; MTG = methanol-to-gasoline. aIncludes the costs of CO2 transport and geologic storage and is expressed as dollars per tonne of CO2 equivalent avoided. |

|||||

10,000 bbl/d of fuels with close to zero CO2 emissions. Note that the case shown is for FT, but the economics would look similar if MTG were used. FT primarily produces diesel; MTG produces gasoline. The economics show that the capital costs of coal-and-biomass-to-liquid fuel plants are higher than the costs of coal-to-liquid fuel plants.

The CO2 emissions are near zero on a life-cycle basis because the biomass in the feedstock is a carbon sink, offsetting some of the coal carbon. The key assumption in this case is that biomass availability is limited to 4000 tons per day by regional harvesting and transportation considerations. In those sites where locally sustainable biomass densities are higher (see Figure 5.1), larger plants—perhaps as many as 100 nationwide—could be built at similar biomass-to-coal

ratios and result in lower cost for carbon-neutral fuels. The last column of Table 5.4 shows the case for gasification with biomass as the single feedstock. The costs are high because of the small plant size, limited by feedstock availability. However, the life-cycle CO2 emissions are net negative, which would be attractive if overall costs of production could be brought down.

The area of greatest uncertainty for conversion of coal and biomass into liquid fuels is the geologic storage of CO2. As of late 2008, few commercial-scale geologic storage demonstrations had been carried out or were ongoing. Yet well-monitored and commercial-scale demonstrations are needed to gather data sufficient to assure industry and governments of the long-term viability, costs, and safety of geologic CO2 storage and to develop procedures for site choice, permitting, operation, regulation, and closure. These objectives are particularly critical to the commercial success of thermochemical technology, which relies on the political and commercial acceptability of large-scale geologic storage of CO2.

The potential costs of CCS of $10–15 per tonne of CO2 avoided are “bottom-up” estimates, based largely on engineering estimates of expenses for transport, land purchase, permitting, drilling, capital equipment, storage, well capping, and monitoring for an additional 50 years. However, uncertainty about the regulatory environment arising from concerns of the general public and policy makers has the potential to raise storage costs and slow commercialization of thermochemical fuel production technology. Ultimate requirements for design, monitoring, carbon-accounting procedures, and liability for long-term monitoring of geologically stored CO2, as well as the associated regulatory frameworks, are dependent on future commercial-scale demonstrations of geologic storage of CO2. These demonstrations will have to be pursued aggressively over the next few years if thermo-chemical conversion of biomass and coal with geologic storage of CO2 is to be ready for commercial deployment in 2020 or sooner.

As a first step toward accelerating the commercial demonstration of coal-to-liquid and coal-and-biomass-to-liquid fuels technology and addressing the CO2 storage issue, commercial-scale demonstration plants could serve as sources of CO2 for geologic storage demonstration projects. So-called capture-ready plants that vented CO2 would create liquid fuels with higher CO2 emissions per unit of usable energy than petroleum-based fuels produce; commercialization of these plants would not be encouraged unless they were integrated with geologic storage of CO2 at their start-up.

Direct liquefaction of coal—which involves relatively high temperature, high hydrogen pressure, and liquid-phase conversion of coal directly into liquid

products—has a long history, as does the FT process. Direct liquefaction products generally are heavy liquids that require significant further upgrading into liquid transportation fuels. The technology is not ready for commercial deployment. Further, because of the absence of recent detailed design studies in the available literature, the committee’s ability to estimate costs and performance is limited.

The three most significant R&D priorities for commercialization of thermochemical technologies are these:

-

Immediate construction of a small number of commercial first-mover projects, combined with geologic storage of CO2, that put the technology on the path toward reduced cost, improved performance, and robustness. These projects would have major R&D components that focus on solving problems identified in the operation of plants and on developing technology for specific improvements.

-

R&D programs, associated with commercial-scale geologic CO2 storage demonstrations, that involve detailed geologic analysis and a broad array of monitoring tools and techniques to provide the data and understanding upon which future commercial projects will depend.

