9

Electricity Transmission and Distribution

Electric power transmission and distribution (T&D) in the United States, the vital link between generating stations and customers, is in urgent need of expansion and upgrading. Growing loads and aging equipment are stressing the system and increasing the risk of widespread blackouts. Modern society depends on reliable and economic delivery of electricity.

Recent concerns about T&D systems have stemmed from inadequate investment to meet growing demand, the limited ability of those systems to accommodate renewable-energy sources that generate electricity intermittently, and vulnerability to major blackouts involving cascading failures. Moreover, effective and significant utilization of intermittent renewable generation located away from major load centers cannot be accomplished without significant additions to the transmission system. In addition, distribution systems often are incompatible with demand-side options that might otherwise be economical. Modernization of electric T&D systems could alleviate all of these concerns.

The U.S. T&D system has been called the world’s largest machine and part of the greatest engineering achievement of the 20th century (NAE, 2003). This massive system delivers power from the nearly 3000 power plants in the United States to virtually every building and facility in the nation.

This chapter reviews the status of current T&D systems and discusses the potential for modernizing them (thus creating the “modern grid”). The focus is on the technologies involved—their potential performance, costs, and impacts—and potential barriers to such a deployment in the United States over the next several decades.

BACKGROUND

The Current Transmission and Distribution System

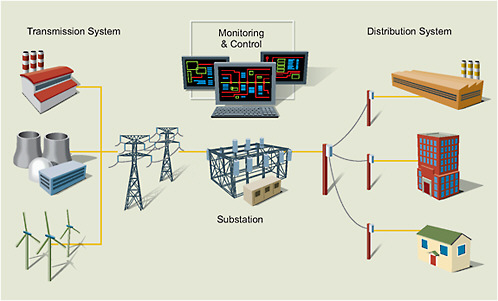

T&D involves two distinct but connected systems (as shown in Figure 9.1):

-

The high-voltage transmission system (or grid) transmits electric power from generation plants through 163,000 miles of high-voltage (230 kilovolts [kV] up to 765 kV) electrical conductors and more than 15,000 transmission substations. The transmission system is configured as a network, meaning that power has multiple paths to follow from the generator to the distribution substation.1

-

The distribution system contains millions of miles of lower-voltage electrical conductors that receive power from the grid at distribution substations. The power is then delivered to 131 million customers via the distribution system. In contrast to the transmission system, the distribution system usually is radial, meaning that there is only one path from the distribution substation to a given consumer.

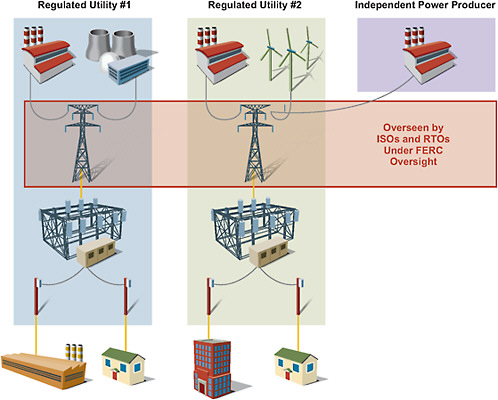

The U.S. T&D system includes a wide variety of organizational structures, technologies, economic drivers, and forms of regulatory oversight. Federal, state, and municipal governments and customer-owned cooperatives all own parts of these systems, but approximately 80 percent of power transactions occur on lines owned by investor-owned regulated utilities (IOUs). These fully integrated utilities own generating plants as well as the T&D systems that deliver the power to their customers. In the past, this was the dominant model, but deregulation in some states has transformed the industry. In deregulated areas, generation, transmission, and distribution may be handled by different entities. For example, independent power producers (IPPs) may sell power to distribution utilities, or even directly to end users, using the transmission system as a common carrier (as shown in Figure 9.2).

The Federal Energy Regulatory Commission (FERC) has long had the authority to regulate financial aspects of the transmission of electricity in inter-

FIGURE 9.1 The current T&D system comprises two distinct but connected systems: transmission and distribution.

Source: Courtesy of NETL Modern Grid Team.

state commerce. The Energy Policy Act of 2005 expanded FERC’s mandate, giving it the authority to impose mandatory reliability standards on the bulk transmission system and to impose penalties on entities that manipulate electricity markets. As part of its new authority, FERC has in turn granted the North American Electric Reliability Corporation (NERC)—a private organization created by the utility industry in 1968 to advise on reliability—the authority to develop and enforce reliability standards. The National Institute of Standards and Technology also is involved in developing standards for the grid.

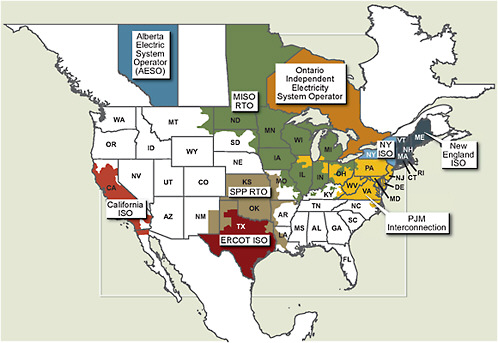

In some areas, independent system operators/regional transmission operators (ISO/RTOs) are responsible for operating the transmission system reliably, including constantly dispatching power to balance demand with supply and monitoring the power flows over transmission lines owned by other public or private entities. The ISO/RTOs, with oversight by FERC and NERC, monitor their systems’ capac-

FIGURE 9.2 Key players in the T&D system. Power is produced by regulated investor-owned utilities (IOUs), which own the majority of the T&D systems, and in some areas by independent power producers (IPPs). IOUs typically provide electricity to end users through their own distribution systems, while IPPs sell to a utility or purchase transmission services to deliver electric power directly to an end user. There are also utilities that are federally or locally owned, such as municipal and rural co-ops. Most of these utilities own generating plants as well as T&D lines.

Source: Courtesy of NETL Modern Grid Team.

ities and conduct the wholesale market to clear short-term transactions.2 There are nine ISO/RTOs in North America, as shown in Figure 9.3. Seven of the nine come

FIGURE 9.3 Independent System Operators (ISO) and Regional Transmission Organizations (RTO) in North America. Regions in which the power industry has been restructured, such as Texas, the Northeast, the Upper Midwest, and much of California, are colored. In these areas, ISO/RTOs are responsible for operating the transmission system. In the white regions, where the industry has not been restructured, vertically integrated power utilities continue to operate the transmission system.

Source: North American Electric Reliability Corporation.

under FERC’s reliability oversight. The remaining two are subject to Canadian regulations.

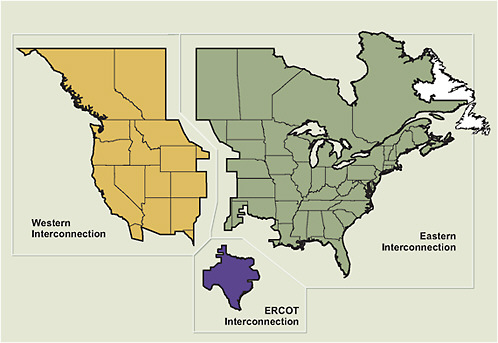

Operationally, the electric transmission systems of the United States and Canada are divided into four large regions known as “interconnections,” as shown in Figure 9.4:

-

The Eastern Interconnection, which includes most of the United States and Canada from the Rocky Mountains to the Atlantic coast;

FIGURE 9.4 North American power interconnections. The Quebec Interconnection is shown as part of the Eastern Interconnection because operations are coordinated.

Source: North American Electric Reliability Corporation.

-

The Western Interconnection, which extends from the Pacific coast to the Rockies;

-

The ERCOT Interconnection, which encompasses most of Texas;

-

The Quebec Interconnection, which is shown in Figure 9.4 as part of the Eastern Interconnection because they are operated jointly.

Within each interconnection, all generators operate in synchronism with each other. That is, the 60-Hertz alternating current (AC) is exactly in phase across the entire interconnection. While all interconnections operate at 60 Hz, no attempt is made to synchronize them with each other. Electricity is transmitted between interconnections, but that is done by converting to direct current (DC) and then back to AC.

