6

Hybrid Power Trains

INTRODUCTION

Hybrid vehicles achieve reduced fuel consumption by incorporating in the drive train, in addition to an internal combustion (IC) engine, both an energy storage device and a means of converting the stored energy into mechanical motion. Some hybrids are also able to convert mechanical motion into stored energy. In its most general sense, the storage device can be a battery, flywheel, compressible fluid, elastomer, or ultra capacitor. The means of converting energy between storage and mechanical motion is through the use of one or more motors/generators (e.g., electric, pneumatic, hydraulic). In motor mode, these devices convert stored energy into mechanical motion to propel the vehicle, and in generator mode, these devices convert vehicle motion into stored energy by providing part of the vehicle braking function (regeneration). Similarly, a fuel cell vehicle is also a hybrid in which the internal combustion engine is replaced by the fuel cell, but this system will likely need supplemental energy storage to meet peak power demands and to allow the fuel cell to be sized for the average power requirement.

In this chapter, hybrid vehicle designs employing an internal combustion engine and battery-energy storage are considered. Battery electric and fuel cell vehicles (BEVs and FCVs) are also briefly discussed as other alternative power trains.

Hybrid electric vehicles incorporate a battery, an electric motor, and an internal combustion engine in the drive train. In its most effective implementation this configuration permits the IC engine to shut down when the vehicle is decelerating and is stopped, permits braking energy to be recovered, and permits the IC engine to be downsized and operated at more efficient operating points. It should be emphasized that the benefits of hybrids are highly dependent on the drive cycle used to measure fuel consumption. For example, a design featuring only idle-stop operation, which shuts off the internal combustion engine when the vehicle is stopped, will demonstrate a large improvement on the city cycle portion of the Federal Test Procedure (FTP), where stop-start behaviors are simulated, but virtually no improvement on the highway cycle.

In addition to the introduction of an electric motor, hybrid designs may include the functions of idle-stop and regenerative braking, and the IC engine is frequently downsized from that in its equivalent conventional vehicle. As shown in Table 6.A.1 in the annex at the end of this chapter, for a hybrid vehicle, these operational and physical changes alone or in combination can result in an increase in fuel economy (mpg) of between 11 and 100 percent or a decrease in fuel consumption (gallons per 100 miles driven) of between 10 and 50 percent, depending on the vehicle class, as is discussed below in this chapter. Hybrid vehicles are the fastest-growing segment of the light-duty vehicle market, although they still make up less than 3 percent of the new car market in the United States.

HYBRID POWER TRAIN SYSTEMS

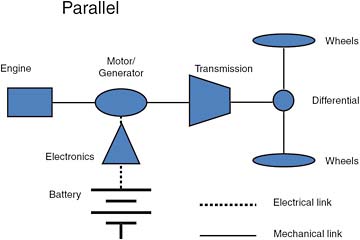

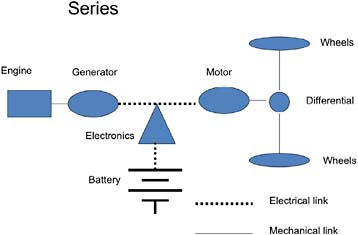

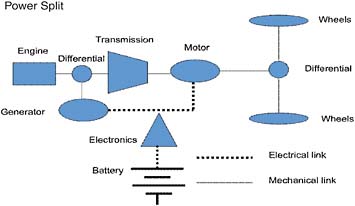

As stated above, hybrid vehicles are defined as having an internal combustion engine and one or more electric machines that in some combination can provide tractive force to propel the vehicle. An exception to this definition is the simple idle-stop design, which provides no electrically derived tractive force. Depending on the architectural configuration of the motors, generators, and engine, hybrid designs fall into three classes—parallel, series, and mixed series/parallel. The third design is commonly known as power split architecture. Schematics of these architectures are shown in Figures 6.1, 6.2, and 6.3. Within each class there are variations of implementation. Broadly defined, the series hybrid uses the internal combustion engine for the sole purpose of driving a generator to charge the battery and/or powering an electric drive motor. The electric motor provides all the tractive force. Energy flows from the IC engine through the generator and battery to the motor. In the parallel and mixed series/parallel designs, the IC engine not only charges the battery but also is mechanically connected to the wheels and, along with the electric motor, provides tractive power.

FIGURE 6.1 Schematic of parallel hybrid power train configuration.

FIGURE 6.2 Schematic of series hybrid power train configuration.

FIGURE 6.3 Schematic of power-split hybrid power train configuration.

Hybrid vehicles are further differentiated by the relative sizes of the IC engine, battery, and motor. Some of the more common variants of these broad classes are described in the following paragraphs. In all cases an economically and functionally significant component of the system is the power electronic subsystem necessary to control the electrical part of the drive train.

The hybridization of diesel (compression ignition; CI) vehicles is expected to have somewhat lower efficiency benefits than hybridization of gasoline vehicles, in part because conventional CI vehicles already exhibit lower fuel consumption than comparable gasoline vehicles. Further, CI vehicles also have very low fuel consumption at idle, making the benefits of idle-stop less attractive. Conventional CI power trains are more expensive than their gasoline counterparts (see Tables 5.4, 5.5, and 5.6), which, when added to the cost of hybridization, makes a CI hybrid power train very expensive for the additional fuel consumption reductions provided over and above just moving to a hybrid or CI power train alone. As a result, it is unlikely that original equipment manufacturers (OEMs) will offer a wide array of CI hybrids. The most likely levels of CI hybridization will be idle-stop and, perhaps, some mild hybrids. Idle-stop will not provide much fuel consumption reduction on the city driving portion of the FTP test cycle, upon which the judgments in this report are based. However, OEMs may still offer such technologies since they provide in-use fuel consumption reductions. In Europe, a number of new diesel hybrid vehicles have been announced for production in 2010 or 2011, especially for larger and heavier vehicles (e.g., Land Rover).

There are numerous hybrid vehicles now in production, and the committee believes it is more representative to quote actual data rather than analyze the effectiveness of each design to estimate fuel consumption benefits. This is preferable to having the committee and its consultants estimate fuel consumption benefits through simulations. It is assumed that the production vehicles are designed to meet customer expectations, including acceleration, passenger space, and adequate trunk space. The average fuel consumption of production hybrid HEVs was determined from fuel economy data supplied by Oak Ridge National Laboratory and included as Table 6.A.1 in the annex at the end of this chapter.

Belt-Driven Alternator/Starter

In the belt-driven alternator/starter (BAS) design, sometimes known as a micro or mild hybrid, the starter and generator of a conventional vehicle are replaced by a single belt- or chain-driven larger machine, capable of both starting the engine and generating electric power. In some BAS designs, in addition to the new belt-driven starter generator, the original geared-to-flywheel starter is retained for cold starts. Fuel consumption is reduced by turning off and decoupling the engine at idle and during deceleration. In some designs, particularly those that have replaced the belt with a chain for

increased torque transmission, both electric vehicle launch and some degree of braking energy regeneration are possible.

