4

Power Train Technologies for Reducing Load-Specific Fuel Consumption

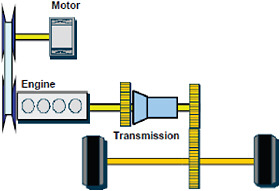

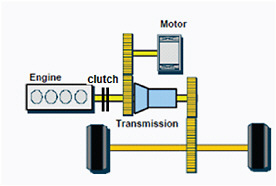

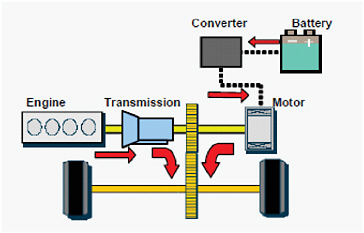

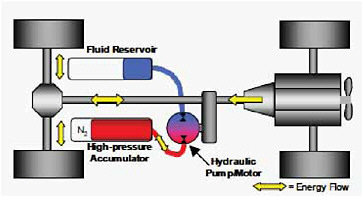

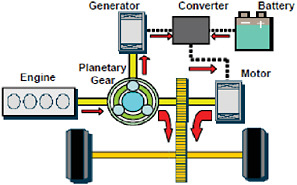

Technologies for reducing fuel consumption of medium-and heavy-duty vehicles depend on the power train type. For instance, replacing gasoline engines with diesel engines in medium-duty trucks is a very effective technology, but heavy-duty trucks are already more than 99 percent dieselized. This chapter discusses the energy balance for a typical diesel engine that leads to a resulting brake power or brake thermal efficiency. It presents technologies for improving the efficiency of diesel and gasoline engines (including fuels and emission systems) as well as technologies for transmissions and drive axles. It also discusses the role of hybrid power trains (electric and hydraulic) in reducing fuel consumption.

DIESEL ENGINE TECHNOLOGIES

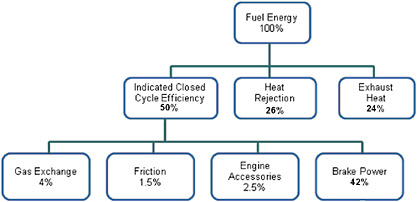

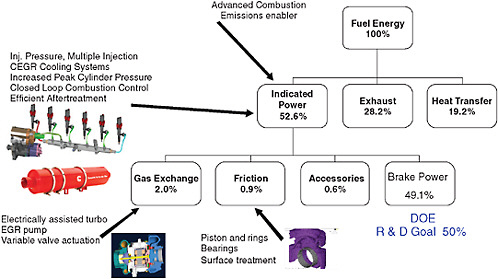

Diesel engines use the high gas temperatures generated by compression as the ignition source. The timing of ignition is determined mainly by when the fuel is injected. These engines operate on the four-stroke-cycle principle and are arranged either in-line or in a “vee” configuration. Displacements range from 3.0 to 16.0 liters. These engines typically burn diesel fuel, and also some kerosene and some biodiesel blends. Some engines that were originally designed as diesel engines are converted to use spark ignition to take advantage of alternative fuels. These engines typically burn gaseous fuels such as compressed natural gas (CNG), liquefied natural gas (LNG), or propane, but other spark ignition fuels can also be used. Essentially all of the diesel engines used today in medium- and heavy-duty vehicles are turbocharged, direct fuel injected, and electronically controlled; most are intercooled or after cooled. In addition, they use exhaust gas recirculation (EGR) to limit in-cylinder formation of nitrogen oxides (NOx) and some form of exhaust aftertreatment (diesel oxidation catalyst [DOC] diesel particulate filter [DPF], or other system) to control particulate matter (PM) emissions. Starting in 2010, most diesel engines will add selective catalytic reduction systems (SCR) as a form of NOx aftertreatment to meet 2010 requirements. A typical diesel engine energy audit is shown in Figure 4-1, where the fuel energy is converted to brake power and the efficiency associated with the output power will be referred to as brake thermal efficiency. The accessory losses are for engine-driven pumps that are necessary to run the engine on a dynamometer or on the road (fuel, lubricating oil, cooling water). Auxiliary loads such as alternator, air compressor, and power steering pump will use a portion of the brake power.

The following material summarizes various technologies for reducing fuel consumption from diesel engines. Some of the engine technologies listed here are the products of participants in the multiagency, multicompany 21st Century Truck Partnership. The partnership’s goals for engines are to achieve 50 percent thermal efficiency, while meeting 2010 emissions standards, by 2010 and to develop technologies to achieve 55 percent thermal efficiency by 2013 (NRC, 2008).

Turbochargers

In a turbocharger the radial exhaust-driven turbine drives the radial compressor to increase the air density going into the engine. The turbochargers can have a fixed geometry or more commonly a variable geometry turbine, or they can have a “wastegated” turbine (a bypass). Improved efficiency of the compressor or turbine will improve fuel consumption. Higher pressure ratio radial compressors or axial compressors are emerging technologies. Improvements in compressor efficiency and/or turbine efficiency can contribute to improved fuel consumption. A presentation1 to the committee on Japan’s Top Runner fuel efficiency regulation estimated 0.3 to 0.5 percent improvement from increased supercharging efficiency. The TIAX investigation, by contract to the committee, put the improvement at up to 2 percent (TIAX,

FIGURE 4-1 Energy audit for a typical diesel engine. SOURCE: Adapted from Vinod Duggal, Cummins, Inc., “Industrial Perspectives of the 21st Century Truck Partnership,” presentation to the committee, Dearborn, Mich., April 6, 2009, Slide 14 (and TIAX (2009), p. 4-3, Table 4-1).

2009, pp. 3-5 and 4-14). NESCCAF/ICCT (2009, p. 83) estimates the fuel savings of an improved-efficiency single-stage turbocharger at 1 percent. Another source projects that a high-pressure-ratio axial compressor will reduce fuel consumption by 1.1 to 3.6 percent.2

Almost all heavy-duty diesel engines sold in North America today use high-pressure loop EGR for control of engine-out NOx levels. To get EGR to flow from the exhaust manifold to the intake manifold, the pressure in the exhaust manifold must be higher than the pressure in the intake manifold. When the exhaust manifold pressure is higher than the intake manifold pressure, this is called having a negative ∆p, where ∆p refers to the difference in pressure between the intake and exhaust manifolds. High-efficiency turbochargers naturally produce a positive ∆p over much of their operating range, so turbocharger efficiency must be intentionally compromised in order to facilitate EGR flow. If it is possible to produce adequate EGR flow without reducing turbo efficiency, the overall engine efficiency will increase.

Dual-Stage Turbocharging with Intercooling

Modern engines use high-pressure ratios, which limit the efficiency of turbochargers. Using two turbochargers in series with intercooling would allow higher turbocharger efficiency, but this adds cost and packaging complexity and requires an EGR pump or other device such as a turbocompound system to facilitate EGR flow. Air-to-water intercooling is used after the first-stage compressor, in some applications, and air-to-air aftercooling is used after the second-stage compressor.

Conventional two-stage turbocharging employs two turbochargers working in series at all times. True sequential turbocharging switches turbochargers in and out of use as required, but they are normally connected in parallel. A modulated two-stage system brings some of the benefits of each of these two approaches. At low engine speeds it works as a two-stage system, delivering high-boost pressure despite the low engine speed. At high engine speeds it bypasses the small high-pressure turbocharger, allowing the bigger, low pressure turbocharger to work on its own and produce the higher flows at high engine speeds. Modulated two-stage systems offer the benefits of both high-boost pressure and wide-flow range, mainly due to the fact that two different-sized compressors are used. Using two compressors replicates the effect of a variable compressor without the need for a complex housing. The modulated two-stage system can have a high-pressure turbocharger far smaller than that of a conventional two-stage system, improving transient performance by reducing the turbo lag that affects both drivability and emissions.3

Dual-stage turbocharging is used in production by Navistar, Daimler Trucks, and Caterpillar in the United States and by MAN and Mercedes in Europe. Ford has announced that the 2011 diesel engine used in its Class 2b to 7 trucks will use a twin-compressor turbocharger (back-to-back compressors on the same shaft). Another source estimates a 2 to 5 percent reduction in fuel consumption.4 These benefits are only available if a way to provide the required EGR flow is available.

