2

Assessments of the Projects of the Exploration Technology Development Program

This chapter contains the committee’s findings and recommendations on the 22 projects constituting NASA’s Exploration Technology Development Program (ETDP). Following a summary of each project’s objectives and status is the committee’s review of the quality of each project, the effectiveness with which the project is being developed and transitioned to the Constellation Program, and the degree to which the project is aligned with the Vision for Space Exploration (VSE).

Each of the 22 ETDP projects was evaluated on the basis of the following criteria:

-

The quality of the research effort, taking into account the research team, contacts with appropriate non-NASA entities, and the plan for achieving the objectives;

-

The effectiveness with which the research is carried out and transitioned to the exploration program, including progress to date, facilities, apparent gaps in the program, and the likelihood that the required technology readiness level (TRL) will be reached1 (the committee decided that simply noting gaps, as stated in the study task, was too narrow an objective and that gauging “effectiveness” as defined here was more appropriate); and

-

The degree to which the research is aligned with the Vision for Space Exploration (since the VSE includes the wording “in preparation for human exploration of Mars,” the committee chose to highlight any project that did not appear to have considered plans that included this aspect).2

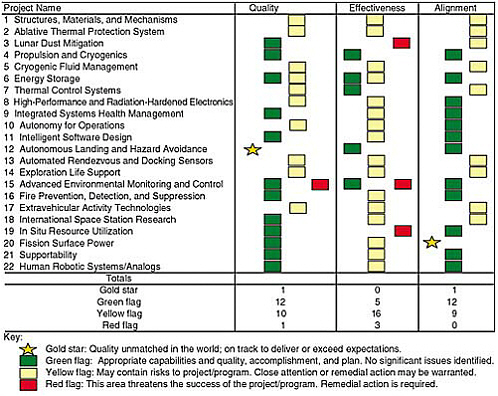

In each of these three areas, the committee rated the projects using a flag whose color represents the committee’s findings on the project. A summary of the ratings scheme is provided in Table 2.1. A few projects were given two flag colors stemming from major distinctions between elements in the project. In the sections below, detailed observations on each project are presented, and gaps within a given project are identified. As is noted at

|

1 |

See Appendix D for definitions of technology readiness levels. |

|

2 |

The committee notes that after the completion of its assessments of the 22 individual projects in late 2007, the Congress passed the fiscal year 2008 Omnibus Appropriations Bill, which contained a provision prohibiting NASA from funding any activities devoted solely to preparing for the human exploration of Mars. The committee chose not to modify its findings on alignment with the VSE based on this language for several reasons. First, the committee interpreted as dominant its statement of task, which includes reference to the entire Vision for Space Exploration, explicitly including the human exploration of Mars. Second, by and large, on this alignment criterion the committee was critical of technology projects that did not consider extensibility of their technology to Mars. An example of potentially extensible technology is the Orion thermal protection system for Earth reentry. The committee did not criticize in the assessment of the 22 projects the absence of a Mars-unique technology, an example of which is a martian aerodynamic entry descent and landing system. |

TABLE 2.1 Summary of the Committee’s Assessment Ratings Scheme

the end of the chapter, the ratings constitute the committee’s findings on the 22 projects. The committee’s general recommendation is that those projects should be improved whose ratings indicate the need for positive change.

The 22 projects assessed, with a short description of each, are as follows:

01 Structures, Materials, and Mechanisms: Technologies for lightweight vehicle and habitat structures and low-temperature mechanisms.

02 Ablative Thermal Protection System for the Crew Exploration Vehicle: Prototype, human-rated, ablative heat shield for Orion (the crew vehicle) and advanced thermal protection system materials.

03 Lunar Dust Mitigation: Technologies for protecting lunar surface systems from the adverse effects of lunar dust.

04 Propulsion and Cryogenics Advanced Development: Non-toxic propulsion systems for Orion and the Lunar Lander.

05 Cryogenic Fluid Management: Technologies for long-term storage of cryogenic propellants.

06 Energy Storage: Advanced lithium-ion batteries and regenerative fuel cells for energy storage.

07 Thermal Control Systems: Heat pumps, evaporators, and radiators for thermal control of Orion, and lunar surface systems such as habitats, power systems, and extravehicular activity (EVA) suits.

08 High-Performance and Radiation-Hardened Electronics: Radiation-hardened and reconfigurable, high-performance processors and electronics.

09 Integrated Systems Health Management: Design, development, operation, and life-cycle management of components, subsystems, vehicles, and other operational systems.

10 Autonomy for Operations: Software tools to maximize productivity and minimize workload for mission operations by automating procedures, schedules, and plans.

11 Intelligent Software Design: Software tools to produce reliable software.

12 Autonomous Landing and Hazard Avoidance Technology: Autonomous, precision-landing and hazard avoidance systems.

13 Automated Rendezvous and Docking Sensor Technology: Development of sensors and software to rendezvous and dock spacecraft.

14 Exploration Life Support: Technologies for atmospheric management, advanced air and water recovery systems, and waste disposal.

15 Advanced Environmental Monitoring and Control: Technologies for monitoring and controlling spacecraft and habitat environment.

16 Fire Prevention, Detection, and Suppression: Technologies to ensure crew health and safety on exploration missions.

17 Extravehicular Activity Technologies: Component technologies for an advanced EVA suit.

18 International Space Station Research: Fundamental microgravity research in biology, materials, fluid physics, and combustion using facilities on the International Space Station.

19 In Situ Resource Utilization: Technologies for regolith (loose rock layer on the Moon’s surface) excavation and handling, for producing oxygen from regolith, and for collecting and processing lunar ice and other volatiles.

20 Fission Surface Power: Concepts and technologies for affordable nuclear fission surface power systems for long-duration stays on the Moon and the future exploration of Mars.

21 Supportability: Technologies for spacecraft and lunar surface system repair.

22 Human-Robotic Systems/Analogs: Technologies for surface mobility and equipment handling, human-system interaction, and lunar surface system repair.

Descriptions of the ETDP and its technology infusion plans can also be found in two public documents.3,4

01

STRUCTURES, MATERIALS, AND MECHANISMS

Objective

The Structures, Materials, and Mechanisms project has two goals: (1) to develop lightweight structures for lunar landers and surface habitats, which may be used in future modes of the Crew Exploration Vehicle (CEV) and crew launch vehicle to save weight and/or cost, and (2) to develop low-temperature mechanisms for rovers, robotics, and mechanized operations that may need to operate in shadowed regions of the Moon.

Status

The structures element of the Structures, Materials, and Mechanisms project consists of inflatable (expandable) structures for buildings on the surface of the Moon and very large single-segment propellant tank bulkheads made

|

3 |

C. Moore and F. Peri, “The Exploration Technology Development Program,” AIAA Paper 2007-136 in 45th Aerospace Sciences Meeting Conference Proceedings, American Institute of Aeronautics and Astronautics, Reston, Va., 2007. |

|

4 |

D.C. Beals, “Technology Infusion Planning Within the Exploration Technology Program,” IEEEAC Paper #1108, available at http://ieeexplore.ieee.org/iel5/4161231/4144550/04161576.pdf. |

of aluminum-lithium (Al-Li). The materials element consists of parachute material, radiation shielding kit materials, and Al-Li for very large propellant tank domes. Little in the way of advanced materials for lightweight vehicles, landers, rovers, and habitats was presented to the committee. The mechanisms element consists of gear boxes, electric motor sensors, and motor controls for robotic systems that would operate in continuous darkness at the poles.

Most elements of this project use system engineering principles to provide minimum risk and to ensure on-time delivery. Designing, fabricating, and testing a piece of demonstration hardware are aspects of all three elements. This project is staffed and conducted primarily at NASA, with a few industry and academic partnerships.