This mode of operation is known as idle-stop, and while not technically qualifying as a hybrid since the motor/generator provides no or little tractive power, it is included in this chapter for completeness. Idle-stop designs reduce fuel consumption by up to 6 percent in urban driving with SI engines (Ricardo, Inc., 2008). For SI engines having variable valve timing to reduce inlet throttling loss the benefit may be less than 6 percent. For CI engines, the benefit of idle-stop drops to about 1 percent because CI engines are more efficient at idle due to their lack of inlet throttling.

The BAS design is not quite as simple as it first appears. Maintaining hydraulic pressure in the automatic transmission is necessary for smooth and rapid restart, and safety issues related to unexpected restart must be considered. The company ZF has designed a transmission that provides a means of maintaining hydraulic pressure using a “hydraulic impulse storage device” that appears to address the transmission problem (Transmission Technology International, 2008), which is also addressed in existing designs by an electrically driven hydraulic pump.

Full Hybrid

The full hybrid (HEV) has sufficient electrical energy storage and a powerful enough electric motor to provide significant electrical assist to the IC engine during acceleration and regeneration during braking. There are several architectural approaches to achieving a full hybrid, the three in current production being the integrated starter/generator (ISG) or integrated motor assist (IMA), the power split, and the two-mode. These are all parallel or power split designs. The HEV may also provide a limited electric-only range if the battery capacity and motor size are sufficient.

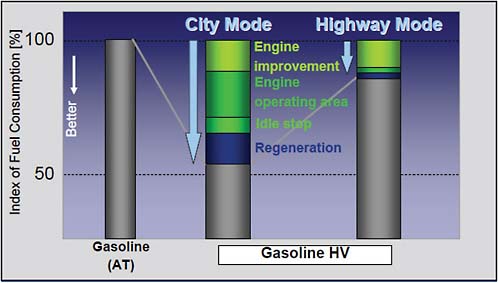

The ratio of electric to mechanical power provided for propulsion of an HEV varies with driving conditions and the state of charge of the battery. This operational feature is accomplished with sophisticated computer controls. Commercially available HEVs such as the Toyota Prius, Honda Civic, Nissan Altima, or Ford Escape can support a limited all-electric range at limited speeds. In these vehicles the battery is operated in a charge-sustaining (CS) mode; that is, the state of charge (SOC) of the battery is allowed to vary over a very narrow range, typically 15 to 20 percent, to ensure long battery life. The IC engine operates over a narrow speed/load range to improve efficiency, and regeneration is employed to recover braking energy. According to Toyota, as shown in Figure 6.4, the contributions of stop-start, regenerative braking, and engine modifications to fuel consumption improvements are approximately 5, 10, and 30 percent, respectively.

ISG/IMA Hybrid

In the ISG/IMA design, the starter and generator are replaced by a larger electrical machine connecting the engine and transmission. These vehicles generally use a larger

FIGURE 6.4 Individual technology contributions to fuel consumption in hybrid electric vehicles. SOURCE: Fushiki and Wimmer (2007). Reprinted with permission.

battery and a higher voltage (e.g., 140 V) than the BAS. Additionally, the motor/generator and battery are powerful enough to provide electrical launch from a stop and the ability to support some degree of electric-only travel. In its simplest form the ISG is mechanically fixed to the IC engine crankshaft, but in some designs a second clutch isolates the engine and the electrical machine to enable larger regeneration of braking energy (Dan Hancock, General Motors, personal communication, November 30, 2007). When incorporating an effective regenerative braking system, the ISG hybrid achieves a fuel consumption reduction of 34 percent in the combined driving cycle, as demonstrated by the Honda Civic. A part of the improved fuel consumption comes from vehicle modifications, including the use of a smaller, more efficient SI engine.

Power-Split Hybrid

The power-split hybrid design, typified by the Toyota Prius, the Ford Escape, and the Nissan Altima, incorporates a differential gear set that connects together the IC engine, an electrical generator, and the drive shaft. The drive shaft is also connected to an electric motor. This mechanical configuration incorporating the addition of a generator provides the flexibility of several operational modes. In particular the wheels can be driven by both the IC engine and the electric motor, with the motor’s power coming from the generator, not the battery. The car is thus driven in both series and parallel modes simultaneously, which is not a possible mode for the ISG design. This operational mode allows the IC engine operation to be optimized for maximum reduction in fuel consumption. The vehicles that use this power split design show a range of fuel consumption reduction from 10 to 50 percent. The low end of this range is the Toyota Lexus, the design of which is optimized for performance, not low fuel consumption. In Chapter 9, where the committee estimates fuel consumption benefits for vehicle classes, the Lexus is not used in the range of benefits for the power split design. This gives the fuel consumption benefits from the power split design a range of 24 to 50 percent.

General Motors (GM) is working with BMW and Chrysler on a different split hybrid architecture that uses the so-called two-mode system (Grewe et al., 2007). This also splits the power flow from the engine but uses more clutches and gears to match the load to the drive and minimize electrical losses. The claim is that by using multiple gears the drive is more efficient in real-world driving situations and reduces fuel consumption when towing a trailer or driving at high speed. Toyota is using a similar approach with one or two gears in its latest hybrid systems. The fuel consumption reduction for the two-mode power split design, characterized by the Chevrolet Tahoe and Saturn Vue, ranges from 25 to 29 percent. However, the committee thinks that other implementations of the two-mode system could provide a maximum fuel consumption benefit of about 45 percent.

Series Hybrid

The series HEV is configured with the engine driving a generator providing electric power to charge the battery. The wheels are driven by an electric motor powered from the battery. The only function of the IC engine is to charge the battery while driving. Because there is no mechanical connection between the IC engine and the wheels, the motor and the battery must be sized for the vehicle’s full torque and power requirements. The advantages of this configuration are that a smaller engine can be used since it is not required to provide the power needed for acceleration, and the engine can be optimized with respect to fuel consumption. At present the only OEM planning a series hybrid is GM, which is proposing it as a plug-in hybrid electric vehicle (PHEV).

Plug-In Hybrid

The principal difference between the previously described HEV variants and the PHEV is that the latter is fitted with a larger battery that can be charged from the electric utility grid (“plugged in”) and that operates in a charge-depleting mode; that is, the state of charge of the battery is allowed to vary over a much larger range, 50 percent being typically proposed. The significant fuel consumption benefit is obtained during urban driving when the vehicle can be driven on electric power only. Once the all-electric range has been achieved and the battery discharged to its lowest allowable state of charge, the vehicle is operated in the charge-sustaining mode and differs little from the HEV. A small industry has developed around the conversion of the Prius power-split HEVs to PHEVs by supplementing the battery and modifying the control electronics.