Mechanical Turbocompound

The base turbocharged engine remains unchanged and a power turbine is added to the exhaust stream to extract additional energy from the exhaust. The power turbine is connected to the crankshaft to supply additional power (NESCCAF/ICCT, 2009, p. 81). Typically, the attachment includes a fluid coupling (to allow for speed variation and to protect the power turbine from engine torsional vibration) and a gear set to match power turbine speed to crankshaft speed. Published information on the fuel consumption reduction from mechanical turbocompounding varies, as evidenced by the following: 3 percent, according to the Detroit Diesel Corporation,5 which has a turbocompound engine in production; 2.5 to 3 percent (NESCCAF/ICCT, 2009, p. 54); 3 percent (K.G. Duleep, Energy and Environmental Analysis)6 and 4 to 5 percent (Kruiswyk, 2008, pp. 212-214); TIAX (2009, pp. 4-17) used 2.5 to 3 percent. Some of these differences may depend on the operating condition or duty cycle that was considered by the different researchers. The performance of a turbocompound system tends to be highest at full load and much less or even zero at light load.

Electric Turbocompound

This approach is similar in concept to mechanical turbocompound, except that the power turbine drives an electrical generator (NESCCAF/ICCT, 2009, p. 29). The electricity produced can be used to power an electrical motor supplementing the engine output, to power electrified accessories, or to charge a hybrid system battery. Electric turbocompound is a technology that fits particularly well with a hybrid electric power train for long-haul applications where regenerative braking opportunities are limited. The benefits of electric turbocompound and an electric hybrid power train can be additive. Energy and Environmenal Analyis7 has said that “electric turbo-compound is more efficient and possible as part of hybrid packages.” Fuel consumption reduction benefits as large as 10 percent are claimed. The NESCCAF/ICCT study (p. 54) modeled an electric turbocompound system and estimated benefits at 4.2 percent, including electrification of accessories. Caterpillar, Inc., as part of Department of Energy (DOE) funded work, modeled a system that showed 3 to 5 percent improvement, while John Deere investigated a system (off-highway) that offered 10 percent improvement (Vuk, 2006; TIAX, 2009, p. A-10). None of these systems have been demonstrated commercially. TIAX (2009, pp. 3-5) used a range of 4 to 5 percent for its estimates, which included the benefits of electric accessories. Achieving the full benefit of electric turbocompound requires the electrification of vehicle accessories, the addition of an electric motor to apply turbocompound energy to supplement engine output, and an electric storage system (battery) to store any energy from the power turbine that is not immediately required. Making all of these changes to the vehicle will pose significant development and cost challenges.

Variable Valve Actuation

Variable valve actuation (VVA), also called variable valve timing or discrete variable valve lift, allows the valve actuation to be adjusted independently from the crankshaft angle. There are many implementations of VVA. Some are hydromechanical, such as the system used on some BMW passenger car engines. Other designs use electromagnets or high-pressure hydraulic systems. Some versions offer “full authority,” or unlimited, control of valve timing and lift, while other implementations offer limited control, such as variable duration only, variable lift only, or even more limited control, such as with the system used on some Caterpillar engines to permit a Miller cycle to be used under some operating conditions. VVA technology can also be used for cylinder deactivation. One of the primary drivers for introducing VVA in diesel engines is to facilitate the use of nonconventional combustion modes. According to several sources, variable valve timing can improve fuel consumption by about 1 percent when standard diesel combustion is used (NESCCAF/ICCT, 2009, p. 55).

Low-Temperature Exhaust Gas Recirculation (Also Called Advanced EGR Cooling)

Most medium- and heavy-duty vehicle diesel engines sold in the U.S. market today use cooled EGR, in which part of the exhaust gas is routed through a cooler (rejecting energy to the engine coolant) before being returned to the engine intake manifold. EGR is a technology employed to reduce peak combustion temperatures and thus NOx. Low-temperature EGR uses a larger or secondary EGR cooler to achieve lower intake charge temperatures, which tend to further reduce NOx formation. If the NOx requirement is unchanged, low-temperature EGR can allow changes such as more advanced injection timing that will increase engine efficiency slightly more than 1 percent (NESCCAF/ICCT, 2009, p. 62). Because low-temperature EGR reduces the engine’s exhaust temperature, it may not be compatible with exhaust energy recovery systems such as turbocompound or a bottoming cycle.

Electrification of Engine-Driven Accessories

Accessories that are traditionally gear or belt driven by a vehicle’s engine can be converted to electric power. Ex-

amples include the engine water pump, the air compressor, the power-steering pump, cooling fans, and the vehicle’s air-conditioning system. In many cases this can result in a reduction in power demand, because electrically powered accessories (such as the air compressor or power steering) operate only when needed if they are electrically powered, but they impose a parasitic demand all the time if they are engine driven. In other cases, such as cooling fans or an engine’s water pump, electric power allows the accessory to run at speeds independent of engine speed, which can reduce power consumption. Electrification of accessories can individually improve fuel consumption, but as a package on a hybrid vehicle it is estimated that 3 to 5 percent fuel consumption reduction is possible.8 The TIAX (2009, pp. 3-5) study used 2 to 4 percent fuel consumption improvement for accessory electrification, with the understanding that electrification of accessories will have more effect in short-haul/urban applications and less benefit in line-haul applications.

Engine Friction Reduction

Reduced friction in bearings, valve trains, and the piston-to-liner interface will improve efficiency. Any friction reduction must be carefully developed to avoid issues with durability or performance capability. An example would be to develop heavy-duty diesel engines to run on 10W-30 oil instead of the current standard of 15W-40. The lower viscosity oil would reduce friction, at the expense of bearing capability. Fuel consumption improvement from one source9 was 2 percent, whereas another source10 claims 1 to 1.5 percent. The use of a thermatic oil cooler (thermostatically controlled oil cooler) in conjunction with lower viscosity lubricating oils could yield 1.5 percent improvement.11 The effect of friction reduction and oil temperature control will be greatest during cold starts and under light load operation, where friction accounts for a larger portion of total energy consumption.

Alternative Combustion Cycles

Alternatives to the standard diesel combustion cycle are available, such as low-temperature combustion (LTC), homogeneous charge compression ignition (HCCI), and premix charge compression ignition (PCCI). These combustion modes can be more efficient than standard diesel combustion under some conditions, particularly when very low NOx is a requirement. There are significant control requirements to make these alternative combustion modes work, and these modes cannot generally be used over the whole operating range of the engine, nor have they demonstrated inherent fuel consumption advantages (NRC, 2008, Finding 3-8, p. 42). The primary purpose of alternative combustion cycles is to lower engine-out emissions. This can lead to either lower overall emissions or lower cost for exhaust aftertreatment.

Effects of DPF and SCR on Engine Efficiency

The use of emissions control devices has an influence on engine efficiency. This is true whether the emissions are controlled on an in-cylinder basis or via the aftertreatment. In most cases, the effect of adding an emissions control device increases fuel consumption, either directly by reducing the efficiency of energy extraction from the combustion process or indirectly by requiring the use of additional fuel to maintain the performance of an aftertreatment system.

Improved SCR Conversion Efficiency

NOx is formed in a reaction that occurs naturally whenever nitrogen and oxygen are heated above a certain temperature. The higher the temperature, the more rapid the NOx-forming reaction occurs. In-cylinder technologies to control NOx formation in diesel engines are aimed at reducing the maximum temperature reached by the gases in the combustion chamber. The approaches used include retarded injection timing, multiple injection events and injection rate shaping, EGR, charge air cooling, and alternative combustion modes (such as HCCI, PCCI, LTC). Some of these approaches leads to a decrease in work output of the engine due to exhaust emissions control (NRC, 2008), except charge air cooling.

The DPF is used to eliminate PM on an aftertreatment basis. A DPF requires energy for regenerating the filter on a periodic basis. This energy most commonly comes from injecting diesel fuel into the exhaust stream. By definition, fuel injected into the exhaust stream will not contribute to crankshaft power and thus represents a decrease in efficiency. A DOC or other device oxidizes the fuel in the exhaust stream, providing the heat required for DPF regeneration and increasing the fuel consumption of the vehicle. Another method to provide the heat required for DPF regeneration is to revise the air/fuel ratio of the engine to produce exhaust constituents and heat that are used to regenerate the DPF. This approach also increases the fuel consumption of the vehicle.

