6.C GENERAL PROCEDURES FOR WORKING WITH HAZARDOUS CHEMICALS

6.C.2 Minimizing Exposure to Hazardous Chemicals

6.C.2.3 Avoiding Ingestion of Hazardous Chemicals

6.C.2.4 Avoiding Inhalation of Hazardous Chemicals

6.C.2.5 Avoiding Injection of Hazardous Chemicals

6.C.2.6 Minimizing Skin Contact

6.C.6 Use and Maintenance of Equipment and Glassware

6.C.7 Working with Scaled-Up Reactions

6.C.8 Responsibility for Unattended Experiments and Working Alone

6.C.9 Chemistry Demonstrations and Magic Shows

6.C.10 Responding to Accidents and Emergencies

6.C.10.1 General Preparation for Emergencies

6.C.10.2 Handling the Accidental Release of Hazardous Substances

6.C.10.3 Notification of Personnel in the Area

6.C.10.4 Treatment of Injured and Contaminated Personnel

6.C.10.7 Handling Leaking Gas Cylinders

6.C.10.8 Handling Spills of Elemental Mercury

6.D WORKING WITH SUBSTANCES OF HIGH TOXICITY

6.D.2 Experiment Protocols Involving Highly Toxic Chemicals

6.D.5 Special Precautions for Minimizing Exposure to Highly Toxic Chemicals

6.D.6 Preparing for Accidents with and Spills of Substances of High Toxicity

6.E WORKING WITH BIOHAZARDOUS AND RADIOACTIVE MATERIALS

6.F WORKING WITH FLAMMABLE CHEMICALS

6.F.4 Catalyst Ignition of Flammable Materials

6.G WORKING WITH HIGHLY REACTIVE OR EXPLOSIVE CHEMICALS

6.G.2 Reactive or Explosive Compounds

6.G.2.2 Personal Protective Apparel

6.G.2.3 Evaluating Potentially Reactive Materials

6.G.2.4 Determining Reaction Quantities

6.G.2.5 Conducting Reaction Operations

6.G.3.1 Peroxidizable Compounds

6.G.3.2 Peroxide Detection Tests

6.G.4 Explosive Gases and Liquefied Gases

6.G.7 Chemical Hazards of Incompatible Chemicals

6.H WORKING WITH COMPRESSED GASES

6.H.1 Chemical Hazards of Compressed Gases

6.H.2 Specific Chemical Hazards of Select Gases

6.I WORKING WITH MICROWAVE OVENS

6.J WORKING WITH NANOPARTICLES

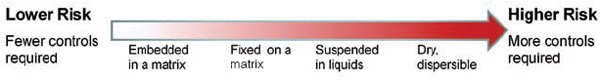

6.J.1.1 Nanomaterial Work Planning and Hazard Assessment

6.J.1.2 A Graded Approach to Determining Appropriate Nanomaterial Controls

Prudent execution of experiments requires not only sound judgment and an accurate assessment of the risks involved in the laboratory, but also the selection of appropriate work practices to reduce risk and protect the health and safety of trained laboratory personnel as well as the public and the environment. Chapter 4 provides specific guidelines for evaluating the hazards and assessing the risks associated with laboratory chemicals, equipment, and operations. Chapter 5 demonstrates how to control those risks when managing the inventory of chemicals in the laboratory. The use of the protocols outlined in Chapter 4 in carefully planned experiments is the subject of this chapter.

This chapter presents general guidelines for laboratory work with hazardous chemicals rather than specific standard operating procedures for individual substances. Hundreds of thousands of chemicals are encountered in the research conducted in laboratories, and the specific health hazards associated with most of these compounds are generally not known. Also, laboratory work frequently generates new substances that have unknown properties and unknown toxicity. Consequently, the only prudent course is for laboratory personnel to conduct their work under conditions that minimize the risks from both known and unknown hazardous substances. The general work practices outlined in this chapter are designed to achieve this purpose.

Specifically, section 6.C provides guidelines that are the standard operating procedures where hazardous chemicals are stored or are in use. In section 6.D, additional special procedures for work with highly toxic substances are presented. How to determine when these additional procedures are necessary is discussed in detail in Chapter 4, Section 4.C. section 6.E gives detailed special procedures for work with substances that pose risks due to biohazards and radioactivity, section 6.F addresses flammability, and section 6.G, reactivity and explosivity. Special considerations for work with compressed gases are the subject of Section 6.H. section 6.I covers microwave ovens, and section 6.J describes working with nanoparticles.

Chapter 7 provides precautionary methods for handling laboratory equipment commonly used in conjunction with hazardous chemicals. Chapters 4, 6, and 7 should all be consulted before working with hazardous chemicals.

Four fundamental principles underlie all the work practices discussed in this chapter. Consideration of each should be encouraged before beginning work as part of the culture of safety within the laboratory.

• Plan ahead. Determine the potential hazards associated with an experiment before beginning.

• Minimize exposure to chemicals. Do not allow laboratory chemicals to come in contact with skin. Use laboratory chemical hoods and other ventilation devices to prevent exposure to airborne substances whenever possible.

• Do not underestimate hazards or risks. Assume that any mixture of chemicals will be more toxic than its most toxic component. Treat all new compounds and substances of unknown toxicity as toxic substances. Consider how the chemicals will be processed and whether changing states or forms (e.g., fine particles vs. bulk material) will change the nature of the hazard.

• Be prepared for accidents. Before beginning an experiment, know what Specific action to take in the event of accidental release of any hazardous substance. Post telephone numbers to call in an emergency or accident in a prominent location. Know the location of all safety equipment and the nearest fire alarm and telephone, and know who to notify in the event of an emergency. Be prepared to provide basic emergency treatment. Keep your co-workers informed of your activities so they can respond appropriately.

Virtually every laboratory experiment generates some waste, which may include such items as used disposable labware, filter media and similar materials, aqueous solutions, and hazardous chemicals. (For more information about disposal of chemical waste, see Chapter 8.)

Before beginning any laboratory work, determine the hazards and risks associated with the experiment or activity and implement the necessary safety precautions. Ask yourself a hypothetical question before starting work: “What would happen if …?” Consider the possible contingencies and make preparations to take appropriate emergency actions. For example, what would be the consequences of a loss of electrical power or water pressure? Within each laboratory, all personnel should know the location of emergency equipment and how to use it, be familiar with emergency procedures, and know how to obtain help in an emergency. Laboratories should have a standing operational plan that describes how reactions, chemicals, and other laboratory processes will be handled in the case of a natural disaster or in the event that the individual responsible for laboratory activities is unavailable indefinitely (i.e., in the case of illness or death). Included in the plan should be emergency procedures and actions to be taken in the event that laboratory personnel experience a sudden medical emergency while performing an experiment.

Pay attention to the potential safety implications of subtle changes to experimental procedures. Slight changes to commonly performed operations often present unrecognized hazards. Changing solvents, suppliers, reagent concentration, reaction scale, and materials of construction may bring unintended consequences.

Determine the physical and health hazards associated with chemicals before working with them. This determination may involve consulting literature references, laboratory chemical safety summaries (LCSSs), material safety data sheets (MSDSs), or other reference materials (see also Chapter 4, section 4.B) and may require discussions with the laboratory supervisor, safety personnel, and industrial hygienists. Check every step of the waste minimization and removal processes against federal, state, and local regulations. Before producing mixed chemical-radioactive-biological waste (see Chapter 8, section 8.C.1.3) consult your institution’s or firm’s environmental health and safety (EHS) personnel.

Many of the general practices applicable to working with hazardous chemicals are given elsewhere in this volume (see Chapter 2). (See Chapter 5, section 5.F for detailed instructions on the transport of chemicals and section 5.E on storage; Chapter 7 for information on use and maintenance of equipment and glassware; and Chapter 8 for information on disposal of chemicals.)