Controlling the dynamic behavior of this interconnected transmission system presents an engineering and operational challenge. Demand for electricity is constantly changing as millions of consumers turn on and off appliances and industrial equipment. The generation of and demand for electricity are balanced regionally by about 140 balancing authorities to ensure that voltage and frequency are maintained within narrow limits (typically 5 percent for voltage and 0.02 Hz for frequency). If more power is drawn from the grid than is being pumped into it, the frequency and voltage will decrease, and vice versa. If the voltage or frequency strays too far from its prescribed level, the resulting stresses can lead to system collapse and possibly damage to power system equipment.

Problems with the Current System

Most U.S. transmission lines and substations were constructed more than 40 years ago and are based on 1950s’ technology, but demands on the electric power system have increased significantly over the years. Since 1990, electricity generation has risen from about 3 trillion kilowatt-hours (kWh) to about 4 trillion in 2007. Long-distance transmission has grown even faster for reliability and economic reasons, including new competitive wholesale markets for electricity, but few new transmission lines have been built to handle this growth.3

Figure 9.5 shows transmission investment from 1975 to 2007. From 1985 through 1995, transmission investment was fairly stable at the level of about $4.5 billion per year. Although this was about $2 billion per year lower than during the previous decade, reserve margins4 were adequate because of prior over-building and slow growth in demand. However, in the late 1990s, the restructuring and re-regulation of the U.S. transmission system led to a decrease in invest-

FIGURE 9.5 Transmission investment by integrated and stand-alone transmission companies. The IOU data cover only 80 percent of the transmission system. All investment is shown in 2007 dollars. Data were adjusted as necessary using the Handy-Whitman index of Public Utility Construction Costs.

Sources: 1975–2003 from EEI, 2005; 2000–2007 from Owens, 2008.

ment. This decrease “was principally due to uncertainty in the rate of return on investment (and whether it would be modified or disallowed in future years) offered to transmission owners/investors” (EPRI, 2004). Transmission investment averaged about $3 billion per year from 1995 to 2000.

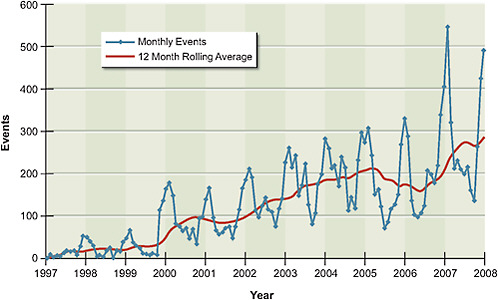

The deficit of the late 1990s is still affecting reliability; it has contributed to transmission bottlenecks and other transmission deficiencies throughout North America, even with the more recent upward trend in transmission expenditures since 2000. According to NERC, the transmission system is being operated at or near its physical limits more of the time (Nevius, 2008). Stressed grids have less reserve margin for handling disturbances. Figure 9.6 shows the increase in transmission loading relief events. (TLR is a measure of when scheduled transmission requests could not be accommodated.5)

Inadequate system maintenance and repair also have contributed to an

FIGURE 9.6 Transmission loading relief (TLR) events. The number of TLR events is not an outage measure; it is the number of times a congestion limit is reached. Although this measure has been used to characterize transmission reliability, congestion limits can be reached purely for market reasons.

Source: See www.nerc.com/docs/oc/scs/logs/trends.htm.

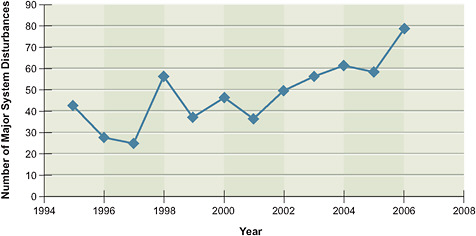

increase in the likelihood of major transmission system failures (EPRI, 2004), and the number of such disturbances has in fact been increasing in recent years, as shown in Figure 9.7. Of greatest concern is the risk of these disturbances cascading over large portions of the T&D systems. The 2003 blackouts in the world’s two largest grids—the North American Eastern Interconnection and the West European Interconnection—resulted from such cascading failures (see Box 9.1). Each event affected 50 million people.

Another result of diminished investment in transmission is that the manufacturing of associated equipment has largely disappeared from the United States, along with commercial research and development (R&D) for transmission equipment (including transformers, switchgear, and high-voltage DC [HVDC] technology). Today, essentially all large power-transmission equipment is imported from Europe and Japan. This could become a potentially

FIGURE 9.7 Major transmission system disturbances reported to NERC. Disturbances include electric service interruptions, unusual occurrences, demand and voltage reductions, public appeals, fuel supply problems, and acts of sabotage that can affect the reliability of the bulk electric systems.

Source: Compiled from data in NERC, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, and 2006.

serious problem, especially with long lead-time components, in case of major natural disaster or terrorist attack.

Modernization is progressing much more rapidly abroad. For example, China and India are building 800 kV HVDC and 1000 kV AC transmission lines, along with the underlying high-power infrastructure. About 30 high-power HVDC projects are under construction in Europe, including many submarine cable connections to increase utilization of offshore wind power. Two-way metering is common in Europe because it helps to maximize the potential of rooftop photovoltaics, which are being heavily promoted in Germany and other countries. Although the United States has vast potential for wind and solar generation, there is no consensus or plan for how this power could be transmitted to load centers.

While expenditures on the replacement and new construction of American T&D assets have increased recently (see Figure 9.5), grid assets are aging, and investments are still not keeping pace with the growing demand for electric power and power marketing. To meet these challenges, transmission

|

BOX 9.1 The Northeast Blackout of August 14, 2003 A modern T&D system could have helped to avoid the circumstances that initiated the August 2003 Northeast blackout. Two major issues contributed to this blackout: first, the operators did not know the system was in trouble; and second, there was poor communication between the utilities operating the transmission lines—First Energy and American Electric Power—and also between these utilities and the ISO responsible for the area (the Midwest Independent System Operator). The U.S.-Canada Power System Outage Task Force (2004) noted that four major factors contributed to the blackout:

A modern T&D system could have provided better understanding of the state of the system, better communications, and, ultimately, better controls. Adequate monitoring, communication, and dynamic reactive power support during the initial voltage sag could have helped to prevent lines from overloading, heating up, and sagging excessively. Operators would have been better informed, and online real-time dynamic contingency analysis of potential system collapse would have helped operators stay aware of possible risks and actions to be taken in response. Finally, automatic actions could have been taken to island (isolate) portions of the system and prevent the ultimate cascading event (which spread the localized outage across much of the northeast United States and Canada). The system could also have been restored much more rapidly if a modern grid had been in place. |

systems must be modernized—a complex but vital undertaking.6 However, orders for modern transmission technologies remain low, largely because they are perceived to be risky and uneconomic,7 as discussed in more detail later in this chapter. Thus if business continues as usual, investment will focus on new construction to meet peak load growth, which is projected to increase

|

6 |

Modernization is defined here as the deployment of a suite of technologies (described in the coming sections) that will enable the T&D systems to meet a variety of challenges, particularly the seven characteristics (adapted from NETL, 2007d) discussed in more detail in the section titled “A Modern Electric T&D System.” |

|

7 |

This view was presented repeatedly to the committee by industry representatives, including those representing Southern California Edison Co., Areva, ABB, and Siemens. |

by 0.7 percent per year to 20308 according to the reference case of the DOE Energy Information Administration (EIA, 2008) and the replacement of aging components with equivalent technology.