The SCR aftertreatment system for reducing NOx also requires a fluid, which is urea mixed with water (called Adblue in Europe and DEF [Diesel Exhaust Fluid] in the United States), to supply the reducing agent. The urea is made from natural gas. The energy use of this fluid and/or its cost must be accounted for in the calculation of energy consumption. The use of SCR can allow a higher engine-out NOx level, which in turn can be used to reduce fuel consumption, but

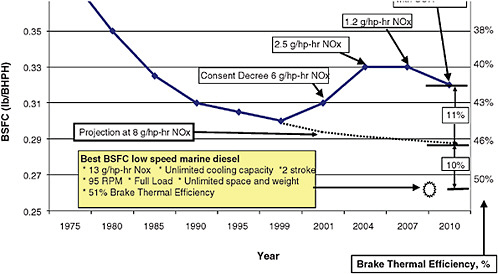

FIGURE 4-2 Historical trend of heavy-duty truck engine fuel consumption as a function of NOx requirement. SOURCE: Tony Greszler, Volvo, October 2009.

this improvement must be weighed against the urea consumption of the SCR aftertreatment system. The upcoming 2010 heavy-duty emissions standards reduce the allowable NOx level by a factor of 6 from 1.2 g/hp-hr to 0.2 g/hp-hr, which limits the ability of some manufacturers to use SCR to increase engine-out emissions.

There is a close relationship between emissions control requirements and fuel consumption. In particular, certain technologies that are used to control NOx emissions have the effect of increasing fuel consumption. See Figure 4-2 for an example of this trend. Figure 4-2 also compares truck engines with the most efficient large marine engines, which so far do not face any emissions constraints. The efficiency of large marine engines is due to several factors that cannot be reproduced in vehicle applications. Marine engines are very large and heavy, they run at very low speeds, they have a source of unlimited cooling capacity (seawater), and they face (for the time being) no emissions constraints. All four of these factors contribute to the high efficiency of marine engines. According to information provided by Volvo,12 the fuel consumption of truck diesel engines is about 10 percent higher than for marine engines due to the size, weight, and cooling factors that are limits faced in vehicle applications. The 2010 model truck engines will suffer an 11 percent fuel consumption penalty for NOx control (compared with an 8 g/hp-hr NOx engine, see Figure 4.2), which is less than the penalty of 2002 and 2007 engines. This penalty does not include the energy content of DEF (urea) for the SCR system.

Most 2010 engines will use SCR aftertreatment to reduce NOx emissions. Daimler’s Detroit Diesel estimates that, with the installation of SCR in 2010, fuel consumption will be reduced 3 to 4 percent by a combination of higher engine-out NOx, controls and fuel system improvements, reduced DPF regeneration frequency, and other efficiency gains, while Volvo estimates the potential improvement of its 2010 engines at 2 percent. As the SCR system conversion efficiency improves, it allows higher engine-out NOx emissions. Engine manufacturers can take advantage of this by making changes in fuel injection timing or by using less EGR, in order to reduce fuel consumption.

Thermal Insulation of Ports and Manifolds

Thermal insulation would reduce heat rejection to the engine coolant (from exhaust ports) or to the ambient air (from manifolds). The energy retained in the exhaust can

be used by downstream devices such as a turbocompound system or bottoming cycle. Caterpillar Inc. made components, such as air gap pistons and exhaust port liners as part of the 21st Century Truck Partnership, but reported results are not available (NRC, 2008, p. 30). The anticipated benefit is small.

Improved Work Extraction from Combustion Process

The compression ratio, expansion ratio, combustion chamber shape, injection spray pattern, injection pressure, injection timing, injection rate shaping, air/fuel mixing, peak cylinder pressure limit, air/fuel ratio, and EGR rate are all parameters that can be modified in an effort to reduce fuel consumption. Improved combustion chamber design allows for improved air management and mixing. Improved materials and structural design enable higher cylinder pressures. These enhancements allow more precise control of the timing and rate of heat release (combustion) as well as higher combustion temperatures, both of which can improve thermal efficiency. Unfortunately, higher combustion temperatures also lead to higher NOx. Combustion chamber design enhancements may require more advanced materials and a more complex machining process. More complex and expensive fuel systems allow greater control of injection pressure, timing, and rate shaping. In addition, because higher cylinder pressures must not result in higher NOx, measures must be taken to allow the improved fuel consumption without creating an increase in emissions. These measures may include improved NOx conversion efficiency by the aftertreatment, advanced fuel injection techniques (which enable more detailed control of combustion), and improved engine controls. The efficiency benefit of these improvements is estimated at 1 to 3 percent.13

Finely controlled, high-pressure fuel injection is a key enabler for more fuel efficient combustion and a cleaner, more consistent fuel burn. Current state-of-the-art systems planned for deployment in 2010 engines include very high pressure (2,000 to 2,400 bar) common rail injection systems with advanced nozzle designs that are capable of finely shaped and controlled spray, along with multiple injection events per cycle.

Potential future improvements will continue to improve control, allow more accurate timing and metering of injection with combustion events, and further increase fuel injection pressure. Improved material properties and controls could enable pressures of up to 3,000 bar in the 2015 time frame and perhaps 4,000 bar by 2020. Future systems will also utilize increasingly sophisticated injection techniques such as variable-spray nozzles, piezo-electric nozzles, or supercritical fuel injection (fuel changing instantaneously from liquid state to supercritical gaseous state at injection based on site visits). These advances may be possible in the 2013 to 2015 time frame (TIAX, 2009). Fuel injection systems were estimated on site visits to offer between 1 and 4 percent improvement in fuel consumption; Vyas et al. (2002) estimates fuel injection systems have the potential to improve fuel consumption by 6 percent, although this estimate is now several years old, and considerable improvement in fuel systems has already been made since 2002. Real-time combustion control with start of combustion sensors can also yield a fuel consumption reduction of 1 percent to 4 percent.14

Engine Electronic Controller Calibration Management

Advanced engine controls will be enabled in part by the onboard diagnostic systems that are mandated for medium and heavy trucks beginning in 2010 on one family and across the board in 2013. Increasingly sophisticated engine controls, particularly a transition to closed-loop control approaches, will enable engine efficiency improvements. Closed-loop controls will feed information about the engine’s operating regime and emissions back to the system controls. This improved feedback will allow manufacturers to optimize emissions and fuel consumption within the constraints of emissions requirements across a variety of operating conditions.

Better use of calibration tools to improve control of EGR, injection rate shapes, multiple injection events, and increased injection pressure can yield 1 to 4 percent fuel consumption reduction. These benefits are redundant with those described above for improved work extraction from the combustion process. Another feature already in use on some long-haul trucks is adding 200 lb-ft of torque in the top two transmission gears, which manufacturers claim can give 2 percent reduction in fuel consumption by reducing the need for downshifting on modest grades. With the next generation electronic controller, using model-based controls, it is predicted that another 1 to 4 percent fuel consumption reduction will be achieved.15 Note that the reductions listed in here may be repeats of reductions from previous sections, and there may be some redundancy in the percentages quoted, but the concepts and percentages presented here came from committee site visits where engineers talked about these reductions. The overall approach of more sophisticated control of the combustion process tends to include several building blocks, such as upgraded fuel system capabilities, sophisticated control algorithms, additional sensor inputs for feedback control, and technologies such as model-based controls. The benefits of this approach are often claimed by each of the individual building blocks, leading to redundant claims on the same fuel consumption benefit.

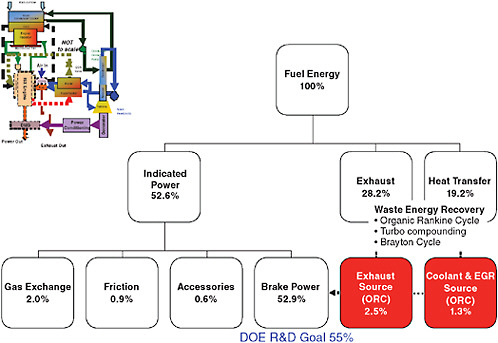

Bottoming Cycle

A bottoming cycle is basically a secondary engine that uses exhaust energy or other heat sources from the primary engine to develop additional power without using additional fuel. The energy sources used by the bottoming cycle are sources that normally go to waste in a conventional engine. A typical bottoming cycle includes the following components: a feed pump to drive the working fluid from the condenser to the evaporator (or boiler); the evaporator, which transfers waste heat energy from the primary engine to the working fluid; an expander, which takes energy from the working fluid to make mechanical power; and a condenser that rejects unused heat energy from the bottoming cycle working fluid before starting a new cycle. The power generated by the expander can be used to make electricity, which in turn can power an electric motor supplementing the engine output, power electrified accessories, or charge a hybrid system battery. Sources of energy to power a bottoming cycle can include the EGR stream, exhaust stream, charge air stream, and engine coolant circuit (NESCCAF/ICCT, 2009, pp. 85-88). Cummins, Inc. has shown a projected increase of thermal efficiency from 49.1 to 52.9 percent (7.2 percent decrease in fuel consumption) using an organic Rankine cycle. Cummins also lists turbocompounding and a Brayton cycle as alternative methods of extracting work from unused energy in the exhaust stream. Cummins reports recovering 2.5 thermal efficiency points from the exhaust and 1.3 thermal efficiency points from the coolant and EGR stream.16 The NESCCAF/ICCT report (2009, pp. 55-56) showed the effect of a steam bottoming cycle to reduce fuel consumption by up to 10 percent.

