9.B GENERAL LABORATORY DESIGN CONSIDERATIONS

9.B.1 Relationship Between Wet Laboratory Spaces and Other Spaces

9.B.1.1 Relationship Between Laboratory and Office Spaces

9.B.2.1 Considerations for Open Laboratory Design

9.B.3 Closed Laboratories and Access

9.B.4 Equivalent Linear Feet of Workspace

9.B.5 Laboratory Layout and Furnishing

9.B.5.2 Casework, Furnishings, and Fixtures

9.B.5.5 Doors, Windows, and Walls

9.B.6 Noise and Vibration Issues

9.B.7 Safety Equipment and Utilities

9.B.8 Americans with Disability Act: Accessibility Issues Within the Laboratory

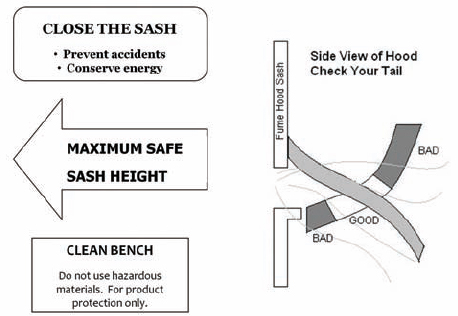

9.C.2 Laboratory Chemical Hoods

9.C.2.1 Laboratory Chemical Hood Face Velocity

9.C.2.2 Factors That Affect Laboratory Chemical Hood Performance

9.C.2.3 Prevention of Intentional Release of Hazardous Substances into Chemical Hoods

9.C.2.4 Laboratory Chemical Hood Performance Checks

9.C.2.7 Constant Operation of Laboratory Chemical Hoods

9.C.2.8 Testing and Verification

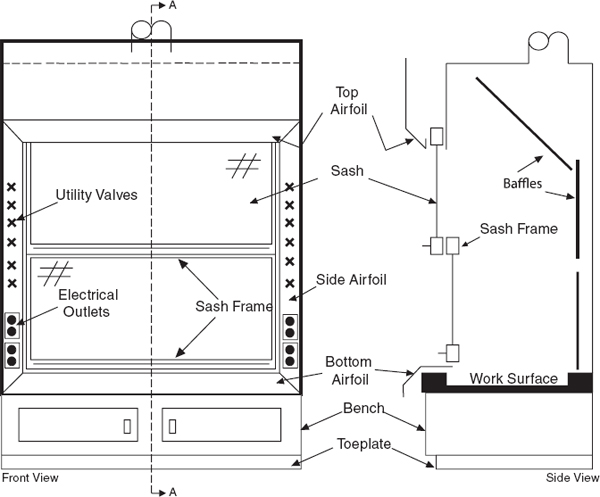

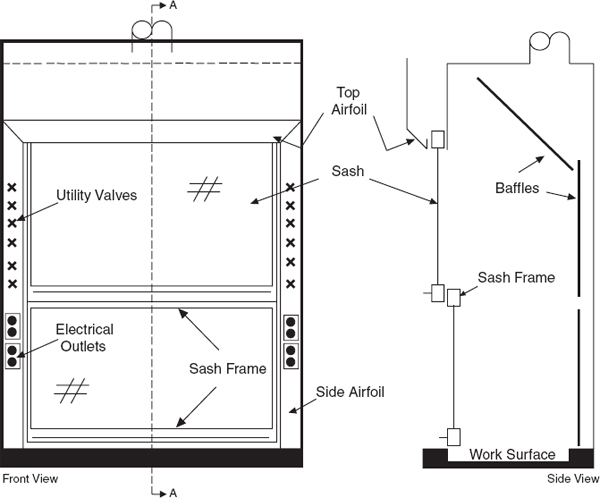

9.C.2.9 Laboratory Chemical Hood Design and Construction

9.C.2.10 Laboratory Chemical Hood Configurations

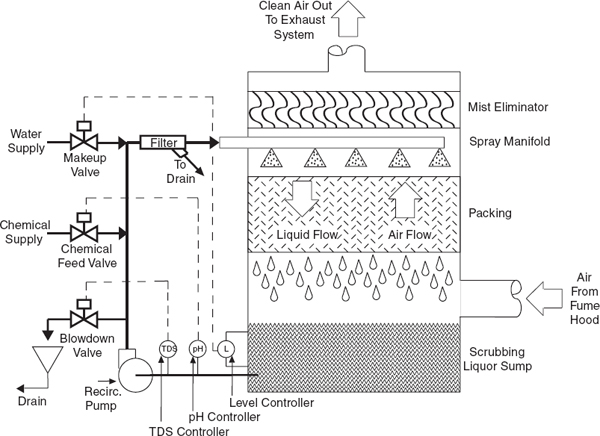

9.C.2.11 Laboratory Chemical Hood Exhaust Treatment

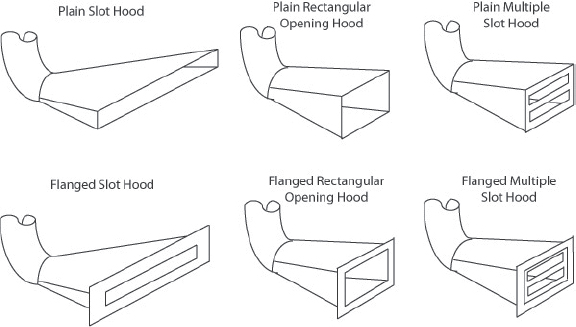

9.C.3 Other Local Exhaust Systems

9.C.3.1 Elephant Trunks, Snorkels, or Extractors

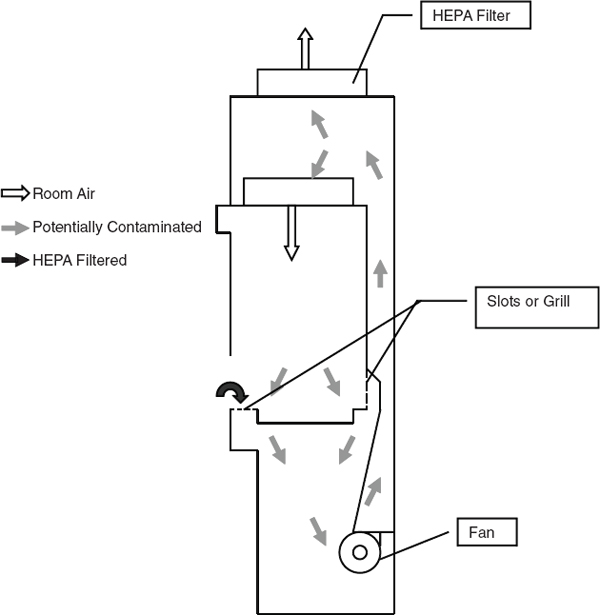

9.C.3.5 Clean Benches or Laminar Flow Hoods

9.C.3.8 Flammable-Liquid Storage Cabinets

9.C.4 General Laboratory Ventilation and Environmental Control Systems

9.C.4.1 Constant Air Volume (CAV) Systems

9.C.4.2 Variable Air Volume (VAV) Systems

9.C.6.1 Individual Laboratory Chemical Hood Fans

9.C.6.2 Manifolded (Common Header) Systems

9.C.6.3 Hybrid Exhaust Systems

9.D ROOM PRESSURE CONTROL SYSTEMS

9.E.2.1 Clean Room Classification

9.E.2.3 Laboratory Chemical Hoods and Laboratory Furniture in Clean Rooms

9.E.3 Environmental Rooms and Special Testing Laboratories

9.E.3.1 Alternatives to Environmental Rooms

9.E.4 Biological Safety Cabinets and Biosafety Facilities

9.E.4.2 Using a Biosafety Cabinet for Biological Materials

9.E.5 Nanoparticles and Nanomaterials

9.E.6 Explosion-Proof Chemical Hoods

9.F MAINTENANCE OF VENTILATION SYSTEMS

9.G VENTILATION SYSTEM MANAGEMENT PROGRAM

9.G.3 Inspection and Maintenance

9.G.4 Goals Performance Measurement

9.H.1 Low-Flow or High-Performance Laboratory Chemical Hoods

9.H.3 Variable Air Volume (VAV) Systems with Setback Controls

9.H.4 Variable Air Volume Systems, Diversity Factors

9.H.5 Lower General Ventilation Rates

9.H.6 Laboratory Chemical Hood Alternatives

9.H.8 Components of Heating, Ventilation, and Air-Conditioning (HVAC)

9.H.9 How to Choose a Ventilation System

9.I LABORATORY DECOMMISSIONING

Trained laboratory personnel must understand how chemical laboratory facilities operate. Given the chance, they should provide input to the laboratory designers to ensure that the facilities meet the needs of the functions of the laboratory. Laboratory personnel need to understand the capabilities and limitations of the ventilation systems, environmental controls, laboratory chemical hoods, and other exhaust devices associated with such equipment and how to use them properly. To ensure safety and efficiency, the experimental work should be viewed in the context of the entire laboratory and its facilities.

9.B GENERAL LABORATORY DESIGN CONSIDERATIONS

9.B.1 Relationship Between Wet Laboratory Spaces and Other Spaces

Modern laboratories, particularly in academia, often have contiguous spaces that include wet laboratories, computer laboratories, instruments, write-up spaces, office areas, and other spaces with varying degrees of chemical use and hazards. Maintaining a positive safety culture and at the same time meeting the safety and comfort needs of laboratory personnel are challenging under these circumstances.