-

Research that determines the penalties associated with preprocessing of biomass, the choice of a best gasifier for a given biomass type, the technical problems with feeding biomass to high-pressure gasification systems, and the answers to related questions. Biomass gasification and combined biomass and coal gasification have potential CO2-reduction benefits, but they can be brought to commercialization only if such practical issues are resolved.

Findings: Thermochemical Conversion

Technologies for the indirect liquefaction of coal to transportation fuels are commercially deployable today; without geologic storage of the CO2produced in the conversion, however, greenhouse gas life-cycle emissions will be about twice those of petroleum-based fuels. With geologic storage of CO2, coal-to-liquid transportation fuels could have greenhouse gas life-cycle emissions equivalent to those of equivalent petroleum-derived fuels.

Technologies for the indirect liquefaction of coal to produce liquid transportation fuels with greenhouse gas life-cycle emissions equivalent to those of petroleum-

based fuels can be commercially deployed before 2020 only if several first-mover plants are started up soon and if the safety and long-term viability of geologic storage of CO2is demonstrated in the next 5–6 years.

Indirect liquefaction of combined coal and biomass to transportation fuels is close to being commercially deployable today. Coal can be combined with biomass at a ratio of 60:40 (on an energy basis) to produce liquid fuels that have greenhouse gas life-cycle emissions comparable to those of petroleum-based fuels if CCS is not implemented. With CCS, production of fuels from coal and biomass would have a carbon balance of about zero to slightly negative. A program of aggressive support for first-mover commercial plants that produce coal-to-liquid transportation fuels and coal-and-biomass-to-liquid transportation fuels with integrated geologic storage of CO2 would have to be undertaken immediately if the United States were to address energy security with those fuels that have greenhouse gas emissions similar to or less than those of petroleum-based fuels. If decisions to proceed with commercial demonstrations are made soon so that the plants could start up in 4–5 years, and if CCS is demonstrated to be safe and viable, those technologies would be commercially deployable by 2020.

The technology for producing liquid transportation fuels from biomass or from combined biomass and coal via thermochemical conversion has been demonstrated but requires additional development to be ready for commercial deployment. For example, key technologies for biomass gasification would have to be demonstrated on an intermediate scale, alone and in combination with coal, to obtain the engineering and operating data required to design synthesis-gas-production units on a commercial scale.

Geologic storage of CO2on a commercial scale is critical for producing liquid transportation fuels from coal without a large adverse greenhouse gas impact. This is similar to the situation for producing power from coal. The operational procedures, monitoring, safety, and effectiveness of commercial-scale technology for geologic storage of CO2 would have to be demonstrated in an aggressive program if geologic storage of CO2 is to be ready for commercial deployment by 2020. Three to five commercial-scale demonstrations (each with about 1 million tonnes of CO2 per year and operated for several years) would have to be set up within the next 3–5 years in areas with different geologic stroage media. The demonstrations would focus on the site choice, permitting, monitoring, operation,

closure, and legal procedures needed to support the broad-scale application of the technology and would provide the needed engineering data and other information to determine the full costs of geologic storage of CO2.

COSTS, CO2EMISSIONS, AND SUPPLY

This section compares the life-cycle costs, CO2 emissions,5 and potential supplies of the alternative liquid fuel options for technologies deployable by 2020. The result of its analyses is a supply curve of fuels that use biomass, coal, or combined biomass and coal as feedstocks.

It should be noted that the supply curve does not represent the actual amounts of fuels that would be commercially available in 2020. Those supplies could well be smaller because of critical lags—both in the decisions to construct new conversion plants and in the construction itself—as discussed in the deployment section that follows. In addition, some of the coal and biomass supplies that appear to be economical might not be made available for conversion to alternative fuels because of logistical, infrastructural, and organizational issues or because they have already been committed to electric power plants. The analyses show how the potential supply curve might change with alternative carbon dioxide prices and alternative capital costs.

As mentioned earlier, the committee worked with several research groups to develop the costs and CO2 emissions of the individual conversion technologies and the cost of biomass. The analyses presented in this section use those inputs to derive life-cycle costs and CO2 emissions for the alternative fuels.