Other Technologies

Other technologies for reducing the fuel consumption of diesel engines are discussed in the press almost every day (e.g., Automotive News, Transport Topics, Diesel Fuel News, DieselNet.com). Some are emerging technologies and may not become production feasible, including new diesel engines of two-stroke-cycle design, split-cycle design, free-piston design, rotary design and camless engines with digital valve control such as the Sturman Industries concept. The list of potential technologies also includes oxygen injection into the intake air, hydrogen injection into the intake air, air injection from the air compressor to overcome turbo lag, or the use of fuel-borne catalysts such as platinum and cerium.

Diesel Engine Summary

In summary, to add up all these individual potential reductions to arrive at an overall potential fuel consumption reduction would not be correct because there would be double counting of some effects. The best recent attempts at packaging fuel-saving technologies for engines were in the DOE programs with a goal of demonstrating 50 percent thermal efficiency while meeting 2010 emissions. The National Research Council (2008) review of that program showed a baseline thermal efficiency of 42 percent with a goal of 50 percent, or a 19 percent improvement in thermal efficiency and a 16 percent fuel consumption reduction. Three engine manufacturers—Caterpillar, Cummins, and Detroit Diesel—were funded at a level exceeding $116 million over five years with the following result, according to the report: “These results show that none of the industry partners achieved the goal of measuring 50 percent thermal efficiency at 2010 emissions from a complete engine system.”

Cummins has supplied the committee with the following research roadmaps for achieving 49.1 percent thermal efficiency and 52.9 percent thermal efficiency. Figure 4-3 is a research roadmap for 49.1 percent thermal efficiency by 2016, which is an improvement of 17 percent from the 42 percent baseline (14.5 percent reduction in fuel consumption). Figure 4-4 is a research roadmap for 52.9 percent thermal efficiency by 2019, which is an improvement of 26 percent from the baseline 42 percent (20.6 percent reduction in fuel consumption). These roadmaps can be compared to the baseline shown in Figure 4-1. Note that these are plans and goals, not actual development results. Actual results that will be achieved in development may vary from the planned benefits.

In its report for the committee, TIAX (2009, Tables 5-8 and Table 5-9) summarized the diesel engine fuel consumption potential reductions by range of years and by application as shown in Table 4.1.

GASOLINE ENGINE TECHNOLOGIES

Gasoline engines operate with a premixed charge of fuel and air and use spark ignition to start the combustion process. They are used in many Class 2b applications as well as Class 3 to 6 applications. Within the medium-duty truck sector, all gasoline engines operate on the four-stroke-cycle principle and are of an in-line or “vee” configuration. Displacements of these engines typically range from 6 to 8 liters. These engines normally burn gasoline, but with slight changes they can burn natural gas (compressed [CNG] or liquefied [LNG]), propane, hydrogen, ethanol, methanol, and so forth.

The fundamental operating principle for gasoline engines used today relies on creating a well-mixed charge of gasoline and air at the time the spark plug fires. After the combustion process is over, a catalyst in the exhaust system is used to perform the final emissions cleanup. Emissions of NOx, carbon monoxide, and unburned hydrocarbons are the principal species being treated by the catalyst in the exhaust. The three-way catalyst treats all three of these emissions simultaneously; however, the three-way catalyst will function

FIGURE 4-3 Research roadmap for 49.1 percent thermal efficiency by 2016. SOURCE: Provided under license by Cummins Inc. Copyright 2009 Cummins Inc. All rights reserved.

properly only if the air/fuel ratio is carefully controlled to be chemically correct, or stoichiometric.17

Heavy-duty gasoline engines, and most heavy-duty engines using spark-ignited alternative fuels such as natural gas, use a relatively simple emissions control strategy. The engine operates at a stoichiometric air/fuel ratio across most of the operating range, with relatively high engine-out emissions levels. A three-way catalyst is used both to oxidize hydrocarbon and carbon monoxide emissions and to reduce NOx. The three-way catalyst can function properly only if the air/fuel ratio is carefully controlled in order to meet current and future emissions requirements. Additional considerations for gasoline engine emissions control include achieving rapid catalyst light-off on startup and controlling evaporative emissions, but the basic emissions control technology for spark-ignited engines is the relatively simple and inexpensive three-way catalyst.

There is a fuel consumption penalty that comes with the three-way catalyst used on gasoline engines. Because the air/fuel ratio must be maintained at stoichiometric all the way down to idle, the pumping losses from throttling are large. Lean operation could provide significant fuel savings but would not allow the NOx reduction function of the three-way catalyst to work. Many technologies that could be applied to gasoline engines to reduce fuel consumption are not used, primarily because of the need to maintain low NOx emissions. For example, lean gasoline direct injection (GDI) has the potential to provide double-digit percentage reductions in fuel consumption, but it is not used, because it would result in higher NOx emissions. The NOx emissions of a lean GDI engine could be much lower than those of an unregulated engine, but engine makers have not been able to make lean GDI reach the very stringent U.S. NOx standards applied to new cars and trucks today. GDI has been used in Europe, where NOx is less stringently regulated.

One consequence of requiring a stoichiometric mixture of air and fuel is that the intake airflow needs to be throttled for lighter load operation. Lighter loads necessitate a lower fuel flow rate into the engine, and since the air/fuel mixture is to be maintained in stoichiometric proportions, the airflow rate needs to be reduced in proportion to the fuel flow rate. The process of throttling the intake airflow results in significant pumping losses that are not present in diesel engines that operate using traditional diesel combustion. This pumping loss is one of the main reasons spark ignition engines are less efficient than diesel engines. The magnitude of the pumping loss depends on the operating duty cycle of the engine. If the engine spends most of its time in light load operation, its throttling losses will be higher than for an engine that spends most of its operation under heavier load. Also, the pumping work will depend on the engine size relative to the vehicle. A smaller engine size in a given vehicle application will spend a higher portion of its operation at a higher load, relative to a

FIGURE 4-4 Research roadmap for 52.9 percent thermal efficiency by 2019. SOURCE: Provided under license by Cummins Inc. Copyright 2009 Cummins Inc. All rights reserved.

TABLE 4-1 Diesel Engine Fuel Consumption (percentage) by Years and Applications

|

Application |

2013-2015 |

2015-2020 |

|

Tractor trailer |

10.5 |

20 |

|

Class 6 box truck |

9 |

14 |

|

Class 6 bucket truck |

7.2 |

11.2 |

|

Refuse truck |

10.5 |

14 |

|

Urban bus |

9 |

14 |

|

Motor coach |

10.5 |

20 |

|

Class 2b pickup and van |

14 |

23 |

|

SOURCE: TIAX (2009). |

||

larger engine in the same vehicle, and consequently will have a lower pumping loss than the corresponding larger engine. As an approximate guide, pumping losses might range from 2 to 5 percent of the fuel energy (Patton et al., 2002).

Compared to diesel engines, spark ignition engines are generally simpler and less expensive, they have more effective and lower cost exhaust emissions aftertreatment systems, and they have higher fuel consumption.

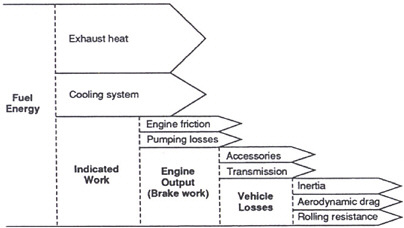

The current emphasis in the development of spark ignition engines is on reducing fuel consumption. Figure 4-5 gives a qualitative partitioning of the fuel energy for a typical gasoline-fueled vehicle. This is analogous to Figure 4-1, which gives an energy partitioning for diesel-powered vehicles. Figure 4-5 is illustrative in describing the technologies being considered to reduce gasoline engine fuel consumption.

The proportion of the fuel energy that gets converted into indicated work is a direct measure of the engine’s fuel conversion efficiency. Factors that affect an engine’s fuel conversion efficiency include irreversibilities18 in the combustion process, the amount of energy leaving the engine cylinder as heat transfer, and the energy remaining in the exhaust at the end of the expansion process. These losses represent fuel energy that did not get converted into useful shaft work. Not all of the energy that was converted into work in the combustion process makes it to the final shaft output.