6.C GENERAL PROCEDURES FOR WORKING WITH HAZARDOUS CHEMICALS

6.C.1 Personal Behavior

Demonstrating prudent behavior within the laboratory is a critical part of a culture of safety. This includes following basic safety rules and policies (see Chapter 2, section 2.C.1), being cognizant of the hazards within the laboratory (see Chapter 4), and exhibiting professionalism with co-workers. Maintaining an awareness of the work being performed in nearby hoods and on neighboring benches and any risks posed by that work is also important.

6.C.2 Minimizing Exposure to Hazardous Chemicals

Take precautions to avoid exposure by the principal routes, that is, contact with skin and eyes, inhalation, and ingestion (see Chapter 4, section 4.C, for a detailed discussion).

The preferred methods for reducing chemical exposure are, in order of preference,

1. substitution of less hazardous materials or processes (see Chapter 5, section 5.B, Green Chemistry for Every Laboratory),

2. engineering controls (Chapter 9),

3. administrative controls (Chapter 2), and

4. personal protective equipment (PPE)

See also the Occupational Safety and Health Administration’s (OSHA) Safety and Health Management eTool, Hazard Prevention and Control module available at www.osha.gov. Before beginning work, review all proposed laboratory procedures thoroughly to determine potential health and safety hazards. Refer to the MSDS for guidance on exposure limits, health hazards and routes of entry into the body, and chemical storage, handling, and disposal. Avoid underestimating risk when handling hazardous materials.

6.C.2.1 Engineering Controls

Engineering controls are measures that eliminate, isolate, or reduce exposure to chemical or physical hazards through the use of various devices. Examples include laboratory chemical hoods and other ventilation systems, shields, barricades, and interlocks. Engineering controls must always be considered as the first and primary line of defense to protect personnel and property. When possible, PPE is not to be used as a first line of protection. For instance, a personal respirator should not be used to prevent inhalation of vapors when a laboratory chemical hood (formerly called fume hoods) is available. (See Box 6.1 and Chapter 9 for more information about laboratory design and ventilation.)

6.C.2.2 Avoiding Eye Injury

Eye protection is required for all personnel and visitors in all locations where laboratory chemicals are stored or used, whether or not one is actually performing a chemical operation. Visitor eye protection should be made available at the entrances to all laboratories.

Researchers should assess the risks associated with an experiment and use the appropriate level of eye protection:

• Safety glasses with side shields provide the minimum protection acceptable for regular use. They must meet the American National Standards Institute (ANSI) Z87.1-2003 Standard for Occupational and Educational Eye and Face Protection, which specifies minimum lens thickness and impact resistance requirements.

• Chemical splash goggles are more appropriate

BOX 6.1

A Simple Qualitative Method to Verify Adequate Laboratory Chemical Hood Ventilation

Materials

200 g (approximately 250 mL) of dry ice pellets (5-to 10-mm diam)

Shallow bowl, approximately 3-L volume

1 L water at 43 °C (mix hot and cold water as needed to obtain the target temperature)

Thermometer

Procedure

1. Open the chemical fume hood sash to simulate actual operation. Position laboratory equipment as close as possible to where it will be used.

2. Place the shallow bowl approximately 15 cm into the chemical fume hood and in the center of the sash opening.

3. Add 1 L of the warm water to the bowl.

4. Add the dry ice pellets to the water.

5. After approximately 5 s, observe the vapor flowing from the bowl.

6. Repeat the observation while a colleague walks past or moves around the chemical fume hood to simulate actual operation.

7. If vapors are observed escaping the chemical fume hood face, the result is a fail; none escaping is a pass.

In the event of a failure or if there is any concern about proper operation, contact appropriate personnel and take corrective action. Adjustment of the sash opening and the baffles and relocation of equipment in the chemical fume hood should be considered.

NOTE: In addition, airflow should be measured on an annual basis.

than regular safety glasses to protect against hazards such as projectiles, as well as when working with glassware under reduced or elevated pressures (e.g., sealed tube reactions), when handling potentially explosive compounds (particularly during distillations), and when using glassware in high-temperature operations.

• Chemical splash goggles or face shields should be worn when there is a risk of splashing hazardous materials or flying particles.

• Because chemical splash goggles offer little protection to the face and neck, full-face shields should be worn in addition to safety glasses or goggles when conducting particularly hazardous laboratory operations (e.g., working with glassware under vacuum or handling potentially explosive compounds). In addition, glassblowing and the use of laser or ultraviolet light sources require special glasses or goggles.

• Operations at risk of explosion or that present the possibility of projectiles must have engineering controls as a first line of protection. For instance, in addition to chemical splash goggles or full-face shields, these operations must be conducted behind blast shields, in rubber-coated or taped glassware.

Ordinary prescription glasses do not provide adequate protection against injury because they lack side shields and are not resistant to impact, but prescription safety glasses and chemical splash goggles are available.

Similarly, contact lenses offer no protection against eye injury and do not substitute for safety glasses and chemical splash goggles. They should not be worn where chemical vapors are present or a chemical splash or chemical dust is possible because contact lenses can be damaged under these conditions. If, however, an individual chooses to wear contact lenses in the laboratory, chemical splash goggles must be worn. Note that there has been a change in recommended guidance regarding the wearing of contact lenses since the previous edition. Many organizations, including the National Institute for Occupational Safety and Health (NIOSH) (HHS/CDC/NIOSH, 2005) and the American Chemical Society (Ramsey and Breazeale, 1998) have removed most restrictions on wearing contact lenses in the laboratory.

6.C.2.3 Avoiding Ingestion of Hazardous Chemicals

Eating, drinking, smoking, gum chewing, applying cosmetics, and taking medicine in laboratories where hazardous chemicals are used or stored should be strictly prohibited. Food, beverages, cups, and other drinking and eating utensils should not be stored in areas where hazardous chemicals are handled or stored. Glassware used for laboratory operations should never be used to prepare or consume food or beverages. Laboratory refrigerators, ice chests, cold rooms, and ovens should not be used for food storage or preparation. Laboratory water sources and deionized laboratory water should not be used as drinking water. Never wear gloves or laboratory coats outside the laboratory or into areas where food is stored and consumed, and always wash laboratory apparel separately from personal clothing.

Laboratory chemicals should never be tasted. A pipet bulb, aspirator, or mechanical device must be used to pipet chemicals or to start a siphon. To avoid accidental ingestion of hazardous chemicals, pipetting should never be done by mouth. Hands should be washed with soap and water immediately after working with any laboratory chemicals, even if gloves have been worn.

6.C.2.4 Avoiding Inhalation of Hazardous Chemicals

Only in certain controlled situations should any laboratory chemical be sniffed.1 In general, the practice is not encouraged. Toxic chemicals or compounds of unknown toxicity should never be deliberately sniffed. Conduct all procedures involving volatile toxic substances and operations involving solid or liquid toxic substances that may result in the generation of aerosols in a laboratory chemical hood. Air-purifying respirators are required for use with some chemicals if engineering controls cannot control exposure. Significant training, along with a medical evaluation and respirator fit, are necessary for the use of respirators. For further guidance on the use of respirators with specific chemicals refer to Chapter 7, section 7.F.2.4 of this book, the OSHA Respiratory Protection Standard (29 CFR § 1910.134), and ANSI Standard Z88.2-1992.

Laboratory chemical hoods should not be used for disposal of hazardous volatile materials by evaporation. Such materials should be treated as chemical waste and disposed of in appropriate containers according to institutional procedures and government regulations. (See Chapter 8 for information on waste handling.)

6.C.2.4.1 General Rules for Laboratory Chemical Hoods

Detailed information regarding laboratory ventilation can be found in Chapter 9. The information here is intended to provide a brief overview. These general rules should be followed when using laboratory chemical hoods:

• Before using a laboratory chemical hood, learn how it operates. They vary in design and operation.

• For work involving hazardous substances, use only hoods that have been evaluated for adequate face velocity and proper operation. They should be inspected regularly and the inspection certification displayed in a visible location.