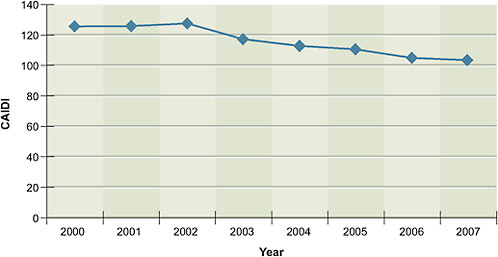

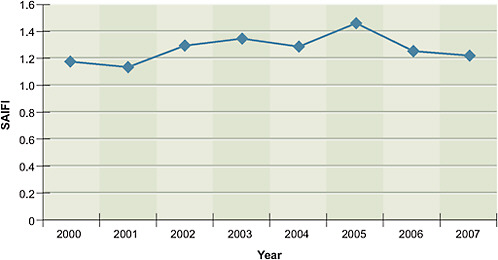

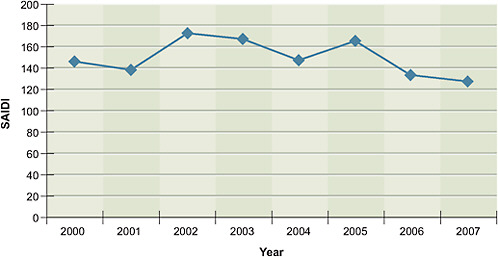

Distribution systems are in better condition. Reliability, for example, has increased steadily over the last 7 years—in part because these systems have to be enlarged to handle new consumers. Public utility commissions usually provide revenue incentives based on indexes, shown in Annex 9.A, that directly measure customer service reliability. Consequently, the distribution companies have improved or at least held steady their customer outage statistics.9

Growth provides the opportunity for distribution companies to introduce new and smarter technologies on a limited basis before undertaking a wider application. For example, a utility can introduce modern, smart technologies on a substation-by-substation basis as it is determined that portions of the distribution network need upgrading. The nature of the distribution system allows upgrades to be done in such “modular” steps.

Addressing the Problems

T&D systems will require considerable investment just to maintain current capabilities and reliability, and the use of new technology could make the grid considerably more resilient. For example, the present system of local automatic controls overseen by human operators at regionally based control centers is not able to adequately foresee that disturbances in Cleveland can black out New York, Toronto, and Detroit, or that transmission outages in Switzerland can black out all of Italy. Modern communications and controls can move much faster to diagnose problems and bypass or isolate them. The same technology can provide cost benefits by maximizing power flows and integrating power from renewable energy sources.

New technology is an important part of the answer to the challenges facing the grid, but policy and regulatory changes will also be needed, particularly with

respect to the transmission system. Policies regarding T&D systems are varied and imposed by many entities; there is significant public resistance to siting new transmission lines; and the business cases for utilities to invest in modern grid processes and technologies are often incomplete, as societal costs and benefits are not typically internalized in companies’ decision making. For example, the cost of not having power when it is needed is far greater to the user than the lost revenues to the utility that cannot provide it. Recognizing the value of a reliable, efficient, and flexible grid, and supporting the investments to make that possible, may require a national-level strategy.

As discussed below in this chapter, expanding and modernizing distribution systems will require considerably more investment than for transmission systems. Much of the expansion will be noncontroversial because it will be required to meet growing loads and can be done without much impact on people who do not directly benefit from it. In addition, modernization of distribution can be achieved on a more limited basis than for transmission, which will require coordination across many systems. Therefore, the emphasis in this chapter will be on transmission.

A MODERN ELECTRIC T&D SYSTEM

A modern T&D system should have capabilities beyond the reach of current systems through their incorporation of new technologies (hardware and software). They must also be expanded to meet future needs. New technologies such as power electronics, real-time thermal rating of transmission lines, and composite conductors can allow an increase in power flow on the existing T&D system, but new lines also will be needed.

Modern T&D systems are intended to provide effective operation, asset optimization, and systems planning capabilities under routine conditions and emergency response and fast restoration after a system failure. The characteristics required to achieve these performance standards are as follows:10

-

Accommodates all generation and storage options. A modern transmission infrastructure would include emerging technologies such as large-scale variable power sources and advanced energy storage devices. For example, it could smooth the variability of power from remotely located intermittent renewable resources11 and maintain reactive power12 on the system. The distribution system should be able to accommodate increasing amounts of distributed generation—often variable (such as rooftop photovoltaic devices)—and smaller-scale advanced energy storage devices.

-

Enables wholesale power markets. A modern T&D system should be enlarged to handle increased long-distance power flows and equipped with new communications and control capabilities to manage the vast amount of information required for wholesale power transactions (NETL, 2007a). In addition, the distribution system should enable the end user to participate in power markets by allowing self-generation opportunities.

-

Is self-healing. A modern T&D system would incorporate methods to automatically stop outages before they spread, thereby preventing major system collapses.13 If a major system did collapse, the means would be available to isolate the problem, prevent it from spreading, and restore it rapidly and effectively. A modern T&D system would be able to monitor the state of the system, communicate key information to control centers, and take appropriate action automatically.

-

Motivates and includes the customer. The modern distribution system would empower customers to make end-use decisions that increase

-

energy efficiency, help in load-leveling,14 and enable residential and small-scale power generation. It would allow for self-generation and storage as well as for customers to participate in an interactive mode by responding to price signals.

-

Provides high power quality where needed. The modern distribution system would be capable of supplying higher “power quality”15 where needed for a digital society that increasingly relies on sensitive microprocessor-based devices in homes, offices, commercial buildings, and industrial facilities. The highest power quality is not necessarily cost-effective for all users, so some may still need to provide additional sources of power, standby generation, or other devices that can ride through minor electrical disturbances on either the transmission or the distribution system.

-

Is secure. The modern T&D infrastructure would be minimally vulnerable to human error, natural disasters, and physical and cyber attacks. Resilience would be built into each element, and the overall system would be designed to deter, detect, respond to, and recover from any plausible disruption. The modern transmission system would also reduce the consequences of a successful attack through its self-healing and “islanding”16 capabilities.

-

Optimizes assets and operates efficiently. A modern transmission system would utilize power lines as efficiently as possible, integrating and coordinating assets to maximize their overall function in an economical way.

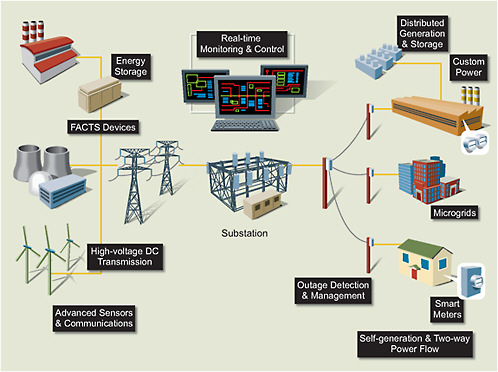

These characteristics cannot be fully achieved by introducing individual modern technologies in isolation. Key technologies (such as high-speed measurements and communications and automated controls, discussed in the sections that follow) must be integrated using a systems approach designed to meet performance

FIGURE 9.8 Components of a modern T&D system.

Source: Courtesy of NETL Modern Grid Team.

goals and metrics. A set of technologies that could be integrated as part of a modern grid is shown in Figure 9.8 and discussed in the following section.

KEY TECHNOLOGIES FOR A MODERN ELECTRIC T&D SYSTEM

Many of the technologies needed for a modern T&D system already exist, and some, to a limited extent, are already deployed in parts of the T&D systems. However, many technologies will need to be deployed in a systematic and integrated way to realize maximum benefits from a modernized T&D system. These technologies can be roughly divided into three categories: (1) advanced equipment and components; (2) measurements, communications, and controls; and

(3) improved decision-support tools. The major technologies within each category are discussed in the following sections, and the annex provides more detail.

Advanced Equipment and Components

Advanced equipment and components include technologies for improving and controlling power flows, enabling greater efficiency in long-distance transmission, storage of electrical energy (to be dispatched into the grid as needed), and grid operation. Advanced electronic equipment is also being used for smart metering and control in the distribution networks. The status of these technologies, likely future technology improvements, and potential for deployment into the T&D system are addressed in the five subsections below.

Power Electronics

A T&D system requires power-flow control and protection against overloads and instability. The electromechanical devices currently used for these purposes are slow and cannot react quickly enough to handle rapid transients, but modern solid-state power electronics can overcome this problem. Power electronics are not new, but their deployment has been limited to particular applications in which their higher cost is offset by their benefits to investors. Power electronics can be used in the transmission system (for both AC and HVDC applications),17 and in the distribution system.