To examine the potential supply of liquid transportation fuels from non-petroleum sources, the committee developed estimates of the unit costs and quantities of various biomass sources that could be made available. The committee’s analysis was based on use of land that is currently not used for growing foods, although the committee cannot ensure that this land would not be used for food production in the future. The estimates of biomass supply were combined with estimates of supply of corn grain to satisfy the current legislative requirement to produce 15 billion gallons of ethanol per year. The analysis allowed the estimation

of a supply curve for biomass that shows the quantities of biomass feedstocks that would potentially be available at various unit costs. Coal was assumed to be available in sufficient quantities at a constant unit cost if used with biomass in thermochemical conversion processes. Quantitative analyses were developed to compare alternative pathways to convert biomass, coal, or combined coal and biomass to liquid transportation fuels using thermochemical technologies. Biochemical technology that produced ethanol from biomass was also evaluated quantitatively on as consistent a basis as possible. Various combinations of biomass feedstocks could, in principle, be converted with either thermochemical or biochemical conversion processes.6 However, rather than examining all possible combinations, the committee first examined the cost of and CO2 emission associated with each of the various thermochemical and biochemical conversion processes by using a generic biomass feedstock with approximately a median cost and biochemical composition (the committee used Miscanthus in the analysis) and then examined the costs, supplies, and CO2 emissions associated with one thermochemical conversion process and one biochemical conversion process that would use each of the different biomass feedstocks. The following assumptions underlie the analyses:

-

All suitable CRP land is allocated to the growing of biomass for liquid fuels. Conversion plants that use biomass as a feedstock by itself or combined with coal (with 60 percent coal and 40 percent biomass on an energy basis) have the capacity of about 4000 dry tons of biomass per day.

-

All product prices are free of government subsidies. The total cost of CO2 avoided, which includes the costs of drying, compression, pipelining, and geologic storage of CO2, is estimated to be in the range of $10–15 per tonne.

-

If a carbon price is imposed, it applies to the entire life-cycle CO2 net emissions—the balance of CO2 removal from the atmosphere by plants, CO2 released in the production of biomass, emissions from conversion of the feedstock to fuel, and emissions from combustion of the fuel. A process that removes more CO2 from the atmosphere than it produces receives a net payment for CO2.

-

No indirect greenhouse gas emissions result from land-use changes in the growing and harvesting of biomass.

-

The price of subbitumimous Illinois #6 coal is $42 per dry ton.

-

Electricity generated as a coproduct is valued at $80/MWh, absent any price placed on greenhouse gas emissions.

-

The biomass and co-fed coal/biomass conversion plants are sized for biomass feed rates of approximately 4000 dry tons per day.

-

The biomass feedstock is Miscanthus, a high-yield perennial grass costing $101 per dry ton.

Costs and CO2Emissions

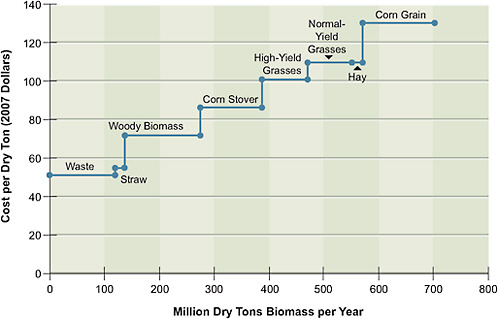

The estimated 2020 supply function for biomass cost versus availability is shown in Figure 5.3. The costs of two of the feedstocks—corn grain and hay—are based on recent market prices. The corn price in particular is assumed to have dropped sharply from the 2008 high of $7.88 per bushel to $3.17 per bushel in 2020, corresponding to $130 per dry ton—a price more consistent with its historical levels. The price of hay is assumed to be $110 per dry ton, also similar to historical prices. The costs of most of the other feedstocks—corn stover, straw, high-yield grasses (such as Miscanthus), normal-yield grasses (such as native and mixed grasses and switchgrass), and woody biomass—are estimated from the growing, harvesting, transportation, and storage costs reported in the literature. Finally, the cost of using municipal solid wastes is based on a rough estimate of the costs of gathering, transporting, and storing them; although such costs can be highly variable, the committee assumes that they add up to $51 per dry ton.