The potential application of lean manufacturing and rapid prototyping technologies needs to be fully explored in the current ETDP. Experience has shown that these technologies can have a significant impact on cost and schedule.

Ratings

Quality: Yellow Flag

Some team members appear to have little or no expertise in their project area. A lack of experience combined with limited interaction with industry can have a serious adverse impact on the quality of work. The lack of interaction with industry has resulted in situations in which NASA work has not yet reached the TRL level of similar projects in industry that are currently at TRLs of 6 or 7. An example of industry capability is Al-Li structures and welding. In addition, industry has demonstrated large friction stir weld-spun domes that are very close to the Ares I requirements. The alloy Ti Al Beta 21 S is currently being used by industry and is not being considered by NASA in the VSE program. The project group itself identified some existing manufacturing techniques not being used by NASA owing to licensing issues rather than technology development issues. It also appears that a lack of specific requirements in some cases has allowed in-house projects to float goals and produce simplistic measures of success.

Effectiveness in Developing and Transitioning: Yellow Flag

This set of activities seem to lack direct tie-in to an integrated, overarching plan. The objectives for most of the tasks are not rooted directly in supporting the VSE or Constellation Program requirements, which limits their ability to be transitioned to the customer. While this limits the risk to the customer, it also limits the overall effectiveness of the work. It is not clear why some specific elements of this project were selected; nevertheless, overall, the project is proceeding in a timely manner and the results are expected to be available to meet VSE and Constellation Program schedules.

Following are comments of the committee on specific project issues:

-

Aluminum-lithium manufacturing: friction stir weld-spun domes. The metals industry has been crafting friction stir weld and spun domes for a long time. The main reason for pushing this technology is the required size—that is, the 5.5-meter diameter. However, other non-NASA organizations have achieved this technology in sizes very close (5.2 m) to what NASA is trying to achieve. The benefit to the Constellation configuration from incorporating this technology with a small delta in dimension from the state of the art is not clear.

-

Low-temperature mechanisms. This project element has selected a few components and tested them under the cold temperature extremes present on the Moon. However, when asked about its specific application, the project team was unsure. Some components may work individually under the specified environment but may not function as part of higher-level subsystems or systems.

-

Advanced material for parachutes. This project element lacks a useful figure of merit. Material is being evaluated for potential application as the CEV parachute material. Team members stated that this material has a strength-to-weight ratio approximately twice that of other currently available fibers, and consequently, that it will yield more than 40 kg in mass savings for the three CEV parachutes. Unanswered is the question of the cost per kilogram to achieve this reduction in mass and the resulting overall gain in system performance.

-

Expandable structures. This project element uses lunar regolith as part of a pressurized architecture, which is somewhat cumbersome. It is not clear that this is the best design solution because, for example, the abrasive dust in a low-gravity situation could be a menace to equipment and personnel.

-

Advanced composite structures. Exotic materials, such as lightweight composites, often promise great advantages on paper and sometimes in practice. It was not clear from the presentation of the team responsible for this element how and where these composite materials were going to be applied throughout the Constellation Program. The performance benefit or the figure of merit was not clearly identified. Composite materials may potentially provide significant advantages in weight reduction, but system trade-offs are needed in order to identify and quantify those gains.

-

Facilities. No new facilities were identified by the committee as needed to validate performance capabilities.

-

Radiation shielding kit. This technology, which proposes a type of blanket or sleeping bag approach as a portable shield, is a good fundamental research area. However, unless its specific application to various program elements is identified, it is very difficult to see its impact. The use of this kit was not traded against other competing options, and it requires figures of merit.

Alignment with the Objectives of the Vision for Space Exploration: Yellow Flag

The performance benefit to the VSE and Constellation programs from the Structures, Materials, and Mechanisms project may not be fully achieved because of an apparent lack of specific requirements coming from the Constellation Program office. There appears to be little in the way of enabling technology in this project. Therefore, a strong push for these technologies by the customer is not apparent.

02

ABLATIVE THERMAL PROTECTION SYSTEM FOR THE CREW EXPLORATION VEHICLE

Objective

Extremely large heat fluxes are experienced by the Crew Exploration Vehicle (CEV) during reentry from the Moon or Mars. An ablative heat shield is required for thermal protection. The heat shield design and thermal protection system (TPS) material qualification represent major technological challenges. The NASA team for this project stated that the present TRL is 4. The TRL needs to be advanced to 6 to support the CEV project.

Status

The project team is composed of NASA, the companies producing the materials, and the CEV contractor. The work is being carried out in a coordinated manner and, overall, is of good quality. The currently used metrics are appropriate. It appears that an upgrade to the arc-jet facility at NASA’s Ames Research Center (ARC) will take place that will improve its flow simulation capabilities.

Material test specimens and TPS materials for the primary and backup CEV heat shields are being produced by aerospace companies. The CEV contractor has built a full-scale heat shield test article and will build the flight heat shield. These developments are being directed and reviewed by NASA to ensure the coordinated consideration of reentry mechanical and thermal loads. There is no possibility of alternate technologies being developed within the ETDP. The plan is to have an acceptable TPS design by CEV Preliminary Design Review (PDR) and to have the technology matured by CEV Final Design Review (FDR).

Ratings

Quality: Yellow Flag

The heat shield is being designed using heating rate predictions from an uncoupled analysis; that is, the char surface temperatures are assumed to be radiation equilibrium temperatures rather than being calculated from a heat

balance for the ablating heat shield. The injection of the pyrolysis gases and char oxidation products (which may significantly change the prediction of the heating rate) is ignored. This approach does not represent the current state of the art and could lead to either an over- or underprediction of the bond-line temperatures late in the entry.

While industry has been involved in producing candidate TPS material, there is no significant involvement of the national laboratories. However, organizations such as Sandia National Laboratories as well as other Department of Energy (DOE) and Department of Defense (DOD) laboratories could contribute to this effort.

Effectiveness in Developing and Transitioning: Yellow Flag

Even though 40 years have elapsed since the Apollo 4 flight test and the state of the art in heat shield design has advanced significantly during that time, the ability to simulate a lunar-return Earth entry in ground-based facilities still does not exist. The planned ground-test arc-jet facility improvements are desirable, but they will not provide an adequate approximation of all flight conditions and cannot be scaled to the full heat shield dimensions. Within the present state of the art, it is not possible to build ground test facilities that will duplicate (or even adequately approximate) flight conditions. Only a reentry flight test at lunar-return velocity and at a scale sufficient to assess the effects of joints and gaps between the heat shield panels will qualify the heat shield for use on a crewed lunar-return mission. Because NASA had not made a decision at the time that the committee was carrying out its data gathering, the committee was not clear as to whether an uncrewed flight test is planned; if not, the effectiveness with which this project is being developed and transitioned would be labeled with a red flag.

Alignment with the Vision for Space Exploration: Yellow Flag

Planetary-return heating rates are much higher than lunar-return heating rates. A CEV-like vehicle entering at 13 km/s from Mars will experience peak stagnation-point heating rates (convective and radiative) three times greater than the lunar-return values. Furthermore, at 13 km/s the stagnation-point heat load is approximately 70 percent radiative, whereas for lunar-return entries it is less than 25 percent. Therefore, an entirely different heat shield design may be required for reentry from Mars; hence the present technology does not fully support the entire VSE.