PHEVs require a much larger battery than other hybrids (4 to 24 kWh)1 depending on the desired electric-only range. There has been much activity related to PHEVs since the committee inaugurated its work in 2007. The General Motors Volt mentioned above is planned for introduction in 2010 provided that a suitable battery is developed (Tate et al., 2009). The Volt currently is expected to be launched late in 2010 as a 2011 model. Toyota has also announced plans for a plug-in hybrid for 2011, although it will be built on a Prius platform using its power split architecture (Fushiki and Wimmer, 2007). In addition to the Volt and the Prius, the Volkswagen Golf PHEV is expected in 2010 and Ford’s Escape SUV PHEV is due out to the general public in 2012. A PHEV in China went on sale to the public in China early in 2010.

While the micro and ISG hybrids offer some improvement in fuel consumption for a relatively modest cost, it is

the power-split HEV and PHEV architectures that promise a significant improvement. The PHEV also offers the long-term potential for displacing fossil fuels with other primary energy sources such as nuclear or renewable sources of electricity, depending on the fuel source of the electric grid from which the PHEV draws electricity.

Battery Electric Vehicles

The prospect for widespread introduction of full-performance all-electric vehicles depends on significant advancements of the battery technologies discussed above, and the commercial viability of these vehicles depends on a battery cost breakthrough. Advances in electric motors, power electronics, and batteries for automotive applications, which have resulted from the development and production of hybrid vehicles, have renewed interest in the development of battery electric vehicles. However, the cost, low energy density, and required charging time of batteries will continue to constrain the introduction of BEVs. The high low-speed torque performance of electric motors gives the BEV a potential acceleration advantage over conventional internal combustion engine-powered vehicles, and this can be an attractive feature for some customers

A review of zero-emission vehicle technology commissioned by the California Air Resources Board (CARB) concluded that commercialization (tens of thousands of vehicles) of full-performance battery electric vehicles would not occur before 2015 and that mass production (hundreds of thousands of vehicles) would not occur before 2030 (Kalhammer et al., 2007). These projections were based on the continued development of lithium-ion (Li-ion) battery technology leading to reduced cost, higher energy densities, and reduced charging times, all of which allow greater range. They pointed to a possible role for a limited range, city electric vehicle (CEV), which could meet the requirements of a majority of household trips. However, recent BEV introductions suggest that progress in the technology and acceptance of Li-ion batteries may be more rapid than the CARB study concluded.

Early commercial application of Li-ion battery technology to vehicles includes the Tesla Roadster, a high- performance sports car. This vehicle, of which about 1,000 have been sold, has a fuel consumption of 0.74 gal/100 miles (energy equivalent basis, EPA combined city/highway).2 The manufacturer claims a range of 244 miles (also EPA combined city/highway) and a useful battery life of more than 100,000 miles.3 The base price of $128,000 indicates the continuing problem of battery cost when used in near full-performance vehicles. Tesla has announced that it will produce and sell, at about half the price of the Roadster, a five-passenger BEV, the Tesla S, with a range of 160, 230, or 300 miles, depending on optional battery size.4 Nissan has also announced production of its Leaf EV, a five-passenger car with a range of 100 miles.5 This vehicle has a Li-ion battery with a total storage capacity of 24 kWh.

Within the horizon of this study, the most likely future for large numbers of battery electric vehicles in the United States is in the limited-range, small-vehicle market. Range extended electric vehicles (hybrids and PHEVs) are more likely to satisfy the electricity-fueled full-performance—market, from both cost and technological considerations, over the next 15 years.

BATTERY TECHNOLOGY

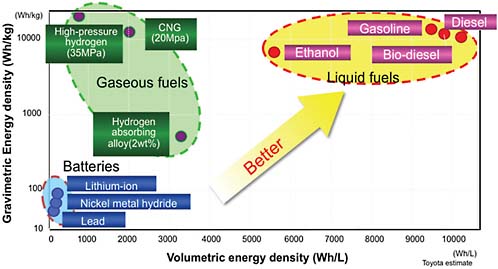

In spite of the significant progress that battery technology has experienced in the last 20 years, the battery is still the most challenging technology in the design of hybrid vehicles. Figure 6.5 illustrates the dramatic difference between the energy densities of today’s commercial batteries and gasoline, diesel fuel, ethanol, compressed natural gas, and hydrogen. At the time of this report, all production hybrid vehicles used batteries employing nickel-metal-hydride (NiMH) chemistry. It is anticipated that the NiMH battery will be replaced by Li-ion batteries in the near future. The acceptability of today’s hybrid vehicles has been shown to be strongly dependent on the price of gasoline, as evidenced by the rapid growth of hybrid sales in 2008, when gasoline prices were high, and the fact that hybrid sales dropped dramatically in early 2009 when prices returned to lower values. The key to improving the competitive position of hybrid vehicles of the HEV and PHEV types is the commercial development of batteries with parameters that are substantially better than those of today’s batteries, leading to reduced cost and size. The required parametric improvements are as follows:

-

Higher cycle life at increased SOC variation,

-

Higher energy density,

-

Higher power density, and

-

Lower cost.

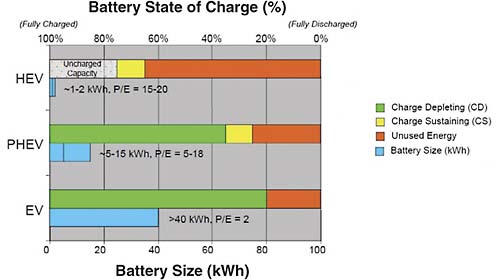

Figure 6.6 shows the desirable characteristics of batteries suitable for the HEV, the PHEV, and the all-electric (EV or BEV) vehicles. The HEV uses electric propulsion primarily as an assist to the IC engine, thus requiring a battery with a high power capability but relatively little energy capacity, i.e., a high power to energy (P/E) ratio. To preserve battery life and maintain the capacity to recover charge through regenerative braking, the battery is cycled over a relatively small state of charge. This mode of operation is known as charge sustaining (CS). The PHEV is expected to provide

|

2 |

California Air Resources Board (2009), available at http://www.driveclean.ca.gov. |

|

3 |

Tesla Motors (2009), available at http://www.teslamotors.com/display_data/teslaroadster_specsheet.pdf; IEEE Vehicular Technology, March 2010. |

|

4 |

See http://news.cnet.com/tesla-motors-ceo-model-s-is-cheaper-than-it-looks/. |

|

5 |

See http://www.nissanusa.com/leaf-electric-car/tour.jsp#/details. |

FIGURE 6.5 Volumetric and gravimetric energy densities of different energy storage mechanisms. SOURCE: Fushiki and Wimmer (2007). Reprinted with permission.