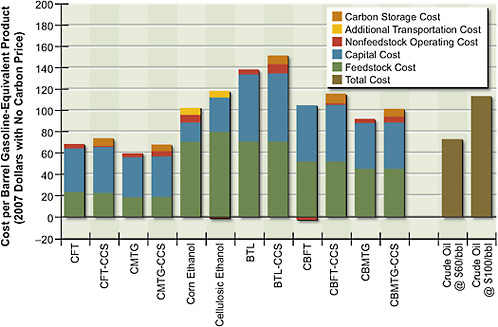

The costs of producing alternative liquid fuels through the various pathways were estimated on the basis of the feedstock, capital, and operating costs, the conversion efficiencies, and the assumptions outlined above. Figure 5.4 shows the estimated gasoline-equivalent7 costs of alternative liquid fuels, without a CO2 price, produced from biomass, coal, or combined coal and biomass. Liquid fuels are produced using biochemical conversion—to make cellulosic ethanol from Miscanthus—or using thermochemical conversion via FT or MTG. For thermochemical conversion, FT and MTG are shown both with and without CCS. The cost of ethanol produced from corn grain is also included in Figure 5.4. For

FIGURE 5.3 Supply function for biomass feedstocks in 2020. High-yield grasses include Miscanthus and normal-yield grasses include switchgrass and prairie grasses.

comparison, costs of gasoline are shown in Figure 5.4 for two different crude oil prices: $60/bbl and $100/bbl (that is, $73 and $113 per barrel of gasoline equivalent). Results are also shown in Table 5.5.

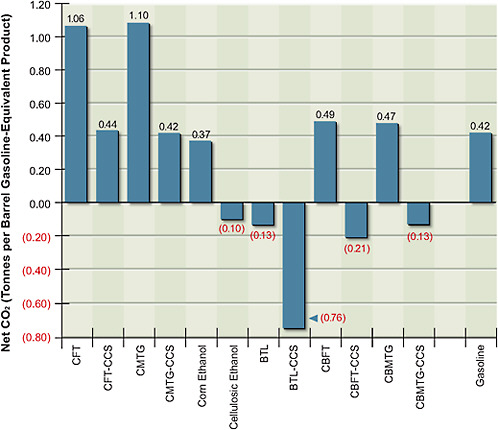

Figure 5.5 shows the net CO2 emissions per barrel of gasoline equivalent produced by various production pathways. The CO2 released during combustion of the fuel is similar among the options, with ethanol releasing less CO2 than is released with either gasoline or synthetic diesel and gasoline. But a large variation in net releases results from the CO2 taken out of the atmosphere when biomass is grown and from the significant differences in CO2 released into the atmosphere during the conversion process. CO2 emissions for corn grain ethanol are slightly lower than those of gasoline. In contrast, CO2 emissions of cellulosic ethanol without CCS are close to zero.

Figure 5.4 shows that FT coal-to-liquid fuel products with and without geologic CO2 storage are cost-competitive at gasoline-equivalent prices below $70/bbl (this represents equivalent crude-oil prices of about $55/bbl) and that prices for MTG are somewhat lower. Figure 5.5 shows that without CCS, both FT and MTG vent a large amount of CO2—over twice that of petroleum gasoline on a

FIGURE 5.4 Cost of alternative liquid fuels produced from coal, biomass, or coal and biomass with no carbon price.

Note: BTL = biomass-to-liquid fuel; CBFT = coal-and-biomass-to-liquid fuel, Fischer-Tropsch; CBMTG = coal-and-biomass-to-liquid fuel, methanol-to-gasoline; CCS = carbon capture and storage; CFT = coal-to-liquid fuel, Fischer-Tropsch; CMTG = coal-to-liquid fuel, methanol-to-gasoline.

life-cycle basis. With CCS, the life-cycle CO2 emissions from FT and MTG are about the same as those from petroleum gasoline.