• Review the MSDS and the manufacturer’s label before using a chemical in the laboratory or hood. Observe the permissible exposure limit, threshold limit value, the primary routes of exposure, and any special handling procedures described within the document. Confirm that the experimental methods and available engineering controls are capable of controlling personnel exposure to the hazardous chemicals being used.

• Keep reactions and hazardous chemicals at least 6 in. (15 cm) behind the plane of the sash, farther if possible.

• Never put your head inside an operating hood to check an experiment. The plane of the sash is the barrier between contaminated and uncontaminated air.

• On hoods where sashes open vertically, work with the sash in the lowest possible position. Where sashes open horizontally, position one of the doors to act as a shield in the event of an accident. When the hood is not in use, the sash should be kept at the recommended position to maintain laboratory airflow.

• Keep laboratory chemical hoods clean and clear; do not clutter with bottles or equipment. If there is a grill along the bottom slot or a baffle in the back, clean it regularly so it does not become clogged with papers and dirt. Allow only materials actively in use to remain in the hood. Following this rule provides optimal containment and reduces the risk of extraneous chemicals being involved in any fire or explosion. Support any equipment in hoods on racks or feet to provide airflow under the equipment.

• Do not remove the airfoil, alter the position of inner baffles, block exterior grills, or make any other modifications without the approval of the appropriate staff.

• Report suspected laboratory chemical hood malfunctions promptly to the appropriate office, and confirm that the problems are corrected.

• If working in a glovebox, check the seals and pressures on the box before use.

Post the name of the individual responsible for the hood in a visible location. Clean hoods before maintenance personnel work on them.

(See Chapter 9, section 9.C, for more information on laboratory chemical hoods.)

_______________

1In a controlled instructional setting, students may be told to sniff the contents of a container. In such cases, the chemical being sniffed should be screened ahead of time to ensure that it is safe to do so. If instructed to sniff a chemical, gently waft the vapors toward your nose using a folded sheet of paper. Do not directly inhale the vapors.

6.C.2.5 Avoiding Injection of Hazardous Chemicals

Solutions of chemicals are often transferred in syringes, which for many uses are fitted with sharp needles. The risk of inadvertent injection is significant, and vigilance is required to avoid an injury. Use special care when handling solutions of chemicals in syringes with needles. When accompanied by a cap, syringe needles should be placed onto syringes with the cap in place and remain capped until use. Do not recap needles, especially when they have been in contact with chemicals. Remove the needle and discard it immediately after use in the appropriate sharps containers. Blunt-tip needles, including low-cost disposable types, are available from a number of commercial sources and should be used unless a sharp needle is Specifically required to puncture rubber septa or for subcutaneous injection.

6.C.2.6 Minimizing Skin Contact

6.C.2.6.1 Gloves

The OSHA Personal Protective Equipment (PPE) Standard (29 CFR §§ 1910.132-1910.138) requires completion of a hazards assessment for each work area, including an evaluation of the hazards involved and selection of appropriate hand protection. Wear gloves whenever handling hazardous chemicals, sharp-edged objects, very hot or very cold materials, toxic chemicals, and substances of unknown toxicity. No single glove material provides effective protection for all uses. Before starting, carefully evaluate the type of protection required in order to select the appropriate glove. The discussion presented here is geared toward gloves that protect against chemical exposure. (For information about gloves that protect against other types of hazards, see Chapter 7, section 7.F.1.4)

Select gloves carefully to ensure that they are impervious to the chemicals being used and are of correct thickness to allow reasonable dexterity while also ensuring adequate barrier protection. Choosing an improper glove can itself be a serious hazard in handling hazardous chemicals. If chemicals do penetrate glove material, they could be held in prolonged contact with the hand and cause more serious damage than in the absence of a proper glove. The degradation and permeation characteristics of the selected glove material must be appropriate for protection from the hazardous chemicals that are handled. Double gloves provide a multiple line of defense and are appropriate for many situations. Find a glove or combination of gloves that addresses all the hazards present. For example, operations involving a chemical hazard and sharp objects may require the combined use of a chemical-resistant (butyl, viton, or neoprene) glove and a cut-resistant (e.g., leather, Kevlar®) glove. Reusable gloves should be washed and inspected before and after each use. Be sure to wash your hands after wearing gloves and handling laboratory chemicals, to remove any skin contamination that might have occurred.

Gloves that might be contaminated with toxic materials should not be removed from the immediate area (usually a laboratory chemical hood) in which the chemicals are located. To prevent contamination of common surfaces that others might touch bare-handed, never wear gloves when handling common items such as doorknobs, handles, or switches on shared equipment, or outside the laboratory. Along the same lines, consider, before touching a surface while wearing gloves, whether it would be common for people to touch the surface with or without gloves and use appropriate precautions. For example, controls for hood nitrogen or water may be located outside the hood itself but may well be contaminated.

When working with chemicals in the laboratory, wear gloves of a material known to be resistant to permeation by the substances in use. Glove selection guides for a wide array of chemicals are available from most glove manufacturers and vendors. In general, nitrile gloves are suitable for incidental contact with chemicals. Both nitrile and latex gloves provide minimum protection from chlorinated solvents and should not be used with oxidizing or corrosive acids. Latex gloves protect against biological hazards but offer poor protection against acids, bases, and most organic solvents. In addition, latex is considered a sensitizer and triggers allergic reactions in some individuals. (For more information, see section 6.C.2.6.1.1) Neoprene and rubber gloves with increased thickness are suggested for use with most caustic and acidic materials. Barrier creams and lotions can provide some skin protection but are never a substitute for gloves, protective clothing, or other protective equipment. Use these creams only to supplement the protection offered by PPE.

According to the National Ag Safety Database (www.nasdonline.org), a program supported by NIOSH and the Centers for Disease Control and Prevention, materials that are used in the manufacture of gloves designed to provide chemical resistance include the following:

• Butyl is a synthetic rubber with good resistance to weathering and a wide variety of chemicals.

• Natural rubber latex is a highly flexible and conforming material made from a liquid tapped from rubber plants. It is a known allergen. (See section 6.C.2.6.1.1 for more information.)

• Neoprene is a synthetic rubber having chemical and wear-resistance properties superior to those of natural rubber.

• Nitrile is a copolymer available in a wide range of acrylonitrile content; chemical resistance and stiffness increase with higher acrylonitrile content.

• Polyethylene is a fairly chemical-resistant material used as a freestanding film or a fabric coating.

• Poly(vinyl alcohol) is a water-soluble polymer that exhibits exceptional resistance to many organic solvents that rapidly permeate most rubbers.

• Poly(vinyl chloride) is a stiff polymer that is made softer and more suitable for protective clothing applications by the addition of plasticizers.

• Polyurethane is an abrasion-resistant rubber that is either coated into fabrics or formed into gloves or boots.

• 4H®or Silvershield® is a registered trademark of North Hand Protection; it is highly chemical-resistant to many different class of chemicals.

• Viton®, a registered trademark of DuPont, is a highly chemical-resistant but expensive synthetic elastomer.

When choosing an appropriate glove, consider the required thickness and length of the gloves as well as the material. Consult the glove manufacturer for chemical-specific glove recommendations and information about degradation and permeation times. Certain disposable gloves should not be reused. (For more information, see OSHA PPE Standard, 29 CFR § 1910.138, regarding hand protection.)

The following general guidelines apply to the selection and use of protective gloves:

• Do not use a glove beyond its expiration date. Gloves degrade over time, even in an unopened box.

• When not in use, store gloves in the laboratory but not close to volatile materials. To prevent chemical contamination of nonlaboratory areas by people coming to retrieve them, gloves must not be stored in offices or in break rooms or lunchrooms.

• Inspect gloves for small holes, tears, and signs of degradation before use.

• Replace gloves periodically because they degrade with use, depending on the frequency of use and their permeation and degradation characteristics relative to the substances handled.

• Replace gloves immediately if they become contaminated or torn.

• Replace gloves periodically, depending on the frequency of use. Regular inspection of their serviceability is important. If they cannot be cleaned, dispose of contaminated gloves according to institutional procedures.