FIGURE 4-5 Partitioning of the fuel energy in a gasoline-fueled engine (proportions vary with vehicle design, type of engine, and operating conditions). SOURCE: NRC (1992).

Some gets used to overcome friction, some is used to pump air and fuel into the engine, and the exhaust gases out of the engine, and some is used to power accessories. The work that makes it to the drive wheels is used to overcome vehicle inertia, aerodynamic drag, and rolling resistance. The relative ranking of these energy uses is highly dependent on the vehicle and the application to which it is being applied.

As indicated in the discussion of the pumping work above, the magnitude of these energy partitions is highly dependent on the engine size, its application in the vehicle, and the duty cycle under which the vehicle is operating. The best way to quantify the partitioning shown in Figure 4-5 would be to take the specific data for the application of interest or through the application of a verified system simulation program.

Opportunities to reduce the fuel consumption of gasoline engines include improving engine efficiency (trying to reduce the proportion of the fuel energy leaving as heat transfer, exhaust energy, and pumping work), reducing the energy lost to friction, and reducing the power required for running accessories. Brief descriptions of different technologies for reducing fuel consumption are given below.

Variable Valve Actuation and Cylinder Deactivation

There are many approaches to VVA. These include cam phasers, variable lift mechanisms, fully flexible valve trains, and cylinder deactivation. The primary loss that the VVA systems are trying to reduce is the pumping, or throttling, loss. A variable compression ratio allows the engine to operate at different compression ratios for different loads in order to maximize the engine efficiency over the widest load range possible. The combination of VVA and variable compression ratio keeps the engine operation closer to its maximum efficiency point, with minimal pumping work, over larger portions of the duty cycle.

Cylinder deactivation is an approach that minimizes pumping losses by varying the total working displacement of the engine. The “smaller” engine operates closer to wide-open throttle at lower loads, which reduces the pumping work.

Cam phasers allow the valve timing to be changed with engine operating conditions. For example, the timing can be shifted with engine speed to optimize the engine breathing with engine speed. VVT can also be used in place of the intake throttle. Either opening the intake valve late or closing it late can regulate the amount of air/fuel mixture captured in the cylinder. This can be done with lower throttling losses than would occur with the conventional intake throttle.

Different engine designs will lend themselves more easily to different valve control technologies. For example, overhead valve systems with the cam in the block versus a single overhead cam versus a double overhead cam design will have to invoke different VVA approaches, which may favor different valve manipulation strategies for the different engine configurations. So decisions as to which valve technology to invoke would be based on the engine configuration, the application’s duty cycle, and the incremental cost of implementation. Estimates for the fuel consumption reduction achievable through variable valve lift and/timing range from 1 to 3.5 percent (TIAX, 2009, p. 4-33).

Gasoline Direct Injection Engines

GDI engines refer to an embodiment in which the fuel injector is mounted so that the fuel is directly injected into the cylinder, as opposed to the more common port fuel injection,

where the fuel injector is mounted in the intake port. There are two philosophies of engine operation that fall under the classification of GDI engines.

In one case the engine is still operated with a stoichiometric mixture of air and fuel. This approach enables a three-way catalyst to be used in the exhaust, so emissions standards can be met. However, by mandating operation with a stoichiometric mixture, the engine still needs to be throttled. For a direct-injected stoichiometric engine the efficiency improvements come from less fuel being used during transient engine responses and from internal cooling of the cylinder charge from the fuel vaporization. This leads to a higher knock margin, which allows a higher compression ratio to be used. These engines are also more tolerant of EGR, so higher compression ratios can be used without an NOx penalty. There will be an attendant efficiency improvement with the higher compression ratio. The reduction in fuel consumption achieved via stiochiometric direct injection will be dependent on the extent to which this technology is combined with other technology packages. Based on estimates from a light-duty study (NHTSA, 2009), referenced by TIAX, a fuel consumption reduction with stoichiometric direct injection engines relative to a port-injected engine with VVT described above would range from 2 to 3 percent (TIAX, 2009, p. 4-33).

The other approach to GDI is to attempt to replicate the breathing characteristics of the diesel engine by minimizing the throttling of the intake air and controlling the load by varying the air/fuel ratio. Reduction in fuel consumption with this approach to direct injection comes from reduced pumping losses and higher efficiency from the lean-burning mixture, as well as the potential to increase the compression ratio as with the stoichiometric direct injection. The drawback to this approach is that the three-way catalyst is no longer effective, so the engine has the same aftertreatment challenges and expense as the diesel engine. The application of the lean burn direct injection technology will almost certainly be coupled with using turbocharging (described below) as well, so one must consider the combination of technology packages. Referencing the same NHTSA report referred to above, TIAX reported a potential reduction in fuel consumption by applying turbocharged lean burn GDI technology relative to the VVA nonturbocharged stoichiometric engine of 10 to 14 percent (TIAX, 2009, p. 4-33).

Different Combustion Modes

VVA mechanisms and fuel injection systems open up the possibility of incorporating advanced combustion regimes into the engine operating map. For example LTC, a general classification for auto-igniting combustion modes such as HCCI, partially PCCI, and compression-aided ignition, offers potential for lean low-emissions combustion in which throttling losses are minimized and catalytic converters are not needed (Zhao et al., 2003). Incorporating these alternative modes of combustion into the engine’s operating map will require much higher levels of sensing and control than are currently in use in today’s engines. For example, it is likely that real-time cylinder pressure sensing would be necessary to activate and control transitions between conventional combustion and LTC-type combustion during engine operation. If these combustion regimes can be incorporated into the operating map of gasoline engines, fuel consumption could be reduced via lean combustion at light loads, with minimal pumping losses, without the need for lean exhaust aftertreatment. Then during higher load operation, where throttling requirements are low, the engine could revert back to stoichiometric operation where the three-way catalyst is effective. It has been estimated that incorporation of LTC operation into the engine could reduce fuel consumption by 10 to 12 percent (TIAX, 2009). See Table 4-2.

Turbocharging and Downsizing

Turbocharging a gasoline engine is similar to turbocharging a diesel engine in that it is motivated by the desire to redirect energy that was leaving the engine in the exhaust gases back into the engine. The turbocharger converts exhaust energy into higher pressure and temperature intake gases using a turbine in the exhaust gas stream and a compressor in the intake air stream. Because of the differences in the fuels and the combustion processes between the two types of engines, there are different constraints that limit the application of turbocharging in a spark ignition engine relative to a compression ignition engine. Because the air and fuel are premixed in a spark ignition engine, as the pressure and temperature of the mixture at the start of compression is increased via turbocharging, the possibility of knocking combustion increases. Consequently it is common for the compression ratio to be decreased when the spark ignition engine is turbocharged. This tends to decrease the thermal efficiency of the engine. It is also likely that more exhaust gas will be recirculated when the engine is turbocharged. However, if successfully implemented, the turbocharged engine will have a higher power density than the nonturbocharged engine so it can be smaller and lighter for the same power output. This reduction of weight and potential reduction in frontal area of the vehicle has an attendant fuel consumption reduction benefit.

Turbocharging can be combined with other technologies, like in-cylinder direct injection and/or VVA to compound the benefits of the various technologies. The direct injection of fuel results in in-cylinder evaporative cooling, which helps counter the increased tendency toward knocking attributable to the turbocharging. Consequently the compression ratio may not need to be lowered to avoid knocking combustion to the same extent it would with turbocharging without direct injection. This coupled with the increased EGR tolerance of the direct injection and turbocharged engines helps keep NOx emissions from rising. In addition, because the power

density of the engine has been increased, it may be possible to run at lower speeds and still generate the power required to drive the vehicle. The lower engine speeds result in lower friction losses, which is beneficial to fuel consumption. So it is possible to combine many of the technologies to compound their benefits. The technology review by TIAX found that a turbocharged downsized engine offers a fuel consumption reduction potential of approximately 2 percent, while a turbocharged downsized direct injection engine with VVA offers a potential 10 to 14 percent reduction in fuel consumption (TIAX, 2009).

Once such technologies as turbocharging, direct injection, and variable valve actuation, and so forth, have been incorporated into the power train, the engine becomes quite flexible. For example, with such flexibility it is possible to use multiple fuels which that are carried separately onboard the vehicle. Approaches such as using gasoline and E85 (Stein et al., 2009) or varying mixtures of gasoline and diesel (Hanson et al., 2010) have been demonstrated. In these demonstrations, fuel consumption levels comparable, or superior to, that of conventional diesel engines have been achieved. The fundamental concept is one of optimizing the fuel characteristics and engine operating conditions for best performance—for example, the lowest fuel consumption and emissions, at each operating point. Such an engine would have characteristics of both gasoline and diesel engines. The duel-fuel concept would require infrastructure changes to address dispensing two separate fuels to a vehicle.

