THE NATIONAL ACADEMIES

Advisers to the Nation on Science, Engineering, and Medicine

Division on Engineering and Physical Sciences

Board on Army Science and Technology Mailing Address:

500 Fifth Street, NW Washington, DC 20001 www.nationalacademies.org

April 22, 2010

J. Michael Gilmore

Director,

Operational Test and Evaluation Department of Defense

1700 Defense Pentagon Washington, DC 20301-1700

RE: Phase II Report on Review of the Testing of Body Armor Materials for Use by the U.S. Army

Dear Dr. Gilmore:

At your request, the National Research Council (NRC) of the National Academies established the Committee to Review the Testing of Body Armor Materials for Use by the U.S. Army to assess the methodologies used for body armor testing. The committee provided its Phase I report to you on January 4, 2010. What follows is the evaluation developed in satisfaction of the Phase II component of the statement of task (see Attachment A):

In Phase II, the committee will consider in greater detail [than in Phase I] the validity of using the column drop performance test described by the Army for assessing the part-to-part consistency of a clay body within the level of precision that is identified by the Army test procedures.

The committee will prepare a letter report documenting the findings from its Phase II considerations.

This Phase II report is focused on the behavior of ballistic clay and on other issues relating to the test process that were raised in Phase I of the study. More detailed evaluations of the array of issues surrounding body armor testing, both present and future, will be presented in the final Phase III report.

The recommendations in this letter report are based on the information that the committee received from the Army and on discussions and observations during a single 4-day meeting that included a site visit to the Aberdeen Test Center (ATC) at the Aberdeen Proving Ground, Maryland. At this meeting, the committee received briefings on specific issues raised in Phase I and by the Phase II statement of task that were of interest to the sponsor. The committee reviewed documentation on the Army’s body armor testing program in general and on its tasks for Phase II in particular.

During the site visit, the committee members observed how ATC tests body armor using consistent methodologies for the handling and calibration of the clay (the

column drop performance test) and for the measurement of the backface deformation, including procedures for assessing the part-to-part consistency of the clay. In addition, the committee reviewed the statistical basis for the testing and analyzed proposed revisions to the statistical protocols used.

The Phase II Committee was greatly appreciative of the dedication, qualifications, and openness of the ATC staff. Clearly they seek to achieve the highest standards possible for armor testing and are pursuing refinements in established techniques and advances in technology to provide the very best armor performance for our soldiers. As described in the pages that follow, adequate resources are required to achieve such a goal. The committee’s analysis of the Phase II issues resulted in the development of 19 recommendations that are summarized in Box S-1 on page 3. These actions are urgently needed to achieve greater part-to-part consistency in the ballistic clay, to analyze BFD dynamics, to determine possible replacements for modeling clay, to achieve a national clay standard for testing body armor, and to implement statistically based protocols. The overarching recommendation is as follows:

Overarching Recommendation: The committee applauds DOT&E for assuming a national-level leadership role in bringing the body armor test community together. The committee recommends that the DOT&E (1) work with Congress, DoD, the military services, and other organizations to find the resources necessary to implement the recommendations described in this report and summarized in Box 1 and (2) oversee, review, track, and assist the designated action organizations with implementing these recommendations. This approach should result in more consistent test results that will provide equally survivable but lighter-weight body armor to our military service members and civilian police forces.

Sincerely,

MG (ret.) Larry G. Lehowicz,

Chair

Committee to Review the Testing of Body Armor Materials for Use by the U.S. Army

Phase II Report on Review of the Testing of Body Armor Materials for Use by the U.S. Army

The committee’s analysis of the Phase II issues resulted in the development of 19 recommendations that are summarized in Box S-1 and discussed in detail in the following sections of the report.

Box S-1

Phase II Recommendations to Improve Body Armor Testing

Achieving Greater Part-to-Part Consistency in Clay

-

Quantify the Medical Results of Blunt Force Trauma on Tissue and Incorporate Results into the BFD Methodology

-

Determine Short-Term Standard Clay Specification

-

Conduct Rheological and Thermogravimetric Measurements

-

Procure and Experiment with a Clay Compounding Machine

-

Examine Technologies for “In Box” Mechanical Clay Working

-

Modify TOP 10-2-210 Procedures to Add a Post-calibration Drop (ATC, 2008)

-

Experiment with Various Clay Box Sizes and Shapes

-

Develop and Experiment with a Gas Gun Calibrator or Equivalent Device

Analyzing Backface Deformation Dynamics

-

Analyze the Signal-to-Noise of Flash X-Ray Cineradiography

-

Experiment with Microscopic Temperature and Displacement Sensors in Clay

-

Experiment with the High-Speed Photographic Analysis of BFD Creation in Ballistic Gelatin

Determining Possible Replacements for Modeling Clay

-

Study Ballistic Gelatin as a Mid-Term Alternative to Modeling Clay

-

Study Microcrystalline Waxes as a Long-Term Alternative to Modeling Clay or Ballistic Gelatin.

Achieving a Single National Clay Standard for Body Armor Testing

-

Empower and Resource the Ad Hoc Clay Working Group

-

Convene a Nationally Recognized Group to Establish a Single National Standard for Handling and Validating Clay

Implementing Statistically Based Protocols

-

Compare the Proposed Statistically Based Protocol with the Existing USSOCOM Protocol

-

Quantify the Variation in the Body Armor Test Process and Incorporate in the Protocol

-

Develop a Statistically Based LAT Protocol

-

Conduct Due Diligence Before Implementing and Formally Adopting a Set of Statistically Based Protocols

INTRODUCTION

This section describes the expertise of the Phase II Committee membership, the ceramic armor plates being tested, the testing process, the layout of the testing range, and relationships between medical studies and use of modeling clay in body armor testing.

Phase II Committee Expertise

At the conclusion of Phase I, the Phase I Committee felt that greater consistency in the oil-based modeling clay could reduce variability in the body armor test and give more consistent and precise results. More precise results, in turn, could allow certifying with a high degree of confidence lighter weight armor plates that achieve the same survivability for a soldier. As a consequence, the membership of the Phase II Committee included additional experts on clay, who could address the statement of task requirement to “assess the part-to-part consistency of clay” in more detail.

The sponsor appreciated the Phase I Committee’s support for the development of a statistically based protocol to determine test sample sizes and other aspects of testing. The Phase II Committee was asked to continue that work in Phase II, and an additional statistician was appointed to the Phase II Committee.

Ceramic Armor

Ceramic materials have been used successfully in personal armor systems to defeat small-arms threats. They are preferred for personal armor systems because they are lighter than more traditional armor made of metallic alloys. Properties that contribute to the performance of ceramic armor include superior hardness, low density, favorable elastic constants, and high compressive strength. However, as stand-alone items, ceramics would not be particularly good because of their low tensile strength, brittle response, and sensitivity to small mechanical defects such as pores and cracks. Hence, ceramics are used in combination with other materials, such as polymers and metals, to form laminar composites that provide excellent properties for body protection. A typical insert (also referred to as a “plate”) of body armor consists of a layer of dense boron carbide or silicon carbide backed by a layer of metal or polymer composite; The entire plate is wrapped in tightly woven ballistic fabric. The ceramic layer breaks up an incoming projectile and dissipates its kinetic energy. The layer of polymer composite and/or metallic alloy provides ductility and structural integrity and spreads the forces resulting from the impact of a projectile over a larger area.

All hard body armor systems currently add a significant burden of weight on the soldier. Armor testing therefore has implicit goals of ensuring that body armor meets survivability standards while allowing sufficient soldier mobility and flexibility. To provide soldiers with more weight than necessary to defeat a specified threat can lead to unintended consequences such as premature exhaustion and restricted ability to rapidly move and react in life threatening situations.