• Decontaminate or wash gloves appropriately before removing them. [Note: Some gloves, e.g., leather and poly(vinyl alcohol), are water permeable. Unless coated with a protective layer, poly(vinyl alcohol) gloves will degrade in the presence of water.]

• Do not wear gloves outside the laboratory, to avoid contamination of surfaces used by unprotected individuals.

• Gloves on a glovebox should be inspected with the same care as any other gloves used in the laboratory. Disposable gloves appropriate for the materials being handled within the glovebox should be used in addition to the gloves attached to the box. Protect glovebox gloves by removing all jewelry prior to use.

6.C.2.6.1.1 Latex Gloves

Although natural rubber latex gloves can be used as protective equipment to prevent transmission of infectious diseases and for skin protection against contact with some chemicals, they can also cause allergic reactions. In addition to causing skin contact allergic reactions to individuals wearing the gloves, they can also cause allergic reactions through inhalation of latex proteins that may be released into the air when the powders used to lubricate the interior of the glove are dispersed as gloves are removed. Thus the risk of exposure via inhalation presents a risk both to the wearer of latex gloves and to sensitized individuals who may be working nearby.

Latex exposure symptoms include skin rash, respiratory irritation, asthma, and, in rare cases, anaphylactic shock. The amount of exposure needed to sensitize an individual to natural rubber latex is not known, but when exposures are reduced, sensitization decreases. Individuals with known latex allergies should never wear latex gloves and may not be able to work in areas where latex gloves are used. Persons with known latex allergies should follow their organization’s procedures to ensure that they are not exposed.

To help minimize the risk of exposure to latex allergens, NIOSH issued an alert, Preventing Allergic Reactions to Latex in the Workplace (HHS/CDC/NIOSH, 1997). NIOSH recommends the following to reduce exposure to latex:

• Whenever possible, substitute another glove material.

• If latex gloves are the best choice, use reduced-protein, powder-free gloves.

• Wash hands with mild soap and water after removing latex gloves.

6.C.2.6.2 Clothing and Protective Apparel

Protective clothing should be used when there is significant potential for skin-contact exposure to chemicals. Protective clothing does not offer complete protection to the wearer and should not be used as a substitute for engineering controls. The protective characteristics of any protective clothing must be matched to the hazard. As with gloves, no single material that provides protection to all hazards is available. When multiple hazards are present, multiple layers of protective clothing may be required. Some types of PPE, such as aprons of reduced permeability and disposable laboratory coats, offer additional safeguards when working with toxic materials. (See also Chapter 7, section 7.F.1.1)

Commercial lab coats are fabricated from a variety of materials, such as cotton, polyester, cotton-polyester blends, polyolefin, and polyaramid. Selection of the proper material to deal with the particular hazards present is critical. For example, although cotton is a good material for laboratory coats, it reacts rapidly with acids. Plastic or rubber aprons can provide good protection from corrosive liquids but can be inappropriate in the event of a fire. Because plastic aprons can also accumulate static electricity, they should not be used around flammable solvents, explosives sensitive to electrostatic discharge, or materials that can be ignited by static discharge. Because many synthetic fabrics are flammable and can adhere to the skin, they increase the severity of a burn and should not be worn if working with flammable materials or an open flame. When working with flammable materials or pyrophorics, use laboratory coats made from flame-resistant, nonpermeable materials (polyaramids). Disposable garments may be a good option if handling carcinogenic or other highly hazardous materials. However, these provide only limited protection from vapor or gas penetration. Take care to remove disposable garments without exposing any individual to toxic materials and dispose of as hazardous waste.

To prevent chemical exposure from spilled materials in the laboratory, wear shoes that cover the entire foot. Perforated shoes, open-toe and open-heel shoes, sandals, or clogs should not be permitted. Shoes should have stable soles that provide traction in slippery or wet environments to reduce the chance of falling. Socks should cover the ankles so as to protect against chemical splashes. High heels should not be worn in the laboratory.

Once they have been used, laboratory coats and other protective apparel may become contaminated. Therefore, they must be stored in the laboratory and not in offices or common areas. Institutions should provide a commercial laundry service for laboratory coats and uniforms; they should not be laundered at home.

6.C.3 Housekeeping

A definite correlation exists between orderliness and the level of safety in the laboratory. In addition, a disorderly laboratory can hinder or endanger emergency response personnel. The following housekeeping rules should be adhered to:

• Never obstruct access to exits and emergency equipment such as fire extinguishers and safety showers. Comply with local fire codes for emergency exits, electrical panels, and minimum aisle width.

• Store coats, bags, and other personal items in the proper area, not on the benchtops or in the aisles.

• Do not use floors, stairways, and hallways as storage areas. Items stored in these areas can become hazards in the event of an emergency.

• Keep drawers and cabinets closed when not in use, to avoid accidents.

• Properly label (see Chapter 4, section 4.B.5) in permanent marker and store (see Chapter 5, section 5.E) all chemicals appropriately by compatibility.

• Label transfer vessels2 with the full chemical name, manufacturer’s name, hazard class, and any other special warnings.

• Store chemical containers in order and neatly. Face labels outward for easy viewing. Containers themselves should be clean and free of dust. Containers and labels that have begun to degrade should be replaced, repackaged, or disposed of in the proper location. Do not store materials or chemicals on the floor because these may present trip and spill hazards.

• Keep chemical containers closed when not in use.

• Secure all compressed gas cylinders to walls or benches in accordance with the guidance provided in Chapter 5, section 5.E.6.

• Secure all water, gas, air, and electrical connections in a safe manner.

• Return all equipment and laboratory chemicals to their designated storage location at the end of the day.

• To reduce the chance of accidentally knocking containers to the floor, keep bottles, beakers, flasks, and the like at least 2 in. from the edge of benchtops.

• Keep work areas clean (including floors) and uncluttered. Wipe up all liquid and ice on the floor promptly. Accumulated dust, chromatography adsorbents, and other chemicals pose respira-

_______________

2Transfer vessels may also be known as “secondary containers.” The term “transfer vessel” is used here to avoid confusion with secondary containment, which is a tray, bucket, or other container used to control spills from a primary container in the event of breakage.

tory hazards. To avoid formation of aerosols, dry sweeping should not be used in the laboratory. Remove broken glass, spilled chemicals, and paper litter from benchtops and laboratory chemical hoods.

• To avoid flooding, do not block the sink drains. Place rubber matting in the bottom of the sinks to prevent breakage of glassware and to avoid injuries.

• Do not pile up dirty glassware in the laboratory. Wash glassware carefully. Remember that dirty water can mask glassware fragments. Handle and store laboratory glassware with care. Discard cracked or chipped glassware promptly.

• Dispose of all waste chemicals properly and in accordance with organizational policies.

• Dispose of broken glass and in a specially labeled container for broken glass. Treat broken glassware contaminated with a hazardous substance as a hazardous substance.

• Dispose of sharps (e.g., needles and razor blades) in a specially labeled container for sharps. Treat sharps contaminated with a hazardous substance as hazardous substances.

Formal housekeeping and laboratory inspections should be conducted on a regular basis by the Chemical Hygiene Officer or a designee.

6.C.4 Transport of Chemicals

For more detailed information about transfer and transport of chemicals, see Chapter 5, section 5.F.

When transporting chemicals outside the laboratory or between stockrooms and laboratories, use only break-resistant secondary containment. Commercially available secondary containment is made of rubber, metal, or plastic, with carrying handle(s), and is large enough to hold the contents of the chemical containers in the event of breakage. Resealable plastic bags serve as adequate secondary containment for small samples.

When transporting cylinders of compressed gases, the cylinder must always be strapped in a cylinder cart and the valve protected with a cover cap. When cylinders must be transported between floors, passengers should not be in the elevator.