FIGURE 6.6 Energy capacity, state-of-charge variation, and relative power density to energy density ratios for batteries applicable to full-hybrid (HEV), plug-in hybrid (PHEV), and all-electric (EV) vehicles. The units of P/E are kW/kWh. SOURCE: Amine (2007).

some degree of electric-only range. Its battery must therefore contain sufficient energy to provide this range. The battery may be allowed to expend all of its stored energy to achieve this range goal, in which case the battery is said to be operated in the charge-depleting (CD) mode. The power requirement of this battery is not much different from that of the HEV battery, but because of the higher energy requirement, the P/E ratio is smaller. The BEV requires an even higher energy capacity battery than the PHEV, the value depending on the desired driving range. Since the BEV has no IC engine, its battery cannot be charged during driving, and therefore it cannot operate in a CS mode. In all cases the SOC variation

is limited to a specified range by the vehicle manufacturer to preserve battery cycle life. Figure 6.6 shows typical ranges for the HEV, PHEV, and BEV. Thus the usable energy is less than the battery rated (or “nameplate”) capacity.

Despite substantial improvements in the packaging and performance of lead-acid batteries, their energy and power densities are still considerably inferior to those of NiMH. And while other chemistries, like Li-air, have theoretically better performance than Li-ion, their development is not at a stage where one could envision them in practical automotive applications within the timeline of this study. Therefore the committee considers only NiMH and Li-ion as chemistries of interest here.

NiMH Batteries

The highest-performance battery currently available in commercially significant quantities for HEVs and PHEVs uses NiMH chemistry. Despite significant improvements in lifetime and packaging, these batteries are still expensive, heavy, and in application are restricted to a SOC range of about 20 percent to preserve battery cycle life. Because of their relatively poor charge/discharge efficiency, special consideration must be given to their thermal management. The NiMH chemistry also exhibits a high rate of self-discharge.

The most technically advanced NiMH battery used in the Toyota Prius has a weight of 45 kg and an energy capacity of 1.31 kWh. This results in a usable energy of approximately 0.262 kWh when applied with a SOC variation of 20 percent.

Li-Ion Batteries

The most promising battery technologies are those employing various Li-ion chemistries. Characteristics of the more common lithium-based cell compositions are shown in Table 6.1. The column heads denote the common abbreviation for the different chemistries: NCA ( nickel-cobalt-aluminum), LFP (lithium-iron-phosphate), MS (manganese-spinel), MNS (manganese-nickel-spinel), and MN (manganese-nickel). The first entry gives the detailed composition of the anode and cathode materials, with the positive (cathode) material shown first. The second entry gives the gravimetric energy density of the chemistry in milliampere-hours/gram (mAh/g), the third entry shows the open-circuit terminal voltage when the cell is 50 percent depleted (50 percent state of charge), and the fourth entry gives the area specific impedance (ASI) as measured during a 10-second pulse at the 5C rate, which is indicative of the battery’s ability to provide power necessary for acceleration. The relative safety of the different chemistries is given in the fifth entry. The safety of using Li-ion batteries has received considerable attention since the 2006 recall of Li-ion batteries used in laptops. In some of the chemistries, particularly those using a cobalt (Co)-based cathode, failure can occur due to overheating or separator failure. This problem is well known, and safety is a characterizing parameter common to all the Li systems. Some manufacturers believe they can solve the safety problem through careful monitoring and charge control. Relative cost among the different Li chemistries is shown in the seventh entry, although at this time the absolute cost of all is considerably higher than the cost for NiMH. The last entry in Table 6.1 indicates the state of the technology. Pilot scale indicates that cells are currently being manufactured in sufficient quantities for testing in vehicle fleets of limited size. Development means that the chemistry is well controlled, but the production of practical cells is anticipated and under development. Research indicates just that—the chemistry is still a subject of research, and the production of cells using the chemistry has not been demonstrated to an extent sufficient to anticipate their use.

TABLE 6.1 Comparative Characteristics and Maturity of Lithium-Ion Battery Chemistries

The relative gravimetric energy densities of Li-ion, NiMH, and Pb-acid are approximately 4, 2, and 1, respectively. An additional advantage of the Li systems is their high cell potential, approximately 3 times that of NiMH. This means that 66 percent fewer Li-ion cells are required to achieve a given battery voltage. The ecologically benign materials in the Li-ion systems are also an advantage. A disadvantage of Li-ion cells is that the requirement for cleanliness in the manufacturing environment is considerably more severe than for NiMH cells (Zempachi Ogumi, Kyoto University, personal communication, December 8, 2008). This increases manufacturing costs. Another critical issue is how the performance of Li-ion batteries is impacted by low and high temperatures (Amine, 2007; Reilly, 2007; Andermann, 2007).

The first three columns in Table 6.1—NCA-Graphite, LFP-Graphite, and MS-TiO—represent the most promising Li-ion systems currently under development. The NCA-graphite chemistry is used by JCS/SAFT in its VL41M module that has undergone dynamometer testing in a Toyota Prius at Argonne National Laboratories (ANL) (Rousseau et al., 2007). The lithium-iron phosphate (LFP) system is currently receiving a great deal of attention because of its stability, potentially lower material costs, and its application in power tools. Its development is being aggressively pursued by A123 and Enerdel. The manganese-spinel-lithium-titanate system (MS-TiO) is the safest of any being studied because of the mechanical stability of the spinel structure, but its cell voltage is considerably lower than those of the NCA and LFP systems. However, it has the highest charge/discharge efficiency, and it is predicted to be the lowest-cost system. To put in perspective the merits of the Li-ion battery relative to NiMH, consider the requirements for a 20-mile all-electric range PHEV. According to an ANL study (Nelson et al., 2007), which assumed a 100 to 10 percent SOC range, the required battery capacity for its assumed vehicle is 6.7 kWh. For an MS-TiO battery the calculated weight is 100 kg. If an NiMH battery were used, with a SOC range of 20 to 80 percent and a gravimetric energy density one-half that of the MS-TiO system, the committee estimates that it would require a capacity of 10.35 kWh and weigh 300 kg.

The needs of HEVs and PHEVs are quite distinct, as shown in Figure 6.6. HEVs need high power density and long cycle life over a very small excursion of the SOC. For example the Prius battery has a nominal rating of 1.3 kWh but it uses only 260 Wh in +/−10 percent excursions around 50 percent SOC. On the other hand, the larger energy requirement of the PHEV argues for a battery with a higher energy rating and the capability of deeper cycling. The Volt, the PHEV being developed by GM, uses a 16-kWh battery to meet its advertised all-electric range of 40 miles. This is a substantial challenge to achieve at acceptable weight, volume, and cost. The Li-ion chemistry comes closest to meeting it, given the present state of battery development. It should be noted that the Volt is designed to use only 8 kWh by operating from 80 percent to 30 percent SOC.