03

LUNAR DUST MITIGATION

Objective

Dust was an issue for the Apollo astronauts, and it continues to be an issue for the Mars Exploration Rovers (MERs). Dust presents both a health risk (e.g., from inhalation and damage to spacesuits) and a mission risk (e.g., for its obscuring of landing sites, causing equipment to overheat, and covering solar arrays). In response to these dust issues, NASA established the Lunar Dust Mitigation project, with the goal of providing the “knowledge and technologies (to TRL 6) required to address adverse dust effects to humans and to exploration systems and equipment, which will reduce life cycle cost and risk, and will increase the probability of sustainable and successful lunar missions.”5

Status

The Lunar Dust Mitigation project has clearly defined requirements that have been delineated into well-stated project plans to bring the TRL to 5. The development objectives of each of these plans were understood by the team members as clearly stated deliverables. Interaction within the NASA organizations involved in the project seems appropriate. The expertise of dealing with regolith resides within NASA, but outside sources are being sought in appropriate areas where industrial cooperation can benefit the program. The extensibility to Mars appears to be assumed, as the Moon is the current focus. The team seems to be motivated and enthusiastic about achieving its

goals. The team has test plans within the scope of available resources—that is, test facilities—but the need for full-scale testing is not reflected in the current project plan or the Constellation plan. Individual experiences within the Apollo program are being folded in to the development of the projects, except for the overall experience of equipment being crippled by dust contamination on the surface.

Ratings

Quality: Green Flag

The Lunar Dust Mitigation project plan has well-developed requirements and an appropriate layout of program elements to achieve a TRL of 5. Requirements from many sources are driving the correct program development to satisfy the goals. Outside sources have been sought for expertise in dust mitigation within the mining industry—more interaction with hard-rock mining would enhance this effort. Small Business Innovation Research (SBIR) projects are also being used to solicit outside expertise and advance the TRL in some areas. Apollo experiences with dust effects are being folded in to the technology plans. Component-level testing of various mechanisms in a vacuum environment is a good element of this program.

Effectiveness in Developing and Transitioning: Red Flag

Low-TRL ideas that would be matured later than 2013 are not being considered currently in SBIR or other programs; this will limit the continuity of new ideas being inserted into this project’s long-term goals. The production of regolith simulant in the time necessary to allow for testing also poses a risk to this effort. Currently, the risks are very high owing to the lack of full-scale, long-term testing to prove the effectiveness of the developed products. A full-scale test facility and the testing of equipment (e.g., bearings and seals, robots, EVA suits, crawlers) under long-term exposure are necessary for the ETDP to develop and prove the criticality of these vital resources on the Moon and Mars. The lack of plans to include a full-scale test facility negatively impacts the effectiveness of the effort in a major way and if left unresolved virtually guarantees failure to reach project goals expressed as TRL 6.

Alignment with the Vision for Space Exploration: Yellow Flag

The impact of the Lunar Dust Mitigation project on the VSE is clearly enabling, and this is understood by the Constellation Program. Without control of the effects of dust, exploration on the surface would be seriously compromised. Even robotic precursors could be less effective without this control. This is recognized by the NASA team and included in its project plans. The yellow flag rating reflects the lack of any development for the Mars environment—which may have its own problems with dust as shown by the MERs—as the lunar environment appears to be the sole focus of this project.

04

PROPULSION AND CRYOGENICS ADVANCED DEVELOPMENT

Objective

The Propulsion and Cryogenics Advanced Development (PCAD) project is focused on the development of the ascent and descent propulsion systems for the Lunar Lander. The team is working on three main areas: the descent main engine, the ascent main engine, and reaction control system (RCS) thrusters for the ascent propulsion system. According to NASA, the ascent liquid oxygen/methane (LOX/CH4) main engine is currently at TRL 3, the RCS thrusters are at TRL 4, and the descent main engine is at TRL 5.

Status

The PCAD team is composed of NASA employees and several contractors for the main engines and the RCS. The contractors include major aerospace companies and smaller companies. The PCAD project is well focused

around the established risk areas for each of the three main project elements that are being worked on. The main customers of PCAD are the Lunar Lander Projects Office (LLPO) and the Orion Crew Module Project Office.

For the descent main engine, the current choice of propellants is liquid oxygen/liquid hydrogen (LOX/LH2). This choice was made to meet the lander weight budget because the performance of LOX/LH2 is better than that of storable propellants. Meeting the throttle requirement for this engine (currently about 30 percent, but for some versions it could be lower) is mission enabling for the Lunar Lander. The main risks with this engine are stable throttling, performance, and reliable ignition.

For the ascent propulsion system, nitrogen tetroxide/monomethyl hydrazine (NTO/MMH) and LOX/CH4 are under consideration. However, the current technology project is focused only on LOX/CH4, since this is a new propellant combination to be used for this application. The projected benefits of using LOX/CH4 versus hypergolic fuels are higher performance, which translates into mass savings of approximately 180 kg to 360 kg; lower costs; and a comparable development schedule and achievable reliability. The main challenges that need to be resolved for the LOX/CH4 engine to be chosen over the storable propellants are reliable ignition (especially after long-term missions on the order of 6 months), performance, and fast start. RCS thrusters using LOX/CH4 are also being developed that are intended to have higher performance and maneuverability than those using storable propellants. In this case, the major risks are reliable ignition, performance, storability, and repeatable pulse width.

Although Russia, Korea, Pratt & Whitney Rocketdyne, and others are designing or have designed liquid oxygen/methane (LOX/CH4) engines, they are not designed for a similar application and therefore are not being used as a baseline for comparison with the current ascent engine being developed.

Both main engines and the proposed RCS described above minimize the contamination of the vehicle and landing area and improve ground procedures on the launch pad.

Ratings

Quality: Green Flag

The work of the PCAD project seems to be well coordinated among the primary customers, namely, the Lunar Lander Projects Office and the Orion Crew Module Project Office, the NASA technology development teams from the NASA Glenn Research Center (GRC), the NASA Johnson Space Center (JSC), and the NASA Marshall Space Flight Center (MSFC), and the contractors. The existing test facilities seem to be sufficient for this project.

For the descent engine, the team is pursuing a LOX/LH2 engine based on the RL-10 and is working with Pratt & Whitney Rocketdyne to develop the new engine. The team is tackling critical design issues, such as the injector design. Its metrics are well defined and relevant to the development program. The team is aware of the risks that it faces. However, there are gaps in the project that the team is aware of but could not address owing to insufficient resources: controls, turbomachinery, and high-heat-transfer chambers.

For the ascent module, the team is focusing on LOX/CH4 for the reasons mentioned above. The team plans to mature this technology before the LLPO has to choose between this new technology and hypergolic fuels. The team is very aware of the key parameters that it must demonstrate: reliable ignition, performance, and fast start. Its program is well tailored to these objectives. The team is simultaneously carrying out a development project for LOX/CH4 RCS thrusters that would go hand in hand with the main engine.

Effectiveness in Developing and Transitioning: Green Flag

The LLPO is considering two choices for the main ascent engine: LOX/CH4 and storables. Because the risks associated with developing an LOX/CH4 engine are greater than those associated with developing a storable propellant engine for this application, the decision has been made to focus only on the LOX/CH4 engine in the technology project. As a result of a first set of vehicle studies carrying out both options, the LLPO found that an LOX/CH4 engine could result in a mass savings of 180 kg to 360 kg. As of this writing, the decision about which type of engine to procure was slated for 2011 or so, after the PCAD team has had a chance to investigate in detail the prospect of using LOX/CH4 and has given its results to the LLPO and others to support an informed decision.

Within PCAD, preliminary tests carried out by the two contractors working on the LOX/CH4 engine are underway. Alternative designs are also being considered. The PCAD team and the LLPO are working closely to feed each other the results from their studies.