6.C.5 Storage of Chemicals

Avoid the accumulation of excess chemicals by acquiring the minimum quantities necessary for each procedure or research project. Properly label all chemical containers. Indicate any special hazards on the label. For certain classes of compounds (e.g., ethers as peroxide formers), write the date the container was opened on the label. For peroxide formers, write the test history and date of discard on the label as well.

Keep only small quantities (<1 L) of flammable liquids at workbenches. Larger quantities should be stored in approved storage cabinets. Store large containers (>1 L) below eye level on low shelves. Unless additional protection and secondary containment are provided, never store hazardous chemicals and waste on the floor. Be aware that fire codes dictate the total volume of flammable liquids, liquefied gases, and flammable compressed gases in a given work area. Ask your institution’s EHS expert for the fire code’s maximum flammable liquid and gas load for your laboratory, and ensure that your laboratory is in compliance with this code.

Refrigerators used for storage of significant quantities of flammable chemicals must be explosion-proof laboratory-safe units. Explosion-proof refrigerators are sold for this purpose and are labeled and hardwire installed. Such a refrigerator is mandatory for a renovated or new laboratory where flammable materials need refrigeration. Because of the expense of an explosion-proof refrigerator, a modified sparkproof refrigerator is sometimes found in older laboratories and laboratories using very small amounts of flammable materials. However, a modified sparkproof refrigerator cannot meet the standards of an explosion-proof refrigerator. Where they exist, a plan to phase out the sparkproof refrigerator is recommended.

Materials placed in refrigerators should be clearly labeled with water-resistant labels. Storage trays or secondary containment should be used to minimize the distribution of material in the event a container should leak or break. Retaining the shipping can for secondary containment is good practice. Regularly inspect storage trays, shipping cans, and secondary containment for primary container leaks and degradation. Laboratory refrigerators should have permanent labels warning against the storage of food and beverages for human consumption.

All chemicals should be stored with attention to incompatibilities so that if containers break in an accident, reactive materials do not mix and react violently.

(See Chapter 5, section 5.E, and Chapter 8, section 8.C.1.2, for more information.)

6.C.6 Use and Maintenance of Equipment and Glassware

Good equipment maintenance is essential for safe and efficient operations. Laboratory equipment should be regularly inspected, maintained, and serviced on schedules that are based on the manufacturer’s recom-

mendations, as well as the likelihood and hazards of equipment failure. Maintenance plans should ensure that any lockout procedures cannot be violated.

Carefully handle and store glassware to avoid damage. Discard or repair chipped or cracked items. Handle vacuum-jacketed glassware with extreme care to prevent implosions. Evacuated equipment such as Dewar flasks or vacuum desiccators should be taped, shielded, or coated. Only glassware designed for vacuum work should be used for that purpose.

Use tongs, a tweezer, or puncture-proof hand protection when picking up broken glass. Small pieces should be swept up with a brush into a dustpan. Glassblowing operations should not be attempted unless an area has been made safe for both fabrication and annealing. Protect your hands and body when performing forceful operations involving glassware. For instance, leather or Kevlar® gloves should be used when placing rubber tubing on glass hose connections. Cuts from forcing glass tubing into stoppers or plastic tubing are a common laboratory accident and are often serious. (See Vignette 6.1.) Constructing adaptors from glass tubing and rubber or cork stoppers is obsolete; instead, use fabricated, commercial adaptors made from plastic, metal, or other materials.

(See Chapter 7 for more discussion.)

6.C.7 Working with Scaled-Up Reactions

Special care and planning is necessary to ensure safe scaled-up work. Scale-up of reactions from those producing a few milligrams or grams to those producing more than 100 g of a product may magnify risks by several orders. Although the procedures and controls for large-scale laboratory reactions may be the same as those for smaller-scale procedures, significant differences may exist in heat transfer, stirring effects, times for dissolution, and the effects of concentration—all of which need to be considered. (See Vignette 6.2.) When planning large-scale work, practice requires consulting with experienced workers and considering all possible risks.

VIGNETTE 6.1

Finger laceration from broken tubing connector

A technician planned to replace the rubber vacuum tubing leading from a vacuum pump to a glass cold trap. While attempting to remove the old rubber tubing from the trap, the glass nipple broke and the broken glass cut the employee’s thumb. The technician did not don protective gloves or attempt to precut the rubber tubing to ease removal. The employee received three sutures.

VIGNETTE 6.2

Runaway reaction during scale-up

A researcher scaled up the cycloaddition reaction of maleic anhydride with quadricyclane, a strained high-energy hydrocarbon. This reaction is reported in the literature and was also previously performed in the researcher’s laboratory without incident, albeit at small scale (<10 g). No solvent is used in the procedure. The researcher combined the reagents (approximately 250 g total, a 20-fold scale-up) and began heating to the 60-70 °C target temperature. On reaching 50-60 °C the internal temperature rose very rapidly to more than 220 °C. The subsequent rapid boiling of the reagents dislodged the reflux condenser and expelled some liquid and solid into the chemical fume hood. There was no fire. The materials were fully contained within the chemical fume hood, with no injuries, personnel exposure, or equipment damage.

The likelihood of runaway exothermic reactions must be considered whenever conducting a reaction on a larger scale than previous experience. In the present example this possibility was increased by the use of ultrapure reagents and the lack of solvent. When using high-energy reagents, it is preferable to run them as dilute as possible in a solvent. This practice significantly lowers the energy density and significantly adds to the thermal mass, which help to decrease the chance of a runaway reaction. Slow addition of one reagent also limits the effects of an exothermic reaction.

Although one cannot always predict whether a scaled-up reaction has increased risk, hazards should be evaluated if the following conditions exist:

• The starting material and intermediates contain functional groups that have a history of being explosive (e.g., N—N, N—O, N—halogen, O—O, and O—halogen bonds) or that could explode to give a large increase in pressure.

• A reactant or product is unstable near the reaction or workup temperature. A preliminary test to determine the temperature and mode of de-

composition consists of heating a small sample in a melting-point tube.

• A reactant is capable of self-polymerization.

• A reaction is delayed; that is, an induction period is required.

• Gaseous byproducts are formed.

• A reaction is exothermic. What can be done to provide, or regain, control of the reaction if it begins to run away?

• A reaction requires a long reflux period. What will happen if solvent is lost owing to poor condenser cooling?

• A reaction requires temperatures less than 0 °C. What will happen if the reaction warms to room temperature?

• A reaction involves stirring a mixture of solid and liquid reagents. Will magnetic stirring be sufficient at large scale or will overhead mechanical stirring be required? What will happen if stirring efficiency is not maintained at large scale?

In addition, thermal phenomena that produce significant effects on a larger scale may not have been detected in smaller-scale reactions and therefore could be less obvious than toxic or environmental hazards. Thermal analytical techniques should be used to determine whether any process modifications are necessary.

Consider scaling up the process in multiple small steps, evaluating the above issues at each step. Be sure to review the literature and other sources to fully understand the reactive properties of the reactants and solvents, which may not have been evident at a smaller scale.

(See sections 6.D.1 and 6.G.1 and Chapter 5, section 5.B, for more information.)

6.C.8 Responsibility for Unattended Experiments and Working Alone

It is prudent practice to avoid working alone at the bench in a laboratory building. Individuals working in separate laboratories outside normal working hours should make arrangements to check on each other periodically, or ask security guards to check on them. Experiments known to be hazardous should not be undertaken by a person who is alone in a laboratory. Under unusually hazardous conditions, special rules, precautions, and alert systems may be necessary. (See also Chapter 2, section 2.C.2.)

Laboratory operations involving hazardous substances are sometimes carried out continuously or overnight with no one present. Although unattended operations should be avoided when possible, personnel are responsible for designing experiments to prevent the release of hazardous substances if utility services such as electricity, cooling water, and flow of inert gas are interrupted.

For unattended operations, laboratory lights should be left on, and signs should be posted identifying the nature of the experiment and the hazardous substances in use. If appropriate, arrangements should be made for other workers to periodically inspect the operation. Information should be posted indicating how to contact the responsible individual in the event of an emergency.

