Summary

Liquid fuel consumption by medium- and heavy-duty vehicles (MHDVs) represents 26 percent of all U.S. liquid transportation fuels consumed and has increased more rapidly—in both absolute and percentage terms—than consumption by other sectors. In early recognition of these trends, which are forecast to continue until 2035 (DOE, EIA, 2009), the Energy Independence and Security Act of 2007 (EISA; Public Law 110-140, Dec. 19, 2007), Section 108, was passed, requiring the U.S. Department of Transportation (DOT), for the first time in history, to establish fuel economy standards for MHDVs. In December 2009 the U.S. Environmental Protection Agency (EPA) formally declared that greenhouse gas (GHG) emissions endanger public health and the environment within the meaning of the Clean Air Act, a decision that compels EPA to consider establishing first-ever GHG emission standards for new motor vehicles, including MHDVs. If the United States is to reduce its reliance on foreign sources of oil, and reduce GHG emissions from the transportation sector, it is important to consider how the fuel consumption of MHDVs can be reduced.

Following the passage of EISA, the National Research Council appointed the Committee to Assess Fuel Economy Technologies for Medium- and Heavy-Duty Vehicles. The committee considered approaches to measuring fuel economy (the committee uses fuel consumption), assessed current and future technologies for reducing fuel consumption, addressed how such technologies may be practically implemented in vehicles, discussed the pros and cons of approaches to improving the fuel efficiency of moving goods as opposed to setting vehicle fuel consumption standards, and identified potential costs and other impacts on the operation of MHDVs (see Chapter 1 and Appendix A for the complete statement of task).

The legislation also requires DOT’s National Highway Traffic Safety Administration (NHTSA) to conduct its own study on the fuel consumption of commercial medium- and heavy-duty highway vehicles and work trucks and then to establish a rulemaking to implement a commercial medium-and heavy-duty on-highway and work-truck fuel efficiency improvement program.

The organization of this Summary follows that of the report’s chapters: Chapter 1 provides background; Chapter 2 provides vehicle fundamentals; Chapter 3 surveys the current U.S., European, and Asian approaches to fuel economy and regulations; Chapters 4 and 5 review and assess technologies to reduce fuel consumption; Chapter 6 assesses direct and indirect costs and benefits of integrating fuel consumption reduction technologies into vehicles; Chapter 7 presents a review of potential unintended consequences and the alternative nontechnology approaches to reducing fuel consumption; and Chapter 8 reviews options for regulatory design. The Summary presents the committee’s major findings and recommendations from each chapter; fuller discussion and additional findings are found in the report.

VEHICLE FUNDAMENTALS, FUEL CONSUMPTION, AND EMISSIONS

Medium- and heavy-duty trucks, motor coaches, and transit buses, Class 2b through Class 8, are used in every sector of the economy. The purposes of these vehicles range from carrying passengers to moving goods. For some vehicles and driving cycles this simple relationship breaks down (as with a bucket truck, which carries one or two passengers but delivers no freight). It brings services and capability (the bucket, tools, and spare parts) to a job site. This results in a broad range of varying duty cycles, from high-speed operation on highways with few stops to lower-speed urban operation with many stops per mile. For the purposes of estimating fuel consumption benefits of various technologies in this report, the committee examined seven different types of vehicles and made assumptions about the duty cycles that would characterize their operations: (1) tractor trailer, (2) Class 6 box truck, (3) Class 6 bucket truck, (4) refuse truck, (5) transit bus, (6) motor coach, and (7) pickup/van. When DOT promulgates standards for fuel consumption, it will have to

address the duty cycles that characterize different types of vehicles and their wide range of applications.