• Wherever possible, separate wet chemical areas or those with a higher degree of hazard from other areas with a physical barrier, such as a wall, divider, or control device. The objective is to protect the computer laboratory or otherwise low-hazard area from the risk of the higher hazard, and thus eliminate the need to use protective equipment in the low hazard area.

• When such areas cannot be physically separated, or where the risk cannot be eliminated completely, individuals working at the computer or in the write-up area need to evaluate what level of protection may be needed to control the risk of exposure to the hazards in the other areas. For example, all individuals in a computer laboratory must wear eye protection if there is a risk of eye injury from operations in a contiguous area.

9.B.1.1 Relationship Between Laboratory and Office Spaces

Almost all laboratory personnel require both laboratory and office support space. Their desire to be aware of procedures and to have a constant presence in the laboratory usually demands that office space be located near the laboratory. The need for personnel safety, evolutionary technology allowing for computer-based research and data monitoring outside of the laboratory, as well as a desire to foster better interaction between researchers has driven the offices outside the laboratory proper.

Locating all offices outside the laboratory environment allows for a safer workspace where food can be consumed, quiet work can be done, and more paper and books can be stored. Locating the office zone very close to or adjacent to the laboratory for easy access and communication is desirable.

Some laboratories have office spaces within research areas. In this design, it is best to have an obvious separation between the laboratory area and the office area using partitions or, at a minimum, aisle space, but preferably using a wall and a door that can be closed. Occupants should not have to walk through laboratory areas to exit from their office space. Visitors and students should not have to walk through laboratories to get to researchers’ offices, because those persons do not have personal protective equipment (PPE). (See Vignette 9.1.)

9.B.2 Open Laboratory Design

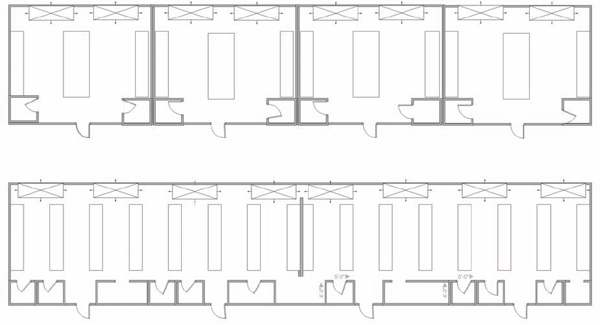

Traditionally, laboratories were designed for individual research groups with walls separating the laboratories and support spaces. Group sizes ranged from 2 to 10 people, and most groups were completely self-contained, each with its own equipment and facilities (Figure 9.1).

Since the 1990s, the trend has been for researchers to collaborate in a cross-disciplinary nature; chemists, biologists, physicists, engineers, and computer scientists work together on a common goal. At the same time, laboratory designers have moved to open multiple-module laboratories that allow a wide variety of configurations for casework and equipment setups. These laboratories often support large or multiple teams and are configured with relocatable furnishings.

Even when not using a multidiscipline approach, many facilities have moved toward larger, more open laboratories with the belief that working in teams raises overall productivity, promote open communication, and facilitates resource sharing. Team sizes, in some disciplines, have risen and are frequently as high as 12 to 20 individuals.

9.B.2.1 Considerations for Open Laboratory Design

There are advantages and disadvantages to open laboratory design.

VIGNETTE 9.1

Appropriate use of personal protective equipment in shared spaces

In both these incidents, the research laboratories contained writing spaces with computer workstations and desks that were separated from the working part of the laboratory by only an aisle.

In one laboratory, a person was holding a 250-mL glass flask when it overpressurized and burst, spraying shards of glass across the laboratory. Not only did the person holding the flask receive multiple lacerations, but another person not involved in the procedure, sitting 3 m away at a desk, was hit by flying glass and received lacerations that required sutures.

In another laboratory, a container of nitric acid and methanol sitting in a chemical fume hood overpressurized and burst, spraying shards of glass and nitric acid over every surface of the laboratory. A person sitting 3 m away at a desk received some nitric acid and glass on the laboratory coat, but nowhere else.

In both cases, the potential for eye injuries, chemical burns, and physical injury to a person not involved in the experiment existed. Both incidents illustrate the importance of wearing eye protection and other protective equipment, as appropriate, whenever a risk is present.

Advantages include

• visibility among researchers;

• better communication and collaboration;

• easy to share resources, including equipment, space, and support staff;

• flexibility for future needs because of open floor plan with adaptable furnishings;

• significant space savings compared with smaller, enclosed laboratories; and

• cost savings (first building/renovation costs and ongoing operating costs) compared with smaller, enclosed laboratories.

Disadvantages and limitations include

• for large spaces, challenging to balance the ventilation system;

• limitations to the size or placement of the laboratory (e.g., the floor of the building, the type of research) because of chemical storage code limitations for flammable and other materials;

• need for isolated spaces because of specific types of work being conducted, such as cell or tissue work where cross-contamination is an issue, use of certain radioactive materials, lasers, materials requiring special security measures, glass-washing facilities (see section 9.B.3 for more information);

• challenge of storing chemicals and supplies when there is a lack of natural spaces created by walls and other fixtures;

• noise from people and equipment may be higher than in a closed laboratory; and

• inability of some researchers to work effectively in an open laboratory environment.

Design teams should work with the research teams to find solutions that accommodate the needs of the researchers as much as possible. A combination of open laboratory spaces with smaller areas dedicated to special functions is often necessary.

9.B.3 Closed Laboratories and Access

Closed or separate laboratory spaces are often necessary for certain functions because of the nature of the operation, equipment needs, or security concerns. These areas may or may not be separated with a door. The need for a door and access control should be examined carefully for code requirements, safety protocol, and containment concerns.

The following issues should be considered:

• Do the exits require doors by code?

• Must the corridor walls, doors, and frames be fire-rated by code?

• Is containment of spills or smoke an issue that demands doors?

• Is noise an issue that demands separation and attenuation?

• Does the need for room air pressure control necessitate a door closing the laboratory space off from other areas?

• Does the work present a hazard that requires that access by untrained personnel be controlled?

• Do some materials or equipment present a security risk?

• Do the materials require compliance with bio-safety guidelines?

Examples of operations or activities that may require separation from the main laboratory are in Table 9.1.

The use of unusually hazardous materials may re-

FIGURE 9.1 Open versus closed laboratory design. The top figure is an example of a typical closed laboratory design with four separate laboratories. The three walls separate the space and extend from floor to ceiling, with no shared spaces. The bottom figure is an example of an open laboratory in the same space. The wall extends from floor to ceiling but not from wall to wall (although in some designs, it could). Smaller working rooms with permanent or movable walls are set up for storage or activities that require closed spaces.

quire a dedicated area for such work to most efficiently manage security, safety, and environmental risk.

9.B.4 Equivalent Linear Feet of Workspace

When designing new laboratory spaces, consider the equivalent linear feet (ELF) of work surface within the laboratory. ELF can be divided into two categories: bench and equipment. Bench ELF is the required length of benchtop on which instruments can be set and where preparatory work takes place, as well as the length of laboratory chemical hoods. Equipment ELF includes the length of floor space for equipment that does not fit on a bench. Typically, every two laboratory personnel whose work mostly involves hazardous chemicals should have at least one chemical hood, and these should be large enough to provide each person with a minimum of 3 linear ft, but it could be 8 ft or more depending on the planned activities and type of chemistry.

|

|

|

|

Autoclaves |

Animal Handling Areas |

|

|

|

|

Darkrooms |

Electron microscopes |

|

Glasswashing facilities |

High-powered lasers |

|

Some radioactive materials |

Tissue culture work |

|

Exceptionally toxic materials |

High-pressure equipment |

|

|

|

Typical chemistry laboratories are designed to provide from 28 to 30 ELF per person. Quality control, biology, and analytical laboratories range from 20 to 28 ELF per person. Quality control and production laboratories tend toward the low end of this range, whereas research laboratories are at or above the high end of the range. This number includes the support space outside the laboratory that is needed. These values can vary widely and must be addressed carefully for each project.

9.B.5 Laboratory Layout and Furnishing

9.B.5.1 Adaptability

The frequency of change in laboratory use has made it desirable to provide furnishings and services that can be moved and adapted quickly. Although some services and surfaces will be fixed elements in any laboratory, such as sinks and chemical hoods, there are several options available to meet the adaptable needs for various types of research.

Current design practice is to locate fixed elements

such as laboratory chemical hoods and sinks at the perimeter of the laboratory, ensuring maximum mobility of interior equipment and furniture. Although fixed casework is common at the perimeters, moveable pieces are at the center to maximize flexibility. The central parts of the laboratory are configured with sturdy mobile carts, adjustable tables, and equipment racks.

Another trend for new laboratory buildings is to design interstitial spaces between the floors and to have all the utilities above the ceiling. The interstitial spaces are large enough to allow maintenance workers to access these utilities from above the ceiling for both routine servicing and to move plumbing and other utilities as research demands change.

Where interstitial spaces are not possible, overhead service carriers may be hung from the underside of the structural floor system. These service carriers may have quick connects to various utilities, such as local exhaust ventilation, computer cables, light fixtures, and electrical outlets.

