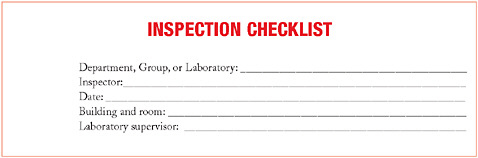

SAMPLE INSPECTION CHECKLIST

LABORATORY ENVIRONMENT

|

Work areas illuminated |

Y |

N |

NA |

|

Storage of combustible materials minimized |

Y |

N |

NA |

|

Aisles and passageways clear and unobstructed |

Y |

N |

NA |

|

Trash removed promptly |

Y |

N |

NA |

|

No evidence of food or drink in active laboratory areas |

Y |

N |

NA |

|

Wet surfaces covered with nonslip materials |

Y |

N |

NA |

|

Exits illuminated and unobstructed |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

|

Other elements that the checklist can include |

|

|

|

EMERGENCY EQUIPMENT AND PLANNING

|

Fire extinguishers mounted and unobstructed |

Y |

N |

NA |

|

Fire extinguishers fully charged with tamper indicators in place |

Y |

N |

NA |

|

Fire extinguisher inspection up to date |

Y |

N |

NA |

|

Eyewash unit and safety shower within 10 seconds of hazard |

Y |

N |

NA |

|

Eyewash unit and safety shower inspection up to date |

Y |

N |

NA |

|

Fire alarm pull stations unobstructed |

Y |

N |

NA |

|

Spill control materials available and adequate for potential spills |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

PERSONAL PROTECTIVE EQUIPMENT

|

Personnel wearing appropriate eye and face protection |

Y |

N |

NA |

|

Personnel wearing appropriate gloves |

Y |

N |

NA |

|

Shoes appropriate to the hazard |

Y |

N |

NA |

|

Clothing appropriate to the hazards posed in the laboratory |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

SIGNS, LABELS, PLANS, AND POSTINGS

|

Emergency action plan available |

Y |

N |

NA |

|

Material-safety data sheets accessible |

Y |

N |

NA |

|

Chemical-hygiene plan available |

Y |

N |

NA |

|

Contact sheet posted and up to date |

Y |

N |

NA |

|

Telephones labeled with emergency number |

Y |

N |

NA |

|

Building evacuation routes posted |

Y |

N |

NA |

|

Ice-making machines labeled “Not for human consumption” |

Y |

N |

NA |

|

Chemical refrigerators labeled “No food” |

Y |

N |

NA |

|

Food refrigerators labeled “Food only—no chemicals” |

Y |

N |

NA |

|

Lasers properly labeled |

Y |

N |

NA |

|

High-voltage equipment properly labeled |

Y |

N |

NA |

|

Emergency equipment labeled with highly visible signs |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

ELECTRICAL HAZARDS

|

Flexible cords in good condition |

Y |

N |

NA |

|

Cords not on surfaces where flammable liquids may pool |

Y |

N |

NA |

|

Cover plates in place for outlets and switches |

Y |

N |

NA |

|

Circuit-breaker panels unobstructed |

Y |

N |

NA |

|

Multiplug adapters have overload protection |

Y |

N |

NA |

|

No extension cords in use |

Y |

N |

NA |

|

Ground-fault circuit interrupters (GFCI) used for wet areas |

Y |

N |

NA |

|

Guards or covers in place for electrophoresisdevices |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

STORAGE

|

Heavy items on lower shelves |

Y |

N |

NA |

|

Storage at least 18 in. below sprinkler heads |

Y |

N |

NA |

|

Storage at least 24 in. below ceiling |

Y |

N |

NA |

|

Means available to reach items stored above shoulder level |

Y |

N |

NA |

|

Shelving adequate for loads imposed |

Y |

N |

NA |

|

Chemicals stored by compatibility and hazard class |

Y |

N |

NA |

|

Chemical containers clearly labeled with contents |

Y |

N |

NA |

|

Corrosive chemical stored below eye level |

Y |

N |

NA |

|

Materials with shelf-lives dated on receipt |

Y |

N |

NA |

|

Secondary containment used near sinks and drains |

Y |

N |

NA |

|

Waste containers sealed except during transfers |

Y |

N |

NA |

|

Waste containers labeled with contents, “Hazardous Waste” |

Y |

N |

NA |

|

Storage limited to less than 1 quart of acutely hazardous waste |

Y |

N |

NA |

|

Storage limited to less than 55 gallons hazardous waste |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