The fundamental engineering metric for measuring the fuel efficiency of a vehicle is fuel consumption, the amount of fuel used, assuming some standard duty or driving cycle, to deliver a given transportation service, for example, the amount of fuel a vehicle needs to go a mile or the amount of fuel needed to transport a ton of goods a mile. For light-duty vehicles (cars and light trucks), the corporate average fuel economy (CAFE) program uses miles per gallon (mpg). This measure, although derived from measurements of fuel consumption in gallons/mile, is not the appropriate measure for MHDVs, since these vehicles are designed to carry loads in an efficient and timely manner. A partially loaded tractor trailer would consume less fuel per mile than a fully loaded truck, but this would not be an accurate measure of the fuel efficiency of moving goods. However, normalizing fuel consumption by the payload and using the calculation of gallon/ton-mile—the load-specific fuel consumption (LSFC)—the fully loaded truck would have a much lower LSFC number than the partially loaded truck, reflecting the ability of the truck to accomplish the task of delivering goods.

Finding 2-1. Fuel consumption (fuel used per distance traveled; e.g., gallons per mile) has been shown to be the fundamental metric to properly judge fuel efficiency improvements from both engineering and regulatory viewpoints, including yearly fuel savings for different technology vehicles.

Finding 2-2. The relationship between the percent improvement in fuel economy (FE) and the percent reduction in fuel consumption (FC) is nonlinear; e.g., a 10 percent increase in FE (miles per gallon) corresponds to a 9.1 percent decrease in FC, whereas a 100 percent increase in FE corresponds to a 50 percent decrease in FC. This nonlinearity leads to widespread consumer confusion as to the fuel-savings potential of the various technologies, especially at low absolute values of FE.

Finding 2-3. MHDVs are designed as load-carrying vehicles, and consequently their most meaningful metric of fuel efficiency will be in relation to the work performed, such as fuel consumption per unit payload carried, which is load-specific fuel consumption (LSFC). Methods to increase payload may be combined with technology to reduce fuel consumption to improve LSFC. Future standards might require different values to accurately reflect the applications of the various vehicle classes (e.g., buses, utility, line haul, pickup, and delivery).

Recommendation 2-1. Any regulation of medium- and heavy-duty vehicle fuel consumption should use LSFC as the metric and be based on using an average (or typical) payload based on national data representative of the classes and duty cycle of the vehicle. Standards might require different values of LSFC due to the various functions of the vehicle classes e.g., buses, utility, line haul, pickup, and delivery. Regulators need to use a common procedure to develop baseline LSFC data for various applications, to determine if separate standards are required for different vehicles that have a common function. Any data reporting or labeling should state an LSFC value at specified tons of payload.

COMPARING THE REGULATORY APPROACHES OF THE UNITED STATES, JAPAN, AND EUROPEAN COMMUNITY

Although a CAFE regulatory program has been implemented for light-duty vehicles, where the responsibility for the manufacture and certification of vehicles is well defined and the configurations of cars and light trucks for sale are well defined and of limited number, the MHDV world is much more complicated. There are literally thousands of different configurations for vehicles, including bucket trucks, pickup trucks, garbage trucks, delivery vehicles, and long-haul tractor trailers. Their duty cycles vary greatly. Some stop and go every few seconds; others spend most of their time at highway speeds. Furthermore, the party responsible for the final truck configuration is often not well defined. For example, a body builder (vehicle integrator) may be the manufacturer of record, but the body builder may not design or even specify the chassis and power train. For tractor-trailer combinations, the tractor and trailer are always made and often owned by different companies, and a given tractor may pull hundreds of different trailers of different configurations over its life. Many trucks are custom made, literally one of a kind.

Even though the regulation of such vehicles will be much more complicated than it is for light-duty vehicles, the barriers are not insurmountable. Safety and emission regulations have been implemented, and regulations for fuel consumption in medium- and heavy-duty trucks already exist in Japan and are under development by the European Commission. California is building on the EPA’s SmartWay Partnership to implement its own approach to regulating truck fuel consumption.

Major Findings and Recommendations— Chapter 3: Current Regulatory Approaches

Finding 3-1. Although it took years of development and substantial effort, regulators have dealt effectively with the diversity and complexity of the vehicle industry for current laws on fuel consumption and emissions for light-duty vehicles. Engine-based certification procedures have been applied to address emissions from heavy-duty vehicles and the myriad of nontransportation engines.