9.B.5.2 Casework, Furnishings, and Fixtures

Casework should be durable and designed and constructed in a way that provides for long-term use, reuse, and relocation. Some materials may not hold up well to intensive chemistry or laboratory reconfiguration. Materials should be easy to clean and repair. For clean rooms, polypropylene or stainless steel may be preferable.

Work surfaces should be chemical resistant, smooth, and easy to clean. Benchwork areas should have knee space to allow for chairs near fixed instruments or for procedures requiring prolonged operation.

Work areas, including computers, should incorporate ergonomic features, such as adjustability, task lighting, and convenient equipment layout. Allow adequate space for ventilation and cooling of computers and other electronics.

Handwashing sinks for particularly hazardous materials may require elbow, foot, or electronic controls. Do not install more cupsinks than are needed. Unused sinks may develop dry traps that result in odor complaints.

9.B.5.3 Shared Spaces

Many facilities encourage sharing of some pieces of equipment. Locating the equipment in a space that is not defined as part of an individual’s work zone facilitates sharing. Some examples of equipment that can be shared are in Table 9.2.

In an open laboratory setting, duplication of much of this equipment can be avoided. Often, if the equipment is centrally located near a laboratory, it can be walled off to reduce noise.

The team needs to carefully address the need for alarms on specific pieces of equipment such as freezers and incubators that contain valuable samples.

Care must be taken, however, not to assume that sharing is always effective. There are certain pieces of equipment that must be dedicated to specific users.

9.B.5.4 Flooring

Wet laboratories should have chemically resistant covered flooring. Sheet goods are usually preferable to floor tiles, because floor tiles may loosen or degrade over time, particularly near laboratory chemical hoods and sinks. Rubberized materials or flooring with a small amount of grit may be more slip-resistant, which is desirable in chemical laboratories. Coved flooring that allows 4 to 8 in. of flooring material secured to the wall to form a wall base is also desirable.

Floors above areas with sensitive equipment, such as lasers, should be sealed to prevent leaks.

9.B.5.5 Doors, Windows, and Walls

Walls should be finished with material that is easy to clean and maintain. Fire code may require certain doors, frames, and walls to be fire-rated.

Doors should have view panels to prevent accidents caused by opening the door into a person on the other side and to allow individuals to see into the laboratory in case of an accident or injury. Doors should open in the direction of egress.

Laboratories should not have operable windows, particularly if there are chemical hoods or other local ventilation systems in the lab.

9.B.6 Noise and Vibration Issues

Many laboratories utilize equipment that may emit significant noise, require a stable structural environment, or both. During early planning stages, all equip-

ment should be discussed regarding any unique noise or vibration sensitivity in order to locate the equipment properly.

TABLE 9.2 Examples of Equipment That Can Be Shared Between Researchers and Research Groups

|

|

|

|

Balances |

Centrifuges |

|

|

|

|

Gas chromatographs |

High-performance liquid chromatographs |

|

Ice machines |

Incubators |

|

Mass spectrometers |

NMRs |

|

Ovens |

pH meters |

|

Refrigerators/freezers |

Weigh enclosures |

|

|

|

Large equipment such as centrifuges, shakers, and water baths often work best in separate equipment rooms. Pumps for older mass spectrometer units are both hot and noisy and are often located in either a small room or a hall. If in a closet, the area must have extra exhaust to remove heat, or else equipment may fail from overheating. With smaller and newer mass spectrometers, the pumps are often small and can fit into cabinets specifically designed for them. These pumps work especially well when water cooling is not required. Very few researchers need to hear their instrumentation running, but many want to see the equipment.

Another consideration crucial to equipment-intensive areas is the allowable vibration tolerance. Most analytical equipment such as NMRs, sensitive microscopes, mass spectrometers, and equipment utilizing light amplification (laser) require either vibration isolation tables or an area that is structurally designed to allow for very little vibration. Clarify the tolerance requirements with the user and equipment manufacturer during the equipment-programming phase, or early design process, so that the appropriate structure can be designed and the construction cost can be estimated more accurately.

9.B.7 Safety Equipment and Utilities

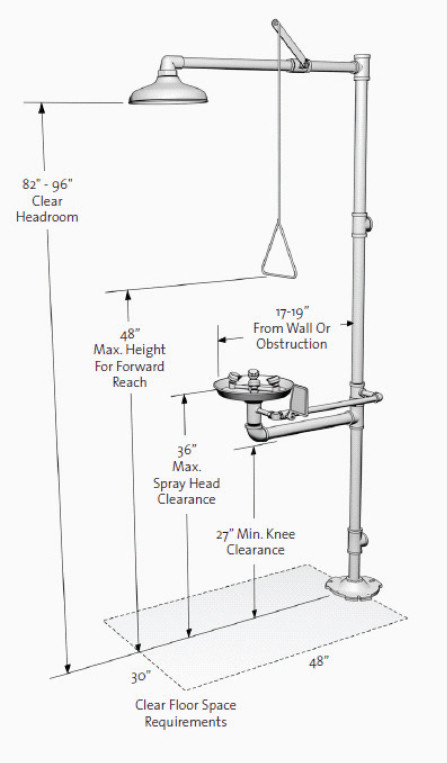

Each laboratory should have an adequate number and placement of safety showers, eyewash units, and fire extinguishers for its operations. (See Chapter 6, section 6.C.10, for more information.) The American National Standards Institute (ANSI) Z358.1-2004 standard provides guidance for safety shower and eyewash installation. The 2004 version recommends provision of tepid water, which can be complicated from an engineering standpoint. Although this standard does not address wastewater, most designers agree that emergency eyewash and shower units should be connected to drain piping. It is prudent to have floor drains near the units, preferably sloped to the drain to prevent excessive flooding and potential slip hazards. Consider choosing barrier-free safety showers and eyewash units that can accommodate individuals with disabilities. The maximum reach height for the activation control for safety showers is 48 in.

Sprinkler systems may be required by the building code and are almost always recommended. For areas with water-sensitive equipment or materials, consider preaction systems. Most dry or alternative systems do not function in a laboratory environment with chemical hoods and other ventilation. There may be resistance to the idea of installing sprinkler systems in laboratories, particularly laboratories that use water-sensitive chemicals or equipment. The following facts may be helpful:

• Each sprinkler head is individually and directly activated by the heat of the fire, not by smoke or an alarm system. Thus, small fires are not likely to activate the sprinkler and moderate-size fires will likely activate only one or two heads. Indeed, more than 95% of fires are extinguished by one or two sprinkler heads.

• Statistics show that the sprinkler head failure rate is 1 in 16 million.

• In the event that the water from the sprinkler system reacts with water-sensitive materials, ensuing fires would be quenched once the reaction stopped. Damage is likely to be less severe than if a fire was not suppressed and was allowed to reach other flammable or combustible materials in the laboratory.

• Laboratory equipment, including lasers, is just as likely to be harmed by the fire as by the water. Without the sprinkler system, a fire that is large enough to activate the sprinkler system would result in response by the fire department. The sprinkler heads are designed to release water at a rate of 10–15 gallons per minute (gpm), whereas a firefighter’s hose delivers 250–500 gpm.

• Dry chemical systems can seriously damage electronic and other laboratory equipment and are impractical in a building-wide system. Alternative agents are impractical because of the amount of space required for the cylinders and are most effective in rooms or areas that are sealed, which is not how laboratories are designed. These systems are most practical for an individual application, such as a piece of equipment or a “sealed” room.

• Locate utility shutoff switches outside or at the exit of the laboratory. The purpose of the switch is to shut down potentially hazardous operations quickly in the event of an emergency.

• Locate room purge buttons at the exits in laboratories with chemical hoods. For most laboratory buildings, activating the room purge button shuts down or minimizes supply air while increasing exhaust ventilation. In the event of a chemical spill, activating the purge system will help ventilate the resulting chemical vapors more quickly.

• Laboratories should have abundant electrical supply outlets to eliminate the need for extension cords and multiplug adapters. Place electrical panels in an accessible area not likely to be ob-

structed. Install ground-fault circuit interrupters near sinks and wet areas.

• Assess and provide for emergency power needs.

• Where possible, install chilled water loops for equipment requiring cooling. Chilled water loops save energy, water, and sewer costs.

9.B.8 Americans with Disability Act: Accessibility Issues Within the Laboratory

Title 1 of the Americans with Disabilities Act (ADA) of 1990 requires an employer to provide reasonable accommodation for qualified individuals with disabilities who are employees or applicants for employment, unless doing so would cause undue hardship. The design team and the owner are responsible for identifying what reasonable accommodations should and can be made to meet ADA guidelines or requirements.

In addition, some school systems and municipalities require a minimum number or percentage of accessible work areas in teaching laboratories. Accessible furniture, including laboratory chemical hoods, are readily available from most suppliers. The American Chemical Society has an excellent resource available online or in print, Teaching Chemistry to Students with Disabilities: A Manual for High Schools, Colleges, and Graduate Programs (ACS, 2001).

It is prudent to provide barrier-free safety showers and eyewash units for all laboratories. Figure 9.2 illustrates the specifications for barrier-free emergency equipment, according to ANSI 117.1-1992, “Accessible and Usable Building Facilities.”