COMPRESSED GASES AND CRYOGENICS

|

Toxic, flammable, corrosive gases used inchemical-fume hood |

Y |

N |

NA |

|

Stored upright, secured from tipping |

Y |

N |

NA |

|

Regulator compatible with gas cylinder |

Y |

N |

NA |

|

Cylinder carts used for transport |

Y |

N |

NA |

|

Valve caps in place when not in use |

Y |

N |

NA |

|

Empty or unused cylinders returned to supplier |

Y |

N |

NA |

|

Gases and cryogenicliquids dispensed with good ventilation |

Y |

N |

NA |

|

Cryogenic dewars vented or have pressure-relief devices |

Y |

N |

NA |

|

Glass dewars shielded |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

PRESSURE AND VACUUM SYSTEMS

|

Vacuum glassware in good condition |

Y |

N |

NA |

|

Vacuum pressure-relief devices in place and inspected |

Y |

N |

NA |

|

Glass vessels shielded or enclosed |

Y |

N |

NA |

|

Temperature and pressure measuring devices in place where needed |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

CHEMICAL HOODS AND VENTILATION

|

Each chemical fume hood tested within last year |

Y |

N |

NA |

|

Sash closed when not in active use |

Y |

N |

NA |

|

Chemical-fume hood vents (baffles) unobstructed |

Y |

N |

NA |

|

Chemical-fume hood used with sash in appropriate position |

Y |

N |

NA |

|

Chemical storage limited in actively used hood |

Y |

N |

NA |

|

Chemicals and equipment at least 6 in. from the sash |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

SECURITY

|

Doors to lab operate, close and lock properly |

Y |

N |

NA |

|

Windows operate, close, and lock properly |

Y |

N |

NA |

|

Alarm systems operating properly |

Y |

N |

NA |

|

Keys and access cards kept in secure area out of sight |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

TRAINING AND AWARENESS

|

Workers have attended all appropriate training |

Y |

N |

NA |

|

Training has been documented |

Y |

N |

NA |

|

Laboratory personnel know… |

|

|

|

|

What to do in event of an emergency, such as fire or injury |

Y |

N |

NA |

|

How to clean up chemical spills |

Y |

N |

NA |

|

Location and contents of the chemical hygiene plan |

Y |

N |

NA |

|

Chemical hygiene officer or safety manager |

Y |

N |

NA |

|

What MSDSs are and where to find them and other safety info |

Y |

N |

NA |

|

What type of personal protective equipment to use and when to use it |

Y |

N |

NA |

|

What to do with chemical waste |

Y |

N |

NA |

|

What are the most hazardous materials they use and what precautions to take |

Y |

N |

NA |

|

Where and how to use safety showers and eyewash units |

Y |

N |

NA |

|

To question unfamiliar visitors in the lab |

Y |

N |

NA |

|

How and when to report injuries, illnesses, or incidents |

Y |

N |

NA |

|

COMMENTS: |

|

|

|

EXAMPLE CLASSROOM LESSON FOR LABORATORY MANAGERS

Instructors’ Guide

In this Instructors’ Guide, there are 10 lessons [one example is provided here] to be used in training laboratory staff, students, and volunteers. Each lesson contains the following elements:

-

An introduction that summarizes the content of the lesson and provides ideas for teaching the content to training participants;

-

Objectives, or concepts that all participants should master after studying each lesson;

-

One or more segments that describe a problematic situation in a laboratory;

-

Questions for participants to answer and discuss as a group; and

-

Commentary on each question for Instructors to use in guiding participants in their discussions.