Current Army Body Armor Testing Process

As described in the Phase I report (NRC, 2009), the Army’s procedures for testing hard body armor using a clay backing for the measurement of deformations in the clay from ballistic impacts are documented in “Test Operations Procedure (TOP) 10-2-210: Ballistic Testing of Hard Body Armor Using Clay Backing,” dated October 1, 2008 (ATC, 2008). The approach may be summarized in four paragraphs:

-

A clay box1 and clay chest plate appliqué2 (Figure 1) are assembled, appropriately calibrated for part-to-part consistency using the column-drop performance test, and placed upright in the test holder. Independently, a “shoot pack” is prepared. To create a shoot pack, the armor plate is placed in a fabric envelope together with multiple layers of Kevlar to replicate the vest worn by the soldier. The dimensions of the armor plate depend on the size of the vest and can range from 18 cm × 29 cm to 28 cm × 36 cm, with a thickness of approximately 2 cm. The vest has a significant nonconstant radius of curvature.

-

Once assembled, the shoot pack is pressed firmly into the surface of the appliqué to ensure conformance. The shoot pack is then removed and the laser scanning system scans the surface of the appliqué to provide a reference surface relative to which subsequent deformations caused by the firing of the projectiles can be compared. The laser scanning system is moved out of the way, the shoot pack is repositioned onto the surface of the clay, with care taken not to disturb the reference surface, and the shoot pack is secured.

-

The projectile being tested is then fired into the shoot pack, after which the shoot pack is removed from the clay and inspected for penetration. The displacement or indent in the clay made by the deformation of the armor is thereby exposed. The velocity of the projectile was measured using Oehler Model 57 Ballistic Screens to verify that it was within the desired range.

FIGURE 1 The clay appliqué applied to the clay box. SOURCE: Richard Sayre, Deputy Director, and Tracy Sheppard, Executive Officer and Staff Specialist, Office of the Secretary of Defense, Director of Operational Test and Evaluation (OSD DOT&E) Live Fire Test and Evaluation, “DoD in brief to the National Research Council study team,” Presentation to the committee, on November 30, 2009.

-

The deformation is measured with the laser scanning system. The data are collected and used to compute the profile (depth distribution) indent. The deformation is analyzed and serves as an indication of the survivability of a soldier subjected to a similar shot and protected by a similar plate in a protective vest.3

-

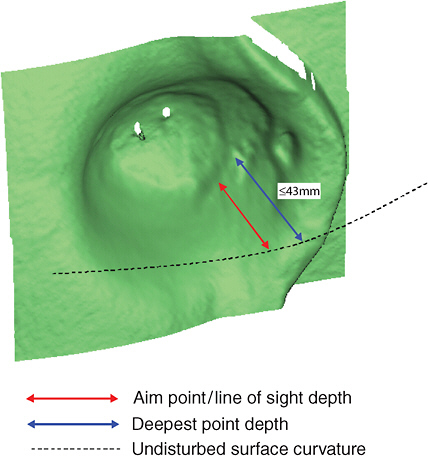

A representative deformation is shown in Figure 2. The nominal design specification is that the maximum depth in the clay relative to the original surface be less than 43 mm. That is, a backface deformation (BFD) with a maximum depth of less than 43 mm is considered to indicate acceptable performance of body armor in service. Experimental data collected by the Army indicate that under nominally identical conditions the standard

-

-

deviation for the maximum depth of the BFD (hard armor) is in the range of 2.5 to 4 mm.4 The BFD measurements in combination with the penetration data are used to evaluate the armor.

FIGURE 2 Surface of the BFD as measured by a laser scanning system. SOURCE: Richard Sayre, Deputy Director and Tracy Sheppard, Executive Officer and Staff Specialist, Office of the Secretary of Defense, Director of Operational Test and Evaluation (OSD DOT&E) Live Fire Test and Evaluation, “DoD in brief to the National Research Council study team,” Presentation to the committee, on November 30, 2009.

Body Armor Testing Range

A typical firing range used to test body armor consists of: a rifle-like device to fire a projectile; an instrument to measure the velocity of the projectile; the armor plate being tested, which is affixed to an oil-based clay backing of modeling (clay this backing becomes indicated in response to the kinetic forces created on the plate); and a laser system to measure the geometry of the indentation in the clay. A photograph of an indoor range set up for testing body armor at the Aberdeen Test Center (ATC) is shown in Figure 3.

FIGURE 3 The body armor test range at ATC. SOURCE: John Wallace, Technical Director, ATC, “Body armor test capabilities,” Presentation to the committee, on March 10, 2010.

The highest priority of the Phase I report was to examine the validity of the laser profilometry system to determine the contours of the indentation in the oil-based modeling clay, the BFD, at the level of precision established by Army procedures. The committee found the Army’s laser system5 used in accordance with its ATC Internal Operating Procedure No. 001 provides a valid approach for measuring the BFD indentation at the appropriate level of precision.

The Phase I report also asked the committee to address the oil-based modeling clay medium in which the BFD is formed. Specifically, the committee was asked to provide interim observations on the Army’s column-drop performance test used to

determine that the clay-filled boxes in the test are consistent from box to box. This is referred to as “part-to-part consistency.” The committee’s Phase I report found that the column-drop performance test (including testing protocols, facilities, and digital caliper instrumentation) is a valid method for assessing the part-to-part consistency of the clay boxes used for testing body armor.

Medical Study Basis for Use of Modeling Clay in Testing Body Armor

The use of clay as a recording medium for body armor testing dates from a 1977 study that correlated the depth that a 200-g, 80-mm hemispherical missile, impacting at approximately 55 m per second (Prather et al., 1977), penetrated live animal tissue and other media. The goal of the study was to develop a simple, readily available backing material for characterizing both the penetration and deformation effects of ballistic impacts on body armor materials and to relate this information to the injury potential of nonpenetrating ballistic impacts. The depth of penetration into various media as a function of time was compared to the probability of lethality for the same penetrator entered into a live animal model (in this study goats were used as models) (Clare et al., 1975).

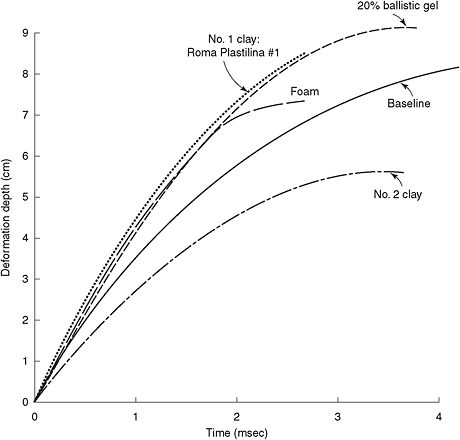

The study observed strong correlations between lethality probability and penetration into ballistic gelatin6 and also into modeling clay Roma Plastilina #1. The ballistic gel required the use of high-speed photography to record BFDs, because the gel was elastic and returned to its original shape after the projectile firing. To avoid the necessity of using expensive high-speed photography, an alternative material was sought that would retain its deformation The first conclusion of the Prather et al. (1977) report had a profound effect on testing over the next 30 years. It reads as follows (Prather et al., 1977, p. 11):

A readily available, easy-to-use backing material, Roma Plastilina 1, has been found which can be correlated to tissue response for use in characterizing both the penetration and deformation effects of ballistic impacts on soft body armor materials.

Roma Plastilina #1 has since been adopted as a recording medium to assess the likelihood of injury or death from ballistics, and its use has been extended from assessing soft armor such as Kevlar vests to assessing hard armor plates, knife wounds, industrial injuries to a drop-forge operator, and nonlethal projectiles (Lyon, 1997; Chadwick et al., 1999; O’Callaghan et al., 2001; Vaughan, 2001; and Karahan, 2008). Roma Plastilina #1 appears to have become an industry standard despite being an imperfect simulant of the human body.

The procedures for the use of this clay have evolved with time. In part, this is because the behavior of the material has changed over time. The manufacturer confirmed

that the formulation sold as Roma Plastilina #1 has changed as the sources of raw material have changed and in response to the needs of artists.