Finding 3-2. The heavy-duty-truck fuel consumption regulations in Japan, and those under consideration and study by the European Commission, provide valuable input and experience to the U.S. plans. In Japan the complexity of MHDV configurations and duty cycles was determined to lend itself to the use of computer simulation as a cost-effectives means to calculate fuel efficiency, and Japan is not using extensive full-vehicle testing in the certification process.

TECHNOLOGIES AND COSTS OF REDUCING FUEL CONSUMPTION

The committee has evaluated a wide range of fuel-saving technologies for medium- and heavy-duty vehicles. Some technologies, such as certain aerodynamic features, automated manual transmissions, and wide-base single low-rolling-resistance tires, are already available in production. Some of the technologies are in varying stages of development, while others have only been studied using simulation models. Reliable, peer-reviewed data on fuel-saving performance is available only for a few technologies in a few applications. As a result, the committee had to rely on information from a wide range of sources, (e.g., information gathered from vehicle manufacturers, component suppliers, research labs, and major fleets during site visits by the committee), including many results that have not been duplicated by other researchers or verified over a range of duty cycles.

There is a tendency among researchers to evaluate technologies under conditions which are best suited to that specific technology. This can be a serious issue in situations where performance is strongly dependent on duty cycle, as is the case for many of the technologies evaluated in this report. One result is that the reported performance of a specific technology may be better than what would be achieved by the overall vehicle fleet in actual operation. Another issue with technologies that are not fully developed is a tendency to underestimate the problems that could emerge as the technology matures to commercial application. Such issues often result in implementation delays as well as a loss of performance compared to initial projections. As a result of these issues, some of the technologies evaluated in this report may be available later than expected, or at a lower level of performance than expected. Extensive additional research would be needed to quantify these issues, and regulators will need to allow for the fact that some technologies may not mature as expected.

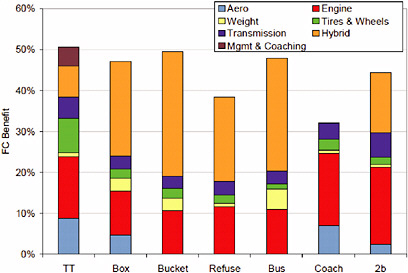

The fuel-saving technologies that are already available on the market generally result in increased vehicle cost, and purchasers must weigh the additional cost against the fuel savings that will accrue. In most cases, market penetration is low at this time. Most fuel-saving technologies that are under development will also result in increased vehicle cost, and in some cases, the cost increases will be substantial. As a result, many technologies may struggle to achieve market acceptance, despite the sometimes substantial fuel savings, unless driven by regulation or by higher fuel prices. Power-train technologies (for diesel engines, gasoline engines, transmissions, and hybrids) as well as vehicle technologies (for aerodynamics, rolling resistance, mass/weight reduction, idle reduction, and intelligent vehicles) are analyzed in Chapters 4 and 5. Tables S-1 and S-2 provide the committee’s estimate of the range of fuel consumption reduction that is potentially achievable with new technologies in the period 2015 to 2020, compared to a 2008 baseline.1 Figure S-1 provides estimates for potential fuel consumption reductions for typical new vehicles in the 2015 to 2020 time frame.

The technologies were grouped into time periods based on the committee’s estimate of when the technologies would be proven and available. In practice, the timing of their introduction will vary by manufacturer, based in large part on individual company product development cycles. In order to manage product development costs, manufacturers must consider the overall product life cycle and the timing of new product introductions. As a result, widespread availability of some technologies may not occur in the time frames shown.

The percent fuel consumption reduction (% FCR) numbers shown for individual technologies and other options are not additive. For each vehicle class, the % FCR associated with combined options is as follows:

where % FCRtechx is the percent benefit of an individual technology.

The major enabling technologies necessary to achieve these reductions are hybridization, advanced diesel engines, and aerodynamics. Hybridization is particularly important in those applications with the stop-and-go duty cycles characteristic of many MHDVs, such as refuse trucks and transit buses, as well as bucket trucks. Diesel and gasoline engine advancements are helpful in all applications and will include continuing improvements to fuel injection systems, emissions control, and air handling systems, in addition to commercialization of waste heat recovery systems. Essentially all Class 8 vehicles will continue with diesel engines as the prime mover. The third major technology improvement is total vehicle aerodynamics, especially in over-the-road applications like tractor trailers and motor coaches. Other technologies that will play a role in reducing fuel consumption in all vehicle segments include low-rolling-resistance tires, improved transmissions, idle-reduction technologies, weight reduction, and driver management and coaching.