Additional accommodations will likely need to be made individually, depending on the special needs of the researcher. Partnering with the researcher, supervisor, and a laboratory safety professional will help determine the extent of the accommodations.

For wet laboratories, service animals should either have a place outside the lab or an area within the laboratory that is accessible without the animal having to traverse areas where chemicals or other hazardous materials could be present at floor level, including spills.

9.B.9 Older Facilities

Aging facilities can present multiple challenges. As materials of construction begin to degrade, the safety and environmental provisions of the facility often degrade as well. Although some equipment and materials may continue to function well for many years, modern alternatives may offer better safety and environmental sustainability features.

For older facilities, it is important to have a strong operations and maintenance program that monitors and maintains plumbing, ventilation, and structural components. Nonetheless, as individual laboratories or spaces are renovated for new uses or upgrades, there are opportunities for improving and modernizing building systems.

FIGURE 9.2 Specifications for barrier-free safety showers and eyewash units.

Depending on the location of the laboratory building, there may be requirements for bringing the entire building up to current building codes and standards once a certain percentage of the building is under renovation. These code requirements may include fire protection systems, accessibility, plumbing, ventilation, alarm systems, chemical storage restrictions, and egress issues.

With rising interest in energy conservation, there have been numerous studies and instances of retrocommissioning of laboratories. The focus is generally

on the laboratory ventilation system, with the goal of managing airflow and temperature control to eliminate waste and reduce overall energy use. In “Laboratories for the 21st Century” the U.S. Environmental Protection Agency (EPA/DOE, 2006), reports that in most studied cases, retro-commissioning, when planned and executed well, resulted in reductions of at least 30% of overall facility energy use with a payback period of less than 3 years.

The typical retro-commissioning process proceeds in five major steps:

1. Planning. Bring facility and EHS staff, design engineers, and users together to discuss goals. Gather information about the current system, including the original plans, as-built plans, major alterations, and current function, including ventilation rates. Develop the retro-commissioning plan.

2. Preinvestigation. Verify all systems including the direct digital control or building automation systems, evaluate all components that affect energy use, and verify monitoring systems.

3. Investigation. Benchmark utility and energy use data, analyze trends, and test all equipment. Testing should include functional testing of chemical hoods and related components, including face velocity tests, containment tests, etc.

4. Implementation. Select which improvements will be made and prioritize them. Implement the improvements and test performance.

5. Handoff. Clearly document information and provide training to laboratory personnel and maintenance personnel.

Common conditions that lead to energy waste include

• overabundance of laboratory chemical hoods,

• laboratory chemical hoods with large bypass openings,

• dampers in fixed positions,

• overventilated laboratory spaces,

• excessive duct pressure,

• fans set to override position,

• fans that are no longer operating efficiently,

• constant volume systems with no setback for temperature or airflow when unoccupied, and

• high face velocities.

Whether retro-commissioning for energy efficiency or for safety, ensure that all stakeholders are involved in the process. Once the work is complete, continue to monitor efficiency and safety. It is important to include trained laboratory personnel in the feedback process. If systems are not used correctly or if they are bypassed, the retro-commissioning efficiency may deteriorate.

The laboratory ventilation system, whether it is the general ventilation, a chemical hood, or a specialized exhaust system, is a critical means to control airborne chemicals in the laboratory.

At a minimum, a well-designed laboratory ventilation system should include the following:

• Heating and cooling should be adequate for the comfort of laboratory occupants and operation of laboratory equipment.

• A differential should exist between the amount of air exhausted from the laboratory and the amount supplied to the laboratory to maintain a negative pressure between the laboratory and adjacent nonlaboratory spaces. This pressure differential prevents uncontrolled chemical vapors from leaving the laboratory. Clean rooms may require a slightly positive pressure differential. There should be separation between common spaces and the clean room to prevent migration of airborne contaminants.

• Exhaust ventilation devices should be appropriate to materials and operations in the laboratory.

Many devices are used to control emissions of hazardous materials in the laboratory. A risk assessment helps to determine the best choice for a particular operation or material (Table 9.3).

NOTE: Clean benches are not designed for use with hazardous materials. These are appropriate for use in work with materials that necessitate clean work conditions and should only be used for materials or chemicals that one could safety use on a benchtop.

9.C.1 Risk Assessment

For all materials, the objective is to keep airborne concentrations below established exposure limits (see Chapter 4, section 4.C.2.1). Where there is no established exposure limit, where mixtures are present, or where reactions may result in products that are not completely characterized, prudent practice keeps exposures ALARA (as low as reasonably achievable).

For chemicals, determine whether the material is flammable or reactive or if it poses a health hazard from inhalation. If no significant risk exists, the work does not likely require any special ventilation. If potential risk does exist, look at the physical properties of the chemical, specifically its vapor pressure and vapor density.

TABLE 9.3 Laboratory Engineering Controls for Personal Protection

|

|

||

|

Type of Ventilation |

Typical Number of Air Changes or Face Velocity in Linear Feet per Minute (fpm) as Appropriate |

Examples of Use |

|

|

||

|

General laboratory ventilation |

6–12 air changes/hour, depending on laboratory design and system operation |

• Nonvolatile chemicals • Nonhazardous materials |

|

Environmental rooms |

0 air changes |

• Materials that require special environmental controls • Nonhazardous amounts of flammable, toxic, or reactive chemicals. |

|

Laboratory chemical hoods |

10–15 air changes/minute or 60-100 fpm depending on hood type |

• Flammable, toxic, or reactive materials • Products or mixtures with uncharacterized hazards |

|

Unventilated storage cabinets |

0 air changes |

• Flammable liquids • Corrosives • Moderately toxic chemicals |

|

Ventilated storage cabinets |

1–2 air changes/minute |

• Highly toxic, hazardous, or odiferous chemicals (if equipped with flame arrestors) |

|

Recirculating biosafety cabinets |

A1: 75 fpm A2: 100 fpm B1: 100 fpm |

• Biological materials • Nanoparticles, as of the date of publication • Biological materials • Nanoparticles, as of the date of publication • Minute amounts of volatile chemicals |

|

Total exhaust biosafety cabinet |

B2: 100 fpm |

• Biological materials • Nanoparticles, as of the date of publication • Minute amounts of volatile chemicals |

|

Glovebox |

Varies from no change to very high rate of change, depending on the glovebox and the application |

• Positive pressure for specialty environments • Negative pressure for highly toxic materials |

|

Downdraft table |

150–250 fpm depending on design |

• Perfusions with paraformaldehyde, work with volatile, low to moderately hazardous materials with higher vapor density where access from more than one side is necessary |

|

Elephant trunk |

150–200 fpm at opening |

• Local ventilation of a tabletop • Discharge from equipment such as a gas chromatograph |

|

Canopy |

N/A |

• Ventilation of heat, steam, low or nontoxic materials with low vapor density |

|

Ductless laboratory chemical hood |

10–15 air changes/minute |

• Materials that are compatible with the filtration system, in controlled quantities and under controlled conditions • Not suitable for particularly hazardous substances |

|

Slot hood |

Varies with application |

• Local ventilation of higher density materials at the source, such as an acid bath |

|

Ventilated balance enclosure |

5–10 air changes/minute |

• Weighing and initial dissolution of highly toxic or potent materials |

|

Benchtop ventilated enclosures |

Variable per the needs of the materials |

• Benchtop equipment, such as rotovaps |

|

|

||

Vapor pressure is usually measured in millimeters of mercury. A low vapor pressure (<10 mmHg) indicates that the chemical does not readily form vapors at room temperature. General laboratory ventilation or an alternative such as the elephant trunk or snorkel may be appropriate, unless the material is heated or in a higher temperature room that might promote vapor formation. High vapor pressure indicates that the material easily forms vapors and may require use of a ventilated enclosure, such as a chemical hood.

Vapor density is compared to that of air, which is 1. A chemical having a vapor density greater than 1 is heavier than air. If the vapors need to be controlled, a chemical hood or a ventilation device that draws air from below, such as a downdraft table or a slot hood or elephant trunk with the exhaust aimed low may be

appropriate. Conversely, a chemical with a vapor density less than 1 is lighter than air. Besides a chemical hood, a ventilation device that draws air from above, such as an elephant trunk or snorkel with the exhaust positioned above the source, may work best.

For radioactive or biological materials, consider whether the operations might cause the materials to aerosolize or become airborne and whether inhalation poses a risk to health or the environment. Determine whether filtration or trapping is required or recommended.

For manipulating solid particulates, a chemical hood and similar equipment with higher airflow may be too turbulent. Weighing boxes or ventilated balance enclosures may be a better fit for such work.

For nanomaterials, a laboratory chemical hood might be too turbulent for manipulating the materials. Also, consider whether the exhaust containing these tiny particles should be filtered. Studies have shown that high-efficiency particulate air (HEPA) filters are very effective for nanosize particles. Containment tests for chemical hoods allow for a very minor amount of leakage into the breathing zone of the user. For chemical vapors, such an amount may be insignificant, but in the same volume of nanoparticles, the number of particles may be quite large, and biosafety cabinets, gloveboxes or filtering hoods would be better. (See section 9.E.5 for more information.)

More specialized ventilation systems, such as biosafety cabinets and gloveboxes, may be necessary to control specific types of hazards, as discussed later in this chapter.