For the descent engine, the team is carrying only one contractor, Pratt & Whitney Rocketdyne, owing to cost constraints, which means that only one design is being considered. However, in terms of transition, the team is well positioned because the contractor has been involved from the beginning and has the experience to complete the full cycle of design, development, testing, and production.

Alignment with the Vision for Space Exploration: Green Flag

An LOX/CH4 main ascent engine would be a great benefit for Mars exploration because it is amenable to in situ resource utilization. The team has also tried to foresee what requirement changes the LLPO might present to it and has tried to develop flexible designs. For example, its LOX/CH4 engine project is expected to be flexible with respect to thrust changes and the number of the starts required.

The PCAD technology development team is pursuing “green” propellants such as LOX, LH2, and CH4, as opposed to hypergolic fuels, for both the descent and the ascent engines. One can only assume that such “green” propellants will continue to be the preferred choice for other exploration-class missions.

05

CRYOGENIC FLUID MANAGEMENT

Objective

The objective of the Cryogenic Fluid Management (CFM) project is to develop the technologies for the long-duration storage and distribution of cryogenic propellants in support of all Exploration missions. The development of these enabling technologies is crucial for various NASA customers in the Constellation Program including the Lunar Lander, Earth Departure Stage, and Lunar Surface Operations projects as well as for the Mars program.

Status

The scope of the Cryogenic Fluid Management project includes a number of interrelated elements: Long-Duration Propellant Storage, Cryogenic Propellant Distribution System, and Propellant Management Under Low-Gravity Environment. A number of design and test qualification tasks under each of these elements have been defined and are being executed according to the plan in place. The tasks are being performed primarily at various NASA centers—specifically, GRC, MSFC, JSC, ARC, Goddard Space Flight Center (GSFC), and Kennedy Space Center (KSC). The project includes a relatively smaller involvement from external agencies, including universities and small companies. The current TRLs were stated by the NASA team as follows: Propellant Storage—TRL 4, Propellant Distribution—TRL 5, Liquid Acquisition—TRL 4, Mass Gauging—TRL 3. However, based on the current technical maturity, a TRL of 4 for the Propellant Distribution System would be more appropriate.

The plans to achieve the desired TRL of 6 by the PDR of various Constellation elements include a combination of analytical modeling with component and integrated system tests under specified nonspace and simulated space environments. In some cases, such as Mass Gauging systems, a number of competing systems such as the Pressure-Volume-Temperature system, Radiofrequency Gauge, and Optical Mass Gauge are in the process of being evaluated.

Ratings

Quality: Yellow Flag

The CFM project is spearheaded by a very competent group. The involvement of industries and universities appears to be minimal compared with the direct NASA involvement. The analytical modeling work or the subscale-

level testing under a nonspace environment cannot be extrapolated to determine the performance and functions of the full-scale systems under zero- or low-gravity applications.

Effectiveness in Developing and Transitioning: Yellow Flag

A number of technology gaps may have serious consequences for the overall exploration program. Testing subscale or full-scale systems under low gravity is essential in order to demonstrate the applicability of the selected technologies or systems. The achievement of a TRL of 6 or higher before the PDR of various exploration elements may not be realized owing to the lack of these essential tests, mostly caused by funding or scheduling limitations. In some cases, the lack of a fully integrated system test before the flight may lead to undesirable risks. It was mentioned that the Constellation Program Office is evaluating the risks associated with bypassing some of these tests or the eventuality of not achieving the desired TRL 6 by the PDR. This position is in direct conflict with the “Enabling Technologies” designation assigned to the CFM project by the Exploration Program Office. (An “enabling technology” is understood to mean one that must be achieved to enable the success of the mission or an important component of the mission.) However, the committee did not see the absence of achieving a TRL of 6 as a major deficiency if an analysis of the program-level risks, underway at the time of writing, concludes that a TRL of 6 is not required.

Alignment with the Vision for Space Exploration: Yellow Flag

The architectural benefit of using cryogenic propellants in the exploration program is well understood and identified. The selection of LOX/LH2 for the Earth Departure Stage and the Lander Descent Module provides a significant performance benefit compared with other competing propellant systems. However, a number of technical risks associated with the long-duration-in-space storage, propellant distribution, and acquisition remain unresolved. Similarly, the same issues exist for the LOX/CH4 propulsion system that is currently being evaluated for application in the Lander Ascent Module. The lunar surface operations for later and longer missions covering up to 210 days require well-proven technologies for long-term cryogenic storage and fluid transfer between surface assets. However, the relationship and dependencies of the CFM systems and the lunar surface concepts of operations (CONOPS) were not described or presented to the committee. The applicability of the technologies and the design solutions identified for lunar missions to long-duration missions to Mars and beyond were not addressed.

06

ENERGY STORAGE

Objective

The objective of the Energy Storage project is to reduce risks associated with the use of lithium batteries, fuel cells, and regenerative fuel cells for the Lunar Lander, lunar surface systems, EVA, and both Ares I and Ares V. Major deliverables are rechargeable batteries for lander ascent, EVA, and lunar surface mobility; primary fuel cells for lander descent; and regenerative fuel cells for lunar surface power and lunar mobility. Rechargeable batteries and regenerative fuel cells are energy storage devices and cannot by themselves provide all the power needed for long-duration missions; a power source (solar or nuclear) is also needed. The objective is to deliver TRL 5 technologies to Constellation System Requirements Reviews and TRL 6 hardware for their PDRs.

Status

The battery and fuel cell research for the Energy Storage project is being carried out at GRC, the Jet Propulsion Laboratory (JPL), JSC, KSC, and a few university and industrial collaborators and contractors. NASA has very good facilities for both battery and fuel cell research and testing. The project is well coordinated among the NASA centers.

It is not clear if the current performance targets for the Energy Storage project will meet the future mission requirements. Customer requirements are not yet well established but presumably will be much better defined in the future. The present metrics are based on a bottom-up approach and, in lieu of established customer requirements, are appropriate as a temporary measure.

The NASA research effort is quite small compared with that of other agencies and of the battery and fuel cell companies. Consequently, by focusing on issues that are specific to its needs rather than trying to make fundamental advances in the technology, the project will reach its goals more effectively and at lower cost. Some NASA-focused issues include low-temperature operation and lightweight packaging for batteries, and fuel cell technologies that achieve high performance and long-term reliability without the cost constraints of the commercial market.

Ratings

Quality: Fuel Cells: Green Flag; Batteries: Yellow Flag

NASA’s needs for fuel cell development will not be met solely by the commercial market in that NASA’s focus is on mass reduction and the commercial market is focused on cost reduction. Furthermore, NASA fuel cells will operate on H2/O2, whereas commercial products operate on H2/air or gas mixtures (H2, CO2, and so on) derived from the reforming of conventional fossil fuels (e.g., natural gas, propane). The NASA fuel cell team is conducting high-quality research with modest resources. The project is fully cognizant of ongoing work in industry and other agencies and makes good use of related research underway in the broader fuel cell community. The team has benefited from a good investment in research and testing facilities.

Although GRC has a long history in electrochemical technology, the current battery team is in a state of transition, with a new project manager and a new principal investigator. Little evidence was presented to the committee to indicate that the battery work is well coordinated with non-NASA efforts. There appears to be only limited collaboration with DOE and DOD efforts. The battery team’s characterization of the current performance of space-rated batteries as a specific energy of 130 Wh/kg at 30°C at the cell level significantly underestimates the current state of the technology: space-rated cells with specific energies of greater than 165 Wh/kg are currently available from ABSL Space Products, SAFT S.A., and Quallion, although these cells are not yet qualified for human-rated applications. The team has good facilities for research and testing but does not have a capability for fabricating 18650-size cells (18 mm diameter by 65 mm length, a size commonly used in laptops) or larger cells. This indicates a lack of a well-developed plan and/or capability for transitioning NASA’s electrode and electrolyte materials development into full-scale hardware and its subsequent technology insertion into the Constellation Program. However, GRC is conducting a testing program on large cells procured from industrial battery developers, and other NASA centers are conducting a materials development effort in which new materials are tested in very small cells.