Modeling clay provides an approximation of the actual BFD. It does not record maximum displacement since the clay may exhibit some elastic recovery, nor does it record the rate of deformation. Both of these dynamic events may be important in predicting the magnitude of injury to a person. To address these issues DoD conducted a medical research program, the Body Armor Blunt Trauma Assessment (BABTA) Project, from 2002 to 2006.7

The BABTA project developed an anthropomorphic test module (ATM) onto which body armor plates could be placed and firing tests performed. The ATM was equipped with sensors that directly measured the spatial and temporal distribution of the forces and motions caused by a bullet impacting armor. The pressure sensors in the ATM are on the backside of an approximately 25 mm thick layer of Dragon Skin, a high-performance silicone polymer that simulates the mechanical properties of the body. The layer of Dragon Skin is necessary to avoid damaging the sensors during the test. The spatial and temporal distribution of the forces at the surface was inferred using a finite-element calculation. Based on this, a blunt projectile was developed that when fired from an air-gun impactor at the ATM without an armor plate resulted in a distribution of forces and motions believed to accurately simulate those produced by the bullet impacting armor, assuming that the armor was not completely penetrated. The blunt projectile was a ~60 mm hemisphere mounted on the end of a smaller cylinder. Using this blunt projectile impactor, the project team experimented with highly instrumented and anesthetized human surrogates (in this case, pigs). From the response of the human surrogates, including in some cases postmortem analysis, a large database was generated that related the temporal and spatial distribution of forces to the injury. The BABTA project and numerous others indicate that depth of indentation alone is an inadequate indicator of injury probability (Cannon, 2001; Bass et al., 2006).

The BABTA study suggests that a means of easily and economically measuring the temporal and spatial distribution of the forces during the BFD would enable a more accurate assessment of armor efficacy and could lead to lighter armor that provides equal protection. The BABTA project established the need to develop testing methodologies that determine not just the BFD but also the dynamic forces that result from the impact of the projectile on body armor.

During presentations to the committee on March 9, 2010, Dr. Prather and Dr. Legierri agreed that the initial conclusions on BFD in the 1977 Prather study are very conservative. That is, humans may be capable of more easily surviving forces that correspond to those that make a BFD larger than the 43 mm BFD that is currently accepted by the body armor community. The committee applauds the efforts of the medical and testing communities to better quantify and correlate laboratory-generated mechanical impacts with the blunt force trauma caused in surrogate human beings. During Phase III the committee hopes to be able to further investigate (1) the relationships between temporal and spatial forces that cause blunt force trauma in the laboratory and injuries experienced by soldiers on the battlefield and (2) ways to more

accurately correlate blunt force trauma impacts experienced by soldiers with the signatures that similar forces cause in body armor media that are not restricted to oil-based modeling clay or similar approaches.

Recommendation 1: The Army’s medical and testing communities should be adequately funded to expedite the research necessary both to quantify the medical results of blunt force trauma on tissue and to use those results as the updated mathematical underpinnings of the back face deformation (BFD) body armor testing methodology.

Regardless of the current imperfect correlation between existing medical data and the BFD approach, the committee believes that the current methodology for testing body armor should be continued, mainly because this approach has allowed the Army to send body armor with adequate survivability characteristics to soldiers in combat. Importantly, the committee was informed earlier by the Program Executive Office–Soldier that no soldier deaths are known to be attributable to a failure of the issued ceramic body armor.8,9,10 The committee agrees with a number of briefers that additional study in these areas could lead to insights that that current body armor, which provides an adequate level of survivability, may be unnecessarily heavy for a given threat.

CLAY PROPERTIES AND TESTING METHODOLOGY

This section provides brief descriptions of clay properties and behavior, clay in testing methodology, and short-term development of a standard clay formulation. It also discusses the procedures for preparing and working clay, calibrating clay, and analyzing BFD dynamics. It concludes with recommendations on possible mid-term and long-term replacements for modeling clay in the testing of body armor.

Clay Properties and Behavior

“Clay” is a common word with different definitions. To a mineralogist, clay is a well-defined chemical composition having the crystal structure of a hydrous aluminosilicate. The same word is also commonly used for a geological formation of minerals that occur in nature. In practice, the term “clay body,” which contains multiple constituents formulated in industry, is often shortened to “clay.” Roma Plastilina #1 is an oil-based modeling clay that is not designed to be fired, such as is often done by artists to produce a densified ceramic part. This prescription allows the manufacturer to formulate the clay to obtain a given set of rheological (or flow) characteristics–modeling clay, for instance, is made to offer a given feel or particular consistency. Some materials, such as “polymer clay” and “precious metal clay,” do not contain any clay minerals but are called clays because of their consistency based on the fact that they offer the user similar flow properties. Accordingly, it is important to be specific when “clay” is used to convey a technical meaning.

Typically, an artist who uses clay desires a particular “feel”—that is, he or she can shape the clay by handling it in a certain way. When clay is used for technical purposes, its flow behavior must be quantified. That is, the rheological parameters that describe its response to applied stress must be determined under the relevant conditions. Typical parameters include yield strength, viscosity, and elastic modulus.

A clay’s flow characteristics are determined by the details of its formulation, the ambient conditions (temperature and pressure), and the shear history of the mass. To understand why this is so, it is helpful to consider the role of the constituents in an oil-based modeling clay. According to the manufacturer, “the main ingredients [of Plastilina] are wax, oil, and clay flour…”11 Although the details of the formulation are proprietary, this description of ingredients more or less matches open-source formulations for plasticine, a formerly trademarked term for oil-based modeling clay that has moved into common use. A typical open-source formulation for plasticine contains microcrystalline wax, grease, oil, and clay. While proportions vary, a wax:grease:oil:clay ratio of roughly 25:7:8:60 by weight or 38:14:16:32 by volume is reasonable.

Microcrystalline wax is a food-grade additive obtained from de-oiling petrolatum. Microcrystalline waxes can be alloyed with oils to alter the flow properties (i.e., soften the material) and will remain homogeneous (i.e., it will not separate) over time after the initial mixing.

The distinction between oil and grease is that the former is a fluid at room temperature and the latter a solid,. And the distinction depends on molecular weight. Commercial greases and oils often contain multiple components and include additives designed to stabilize viscosity or inhibit oxidation, among other things.

What is important for a modeling clay of microcrystalline wax, oil, and grease is its homogeneity and the strong dependence of its rheological properties on temperature and the relative proportions of each constituent (Pena et al., 1994). The rheology also will depend on the shear history of the clay, since clay is thixotropic.

|

11 |

For additional information, see www.sculpturehouse.com/plastilina_info.aspx. |

Thixotropy12 occurs when a three-dimensional structure develops over a long time in a material. The rheological response changes with time when the system is disturbed such that the structure is broken down (i.e., it becomes more flowable) or when it is allowed to rest and the structure reforms (i.e., it becomes less flowable). The distinguishing characteristic of thixotropy is that the changes occur only with the passage of time.

Such behavior is common in clay-containing systems as three-dimensional networks of clay particles develop. Such assemblages of particles can often be broken down by the application of shear forces to the body. However, clay particles are not necessary for thixotropy to be observed. In particular, the above-referenced article on model ointments demonstrates that significant thixotropy is observed in a mixture of microcrystalline wax, grease (white petrolatum), and oil (mineral oil) in the absence of clay (Pena et al., 1994). This is due to the formation of a structural network involving both the amorphous and crystalline fractions of the microstructure.

The above discussion focuses on the four main constituents of modeling clay. However, Isaac Peng of Chavant, the current manufacturer of Roma Plastilina #1, mentioned that there are typically about 10 constituents in a commercial material.13 These include pigments or colorants, antioxidants, and other minor materials as well as an intentional blending of multiple sources of, for example, the microcrystalline wax to dampen out lot-to-lot variations from individual suppliers.