The applications of these technologies can be put into packages and then applied to the seven types of MHDVs analyzed. The resulting fuel consumption reduction for each

|

1 |

More information on the baseline can be found in Chapter 6 and in TIAX (2009). |

TABLE S-1 Range of Fuel Consumption Reduction Potential, 2015-2020, for Power Train Technologies

vehicle type will be dependent on the typical vehicle application and the typical duty cycle. The results of the packages on fuel consumption reduction from a 2008 baseline are shown for the 2015 to 2020 time frame in Figure S-1.

The technology packages that result in the fuel consumption reduction for each application also have projected costs. The costs are estimated assuming the technologies will be produced at large enough volumes to achieve economies of scale in the 2015 to 2020 time frame. The committee has also determined several ways to measure costs versus benefits. The first measure, dollars per percent fuel saved, is the cost of the technology package divided by the percent reduction in fuel consumption. The second measure, dollars per gallon saved per year, accounts for the fact that some vehicles are normally driven more miles than others. The measure calculates how much it costs to save one gallon of fuel each year for the life of the vehicle by adopting the relevant technology. The third measure, “breakeven” fuel price, represents the fuel price that would make the present discounted value

TABLE S-2 Range of Fuel Consumption Reduction Potential, 2015-2020, for Vehicle Technologies

FIGURE S-1 Comparison of 2015-2020 new-vehicle potential fuel-saving technologies for seven vehicle types: tractor trailer (TT), Class 3-6 box (box), Class 3-6 bucket (bucket), Class 8 refuse (refuse), transit bus (bus), motor coach (coach), and Class 2b pickups and vans (2b).

NOTE: TIAX (2009) only evaluated the potential benefits of driver management and coaching for the tractor-trailer class of vehicles. It is clear to the committee that other vehicle classes would also benefit from driver management and coaching, but studies showing the benefits for specific vehicle classes are not available. For more information, see the subsection “Driver Training and Behavior” in Chapter 7. Also, potential fuel reductions are not additive. For each vehicle class, the fuel consumption benefit of the combined technology packages is calculated as follows: [% FCRpackage = 100 [1 − (1 − {% FCRtech1/100}) (1 − {% FCRtech2/100)} … (1 − {% FCRtechN/100})]. Values shown are for one set of input assumptions. Results will vary depending on these assumptions. SOURCE: TIAX (2009).

of the fuel savings equal to the total costs of the technology package applied to the vehicle class.

The breakeven fuel price shown in Table S-3 does not necessarily reflect how vehicle buyers would evaluate technologies, because they often do not plan to own a vehicle for its full life, they may use a different discount rate, and they would need to consider operation and maintenance costs, which are excluded from the calculation. However, a lifetime breakeven price is a useful metric for considering both the private and the societal costs and benefits of regulation. Although incomplete, the measures shown in Table S-3 are suggestive of the differences in economic viability of the various technology options for the indicated vehicle classes. It is important to remember, however, that these breakeven prices are calculated assuming that all the technologies are applied as a package. In fact, individual fuel-saving technologies applied in a given vehicle class may face much lower or much higher breakeven values than the aggregate figures listed in Table S-3. For more detailed information on the values summarized in Table S-3, see Tables 6-18 and 6-19 in Chapter 6.

The findings and recommendations below combine material from Chapters 4 through 6 and therefore do not match the numbering in those chapters but are presented instead as “Finding 4/5/6-X.”