The text and questions of each lesson should be handed out to participants if possible. The introduction and commentary for each lesson are for use by the instructor only and should not be distributed to participants. The introduction and commentary are available to help the instructor guide the discussion, ask the appropriate questions, and make the experience useful for all participants.

Lessons provide an effective method of teaching. Discussing lessons is a way to involve participants in familiar and relevant issues. The purpose of the lessons is to ask participants to consider the choices they face as they attempt to promote a culture of safety and security in the laboratory.

Five of the lessons are directed toward laboratory managers or others who supervise laboratories. The remaining four lessons are directed toward people who work in the laboratories, including students and employees. Discussion begins with participants thinking about what might be going on in the minds of the fictional individuals featured in the cases. Every lesson includes reflective questions that aim to encourage participants to consider the following concerns: Could this happen in our laboratory? Does this happen here? What strategies could we develop to deal with this issue in our workplace?

Below are tips on how to successfully use lessons. The below guidance is taken from Kenneth D. Pimple’s article “Using Case Studies in Teaching Research Ethics.”1 Pimple says that you must:

|

1 |

Adapted from Pimple, Kenneth D., “Using Case Studies in Teaching Research Ethics” (2007). Resources. Paper 293. http://www.ethicslibrary.org/resources/293. |

-

prepare in advance to lead the lesson discussion. Decide what goals to accomplish, how to discuss the situations presented, and how much time to spend on each lesson.

-

set ground rules at the beginning of the session. Remind participants to be open, honest, and respectful.

-

offer participants broad strategies and tactics before discussing lessons. Some of these tactics include:

![]() thinking about immediate, near-future, and long-term steps to take;

thinking about immediate, near-future, and long-term steps to take;

![]() thinking about what might be going on in the minds of the fictional people featured in the lesson;

thinking about what might be going on in the minds of the fictional people featured in the lesson;

![]() considering strategies to deal with the problem in the laboratory; and

considering strategies to deal with the problem in the laboratory; and

![]() taking a personal role in the problem—What would I do in this situation?

taking a personal role in the problem—What would I do in this situation?

For each lesson discussion, follow these suggested procedures:

-

Before starting each lesson discussion, distribute copies of the lesson to participants to make it easier for them to participate.

-

Ask one of the participants to read the lesson aloud. This allows participants to be engaged at an early stage.

-

Give participants about five minutes to think about the lesson individually, write down any thoughts they may have, and answer the questions before discussing them aloud.

-

After participants have been given time to work independently, have them share short responses to the lesson. Then allow participants to discuss answers to the questions.

-

As instructor, listen to the discussion without actively participating, unless the discussion becomes disorderly or off-point.

The goal of instructors is to build trust and encourage honest reflection. Encourage participants to work independently or as a group to devise concrete strategies for dealing with the issues presented in the lessons. Strategies should include immediate steps and future steps.

At the end of each lesson, participants should recognize some of the barriers that prevent laboratory personnel from behaving in a safe or secure manner and should be able to list steps for overcoming those barriers. Only by addressing barriers can laboratory personnel promote a culture of safety and security. In addition, participants should leave the training session feeling empowered to think creatively in response to safety issues. Finally, it is important for all participants to leave the session understanding that everyone is responsible for the safety and security of the laboratory, not just certain individuals.

Lesson 1:

Ensuring the Use of Safety Measures in the Laboratory

For Instructor

Overview: This lesson describes the challenges a new laboratory manager faces in ensuring that staff uses appropriate personal protective equipment.

Objectives:

-

Recognize the importance of personal protective equipment (PPE)

-

Identify barriers to the safe and consistent use of PPE in laboratories

-

Generate action steps that laboratory managers can use to encourage the use of PPE among laboratory workers and visitors

-

Identify methods for convincing supervisors and other institutional leaders of the importance of PPE and its regular use

-

Recognize that there are many ways to encourage the adoption of safe practices in a laboratory

Reasons for not wearing the goggles in this lesson could include

-

cost and/or unavailability of goggles;

-

a lack of habit;

-

a lack of initial understanding of the importance of wearing protective equipment or of the hazards posed by the work;

-

a sense of invincibility;

-

a lack of confidence or respect in the new laboratory manager;

-

a cultural acceptance of risk and destiny;

-

feeling of resistance since the new laboratory manager is an outsider;

-

workers wanting to rebel against the changes to traditional practices;

-

possible anticipation of physical discomfort from wearing the goggles;

-

laboratory manager’s supervisor’s attitude; and

-

feeling of unattractiveness or detracting from their physical appearance.