It is perhaps useful to point out that minor constituents can affect the behavior of modeling clay in the context of armor testing in other indirect ways. One example is the particulate sulfur that is present to make the smoother, more homogeneous texture required by professional artists.14

One complication of the presence of particulate sulfur in Roma Plastilina #1 is that it loses weight during storage due to the sublimation of sulfur. Sulfur is observed to condense in the storage ovens around the door where the ambient temperatures are low. For obvious reasons, it is undesirable for the clay to have volatile constituents when its expected service life can be up to a year.

In summary, the medium used to record the BFD of a ceramic armor system being tested for ballistic impact is a multicomponent, oil-based modeling clay body. Knowing the behavior of the individual constituents that make up the modeling clay makes it possible to develop an expectation about how the consistency will be influenced by thermal history and shear history.

Clay in Testing Methodology

As described in the introduction, the clay backing material used in armor testing has two important purposes. The first is “to simulate [some aspects of] the tissue response appropriately beneath the point of impact so that the ballistic data generated in laboratory

|

12 |

Thixotropy is the property of certain gels or fluids that are thick (viscous) under normal conditions but that flow (become thin, less viscous) over time when shaken, agitated, or otherwise stressed. |

|

13 |

Isaac Peng, Chauvant, “Testing of body armor materials,” Presentation to the committee, on March 9, 2010. |

|

14 |

For additional information, see www.sculpturehouse.com/plastilina_info.aspx. |

tests can be correlated to the effects seen on the human body” (Prather et al., 1977, p. 7). The second purpose of the backing material is to mark the extent of BFD during ballistic testing. Multiple materials are available to simulate a body; in fact, at the time it was introduced, modeling clay was recognized to only approximate tissue response, and empirical correlations were needed to develop a probability for lethality or injury. The chief advantage of modeling clay over other materials available at the time was that it better served the function of recording BFDs; that is, when impacted, modeling clay deforms plastically and a permanent cavity (also termed indent, impression, or crater) is developed under the point of impact. Correlations were developed between the geometry of the cavity and the probability of lethal injury.

Short-Term Development of a Standard Clay Formulation for Ballistic Testing

The Army’s protocol for ballistic testing of soft and hard body armor specifies Roma Plastilina #1 as the backing material (DoD, 2008). Since the initial validation studies (Prather et al., 1977), the formulation of Roma Plastilina #1 has changed, and this has changed its properties.15 Whereas historically calibration and testing could be performed at room temperature, the current formulation of Roma Plastilina #1 must be above 100°F to pass the column-drop performance test (described in the section on Calibrating Clay). The committee was informed that the thermal conditioning temperature has increased of about 1°F every year.16 In response to these known deficiencies of the current backing material, the director, of DOT&E established an ad hoc clay working group whose members are technical clay experts from the Department of Defense (DoD), the National Institute of Standards and Technology (NIST), the National Institute of Justice (NIJ), certified private laboratories testing body armor, for and others. Their purpose is to pursue short-term improvements in clay formulation, the processing of clay, and short and long-term alternatives to clay.17 A short-term goal is to develop a replacement for Roma Plastilina #1 in less than 1 year.

Based on their experience, members of the clay working group have developed the following list of the desirable characteristics of clays for ballistic testing:18

-

Known, controlled, and consistent change in properties as temperature is changed.

-

A long useful life for repeated testing at room temperature.

-

Known, controlled, and consistent change in properties due to cold working (thixotropic effect).

-

Excellent dimensional stability.

-

Minimum “stickiness” to the target (i.e., the clay must not peel away when the target is removed) but high “stickiness” of clay to clay.

-

Easy moldability, so that clay blocks can be formed with no voids, air bubbles, or gaps.

-

Long shelf life (1 year or more??)

-

Nontoxic, minimum odor, and reasonable price

-

Specifiable and controllable mechanical properties: density, seismic velocity, elastic modulus, shear modulus, grain size, hardness, etc.

Because its properties depend on shear history, time, and temperature, Roma Plastilina #1 appears to meet only some of these criteria. For example, it is typically heated to over 100°F to meet the calibration specification, which limits its useful life for testing in a room-temperature test range to less than 45 minutes. As a result of its properties, the current formulation requires a complex preparation and packing procedure to produce boxes with uniform, reproducible properties that are capable of passing the calibration test described in MIL-STD-3027 (DoD, 2008). The goal of the clay working group is to develop a short-term replacement that can meet the calibration specification at ambient temperature and minimize the sensitivity of the properties of the clay in the box to cold working.

In addition to the criteria developed by the clay working group, two additional considerations could facilitate development of the short-term clay replacement. First, the formulation could be simplified by minimizing the number of ingredients. For example, as previously noted, Roma Plastilina #1 contains sulfur, which has an unknown effect on performance in ballistic testing. Minimizing the number of ingredients should reduce variability in performance over time and simplify attempts to characterize and model performance. Second, the current Roma Plastilina #1 formulation of microcrystalline wax, oil, and grease includes clay as an inorganic filler. The inherent anisotropic (i.e., platy) nature of the clay particles may complicate the behavior of Roma Plastilina #1. Eliminating the clay particles or replacing them with an inorganic filler that has an equiaxed particle morphology may provide properties that are less dependent on work history and time.

Two approaches are possible for the procurement of a standard ballistic clay from an industrial supplier. One approach would be to develop a material specification that uses a precise composition formulated with particular raw materials that are called out in the specification. This approach would guarantee a consistent product as long as the raw materials do not change but would not allow the supplier to adjust the formula in the event that properties change because raw materials are no longer available, properties of the raw materials change over time, or other such factors. This approach could cause the properties of the standard ballistic clay to evolve, as happened with Roma Plastilina #1. The second approach would be to develop a performance specification. This approach would allow the supplier to continually evaluate and adjust the composition to produce a consistent product. This would put the burden on the Army to specify the properties that are most important to the application but would seem to be the best approach to meet the Army’s need for a consistent backing material.

Recommendation 2: The Army should develop ballistic testing performance specifications and properties that will lead to a short-term, standard replacement for the current Roma Plastilina #1 oil-based modeling clay.

Preparing and Working Clay

The clay is cut into small pieces and worked with a mallet and by hand into pliant flat sheets that are placed sequentially in overlapping layers to fill the test box, with attention to filling the corners (ATC, 2008). This is a new practice, intended to maintain spatial uniformity in the box. As discussed in the Phase I report, holes formed during column-drop test calibration are filled with worked clay and manually smoothed. The box surface is scraped before calibration and testing to create a flat surface of precisely known elevation, introducing some final mechanical deformation to the immediate surface region.

The Roma Plastilina #1 clay composition currently in use is proprietary but is known to include a multicomponent organic phases(s), a kaolinite filler, and two other inorganics, sulfur and zinc stearate. Multiphase suspensions are often yield-stress materials that exhibit thixotropy— that is, the material does not flow until it experiences a stress that exceeds a critical value (the yield stress)—and the material properties following the initiation of flow depend on time (thixotropy). Before they yield, the materials appear to respond as viscoelastic solids. The probable cause of shear sensitivity and thixotropy is shear-induced modification of the microstructure, which changes the modulus, yield stress, and viscosity, among other things Accordingly, these materials can exhibit aging, shear conditioning, and even “avalanche” (runaway) behavior. The current understanding of thixotropic yield-stress materials has been reviewed in Bonn and Denn 2009). Rheological modeling of the time-dependent mechanical response of these materials is a topic of current research, and the simulation of complex flows is beginning to be studied.