Power electronics on the AC transmission system are referred to as flexible alternating current transmission system (FACTS) devices.18 FACTS devices can control both real and reactive power flows along transmission corridors, thereby maintaining the stability of transmission voltage. FACTS devices can also increase the power transfer capability of transmission lines and improve overall system reliability by reacting virtually instantaneously to disturbances. FACTS can enable wholesale markets, increase security, enable self-healing capacity, and optimize the use of system assets by controlling the flow of power, and they can help to

|

17 |

The transmission system in the United States is almost entirely AC. Transmitting electricity via HVDC involves converting AC to DC, transmitting the electricity in DC, and converting it back to AC at the receiving end. |

|

18 |

Annex 9.A describes specific flexible alternating current transmission system (FACTS) devices and their applications in more detail. |

integrate variable renewables by managing reactive power. FACTS devices are currently available and are already deployed in limited applications.

Power electronics also can be used for lower-voltage applications on distribution systems, where the equivalent to FACTS is known as custom power. Custom power devices can provide for significant improvement in power quality on the customer side by controlling voltage and frequency distortions. High power quality is needed for many modern applications, especially in industries with automated production, which could benefit from more economical local solutions to improved power quality. Power electronics also plays an important role in smart metering with two-way power flow (to encourage local power generation) and in real-time pricing (to shift loads away from expensive peak demand periods).

Custom power technologies that offer such solutions exist now, but their application is restricted to situations where their high cost is offset by significant benefits. R&D could help reduce costs and expand their use by 2020.

AC and DC Lines and Cables

A cost-effective way to obtain extra transmission capacity is to upgrade transmission lines and corresponding substations along existing corridors. Transmission capacity can be increased by “reconductoring” existing lines (using materials such as composite conductors that can carry higher current). These materials are presently available but not widely deployed; taking lines out of service for reconductoring is difficult, and new materials are expensive. In addition, all overhead lines can carry current higher than their nominal rating when weather conditions are favorable, and real-time rating that could be continuously adjusted would increase available capacity.19

HVDC becomes cost-effective at long distances, where the reduced capital costs of the lines and reduced energy losses can compensate for the cost of the converters.20 For example, long-distance, high-power HVDC transmission could

aid in the deployment of large-scale wind generation and, potentially, solar generation by 2020;21 these energy sources are regional, intermittent, and often far away from major population centers. As the down periods for wind vary from region to region, long-distance transmission would help to pool such resources for transmitting the power to load centers. HVDC also is less expensive than AC if lines need to be underground—for example, when passing through pristine areas. Several HVDC lines already exist in the country, and, if planning is started within the next few years, several more large lines22 could be completed before 2020.

Further R&D on advanced materials and nanotechnology could lead to improved lightweight insulators, high-temperature low-sag conductors, and light-weight high-strength structures after 2020. In the longer term, breakthroughs in superconducting materials are needed for superconducting cable technology to become widespread. This is unlikely to occur until after 2030.

Storage

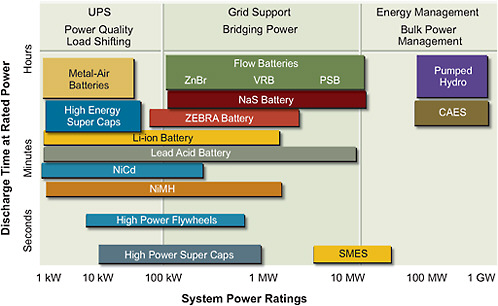

Cost-effective storage would be useful both on transmission and on distribution systems. Transmission systems require large-scale storage capacity with high power ratings (on the order of hundreds of megawatts) and long discharge times (hours to days). The variable power output of renewable resources is currently managed by standby generation, but as large-scale and remote wind or solar generation facilities are built, such storage technologies would be very beneficial for the transmission system that must deliver the power. Today, this type of storage is largely limited to pumped hydro storage, where water is pumped uphill into a reservoir and released to power turbines when needed. Another technology that has been demonstrated and is currently available for commercial deployment is compressed air energy storage (CAES).23 A CAES plant stores energy by using electricity (from off-peak hours) to compress air into an underground geologic formation (or potentially in aboveground tanks). The energy is recovered when a combustion turbine burns natural gas in this compressed air in lieu of operating

|

21 |

These electricity sources are discussed in detail in Chapter 6. |

|

22 |

For example, lines might connect wind resources in Wyoming to California, or deliver wind power in the Dakotas to Chicago. Such lines might account for a large fraction of the cost of that electricity. |

|

23 |

CAES has been demonstrated at a pilot plant in Alabama as well as at locations in Germany. |

its own compressor.24 CAES is now a viable option for providing 100–300 MWe or more of electric power for up to 10 hours. Before 2020, CAES will be the only viable option, aside from pumped hydro, for storing hundreds to thousands of megawatts of energy. Both are dependent on specific features being available (caverns or hills where reservoirs can be built), which greatly limit their applicability.

For distribution systems, storage at lower power ratings (10 MW and below) and lower discharge times (hours to minutes, depending on the application) can be used to improve power quality and security. Distributed storage can help to regulate the system and improve system stability, including reducing the risk of system collapse by supporting islanding and restoration following a disruption. Some battery-storage technologies for these applications, such as lead-acid and sodium-sulfur batteries, have been demonstrated and are currently available for deployment (Bjelovuk, 2008). Batteries are modular and not site specific, meaning they can be located close to intermittent generation sites, near the load, or at T&D substations. However, current battery technologies are expensive and have high losses and reliability issues.

In the longer term, battery storage technology at larger capacities (in the 100 MW range) may help to accommodate variable renewable energy sources, but further R&D is needed before more widespread deployment is likely. Given the large potential in the electric vehicle market for lithium-ion, nickel metal hydride, and other types of batteries, much R&D is now in progress. Advanced batteries with lower cost, high energy density, and higher charge-discharge cycles could also be used for storage in the T&D systems. They may be available for deployment in T&D systems after 2020.

Other longer-term possibilities for energy storage in the grid include supercapacitors, superconducting energy storage, and flywheels. None of these technologies is currently suitable for grid use because of high costs and low energy-storage density. Flywheel storage units are being installed for first-of-a-kind experience with power capacity in the MW range that can smooth out short variations of wind power. However, the technology is a long way from economic deployment on a large scale that would affect daily peaks and day-to-day variations. If advances are made, particularly in materials, all these technologies may become

suitable for energy storage in distribution systems after 2020. Pumped hydroelectric power underground storage, which requires a deep underground water reservoir or aquifer and construction of a power plant deep underground as well, is not considered an effective solution in general because of high costs, but it may be suitable for some sites.

Distribution Transformers

From generation to the customer’s meter, power typically flows through four transformer stages,25 accumulating about 4 percent losses in total. The last transformer in the chain is the distribution transformer for residential/small commercial customers, and because there are so many in the distribution system, they account for a large portion of these losses. Improved materials used to form the transformer’s core can reduce the losses. In the past, grain-oriented steel was universally used as the core material, and there has been sustained but slow progress in reducing its losses. A new material, amorphous steel, has become commercially available in significant quantities over the last 10 years. Transformers made with amorphous steel have about one-third the core loss of those made with grain-oriented steel. The market for amorphous steel transformers has been small, however, primarily because of their higher cost. This material may become more competitive economically as a result of new DOE standards regarding distribution-transformer efficiency for new equipment.26

Potential for Future Deployment

Many of the technologies needed to implement a modern T&D system, such as FACTS and custom power devices, are presently available for commercial deployment. While R&D is needed to reduce costs and improve performance, no breakthroughs are necessary to start using them in large quantities. In addition, some higher-voltage long-distance lines and substations could be deployed before 2020,

|

25 |

Electrical transformers are used to increase or decrease AC voltage. For example, a transformer near the generating plant increases the electrical voltage (“steps it up”) at the transmission line, and a transformer at the distribution substation decreases the voltage (“steps it down”) from transmission voltages to voltages appropriate for distribution. Others are used within the distribution system to deliver the power at levels appropriate to end users. |

|

26 |

These standards are discussed in more detail in the subsection “Economic Benefits” within the section “Potential Benefits of a Modern T&D System.” |

and dynamic thermal rating of power lines could increase capacity along existing lines.