Effectiveness in Developing and Transitioning: Fuel Cells: Green Flag; Batteries: Yellow Flag

The current battery and fuel cell technologies used on EVA and the space shuttle are old technologies, and even technologies available today would provide significant performance benefits. The NASA development plan offers the potential for significant improvements over the state of the art, and it is on track to deliver the hardware at the needed TRL at the appropriate time for advanced lithium-ion batteries. However, lithium-sulfur and lithium-metal batteries will probably not reach the required TRLs to meet the Constellation Program’s schedule for the Lander Ascent Vehicle, EVA, and lunar surface mobility. The time line requires TRL 5 hardware for the Lander system requirement review by March 2012 and TRL 6 hardware for the EVA PDR by September 2012. This is due to the combination of the present state of development of lithium-sulfur and lithium-metal batteries and the very low level of planned future resources allocated to their development, particularly in the areas of safety and cycle life. Similarly, while the work on primary fuel cells is nearly on track to meet schedule requirements, that on regenerative fuel cells needs to be accelerated to meet the Constellation Program’s schedule requirements for the lunar surface systems.

NASA’s battery development efforts will have comparatively little impact on advancing the technology except in those areas where NASA’s requirements are unique (e.g., operations at very low temperatures). The multibillion dollar commercial market for lithium batteries will drive advances by industry, and other federal agencies such as DOE and DOD have much larger programs in lithium battery research and development (R&D). A unique feature of the NASA applications is that life requirements are lower, and thus some trade-offs in packaging can be implemented to reduce weight. Extending the operating temperature range of the batteries to extremely low temperatures would also benefit NASA. NASA’s fuel cell development efforts are less dependent on non-NASA research, as the objectives of the commercial fuel cell research are quite different, with its focus on reducing cost and its operation on air rather than oxygen. The regenerative fuel cell being developed by NASA could readily find application as an energy storage medium for terrestrial markets in intermittent renewable energy systems such as wind and solar.

Alignment with the Vision for Space Exploration: Green Flag

The research on battery and fuel cell technologies is well aligned with the VSE, and these technologies are critical to the Constellation requirements. Batteries have been identified as critical for the Lunar Lander and as enabling for EVA and lunar mobility. Primary fuel cells are critical for Lunar Lander power. Regenerative fuel cells have been identified as critical storage systems for Lunar Surface Systems. These technologies are also enabling for the Mars mission. Long-term durability and reliability under extreme conditions (particularly for fuel cells) may be critical for the Mars mission, and accelerated tests to understand durability and reliability issues should be included in the planning.

07

THERMAL CONTROL SYSTEMS

Objective

Nearly all Constellation hardware will require systems to mitigate the extreme temperature conditions encountered in space and on lunar and planetary surfaces. The objective of the Thermal Control Systems (TCS) project is to advance the technology readiness level for critical lunar thermal control system technologies and to mitigate thermal-control-specific Orion risks.

Status

The TCS technologies include a number of different projects underway at several NASA centers. The effort is focused on active thermal control technologies. Passive technologies are not viewed to be part of this project’s area of responsibility. Project elements include fluids, heat acquisition, evaporative heat sinks, radiators, system design and testing, and two-phase systems. To date, the technology efforts have focused almost exclusively on Orion. Over the next 3 years, NASA’s schedule shows that the efforts move more toward the Lunar Lander. Although it was noted that the lunar exploration goal is to land anywhere at any time, the specific efforts are wholly aimed at the initial landing, planned for not more than 7 days at one of the poles. Much of the team that was working in the thermal technology area has transitioned to roles on the Orion program. The current projects include the Orion efforts, which are now moving toward the integrated system test phase and toward early work on the planned Lander tasks.

Ratings

Quality: Yellow Flag

The emphasis of the Thermal Control Systems project is to re-engineer and optimize the existing Apollo systems to reduce their resource requirements (mass and power). Another aim of the effort is to transfer the technical knowledge from the older to the younger generation of engineers through the redesign of the old systems. While these projects will probably be useful to the Constellation Program in reducing mass and complexity, the focus on

incremental technology developments may miss alternative approaches. No overall vision is pushing new directions or looking far into the future. Furthermore, the movement of people off the technology projects and onto the Constellation hardware programs fosters the idea that the ETDP effort is not a technology development program but only an additional engineering resource for the Constellation thermal effort. There is little outside university or national laboratory involvement. Industry support seems to be focused on those companies with existing ties to specific NASA centers. Some supporting examples are given below.

To date, the technology focus of this project has been on active thermal control systems for Orion. One effort is aimed at replacing the old two-fluid (inside and outside) system with a common fluid used in both places. The benefit of this effort is aimed at reducing complexity, allowing common parts and interfaces between systems. The one stated goal of this effort was to generate long-term stability data for potential fluids. This result seems to be more of a supporting engineering role than a developmental one. Also, there is no metric to define whether this approach is actually beneficial to the Constellation Program’s efforts. Suggested metrics to determine if a single-fluid operation is superior to the two-fluid system are long-term fluid stability, system mass, heat rejection rate, power requirements, and cost.

Another goal was to develop a radiator system with at least a 25 percent mass reduction over the present orbiter radiator design. The issue with fluid-loop-coupled radiators is the connection between the metal fluid loop and the low-mass composite radiator. A significant amount of work has been done on composite radiators from a variety of organizations. The effort presented did not seem to build on any of that existing work. It was reported that the Constellation Program had not decided to go ahead with this technology.

It was noted that the thermal technology project is supporting the In Situ Resource Utilization (ISRU) and Robotics efforts because they do not have thermal expertise. Again, while this effort is useful, it is at some level draining resources from one area to support another. The result may be better systems in those areas that appear to need them, but the cost is the lack of development of new thermal technologies.

Finally, the technology effort is focused only on active systems. Passive systems are not part of this area of responsibility. Any longer-term lunar landing effort will need to combine both active and passive systems. The separation of these two fields means that any synergy that could be achieved by combining active and passive systems will be harder to find.

Effectiveness in Developing and Transitioning: Green Flag

The overall technology development effort of the TCS project seems to be well tied in to the Constellation Program. The project has defined objectives that were driven by Constellation’s needs and perceived risks. Customer service agreements (a form of contract between Constellation, which is the customer, and the ETDP, which is the supplier) are in place and being used. The efforts in the technology areas are reviewed frequently by the Constellation team. The detailed schedule for the technology development activities is in line with the Constellation Program’s reviews. Budgets are tracked and funds can be moved from one area to another on a quarterly basis. However, it is difficult to quickly add new organizations into the effort from a contractual perspective, which limits the project’s ability to include new suppliers.

It is difficult to assess how the project will fit into the overall Constellation effort. Most of the technology items discussed are in the early design stage. Milestones for early in 2008 include design and requirements reviews. Design and analysis reports are due later in the year. Project success will eventually be determined on the basis of how those technology items develop. Since the technology efforts tend to be incremental, there is a low risk of the technologies not achieving their objectives—the existing approach is the backup technology. Probably the most important goal is the change from a consumable-based cooling system to a closed system.

From a technology point of view, the project needs to be careful that the technology efforts are not just performing as the feeder team for the hardware programs. Much of the original Orion technology group has moved to hardware roles on the program. This transition of people is good for transferring ownership of the technology to the Constellation Program, but at the cost of losing experience in the technology team. Part of the technology effort needs to look forward at technologies that will change how things can be done. The present effort is almost entirely focused on improving the existing approach.