The way of preparing and working the clay reflects the thixotropic nature of the clay composition, as well as the temperature dependence of the material properties of the organic phase. Hand kneading produces a consistency that permits the clay to be shaped and formed into the sheets that are placed in the test box, probably by effecting changes in the microstructure. Temperature control changes the consistency, probably in large measure by changing the viscosity of the organic phase and, at sufficiently high temperatures, possibly causing a phase change of one or more microstructural elements; the temperature must be maintained within a fixed interval for the clay to exhibit acceptable mechanical properties. Temperature drift with time appears to have a measurable effect on drop-test penetration, for example. Thus, both the shear history and the operating temperature affect the deformation properties of the clay, and either (1) kneading at fixed temperature or (2) varying the temperature without mechanical processing can be used to change the consistency. These effects have not been quantified in conventional rheological tests for the Roma Plastilina #1 clay, but both mechanical and thermal conditioning are employed in the testing practice.

It is accepted practice, for example, that either mechanical working of the clay in the box or changing the temperature will bring a clay into an acceptable penetration range for column-drop calibration test; the former probably changes the structure, while the latter probably has a small effect on structure. The committee was told of a test intended to determine the effect of thermal changes versus mechanical conditioning to obtain

acceptable performance in calibration in which a statistically significant difference in mean BFD performance was observed between the clays conditioned by the two methods. The single-point measurement (of the column-drop test penetration) for such a complex material as clay in this case may reflect the different macroscopic responses in three-dimensional deformations of the clay’s constituent materials as well as the thermo-mechanical histories of each material. These observations are consistent with a 1994 NIST report on the rheological properties in torsional shear of an earlier formulation of Roma Plastilina #1, which found that the material was highly nonlinear and time dependent, and that the shear properties of kneaded and “melted” (i.e., raised to a temperature of 90°C) clay at a fixed test temperature were different (NIST, 1994). The NIST study also reported that the clay was viscoelastic, in which case the material would be expected to recover a fraction of the imposed deformation upon removal of the load. (This observation is consistent with the unsupported observation in the Aerospace Report ATR-75(7906)-1—namely, that elastic springback of the clay backing material would require correction factors) (Aerospace Corporation, 1974). Low-rate indentation experiment on plasticine indicates recovery would be expected at high rates (Huang et al., 2002; Ji et al., 2009).

Fundamental thermomechanical information about the clay formulation appears to be lacking. Plasticine rheology has been widely studied over the decades due to its technical importance as a model material in a number of scientific and technical fields. It is a complex material with a response that has been shown to depend on strain, strain rate, and thermal and mechanical history. The committee is, however, unaware of any linear viscoelastic measurements at either low or high frequency for either worked or unworked Roma Plastilina #1 to determine the relative recoverable (elastic) and dissipative (viscous) fractions of the response; linear viscoelastic measurement, even at frequencies well below the operational timescales, can be sensitive indicators of structural change. Nor have there been shear measurements at a range of temperatures to determine the viscoelastic solid response prior to yielding, the equilibrium yield stress, aging, the thixotropic response, or the apparent equilibrium viscosity and shear modulus as a function of shear rate. These are properties that are likely to affect (hence correlate with) clay response during calibration and testing. Such measurements are standard practice in other industries that use similar materials, including oil well drilling, personal products, etc. These properties are also required for any simulation intended to relate indirect measurements to the mechanics of body armor deformation. In particular, any viscoelastic recovery may give a measured BFD that is less than the maximum experienced dynamically during the test. A priori calculation of temperature change and straightforward calculation of temperature variations within the box as a function of time require knowledge of the thermal diffusivity of the clay, which has also not been measured for the materials in use. Thermogravimetric measurements to measure weight loss and components that may be eluted over time at a fixed temperature have likewise not been carried out.

The committee notes that rheological measurement is planned by the clay working group, but the particular measurements to be carried out have not been specified. The experiments enumerated above should be part of this program.

Recommendation 3: Rheological and thermogravimetric measurements should be carried out to better understand the properties and behaviors of clay as it is being prepared and worked.

During a briefing to the committee, the ATC Protective Equipment Division science officer stated that in his opinion perhaps some of the most significant variation in the testing process could result from the hand processing that goes into filling the clay boxes and subsequently working it before and after test firing.19 Standardized thermo-mechanical working of the clay prior to filling the box would provide more uniform mixture of the clay and improve part-to-part consistency in clay. This might be accomplished by using a mechanical compounding machine, which might also permit reuse of the clay. ATC personnel indicated that such equipment has been under consideration.

Recommendation 4: If it is demonstrated to achieve improved part-to-part consistency of the clay compared to hand preparation procedures, a mechanical compounding machine for clay preparation should be acquired, experimented with, and used by the Aberdeen Test Center.

Thermal conditioning of the box to obtain a calibration within the acceptable range would make it likely that the clay structure is the same from test to test on the same sample. However, this introduces several complications. First, the test ranges must have appropriate ovens. This imposes a capital cost, dedicated space, and maintenance. Second, the use of high temperature may degrade the modeling clay. This includes oxidation of the waxes and oils as well as the loss of volatile species (such as sulfur). Third, if the modeling clay is equilibrated at a temperature significantly higher than the ambient room temperature (as is current practice), then the cooling that takes place over the time necessary to conduct the test can change the modeling clay response.

An alternative approach would be to develop an automated process that could be used to mechanically condition the clay without removal from the box. There are at least two established processes that embody the desired elements of such a device–friction stir welding and insitu soil mixing. “Friction stir welding” was developed in the early 1990s at the Welding Institute in the U.K. The Welding Institute’s Web site20 provides the following description:

[I]n friction stir welding a cylindrical, shouldered tool with a profiled probe is rotated and slowly plunged into the joint line between two pieces of sheet or plate material, which are butted together. The parts have to be clamped onto a backing bar in a manner that prevents the abutting joint faces from being forced apart. Frictional heat is generated between the wear resistant welding tool and the material of the work pieces. This heat causes the latter to soften without reaching the melting point and allows traversing of the tool along the weld line. The plasticised material is transferred from the leading edge of the tool to the trailing edge of the tool probe and is forged by the intimate contact of the tool shoulder and the pin profile. It leaves a solid phase bond between the

|

19 |

Question-and-answer session between Shane Esola, ATC, and the committee, March 11, 2010. |

|

20 |

Available at http://www.twi.co.uk/content/fswintro.html. |

two pieces. In an experimental study using oil-based modeling clay as a simulant of a metal, friction stir welding was shown to be feasible (Leichty and Webb, 2007).

It seems plausible that this could be extended to a raster pattern that would allow an entire box to be worked in place. Insitu soil mixing, or auger mixing, appears to be primarily used to admix a material such as cement to soil for purposes of creating foundations or to immobilize soil contaminants. In the field, soil mixing works on a length scale of several feet, but there are laboratory-scale mixers used to study auger designs, etc., that would be amenable to the length scale associated with a clay box (Al-Tabbaa and Evans, 2003). In this case as well, an extension to clay box mechanical treatment would require a system to permit x-y translation of the auger.

Recommendation 5: In-box mechanical conditioning might obviate the need for precise temperature control and reduce the need for hand working of the clay. Mechanical working methods should be tested.

In briefing the committee, the clay working group subchair, who is responsible for addressing clay working techniques, stated that he was not authorized by his organization to discuss plans in these areas.21,22 Therefore, some aspects of the above recommendations may already be in motion.

Calibrating Clay

Calibration is conducted to determine that the clay-filled boxes meet a specified level of consistency before and after a body armor test.

Column-Drop Performance Test

The column-drop performance test was described in detail in the Phase I report.23 It is the standard used throughout the body armor testing community and the process for calibrating the clay for use in ballistic testing of armor. Several versions of the drop test are in use. All versions are based on the penetration of indenters of well-defined weight and geometry that have been allowed to fall and impact the surface of a box filled with the modeling clay. One recognized difference between the calibration test and the experience of the system in the ballistic test is that the penetrator speed is calculated to be slightly in excess of 6 m/s at the point of impact, whereas the speed of the backface during ballistic testing is markedly (approximately 10 times) faster.