TABLE S-3 Fuel Consumption Reduction Potential for Typical New Vehicles, 2015-2020, and Cost-Effectiveness Comparisons for Seven Vehicle Configurations

|

Vehicle Class |

Fuel Consumption Reduction (%) |

Capital Cost ($) |

Cost-Effectiveness Metric |

||

|

Dollars per Percent Fuel Saved |

Dollars per Gallon Saved per Year |

Breakeven Fuel Pricea ($/gal) |

|||

|

Tractor-trailer |

51 |

84,600 |

1,670 |

7.70 |

1.10 |

|

Class 6 box truck |

47 |

43,120 |

920 |

29.30 |

4.20 |

|

Class 6 bucket truck |

50 |

49,870 |

1,010 |

37.80 |

5.40 |

|

Class 2b pickup |

45 |

14,710 |

330 |

33.70 |

4.80 |

|

Refuse truck |

38 |

50,800 |

1,320 |

18.90 |

2.70 |

|

Transit bus |

48 |

250,400 |

5,230 |

48.00 |

6.80 |

|

Motor coach |

32 |

36,350 |

1,140 |

11.60 |

1.70 |

|

NOTE: Numbers in last three columns are rounded. Also, these point estimates will vary depending on input assumptions. For each vehicle class, the fuel consumption benefit of the combined technology packages is calculated as follows: [% FCRpackage = 100 [1 − (1 − {% FCRtech1 /100}) (1 − {% FCRtech2/100)} … (1 − {% FCRtechN/100})]. Values shown are for one set of input assumptions. Results will vary depending on these assumptions. aCalculated assuming a 7 percent discount rate and a 10-year life, excluding incremental operating and maintenance costs associated with the technologies. SOURCE: Adapted from TIAX (2009). |

|||||

Finding 4/5/6-1. The fuel consumption reduction potential of specific power train and vehicle technologies is extremely dependent on application (pickup vs. tractor trailer) and duty cycle (start-stop vs. steady state, variations in load, etc.).

Finding 4/5/6-2. Technologies vary significantly in the cost-benefit evaluation. Some technologies are economically viable at today’s fuel prices. Others examined require significantly higher fuel prices or correspondingly high valuations of environmental and security externalities to justify their application.

Finding 4/5/6-3. Cost per percent fuel saved is a widely used metric for evaluating the cost/benefit of fuel-saving technologies, and this metric is also used here. Unfortunately, this metric can be very misleading, because it leaves out the critical component of total annual vehicle fuel consumption. Table S-3 shows great discrepancies between cost per percent fuel saved and cost per gallon saved.

Recommendation 4/5/6-1. The federal government should continue to support programs in industries, national laboratories, private companies, and universities to develop MHDV technologies for reducing fuel consumption.

INDIRECT EFFECTS AND EXTERNALITIES

In addition to the direct costs and benefits associated with the application of new technologies, there are also in-direct costs, benefits, and externalities (impacts that are not expressed in market terms) that should be discussed and addressed. Some of these indirect effects represent unintended consequences associated with technologies or policies designed to spur greater fuel efficiency in MHDVs. Although it recognizes that it did not address an exhaustive list of indirect effects, the committee emphasizes the importance of assessment of such effects during policy development to help avoid or mitigate negative unintended consequences.

Major Findings and Recommendations—Chapter 6: Indirect Effects and Externalities

Finding 6-9. A number of indirect effects and unintended consequences associated with regulations aimed at reducing fuel consumption in the trucking sector can be important. In particular, regulators should consider the following effects in the development of any regulatory proposals: rate of replacement of older vehicles (fleet turnover impacts), increased ton-miles shipped due to the lower cost of shipping (rebound effect), purchasing one class of vehicle rather than another in response to a regulatory change (vehicle class shifting), environmental co-benefits and costs, congestion, safety, and incremental weight impacts.

Finding 6-10. Consumer buying in anticipation of new regulations (pre-buy) and retention of older vehicles can slow the rate of fleet turnover and the rate at which regulatory standards can affect fleet-wide fuel consumption.

Finding 6-11. Elasticity estimates vary over a wide range, and it is not possible to calculate with a great deal of confidence what the magnitude of the “rebound” effect is for heavy-duty trucks. The rebound effect measures the increase in ton-miles shipped resulting from a reduction in the cost of shipping. Estimates of fuel savings from regulatory standards will be somewhat misestimated if the “rebound” effect is not considered.