(See also Chapter 4, section 4.A.)

6.C.9 Chemistry Demonstrations and Magic Shows

All planned demonstrations and chemistry magic shows that will be performed by chemistry personnel that are not a part of normal laboratory activities should be preapproved and authorized by the organization and should follow all institutional policies. Activity organizers should obtain safety advice from experts as necessary. Experienced chemists who are interested in participating in such activities and want to use the organization’s chemicals and apparatus should submit an activity plan in advance of the event. This plan should include

• location of the demonstration,

• date of the event,

• age of the intended audience,

• number of persons who will attend the event,

• degree of audience participation,

• demonstrations that will be performed,

• list of chemicals that will be transported to the demonstration site, and

• PPE that will be worn and by whom.

All chemicals must be transported in accordance with U.S. Department of Transportation regulations, if applicable, and must be handled in a prudent manner, packaged appropriately, labeled properly, and transported back to the institution for disposal via the institution’s chemical waste disposal system. Under no circumstances should any chemicals be left at the demonstration site or disposed of there. Prior to the planned event, organizers should ensure that, if an accident involving chemicals occurs in their personal vehicles, they will be covered under their private insurance policies.

[For more information about safety when performing chemistry demonstrations, see the American Chemical Society’s NCW and Community Activity SAFETY GUIDELINES (available at http://portal.acs.org/).]

6.C.10 Responding to Accidents and Emergencies

6.C.10.1 General Preparation for Emergencies

Every laboratory should have a written emergency response plan that addresses injuries, spills, fires, accidents, and other possible emergencies and includes procedures for communication and response. All laboratory personnel should know what to do in an emergency. Laboratory work should not be undertaken without knowledge of the following points:

• how to report a fire, injury, chemical spill, or other emergency and how to summon emergency response;

• the location of emergency equipment such as safety showers and eyewash units;

• the location of fire extinguishers and spill control equipment;

• the locations of all available exits for evacuation from the laboratory; and

• how police, fire, and other emergency personnel respond to laboratory emergencies, and the role of laboratory personnel in emergency response.

The above information should be available in descriptions of laboratory emergency procedures and in the institution’s Chemical Hygiene Plan. Laboratory supervisors should ensure that all trained laboratory personnel are familiar with this information.

Trained laboratory personnel should know their level of expertise with respect to using fire extinguishers and emergency equipment, dealing with chemical spills, and handling injuries. They should not take actions outside the limits of their expertise but instead should rely on trained emergency personnel. A U.S. Environmental Protection Agency (EPA) regulation, Hazardous Waste Operations and Emergency Response (HAZWOPER), 29 CFR § 1910.120, specifies the training required for various response actions.

Names and contact information for individuals responsible for laboratory operations should be posted on the laboratory door.

6.C.10.2 Handling the Accidental Release of Hazardous Substances

Experiments should always be designed to minimize the possibility of an accidental release of hazardous substances. Laboratory personnel should use the minimum amount of hazardous material possible and perform the experiment so that, as much as possible, any spill is contained.

In the event of an incidental, laboratory-scale spill, follow these general guidelines, in order:

1. Tend to any injured or contaminated personnel and, if necessary, request help (see section 6.C.10.4).

2. If necessary, evacuate the area (see section 6.C.10.3).

3. Notify other laboratory personnel of the accident.

4. Take steps to confine and limit the spill if this can be done without risk of injury or contamination (see section 6.C.10.5).

5. Clean up the spill using appropriate procedures, if this can be done without risk of injury and is allowed by institutional policy. (see section 6.C.10.6).

6. Dispose of contaminated materials properly, according to the procedures described in Chapter 8, section 8.B.6.

(See Chapter 7, section 7.G for more information on emergency procedures.)

6.C.10.3 Notification of Personnel in the Area

Other nearby laboratory personnel should be alerted to the accident and the nature of the chemicals involved. If a highly toxic gas or volatile material is released, the laboratory should be evacuated and personnel posted at entrances to prevent others from inadvertently entering the contaminated area. In some cases (e.g., incidents involving the release of highly toxic substances and spills occurring in nonlaboratory areas), it may be appropriate to activate a fire alarm to alert personnel to evacuate the entire building. The proper emergency responders should be called. Follow your institution’s policies for such situations.

6.C.10.4 Treatment of Injured and Contaminated Personnel

If an individual is injured or contaminated with a hazardous substance, tending to him or her generally takes priority over implementing the spill control measures outlined in section 6.C.10.5 Obtain medical attention for the individual as soon as possible by calling emergency personnel. Provide a copy of the appropriate MSDS to the emergency responders or attending physician, as needed. If you cannot assess the conditions of the environment well enough to be sure of your own safety, do not enter the area. Call emergency personnel and describe the situation as best you can.

Every laboratory should develop specific procedures

for the highest-risk materials used in their laboratory. To identify these materials, consider past accidents, chemicals used in large volumes, and particularly hazardous chemicals. For example, laboratories in which hydrofluoric acid (HF) is used should establish special procedures for accidental exposures, and laboratory personnel should be trained in these emergency procedures. When specific procedures have not been established, the following steps provide general guidance.

For spills covering small areas of skin:

1. Immediately flush with flowing water for no less than 15 minutes; remove any jewelry or clothing as necessary to facilitate clearing of any residual materials.

2. If there is no visible burn, wash with warm water and soap.

3. Check the MSDS to determine if special procedures are needed or if any delayed effects should be expected.

4. Seek medical attention for even minor chemical burns.

5. Do not use creams, lotions, or salves, unless specifically called for.

For spills on clothes:

1. The emergency responder should wear appropriate PPE during emergency treatment to avoid exposure.

2. Do not attempt to wipe the clothes.

3. To avoid contamination of the victim’s eyes, do not remove the victim’s eye protection before emergency treatment.

4. Quickly remove all contaminated clothing, shoes, and jewelry while using the safety shower. Seconds count; do not waste time or limit the showered body areas because of modesty. Take care not to spread the chemical on the skin or, especially, in the eyes.

5. Cut off garments such as pullover shirts or sweaters to prevent spreading the contamination, especially to the eyes.

6. Immediately flood the affected body area with water for at least 15 minutes. Resume if pain returns.

7. Get medical attention as soon as possible. The affected person should be escorted and should not travel alone. Send a copy of the MSDS with the victim. If the institution’s MSDS is digital, hardcopies of the relevant information should be provided to responders. If the MSDS is not immediately available, it is vitally important that the person in charge convey the name of the chemical involved to the responders. The responders can then arrange for an MSDS to be available at the hospital, if necessary.

8. Discard contaminated clothes or have them laundered separately from other clothing.

For splashes into the eye:

1. Immediately flush with tepid potable water from a gently flowing source for at least 15 minutes. Use an eyewash unit if one is available. If not, place the injured person on his or her back and pour water gently into the eyes for at least 15 minutes.

2. Hold the individual’s eyelids away from the eyeball, and instruct him or her to move the eye up and down and sideways to wash thoroughly behind the eyelids.

3. Follow first aid by prompt treatment by medical personnel or an ophthalmologist who is acquainted with chemical injuries.

4. Send a copy of the MSDS with the victim. If the institution’s MSDS is digital, hardcopies of the relevant information should be provided to responders. If the MSDS is not immediately available, it is vitally important that the person in charge convey the name of the chemical involved to the responders. The responders can then arrange for an MSDS to be available at the hospital, if necessary.

For cuts:

1. WARNING: Always wear gloves as a precaution when there is risk of contact with blood or other potentially infectious fluids to prevent the transmission of bloodborne pathogens. (See OSHA 29 CFR § 1910.1030 for more information.)

2. If the injured person has experienced a minor cut, flush the wound with tepid running water to remove any possible chemical contaminants. If there is a cut on a gloved hand, remove the glove after thoroughly washing the affected area to avoid contamination of the cut with chemicals.