Details of the procedures are documented in standards by the NIJ and the Army. Three standards are relevant: NIJ Standard–0101.03; NIJ Standard–0101.06; and MIL-

STD-3027 (NIJ, 1987; NIJ, 2008; DoD, 2008). Also of relevance is the U.S. Army TOP 10-2-210 (ATC, 2008).

As these standards have evolved, drop tests to ensure that the modeling clay has a well-defined consistency have been introduced. It was related by Army personnel that the drop test was introduced specifically to account for the complexity of conditions leading to a given consistency. That is, whereas heating to between 105°F and 110°F was necessary to achieve a drop test penetration in the desired range for undisturbed modeling clay, the same result was achieved at a significantly lower temperature when the clay had been “recently worked.” This indicates an understanding that both thermal history and shear history affect consistency. It assumes that the observed correlations from the 1977 Prather study are preserved no matter which process pathway is used to obtain a drop test within the standard given by TOP 10-2-210 (Prather et al., 1977; ATC, 2008).

To take the above considerations into account, the test-preparation assembly (i.e., attachment of the modeling clay appliqué used to fill the space between the armor pack and the clay box), the column-drop calibration test, and the actual testing of the body armor plate must be completed within 45 minutes.

Personnel who repair and recondition clay boxes follow procedures that are consistent with standard practice by artists and others to fill space without entrapping air. That is, small additions are sequentially made and each is heavily sheared by hand to express any entrapped air. This represents good practice. Army personnel related that periodic x-ray of clay boxes only rarely indicates the presence of entrapped air. The same rebuilding procedure appears to be used both in rebuilding indentations produced during calibration and after an armor test to restore the box.

Boxes are used for as many as 200 shots for a year. Appliqués are prepared for each individual armor plate to be tested. After boxes have been used for their individual service life, the modeling clay is discarded.

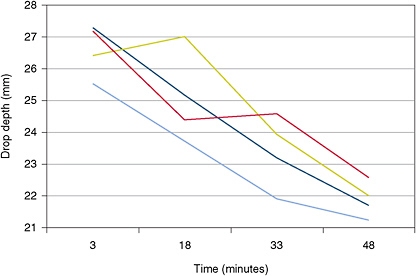

One feature of the Army TOP calls for comment. The column-drop calibration test requires the result of each indentor drop to yield a cavity with a maximum depth of 25±3 mm. Data given to the committee (see Figure 4) indicate that as the clay box cools during the time interval associated with completing the test (up to 45 minutes), the clay hardens to the degree that a drop test cavity will be up to 4.5 mm shallower than would have been the case when the box was first removed from the oven. Given that the full range of the acceptability is only 6 mm (i.e., + 3 mm to – 3 mm), it must be the case that any box that displayed indents shallower than 26.5 mm would necessarily be expected to yield a drop test result that would not be acceptable if a post-test calibration drop were conducted. Thus, as currently written, the TOP allows tests to be conducted on clay that would not pass the initial drop test, thereby introducing additional variation into the testing process and probably into the BFD measurements.

FIGURE 4 Depths resulting from column-drop calibration tests conducted in a standard clay box after undergoing four different environmental conditioning scenarios. As a result of cooling temperatures in the clay box, the depth of penetration decreases systematically over time. The penetration depths were demonstrated to decrease in linear fashion at approximately the same rates of change regardless of conditioning. The observed range spans virtually the entire range ., (+ 3 mm to – 3 mm) of accepted variance associated with the test. SOURCE: Scott Walton and Shane Esola, ATC, “ATC perspective on clay used for body armor testing,” Presentation to the committee, on March 10, 2010.

Recommendation 6: Since oil-based modeling clay is time and temperature sensitive, a post-drop calibration test is needed to validate that the clay remains within specification at the end of a body armor test. The Army should add this requirement for a post-drop calibration test of the clay to its Test Operating Procedure (TOP 10-2-210).

In addition to the observed systematic changes, experimental data collected at the ATC and presented to the committee show spatial variation in the plane parallel to the surface of the clay box (the x-y plane) and through the thickness (z-direction).

The variation in the x-y plane of the box is complicated by the presence of the walls and floor of the box because they constrain the plastic flow of the clay. This fact is recognized, and TOP 10-2-210 stipulates the allowable spacing between drops and proximity to the edges (ATC, 2008). However, it was not demonstrated that either an analysis or an experimental program has been conducted that permits the effect of placement in the x-y plane to be separated from clay property variation. Furthermore, the mixed nature of the results does not permit one to determine the degree to which the test might be improved by redesigning the box in the form of a circle or other.

With respect to variation in the z-direction, the reported data include the results of an experiment in which calibration drops into the top surface of the box were compared to an equivalent set of drops onto what had been the bottom of the clay mass. (The plywood backing was removed from the bottom of the box, moved and fastened to the

top, the box inverted, and the drop test conducted.) Whereas the drop test results for the normal top surface yielded a narrow variation and were all in within specification, the drop test results for the surface that had been at the bottom of the box were on average more than 4 mm shallower, were out of specification, and had a much higher variance.

These results demonstrate that the response of the modeling clay differs by location in all three dimensions and that the differences are large enough to affect the outcome of the test.

Recommendation 7: The spatial variation of modeling clay is significant and three-dimensional. The response of the clay appears to depend on temperature, shear history, and proximity to the edge. Given the confounding effect of box geometry, the Aberdeen Test Center should perform a systematic set of column-drop performance tests as experiments to assess the consequence of variation due to the shape and size of the frame that defines the clay box. These tests should determine if a circular box of approximately the same area as the current box reduces the spatial variation that affects ballistic testing, or if a larger box area eliminates the clay edge effects that affect ballistic testing.

Alternatives to the Column-Drop Performance Test

Clearly the conditions of the column-drop performance test are different from those experienced by the modeling clay during the actual ballistic test of the armor. For example, the velocity of the indenter is much less than the velocity of the penetration of the back of the body armor that forms the BFD. Also, the typical depth of penetration of the indenter, 25 mm, is only half the distance of a “pass” BFD, 43 mm. There are several alternatives to the current column-drop performance tests that appear to offer advantages.

At the time of impact, the velocity of the indenter used in the current calibration test is just over 6 m/s. However, estimates provided to the committee by ATC personnel (W. Scott Walton and Shane A. Esola) are that the backface of the armor moves at a velocity >50 m/s after impact with current threat projectiles. That is, the current calibration occurs under significantly lower strain rates than expected in the armor test. The Army is developing a gas gun capable of directing a penetrator onto the surface of a clay box at velocities were like those of the BFD. Although it is recognized that the gas gun is only one approach to achieving high velocities, and there are others, it will be used in the following discussion for illustrative purposes. The first advantage of employing high speeds is that impactors will penetrate to depths comparable to the BFD in ballistic tests.

In addition, a gas gun will in principle be able to deliver penetrators ranging from spheres to other specialty shapes. The existence of such a device offers a number of opportunities. One is that it allows choosing steel spheres to reproduce a cavity in the clay that approximates the dimensions associated with the BFD in a ballistic test. A second is to reproduce the impactor of the original Prather et al. study, which will permit direct comparison to the original work with modern clay formulations and conditions. Thirdly, it allows using shaped impactors are designed to reproduce that the force distributions expected when a blunt trauma occurs as a projectile strikes hard armor. Shaped impactors are commonly used in injury simulation to induce specific and

reproducible forces over a well-defined area. This option is particularly appealing as work progresses to measure the force distribution associated with armor testing (Raftenberg, 2006).

An additional appealing possibility is using small diameter spheres (as in the study by Weber, because this allows a high-density matrix of small impacts that may permit direct measurement of clay homogeneity (Weber, 2000).

It is important to stress there are two different functions of an improved calibration test. The first is to characterize the variability of clay within a given box at a given time in a manner that is directly relatable to the BFD. The second, equally important role is to use such a system to estimate the variation of BFD measurements both within a given box and between boxes, under realistic testing conditions using existing test protocols. The latter will help to provide information of use in the statistical analysis of armor testing results.