Finding 6-12. Standards that differentially affect the capital and operating costs of individual vehicle classes can cause purchase of vehicles that are not optimized for particular operating conditions. The complexity of truck use and the variability of duty cycles increase the probability of these unintended consequences.

Finding 6-16. Some fuel-efficiency-improving technologies will add weight to vehicles and push those vehicles over federal threshold weights, thereby triggering new operational conditions and affecting, in turn, vehicle purchase decisions. More research is needed to assess the significance of this potential impact.

Finding 6-17. Some fuel-efficiency-improving technologies will reduce cargo capacity for trucks that are currently “weighed-out” and will therefore force additional trucks onto the road. More research is needed to assess the significance of this potential impact.

Recommendation 6-1. NHTSA, in its study, should do an economic/payback analysis based on fuel usage by application and different fuel price scenarios. Operating and maintenance costs should be part of any study.

ALTERNATIVE APPROACHES

There may be more effective, less costly, and complementary approaches than vehicle fuel efficiency standards for reducing fuel consumption of MHDVs, such as training truck drivers on best practices, adjusting size and weight restrictions on trucks, implementing market-based instruments (e.g., fuel taxes), providing incentives for mode shifting, or developing intelligent vehicle and highway systems. As DOT/NHTSA conduct regulatory analyses of fuel efficiency options, indirect costs and alternative approaches will have to be identified.

Major Findings and Recommendations—Chapter 7

Finding 7-1. The committee examined a number of approaches for reducing fuel consumption in the trucking sector and found suggestive evidence that several approaches— particularly driver training and longer combination vehicles (LCVs)—offer potential fuel savings for the trucking sector that rival the savings available from technology adoption for certain vehicle classes and/or types. Any government action taken to reduce fuel consumption in the trucking sector should consider these alternatives.

Finding 7-2. Fuel taxes offer a transparent and efficient method for internalizing the potential societal costs of climate change and oil imports (e.g., energy security) and reducing fuel consumption in road transport. Fuel taxes operate to make fuel-saving technologies more attractive and provide incentives for saving fuel in operations, while involving fewer unintended consequences than standards.

Recommendation 7-1. Although the committee recognizes the political difficulty associated with increasing fuel taxes, it strongly recommends that Congress consider fuel taxes as an alternative to mandating fuel efficiency standards for medium- and heavy-duty trucks.

Finding 7-5. A cap-and-trade system, such as is being considered by Congress that would limit total carbon dioxide (CO2) emissions by primary energy producers, would have implications for the trucking sector. Regulators would then not need to develop standards for CO2 emissions that apply to specific trucks and trucking operations, avoiding the complexity of different classes and duty cycles of trucks. On the other hand, the cap-and-trade system would likely involve new administrative burdens for monitoring emissions from the primary producers and policing the system.

Finding 7-7. When there are several fuel-saving options and complex truck operating conditions, performance standards are likely to be superior to specific technology requirements.

Finding 7-8. Increasing vehicle size and weight limits offers potentially significant fuel savings for the entire tractor-trailer combination truck fleet. This approach would need to be weighed against increased costs of road repair. Example case studies explored in this report demonstrate fuel savings of up to 15 percent or more. These savings are similar in size but independent and accumulative of other actions that may be taken to improve fuel consumption of vehicles; therefore the net potential benefit is substantial. To achieve these savings would require the federal government to:

-

Change regulatory limits that currently restrict vehicle weight to 80,000 lb and that freeze LCV operations on the Federal Interstate System.

-

Establish a regulatory structure that assures safety and compatibility with the infrastructure. One possible regulatory structure has been proposed by the Transportation Research Board in Regulation of Weights,

-

Lengths, and Widths of Commercial Motor Vehicles, Special Report 267 (TRB, 2002).

-

Consider the necessary changes that would be required to permit reasonable access of LCVs to vehicle breakdown yards and major shipping facilities in close proximity to the interstate.

Recommendation 7-2. Congress should give serious consideration to liberalizing weight and size restrictions and should consider how the potential fuel savings and other benefits of such liberalization can be realized in a way that maintains safety and minimizes the cost of potential infrastructure changes.