Accessory Loads

As with diesel-powered vehicles, decoupling the direct drive of the accessories from the engine offers the potential to optimally match the accessory use to the duty cycle. Examples of this technology that offer potential to reduce fuel consumption by reducing the amount of engine shaft work that was originally going to the driveline but was tapped to run the accessories instead include electrically driven engine oil and cooling pumps, mechanically clutched or electrically driven radiator cooling fans, electrically driven air-conditioner compressors, and high-efficiency alternators. One benefit of accessory load reduction is that the work saved through accessory optimization goes directly to the vehicle. The fuel-savings potential is highly dependent on the duty cycle of the engine.

Integrated Technologies

It is important to realize that the technologies described above may not be discrete. For example, using VVA for intake throttling reduction along with cylinder deactivation for engine displacement reduction are technologies motivated by the desire to reduce pumping work. Using them together will not result in fuel consumption reductions that are additive. Also, some technologies are facilitators for addressing multiple losses. For example, electric hybrids enable one to downsize the engine, operate the engine over a narrower and optimal portion of it operational map, and reduce accessory load on the engine through accessory electrification.

As discussed above, the fuel savings that comes from reducing any of the losses described above will be highly dependent on the vehicle itself and its duty cycle. To evaluate the potential for the various technologies to reduce the vehicle’s fuel consumption, it is best to evaluate the technologies as integrated packages applied to a specific vehicle operating on a representative duty cycle. For example, consider the package cited above of a downsized turbocharged direct injection engine with VVA. Engine and vehicle simulation packages exist that are capable of giving good comparative rankings of the fuel consumption reduction potential of different combinations of technologies.

One such example of a technology assessment program is HEDGE (High Efficiency Dilute Gasoline Engines) at SwRI.19 In this program a combination of technologies is being evaluated, including a downsized, turbocharged, direct injection, high-EGR, VVA engine, which is fueled with either gasoline or gasoline and diesel (dual fuel), with an emphasis on lower speed operation. Results presented to the committee were encouraging. Laboratory tests showed combinations of technologies that demonstrated gasoline engine thermal efficiencies greater than 40 percent, with fuel consumption reductions on the order of 20 percent, with 35 and 45 percent reductions in particulate matter and NOx emissions, respectively. It is evident from this work that, as stated above, it is the synergistic combination of various technologies, matched to engine duty cycle, that are critical for achieving reduced fuel consumption with low emissions. Note that introducing such a technology package may require a significant redesign of the engine. An ignition system tolerant of a high-EGR rate is required, and cylinder pressures are higher than in typical gasoline engines.

Shifting to Diesel Engines

Shifting from gasoline to diesel engines offers significant fuel efficiency benefits. This is primarily due to higher compression ratios and reduced gas exchange losses. However, it should be noted that, due to emissions regulations (which have degraded the efficiency of diesels), and advances in spark ignition technology (e.g., HCCI, turbocharging, direct injection), the gap between gasoline and diesels has narrowed considerably. The committee compares diesel and gasoline engines in more detail in the next section.

TABLE 4-2 Technologies for Fuel Consumption Reduction Applicable to Gasoline-Powered Engines for the Medium-Duty Vehicle Class and Estimated Fuel Consumption Reduction and Incremental Costs

|

Technology |

Incremental to… |

Incremental Cost and Benefit |

|

|

Percent Fuel Consumption Benefit |

Cost ($) |

||

|

Friction reduction |

— |

0.5-2.5 |

110-500a |

|

Variable valve timing (VVT) |

Friction |

1-3 |

122 |

|

Variable valve lift (VVL)b |

VVT |

1-3.5 |

400-750 |

|

Cylinder deactivationc |

VVL |

2.5-3 |

75 |

|

Stoichiometric GDId |

Cylinder deactivation |

2-3 |

512-930 |

|

Turbocharging and downsizing |

S-GDI |

2.1-2.2 |

1,229 |

|

Diesele |

— |

19-24 |

7,900-9,400 |

|

Lean-burn GDI |

S-GDI |

10-14 |

750f |

|

Gasoline HCCI |

10-12 |

S-GDI |

685 |

|

Accessory electrification |

Applicable to any package |

2-4 |

1,000-2,000 (current) 500 (high volume) |

|

NOTES AND ASSUMPTIONS: Baselines are explained in the text in the section “Summary of Technologies for Gasoline Engines.” The duty cycle is the typical duty cycle of a medium-duty vehicle with a gasoline engine. The diesel fuel consumption benefit includes the 10 percent higher heating value of diesel fuel. “Friction reduction” includes mechanical accessory improvements. Values assume (roughly) constant performance. The time frame covered is 2015 to 2020. a$13 to $49 per cylinder + $5 for lubricants. b$51 per cylinder for discrete VVL; $70-$75 per cylinder for continuous VVL. cOffers marginal benefit on DOHC engines; these benefits reflect SOHC. d$64 to $93 per cylinder. eDiesel fuel consumption incremental to baseline gasoline engine. fIncremental cost over direct injection stoichiometric engine. SOURCE: TIAX (2009), p. 4-33. |

|||

Summary of Technologies for Gasoline Engines

As part of the committee’s activities, TIAX was contracted to assemble and categorize different engine technologies, their potential fuel consumption benefit, and their incremental costs. Table 4-2 is a tabulation of the technologies discussed above, their potential fuel consumption benefits, and their incremental costs; the baseline engine on which the estimates of fuel consumption are based is a port fuel-injected, naturally aspirated, fixed-valve-timing engine with 8 to 10 cylinders.

DIESEL ENGINES VERSUS GASOLINE ENGINES

Diesel engines offer significant fuel savings over gasoline engines, when measured on a fuel consumption (gallon per mile) or load-specific fuel consumption (gallons per ton-mile) basis. Depending on the engines and operating conditions, diesel engines can provide 19 to 24 percent lower fuel consumption than gasoline engines. Two factors account for this advantage:

-

Diesel fuel has approximately 12 percent higher energy content than gasoline, which allows diesel engines to extract more energy per gallon from the fuel.

-

Diesel engines have a higher thermal efficiency than gasoline engines, which allows diesel engines to provide more shaft power for a given amount of fuel energy released.

Several factors contribute to the higher thermal efficiency of diesel engines. One is the lack of a throttle on traditional diesel engines. Pulling air across a closed throttle imposes significant pumping losses, so diesel engines enjoy a significant advantage in pumping loss, especially at light load. Another factor that contributes to the higher thermal efficiency of diesel engines is high compression ratio. This is made possible by the compression ignition cycle of the diesel. The higher expansion ratio that comes with a higher compression ratio allows the diesel to extract more of the combustion energy before the exhaust valve opens near the end of the power stroke. Because of the high cylinder pressures encountered as a result of high compression ratio, turbocharging, lean air/fuel ratios, and the use of EGR, the diesel engine has the disadvantage of being heavier (pounds/cubic inch) and more costly to manufacture. The fuel system of diesel engines also contributes significantly to the cost penalty of diesel engines.

The most common fuels for medium- and heavy-duty engines are gasoline and No. 2 ultralow-sulfur diesel fuel. Both spark-ignited engines and compression ignition engines can burn “other” fuel types as discussed earlier, but most com-

mon are renewable fuels (as required by the Renewable Fuels Standard of the Energy Policy Act of 2007), such as ethanol for spark-ignited engines and biodiesel for compression ignition engines. Both of these renewable fuels have lower heating values (Btu/gallon) than their counterpart gasoline and diesel fuel, resulting in higher fuel consumption when measured on a volume basis (liters or gallons). Natural gas is also used in gasoline and converted diesel engines but is low in heating value and used in gaseous form, requiring the expression of fuel consumption data on an equivalent energy basis.

Another factor that may arise if diesel engines are substituted for gasoline engines, or renewable fuels play a bigger role in the mix of fuels used for medium- and heavy-duty vehicles, is the impact on petroleum refineries. Each barrel of petroleum produces various proportions of fuels, such as diesel, gasoline, kerosene, fuel oil, and others, to supply the demand for these fuels. If the fuel market were to shift significantly in the demand for diesel fuel versus gasoline, e.g., refineries would need to modify their processes to change the mix of fuels produced from each barrel of petroleum refined.

Both gasoline and diesel engines incorporate exhaust emissions control systems for hydrocarbons HCs, CO, and NOx. Gasoline engines also control evaporative emissions and diesel engines control PM. These emissions are controlled by both the engine combustion process (engine out) and the use of catalytic converters, DOCs, DPFs, lean NOx catalysts, and SCR.