The biochemical conversion of biomass produces fuels that are more expensive than coal-to-liquid fuels because the conversion plants are small and the feedstock is more expensive—biomass costs almost four times as much as coal on an energy-equivalent basis. The production cost of cellulosic ethanol is around $115/bbl on a gasoline-equivalent basis. The cost of thermochemical conversion of biomass, without coal, is higher than the cost of cellulosic ethanol on an energy-equivalent basis and with geologic storage has the potential for large negative net releases of CO2; that is, the process involves a net removal of CO2 from the atmosphere. For biomass-to-liquid and venting of CO2, the estimated fuel cost is $140/bbl if electricity is sold back to the grid at $80/MWh; with geologic storage of CO2, it is $150/bbl if electricity is sold back to the grid at $80/MWh. The

TABLE 5.5 Estimated Costs of Various Fuel Products With and Without a CO2-Equivalent Price of $50 per Tonnea

results of the relatively small co-fed coal and biomass plant (total feed, 8000 tons per day) are particularly interesting. Fuels produced by that plant cost about $95/bbl on a gasoline-equivalent basis without CCS, and CO2 atmospheric releases from plants with CCS are negative. Those results point to the importance of that option in the U.S. energy strategy.

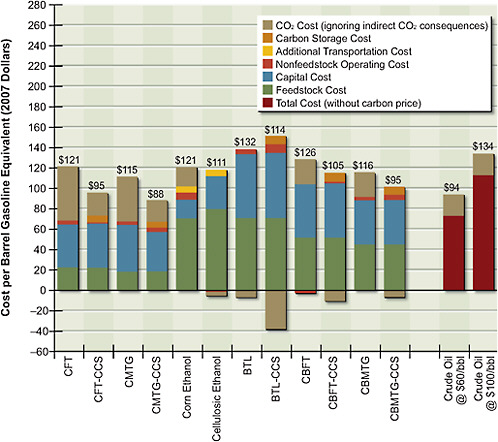

The important influence of CO2 price on fuel price is shown in Figure 5.6. In reading the graph, it is important to note that it shows the breakdown of all costs, including negative costs such as credit from electricity generation or carbon uptake. These negative costs must be subtracted from the positive ones in order to obtain the actual costs. For example, the cost of biomass-to-liquid fuel with CCS is $151/bbl – $37/bbl = $114/bbl. CO2 emissions for corn grain ethanol are slightly lower than for gasoline. In contrast, CO2 emissions of cellulosic ethanol without CCS are close to zero.

Figure 5.6 shows that a CO2 price of $50 per tonne significantly increases the costs of the fossil-fuel options, including the costs of petroleum-based gasoline. The large amount of CO2 vented in the coal-to-liquids process without CO2 storage almost doubles the cost of product once a carbon price of $50 per tonne of CO2 is imposed. The carbon price brings the cost of biochemical conversion options down to about $110/bbl.

FIGURE 5.5 Estimated total carbon dioxide emissions over the life cycle of alternative fuels production—from the mining and harvesting of resources to the conversion to and consumption of fuels.

Note: BTL = biomass-to-liquid fuel; CBFT = coal-and-biomass-to-liquid fuel, Fischer-Tropsch; CBMTG = coal-and-biomass-to-liquid fuel, methanol-to-gasoline; CCS = carbon capture and storage; CFT = coal-to-liquid fuel, Fischer-Tropsch; CMTG = coal-to-liquid fuel, methanol-to-gasoline.

Inclusion of a carbon price does not increase the total costs of all thermochemical pathways. For example, thermochemical conversion of biomass costs about $150/bbl of gasoline equivalent with CCS, but with the carbon price and CCS, the produced fuels become competitive with petroleum-based fuels at about $115/bbl of gasoline equivalent ($100/bbl of crude oil equivalent). In general, if a pathway takes more CO2 from the atmosphere than it releases in other parts of its

FIGURE 5.6 Cost of alternative liquid fuels produced from coal, biomass, or coal and biomass with a $50/tonne CO2price. Negative cost elements must be subtracted from the positive elements; the number at the top of each bar indicates the net costs.

Note: BTL = biomass-to-liquid fuel; CBFT = coal-and-biomass-to-liquid fuel, Fischer-Tropsch; CBMTG = coal-and-biomass-to-liquid fuel, methanol-to-gasoline; CCS = carbon capture and storage; CFT = coal-to-liquid fuel, Fischer-Tropsch; CMTG = coal-to-liquid fuel, methanol-to-gasoline.

life cycle, the inclusion of a carbon price reduces the pathway’s total cost of producing liquid fuel. Note that these estimates are all based on costs for small gasification units operating at a feed rate of 4,000 dry tons per day. If larger units were deployed in regions where potential biomass availability is large—for example, 10,000 dry tons per day—the result could be significantly lower costs.