Some storage technologies will be ready for deployment before 2020; however, significant room for improvement remains. At larger scales that may be needed to support large quantities of intermittent renewable energy sources, pumped hydroelectric power and CAES will be the only viable options before 2020. Batteries may also be used for large-scale storage in the T&D systems but are unlikely to be available for deployment at the hundreds-of-MW scales until after 2020. On a smaller scale (around 10 MW), batteries are already being deployed to enable islanding and load-leveling in the distribution system. Newer technologies (including ultracapacitors and flywheels) may not be ready for wide-scale use before 2035.

Measurements, Communications, and Controls

A modern electric T&D system will need measurement, communications, and control technologies to gather real-time data on the state of the grid, communicate those data, and process them to enhance system controlability. These technologies, including associated software, are the basis for “intelligence in the grid.” The following subsections discuss the status of several of these technologies, likely technology improvements, and the potential for their deployment in the U.S. T&D system.

Sensing and Measurements

Understanding and acting on the current state of the U.S. T&D system requires measuring the power characteristics at numerous points. The basic measurements needed are current (amperes) and voltage (volts) at every electrical connection and the status of all switches (on or off). These data provide information on the grid’s electrical condition and connectivity.27

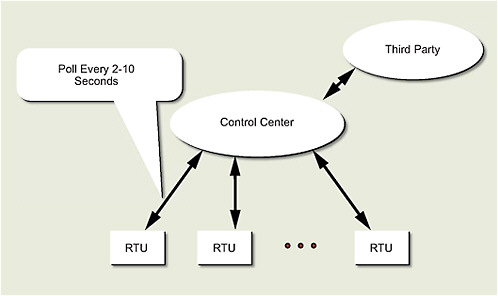

Measurements are made at each T&D substation and are used to drive its controls and protective devices (relays).28 Supervisory control and data acquisi-

tion (SCADA) systems collect and transmit this information to control centers.29 In most existing substations, the data can be sampled every few seconds, entered into a remote terminal unit (RTU), polled by the SCADA, and sent to the control center over relatively slow communications channels—usually microwave. In modern substations, some of which are already in place, the substation control and protection system is digital and the connectivity is through a local area network (LAN) within the substation. Data can be sampled many times per second, rather than once every few seconds. Most of the substation’s controllers and protection systems, known collectively as intelligent electronic devices (IEDs), are based on microprocessors, as are recording systems such as fault recorders and sequence-of-events recorders.

Monitoring of the state of the transmission system is best if the high-voltage substations are equipped with measurement systems that sample at rates of 60–120 times per second30 and incorporate global positioning system (GPS) signals.31 Although the individual hardware costs of these measurement units are now very modest,32 the cost of retrofitting them into the thousands of existing substations will be significant.

There are approximately four times more low-voltage distribution substations than there are high-voltage substations. Although the sampling speed does not need to be as large, high-bandwidth communication will be needed in order to use these data for system control.

Existing customer billing meters could be replaced with microprocessor-based meters which could provide the customer with new buying options such as time-of-day pricing, and could increase end user efficiency. These meters could also allow control signals from the power company to be brought directly into appliances and equipment on the customer side for load management.

|

29 |

For further explanation of SCADA systems, see Annex 9.A. |

|

30 |

Automatic control action to stabilize the power system after a disturbance has to be taken in well under a second, thus requiring measurement sampling of around 60 times a second. The available phasor measurement units (PMUs) routinely provide measurement sampling at 30 or 60 Hz, and faster sampling rates are already appearing in the market. |

|

31 |

Global positioning system (GPS) signals and the associated absolute-time references allow accurate phase shifts in AC quantities to be measured between widely separated substations. |

|

32 |

PMUs were priced at around $50,000 when first introduced in the 1980s, but they cost less than $10,000 today; moreover, other substation equipment such as protective relays today can perform this function at almost no incremental cost. |

Integrated Communications

Real-time measurements can be used to monitor and control the T&D system, but the measurement data must be transmitted to a location where they can be processed. To appropriately process the data, a fully integrated communications system with universal standards (protocols) must be developed, along with real-time data handling software that can collect and move the data to where they are needed.

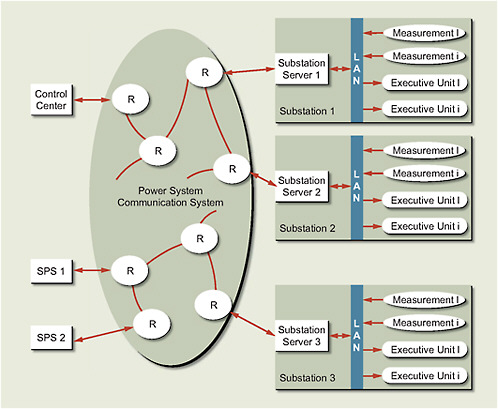

If the measurement technologies described above are fully implemented, each control center will need to process approximately one million data points per second.33 The existing communication channels between the control centers and the substations, many dating from the 1960s, cannot handle these data rates. They are currently being replaced with high-bandwidth optical fiber. However, even with increased bandwidth, the present system (in which all data from substation RTUs are collected at the control center SCADA) cannot handle the expected proliferation of real-time measurement data.

An alternative to this communications architecture is shown in Figure 9.9. Each substation has its own data-gathering system connected internally by a LAN. A gateway server connects these data to the rest of the system through a high-speed network of switching routers, which can move the needed data efficiently to monitoring and control applications. These applications require coordination across several substations, either regionally or over the entire interconnection. Such applications are often referred to as wide-area controls or special protection schemes. Today’s local controls are contained within a substation and will remain part of the substation automation design.

Communication systems must be able to handle a wide range of speed and data flow requirements, and the switching network and distributed database will have to be designed. Although similar systems exist today (e.g., cellular telephone systems), the communications needs for the power grid are unique; specialized software will have to be designed and developed. Such a communications system should be ready for deployment by 2020, possibly continuing into the 2020–2030 time period.

FIGURE 9.9 An alternative measurement architecture for the transmission system. Each substation (shown on the right) takes measurements that are collected by its own data-gathering system. These measurements are communicated internally by a local area network (LAN). A substation server communicates these data to the rest of the system through a high-speed network of switching routers (shown as circles) that can move the data efficiently as needed to specific monitoring and control applications.

Advanced Control Methods

Measurement and communication technologies create a picture of the state of the systems, which control technology can use for greater reliability and security (including self-healing following a disruption) and more efficient operation and optimization of assets. If the T&D system is equipped with new measurement sensors, a high-speed communication network, and power electronics, fast wide-area controllers can be designed and installed with software only. This will enable the evolution of better controls to make the grid increasingly reliable and efficient.

The thousands of mostly local controllers in existing T&D systems are slow; response times typically are measured in seconds. In contrast, FACTS devices (already in use as fast local controllers) can control voltages and power flows with response times measured in milliseconds. Moreover, fast wide-area controls, combining rapid communications with remotely controlled FACTS devices, are becoming feasible. Time-stamped measurements will make multiple inputs available to the controller, which can then send out multiple output signals to several FACTS controllers simultaneously.

With these technologies, many types of grid monitoring and control will become possible.34 Digitized measurements that incorporate data at high sampling rates will allow faster and more frequent calculation of the state of the transmission system. This can provide better predictions of the T&D system’s behavior under contingencies (natural, human error, or malicious), thus enabling automatic corrective and preventive actions. Cascading failures can be predicted, and defensive actions such as islanding can prevent the spread of the disturbance. Advanced distribution controls can accommodate two-way power flow from distributed generation by balancing the load on all the distribution feeders. In addition, demandside responses can be efficiently coordinated if appropriate sensors and communications are in place. Such control technologies could begin to be deployed by 2020.