Finding 7-10. Intelligent transportation systems enable more efficient use of the existing roadway system by improving traffic flow and reducing or avoiding congestion.

Finding 7-12. There are significant opportunities for savings in fuel, equipment, maintenance, and labor when drivers are trained properly. Indications are that this could be one of the most cost-effective and best ways to reduce fuel consumption and improve the productivity of the trucking sector. For example, cases evaluated herein demonstrate potential fuel savings of ~2 to 17 percent with appropriately trained drivers.

Recommendation 7-3. The federal government should encourage and incentivize the dissemination of information related to the relationship between driving behavior and fuel savings. For example, one step in this direction could be to establish a curriculum and process for certifying fuel-saving driving techniques as part of commercial driver license certification and to regularly evaluate the effects of such a curriculum.

APPROACHES TO FUEL CONSUMPTION REDUCTION AND REGULATIONS

This is an important juncture for the nation. The choices that will be made over the course of the next few years will establish the regulatory design for MHDV fuel consumption standards for the next several decades at least. While the stringency of the standards themselves may be revisited from time to time, the regulatory design elements (regulated parties, certification tests and procedures, compliance methods)—once established—are far more difficult to modify.

In many cases, the commercial vehicle market is sophisticated, driven by knowledgeable purchasers who focus on the efficiency of their operations, including the fuel costs associated with accomplishing their tasks. Thus, one of the most important challenges facing NHTSA is how to enhance and improve upon the commercial trucking industry’s existing desire to maximize the fuel economy of its trucks and fleets.

At the same time, there are commonly acknowledged characteristics in the commercial truck and buses market-place that may be improved by a regulatory approach, such as split incentives between owners and operators (e.g., trailers) and the short payback period of 18 months to 2 years, that create barriers to the adoption of efficiency technologies for many purchasers, suggesting that a well-designed regulatory program may yield important benefits.

Due to the complexity of the vehicle market, the committee was not able to give adequate consideration to the non-commercial markets such as personal pickup trucks, school buses, and personal motor homes. NHTSA should consider these applications in its regulatory proposal.

A fundamental concern raised by the committee and those who testified during its public sessions was the tension between the need to set a uniform test cycle for regulatory purposes and existing industry practices of seeking to minimize fuel consumption of medium- and heavy-duty vehicles designed for specific routes that may include grades, loads, work tasks, or speeds inconsistent with the regulatory test cycle. This concern emphasizes the critical importance of achieving fidelity between certification values and real-world results, in order to avoid driving decisions that hurt rather than help real-world fuel consumption.

Because regulations can lead to unintended consequences, either because the variability of tasks within a vehicle class is not adequately dealt with or because regulations may lead to distortions between classes in the costs of accomplishing similar tasks, the committee urges NHTSA to carefully consider all factors when developing its regulatory proposal.

Major Finding and Recommendations—Chapter 8

Finding 8-1. While it may seem expedient to focus initially on those classes of vehicles with the largest fuel consumption (i.e., Class 8, Class 6, and Class 2b, which together account for approximately 90 percent of fuel consumption of MHDVs), the committee believes that selectively regulating only certain vehicle classes would lead to very serious unintended consequences and would compromise the intent of the regulation. Within vehicle classes, there may be certain subclasses of vehicles (e.g., fire trucks) that could be exempt from the regulation without creating market distortions.

Finding 8-2. Large original equipment manufacturers (OEMs), which have significant engineering capability, design and manufacture almost all Class 2b, 3, and 8b vehicles. Small companies with limited engineering resources make a significant percentage of vehicles in Classes 4 through 8a, although in many cases they buy the complete chassis from larger OEMs. Regulators will need to take the limitations of these smaller companies into account.

Finding 8-3. Commercial trailers are produced by a separate group of manufacturers that are not associated with truck

manufacturers. Trailers, which present an important opportunity for fuel consumption reduction, can benefit from improvements in aerodynamics and tires.