Specifically, statistical analyses of the test protocols require quantification of how much of the observed variation in BFD is due to the clay medium (and the test protocol in general) and how much is due to variation in the plates themselves. Using actual plates cannot answer this question because of the destructive nature of the tests (confounding the results of the individual plates with the testing). Thus, a surrogate must be used. However, unless the degree to which the surrogate mimics actual plates is high and well determined, a different type of confounding may be introduced.

Recommendation 8: As an alternative to the current column-drop performance test the Army should quickly develop and experiment with a gas gun calibrator, or equivalent device, that delivers impactors to the surface of clay boxes and that determines local variation within a clay box at speeds and depths corresponding to those involved in the generation of the backface deformation. These experiments should be used to estimate as accurately as possible the variation of backface deformation measurements both within a given box and between boxes, under realistic testing conditions using existing test protocols.

Analyzing BFD Dynamics

Description of the Problem

As described earlier, the medical analysis by the BABTA project indicated that in order to predict blunt trauma injury resulting from BFD of the armor plate, information on both the shape and the rate of formation of the deformation is needed. This is because the rate at which BFD occurs was found to be the primary determinant of the probability of injury and the nature of the injury. This conclusion of BABTA is supported by numerous independent studies of damage to animals and cadavers caused by blunt trauma (Cannon, 2001; Bass et al., 2006). Thus, both the shape of the BFD and the rate at which it occurs are needed to make reliable predictions of injury. Expressed another way, for two identical BFDs, the one that occurs faster is highly likely to produce greater injury, so measuring the dynamics of BFD in clay is of significant interest.

Measuring BFD Dynamics

When clay is used as the backing of an armor plate being tested, its optical opacity necessitates a nonoptical method to determine the rate and shape of BFD. A flash x-ray source available at ATC has been proposed for studying BFD dynamics as the plate deforms into modeling clay. Calculations by the committee indicate that during a single flash of the proposed flash x-ray cineradiography system, the number of x-rays that will penetrate the clay box and impinge on a resolution element (i.e., a pixel) of the scintillator screen, where they can be detected, may be too small to provide the desired information. That is, the images expected from the x-ray cineradiography may be too blurry to determine BFD shape and rate with the desired spatial and temporal resolution.

Recommendation 9: While the committee applauds the Aberdeen Test Center efforts to understand and attempt to measure the dynamics associated with the creation of a backface deformation, the signal-to-noise ratio of the flash x-ray cineradiography approach should be thoroughly analyzed to determine if the desired spatial and temporal resolution can be achieved.

It would be helpful to have means other than the flash x-ray of measuring the forces that create the BFD. One alternative is to borrow from the technologies that are used in the auto industry to study the impact of automobile crash forces on the human being. These studies typically use dummies that are instrumented with sensors. The instrumented dummies are subjected to experimental accidents and the sensor data are analyzed to obtain insights into the impact of a similar accident on a person. Similarly, experiments based on the placement of microscopic temperature and displacement sensors in the clay near the site of the BFD could provide insight into the forces that create the BFD. It is possible that experimentation could determine the depth below the clay surface of the appliqué where the sensors survive the impact of the round striking the plate and provide meaningful data. However, the sensors (and other approaches to seeding the clay box with various markers) are likely to affect the behavior of the clay. These changes in the behavior of the clay would have to be carefully analyzed to determine the impact of sensors and markers in accurately measuring the forces that create a BFD.

Recommendation 10: To better understand and measure the forces that create the backface deformation the Army should experiment with inserting microscopic temperature and displacement sensors into the clay near the site of the backface deformation.

Ballistic gelatin may be a suitable alternative to understanding and measuring the forces behind the BFD since it is optically transparent and its mechanical properties are well understood. Optical transparency permits the use of high-speed photographic equipment to record the dynamics of BFD. Several high-speed photographic systems are available commercially and have come down in price considerably since the original work of Prather, which led to the use of Roma Plastilina #1 for BFD measurement. Appendix 1 presents calculations that illustrate the requirements for photographic BFD

dynamic analysis in ballistic gelatin; it shows that photographic equipment capable of such analysis is readily available.

Recommendation 11: The Army should consider experimenting with high-speed photographic analysis of backface deformation in ballistic gelatin as an alternative for providing needed information on the forces that shape the backface deformation.

Mid-Term and Long-Term Replacements for Modeling Clay

As stated previously, Roma Plastilina #1 is used as a backing material in current ballistic testing of body armor based in part on the Prather study that compared it to a standardized gelatin composition (DoD, 2008). Also, as discussed earlier, the Army is looking at short-term modeling clay formulations alternative to Roma Plastilina #1 that have better thermal and other properties for body armor testing. However, ballistic gelatin and microcystalline waxes are possible mid- and long-term replacements for modeling clay.

Ballistic Gelatin

Ballistic gelatin may offer advantages as a mid-term backing material for body armor testing that is an alternative to clay. Gelatin has been deemed a suitable simulant for the penetration of the human body during a ballistic event (Metker et al., 1975). As previously discussed in this report, gelatin differs from clay in that it exhibits complete elastic recovery after the ballistic event.

Gelatin offers several attractive characteristics that overcome the shortcomings of the current backing material, including these: (1) gelatin offers consistent, reproducible properties; (2) it is widely used in the ballistic community; and (3) as previously described, it is transparent (Nicholas and Welsch, 2004). The last characteristic allows for optical characterization of BFD in real time, which can be used to evaluate quantities such as local acceleration that are suitable for input in damage models for blunt force trauma. In addition to its other attributes, gelatin can be reused and recycled if it is properly stored and handled. Along with its advantages, gelatin also brings possible concerns, including consistent/repeatable processing, storage conditions, potential spoilage, and recyclability, that will also need to be considered.

The Prather study concluded that the standard gelatin and Roma Plastilina #1 (as it was formulated in 1977) had similar responses (Figure 5). The disadvantage of gelatin at the time was the cost of the high-speed photography needed to record the deformation response during ballistic testing. The relatively low cost of technology for capturing digital images and for computer storage media has reduced price as a consideration and would likely bring the cost of testing with gelatin down to or below that associated with clay. The main technical impediment to implementation of gelatin is the need for a modern study to compare the response of gelatin to Roma Plastilina #1 (as it is now formulated) as a backing material. Unlike the Prather study, which focused solely on soft armor applications, the modern study should validate gelatin or another replacement

material for testing of both soft and hard body armors. Other possible considerations in the use of ballistic gelatin are the need to modify standard test procedures to include gelatin and to modify acquisition contracts to allow the Army to purchase armor that has been tested with standard ballistic gelatin.

Recommendation 12: The Army should conduct rheology and other studies on ballistic gelatin as a mid-term alternative to modeling clay due to its properties, which include the ability to directly record BFD using high-speed photography and the elimination of the effects of shear history, time, and temperature on the response of the backing material. However, correlation studies and tests are needed to better understand the differences in the extent of deformation and dynamics among gelatin and alternative clay formulations.

Microcrystalline Wax Mixtures

Microcystalline wax mixtures may offer some of the attractive features of gelatin (its reproducibility) with the flexibility to control temperature-dependent behavior. The proportions of microcrystalline wax, petroleum jelly, and oils can be varied to control properties such as melting temperature, viscosity, and temperature-dependent response (Pena et al., 1994). The mixtures have a number of potentially desirable attributes. First, they are the organic constituents of Roma Plastilina #1, so it may be possible to replicate not only the properties of the current formulations of Roma Plastilina #1 but also the historic response of previous generations of Roma Plastilina #1 by changing the proportions of the constituents. The composition of the mixture could be adjusted to allow for use at ambient temperature, eliminating the need for thermal conditioning and the time limitations on testing. Second, the mixtures are plastic, which would allow BFD during ballistic tests to be captured directly, as they are with the current material. The waxes may also eliminate concerns related to cold working and temperature history. These compositions could be formed by melting the ingredients or remelting a previously used batch at a moderate temperature (i.e., 150°C), pouring the liquid into the test box, and then allowing the liquid to cool to room temperature. The melt casting process should produce a consistent, reproducible test material that would not require cold working or temperature conditioning prior to use. Finally, the wax mixtures may allow for optical characterization of BFD such as optical time domain reflectometry. Because these mixtures are used by the cosmetics industry and are similar in composition to the current backing material, the technical risk of developing a new, simpler material for ballistic testing is low. However, the response during ballistic testing is unknown and requires investigation.