Alignment with the Vision for Space Exploration: Yellow Flag

The technology development plan of the TCS project is aimed at performance rather than at architectural benefits. A main goal for the elements of the projects is to reduce resources (mass, power, complexity) used by the active thermal control elements on the Orion and Lunar Lander systems.

The technology efforts are hampered by the fact that little work is being done on exploration technologies outside the Constellation Program. The project approaches presented to the committee focus on the Apollo architecture for getting to the Moon and staying there for a short period. The technologies will be of help in updating the Apollo designs for future use, but this inward focus may keep other ideas from surfacing that would support different architectural approaches.

The technologies discussed are specific to the Apollo architecture. Technologies for the lunar outpost and rovers are left to future years. The approach for any long-term habitats, in regions other than the poles, assumes that electrical power will be there to support large-scale heat pumps and cooling systems. Operation in the martian atmosphere and mitigation of long-term dust effects are gaps.

08

HIGH-PERFORMANCE AND RADIATION-HARDENED ELECTRONICS

Objective

The intent of the High-Performance and Radiation-Hardened Electronics (RHESE) project is to advance the current state of the art for radiation-hardened electronics. This is and will always be an issue of significant importance across all elements—with or without a crew—of U.S. space assets.

Status

The RHESE project includes close partnerships between NASA and academia. The project maintains some relationships with the DOD. The RHESE project includes five subprojects: modeling of radiation effects on electronics, single-event-effects-immune reconfigurable field-programmable gate arrays, high-performance processors, reconfigurable computing, and silicon-germanium (SiGe) electronics for extreme environments. The SiGe project has successfully demonstrated technology advances. This project will wrap up in 2009; the high-performance processor and reconfigurable computing projects are expected to ramp up around the same time.

Ratings

Quality: Yellow Flag

Although this work has elements that are quite interesting, and JPL is credibly among the best civilian agencies in the world in this arena, there are significant gaps in the RHESE project team’s knowledge of the state of the art across the panorama of U.S. agencies that conduct work in this area. A number of DOD activities are making significant progress in this field, and NASA will find it useful to make contact with them. The fact that NASA is currently collaborating with the Defense Advanced Research Projects Agency (DARPA) and the Defense Threat Reduction Agency on high-performance processor development was not elaborated on in the presentation to the committee but is hinted at in the project’s documentation. The extent of NASA’s collaboration is unclear with respect to tasking, funding split, and status, and it is uncertain that the project has the best approach to move forward. There is a pressing need for RHESE in NASA’s future missions, both human and robotic; however the roadmap, roles, and responsibilities between DOD and NASA need to be clarified and properly funded.

NASA has world-class researchers in this area, but management does not appear to have a sufficiently strong technical background to appreciate the opportunities for significant advancements in this field. This is an area in which the management of the project should be drawn from field expertise. Failure to resolve this issue is likely to limit NASA’s ability to truly understand the advances being made across all researchers in the United States and abroad in this key area. When these management issues are resolved, NASA will be in a position to determine

how to integrate its knowledge with input from external agencies. In this way, a complete understanding of the combined effects of radiation, thermal, volatile, and particulate environments that will be likely on the Moon can be brought to bear on the design of reliable electronic components.

Effectiveness in Developing and Transitioning: Yellow Flag

Those with experience in the long-term life of critical electronic components and systems in uncrewed systems (NASA has plenty of expertise, especially at JPL as well as at GSFC) know how much likelihood of failure should be allocated to these systems. It does not appear that the highest management levels for the Constellation/Orion missions understand these risks, nor is it even clear that appropriate industrial firms have been involved in risk allocations associated with the long-term functioning of space electronics for these missions. This concern is derived from the lack of concrete requirements, the apparent lack of any reasonable priority (by virtue of extremely low funding levels of some of the subtasks), and the apparent lack of upper management’s incorporation of electronics issues into mission architectures and planning.

An example of the lack of concern is that currently funded R&D teams in this area, as presented to the committee, are not deeply informed about the radiation or volatile environment on the lunar surface—an absolutely necessary prerequisite to the proper modeling of radiation effects on electronics. Radiation-hardened electronics can be an extremely expensive endeavor in terms of both cost and risk—improper design (ill-informed by physical realities) could deeply jeopardize deliverables such as electronics-based systems fabricated with these components, launch schedules, and even missions.

Finally, the work that was presented to the committee would apparently not be closed-loop system tested in a relevant environment, owing in large part to limited buy-in from mission elements. This fact limits the likelihood that these technologies can be validated for flight in time for insertion into mission architectures. Thus the incorporation of novel electronics concepts, such as redundancy and maintainability strategies, into mission architectures is effectively precluded, virtually eliminating any efficiencies that could be built in through more robust electronics.

Alignment with the Vision for Space Exploration: Green Flag

Clearly the work of the RHESE project has enormous applicability to lunar outpost and Mars missions. All of the work being done in its project elements is highly extensible to longer-term missions and to long-duration spaceflight and missions to the surface of Mars.

09

INTEGRATED SYSTEMS HEALTH MANAGEMENT

Objective

Integrated Systems Health Management (ISHM) is a system engineering discipline that addresses the design, development, operation, and life-cycle management of components, subsystems, vehicles, and other operational systems. The primary objectives of ISHM are to maintain nominal system behavior and function and to ensure mission safety and effectiveness under off-nominal conditions. ISHM is an enabling capability for risk mitigation, mission safety, and mission assurance for space exploration. Specifically, ISHM is to provide a systematic methodology to increase ground system availability for Constellation. The project elements presented were as follows:

-

Solid-rocket motor health management, with an add-on proof-of-concept test for NASA that will be accommodated in a flight demonstration on a DOD microsatellite called Tactical Satellite-3;

-

Integrated ground system diagnostics, with infusion into ground support and analyses infrastructure; and

-

In-space, closed-loop, long-duration validation of a complete ISHM system.

Status

The ISHM project plan contains a good analysis of the state of the art outside NASA and has a well-characterized and specific set of objectives. Integration of the objectives into operational missions a still a somewhat ambiguous matter to the committee.

Ratings

Quality: Green Flag

In the ISHM project, mid-TRL historical developments are used, with limited flight demonstrations, to develop flight heritage technologies that can be inserted into the Constellation Program. The technical approaches are solid, if somewhat limited. A good assessment has been made of what is required for the maturation of ISHM technologies such that actual mission program insertion can occur.

Effectiveness in Developing and Transitioning: Yellow Flag

There was no clear visibility for the roadmap and risks associated with the ISHM effort to expand and enhance the limited scope of developments underway to include the addition of new systems and subsystems. This seems, in part, a result of what appears to the committee to be limited buy-in from the customer, despite significant performance parameters assigned to this project for risk reduction in Constellation. For example, a full assessment of failure modes for a complete validation of models was described as needing 20 or so more hot-fire tests of an Ares I that were not included in either the project budgets or time lines.

A roadmap for building the end-to-end ISHM and its integration into the end-to-end flight controls would be a critical element in moving this rating from a yellow to green flag. Also important to effective transitioning would be a more detailed roadmap for flight qualification for the eventual end-to-end model.

Alignment with the Vision for Space Exploration: Green Flag

If effectively developed, integrated, and validated through lunar experience, ISHM technologies will provide critical risk management tools for future missions. Automated system health monitoring and management technologies are well aligned with the VSE, and they are critical to the Constellation requirements. These technologies are also clearly enabling for the Mars mission.