Recommendation 8-1. When NHTSA regulates, it should regulate the final-stage vehicle manufacturers since they have the greatest control over the design of the vehicle and its major subsystems that affect fuel consumption. Component manufacturers will have to provide consistent component performance data. As the components are generally tested at this time, there is a need for a standardized test protocol and safeguards for the confidentiality of the data and information. It may be necessary for the vehicle manufacturers to provide the same level of data to the tier suppliers of the engines, transmissions, and after-treatment and hybrid systems.

Recommendation 8-3. NHTSA should establish fuel consumption metrics tied to the task associated with a particular type of MHDV and set targets based on potential improvements in vehicle efficiency and vehicle or trailer changes to increase cargo-carrying capacity. NHTSA should determine whether a system of standards for full but lightly loaded (cubed-out) vehicles can be developed using only the LSFC metric or whether these vehicles need a different metric to properly measure fuel efficiency without compromising the design of the vehicles.

Finding 8-7. Some certification and compliance methods seem more practical than others, and the committee acknowledges that there may be other options or variations that have yet to be identified. Regulating total vehicle fuel consumption of MHDVs will be a formidable task due to the complexity of the fleet, the various work tasks performed, and the variations in fuel-consumption-related technologies within given classes, including vehicles of the same model and manufacturer.

Finding 8-9. Using the process and results from existing engine dynamometer testing for criteria emissions to certify fuel economy standards for MHDVs would build on proven, accurate, and repeatable methods and put less additional administrative burden on the industry. However, to account for the fuel consumption benefits of hybrid power trains and transmission technology, the present engine-only tests for emissions certification will need to be augmented with other power train components added to the engine test cell, either as real hardware or as simulated components. Similarly, the vehicle attributes (aerodynamics, tires, mass) will need to be accounted for, one approach being to use vehicle-specific prescribed loads (via models) in the test cycle. This will require close cooperation among component manufacturers and vehicle manufacturers.

Recommendation 8-4. Simulation modeling should be used with component test data and additional tested inputs from power train tests, which could lower the cost and administrative burden yet achieve the needed accuracy of results. This is similar to the approach taken in Japan, but with the important clarification that the program would represent all of the parameters of the vehicle (power train, aerodynamics, and tires) and relate fuel consumption to the vehicle task.

Finding 8-13. There is an immediate need to take the findings and recommendations in this report and begin the development of a regulatory approach. Significant engineering work is needed to produce an approach that results in fuel efficiency standards that are cost-effective and that accurately represent the effects of fuel-consumption-reducing technologies. The regulations should fit into the engineering and development cycle of the industry and provide meaningful data to vehicle purchasers.

Recommendation 8-5. Congress should appropriate money for and NHTSA should implement as soon as possible a major engineering contract that would analyze several actual vehicles covering several applications and develop an approach to component testing and related data collection in conjunction with vehicle simulation modeling to arrive at LSFC data for these vehicles. The actual vehicles should also be tested by appropriate full-scale test procedures to confirm the actual LSFC values and the reductions measured with fuel consumption reduction technologies in order to validate the evaluation method.

Recommendation 8-6. NHTSA should conduct a pilot program to “test drive” the certification process and validate the regulatory instrument proof of concept. It should have these elements:

-

Gain experience with certification testing, data gathering, compiling, and reporting. There needs to be a concerted effort to determine the accuracy and repeatability of all the test methods and simulation strategies that will be used with any proposed regulatory standards and a willingness to fix issues that are found.

-

Gather data on fuel consumption from several representative fleets of vehicles. This should continue to provide a real-world check on the effectiveness of the regulatory design on the fuel consumption of trucking fleets in various parts of the marketplace and in various regions of the country.

REFERENCES

DOE, EIA. 2009. Annual Energy Outlook 2010 (Preliminary). Washington, D.C., December.

TIAX, LLC. 2009. Assessment of Fuel Economy Technologies for Medium-and Heavy-Duty Vehicles. Final Report. Report to the National Academy of Sciences. Cambridge, Mass. September.

TRB (Transportation Research Board). 2002. Special Report 267: Regulation of Weights, Lengths, and Widths of Commercial Motor Vehicles. Washington, D.C.: TRB.