Recommendation 13: The Army should perform rheology and other evaluations on microcrystalline wax mixtures as a possible long-term replacement for Roma Plastilina #1 as a backing material for ballistic testing. Studies are needed to optimize the composition of the mixtures to produce the desired properties. In addition, correlation studies are needed to compare the response of the microcrystalline wax mixtures to the current material and/or ballistic gelatin.

FIGURE 5 Comparison of the deformation depth as a function of time for various materials including Roma Plastilina #1 and ballistic-grade gelatin. SOURCE: Prather et al., 1977.

ACHIEVING A COMMON NATIONAL TESTING STANDARD FOR HANDLING AND VALIDATING CLAY

The NIJ, with assistance from the NIST, has developed technical standards for clay handling and validation for body armor testing. These standards are used by DoD testing organizations to guide clay procedures and processes that in turn determine if various body armors are adequate for military applications. Other non-DoD and private testing laboratories also use NIJ standards to guide their procedures and processes to test body armor that is used by police forces and other organizations. Over time the NIJ has developed several different standards. Different standards have been adopted by different testing organizations at different times in their organizational histories. As a result, it is possible at this time that identical body armor plates could be tested by different organizations, using different standards, and that they could achieve dissimilar and not easily comparable results. In the extreme case, one plate could be deemed acceptable at

one testing facility and another identical plate could be deemed unacceptable at another testing facility due to standard differences.

The committee was presented with briefings on the two main NIJ testing standards.24,25 NIJ Standard 0101.03 and NIJ Standard 0101.06, which includes elements of 0101.03 and earlier standards 0101.04a and 0101.4, or slight variations are used by the U.S. Army , the U.S. Marine Corps, the U.S. Special Operations Command, the NIJ certified private laboratories, and others. Table 1 was presented to the committee as an overview of some of the differences in testing procedures that have resulted from major testing organizations adopting different NIJ standards.

TABLE 1 Major Differences in Clay Calibration Techniques

|

Point of Comparison |

Army (TOP 10-2-210) |

NIJ (0101.06) |

U.S. Special Operations Command |

|

Origin |

Revisions as necessary |

NIJ 0101.04a |

|

|

|

Adaptation from NIJ 0101.03 |

NIJ 0101.04 |

|

|

|

NIJ 0101.03 |

|

|

|

Drop weight |

Cylinder |

Sphere |

Cylinder |

|

|

1-kg, 44.5-mm diameter cylinder with a hemispherical striking end |

1043-g, 63.5-mm sphere |

Varies, but historically the 1-kg, 44.5-mm diameter cylinder with hemispherical striking end |

|

|

Sphere eliminates yaw, but does not go deep enough |

||

|

|

Cylinder may have some yaw, but it impacts to a deeper depth |

|

|

|

Pass/fail criteria: |

Individual |

Arithmetic mean |

Individual |

|

Individual drop depth vs. arithmetic mean |

Three drop indentations are scored individually. If any one drop is out of the 25 mm ± 3 mm range, the clay fails calibration. |

The arithmetic average of five drop indentations scored against a 19 mm ± 2 mm passing range |

Historically, drop indentations scored individually |

|

Drop pattern |

No pattern |

Specified pattern |

No pattern |

|

|

No specified drop pattern. Ideally want to test near the projected test area but avoid shot lines. |

Specified five-location, symmetrical drop pattern |

Follows NIJ 0101.03; no pattern specified |

|

|

Random location sampling is best way to determine bulk clay block properties |

|

|

|

Point of Comparison |

Army (TOP 10-2-210) |

NIJ (0101.06) |

U.S. Special Operations Command |

|

Pretest vs. post test calibration |

Pretest calibration only |

Pre- and post-test calibration |

Pre- and post test calibration |

|

|

Imposes 45-min limit on the useful life of the clay block |

|

|

|

|

|

Five pretest drops (chest mold and clay block) |

|

|

|

|

|

Three post test drops (just clay block) |

|

Calibration of the chest mold and built-up areas |

Does not drop on chest mold |

Does not drop on chest mold |

Drops on chest mold |

|

Reconditioning and retesting of failed clay blocks |

Allows for reconditioning and retesting |

Allows for reconditioning and retesting |

Allows for reconditioning and retesting |

|

|

Maximum of two attempts to pass calibration |

Unlimited attempts to retest failed clay blocks |

|

|

|

Working on establishing rules to govern reconditioning and retesting |

|

|

|

Conditioning time |

Minimum of 3 hours |

Not specified (changed over the years) |

? |

|

Other |

Fixture construction: metal with 0.75 in. wood or plywood backing |

Fixture construction: Wood or metal with 0.75 in. wood or plywood backing |

Processes may vary; techniques are adjusted according to the range capability of the facility at which testing is performed and the customer |

|

|

Clay conditioning temperature requirements have changed over the years |

“Actual conditioning temperature and recovery time between uses will be determined by the results of the validation drop test.” |

|

|

SOURCE: Shane Esola, ATC, “Major clay calibration technique differences,” Presentation to the committee, on March 10, 2010. |

|||

The committee agrees that it could be helpful if there were one national standard for all body armor testing. Such a standard could lead to more consistent procedures and more consistent results across the testing community. The committee appreciates that the different commands and laboratories have different missions, customers, resources and organizational cultures and that eventual adoption of a single national standard would require detailed analysis of key issues such as the various threats that are being tested and the rationale for variation in testing processes being used. Ideally, the development of consensus across all organizations involved in body armor testing will likely be more effective than mandating a single national standard. As an important step in this process, the committee agrees that the ad hoc clay working group approach that was started by and is currently chaired by DOT&E provides a way ahead. The clay working group

consists of four sub-groups: clay properties, clay calibration, clay working techniques, and future efforts. The working group and its subgroups consist of testing experts that represent the expertise of various organizations involved with body armor testing. The committee received several briefings from members of the working group. The committee was impressed that all briefers conveyed the impression of willingness to exchange information, learn from each other, and work toward achieving more consistent testing procedures. The committee applauds this approach and believes that the effort should be continued and emphasized by DOT&E and the other participating organizations. Some continuing and future actions should be emphasized and resourced for the clay working group that could help lead to a single national body armor testing standard:

-

Continue to improve existing body armor testing procedures by collaborating and investigating clay properties, formulation, calibration and working techniques.

-

Continue to collaborate on alternatives to the procedures and standards.

-

Continue to gather detailed information that defines and explains the reasons for different testing procedures that are used by various organizations.

-

Determine areas where synchronization of processes among organizations makes sense.

-

Determine areas where different missions, customer requirements, resources, and other organizational considerations provide a reasonable rationale for different testing procedures to be retained, at least in the short term.

-

Determine areas that need more detailed data and analysis before procedure and process synchronization recommendations can be made. In these cases, it would be useful to design experiments, gather data, and perform analysis that could lead to informed recommendations to the chains of commands of the participating organizations.

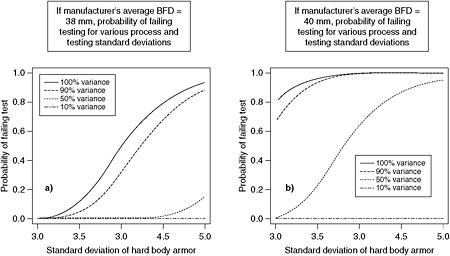

-