3. Apply a bandage and advise the victim to report any signs of infection to a physician. If there is a possibility that the wound is contaminated by broken glass or chemicals, the victim should seek immediate medical attention.

4. If the injured person has experienced a serious injury (if sutures will be necessary), call emergency personnel (911) and apply sterile gauze pads to the wound. If necessary, apply direct pressure to the wound to stop the bleeding.

5. Apply additional pads if blood soaks through the first sterile pad. If bleeding continues, encourage the victim to lie down and elevate the wound area to a position above the heart. If you are unable to stop the bleeding, remain calm and carefully explain the situation to the emergency dispatcher (911). The dispatcher will advise you on further action.

6. Send a copy of the MSDS with the victim. If the institution’s MSDS is digital, hardcopies of the relevant information should be provided to responders. If the MSDS is not immediately available, it is vitally important that the person in charge convey the name of the chemical involved to the responders. The responders can then arrange for an MSDS to be available at the hospital, if necessary.

For ingestion:

1. Call emergency personnel (911).

2. Do not encourage vomiting except under the advice of a physician. Call the Poison Control Center (800-222-1222) immediately and consult the MSDS for the appropriate action.

3. Save all chemical containers and a small amount of vomitus, if possible, for analysis.

4. Stay with the victim until emergency medical assistance arrives.

5. Send a copy of the MSDS with the victim. If the institution’s MSDS is digital, hardcopies of the relevant information should be provided to responders. If the MSDS is not immediately available, it is vitally important that the person in charge convey the name of the chemical involved to the responders. The responders can then arrange for an MSDS to be available at the hospital, if necessary.

If the victim is unconscious:

1. Call emergency personnel (911).

2. If it is safe for you to enter the area, place the victim on his or her back and cover with a blanket. Do not attempt to remove the victim from the area unless there is immediate danger.

3. Clear the area of any chemical spill or broken glassware.

4. If the victim begins to vomit, turn the head so that the stomach contents are not aspirated into the lungs.

5. Stay with the victim until emergency medical assistance arrives.

6. If the incident involves a chemical exposure, send a copy of the MSDS with the victim. If the institution’s MSDS is digital, hardcopies of the relevant information should be provided to responders. If the MSDS is not immediately available, it is vitally important that the person in charge convey the name of the chemical involved to the responders. The responders can then arrange for an MSDS to be available at the hospital, if necessary.

For convulsions:

1. Call emergency personnel (911).

2. If it is safe for you to enter the area, remove anything that might cause harm to the victim. Clear the area of any chemical spills or broken glassware.

3. If the victim begins to vomit, turn the head so that the stomach contents are not aspirated into the lungs.

4. Try to protect the victim from further danger with as little interference as possible. Do not attempt to restrain the victim.

5. Stay with the victim until emergency medical assistance arrives.

6. If the incident involves a chemical exposure, send a copy of the MSDS with the victim.

For burns from heat:

1. Call emergency personnel (911).

2. For first-degree burns, flush with copious amounts of tepid running water. Apply a moist dressing and bandage loosely.

3. For second-degree (with open blisters) and third-degree burns, do not flush with water. Apply a dry dressing and bandage loosely. Immediately seek medical attention.

4. Do not apply ointments or ice to the wound.

For cold burns:

1. Call emergency personnel (911).

2. Do not apply heat.

3. If it is not in the area involved, loosen any clothing that may restrict circulation.

4. Cryogenic liquids produce tissue damage similar to that associated with thermal burns and cause severe deep freezing with extensive destruction of tissue.

5. Flush affected areas with large volumes of tepid water (41–46 °C [105–115 °F]) to reduce freezing.

6. Cover the affected area with a sterile protective dressing or with clean sheets if the area is large, and protect the area from further injury.

7. Seek medical attention.

6.C.10.5 Spill Containment

All personnel who work in a laboratory in which hazardous substances are used should be familiar with their institution’s policy regarding spill control. For non-emergency3 spills, spill control kits may be available that are tailored to the potential risk associated with the materials being used in the laboratory. These kits are used to confine and limit the spill if such actions can be taken without risk of injury or contamination. An individual should be assigned to maintain the kit. Store spill kits near areas where spills may occur. Typical spill control kits include these items:

• spill control pillows, which are commercially available and generally can be used for absorbing solvents, acids, and caustic alkalis, but not HF;

• inert absorbents such as vermiculite, clay, sand, kitty litter, and Oil Dri, but not paper because it is not an inert material and should not be used to clean up oxidizing agents such as nitric acid;

• neutralizing agents for acid spills such as sodium carbonate and sodium bicarbonate;

• neutralizing agents for alkali spills such as sodium bisulfate and citric acid;

• large plastic scoops and other equipment such as brooms, pails, bags, and dustpans; and

• appropriate PPE, warnings, barricade tapes, and protection against slips or falls on the wet floor during and after cleanup.

In an emergency,4 follow institutional guidelines regarding spill containment.

6.C.10.6 Spill Cleanup

Specific procedures for cleaning up spills vary depending on the location of the accident, the amount and physical properties of the spilled material, the degree and type of toxicity, and the training of the personnel involved. Any cleanup should be performed while wearing appropriate PPE and in line with institutional guidance. General guidelines for handling several common incidental, non-emergency spills follow:

• Materials of low flammability that are not volatile or that have low toxicity. This category of hazardous substances includes inorganic acids (e.g., sulfuric and nitric acid) and caustic bases (e.g., sodium and potassium hydroxide). For cleanup, appropriate PPE, including gloves, chemical splash goggles, and (if necessary) shoe coverings, should be worn. Absorption of the spilled material with an inert absorbent and appropriate disposal are recommended. The spilled chemicals can be neutralized with materials such as sodium bisulfate (for alkalis) and sodium carbonate or bicarbonate (for acids), absorbed on Floor-Dri or vermiculite, scooped up, and disposed of according to the procedures detailed in Chapter 8, section 8.B.6.

• Flammable solvents. Fast action is crucial when a flammable solvent of relatively low toxicity is spilled. This category includes acetone, petroleum ether, pentane, hexane, diethyl ether, dimethoxyethane, and tetrahydrofuran. Other personnel in the laboratory should be alerted, all flames extinguished, and any spark-producing equipment turned off. In some cases the power to the laboratory should be shut off with the circuit breaker, but the ventilation system should be kept running. The spilled solvent should be soaked up with spill absorbent or spill pillows as quickly as possible. If this cannot be done quickly, evacuation should occur, and emergency personnel (911) should be called. Used absorbent and pillows should be sealed in containers and disposed of properly. Nonsparking tools should be used in cleanup.

• Highly toxic substances. The cleanup of highly toxic substances should not be attempted alone. Emergency responders should be notified, and the appropriate EHS expert should be contacted to obtain assistance in evaluating the hazards involved. These professionals will know how to clean up the material and may perform the operation.

• Debris management. Debris from the cleanup should be handled as hazardous waste if the spilled material falls into that category.

6.C.10.7 Handling Leaking Gas Cylinders

Leaking gas cylinders constitute serious hazards that may require an immediate evacuation of the area and a call to emergency responders. If a leak occurs, do not apply extreme tension to close a stuck valve. Wear appropriate PPE, which usually includes a self-contained breathing apparatus or an air-line respirator, when entering the area with the leak. (See also section 6.D.6.) The following guidelines cover leaks of various types of gases:

• Flammable, inert, or oxidizing gases. If safe to do so, move the cylinder to an isolated area, away from combustible material if the gas is flammable or an oxidizing agent. Post signs that describe

_______________

3A non-emergency response is appropriate in the case of an incidental release of hazardous substances where the substance can be absorbed, neutralized, or otherwise controlled at the time of release by personnel in the immediate area or by maintenance personnel.

4An emergency is a situation that poses an immediate threat to personal safety and health, the environment, or property that cannot be controlled and corrected safely and easily by individuals at the scene.

the hazards and state warnings. Take care when moving leaking cylinders of flammable gases so that accidental ignition does not occur. If feasible, move the leaking cylinder into a laboratory chemical hood until it is exhausted.