POWER ELECTRONICS

The term power electronics refers to the semi conductor switches and their associated circuitry that are used to control the power supplied to the electrical machines or to charge the battery in an HEV or PHEV. For purposes of driving electric motors these circuits function as an inverter, changing the battery direct voltage into an alternating voltage of controlled amplitude and frequency. For charging the propulsion battery they function as a controlled rectifier, changing the ac voltage of the machine to the dc value required by the battery. The direction of power flow is either into or out of the battery, depending on vehicle mode of operation. Plug-in hybrids also require power electronic circuits to convert the ac main voltage to a precise dc voltage to charge the propulsion battery.

Power electronic circuits known as dc/dc converters change the propulsion battery dc voltage to the dc voltage appropriate to charging the accessory battery (i.e., the standard 12 V battery retained to power vehicle accessories). A dc/dc converter may also be used to increase system efficiency by stepping up the propulsion battery voltage before it is supplied to the inverter. The latest Toyota Prius uses such a design.

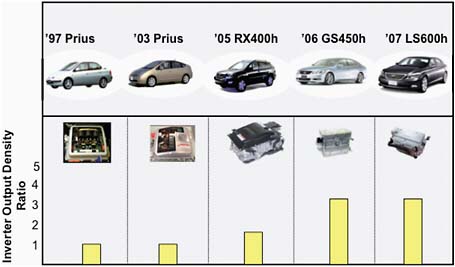

Both inverter and dc/dc converter technologies are well developed for industrial and other applications. The special problems for hybrid vehicles are cost, cooling, and packaging. Although the ambient environment for automotive electronics is much harsher than that in industrial or commercial applications, the cost in the automotive application is required to be lower. Figure 6.7 illustrates the improvement over a 10-year period in the volumetric power density of the motor drive inverter for Toyota’s hybrid product line. The significant improvement after 2005 is due in large measure to the increased switching frequency made possible by the higher-speed motor and higher voltage introduced in 2005. These changes reduce the physical size of magnetic components and improve the utilization of silicon devices. Both these consequences result in improved packaging density.

ROTATING ELECTRICAL MACHINES AND CONTROLLERS

With the possible exception of microhybrids, all vehicles use permanent magnet alternating current motors. Since the battery capacity is the key limitation for hybrid vehicles, electrical machine efficiency is of paramount importance. Most systems employ “buried magnet” rotating machine configurations with expensive rare-earth high-strength magnets. GM and Honda are using flat wire for the armature winding to increase efficiency. Although rectangular conductors are common for large machines, their use in relatively small machines shows the extent to which manufacturers are going to get better efficiency. Rotating machine technologies and designs are well developed, and the automotive applica-

FIGURE 6.7 Evolution of hybrid drive inverter volumetric power density. SOURCE: Fushiki and Wimmer (2007). Figure used with permission of Toyota.

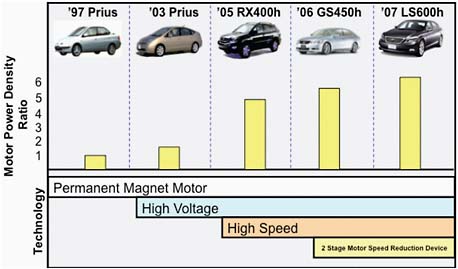

tion challenge is to lower their manufacturing cost. Because rotating machines are such a mature component, the cost of their manufacture in high volumes is driven principally by the cost of materials. Thus their cost is relatively unresponsive to technology developments. Major improvements in volumetric power density can be achieved by increasing the speed of the motor. This volumetric improvement results in materials reduction but generally also in increased losses. High-speed motors also require a gear set to match the mechanical speed required of the drive train. While the design of the motor/inverter system is an optimization problem, no technology breakthroughs that would radically improve the state of the art are foreseen. Figure 6.8 illustrates the improvement in volumetric power density that Toyota has achieved by increasing the speed of the electric motor in its hybrid vehicles.

Computers have been used to control emissions and optimize efficiency of conventional power trains. In addition to engine control, controllers in hybrid vehicles monitor the state of charge of the battery and determine power flows to and from the battery and engine. The control task is more complex for the PHEV where there is a greater opportunity to optimize the tradeoff between electric and IC engine use with respect to fuel consumption. One suggested approach is to have the controller predetermine the propulsion profile from expected route data provided by the driver or an off-board wirelessly connected server. Vehicle computers are powerful enough to handle these tasks, and no technical problems are expected.

FIGURE 6.8 Evolution of the volumetric power density of electric motors used in Toyota’s hybrid vehicles. SOURCE: Fushiki and Wimmer (2007). Figure used with permission of Toyota.

COST ESTIMATES

The objective in determining costs of new technologies is understanding their factory cost. The factory cost is the direct cost to the OEM of replacing existing production technology A by technology B. It is determined as follows:

-

Take the price (B) that a supplier charges the OEM for technology B;

-

Add the engineering cost (C) to the OEM of integrating technology B into a vehicle;

-

Add the cost (D) of any parts that the OEM makes in-house to implement the technology (labor cost plus factory overhead, plus amortization of required new investment); and

-

Subtract the cost (A) of technology A similarly calculated.

The factory cost is then B + C + D − A.

The cost estimates have been validated by soliciting feedback from a number of U.S. and Japanese OEMs and suppliers. The costs presented here are a consensus that the numbers are “about right.” The costs of hybrid technologies vary depending on the degree of hybridization, from a low cost in the case of the BAS design, to a very high cost for a series PHEV. It should be noted that the factory cost definition used here includes engineering costs and other part costs, including labor and overhead, for integrating the technology. Using the studies described in Chapter 3, the committee developed a different markup factor for hybrids that relates the definition of factory cost to RPE. Although different studies use different definitions and allocations for items such as profit, vehicle warranty, corporate overhead, transportation, marketing, and dealer costs, the committee concluded that the factory markup for hybrids should be on the order of 1.33 rather than 1.5 for factory cost to RPE. The committee’s justification for using an RPE of 1.33 for hybrids is that the factory cost estimates it developed already include engineering costs and other part costs, including labor and overhead, for integrating the technology. Using a cost multiplier of 1.5 would double count these costs.

As an example of the process, Table 6.2 shows an estimated breakdown of the factory cost of a “mature” Prius—a Prius-type drive that has benefited from the learning curve and has an annual production volume in excess of 100,000 units. The additional components and their estimated OEM costs from the supplier are listed. The committee also lists the cost decrement of items, such as the automatic transmission, that will be removed from the baseline vehicle, a Toyota Corolla in this case. The net cost increase for the mature Prius is then calculated as $3,385.