However, if the critical risk management tools are to evolve between now and a Mars mission, NASA is encouraged to look at ways to increase safety (reliability) margins in vehicle design, not simply to improve the control and monitoring software. While this project is clearly aligned with the VSE, the approach may not be complete enough to allow a transition to future elements of the VSE without a great deal more work.

10

AUTONOMY FOR OPERATIONS

Objective

The primary objective of the Autonomy for Operations (A4O) project is to provide software tools to maximize productivity and minimize workload for mission operations by automating procedures, schedules of activities, and plans. The primary customer for the technology is Constellation. The technology will provide mission operations software capabilities for Constellation mission operations, onboard control, crew assistance, and robotics. The key technologies are reusable building blocks, the automation of mission operations functions, and support for human interaction. Current testing opportunities have primarily focused on using data from the International Space Station (ISS).

Status

Non-NASA technology development efforts for procedure automation, software validation, and verification (V&V) currently exist. A4O technology has primarily focused on ISS-based applications, in which the state of the practice is primarily manual (for the construction of command sequences). The current team is composed of ARC, JSC, Langley Research Center (LaRC), and JPL personnel. There are some university and industry partnerships. Deliverables include (1) procedure development environment and procedure automation, with success criteria equating to reduction by a factor of 2 to 10 in the time to create procedures, time to validate procedures, and number of errors; and (2) mission control center, training management, and flight product production automation, with success criteria equating to reduction by a factor of 2 in the time to validate the plan. Software validation is primarily through customer feedback, testing on relevant examples, and shadow-operations—that is, running the software in the background and testing to determine if the outputs match with what the humans did.

Ratings

Quality: Yellow Flag

The A4O technology development is focused on specific NASA objectives (in particular, ISS), yet the project does not provide a coherent picture of how individual software technologies under the A4O project address Constellation Program needs. Although advanced technologies in automation and software V&V currently exist, the project does not seem to build on a requirements or human factors perspective, which has been shown to be a standard practice in this area. It was also not fully shown how key performance metrics used to assess quality of effort will be analytically evaluated or compared to the state of the art in industry.

Effectiveness in Developing and Transitioning: Yellow Flag

The Constellation Program requirements that A4O technology seeks to address include five elements that focus on (1) control of automated functions, (2) fault detection and recovery, (3) integrated mission planning and analysis, (4) concurrent monitoring and control of three active space vehicles, and (5) the capability to return crew to Earth without ground communication. Although the goals of the project are properly outlined, a roadmap to project success is not obvious. In particular, it is unclear how these requirements directly map to the technology products (or stated achievements) that are being developed in the A4O project, or in deriving the key performance metrics for this project.

Infusion points into Orion and Lunar Lander operations are highlighted as milestones, but there is not a clear roadmap for transitioning development from ISS-specific examples to Constellation-specific examples. There seems to be a strong disconnect, or at least a lack of good communications, between the ETDP team and the customer, Constellation.

Alignment with the Vision for Space Exploration: Green Flag

The primary objective of providing software tools to maximize productivity and minimize the workload for mission operations, if achieved, could provide significant benefit toward achieving the VSE. The technology concepts would extend to other exploration missions as well as providing significant performance benefits. To achieve these benefits though, the A4O project needs to focus on getting direct buy-in from the mission operators/astronauts/technology user base.

11

INTELLIGENT SOFTWARE DESIGN

Objective

The Intelligent Software Design (ISD) project is intended to provide the Constellation Program with capabilities to analyze the behavior and support the certification of software-intensive, mission-critical systems over a wide range of nominal and off-nominal scenarios, in a highly automated fashion.

Status

Despite problem areas discussed below, the committee found that, overall, this is a well-conceived and well-planned project to develop model-based software validation and automatic code generation capabilities to decrease the costs of software development and the risks it faces in the Constellation Program. The criticality of autonomous and reconfigurable software design appears to be well understood by the ISD project implementers. It is unclear that flight project managers share this assessment, and this fact is reflected in unclear approaches for validation and testing. All elements—validation testing, autocode verification, model-based analysis, and reliable systems—have top-notch personnel and clearly articulated goals. This project is primarily conducted at NASA, however, with very little involvement of communities outside NASA.

In terms of technology infusion, a lack of clarity is inherent in many of the elements regarding the degree of autonomy needed by the customer versus the cost involved for mitigating risks identified in the Constellation Program and documented in the ISD project plan. This appears to be a function of unclear priorities provided by the Constellation Program for the infusion of these technical advances into the flight program.

Ratings

Quality: Green Flag

The ISD project team has made well-thought-out critical choices for addressing the project objectives and risks within the limitations of the unclear customer requirements. In this case, the team is pursuing a set of tools for reducing cost and risks in the complex mission-critical software systems required for Constellation. The team is aware of the risks that is faces. There are gaps in the program that the team is aware of but cannot address owing to cost issues. This is a well-balanced and appropriately focused program. The members of the team were very seasoned and experienced.

To a reasonable extent, the project takes advantage of commercial (non-NASA) work that is open source or what can credibly be called commercial off-the-shelf technology. The project could benefit from the additional involvement of universities and others in investigating the application of commercial concepts that would be considered low TRL because they have not been fully applied to a crewed space endeavor.

Effectiveness in Developing and Transitioning: Yellow Flag

The ISD project is subject to an aggressive schedule, and although the schedule is feasible, funding limits the probability of this project achieving its full goals in the time frame presented to the committee. Exacerbating the scheduling problem is the fact that no credible plans to fully test and verify the advances were presented to the committee. Currently, no subproject technologies are yet human-qualified. In general, although this would not be impossible to achieve, it is unclear how transition to TRL 6 will be successfully accomplished. Nevertheless, the present status does not threaten the success of the overall program.

Alignment with the Vision for Space Exploration: Green Flag

The benefit of this project to both lunar and Mars exploration is well aligned with the goals of the VSE. These technological advances, given the virtual guarantee that mission software will increase in complexity and requirements for reliability, will all be enabling for a Mars mission as well as the lunar mission.

12

AUTONOMOUS LANDING AND HAZARD AVOIDANCE TECHNOLOGY

Objective

The primary objective of the Autonomous Landing and Hazard Avoidance Technology (ALHAT) project is to develop and mature various hardware and software components that will aid lunar descent vehicles. Overall, the goal is for the system to enable safe, accurate, and precise landing near selected landing sites anywhere on the lunar surface unaided by humans. The primary customer for the technology is the Lunar Lander Projects Office.

Status

The technology that the ALHAT project develops includes hardware and software components. Some of the hardware components are locally developed sensors such as flash lidar (Light Detection and Ranging), scanning lidar, optical Doppler lidar, and cameras, whereas other components are commercially available sensors (inertial motion units, star trackers, and altimeters). The software components include algorithms to convert sensor data to vehicle-state information, algorithms that aid vehicle flight, and guidance and navigation algorithms. The TRL for the overall system varies. Some sensors can be considered to be at TRL 3 or 4 (flash lidar), whereas others have flown in space but have not been employed for lunar landing scenarios (scanning lidar). The algorithms range from TRL 3 to TRL 5. The current team is composed of personnel from JSC, LaRC, JPL, the Charles Stark Draper Laboratory, and Johns Hopkins University Applied Physics Laboratory. Moreover, there is some university and industry involvement (by the University of Texas at Austin, Utah State University, Jacobs Engineering Group, Inc., and Fastmetrix, Inc.).

Ratings

Quality: Gold Star

The quality of the NASA development effort on the ALHAT project is high. The team has the experience and expertise to carry out the technology development. Moreover, the team is working in a tightly coordinated manner. It has reported several major accomplishments and significant findings, ranging in scope from technical achievements, to vendor site visits, to written operation concept reports, to independent reviews of the ALHAT project.