• Corrosive gases. Corrosive gases may increase the size of the leak as they are released, and some corrosives are also oxidants, flammable, or toxic. Move the cylinder to an isolated well-ventilated area, and, if possible, use suitable means to direct the gas into an appropriate chemical neutralizer. If there is apt to be a reaction with the neutralizer that could lead to a suck-back into the valve (e.g., aqueous acid into an ammonia tank), place a trap in the line before starting neutralization. Post signs that describe the hazards and state warnings.

• Toxic gases. The same procedure should be followed for toxic gases as for corrosive gases. Be sure to warn others of exposure risks. Move the cylinder to an isolated well-ventilated area. Direct the gas into an appropriate chemical neutralizer. Post signs that describe the hazards and state warnings.

Contact the supplier for specific information and guidance.

6.C.10.8 Handling Spills of Elemental Mercury

When spilled in a laboratory, mercury can become trapped beneath floor tiles, under cabinets, and even between walls. Even at very low levels, chronic mercury exposure can be a serious risk, especially in older laboratory facilities, where multiple historic spills may have occurred. Government and standard-setting organizations have established cleanup standards for laboratory spills. These stringent standards ensure the safety of trained laboratory personnel, students, and future occupants of the space.

A portable atomic absorption spectrophotometer with a sensitivity of at least 2 ng/m3 or other suitable instruments are used to find mercury residues and reservoirs that result from laboratory spills, and for the final clearance survey. Follow institutional procedures in cleaning up spills. General guidelines for handling incidental, non-emergency elemental mercury spills are as follows:

• First, isolate the spill area. Keep people from walking through and spreading the contamination.

• Wear protective gloves, booties, and a Tyvek® suit when necessary, while performing cleanup activities.

• Collect the droplets on wet toweling, which consolidates the small droplets to larger pieces, or with a piece of adhesive tape. Do not use sulfur; the practice is ineffective and the resulting waste creates a disposal problem.

• Consolidate large droplets by using a scraper or a piece of cardboard.

• Use commercial mercury spill cleanup sponges and spill control kits.

• Use specially designed mercury vacuum cleaners that have special collection traps and filters to prevent the emission of mercury vapors. A standard vacuum cleaner should never be used to pick up mercury.

• Waste mercury should be treated as a hazardous waste. Place it in a thick-walled high-density polyethylene bottle and transfer it to a central depository for reclamation.

• Decontaminate the exposed work surfaces and floors by using an appropriate decontamination kit.

• Verify decontamination to the current standards by using a portable atomic absorption spectrophotometer or other suitable instrument as described above.

Prevent mercury spills by using supplies and equipment that do not contain mercury. (For information about reducing the use of mercury in laboratories, see Chapter 5, section 5.B.8.)

6.C.10.9 Responding to Fires

Fires are one of the most common types of laboratory accidents. All personnel should be familiar with the general guidelines below to prevent and minimize injury and damage from fires. Hands-on experience with common types of extinguishers and the proper choice of extinguisher should be part of basic laboratory training. (See also Chapter 7, section 7.F.2.)

Be prepared to respond to a fire:

• Preparation is essential! Make sure all laboratory personnel know the locations of all fire extinguishers in the laboratory, what types of fires they can be used for, and how to operate them correctly. Also ensure that they know the location of the nearest fire-alarm pull station, telephone, emergency contact list, safety showers, and emergency blankets.

• In case of fire, immediately notify emergency response personnel by activating the nearest fire alarm. After initial containment, it is also important to report all fires to appropriate personnel for possible follow-up action.

• Even though a small fire that has just started can

sometimes be extinguished with a laboratory fire extinguisher, attempt to put out such fires only if you are trained to use that type of extinguisher, confident that you can do it successfully and quickly, and from a position in which you are always between the fire and an exit to avoid being trapped. Do not attempt to extinguish fires of any size if the institution’s policy prohibits this. A fire can spread and surround you in seconds. Toxic gases and smoke present additional hazards. When in doubt, evacuate immediately instead of attempting to extinguish the fire. Only attempt to extinguish fires of any size if the institution’s policy allows.

• Put out fires in small vessels by covering the vessel loosely. Never pick up a flask or container of burning material.

• Extinguish small fires involving reactive metals and organometallic compounds (e.g., magnesium, sodium, potassium, and metal hydrides) with Met-L-X or Met-L-Kyl extinguishers or by covering with dry sand. Apply additional fire suppression techniques if solvents or combustibles become involved. Because these fires are very difficult to extinguish, sound the fire alarms before you attempt to put out the fire.

• In the event of a more serious fire, evacuate the laboratory and activate the nearest fire alarm. When the fire department and emergency response team arrive, tell them what hazardous substances are in the laboratory.

• If a person’s clothing catches fire, douse him or her immediately in a safety shower. The drop-and-roll technique is also effective. Use fire blankets only as a last resort because they tend to hold in heat and to increase the severity of burns by creating a chimney-like effect. Remove contaminated clothing quickly. Wrap the injured person in a blanket to avoid shock, and get medical attention promptly.

6.D WORKING WITH SUBSTANCES OF HIGH TOXICITY

Individuals who work with highly toxic chemicals, as identified in Chapter 4 (see section 4.C, Tables 4.1, 4.2, and 4.3), should be thoroughly familiar with the general guidelines for the safe handling of chemicals in laboratories (see section 6.C). They should also have acquired through training and experience the knowledge, skill, and discipline to carry out safe laboratory practices consistently. However, these guidelines alone are not sufficient when handling substances that are known to be highly toxic and chemicals that, when combined in an experimental reaction, may generate highly toxic substances or produce new substances with the potential for high toxicity. Additional precautions are needed to set up multiple lines of defense to minimize the risks posed by these substances. As discussed in section 6.B, preparations for handling highly toxic substances must include sound and thorough planning of the experiment, an understanding of the intrinsic hazards of the substances and the risks of exposure inherent in the planned processes, selection of additional precautions that may be necessary to minimize or eliminate these risks, and review of all emergency procedures to ensure appropriate response to unexpected spills and accidents. Each experiment must be evaluated individually because assessment of the level of risk depends on how the substance will be used. Therefore, a prudent planner does not rely solely on a list of highly toxic chemicals to determine the level of the risk; under certain conditions, chemicals not on these lists may react to form highly toxic substances.

In general, the guidelines in section 6.C reflect the minimum standards for handling hazardous substances and should become standard practice when handling highly toxic substances. For example, although working alone in laboratories should be avoided, it is essential that more than one person be present when highly toxic materials are handled. All people working in the area must be familiar with the hazards of the experiments being conducted and with the appropriate emergency response procedures.

Use engineering controls to minimize the possibility of exposure (see section 6.D.5). The use of appropriate PPE to safeguard the hands, forearms, and face from exposure to chemicals is essential in handling highly toxic materials. Cleanliness, order, and general good housekeeping practices create an intrinsically safer workplace. Compliance with safety rules should be maintained scrupulously in areas where highly toxic substances are handled. Source reduction is always a prudent practice, but in the case of highly toxic chemicals it may mean the difference between working with toxicologically dangerous amounts of materials and working with quantities that can be handled safely with routine practice. Emergency response planning and training are very important when working with highly toxic compounds. Additional hazards from these materials (e.g., flammability and high vapor pressures) can complicate the situation, making operational safety all the more important.

6.D.1 Planning

Careful planning should precede any experiment involving a highly toxic substance whenever the substance is to be used for the first time or whenever an experienced user carries out a new protocol that

increases the risk of exposure substantially. Planning should include consultations with colleagues who have experience in handling the substance safely and in protocols of use. Experts in the institution’s EHS program are a valuable source of information on the hazardous properties of chemicals and safe practice. They also need to be consulted for guidance regarding those chemicals that are regulated by federal, state, and local agencies or by institutional policy. Thoroughly review the wealth of information available in the MSDS, the literature, and toxicological and safety references.