The emissions control approach used with heavy duty diesel engines has been quite different from spark-ignited engines. All strategies used for on-highway trucks through 2009 relied on in-cylinder controls, including EGR, to limit NOx, rather than on aftertreatment. The 2007 U.S. Environmental Protection Agency (EPA) heavy-duty on-highway standards forced the use of DPFs to control PM. DPFs are the first widely used aftertreatment system on diesel engines, although some diesel engines have also used oxidation catalysts to control HC emissions. For 2010 most diesel truck manufacturers plan to add SCR aftertreatment to meet the new 2010 NOx requirements.

Volvo is the first company to publicly price heavy-duty diesel vehicles with 2010 emissions control systems. The company plans to charge $9,600 for the SCR system on 2010 model heavy-duty trucks (Fleet Owner Web magazine, March 3, 2009). Volvo’s surcharge on 2007 emissions levels is $7,500, which covers the cost of a DPF system for PM control and a cooled EGR system for in-cylinder NOx control. The total emissions control surcharge of $17,100 for 2010 is not far below the cost of a complete heavy-duty diesel engine. Navistar, maker of international trucks, announced a $6,000 emissions surcharge for 2010 medium-duty trucks, and an $8,000 surcharge for heavy-duty trucks (Reuters, July 28, 2009). Navistar is the only major truck maker that does not plan to use SCR to comply with the 2010 NOx requirement. The 2010 emissions surcharges are on top of surcharges of $5,000 to $6,000 for medium-duty trucks and $7,000 to $10,000 for heavy-duty trucks that Navistar charged for 2007 emissions (Navistar press release, November 8, 2005). Daimler Trucks North America, makers of Freightliner and Western Star trucks, announced increases of $6,700 to $7,300 for medium-duty trucks and $9,000 for 2010 heavy-duty trucks, compared to 2007 (Transport Topics, August 8, 2009).

The cost of meeting new emissions standards with gasoline engines is typically measured in hundreds, rather than thousands, of dollars. Diesel engines start with a significant cost disadvantage compared to gasoline engines, because of their greater strength (to withstand the high-cylinder pressures of compression ignition) and their far more sophisticated fuel systems. Diesel fuel systems have injection pressures of 1,600 to 3,000 bar, while even the expensive (by gasoline engine standards) GDI fuel systems require only 100 to 200 bar. Port injection systems for gasoline engines typically use injection pressures of only a few bar. The need to create and control extreme pressures has a major effect on diesel fuel system cost.

When the higher cost of diesel engines is added to the far higher cost of diesel emissions control aftertreatment, there is a powerful market incentive to move toward gasoline engines, except where the durability of the diesel engine is required. Over the period from 2004 to 2008, diesel engines lost market penetration to gasoline engines in Class 3, 5, and 7 trucks while increasing market penetration in Class 2 and 4 trucks (see Table 4-3).

This trend can be expected to accelerate in 2010 and beyond, when medium-duty diesel engines with aftertreatment may cost $10,000 more than a gasoline engine option. For any operation with relatively low average vehicle miles per year, gasoline engines will make more economic sense. Since gasoline engines are significantly less fuel efficient than diesel engines, this means that fuel consumption of the medium-duty truck fleet will increase as a result of falling diesel engine market share.

TABLE 4-3 Diesel Truck Sales as a Percentage of Total Truck Sales

|

Class |

2004 |

2005 |

2006 |

2007 |

2008 |

|

1 |

0.10 |

0.1 |

0.0 |

0.0 |

0.0 |

|

2 |

9.2 |

9.5 |

10.1 |

10.4 |

12.9 |

|

3 |

68.6 |

68.6 |

68.6 |

42.5 |

44.1 |

|

4 |

70.6 |

73.8 |

75.7 |

78.5 |

80.9 |

|

5 |

91.7 |

92.2 |

91.6 |

91.8 |

92.3 |

|

6 |

75.8 |

73.4 |

75.3 |

52.4 |

58.0 |

|

7 |

53.6 |

55.8 |

58.5 |

50.4 |

50.3 |

|

8 |

100.0 |

100.0 |

100.0 |

100.0 |

99.7 |

|

Total |

9.1 |

10.3 |

11.6 |

9.3 |

10.8 |

|

SOURCE: DOE, EERE (2009), based on Ward’s Motor Vehicle Facts and Figures. |

|||||

TRANSMISSION AND DRIVELINE TECHNOLOGIES

“Transmission and driveline” together refer to the system that connects the propulsion system to the wheels. It includes the transmission, the final drive, and the axle. Options for realizing fuel consumption benefits by optimizing the transmission and driveline generally fall into one of two categories:

-

Improved driveline efficiency. Strategies that increase the efficiency of the power transfer from the propulsion system to the wheels.

-

Improved system integration. Strategies that enable the engine to operate at higher average drive cycle efficiency.

Improved integration of the driveline with the power train in a tractor trailer can raise the average efficiency of the engine over an actual real-world drive cycle. The easiest form of this approach entails appropriately matching system gearing to the specific application. This process entails selecting a top gear and rear axle ratio that matches typical cruise speed (ensuring that the engine is in its peak efficiency window). These specifications vary from fleet to fleet; to the extent that a vehicle purchaser knows the specific roads on which a truck will travel, systems can be highly optimized to match their application. Conversely, some purchasers simply use standard specifications, or specify vehicles based on what they purchased in the past. As such, all major original equipment manufacturers (OEMs) make a concerted effort to work with purchasing agents to properly manage the vehicle specification process.

Transmissions

Class 3 through 8 vehicles use three basic types of transmission. The most common transmission type is the manual transmission (MT). Class 3 to 7 trucks typically use 5- to 8-speed transmissions, many of which are synchronized. Class 8 vehicles typically use 9-18 speed transmissions, most of which are not synchronized. Synchronizers are universally used in passenger car transmissions to make shifting easier. The synchronizer is a small clutch that matches the transmission input shaft speed to the speed required on shaft of the gear being engaged. Synchronizers are not used in the main box of heavy-duty transmissions both to reduce cost and to eliminate an expensive wear item. They are used in heavy-duty transmissions to synchronize the main box with the auxiliary box. The auxiliary box is used to multiply the number of speeds of the main box of the transmission. For example, a 5-speed main box can be combined with a 2-speed auxiliary box to form a 10-speed transmission. Another example is the 18-speed transmission, which consists of a 5-speed main box with two 2-speed auxiliary boxes. This makes for a total of 20 available ratios, but two of these are redundant.

With MTs, having more ratios can generally lead to a better match between engine speed and road speed, which reduces fuel consumption. However, there are drawbacks to transmissions with more ratios. They require more work on the part of the driver, and they cost more. They are often larger and heavier than transmissions with fewer ratios, and they may be less efficient because more gears are in mesh at any given time. One additional drawback of a high gear count is the frequent power interruptions caused by the need to shift through a large number of gears.

MTs have the highest market share in long-haul truck applications. According to information supplied by Daimler Trucks North America (DTNA) (Freightliner),20 the share of MTs in line-haul trucks declined from 90 percent in 2004 to a still dominant 82 percent in 2008. At the other extreme, MTs are rarely used in urban applications such as transit buses and refuse haulers. For long-haul Class 8 trucks, the most common transmission types are 10-speed, 13-speed, and 18-speed. The 13- and 18-speed transmissions have smaller-ratio steps, which allows the driver to better match the engine rpm to road conditions. However, these transmissions also have more gears in mesh at any given time than 10-speed transmissions do, so there is an efficiency penalty for having the additional ratios available. There is also a penalty involved in the more frequent power interruptions for shifting that occur with a higher gear count transmission. The 13- and 18-speed transmissions are most often used by heavy haulers (operators that run over 80,000 pounds gross vehicle weight) and by on/off highway operators. These operators need the flexibility provided by a larger number of gear ratios. Most standard long-haul operators use 10-speed MTs to achieve the best balance between vehicle performance and fuel consumption. In this situation the market has gravitated toward the most fuel-efficient MT available.

The automated manual transmission (AMT) has been gradually gaining market share over the past 10 years. According to DTNA figures, AMTs represented 10 percent of the line-haul transmissions in 2004, increasing to 18 percent in 2008. The AMT is typically based on the platform of a standard MT. Additional actuators and controls are added to allow the transmission control module to take over the shifting activities of the driver. Actuators perform both the shifting and clutch actuation for the driver. The AMT controller can match the shift performance (shift time and smoothness) of a skilled driver, provided the controls are well designed and carefully tuned. The AMT offers several advantages over a conventional manual transmission:

-

The requirement for driver skill is lower.