There may also be many reasons why the women in the lab are even less likely to use the goggles than the men. Perhaps the female workers believe their tasks are less risky than the ones performed by the men. It is also possible that the women may feel that their health is less important than that of the men in their laboratories and if so, perhaps they are choosing not to diminish the supply of available goggles for their male colleagues.

Segment 1

A recent graduate of a well-respected institution is hired as a laboratory manager for a small chemical company. Soon after starting work, the manager notices that many laboratory personnel do not have safety goggles. To fix the problem, the manager orders pairs for everyone and invites the staff to pick them up from central inventory. A few weeks later, the manager notices that many pairs of goggles are still in storage. On a walk through the labs to see what is going on, the manager notices that many of the goggles are prominently displayed on laboratory shelves but still in boxes. The manager also notices that many of the female employees have not even picked up their goggles from central inventory.

-

Why would the laboratory personnel be reluctant to wear the safety goggles?

Instructor: Encourage participants to share why there is a disregard for safety and consider what could be influencing the workers’ actions. Please refer to the previous page for examples of why personnel may not be wearing goggles.

-

What should the lab manager do?

Instructor: Lead a discussion to find the best course of action. Participants’ suggestions could include:

-

hold a training session for all laboratory personnel that focuses on the importance of PPE and its regular use;

-

post signs in the laboratory to remind personnel of the importance of PPE, especially goggles, and its correct use;

-

regularly remind personnel to use goggles, and check on their proper use;

-

distribute uncollected goggles to personnel; and

-

praise and thank people for properly wearing PPE.

-

Segment 2

As an attempt to rectify the situation, the laboratory manager hands out the remaining goggles to those who had neglected to pick them up and reminds the staff of the importance of using safety goggles while working in the lab. The manager is reassured by the fact that everyone agreed with him. Nevertheless, when walking through the labs a few days later, the manager notes again that many personnel still are not wearing their goggles.

-

What should the lab manager do now? List the strategies the manager could use in the table below. Note the advantages and disadvantages of each option.

-

Instructor: Encourage participants to think about immediate, near-term, and long-term strategies. An example is provided in the first row of the table.

|

Barriers |

Strategies to address barrier |

Advantages |

Disadvantages |

|

goggles are uncomfortable to wear |

remind personnel of the need for goggles to prevent eye injuries |

demonstrates a consistent culture of safety in the lab |

does not address the specific problem of discomfort |

-

What kind of help would the manager need? From whom?

Instructor: Help participants recognize that it is much harder to make change alone. Some solutions could include seeking help from peers, supervisors, or professional societies.

-

Would the situation be different if the laboratory manager were an older, established researcher?

Instructor: Encourage participants to share what they would do if the laboratory manager were an established, older researcher. Ask questions to help participants understand the difficulties faced by younger managers, such as: Do workers listen to older, more experienced managers more than someone who is younger and recently graduated?

-

If the laboratory manager were a woman, would the situation be different? How?

Instructor: Have participants discuss the impacts of having a female laboratory manager in their own laboratory. Encourage participants to recognize any special challenges that a female manager might have that a male manager might not face. Lead participants to brainstorm ways that a female manager might overcome these challenges.

Segment 3

After many weeks of work, the manager succeeds in getting the staff to wear their goggles consistently. One day, as part of a review of the institution, the manager’s supervisor takes a tour of the laboratories. When offered goggles before entering the laboratory, the supervisor waves them off saying, “Oh, I will only be in there for a few minutes. I’m sure I’ll be fine.”

-

What impact could the supervisor’s behavior have on the laboratory staff?