Next the committee projects costs for 5-year increments to 2025, as shown in Table 6.3. Percentage cost reductions

TABLE 6.2 Factory Cost Estimation Process Applied to a Mature Prius-type Hybrid Vehicle in U.S. Dollars

|

20 kW |

Factory Cost (B + C + D − A) |

|

Motor/generator/gears |

1,100 |

|

Control electronics + dc/dc (1.2 kW) |

1,100 |

|

Battery (NiMH 21 kW) |

1,000 |

|

Electrical accessories |

100 |

|

Electric PS and water pump |

200 |

|

Automatic transmission |

−850 |

|

Regenerative brakes |

250 |

|

Electric A/C |

300 |

|

Engine downsize |

−120 |

|

Starter and alternator |

−95 |

|

High-voltage cables (Martec 500 V) |

200 |

|

Body/chassis/special components |

200 |

|

Total |

3,385 |

TABLE 6.3 Projections of the Future Factory Cost of a Mature Prius-type Hybrid in U.S. Dollars

|

20 kW |

Factory Cost (B + C + D − A) |

||||

|

Cost Reductions (%) |

2008 |

2015 |

2020 |

2025 |

|

|

Motor/generator/gears |

5 |

1,100 |

1,050 |

990 |

940 |

|

Control electronics + dc/dc (1.2 kW) |

15 |

1,100 |

940 |

800 |

680 |

|

Battery (NiMH 21 kW, Li-ion Martec) |

15 |

1,000 |

850 |

720 |

720 |

|

Electrical accessories |

5 |

100 |

90 |

90 |

85 |

|

Electric PS and water pump |

5 |

200 |

190 |

180 |

170 |

|

Automatic transmission |

0 |

−850 |

−850 |

−850 |

−850 |

|

Regenerative brakes |

5 |

250 |

240 |

230 |

210 |

|

Electric A/C |

10 |

300 |

270 |

240 |

220 |

|

Engine downsize |

0 |

−120 |

−120 |

−120 |

−120 |

|

Starter and alternator |

0 |

−95 |

−95 |

−95 |

−95 |

|

High-voltage cables (Martec 500 V) |

10 |

200 |

180 |

160 |

150 |

|

Body/chassis/special components |

10 |

200 |

180 |

160 |

150 |

|

Total |

|

3,385 |

2,925 |

2,505 |

2,260 |

appropriate for each component are used. For example, expected reductions are on the order of 15 percent for each 5-year period for the battery and control electronics, 5 percent for the electrical machines, and no change in cost for the mature components such as engine downsizing, and the alternator.

A similar analysis has been done for the other hybrid classes, and the summary results are shown in Table 6.4. It should be noted that future costs for PHEVs and EVs are highly uncertain due to the uncertainties in future battery chemistries and tradeoffs between power and energy. Li-ion batteries for consumer electronics are a commercial technology, and costs have gone down along the learning curve. However, many OEMs and battery suppliers are expecting large cost reductions for Li-ion batteries with increasing applications in vehicles. Among its provisions related to fuel economy, the Energy Independence and Security Act of 2007 requires periodic assessments by the National Research Council of automobile vehicle fuel economy technologies. Thus, follow-on committees will be responsible for responding to this legislative mandate, including the periodic evaluation of PHEVs, EVs, and other technologies and how these technologies can help meet new fuel economy standards.

TABLE 6.4 Retail Price Estimates for Various Types of Hybrids Projected to 2025 (using an RPE of 1.33)

|

Vehicle |

2009 ($) |

2015 ($) |

2020 ($) |

2025 ($) |

|

Prius-type power split |

4,500 |

3,900 |

3,300 |

3,000 |

|

BAS/12 V |

670 |

570 |

490 |

440 |

|

BAS/42 V |

1,500 |

1,200 |

1,100 |

1,000 |

|

ISG 12 kW/144 V |

2,900 |

2,500 |

2,100 |

2,000 |

|

Prius-type PHEV 10 (Li-ion battery) |

8,800 |

7,600 |

6,500 |

5,900 |

|

Series PHEV 40 (Li-ion battery) |

13,000 |

11,000 |

9,800 |

8,900 |

|

HEV crossover (V6) |

6,900 |

6,000 |

5,200 |

4,700 |

|

Large SUV/pickup (V8) |

8,700 |

7,500 |

6,400 |

5,700 |

FUEL CONSUMPTION BENEFITS OF HYBRID ARCHITECTURES

As noted earlier, the average fuel consumption of production hybrid HEVs was determined from fuel economy data supplied by Oak Ridge National Laboratory and included as Table 6.A.1 in the annex at the end of this chapter. For several specific models, these data were compared to data from conventional (nonhybrid) vehicles of approximately similar performance and physical specifications, and the results are shown in Table 6.5. As mentioned earlier, a significant contribution to the fuel consumption benefit of hybrid vehicles is due to modifications to the engine, body, and tires. For example, the fuel economy of the Prius is significantly influenced by engine improvements and optimized operating area. The 2007 model-year version of the Saturn Vue hybrid, which used a BAS design, exhibits a 25 percent improvement in fuel economy on the FTP cycle, but approximately half of that improvement is due to vehicle modifications, including a more aggressive torque converter lockup and fuel cutoff during vehicle deceleration (D. Hancock, General Motors, personal communications, November 30, 2007).

The Oak Ridge data did not include information on the Honda Accord, which was discontinued in 2007. The Accord has a motor/generator of 15 kW in motoring mode and a slightly higher 15.5 kW in regenerative mode (J. German, Honda, personal communication, February 28, 2008). The motor generator has high-energy-density magnets in an interior configuration. It also has flat wire windings that provide better packing density compared to round wire. The NiMH battery has 132 cells with a nominal voltage and energy of 144 V and 0.87 kWh, respectively (Iijima, 2006). Honda calls the system an integrated motor assist.

Plug-In Hybrids

The rules for assigning fuel economy ratings to plug-in hybrids are currently being developed by SAE (revision of J 1711). Thus the committee cannot predict at this time what

TABLE 6.5 Comparison of Fuel Economy, Fuel Consumption, Performance, and Physical Specifications of Hybrid and Comparable SI Engine-Powered Vehicles

|

Architecture |

Volume Trunk |

EPA Test (mpg, combined) |

Fuel Consumption (gal/100 mi) |

EPA Test Car Weight |

Acceleration (Consumer Reports, mph/sec) |

Edmund’s MSRP Price |

||

|

0 to 30 |

0 to 60 |

45 to 65 |

||||||

|

Prius |

|

|

|

|

|

|

|

|

|

Prius/Corolla |

1.33 |

1.64 |

0.61 |

1.13 |

1.06 |

1.07 |

1.05 |

1.36 |

|

Prius/Camry |

1.07 |

2.00 |

0.50 |

0.87 |

1.03 |

1.10 |

1.03 |

1.09 |

|

Honda Civic |

|

|

|

|

|

|

|

|

|

Civic hybrid/Civic SI |

0.83 |

1.51 |

0.66 |

1.00 |

1.22 |

1.16 |

1.22 |

1.45 |

|

Chevy Tahoe 4WD |

|

|

|

|

|

|

|

|

|

Tahoe 4WD Hybrid/Tahoe 4WD SI |

N/A |

1.53 |

0.65 |

1.00 |

1.15 |

1.07 |

0.96 |

1.30 |

the official fuel economy rating of a specific PHEV design will be. At the time of this writing only two PHEVs have been announced for production—the GM Volt, which is expected to have a 40-mile range on battery alone, and the Toyota plug-in Prius, which will have a 12-mile all-electric range and the ability to cruise at highway speeds under all electric power.6 GM has announced that LG Chem of Korea will be supplying the Volt’s Li-ion battery.