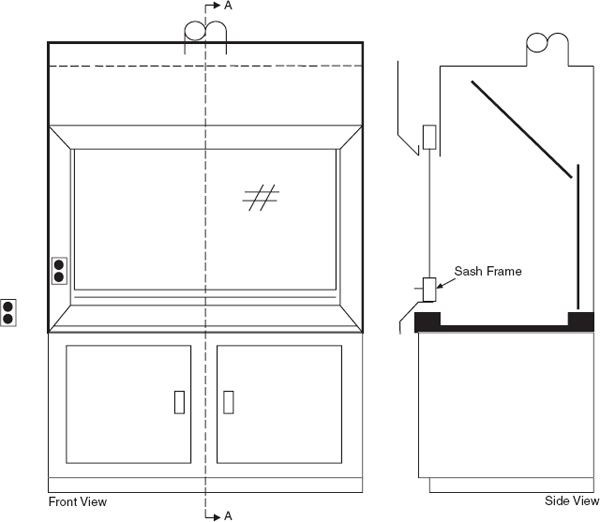

9.C.2 Laboratory Chemical Hoods

Laboratory chemical hoods are the most important components used to protect laboratory personnel from exposure to hazardous chemicals and agents. Functionally, a standard chemical hood is a fire-and chemical-resistant enclosure with one opening (face) in the front with a movable window (sash) to allow user access to the interior. Large volumes of air are drawn through the face and out the top into an exhaust duct to contain and remove contaminants from the laboratory. Note that because a substantial amount of energy is required to supply tempered supply air to even a small hood, the use of hoods to store bottles of toxic or corrosive chemicals is a very wasteful practice, which can seriously impair the effectiveness of the hood as a local ventilation device. Thus, it is preferable to provide separate vented cabinets for the storage of toxic or corrosive chemicals. The amount of air exhausted by such cabinets is much less than that exhausted by a properly operating hood.

A well-designed hood, when properly installed and maintained, offers a substantial degree of protection to the user if it is used appropriately and its limitations are understood. Chemical hoods are the best choice, particularly when mixtures or uncharacterized products are present and any time there is a need to manage chemicals using the ALARA principle.

9.C.2.1 Laboratory Chemical Hood Face Velocity

The average velocity of air drawn through the face of the laboratory chemical hood is called the face velocity. The face velocity greatly influences the ability to contain hazardous substances, that is, its containment efficiency. Face velocities that are too low or too high reduce the containment efficiency.

Face velocity is only one indicator of hood performance and one should not rely on it as a sole basis for determining the containment ability of the chemical hood. There are no regulations that specify acceptable face velocity. Indeed, modern hood designs incorporate interior configurations that affect the airflow patterns and are effective at different ranges of face velocity.

For traditional chemical hoods, several professional organizations have recommended that the chemical hood maintain a face velocity between 80 and 100 feet per minute (fpm). Face velocities between 100 and 120 fpm have been recommended in the past for substances of very high toxicity or where outside influences adversely affect hood performance. However, energy costs to operate the chemical hood are directly proportional to the face velocity and there is no consistent evidence that the higher face velocity results in better containment. Face velocities approaching or exceeding 150 fpm should not be used; they may cause turbulence around the periphery of the sash opening and actually reduce the capture efficiency, and may reentrain settled particles into the air.

With the desire for more sustainable laboratory ventilation design, manufacturers are producing high-performance hoods, also known as low-flow hoods, that achieve the same level of containment as traditional ones, but at a lower face velocity. These chemical hoods are designed to operate at 60 or 80 fpm and in some cases even lower. (See section 9.C.2.9.3.6.)

Average face velocity is determined by measuring individual points across the plane of the sash opening and calculating their average. A more robust measure of containment uses tracer gases to provide quantitative data and smoke testing to visualize airflow patterns. ASHRAE/ANSI 110 testing is an example of this technique (see section 9.C.2.8 for more information). This type of testing should be conducted at the time the chemical hood is installed, when substantial changes are made to the ventilation system, including rebalanc-

ing and periodically as part of a recommissioning or maintenance program.

Once a chemical hood is tested and determined to be acceptable via the ASHRAE/ANSI 110 method or an equivalent means, the face velocity should be noted and used as the reference point for routine testing. Each chemical hood, laboratory, facility, or site must define the acceptable average face velocity, minimum acceptable point velocity, and maximum standard deviation of velocities, as well as when ASHRAE/ANSI 110 or visualization testing is required. These requirements should be incorporated into the laboratory’s Chemical Hygiene Plan and ventilation system management plans (see section 9.H).

When first installed and balanced, a laboratory chemical hood must be subjected to the ASHRAE/ANSI 110 or equivalent test before it is commissioned. When multiple similar chemical hoods are installed at the same time, at least half should be tested, provided the design is standardized relative to location of doors and traffic, and to location and type of air supply diffusers.

9.C.2.2 Factors That Affect Laboratory Chemical Hood Performance

Tracer gas containment testing of chemical hoods reveals that air currents impinging on the face at a velocity exceeding 30 to 50% of the face velocity reduce the containment efficiency by causing turbulence and interfering with the laminar flow of the air entering the chemical hood. Thirty to fifty percent of a face velocity of 100 fpm, for example, is 30 to 50 fpm, which represents a very low velocity that can be produced in many ways. The rate of 20 fpm is considered to be still air because that is the velocity at which most people first begin to sense air movement.

9.C.2.2.1 Proximity to Traffic

Most people walk at approximately 250 fpm (approximately 3 mph [4.8 kph]) and as they walk, vortices exceeding 250 fpm form behind them. If a person walks in front of an open chemical hood, the vortices can overcome the face velocity and pull contaminants into the vortex, and into the laboratory. Therefore, laboratory chemical hoods should not be located on heavily traveled aisles, and those that are should be kept closed when not in use. Foot traffic near these chemical hoods should be avoided when work is being performed.

9.C.2.2.2 Proximity to Supply Air Diffusers

Air is supplied continuously to laboratories to replace the air exhausted through laboratory chemical hoods and other exhaust sources and to provide ventilation and temperature/humidity control. This air usually enters the laboratory through devices called supply air diffusers located in the ceiling. Velocities that exceed 800 fpm are frequently encountered at the face of these diffusers. If air currents from these diffusers reach the face of a chemical hood before they decay to 30 to 50% of the face velocity, they cause the same effect as air currents produced by a person walking in front of the chemical hood. Normally, the effect is not as pronounced as the traffic effect, but it occurs constantly, whereas the traffic effect is transient. Relocating the diffuser, replacing it with another type, or rebalancing the diffuser air volumes in the laboratory can alleviate this problem.

9.C.2.2.3 Proximity to Windows and Doors

Exterior windows with movable sashes are not recommended in laboratories. Wind blowing through the windows and high-velocity vortices caused when doors open can strip contaminants out of the chemical hoods and interfere with laboratory static pressure controls. Place hoods away from doors and heavy traffic aisles to reduce the chance of turbulence reducing the effectiveness of the hood.

9.C.2.3 Prevention of Intentional Release of Hazardous Substances into Chemical Hoods

Laboratory chemical hoods should be regarded as safety devices that can contain and exhaust toxic, offensive, or flammable materials that form as a result of laboratory procedures. Just as you should never flush laboratory waste down a drain, never intentionally send waste up the chemical hood. Do not use the chemical hood as a means of treating or disposing of chemical waste, including intentionally emptying hazardous gases from compressed gas cylinders or allowing waste solvent to evaporate.

For some operations, condensers, traps, and/or scrubbers are recommended or necessary to contain and collect vapors or dusts to prevent the release of harmful concentrations of hazardous materials from the chemical hood exhaust.

9.C.2.4 Laboratory Chemical Hood Performance Checks

When checking if laboratory chemical hoods are performing properly, observe the following guidelines:

• Evaluate each hood before initial use and on a regular basis (at least once a year) to visualize airflow and to verify that the face velocity meets the criteria specified for it in the laboratory’s Chemical Hygiene Plan or laboratory ventilation plan.

• Verify the absence of excessive turbulence (see section 9.C.2.6, below).

• Make sure that a continuous performance monitoring device is present, and check it every time the chemical hood is used. (For further information, see section 9.C.2.8 on testing and verification.)

Box 9.1 provides a list of things to do to maximize chemical hood efficiency.

9.C.2.5 Housekeeping

Keep laboratory chemical hoods and adjacent work areas clean and free of debris at all times. Keep solid objects and materials (such as paper) from entering the exhaust ducts, because they can lodge in the ducts or fans and adversely affect their operation. The chemical hood will have better airflow across its work surface if it contains a minimal number of bottles, beakers, and laboratory apparatus; therefore, prudent practice keeps unnecessary equipment and glassware outside the chemical hood at all times and stores all chemicals in approved storage cans, containers, or cabinets. Furthermore, keep the workspace neat and clean in all laboratory operations, particularly those involving the use of chemical hoods, so that any procedure or experiment can be undertaken without the possibility of disturbing, or even destroying, what is being done.

9.C.2.6 Sash Operation

Except when adjustments to the apparatus are being made, keep the chemical hood closed, with vertical sashes down and horizontal sashes closed, to help prevent the spread of a fire, spill, or other hazard into the laboratory. Horizontal sliding sashes should not be removed. The face opening should be kept small to improve the overall performance of the hood. If the face velocity becomes excessive, the facility engineers should make adjustments or corrections.

