Appendix F

Estimation of Lithium-Ion Battery Pack Costs

BACKGROUND

Battery pack costs will be the prime determinant of when PHEVs will become competitive, but projections of these costs are highly uncertain. This appendix provides additional detail on the committee’s methodology for developing the cost estimates presented in Chapter 2 of the report.1 The committee reviewed the literature and heard presentations given at NRC meetings by experts. It then discussed its preliminary conclusions about current and anticipated battery pack costs with industry and government experts. Its estimates were subject to the National Academies’ report review process during which additional experts commented on the committee’s assumptions and analysis. The committee’s estimates in its final report include a broad range of costs, reflecting the information the committee reviewed.

Several factors must be known before various battery pack cost estimates can be compared. They include whether the estimated cost per kWh applies to nameplate or usable energy, and, if the former, the assumed state of charge (SOC) range to know how much energy is available, and whether the cost is based on the beginning or end of life capacity (Li-ion batteries deteriorate at about 2 percent per year). To calculate the actual battery pack costs for a vehicle with a specified electric driving distance, the Wh/mile (propulsion energy) required to propel the vehicle must also be estimated, and the cooling (e.g., liquid or air) that is required must be specified. Due to the early state of PHEV development and lack of road experience, there is considerable variability in these cost estimates.

The costs reported in Chapter 2 of the report were based on usable energy, that is, the fraction of the total energy stored in the battery that can be withdrawn for propulsion without risking damage to the battery or causing safety issues. That is the most useful measure when determining the performance of the vehicle and is the measure used by the Department of Energy and the U.S. Advanced Battery Consortium in their published goals for battery storage. However, when comparing costs of different batteries, assuming equal propulsion energy (Wh/mile), nameplate (or nominal) capacity better describes the battery pack costs actually put into the PHEV. The difference between these two measures for a specific battery pack (essentially the SOC selected by the vehicle manufacturer) has caused considerable confusion. The discussion below of various sources of estimates compares the nameplate cost unless otherwise specified.

Battery lifetime and safety are also very significant PHEV development issues for the industry. The current life expectancy of Li-ion batteries for computers and power tools is around 3 to 4 years,2 but 10 years or more will be needed for PHEVs to be competitive. R&D programs are reducing battery costs and improving battery durability and safety, but these goals must be met simultaneously and may interfere with each other. The committee concluded that durability and safety goals are more likely to be met than cost goals. Therefore the focus of this discussion is on costs after durability and safety problems have been solved.

CURRENT COSTS

The committee reviewed a variety of sources to establish the most probable and optimistic costs for the current generation of battery packs. The review, discussed below, indicated a range of $500 to $1500/kWh nameplate. The range is so wide in part because different technologies at different stages of development are reported. Based on this range, the committee selected $875/kWh as the most probable value and $625/kWh as an optimistic value for batteries that have already been ordered to be used in the first generation of

|

1 |

This appendix was added to the report after the release of the prepublication version to clarify the basis for the committee’s cost estimates. The estimates themselves are unchanged. |

|

2 |

The Hymotion kit made by A123 Systems to convert the Toyota Prius to a PHEV comes with a 3 year warranty against defects. The all electric range is not specifically guaranteed. See http://www.a123systems.com/hymotion/pop_ups/warranty. |

PHEV-40s, and $825/kWh and $625/kWh for PHEV-10s. Literature results are as follows:

-

The NAS-NAE-NRC report America’s Energy Future concludes that automotive-grade Li-ion battery pack costs today are between $500/kWh and $1000/kWh nameplate (NAS-NAE-NRC, 2009).

-

DOE estimates of current costs are $1,000+/kWh usable energy (Howell, 2009).3 DOE goals are for performance at the end of life. Li-ion batteries deteriorate over time, typically at about 2 percent per year. Assuming a DOE start of life SOC of 70 percent, the committee estimates DOE’s nameplate cost at start of life to be $560+/kWh.

-

A recent McKinsey report concludes that battery pack costs range from $700/kWh to $1,500/kWh nameplate (Hensley et al., 2009).

-

A 2009 paper (Shiau et al.) from researchers at Carnegie Mellon University uses $1000/kWh nameplate.

-

Pesaran et al. (2007) estimated the cost of advanced Li-Ion battery costs as ranging from $800/kWh to $1,000/kWh nameplate or higher.

-

The Zero Emissions Vehicle Report projected a “current” cost of about $500/kWh nameplate in 2006 (Kalhammer et al., 2007).

The following two reports were released after the committee completed its analysis, but they are included here for completeness.

-

The Electrification Coalition’s 2009 report Electrification Roadmap (available at www.electrificationcoalition.org) states that the current cost is $600/kWh nameplate

-

The Boston Consulting Group’s 2009 report Batteries for Electric Cars (available at www.bcg.com/documents/file36615.pdf) says it is $1000-1200/kWh

The committee expects that these early PHEVs will employ a conservatively low SOC, about 50 percent, to ensure battery durability and safety. With experience and improved battery and control technology the SOC may be increased to 70 or even 80 percent, but that is speculation until several years of real-life operating experience indicate whether battery durability would be jeopardized.

At 50 percent SOC, the current cost for usable (or available) energy for a PHEV-40 comes to $1750/kWh (probable) as shown in Chapter 2, and the nameplate cost is $875/kWh. Based on the report’s assumed propulsion energy of 200 Wh/mile, a 16 kWh battery pack (8 kWh usable) such as will be used in the Chevrolet Volt costs $14,000. While neither GM nor LG Chem, the battery supplier, has announced the costs, $7000 for the cells has been reported in the media. The additional systems, materials, and labor to assemble a battery pack are substantial.