Costs and Supply

As previously noted, the cost estimates for biochemical conversion and thermochemical conversion are based on only one biomass feedstock, Miscanthus. Moreover, Figures 5.4 to 5.6 do not show how much fuel could be produced at the estimated costs. To provide a more complete picture of alternative liquid fuels, the supply function from Figure 5.3 for all biomass feedstocks has been combined with the conversion-cost estimates. (The potential supply of gasoline and diesel from coal-to-liquids technology is discussed in the section below titled “Deployment of Alternative Transportation Fuels.”) The results are presented in Figures 5.7 and 5.8.

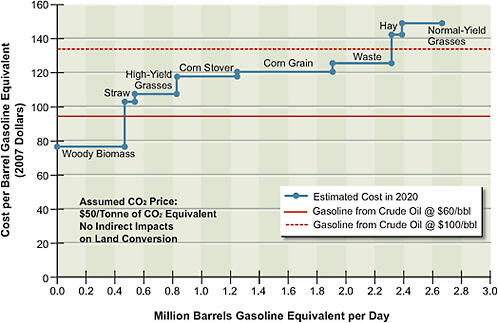

Figure 5.7 shows the potential gasoline-equivalent supply of ethanol from biochemical conversion of lignocellulosic biomass and corn grain, with technology deployable in 2020. The supply of grain ethanol satisfies the current legislative requirement to produce 15 billion gallons of ethanol per year in 2022. Figure 5.7

FIGURE 5.7 Estimated supply of cellulosic ethanol plus corn grain ethanol at different price points in 2020. The red solid and dotted lines show, for comparison, the supply of crude oil at $60 and $100 per barrel.

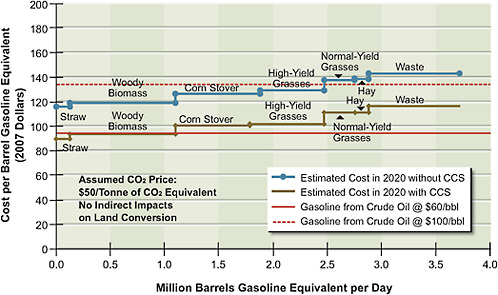

FIGURE 5.8 Estimated supply of gasoline and diesel produced by thermochemical conversion via Fischer-Tropsch, with or without CCS, at different price points in 2020.

shows potential supply and not the committee’s projected penetration of cellulosic ethanol in 2020. This is because it does not incorporate lags in implementation of the technology that will result because of the time required to obtain permits for and build the infrastructure to produce and transport these alternative liquid fuels. The estimated supply of synthetic gasoline and diesel derived from coal and biomass as feedstocks is shown in Figure 5.8. Two different supply functions are plotted, one with CCS and the other without CCS. They show that if the CCS technologies are viable and a price of $50 per tonne of CO2 is implemented, then for each feedstock it will be less costly to use CCS than to release the CO2 into the atmosphere.

Either of the production processes underlying Figures 5.7 or 5.8 would use the same supplies of biomass. Therefore the quantities cannot be added. If all of the production (in addition to ethanol produced from corn grain) were based on cellulosic conversion, the quantities shown in Figure 5.7 would be applicable. If all production were based on thermochemical conversion co-fed with biomass and coal, then the quantities shown in Figure 5.8 would be applicable. Most likely, some of the production would be based on cellulosic processes and some based

on thermochemical processes, so the actual potential supply function would lie between the two sets of supply functions shown in Figures 5.7 and 5.8. If corn grain ethanol (shown in Figure 5.7) has not been phased out by 2020, it would add about 0.67 million barrels per day of gasoline-equivalent production to the supply.