-

There is less driver distraction, improving vehicle safety and productivity.

-

The control module decides when to shift, which can be used to reduce fuel consumption compared to an average driver.

-

Shifts are always performed smoothly, which can improve transmission durability.

The downsides of the AMT are higher cost and more complexity—more parts that can fail. TIAX (2009, p. 4-70) estimates the cost of AMTs at $4,000 to $5,700 over a comparable MT. There is also a slight weight increase. Donnie Stover, fleet manager for Averitt, reported on December 16, 2008 a 3-percent improvement in average fuel consumption when using AMTs in place of standard MTs in sleeper cab team tractors. These are trucks that use two drivers working together to allow nearly 24-hour operation. This fuel consumption reduction comes from allowing the transmission controller to determine shift points rather than the driver. The best drivers can beat the fuel consumption of an AMT, but average drivers cannot match the results of the AMT.

Other features being added to new AMTs include microprocessor technology to continuously monitor changes in road grade, vehicle speed, acceleration, torque demands, weight, and air resistance.21 This technology allows the vehicle to select the best gear and fuel setting while minimizing fuel consumption. It also allows the engine and transmission to know when to go into freewheeling when neither power nor engine braking is needed. In these situations, the engine goes back to idle and the transmission slips into neutral when power is not needed. TIAX estimated a 4 to 8 percent reduction in fuel consumption based on site visits with the committee. The fuel savings potential for AMT will vary based on duty cycle and driver training. Long-haul cycles on level ground require little shifting and thus offer little potential for improvement, while duty cycles involving hills, congestion, and urban driving have much more potential for fuel savings, both with AMT and driver training.

The third transmission type seen in Class 3 to 8 vehicles is the traditional torque converter automatic transmission (AT). These transmissions typically have five to seven gear ratios, with a torque converter and a lockup clutch. Many ATs use the torque converter only at low road speed and run in lockup mode in all the higher gears, a feature reduces fuel consumption. Fully automatic transmissions are most popular in urban applications such as transit buses and refuse haulers, but they are also widely used in other applications, including some very heavy on/off highway vehicle applications. Standard 80,000 lb long-haul trucks are one application where ATs are very rare. The DTNA data show that the share of MTs in Class 8 non line-haul applications is lower than for line-haul applications, at 67 percent in 2008. AMT transmissions have about 9 percent share in these non-line haul trucks, while torque converter automatics enjoy a 24 percent share, up from just over 10 percent in 2004. The share of ATs is probably higher in the Class 2b to 7 range.

ATs share the driver skill, productivity, and safety advantages of AMTs. They also offer the ability to complete upshifts under full engine power, something that cannot be done with manual or automated manual transmissions. This can be a significant productivity (trip time) factor in applications with frequent large changes in vehicle speed, such as urban or suburban driving. With an MT or AMT, the engine fueling is shut off during each upshift. This interrupts power generation during the shift, which typically takes about 1 second in lower gears and up to 2 seconds in higher gears. However, after the shift is completed, the engine still requires some time (typically 2 to 3 seconds) to return to full power once the shift is completed.22 In the future, if the development of heavy-duty dual-clutch transmissions progresses as it has for light-duty vehicles, a dual-clutch transmission will remove the problem of interrupting the power during shifting. There can be a fuel consumption advantage as well as a productivity advantage in performing full-power upshifts, because the engine can continue to operate at an efficient point during and after shifts.

ATs are slightly heavier than MTs, but the use of an AT allows the clutch and flywheel to be replaced by a flexplate and torque convertor. Overall truck weight with an AT is slightly lower than with an MT. TIAX reports the cost of heavy-duty ATs at $15,000 over an MT.

The AT has some fuel consumption penalties compared to a conventional transmission as well. The hydraulic pump required to fill the torque converter and actuate the shift events draws power from the engine. When the transmission operates in converter mode, a significant percentage of the input power from the engine is lost as heat in the torque converter. The AT will operate with an open converter (lockup clutch disengaged) at low engine and vehicle speeds, whereas the MT and AMT use a more efficient closed clutch. The shift schedule of medium- and heavy-duty ATs has evolved over the years to minimize the time spent in converter mode.

The primary disadvantages of the AT compared to other transmission types are much higher cost and more complexity. The warranty period for ATs is much shorter than for MTs, and warranty repairs must be made by the transmission dealership. These factors discourage the use of ATs except in applications where the advantages of using an AT in the vehicle operating cycle are very great. AT applications are typically in urban and suburban operations. There are a number of features under development to improve the efficiency of ATs, including lower friction and lower parasitic hardware, more elaborate shift strategies, a reduced load on the engine during stops, and automatic shift into neutral when the parking brake is applied.23 TIAX (2009, 4-70) estimated a 0 to 5

percent reduction in fuel consumption from the use of ATs, in tractor-trailer applications, in its report to the committee.

Research has been done on other transmission types, such as continuously variable transmissions (CVTs) and dual-clutch transmissions. Several CVT designs have been proposed for heavy-duty vehicles, and Allison Transmission has signed an agreement with Torotrak to develop its CVT design for heavy-duty vehicle applications. It is not yet clear if any of these alternative transmission types will reach volume production. CVTs tend to have lower mechanical efficiency than MTs or AMTs, but they make up for this by allowing an optimum match between engine speed and road speed under all operating conditions. The main challenges facing the use of CVTs for truck and bus applications are mechanical efficiency, reliability, durability, and cost.

A comparison of transmission fuel consumption performance can be made by considering four driving-cycle components: idle, acceleration, steady-speed cruise, and deceleration. At idle the AT has a disadvantage due to torque converter loss and hydraulic pump parasitic power. The addition of an “auto neutral” function greatly reduces this disadvantage. Under acceleration the AT has an advantage over the other types due to power shifting. Shifts are completed without changing the fueling command, so boost pressure is maintained and engine operation is more efficient. The AMT has an advantage over an average driver with an MT because of computer-controlled shift points. At cruise the MT and AMT have a slight advantage because they do not require a hydraulic pump. It should be noted that cruise fuel consumption is very strongly dependent on speed and the final drive gearing, and these selections are independent of the transmission type. Under deceleration the AT has a slight advantage over other types because there is no need to blip the engine fueling for downshifts. This blip is necessary with both manual and automated manual transmissions to get the engine speed to match the speed of the transmission gears.

Overall, the selection of transmission type has only a relatively small impact on vehicle fuel consumption. The exception is in urban and suburban operation, where the AT may offer a modest reduction in fuel consumption, combined with significantly greater productivity (average trip speed).24 The higher productivity is a result of avoiding power interruptions during acceleration. Fuel consumption differences due to transmission selection are normally a few percent or less. The shift calibration schedule for AMTs and ATs can have a modest impact on fuel consumption. A driver’s shift behavior with MTs can have a significant effect on fuel consumption; a driver with poor habits may suffer a 10 to 20 percent fuel consumption penalty in urban and suburban driving.25 The line-haul market is likely to move more in the direction of AMTs as costs fall and reliability is proven. This move will provide a modest fuel consumption benefit. A move to ATs for stop-and-go-type operations may also provide a modest benefit. Just as the engine market is very competitive in terms of fuel consumption, so is the transmission market. Long-haul operators will often change transmission type to gain a 1 or 2 percent reduction in fuel consumption, as long as the cost is reasonable and the reliability of the technology is solid.

Rear Axle Ratio

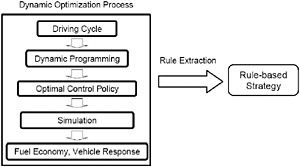

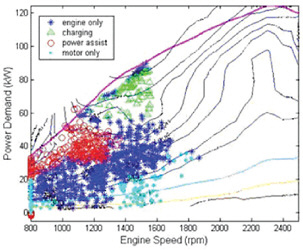

The selection of rear axle ratio is one of the most important decisions in specifying a truck. The axle ratio determines the engine rpm at the vehicle’s cruise speed, which is a very important fuel consumption parameter. The axle ratio also determines the grade capability and acceleration performance of the vehicle. A tall (numerically low) axle ratio is typically good for fuel consumption but bad for acceleration performance and grade capability. This means that the choice of axle ratio involves a trade-off between fuel consumption and vehicle performance. Operators select axle ratios based on the type of loads and routes they expect to operate with. Most engine and vehicle OEMs have sophisticated software that can look at specific trucking operations and recommend the best axle ratio for a given application.