FUEL CELL VEHICLES

Fuel cell vehicles have the potential to significantly reduce greenhouse gas emissions (depending on how hydrogen is produced) as well as U.S. dependence on imported oil over the long term. However, fuel cell vehicle technologies have technical challenges that are severe enough to convince the committee that it is unlikely such vehicles will be deployed in significant numbers within the time horizon of this study.

A recent report (NRC, 2008) states that under the following set of very optimistic assumptions, 2 million fuel cell vehicles could be part of the U.S. fleet in 2020:

-

The technical goals are met and consumers readily accept such vehicles.

-

Policy instruments are in place to drive their introduction.

-

The necessary hydrogen production, supply, distribution, and fueling infrastructure is present.

-

Oil prices are at least $100/barrel by 2020.

-

Fuel cell vehicles are competitive on the basis of lifecycle cost.

Although the committee agrees with that study’s conclusions under these optimistic assumptions, it believes that achieving them is unlikely. Almost every major OEM has a fuel cell vehicle program, and several have deployed limited fleets of experimental vehicles. These fleets invariably represent limited mission, localized experiments, city buses, or postal vehicles, for example. Through interviews and presentations, the committee can find little evidence that a commercially viable fuel cell light-duty vehicle will be available in significant numbers by 2020. The Japanese auto industry will not decide to pursue a commercial development program until 2015, thus making a 2020 introduction date very difficult. The committee confirmed this target decision date with Japan’s NEDO, Japanese academics, and the OEMs themselves. All current fuel cell vehicle research assumes stored hydrogen as the fuel. The monumental difficulty of providing the necessary hydrogen distribution infrastructure is another factor mitigating against the presence of fuel cell vehicles in significant numbers by 2020.

For fuel cells, in spite of hundreds of millions of dollars having been devoted to their development by vehicle builders, equipment suppliers, and government organizations, there remain significant problems requiring technical and economic resolution, including the following:

-

Higher cost of fuel cells compared to other energy converters,

-

Lack of a hydrogen distribution infrastructure,

-

Need for a low carbon source of hydrogen (biomass or water electrolysis using electricity produced with low emissions),

-

Need to demonstrate acceptable durability and reliability, and

-

Weight and volume of an on-board hydrogen storage tank sized for a range of 300 to 400 miles.

Because of these factors, the committee does not expect wide use of fuel cell vehicles before 2025.

FINDINGS

Finding 6.1: The degree of hybridization can vary from minor stop-start systems with low incremental costs and modest reductions in fuel consumption (i.e., the most basic stop-start systems may have a fuel consumption benefit of up to about 4 percent at an estimated incremental retail price equivalent (RPE) cost of $670 to $1,100) to complete vehicle redesign (e.g., Prius) and downsizing of the SI gasoline engine at a high incremental RPE cost ($3,000 to $9,000) and with significant reductions in fuel consumption. A significant part of the improved fuel consumption of production hybrid vehicles comes from vehicle modifications such as low-rolling-resistance tires, improved aerodynamics, and the use of smaller, more efficient SI engines.

Finding 6.2: In the next 10 to 15 years, improvements in hybrid vehicles will occur primarily as a result of reduced costs for hybrid power train components and improvements in battery performance such as higher power per mass and volume, increased number of lifetime charges, and wider allowable state-of-charge ranges.

Finding 6.3: During the past decade, significant advances have been made in lithium-ion battery technology. When the cost and safety issues associated with Li-ion batteries are resolved, they will replace NiMH batteries in HEVs and PHEVs. A number of different Li-ion chemistries are being studied, and it is not yet clear which ones will prove most beneficial.

Finding 6.4: Given the high level of activity in lithium-ion battery development, plug-in hybrid electric vehicles will be commercially viable and will soon enter at least limited production. However, improving the cost-effectiveness of PHEVs depends on the cost of fuel and whether significant reductions in battery cost are achieved.

Finding 6.5: The practicality of full-performance battery electric vehicles (i.e., with driving range, trunk space, volume, and acceleration comparable to those of internal combustion-powered vehicles) depends on a battery cost breakthrough that the committee does not anticipate within the time horizon considered in this study. However, it is clear that small, limited-range, but otherwise full-performance battery electric vehicles will be marketed within that time frame.

Finding 6.6: Although there has been significant progress in fuel cell technology, it is the committee’s opinion that fuel cell vehicles will not represent a significant fraction of onroad light-duty vehicles within the next 15 years.

REFERENCES

Amine, K. 2007. Advanced high power chemistries for HEV applications. Presentation to the National Research Council Committee on the Assessment of Technologies for Improving Light-Duty Vehicle Fuel Economy, November 27, Washington, D.C.

Andermann 2007. Lithium-ion batteries for hybrid electric vehicles: Opportunities and Challenges. Presentation to the National Research Council Committee on the Assessment of Technologies for Improving LightDuty Vehicle Fuel Economy, October 25, Washington, D.C.

California Air Resources Board. 2009. DriveClean. Available at http://www.driveclean.ca.gov. Accessed June 29, 2009.

Fushiki, S., and B. Wimmer. 2007. Perspectives from Toyota. Presentation to the National Research Council Committee on the Assessment of Technologies for Improving Light-Duty Vehicle Fuel Economy, November 27, Washington, D.C.

Grewe, T.H., B.M. Conlon, and A.G. Holmes. 2007. Defining the General Motors 2-mode hybrid transmission. SAE Paper 2007-01-0273. SAE International, Warrendale, Pa.

Iijima, T. 2006. Development of hybrid system for 2006 compact sedan. SAE Paper 2006-01-1503. SAE International, Warrendale, Pa.

Kalhammer, F.R., B.M. Kopf, D.H. Swan, V.P. Roan, and M.P. Walsh. 2007. Status and Prospects for Zero Emissions Vehicle Technology. Report presented to ARB Independent Expert Panel, April 13, State of California Air Resources Board, Sacramento.

Nelson, P., K. Amine, and H. Yomoto, 2007. Advanced lithium-ion batteries for plug-in hybrid-electric vehicles. Paper presented at 23rd International Electric Vehicle Symposium, December, Anaheim, Calif.

NRC (National Research Council). 2008. Transitions to Alternative Transportation Technologies: A Focus on Hydrogen. The National Academies Press, Washington, D.C.

Reilly, B. 2007. Battery Technologies. Presentation to the National Research Council Committee on the Assessment of Technologies for Improving Light-Duty Vehicle Fuel Economy, October 25, Washington, D.C.