Potential for Future Deployment

Measurement, communications, and control technologies are already being deployed to a modest degree and could be fully deployed by 2030. About 15,000 transmission substations will require new sensors, measurement systems, and LANs. To add high-bandwidth communications hardware (mainly fiber-optic cables) across the transmission system of approximately 200,000 miles of network and 20,000 switches, investment in both hardware and software will be needed. The costs of developing the needed software to operate the hardware for control will be significant.

Technologies for distribution systems are different in character from transmission. Sensing, monitoring, and communications technologies will need to be

installed in the approximately 60,000 distribution substations and their associated feeders. These controls will be particularly important as smart metering is introduced into distribution networks. Additional investment will also be needed for coordination between transmission level-controls and distribution-level controls.

Improved Decision-Support Tools

The T&D system in the United States is managed by a large number of private and public entities that have long used computer-based decision-support tools both for commercial and for engineering decisions. These tools need to be further improved because of the massive amounts of data that are available in real time and the need to use these data in system control. This section examines improved decision-support technology (IDST), including those tools necessary for split-second decision making by system operators during emergencies as well as for long-term decision making on investments needed in the grid itself.

System Operations

A recurring theme in blackout investigations has been the need for better visualization capabilities and decision-support tools over a wide geographic area. In many circumstances, a human operator will require at least some seconds to make a decision, but automatic controls operate on the order of milliseconds. IDST enables grid operators and managers to make faster decisions by converting the complex power-system data into information that can be understood at a glance. Improved visualization interfaces and decision-support technologies will increase reliability, decrease outages due to natural causes and human error, and enhance asset management.

IDST covers three general systems-operations categories:

-

Grid visualization. Real-time analysis of system stability will require online analytical tools that process the vast amount of data and automatically determine what actions should be taken to prevent an incipient disturbance from spreading. This objective requires completing the analysis within a fraction of a second and presenting it visually in a control room for fast responses to deteriorating conditions. The algorithms have not yet been developed to perform these functions, but they could be deployed by 2020 and would be continually improved in the 2020–2035 timeframe and beyond.

-

Decision support. Decision-support technologies can identify existing, emerging, and predicted problems and provide analysis to support solutions. By analyzing the consequences of each contingency and its probability of occurrence, decision-support systems can quantify relative risk and severity. These relative risks can be integrated into a composite risk factor and presented to the operator to assist in decision making. Further work on decision-support algorithms will be needed to make them available for deployment before 2020, with continuing improvements in the 2020–2035 timeframe and beyond.

-

Systems operator training. Advanced simulators currently under development will give operators a real-time, faster-than-real-time, or historic view of the power system and its parameters. These dynamic simulators, together with industry-wide certification programs, will significantly improve the skill sets and performance of system operators. Such simulators could be ready for deployment by 2020, as soon as the visualization and decision-support algorithms are in place. IDST, together with system-operator training, will then need to be continuously evaluated and improved.

As the systems become more complex, R&D on software and artificial intelligence will be needed to improve the operator’s ability to control a wide-area transmission system as well as an ever more complicated distribution system. Improved software and artificial intelligence for IDST could begin to be deployed by 2020, and deployment is likely to continue into the 2020–2035 timeframe.

Operations Planning and Design

Decision tools are also needed for decisions that occur over longer timescales than do real-time operating decisions. Applications include next-day planning decisions for the power market, planning for adequate generation, and design of T&D substations as well as distribution feeders.

Operations-planning decisions set the schedules of how the T&D system will be operated over the next day. Decisions include forecasting the load, scheduling dispatchable generation and long-term contracts to meet the load, conducting auction markets, using power contracts to check on possible congestion on the transmission system, and modifying the power contracts if congestion is indicated. The decision tools needed for these tasks are mostly new or have been significantly modified in recent years.

Longer-term planning for new generation and transmission capacity must deal with considerable uncertainty, especially where the industry has been restructured and no one organization holds the ultimate responsibility for building adequate generation. Transmission is still regulated, but transmission planning is dependent on knowing where the new generating plants are going to be located. Computerized planning decision tools must be improved to handle increased uncertainty for the 20- to 30-year time horizon. It is anticipated that renewables will present unique challenges, and the addition of probabilistic methods not in use today may help system operators respond to the changing generation mix.

T&D substations are designed by computerized tools that need to be further coordinated with asset-management tools—inventory management for spare parts and maintenance of all components for example—used by utilities. The two tool sets should be seamlessly coordinated with one another and connected to the operations and operations-planning databases so that customer trouble calls can be coordinated with maintenance crews, spare part inventories, and system operations.

Potential for Future Deployment

Several major conditions must be met before IDST can be effectively implemented. First, modern measurement, communications, and control technologies must be implemented along with the power electronics technologies needed to enable automated controls. In addition, development is needed in applications that integrate advanced visualization technologies with geospatial tools to improve the speed of comprehension and decision making. Some of these technologies could begin to be implemented well before 2020.

Integrating Technologies to Create a Modern Electric T&D System

The key technologies discussed above are in various stages of development, with many already having been deployed in a limited way. However, the primary challenge will be the integrated deployment of these technologies to achieve the desired characteristics and performance of a modern grid. For example, the capabilities of power electronics would be maximized by coupling them with real-time measurement, communications, control, and decision-support tools. Smart meters with two-way communications tied to wireless controllers within the customer’s premises will be needed on distribution systems to maximize the benefits of a modernized transmission system.

It is important to note that even though most modernization technologies are available now, further R&D is very important. All these technologies can be improved upon and would benefit from cost reduction. A few, such as large-scale storage, are simply impractical now. In addition, the nation is facing a critical shortage of power engineers, the very people who will be needed to implement modernization. University R&D funding is vital in persuading students to embark on careers in power engineering.

COSTS OF MODERNIZATION

Projecting the costs of modernizing the U.S. T&D systems is complex, given the expansive and interconnected nature of the system, the difficulty of estimating development costs (especially for software), and uncertainties over technology readiness. Complicating matters further, costs have been escalating sharply in recent years for large-scale T&D construction, as for other energy projects. Transmission investment is anticipated to continue to increase to meet load growth and replace aging equipment, but additional investment will be needed over the next few decades to modernize the T&D system.

A comprehensive discussion of the costs of modernization was published in 2004 by the Electric Power Research Institute (EPRI 2004).35 The AEF Committee reviewed the assumptions made by EPRI in this report and largely agrees with its estimates, with two exceptions for transmission. First, EPRI projected that superconducting cables would be added to the system over the next 20 years, but the committee concluded that high costs and slow technological development would preclude commercial deployment before 2030. The committee has thus modified EPRI’s cost estimates to reflect this judgment.36 Second, the cost of developing and deploying software on the transmission system is routinely underestimated; it is likely that more investment will be required for this purpose.

|

35 |

Estimates by the Electric Power Research Institute (EPRI), originally in 2002 dollars, were escalated to 2007 dollars for the committee’s analysis. In addition, recent real escalation in materials and construction costs were accounted for by using the national average transmission and distribution indexes (33 percent for transmission, 40 percent for distribution). These changes are described in Annex 9.A. |

|

36 |

The investment in superconducting cables has been removed from the total investment needed for the transmission system. It has also been removed from the synergies calculation. These changes are described in detail in Annex 9.A. |

The improvements needed in the T&D system could be completed over the next 20 years, with significant progress by 2020. Modifying the EPRI results as detailed in Annex 9.A suggests that a total investment of $225 billion will be required for transmission systems, and modern distribution systems are likely to require a total of $640 billion.37 If the T&D system is not modernized but simply expanded to meet growing loads, transmission would require $175 billion and distribution $470 billion. Thus the incremental costs of modernization are $50 billion for transmission and $170 billion for distribution spread over the next 20 years.38 Modernization would actually cost about twice this amount, but less expansion would be needed to meet projected loads, and the savings from these synergies would account for the difference. For example, existing lines could carry greater loads if improved control systems prevented overloading, so some new lines would not be needed.