For chemical hoods without face velocity controls (see section 9.C.4.1), the sash should be positioned to produce the recommended face velocity, which often occurs only over a limited range of sash positions. This range should be determined and marked during laboratory chemical hood testing. Do not raise the sash above the working height for which it has been tested to maintain adequate face velocity. Doing so may allow the release of contaminants from the chemical hood into the laboratory environment.

Chemical hood sashes may move vertically (sash moves up and down), horizontally (sash is divided in panes that move side to side to provide the opening to the hood interior), or a combination of both. Although both types of sash offer protection from the materials within the hood and help control or maintain airflow, consider the following:

BOX 9.1

Quick Guide for Maximizing Efficiency of Laboratory Chemical Hoods

Many factors can compromise the efficiency of chemical hood operation, and most are avoidable. Be aware of all behavior that can, in some way, modify the chemical hood and its capabilities. Always consider the following:

• Keep chemical fume hood exhaust fans on at all times.

• If possible, position the chemical hood sash so that work is performed by extending the arms under or around the sash, placing the head in front of the sash, and keeping the sash between the person and the chemical source. View the procedure through the sash, which acts as a primary barrier if a spill, splash, or explosion should occur.

• Avoid opening and closing the sash rapidly, and avoid swift arm and body movements in front of or inside the chemical hood. These actions may increase turbulence and reduce the containment efficiency.

• Place chemical sources and apparatus at least 6 in. behind the face. Paint a colored stripe or apply tape to the work surface 6 in. back from the face to serve as a reminder Quantitative chemical hood containment tests reveal that the concentration of contaminant in the breathing zone can be 300 times higher from a source located at the front of the face than from a source placed at least 6 in. back. This concentration continues to decline as the source is moved farther toward the back.

• Place equipment as far to the back of the chemical hood as practical without blocking the bottom baffle.

• Separate and elevate each instrument by using blocks or racks; air should flow easily around all apparatus.

• Do not use large pieces of equipment in a chemical hood, because they tend to cause dead spaces in the airflow and reduce the efficiency.

• If a large piece of equipment emits fumes or heat outside a chemical hood, have a special-purpose hood designed and installed to ventilate that particular device. This method of ventilation is much more efficient than placing the equipment in a chemical fume hood, and it will consume much less air.

• Do not modify chemical hoods in any way that adversely affects performance. This includes adding, removing, or changing any of the components, such as baffles, sashes, airfoils, liners, and exhaust connections.

• Make sure all highly toxic or offensive vapors are scrubbed or adsorbed before the exit gases are released into the chemical hood exhaust system (see section 9.C.2.11.1 on chemical hood scrubbers).

• Keep the sash closed whenever the chemical hood is not actively in use or is unattended.

• Some experimentation requires the lab personnel to access equipment or materials toward the upper portion of the chemical hood. If the chemical hood is equipped with a vertical sash, it may be necessary to raise the sash completely in order to conduct the procedure.

ο The laboratory chemical hood must provide adequate containment at that sash height. Thus, the chemical hood must be tested in that position.

ο With the sash completely raised, it no longer provides a barrier between the chemical hood user and the materials within the hood.

ο If the only way to keep the sash in a fully raised position requires the use of a sash stop, the laboratory personnel may get into the habit of leaving the sash in this position, potentially reducing the safety and energy efficiency of the chemical hood.

• The standard operating position for the vertical sash may be comfortable for the majority of users. However, shorter laboratory personnel may find that this position does not provide an adequate barrier from the materials within the chemical hood and may need to adjust downward. Taller laboratory personnel may need to raise the sash more in order to comfortably work in the chemical hood.

For chemical hoods with horizontal sashes, the intended operating configuration is to open the panes in such a way that at least one pane is between both arms, providing a barrier between the user and the contents of the chemical hood. In addition,

• Do not remove panes. Permanently removing panes may decrease the safety afforded by the sash barrier and negatively affect containment and waste energy.

• Working with all panes moved to one side or through an opening in the center of the laboratory chemical hood provides no barrier between the user and the materials within the chemical hood. The chemical hood is not intended to be used in this configuration.

Sash panes should be equal width with a maximum of 15 in. (375 mm) to accommodate use of the sash pane as a protective barrier with operator arm on either side.

Conventional glass or plastic sashes are not designed to provide explosion protection per ANSI/NFPA (ANSI, 2004; NFPA, 2004). Sash panes and viewing panes constructed of composite material (safety glass backed by polycarbonate, with the safety glass toward the explosion hazard) are recommended for chemical hoods used when there is the possibility of explosion or violent overpressurization (e.g., hydrogenation, perchloric acid).

For all laboratory chemical hoods, the sash should be kept closed when the hood is not actively attended. Lowering or closing the sash not only provides additional personal protection but also results in significant energy conservation. Some chemical hoods may be equipped with automatic sash-positioning systems with counterweighting or electronic controls (see section 9.H.2).

9.C.2.7 Constant Operation of Laboratory Chemical Hoods

Although turning laboratory chemical hoods off when not in use saves energy, keeping them on at all times is safer, especially if they are connected directly to a single fan. Because most laboratory facilities are under negative pressure, air may be drawn backward through the nonoperating fan, down the duct, and into the laboratory unless an ultralow-leakage backdraft damper is used in the duct. If the air is cold, it may freeze liquids in the hood. The ducts are rarely insulated; therefore, condensation and ice may form in cold weather. When the chemical hood is turned on again and the duct temperature rises, the ice will melt, and water will run down the ductwork, drip into the hood, and possibly react with chemicals in the hood.

Chemical hoods connected to a common exhaust manifold offer the advantage that the main exhaust system is rarely shut down. Hence, positive ventilation is available on the system at all times. In a constant air volume (CAV) system (see section 9.C.4.1), install shut-off dampers to each chemical hood, allowing passage of enough air to prevent fumes from leaking into the laboratory when the sash is closed. Prudent practice allows 10 to 20% of the full volume of flow to be drawn through the laboratory chemical hood in the off position to prevent excessive corrosion.

Some laboratory chemical hoods on variable air volume (VAV) systems (see section 9.C.4.2) have automatic setback controls that adjust the airflow to a lower face velocity when not in use. The setback may be triggered by occupancy sensors, a light switch, or a timer or a completely lowered sash. Understand what triggers the setback and ensure that the chemical hood is not used for hazardous operations when in setback mode.

Some chemical hoods do have on/off switches and may be turned off for energy conservation reasons. They should only be turned off when they are empty of hazardous materials. An example of an acceptable operation would be a teaching laboratory where the

empty chemical hoods are turned off when the laboratory is not in use.

9.C.2.8 Testing and Verification

The OSHA lab standard includes a provision regarding laboratory chemical hoods, including a requirement for some type of continuous monitoring device on each chemical hood to allow the user to verify performance and routine testing of the hood. It does not specify a test protocol.

Laboratory chemical hoods should be tested at least as follows:

• containment test by manufacturer;

• containment test after installation and prior to initial use (commissioning);

• annual or more frequent face velocity and airflow visualization;

• performance test any time a potential problem is reported; and

• containment test after significant changes to the ventilation system, including rebalancing or recommissioning.

9.C.2.8.1 Initial Testing

All laboratory chemical hoods should be tested before they leave the manufacturer according to ANSI/ASHRAE Standard 110-1995 or equivalent, Methods of Testing Performance of Laboratory Fume Hoods (ANSI, 1995). They should pass the low- and high-volume smoke challenges with no leakage or flow reversals and have a control level of 0.05 ppm or less on the tracer gas test. It is highly recommended that chemical hoods be retested by trained personnel after installation in their final location, using ANSI/ASHRAE 110-1995 or equivalent testing. The control level of tracer gas for an “as installed” or “as used” test via the ANSI/ASHRAE 110-1995 method should not exceed 0.1 ppm.

The ANSI/ASHRAE 110-1995 test is the most practical way to determine chemical hood capture efficiency quantitatively. The test includes several components, which may be used together or separately, including face velocity testing, flow visualization, face velocity controller response testing, and tracer gas containment testing. These tests are much more accurate than face velocity and smoke testing alone. Respectively, ASHRAE and ANSI found that 28% or 38% of chemical hoods tested using this method did not meet the pass criteria, even though face velocity testing alone found them to be in an acceptable face velocity range.

Performance should be evaluated against the design Specifications for uniform airflow across the chemical hood face as well as for the total exhaust air volume. Equally important is the evaluation of operator exposure. The first step in the evaluation of hood performance is the use of a smoke tube or similar device to determine that the laboratory chemical hood is on and exhausting air. The second step is to measure the velocity of the airflow at the face of the hood. The third step is to determine the uniformity of air delivery to the hood face by making a series of face velocity measurements taken in a grid pattern.

Leak testing is normally conducted using a mannequin equipped with sensors for the test gas. As an alternative, a person wearing the sensors or collectors may follow a sequence of movements to simulate common activities, such as transferring chemicals. It is most accurate to perform the in-place tests with the chemical hood at least partially loaded with common materials (e.g., chemical containers filled with water, equipment normally used in the chemical hood), in order to be more representative of operating conditions.