Instructor: Help participants recognize that the supervisor acts as a role model. Not wearing goggles may undo the work put in by the laboratory manager.

-

What should the laboratory manager do now?

Instructor: Ask participants to discuss the position the laboratory manager is in. Lead the discussion with questions such as: What is going through the manager’s head? Should the manager publicly challenge the supervisor, or is it best for the manager to talk to the supervisor in private?

Have participants write down all of the options available to the laboratory manager and discuss them to find the best answer. Suggestions could include discussing the situation in private with the supervisor, trying to gently encourage the supervisor to wear the goggles, pointing out that the entire laboratory staff wears goggles regularly, or remind the supervisor that it is really important to set an example for others who look up to him or her. Remind participants that the manager’s goal is to have the supervisor support the manager and the culture of safety throughout their institution.

-

How is this case relevant to your laboratory?

Instructor: Ask participants to draw from their own experiences. Ask questions such as: Have you ever been in a situation similar to this? What did you do?

-

Are safety goggles required in your laboratory at all times? Why or why not?

Instructor: This is a reflective question for participants. Encourage participants to think about reasons why they don’t wear goggles. Ask: Are there times when it is not necessary to wear goggles? Then discuss how to address this issue.

-

Does the staff in your laboratory comply with other similarly important safety measures? Why or why not?

Instructor: This question should be used for self-reflection. Ask participants to write down answers for themselves only, as a way to reflect on their performance as managers.

-

What strategies should laboratories put in place to better promote a culture of safety?

Instructor: Write down participants’ suggestions on a board or large piece of paper. Ideas could include training, signage, better leadership compliance, or investment in PPE and other safety equipment.

-

To better promote a culture of safety, what support will laboratory managers need? From whom?

Instructor: Ask participants to think about what resources they will need to successfully implement the strategies suggested in number 6 above. Encourage participants to seek help from supervisors, peers, other institutions, and professional societies.

-

What is the best way to secure that support for a culture of safety?

Instructor: The answer to this question will be dependent on each individual institution. Some countries may not have ample resources to implement all safety strategies.

For Participants

Segment 1

A recent graduate of a well-respected institution is hired as a laboratory manager for a small chemical company. Soon after starting work, the manager notices that many laboratory personnel do not have safety goggles. To fix the problem, the manager orders pairs for everyone and invites the staff to pick them up from central inventory. A few weeks later, the manager notices that many pairs of goggles are still in storage. On a walk through the labs to see what is going on, the manager notices that many of the goggles are prominently displayed on laboratory shelves but still in boxes. The manager also notices that many of the female employees have not even picked up their goggles from central inventory.

-

Why would the laboratory personnel be reluctant to wear the safety goggles?

-

What should the lab manager do?

Segment 2

As an attempt to rectify the situation, the laboratory manager hands out the remaining goggles to those who had neglected to pick them up and reminds the staff of the importance of using safety goggles while working in the lab. The manager is reassured by the fact that everyone agreed with him. Nevertheless, when walking through the labs a few days later, the manager notes again that many personnel still are not wearing their goggles.

-

What should the lab manager do now? In the table below, list the strategies the manager could use. Note the advantages and disadvantages of each option.

|

Barriers |

Strategies to address barrier |

Advantages |

Disadvantages |

-

What kind of help would the manager need? From whom?

-

Would the situation be different if the laboratory manager were an older, established researcher?

-

If the laboratory manager were a woman, would the situation be different? How?

Segment 3

After many weeks of work, the manager succeeds in getting the staff to wear their goggles consistently. One day, as part of a review of the institution, the manager’s supervisor takes a tour of the laboratories. When offered goggles before entering the laboratory, the supervisor waves them off saying, “Oh, I will only be in there for a few minutes. I’m sure I’ll be fine.”

-

What impact could the supervisor’s behavior have on the laboratory staff?

-

What should the laboratory manager do now?

-

How is this case relevant to your laboratory?

-

Are safety goggles required in your laboratory at all times? Why or why not?

-

Does the staff at your laboratory comply with other similar important safety measures? Why or why not?