A more recent analysis was performed by the Brattle Group, which built on the EPRI analysis (Brattle, 2008). Estimated costs in the two studies are very similar.39 The Brattle study does not distinguish between investments to meet increased load demands and investments in modernizing the system, but it estimates that $233 billion will be needed for the transmission system (compared to EPRI’s $225 billion).40 Brattle estimates that $675 billion will be needed for distribution versus EPRI’s $640 billion.

Neither report explicitly accounted for the construction of new transmission lines to bring power from remote wind or other renewable energy sources to load centers. These lines could be longer than those from conventional power sources and carry power at a lower capacity factor, thus increasing costs. According to a DOE report on achieving 20 percent of U.S. electricity from wind power, an estimated 12,000 miles could be constructed for $20 billion (DOE, 2008). Actual expenditures will be highly dependent on the routes chosen and the capacities of the lines, but additional costs on the order of tens of billions of dollars seem plausible. Large-scale power generation from photovoltaics or solar thermal technology is a longer-term possibility if cost reductions are achieved. Much of this power

|

37 |

These estimates are in 2007 dollars. |

|

38 |

The cost of implementing a T&D system is less than the cost of meeting load growth plus the cost of adding intelligence to the systems because of synergies, which are discussed in Annex 9.A. |

|

39 |

A comparison between these two studies is made in more detail in Annex 9.A. |

|

40 |

Again, these estimates are in 2007 dollars. |

could be generated in the Southwest region, which would require additional long-distance transmission. Construction of such lines will depend on the regulatory environment and government policy; the transmission technology is available, although further improvements would be beneficial.

T&D expenditures are unlikely to be linear over the next 20 years. Representatives of EPRI and the Edison Electric Institute (EEI), which funded the Brattle study, have suggested that the split would be approximately one-third during the first 10 years and the remaining two-thirds over the second 10 years.41 The AEF Committee has assumed that 40 percent of the expenditures should be made before 2020, with the remaining 60 percent between 2020 and 2030. Thus investments averaging $9 billion per year would be needed in the transmission system from 2010 to 2020, with approximately $2 billion per year of this total dedicated to modernization.42 From 2020 to 2030, an average of approximately $14 billion per year will be needed, including $3 billion per year for modernization.

As discussed in the section “Barriers to Deploying a Modern T&D System,” utilities and transmission operators may find it more difficult to raise the relatively small amount needed for modernization than to raise the more substantial amount needed for expansion. If modernization were not included, however, utilities would have to continue using existing technologies for control, sensing, and monitoring equipment, and the nation would be deprived of the many benefits discussed here.

For distribution systems, an investment of $26 billion per year would be needed from 2010 to 2020 ($19 billion for expansion, $7 billion for the modernization increment). From 2020 to 2030, approximately $38 billion per year would be needed (including $10 billion for modernization).

POTENTIAL BENEFITS OF A MODERN T&D SYSTEM

A modern T&D system would offer significant benefits. Costs to consumers could be reduced through more efficient electricity markets; national security could be

enhanced because of greater reliability and reduced vulnerability to major disruptions; greater capacity to accommodate renewables would improve the environment; and public safety would be enhanced. Although these benefits are even harder to estimate than are the costs (as described in the previous section), estimates of the benefits of a modern T&D system significantly outweigh the costs. For example, EPRI estimates these benefits to U.S. society to be about $640–800 billion over the next 20 years for a cost of implementation of $165 billion; that is a cost-benefit ratio of 1:4 (EPRI, 2004). On a more local scale, a recent study by the University of San Diego considered the value of a modern distribution system to the San Diego area. The investigators found about $1.4 billion in system benefits, plus another $1.4 billion in societal benefits, producing an internal rate of return of at least 26 percent (San Diego, 2006).

While the benefits of modernizing the T&D system in the United States are potentially very large—possibly several times the investment—this study had neither the time nor the resources to examine the assumptions and modeling needed for a reliable estimate. The following sections, however, provide some specific examples of potential benefits from modernizing the system.

Economic Benefits

A blackout in a single area can cost approximately $1 billion, and major regional blackouts can cost $10 billion. EPRI estimates the annual cost of power disturbances to the U.S. economy to be between $80 billion and $100 billion (EPRI, 2004). Disturbances to power quality add to the total, and inefficiency and congestion in the current T&D systems also have significant economic costs. These costs could be reduced significantly by a modernized T&D system. Thus improving grid reliability and efficiency could result in substantial economic benefits.

A modern T&D system will benefit the U.S. economy in less direct ways as well, such as by allowing cost information to be made available to buyers and sellers of electricity in real time. These energy price signals will allow customers to more effectively participate in the electricity market, based on current supply-and-demand influences. Overall, markets will be more efficient when consumer decisions are based on realistic prices. There will also be a reduction in grid congestion and forced power outages. A modernized grid will enable a wide array of new options for load management, distributed generation, energy storage, and

revenue opportunities for those who choose to participate, such as residential self-generators.43

Security Benefits

A modern grid can contribute to energy security by reducing the energy system’s vulnerability to terrorist attacks and natural disasters, thereby reducing the risk of a devastating long-duration blackout. In addition, the ability to handle a high level of electricity generated from domestic renewable energy sources has national security benefits as well as the environmental benefits discussed in the next section.44 In other words, the enhanced controllability that a modern T&D system could provide, and the broad penetration of distributed generation, will make the transmission system far more difficult to disrupt. Moreover, sophisticated analytical capabilities can detect and prevent or mitigate the consequences of an attack or disaster, and probabilistic analytical tools can identify inherent weaknesses in the grid so that they can be integrated into an overall national security plan.

However, as T&D systems become increasingly dependent on computer-driven communications and control networks, physical attacks will not be the only concern. Guidelines for cyber-security are already in place, but these may not be adequate for a fully deployed communications and control system. Cyber-security has to be an integral part of modernizing the grid.

A modern grid could improve the diversity of energy supplies by allowing larger proportions of renewable energy into the U.S. energy supply. Coal is the source of about half the nation’s electricity, but although domestic coal reserves will be sufficient for many decades to come, concerns about carbon emissions may affect its future use. Natural gas is also a concern because projected rates of consumption may lead to importing increased amounts of liquefied natural gas, some from politically unstable areas of the world. Little oil is used for electric generation, but the modern grid will reduce oil imports by helping to make electric vehicles commercially viable.

Environmental Benefits

Modernizing the power delivery system is an essential step in reducing emissions of carbon dioxide and other pollutants such as SOx, NOx, and mercury:

|

43 |

Self-generation refers to electricity generation that the end user owns and controls. |

|

44 |

See Chapter 6 for further discussion. |

-

A modern T&D system can allow for greater penetration of large-scale intermittent renewable electricity sources as well as distributed generation and self-generation, thereby reducing the amount of coal that must be burned.45

-

Modern demand-response technologies (such as grid-friendly appliances that can be controlled by the utility to shift load to off-peak times) can be better accommodated, thereby reducing demand that must be met by inefficient generating equipment.

-

Battery electric vehicles (BEVs) can be better accommodated, particularly after 2030.

-

Efficiency can be improved in the T&D system as well as in end-uses, reducing the need for new generation and the siting of new transmission lines.

A modern T&D system can enable intermittent renewable electricity sources (particularly wind power) to contribute substantially to the U.S. energy supply. The electricity provided by wind power varies significantly over the course of a day and over the year because of natural variations in wind speed. As a general rule, a power-delivery system can handle the loss of 10–20 percent of the local generating capacity as long as adequate reserve capacity is available.46 Grid operators normally require generating companies to have spinning reserve (generators that can increase their output very quickly) equivalent to the largest unit on the system; if that unit fails it can be replaced without disrupting delivery of power. Because intermittent sources cannot be depended on, the spinning reserve has to include a significant fraction of the renewable capacity in addition to the largest unit of conventional power.47 Above 10–20 percent, a rapid loss of wind power could cause system instability unless the system was modernized.48 Even at lower

|

45 |

Self-generation is a special case of distributed generation. End users generate some portion of their own energy needs, utilizing, for example, rooftop solar panels. Under some conditions, any excess power may be sold to the utility. |

|

46 |

Grid modernization is not needed for integrating intermittent renewable-electricity sources in relatively small percentages of the overall electricity supply. This is discussed in greater detail in Chapter 6. |

|

47 |

Wind and solar power are the main intermittent renewable-energy sources. Other renewables, such as hydropower, geothermal, and biofuels, are not intermittent. |

|

48 |

The changes needed to accommodate renewables are discussed in more detail in the technology section of this chapter; they involve large-scale storage as well as high-voltage long-distance transmission. |

levels, modernization would help integrate wind power and reduce the need for spinning reserve.