For the ASHRAE 110-1995 leak testing, the method calls for a release rate for the test gas of 4 liters per minute (Lpm), but suggests that higher rates may be used. One-liter per minute release rate approximates pouring a volatile solvent from one beaker to another. Eight liters per minute approximates boiling water on a 500-W hot plate. The 4-Lpm rate is an intermediate of these two conditions. If there is a possibility that the chemical hood will be used for volatile materials under heating conditions, consider a higher release rate of up to 8 Lpm for worst-case conditions.

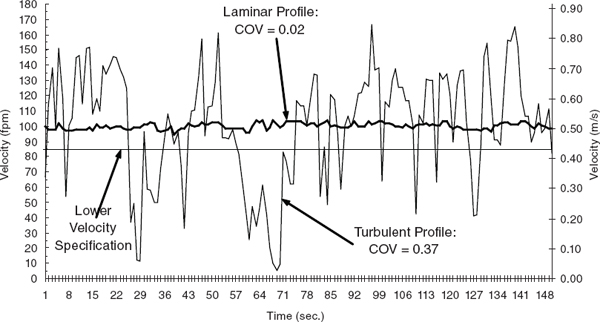

The total volume of air exhausted by a laboratory chemical hood is the sum of the face volume (average face velocity times face area of the hood) plus air leakage, which averages about 5 to 15% of the face volume. If the laboratory chemical hood and the general ventilating system are properly designed, face velocities in the range of the design criteria will provide a laminar flow of air over the work surface and sides of the hood. Higher face velocities (150 fpm or more), which exhaust the general laboratory air at a greater rate, waste energy and are likely to degrade hood performance by creating air turbulence at the face and within the chemical hood, causing vapors to spill out into the laboratory (Figure 9.3).

An additional method for containment testing is the EN 14175, which is the standard adopted by the European Union and replaces several other procedures that were in place for individual countries. Parts 3 (Type tests) and 4 (On-site tests) of this standard address methods for “as manufactured” and “as installed/used” systems, respectively.

9.C.2.8.2 Routine Testing

At least annually, the following test procedures should be conducted for all chemical hoods:

FIGURE 9.3 Laminar versus turbulent velocity profile. Velocity data are from a single traverse point on two separate hoods. The light line represents a hood where supply air interference caused large variations in velocity, a “typical” turbulent profile. Eddy currents and flow reversals caused by a turbulent airflow pattern may cause spillage and leakage of contaminants from the hood into the laboratory environment. In contrast, the bold line represents a hood having an almost ideal velocity profile, indicative of a laminar airflow pattern. The coefficient of variation (COV) is used as a predictor of the level of turbulence experienced at the face of a hood. A high COV indicates a turbulent air profile and most likely is a strong indicator of poor containment; a low COV indicates a laminar flow profile and likely good containment.

SOURCE: Maupins and Hitchings (1998). Reprinted by permission of Taylor & Francis.

• Analyze face velocity using the method and criteria described in section 9.C.2.8.4.

• Visualize airflow using smoke tubes, bombs, or fog generators.

• Verify that continuous flow monitoring devices are working properly.

• Verify that other controls, including automatic sash positioners, alarm systems, etc. are functioning properly.

• Check the sash to ensure that it is in good condition, moves easily, is unobstructed, and has adequate clarity to see inside the laboratory chemical hood.

• Ensure that the laboratory chemical hood is being used as intended (e.g., no evidence of perchloric acid in a chemical hood not designed for it, not using it as a chemical storage device).

• Note any conditions that could affect laboratory chemical hood performance, such as large equipment, excessive storage, etc.

• Take corrective actions where necessary and retest.

Provide information and test results to the chemical hood users and/or supervisors. Document the results in order to maintain a log showing the history of chemical hood performance.

9.C.2.8.3 Additional Testing

Laboratory personnel should request a chemical hood performance evaluation any time there is a change in any aspect of the ventilation system. Thus, changes in the total volume of supply air, changes in the locations of supply air diffusers, or the addition of other auxiliary local ventilation devices (e.g., more chemical hoods, vented cabinets, and snorkels) all call for reevaluation of the performance of all chemical hoods in the laboratory.

9.C.2.8.4 Face Velocity Testing

Visually divide the face opening of a laboratory chemical hood into an imaginary grid, with each grid space being approximately 1 ft2 in area. Using an anemometer, velometer, or similar device, take a measurement at the center of each grid space. Face velocity readings should be integrated for at least 10 seconds (20 is preferable) because of the fluctuations in flow. The measured velocity will likely fluctuate for several seconds; record the reading once it has stabilized. Calculate the average of the velocity for every

grid space. The resulting number is the average face velocity. Analyze the results to determine if any one measurement is 20% or more above or below the average. Such readings indicate the possibility of turbulent or nonlaminar airflow. Smoke tests will help confirm whether this is problematic.

Traditional handheld instruments are subject to probe movement and positioning errors as well as reading errors owing to the optimistic bias of the investigator. Also, the traditional method yields only a snapshot of the velocity data, and no measure of variation over time is possible. To overcome this limitation, take velocity data while using a velocity transducer connected to a data acquisition system and read continuously by a computer for approximately 30 seconds at each traverse point. If the transducer is fixed in place, using a ring stand or similar apparatus, and is properly positioned and oriented, this method overcomes the errors and drawbacks associated with the traditional method. The variation in data for a traverse point can be used as an indicator of turbulence, an important additional performance indicator that has been almost completely overlooked in the past.

If the standard deviation of the average velocity profile at each point exceeds 20% of the mean, or the average standard deviation of velocities at each traverse point (turbulence) exceeds 15% of the mean face velocity, corrections should be made by adjusting the interior baffles and, if necessary, by altering the path of the supply air flowing into the room (see Figure 9.4). Most laboratory chemical hoods are equipped with a baffle that has movable slot openings at both the top and the bottom, which should be moved until the airflow is essentially uniform. Larger chemical hoods may require additional slots in the baffle to achieve uniform airflow across the face. These adjustments should be made by an experienced laboratory ventilation engineer or technician using proper instrumentation.

9.C.2.8.5 Testing Criteria

Prior to the initial tests, determine the acceptance criteria for the ANSI/ASHRAE 110-1995 leak test, face velocity (based on the results of the ANSI/ASHRAE testing and the design of the laboratory chemical hood), and visual airflow tests.

One important factor to consider is acceptable sash position. It is common to set the acceptance criteria as an acceptable level of containment and/or face velocity range at the standard operating position of the sash, often 18 in. However, one must understand how the chemical hood will be used to determine the range of

FIGURE 9.4 Effect of baffles on face velocity profile in a laboratory chemical hood.

sash positions needed. For example, if the users will need to sometimes use the hood with vertical sash fully open, then the test criteria should be for 100% sash opening.

It may be prudent to set the acceptance criteria with the sash 100% open and 80% open, ensuring adequate containment at both of these positions.

9.C.2.8.6 Instrumentation

Anemometers and other instruments used to measure face velocity must be accurate in order to supply meaningful data. Instruments should be calibrated at least once a year and the calibration should be National Institute of Standards and Technology traceable.

9.C.2.8.7 Additional Exposure Monitoring

If there is any concern that a laboratory chemical hood or other ventilation device may not provide enough protection to the trained laboratory personnel, it is prudent to measure worker exposure while the hood is being used for its intended purpose. By conducting personal air-sampling using traditional industrial hygiene techniques, worker exposure (both excursion peak and time-weighted average) can be measured. The criterion for evaluating the hood should be the desired performance (i.e., does the hood contain vapors and gases at the desired worker-exposure level?). A sufficient number of measurements should be made to define a statistically significant maximum exposure based on worst-case operating conditions. Direct-reading instruments may be available for determining the short-term concentration excursions that may occur in chemical hood use.

9.C.2.9 Laboratory Chemical Hood Design and Construction

When specifying a laboratory chemical hood for use in a particular activity, laboratory personnel should be aware of the design features. Assistance from an industrial hygienist, ventilation engineer, or laboratory consultant is recommended when deciding to purchase a chemical hood.

9.C.2.9.1 General Design Recommendations

Construct laboratory chemical hoods and the associated exhaust ducts of nonflammable materials. Equip them with vertical, horizontal, or combination vertical/horizontal sashes that can be closed. For the glass within the sash, use either laminated safety glass that is at least 7/32-in. thick or other equally safe material that will not shatter if there is an explosion inside. Locate the utility control valves, electrical receptacles, and other fixtures outside the chemical hood to minimize the need to reach within the chemical hood proper. Other specifications regarding the construction materials, plumbing requirements, and interior design vary, depending on the intended use. (See Chapter 7, sections 7.C.1.1 and 7.C.1.2) Information regarding the minimum flow rate through hoods can be found in ANSI Z9.5.

Although chemical hoods are most commonly used to control concentrations of toxic vapors, they can also serve to dilute and exhaust flammable vapors. Although theoretically possible, it is extremely unlikely (even under worst-case scenarios) that the concentration of flammable vapors will reach the lower explosive limit (LEL) in the exhaust duct. However, somewhere between the source and the exhaust outlet of the chemical hood, the concentration will pass through the upper explosive limit and the LEL before being fully diluted at the outlet. Both the designer and the user should recognize this hazard and eliminate possible sources of ignition within the chemical hood and its ductwork if there is a potential for explosion. The use of duct sprinklers or other suppression methods in laboratory hood ductwork is not necessary or desirable.