The team has recognized several technology areas that had not previously been identified. These include a need for sensors that can provide real-time elevation maps of terrain during descent; a need to increase and improve the operational range, accuracy, and resolution of flash lidar; and a need for a velocimeter that can provide accurate and precise horizontal velocity measurements. It is noteworthy that the team has identified these gaps and plans to address each one by the Lunar Lander PDR in the year 2011.

The broader community is involved in this project; however, there is room for additional involvement. Facilities at LaRC, JPL, and JSC are being used and are adequate to advance to TRL 5. Achieving TRL 6 will require free-flier tests.

Effectiveness in Developing and Transitioning: Green Flag

The technology roadmap for the ALHAT project shows a systems engineering approach to problem solving. Continued development of hardware and software technology is planned, with significant milestones set for June

and September 2008. Technology testing and integration are ongoing, and will become the primary activity of the project in 2009 and beyond. The schedule shows ALHAT validation (TRL 5) in 2010. The technology transition plan shows that the ALHAT project will be infused into the Lunar Lander Projects Office by 2011. Moreover, tests on a free-flying test vehicle could provide TRL 6 prior to Lunar Lander FDR. The committee voiced some concern as to whether adequate consideration has been given to testing requirements that will take this technology to an integration stage such that TRL 6 is actually achievable within the time frame specified.

The schedule risks appear to be acceptable, and there appear to be no high-risk technology obstacles to the project.

Alignment with the Vision for Space Exploration: Green Flag

Overall, the ALHAT project is well aligned with the needs of the Lunar Lander Projects Office. The technology benefits the Constellation architecture and several elements of the VSE beyond the Constellation Program. The technologies and techniques appear to have an architectural benefit in that the methods will be applicable to any spacecraft landing on planetary surfaces. The approaches are aimed at having a high likelihood of success while minimizing risks and costs.

13

AUTOMATED RENDEZVOUS AND DOCKING SENSOR TECHNOLOGY

Objective

The primary objective of the Automated Rendezvous and Docking Sensor Technology (AR&DST) project is to reduce risk associated with relative navigation sensors for proximity operations and docking through development, testing, and simulation. The primary customer for the technology is the Orion project, but it is important to the Altair Lunar Lander as well as to future Exploration activities.

Status

The technology developed in this project will provide a vision navigation sensor (or suite of sensors) to aid rendezvous, proximity operations, and docking. The sensor(s) shall have an operational range that spans from 5 km to dock. The current effort is focused on the Natural Feature Image Recognition (NFIR) technique, the Next Generation Advanced Video Guidance Sensor (NGAVGS), and simulation and testing. The Orion program is in the process of a contractor-led AR&D sensor procurement, Vision Navigation Sensor (VNS), of its own that did not include NFIR or NGAVGS by definition, so the transition of this technology to the primary customer is unclear. It appears that the development status of both the NFIR and the NGAVGS is near TRL 5. It is important to mention that the predecessor to the NGAVGS, the Advanced Video Guidance Sensor (AVGS), was operational in some space flight testing on Orbital Express and the Demonstration of Autonomous Rendezvous Technology mission (TRL 7 to 8 was achieved), and therefore some elements of the NGAVGS may claim a higher TRL.

It is known that non-NASA technology development efforts for AR&D sensors are underway, but it appears that these techniques are not being strongly considered within the AR&DST project. Some of this is due to International Traffic in Arms Regulations concerns since this is a significant area of work outside the United States. The current team is composed of JSC, MSFC, and JPL personnel. There are no university or industry partnerships except for two recently selected SBIR projects.

Ratings

Quality: Yellow Flag

Critically, other non-NASA efforts may be extremely relevant to the Automated Rendezvous and Docking Sensor Technology project. The absence of university or industry partnerships suggests that these non-NASA potential solutions may be being overlooked.

It is unclear how the team plans to objectively and directly benchmark the NGAVGS and NFIR techniques and how the VNS, the Orion-procured sensor, will fit into the mix. Alternatives being developed outside NASA also may have a role in this objective comparison.

A mix of testing facilities exists within NASA (JSC and MSFC), at contractors, and within the DOD (Naval Research Laboratory). The plan by which all of these capabilities will be fully utilized is unclear since the focus by the NASA presenters addressing the committee was on JSC. The team did mention that it plans to revisit the testing plan to look at this wider set of facilities. Also, in the simulation area it does not appear that previous work both within and outside NASA was being fully utilized, since it was stated that the team is largely developing its own simulations at JSC.

Effectiveness in Developing and Transitioning: Yellow Flag

The project’s technology roadmap shows the continued development of NFIR and NGAVGS on parallel paths to 2010, with technology enhancements to support Orion from 2009 to 2012. Simulation and testing end after 2008, which appears to be a disconnect with continued NFIR and NGAVGS development unless it is assumed that Orion picks up this work. In 2011 Lunar Optical Navigation and technology enhancements begin funding to support the Altair Lunar Lander.

Since this project is only focused on the AR&D sensors rather than on the whole AR&D problem, it lacks a systems engineering approach to solving the problem and largely appears to be responding only to Orion requirements, many of which focus solely on the ISS mission. The sensor technology transition is scheduled for the summer of 2008 and will occur before the Orion PDR, which was moved from May 2008 to September 2008.

Many of the technology risks are associated with meeting the minimum range, maximum range, and frequency requirements. It is noteworthy that four of the five top project risks are ranked as high-likelihood, high-consequence risks. Risk management approaches are mentioned, but the technology development will need to be closely monitored and scrutinized.

Alignment with the Vision for Space Exploration: Yellow Flag

AR&D is often cited as a critical technology needed to support the VSE in the near term for Orion’s mission to the ISS, in the mid-term for the Altair Lunar Lander, and in the long term for future Mars architectures. That is why it is especially important that a holistic, systematic approach be taken to this technology. This project appears to the committee to suffer from a somewhat myopic focus on solely near-term needs for the Orion-to-ISS mission and on the sensors alone. This approach is likely to result in technologies that do not support the VSE as a whole and that penalize future elements.

14

EXPLORATION LIFE SUPPORT

Objective

The objective of the Exploration Life Support (ELS) project is to develop and mature life support system technologies that meet mission requirements approximately 6 years before flight or occupancy of the various elements of the Constellation Program such as the Crew Exploration Vehicle (Orion), Lunar Lander, Lunar Habitat, and the pressurized rovers. The technologies selected cover Air Revitalization Systems, Waste Management Systems, Water Recovery Systems, and Habitation Engineering.

Status

In the ELS project, critical technologies have been defined, responsibilities have been assigned to a large number of NASA centers, and grants and cooperative agreements have been established with non-NASA and non-U.S. organizations. In general, a great deal of this work is being developed and executed in-house, with little

explicit reference to knowledge outside NASA. The committee was advised that at one time there had been considerable collaboration with universities and other cooperative agreements but that these collaborations had all been terminated recently, primarily because of budget reductions. The research scope has also been impacted with the elimination of biological research related to plant and microbe growth, which had been part of the “closed loop life support” strategy followed for several decades previously (e.g., Controlled Ecological Life Support System, or CELSS). Without the fractional gravity research into plant growth and without the quantification of other variables, it is not clear how the life support loop will be closed. It was also unclear whether or not the research plan had been coordinated with the design reference missions for resupply to either lunar or Mars bases. The design reference missions assumed a reduction in costs due to resupply requirements by utilizing CELSS technologies.

In terms of requirements and risk mitigations, this project plan is less definitive than many others in the ETDP portfolio, and there is no clear roadmap for transition from technology development to infusion into final flight hardware.

Ratings

Quality: Yellow Flag