In addition to intermittency, the location of many renewable resources (remote or distributed) poses a challenge that a modern grid could address better than the current T&D system does. Many high-quality renewable resources, such as wind in the Dakotas and solar resources in the deserts of the Southwest, are located far from population centers. More transmission capacity will be required to bring electricity from these locations to areas of high demand, potentially using technologies such as HVDC transmission. Other low-emission and renewable resources are likely to be used as distributed generation (e.g., natural-gas-fired micro-turbines, small wind turbines, and solar panels on residential and commercial rooftops). The modern grid will enable better integration of these resources by incorporating two-way power flow and smart metering on the distribution system.

Many modern demand-response technologies can be regulated in response to grid conditions. With the implementation of time-of-day pricing, such technologies could allow for more cost-effective and efficient electric power generation (i.e., by running primarily at off-peak times, when the price of electricity is lower and generating capacity of greater efficiency is available).

A modern T&D system can also assist in the integration of BEV (including plug-in hybrids), thus reducing the consumption of petroleum fuels for transportation.49 BEVs could result in an overall decrease in greenhouse gas emissions even though some of the electricity is generated at coal-fired power plants. Rapid growth of BEVs might significantly increase the demand on T&D systems, but this is unlikely before 2020, when the use of advanced meters could enable controlled battery charging. With the addition of such technologies, the impact on the grid could also be small even by 2035.

A modern grid can operate more efficiently, reducing the need for construction of new generators and transmission lines. Approximately 10 percent of the total power produced in the United States is lost in the process of delivering it to the end user. For example, reactive power flow over a transmission line not only increases losses in the transmission line but also significantly reduces the power-carrying capacity of the line; the use of power electronics, however, can reduce such flow of reactive power. In addition, power electronics can reduce losses by shifting power flow to the most advantageous transmission paths and by the use

|

49 |

Plug-in hybrid vehicles are discussed in further detail in Chapter 4. |

of more efficient distribution transformers.50 The committee estimates that T&D losses could potentially be reduced by as much as 10–20 percent, resulting in an efficiency improvement in the overall electric system of about 1–2 percent, which in turn would produce significant economic benefits.

Public Safety Benefits

The American Public Power Association reports that about 1000 fatalities and 7000 flash burns occur annually in the electric utility business (Trotter, 2005). Improved monitoring and decision-support systems would quickly identify problems and hazards. For example, the ability to identify equipment that is on the verge of failure is certain to save lives and reduce severe injuries. Also, the modern T&D system would need less maintenance, which means less exposure to accidents and increased safety of maintenance workers. In addition, by reducing the risk of long-term outages following terrorist attacks or natural disasters, modernization could help prevent public health and safety catastrophes.

BARRIERS TO DEPLOYING A MODERN T&D SYSTEM

It should be clear from the previous section that a modernized electric grid is very much in the nation’s best interest. The benefits would be substantial and quite likely to far outweigh the costs. Nevertheless, modernization is unlikely to happen unless it is also in the interests of those who must implement it.

Several barriers have the potential to impede this implementation. First, the technologies that utilities would employ to modernize the grid entail additional costs and uncertainties—particularly regarding how well they will work relative to older technologies. Second, some utilities may be reluctant to invest the additional funds required for modernization even when it would appear to make sense to do so. Third, there is a lack of regulatory and political support that could provide incentives for modernization. Finally, there is difficulty in communicating the need for modernization to the public and to regulatory and political decision makers.

Technical Barriers

Most of the technologies needed for modernization of the T&D system are available now, but some technical hurdles, such as energy storage, remain. In addition, some technologies are still expensive; R&D is necessary to reduce costs and improve performance. Yet the rate of technology research, development, and deployment in the power industry is low compared to that of other industries.

Utilities, at least in part because they are regulated, are relatively risk averse and may be reluctant to deploy new T&D technologies—particularly new transmission technologies—until they are fully proven. Also, modernization technologies must be deployed in unison to achieve their full benefits, posing challenges in integrating technologies. For example, universal communications standards as well as a common architecture that promotes interoperability are needed. However, the security issues that are involved in an open system must be met with industry-approved and -adapted standards and protocols.

Investment Barriers

Modernization will cost more than simply building more transmission lines and replacing aging equipment. Even though the additional investment would eventually pay off, financial markets and regulatory constraints drive utilities to minimize investments.

In addition, some of the benefits of modern grid technologies are societal (higher quality, more reliable power) and not typically internalized in a company’s decision making. The companies, however, must bear the full cost of modernizing the parts of the grid that serve their customers. This barrier is more significant for the transmission system, which is inherently interconnected: many entities own and regulate different parts of it. Cooperation will be needed among utilities and regulatory agencies.

Regulatory and Legislative Barriers

As noted above, utilities are cautious about adopting new technologies that may involve some risk. This is especially true when familiar technologies have lower first costs and utilities are given no incentive to invest more than the minimum required to maintain operations. If modernization is to occur and produce all the advantages it offers, legal and regulatory changes are likely to be necessary.

Legislators and regulators have not taken a strong leadership role regarding grid modernization, nor have they adopted a clear and consistent vision for

the modern grid. There has been significant focus in recent years on individual technologies and on energy-related issues such as environmental impact, but less attention has been paid to developing a vision that integrates technologies, solves the various grid-related issues, and provides the desired benefits to stakeholders and society. The Energy Policy Act of 2005 and the Energy Independence & Security Act of 2007 have been positive steps in the right direction, but much more is needed to directly address the regulatory and policy factors that create significant impediments to the modernization of the U.S. T&D system. For example, a wholesale pricing structure that recognizes the value of reliability and signals when transmission system upgrades are necessary would help provide investment predictability.

In addition, policies regarding the grid are often inconsistent because they are set by multiple groups—individual states (state energy policies and public utility commissions [PUCs]); the Federal Energy Regulatory Commission (FERC); and environmental agencies. Inconsistent policies among states and between state and federal regulators, for example, prevent effective collaboration across transmission regions.

Also, time-of-day rates for consumers that reflect actual wholesale market conditions are not yet widely implemented, thereby preventing the level of demand-side involvement needed in the modern grid. Net metering policies that provide customers with retail credit for energy generated by them are also not widely deployed, which reduces the incentive for end users to install rooftop photovoltaics or other generating technologies. Finally, regulatory policies often do not reward customers for investments that provide substantial societal benefits, such as credits for local storage that has been made dispatchable.51

A reduction in R&D expenditures by utilities, an unintended result of restructuring, has impacted the development and deployment of newer T&D technologies. A more predictable regulatory environment that accounts for societal costs and benefits in the rate structure and supports R&D will be needed.

Cultural and Communication Barriers

The fundamental value of the T&D system in general and the societal and economic benefits of a modernized grid and the costs associated with antiquated sys-

tems in particular have not been adequately communicated to decision makers and the general public. Some electric utility executives assert that their customers value lower rates more than the benefits of a modernized grid, which would increase costs in the short term (NETL, 2007b).

In order to overcome this barrier, significant efforts need to be made to communicate the benefits of a modern grid to all stakeholders. Improved communication with the public is also necessary regarding the costs and benefits associated with the current transmission system in particular, which is experiencing ever increasing congestion and needs expansion. It is difficult to site new transmission lines. Many proposals for new lines generate considerable opposition, usually based on aesthetic, property value, or health and safety concerns. For example, American Electric Power, a large Midwest utility, recently experienced a 12-year approval process for a new 90-mile 765-kV transmission line.52

DEPLOYING A MODERN T&D SYSTEM