9.C.2.9.2 Special Design Features

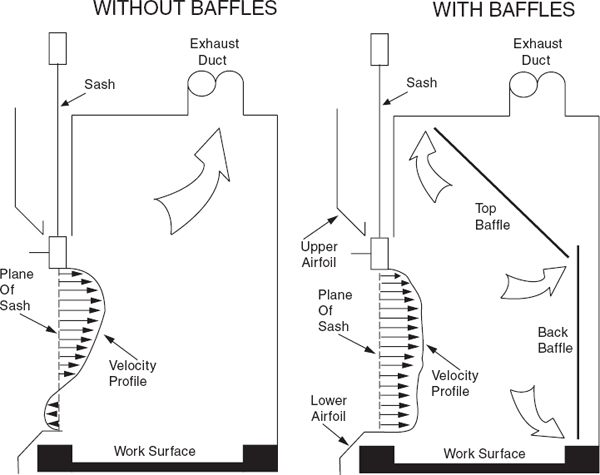

Since the invention of the chemical hood, two major improvements have been made in the design—airfoils and baffles. Include both features on any new purchases.

Airfoils built into the bottom and sides of the sash opening significantly reduce boundary turbulence and improve capture performance. Fit new chemical hoods with airfoils and retrofit any hoods without airfoils

When air is drawn through a laboratory chemical hood without a baffle (see Figure 9.4), most of the air is drawn through the upper part of the opening, producing an uneven velocity distribution across the face opening. All chemical hoods should have baffles. When baffles are installed, the velocity distribution is greatly improved. Adjustable baffles can improve hood performance and are desirable if the adjustments are made by an experienced industrial hygienist, consultant, or technician.

9.C.2.9.3 Laboratory Chemical Hood Airflow Types

The first chemical hoods were simply boxes that were open on one side and connected to an exhaust duct. Since they were first introduced, many variations on this basic design have been made. Six of the major variants in airflow design are listed below with their characteristics. Conventional laboratory chemical hoods are the most common and include benchtop, distillation, and walk-in hoods of the CAV, CAV bypass, nonbypass, and VAV, with or without airfoils. Auxiliary air hoods and ductless chemical hoods are not considered conventional and are used less often.

Trained laboratory personnel should know what kind they are using and what its advantages and limitations are. In general, the initial cost of a CAV system may be less than VAV, but the life-cycle cost of the VAV will almost always be lower than a CAV system.

9.C.2.9.3.1 Constant Air Volume Laboratory Chemical Hoods

A CAV chemical hood draws a constant exhaust volume regardless of sash position. Because the volume is constant, the face velocity varies inversely with the sash position. The laboratory chemical hood volume should be adjusted to achieve the proper face velocity at the desired working height of the sash, and the chemical hood should be operated at this height. (See section 9.C.4.)

9.C.2.9.3.2 Constant Air Volume Nonbypass Laboratory Chemical Hoods

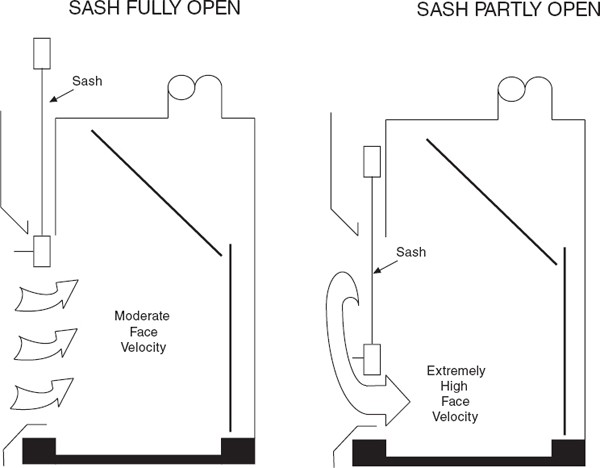

A nonbypass chemical hood has only one major opening through which the air may pass, that is, the sash opening. The airflow pattern is shown in Figure 9.5. A CAV nonbypass chemical hood has the undesirable characteristic of producing very large face velocities at small sash openings. As the sash is lowered, face velocities may exceed 1,000 fpm near the bottom. Face velocities are limited by the leakage through cracks and under the airfoil and by the increasing pressure drop as the sash is closed.

A common misconception is that the volume of air exhausted by this type of chemical hood decreases when the sash is closed. Although the pressure drop increases slightly as the sash is closed, no appreciable change in volume occurs. All chemical hoods should be closed when not in use, because they provide a primary barrier to the spread of a fire or chemical release.

Many trained laboratory personnel are reluctant to close their CAV nonbypass chemical hoods because of the increase in air velocity and noise that occurs when the sash is lowered. This high-velocity air jet sweeping over the work surface often disturbs gravimetric measurements, causes undesired cooling of heated vessels and glassware, and can blow sample trays, gloves, and paper towels to the back of the laboratory chemical hood, where they may be drawn into the exhaust system. Exercise care to prevent materials from entering the exhaust system where they can lodge in the ductwork, reducing airflow, or can be conveyed through the system and drawn into the exhaust fan and damage the fan or cause sparks.

Because of numerous operational problems with the design of nonbypass hoods, their installation in new

FIGURE 9.5 Effect of sash placement on airflow in a nonbypass laboratory chemical hood.

FIGURE 9.6 Effect of sash placement on airflow in a bypass laboratory chemical hood.

facilities is discouraged. If present in existing facilities, their replacement should be considered. In many instances, the cost of replacement can be recouped from the resulting reduction in energy costs.

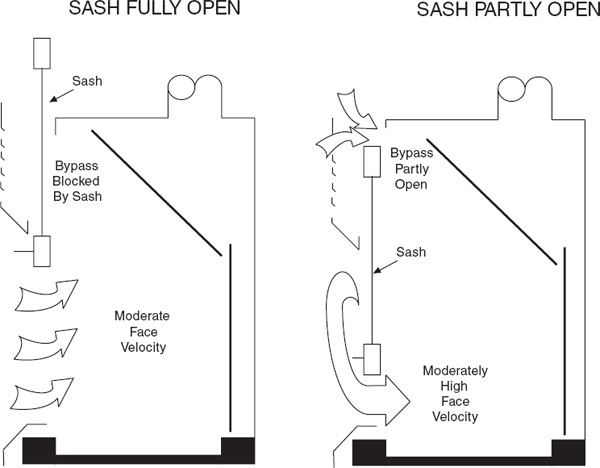

9.C.2.9.3.3 Bypass Laboratory Chemical Hoods

A bypass chemical hood is shown in Figure 9.6. It is similar to the nonbypass design but has an opening above the sash through which air may pass at low sash positions. Because the opening is usually 20 to 30% of the maximum open area of the sash, this hood will still exhibit the increasing velocity characteristic of the nonbypass chemical hood as the sash is lowered. But the face velocity stops increasing as the sash is lowered to the position where the bypass opening is exposed by the falling sash. The terminal face velocity of these types of hoods depends on the bypass area but is usually in the range of 300 to 500 fpm—significantly higher than the recommended operating face velocity. Therefore, the air volume for bypass laboratory chemical hoods should also be adjusted to achieve the desired face velocity at the desired sash height, and the hood should be operated at this position. This arrangement is usually found in combination with a vertical sash, because this is the simplest arrangement for opening the bypass. Varieties are available for horizontal sashes, but the bypass mechanisms are complicated and may cause maintenance problems. For a well-designed bypass hood, the face velocity will stay relatively constant until open about 12 in., then increases rapidly.

9.C.2.9.3.4 Variable Air Volume Laboratory Chemical Hoods

A VAV chemical hood, also known as a constant velocity hood, is one that has been fitted with a face velocity control, which varies the amount of air exhausted from the chemical hood in response to the sash opening to maintain a constant face velocity. In addition to providing an acceptable face velocity over a relatively large sash opening (compared to a CAV hood), VAV hoods also provide significant energy savings by reducing the flow rate when it is closed. These types of hoods are usually of the nonbypass design to reduce air volume (see below). Even though the face velocity responds to the position of the sash, the face velocity may drop off as the sash height increases, depending on the design. As a result, there is a maximum sash height above which the chemical hood becomes less effective.

9.C.2.9.3.5 Auxiliary Air Laboratory Chemical Hoods

Quantitative tracer gas testing of many auxiliary air laboratory chemical hoods has revealed that, even

when adjusted properly and with the supply air properly conditioned, significantly higher personnel exposure to the materials used may occur than with conventional (non-auxiliary air) chemical hoods. They should not be purchased for new installations, and existing ones should be replaced or modified to eliminate the supply air feature. This feature causes a disturbance of the velocity profile and leakage of fumes into the personnel breathing zone.

The auxiliary air chemical hood was developed in the 1970s primarily to reduce laboratory energy consumption and is a combination of a bypass hood and a supply air diffuser located at the top of the sash. They were intended to introduce unconditioned or tempered air, as much as 70% of the air exhausted, directly to the front of the chemical hood. Ideally, this unconditioned air bypasses the laboratory and significantly reduces air-conditioning and heating costs. In practice, however, many problems are caused by introducing unconditioned or slightly conditioned air above the sash, all of which may produce a loss of containment.

9.C.2.9.3.6 Low-Flow or High-Performance Laboratory Chemical Hoods