The committee concluded, based on research and discussions, that the cost of assembling the pack is approximately the same as the cost of the cells, corresponding to the total of $14,000 for the PHEV-40. The committee also estimated a range of costs, recognizing the uncertainty involved, and concluded that under more optimistic assumptions the cost could be $10,000. In comparison, DOE estimates that a PHEV-40 would require 11.6 kWh usable energy in a pack that would cost over $11,600, consistent with the estimating accuracy of this report.

PROJECTED FUTURE COSTS

The committee estimated future costs of Li-ion batteries based on the technology status and cost projections in the literature. Based on this analysis, the committee judged that battery pack costs are likely to decline by about 35 percent by 2020 and 45 percent by 2030, as shown in Tables 2.2 and 2.3. This yields a nameplate 2030 PHEV 40 battery pack cost of about $500/kWh ($1000/kWh usable) or, under more optimistic assumptions, about $360/kWh. The committee did not attempt to estimate the future costs if a major technology breakthrough occurs, such as the development of a durable, safe Li- air battery.

The literature contains a wide range of projected future Li-ion battery and battery pack costs (all costs are nameplate unless otherwise noted):

-

The DOE goal is for a very rapid cost reduction from the estimated $1,000+/kWh current cost to $500/kWh in 2012 to $300/kWh (all costs based on available energy base) in 2014.4 Assuming 70 percent SOC and 20 percent deterioration conversion factors, DOE’s goals correspond to $280/kWh in 2012 and $168/kWh in 2014 on a nameplate capacity basis. Meeting these goals would result in a $1700 cost for a 3.4 kWh battery pack in a PHEV-10, and $3,400 for an 11.6 kWh pack in a PHEV-40. Note that these are goals, not projections. Meeting these goals could result in PHEVs being competitive in the marketplace much more rapidly compared with HEVs and conventional vehicles, as discussed in Appendix C.

-

The U.S. Advanced Battery Consortium (2009) has the same goals as DOE.

-

Nelson et al. (2009) projected pack manufacturing cost of about $350/kWh at 100,000 unit volume for a PHEV-10 and $200/kWh for a PHEV-40.

-

The McKinsey report projected that costs will decrease at 6 percent to 8 percent per year, and, with aggressive cost reduction, could reach $420/kWh nameplate by 2015 (Hensley et al., 2009).

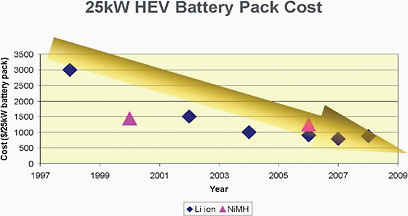

FIGURE F.1 Historical cost reduction experience for NiMH battery packs and for Li-ion battery packs. Recent experience does not suggest rapid further cost reductions. SOURCE: T.Q. Duong, Update on electrochemical energy storage R&D, presentation to the committee, Washington D.C., June 2009.

-

Anderman predicts that the cost of Li-ion batteries will remain at around $600/kWh even with increased production (Anderman, 2007).

-

Kalhammer et al. (2007) project costs from $350/kWh to $400/kWh (nameplate) for PHEV-40 battery packs at volume production (100,000 to 200,000 units per year). Costs for PHEV-10 battery packs are projected to be $560 to 860/kWh for production at 100,000 to 625,000 units per year.

The future cost estimates in this report are higher than most, but not all, other projections, especially the DOE goals. The committee concluded that reductions greater than 50 percent in battery costs are unlikely over the next two decades without a major technology breakthrough, because meeting battery durability and safety goals could slow cost reductions. For example, raising the SOC range would be a significant cost saver but could compromise durability if that put too much stress on the cells.

Cost reductions are likely to come mainly from improvements in technology, with lesser contributions from manufacturing improvements, improved yield, and manufacturing scale.5 Technology will continue to improve, but it is already well developed for current Li-ion cells. Cells for automotive applications will be bigger than current Li-ion cells but are otherwise not very different in either chemistry or manufacturing processes. Thus the potential for large cost reductions from technology improvements is limited. Furthermore, materials represent more than half the cell cost (Nelson et al., 2009), and these costs are unlikely to drop dramatically.

Economies of scale are often cited as a factor that can drive down costs, but hundreds of millions to billions of Liion cells already are being produced in optimized factories. Building more factories is unlikely to have a great impact on costs. The cost of the battery pack enclosure that holds the cells, the electronics required to monitor and control each cell to prevent over-charging and run-away, and the temperature control system to manage battery pack temperature are a major portion of the total battery pack cost. These components are unlikely to undergo larger cost reductions than the cells, and so the committee maintained the same ratio of twice the cell cost for the pack.

Li-ion batteries have undergone large cost reductions over the last 10 years, but the costs seem to be leveling out. Costs of NiMH battery pack for HEVs have declined only modestly in recent years, as shown in Figure F.1, suggesting that further major cost reductions are not very likely without technology breakthroughs, which this study did not try to project.

The committee considered all these projections and other information to come up with its estimates for 2030 future costs of about $500/kWh or, under more optimistic assumptions, of about $360/kWh.

VALIDATION OF COSTS

Based on the above and other related information, discussions with industry and government experts, and its own judgments, the committee developed Tables 2.2 through 2.6 with what it considered the most probable set of numbers for the key battery pack performance parameters and battery pack cost. These were discussed with the companies acknowledged in the front matter of this report to ensure that battery costs and performance were realistic.6 Some adjustments were made based on these discussions, and the estimates presented above were finalized. The committee’s report was subjected to the National Academies’ report review process in which another set of experts critiqued the report and the committee’s assumptions and analysis.