To put the results in perspective, the gasoline and diesel used by light-duty vehicles (LDVs) in the United States in 2008 was estimated to be about 9 million barrels of oil equivalent per day (1 bbl of crude oil produces about 0.85 bbl of gasoline equivalent). Total liquid fuels used in the United States was 21 million barrels per day, 14 million of which were used for transportation and 12 million of which were imported. Thus the 2 million barrels of gasoline equivalent of ethanol produced from cellulosic biomass and the 0.7 million barrels of gasoline equivalent of ethanol produced from corn grain have the potential to replace about 30 percent of the U.S. petroleum-based fuel consumed by LDVs, or almost 20 percent of all transportation fuels.

The potential supply of gasoline or diesel fuel from thermochemical conversion of a combination of biomass and coal (with CCS) is greater than with biochemical conversion of biomass alone. Moreover, the costs of thermochemical conversion of combined coal and biomass are lower than those of either biochemical or thermochemical conversion of biomass alone. The cost differences occur because coal is a lower-cost feedstock than is biomass. In addition, co-feeding coal and biomass allows a larger plant to be built and reduces capital costs per volume of product.

Using 60 percent coal and 40 percent biomass on an energy basis, almost 4 million barrels per day of gasoline equivalent—and thus of oil—can potentially be displaced from transportation. This would amount to 60 billion gallons of gasoline equivalent per year, or almost 45 percent of the gasoline and diesel used by LDVs in 2008. (The calculation assumes that all of the 550 million dry tons of cellulosic biomass sustainably grown for fuel will be used for coal-and-biomass-to-liquid fuel production. Thus the estimates represent the maximum potential supply.)

Findings: Costs and Supply

Alternative liquid transportation fuels from coal and biomass have the potential to play an important role in helping the United States to address issues of energy security, supply diversification, and greenhouse gas emissions with technologies that are commercially deployable by 2020.

-

With CO2emissions similar to those from petroleum-based fuels, a substantial supply of alternative liquid transportation fuels can be produced with thermochemical conversion of coal with geologic storage of CO2 at a gasoline-equivalent cost of $70/bbl.

-

With CO2emissions substantially lower than those from petroleum-based fuels, up to 2 million barrels per day of gasoline-equivalent fuel can technically be produced with biochemical or thermochemical conversion of the estimated 550 million dry tons of biomass available in 2020 at a gasoline-equivalent cost of about $115–140/bbl. Up to 4 million barrels per day of gasoline-equivalent fuel can be technically produced if the same amount of biomass is combined with coal (60 percent coal and 40 percent biomass on an energy basis) at a gasoline-equivalent cost of about $95–110/bbl. However, the technically feasible supply does not equal the actual supply inasmuch as many factors influence the market penetration of fuels.

DEPLOYMENT OF ALTERNATIVE TRANSPORTATION FUELS

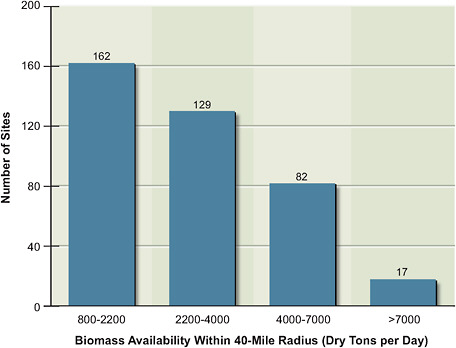

The discussion in this chapter thus far has addressed the potential supply of alternative transportation fuels from technologies ready to be commercially deployed by 2020; potential supply, however, does not translate into what will be available at that time. The rates at which alternative liquid fuels can penetrate the market will depend on many variables. In addition to technological readiness, they include such factors as oil price, carbon taxes, the construction environment, and labor availability. To illustrate the lag between the time when technology becomes commercially deployable and the time when significant market penetration of its product occurs, the committee developed a few plausible scenarios.

Cellulosic Ethanol

Regarding biochemical conversion to cellulosic ethanol, the committee took into account the current activities with demonstration plants, the announced commercial plants, the DOE road map, and the rate of construction of grain ethanol plants. It assumed that a capacity of 1 billion gallons per year of cellulosic ethanol would be achievable by 2015 and that the capacity build beyond 2015 would

follow one of two scenarios. The first tracks the maximum capacity build experienced with grain ethanol (about a 25 percent yearly increase in capacity over a 6-year period); the second scenario is an aggressive capacity build rate that is approximately twice that achieved for grain ethanol. The two scenarios project 7–12 billion gallons of cellulosic ethanol per year (about 0.3–0.5 million barrels of gasoline equivalent per day) by 2020. Continued aggressive capacity build could conceivably achieve the Renewable Fuel Standard’s8 mandated capacity of 16 billion gallons of cellulosic ethanol per year by 2022, but this would be a stretch. Continued aggressive capacity build could yield 30 billion gallons of cellulosic ethanol per year by 2030 and up to 40 billion gallons per year of cellulosic ethanol by 2035. The latter would consume about 440 million dry tons of biomass annually and replace 1.7 million barrels per day of petroleum-based fuels.

Coal-to-Liquid Fuels with CCS

If commercial demonstrations of coal-to-liquids fuel production with CCS were begun immediately and CCS were proven viable and safe by 2015, commercial plants could be starting up before 2020. The subsequent growth rate could be about two to three plants per year. This scenario would reduce dependence on imported oil, but it would not reduce CO2 emissions from transportation. At a build-out rate of two plants (at 50,000 bbl/d of fuel) per year, 2 million bbl/d of liquid fuels would be produced from 390 tons of coal annually by 2035, at a cost of about $200 billion. At a build-out rate of three plants per year, 3 million bbl/d of liquid fuels would be produced from 580 million tons of coal each year. The latter case would replace approximately one-third of the current U.S. oil use in light-duty transportation and increase U.S. coal production by 50 percent. At a build-out rate of three plants starting up per year, five to six plants would be under construction at any one time.

Coal-and-Biomass-to-Liquid Fuels

The technology for co-fed biomass and coal plants is close to being developed, and several commercial plants without CCS have in fact started to co-feed bio-

mass. Although this will allow them to acquire some operational experience and reduce cost, gaining experience with CCS in particular is critical, as it will probably be required. Because coal and biomass plants are much smaller than coal-to-liquid fuel plants (at 10,000 bbl/d of fuel, a coal-and-biomass-to-liquid fuel plant size is one-fifth the size of a coal-to-liquid fuel plant), biomass feed rates are similar to those of cellulosic ethanol plants. Thus, penetration rates should in principle closely follow the cellulosic plant build out. But most likely the coal and biomass build out will be much slower than the aggressive rate of building cellulosic plants just presented because of more complex plant design and the need to site the plants near both biomass and coal production.

Thus, the committee assumed that penetration rates of the coal-and-biomass-to-liquid fuel plants will be slightly less than that of the cellulosic ethanol buildout case that follows the experience of grain ethanol (which has experienced a 25 percent average annual growth rate). At a 20 percent average annual growth rate until 2035, when 280 plants would be in place, 2.5 million bbl/d of gasoline equivalent would be produced. This would consume about 300 million dry tons of biomass (less than the projected biomass availability) and about 250 million tons of coal per year. The analysis shows that capacity growth rates would have to exceed historical rates considerably if 550 million dry tons per year of biomass were to be converted to liquid fuels in 2030.

Findings: Coal-and-Biomass-to-Liquid Fuels

If commercial demonstration of cellulosic-ethanol plants is successful and commercial deployment begins in 2015, and if it is assumed that capacity will grow by 50 percent each year, cellulosic ethanol with low CO2life-cycle emissions can replace up to 0.5 million barrels of gasoline equivalent per day by 2020 and 1.7 million barrels per day by 2035.

If commercial demonstration of coal-and-biomass-to-liquid fuel plants with carbon capture and storage is successful and the first commercial plants start up in 2020, and if it is assumed that capacity will grow by 20 percent each year, coal-and-biomass-to-liquid fuels with low CO2life-cycle emissions can replace up to 2.5 million barrels of gasoline equivalent per day by 2035.

If commercial demonstration of coal-to-liquid fuel plants with carbon capture and storage is successful and the first commercial plants start up in 2020, and if

it is assumed that capacity will grow by two to three plants each year, coal-to-liquid fuels with CO2life-cycle emissions similar to those of petroleum-based fuels can replace up to 3 million barrels of gasoline equivalent per day by 2035. That option would require an increase in U.S. coal production by 50 percent.