Ricardo, Inc. 2008. A Study of Potential Effectiveness of Carbon Dioxide Reducing Vehicle Technologies. Prepared for the U.S. Environmental Protection Agency. EPA420-R-08-004. Contract No. EP-C-06-003. Work Assignment No. 1-14. Ann Arbor, Mich. Available at http://www.epa.gov/oms/technology/420r08004a.pdf. Accessed June 29, 2009.

Rousseau, A., N. Shidore, R. Carlson, and P. Nelson. 2007. Research on PHEV battery requirements and evaluation of early prototypes. Paper presented at the Advanced Automotive Battery Conference, May 17, Long Beach, Calif.

Tate, E.D., M.O. Harpster, and P.J. Savagian. 2009. The electrification of the automobile: From conventional hybrid, to plug-in hybrids, to extendedrange electric vehicles. SAE International 1(April):156-166.

Tesla Motors, Inc. 2009. Tesla Roadster Spec Sheet. Available at http://www.teslamotors.com/display_data/teslaroadster_specsheet.pdf. Accessed June 29, 2009.

Transmission Technology International. 2008. ZF eight-speed hybrid. September, p. 10.

ANNEX

TABLE 6.A.1 Performance of Production Hybrid Vehicles from 2009 CAFE Certification Data

|

Make |

Type |

Model |

Drive |

Volume |

EPA Fuel Economy (unadjusted mpg) |

EPA Test |

Acceleration (Consumer Reports) |

Edmund’s MSRP |

||||

|

Trunk |

City |

Comb. |

Hwy |

Car Weight |

0 to 30 mph, sec. |

0 to 60 mph, sec. |

45 to 65 mph, sec. |

Price |

||||

|

Toyota |

Split |

Highlander Hybrid |

4WD |

NA |

35 |

35 |

35 |

5000 |

3.4 |

8.2 |

5 |

$34,700 |

|

Toyota |

|

Highlander |

4WD |

NA |

21 |

25 |

31 |

4750 |

3 |

8 |

5.1 |

$29,050 |

|

Toyota |

Split |

Prius |

FWD |

16 |

67 |

66 |

65 |

3250 |

3.8 |

10.6 |

6.2 |

$22,000 |

|

Toyota |

|

Corolla |

FWD |

12 |

35 |

40 |

49 |

2875 |

3.6 |

9.9 |

5.9 |

$16,150 |

|

Toyota |

|

Camry |

FWD |

15 |

27 |

33 |

44 |

3750 |

3.7 |

9.6 |

6 |

$20,195 |

|

Toyota |

|

Yaris |

FWD |

13 |

37 |

42 |

49 |

2625 |

4.1 |

11.4 |

6.9 |

$13,765 |

|

Toyota |

Split |

Camry Hybrid |

FWD |

11 |

44 |

46 |

48 |

4000 |

3.5 |

8.5 |

5.1 |

$26,150 |

|

Toyota |

|

Camry |

FWD |

15 |

27 |

33 |

44 |

3750 |

3.7 |

9.6 |

6 |

$20,195 |

|

Toyota |

|

Camry |

FWD |

15 |

25 |

30 |

40 |

3875 |

3.3 |

7.1 |

4.4 |

$24,215 |

|

Ford |

Split |

Escape Hybrid |

FWD |

NA |

45 |

44 |

43 |

4000 |

NA |

NA |

NA |

$29,645 |

|

Ford |

|

Escape |

FWD |

NA |

26 |

30 |

39 |

3625 |

NA |

NA |

NA |

$21,645 |

|

Ford |

|

Escape |

FWD |

NA |

23 |

27 |

36 |

3625 |

NA |

NA |

NA |

$24,465 |

|

Ford |

Split |

Escape Hybrid |

4WD |

NA |

37 |

37 |

37 |

4250 |

4.1 |

10.7 |

5.8 |

$31,395 |

|

Ford |

|

Escape |

4WD |

NA |

24 |

28 |

35 |

3875 |

3.3 |

10 |

6.4 |

$23,395 |

|

Ford |

|

Escape |

4WD |

NA |

22 |

26 |

33 |

3875 |

3 |

7.9 |

5.2 |

$26,215 |

|

Saturn |

Parallel |

Aura Hybrid |

FWD |

16 |

33 |

39 |

48 |

NA |

NA |

NA |

NA |

$26,325 |

|

Saturn |

|

Aura |

FWD |

16 |

28 |

34 |

47 |

4000 |

3.4 |

9.4 |

6.9 |

$22,655 |

|

Saturn |

|

Aura |

FWD |

16 |

21 |

26 |

36 |

4000 |

2.8 |

6.6 |

4.3 |

$27,250 |

|

Saturn |

|

Vue Hybrid |

FWD |

NA |

32 |

37 |

45 |

4000 |

4.2 |

10.9 |

7.3 |

$28,160 |

|

Saturn |

|

Vue |

FWD |

NA |

24 |

28 |

37 |

4000 |

NA |

NA |

NA |

$23,280 |

|

Saturn |

|

Vue |

FWD |

NA |

21 |

25 |

33 |

4250 |

NA |

NA |

NA |

$26,435 |

|

Honda |

Parallel |

Civic Hybrid |

FWD |

10 |

55 |

59 |

65 |

3125 |

4.4 |

11.7 |

7.3 |

$23,650 |

|

Honda |

|

Civic |

FWD |

12 |

33 |

39 |

51 |

3125 |

3.6 |

10.1 |

6 |

$16,305 |

|

Nissan |

Parallel |

Altima Hybrid |

FWD |

10 |

47 |

47 |

47 |

3750 |

3.1 |

7.6 |

4.4 |

$26,650 |

|

Nissan |

|

Altima |

FWD |

15 |

29 |

34 |

43 |

3500 |

3.2 |

8.1 |

5 |

$19,900 |

|

Mazda |

Split |

Tribute Hybrid |

FWD |

NA |

45 |

44 |

43 |

NA |

NA |

NA |

NA |

$28,175 |

|

Mazda |

|

Tribute |

FWD |

NA |

26 |

30 |

39 |

NA |

NA |

NA |

NA |

$21,790 |

|

Mazda |

|

Tribute |

FWD |

NA |

23 |

27 |

36 |

NA |

NA |

NA |

NA |

$23,055 |

|

Mazda |

Split |

Tribute Hybrid |

4WD |

NA |

37 |

37 |

37 |

NA |

4.1 |

10.7 |

5.8 |

$29,925 |

|

Mazda |

|

Tribute |

4WD |

NA |

24 |

28 |

35 |

NA |

3.3 |

10 |

6.4 |

$23,545 |

|

Mazda |

|

Tribute |

4WD |

NA |

22 |

26 |

33 |

NA |

3 |

7.9 |

5.2 |

$24,805 |

|

Mercury |

Split |

Mariner Hybrid |

FWD |

NA |

45 |

44 |

43 |

NA |

NA |

NA |

NA |

$30,090 |

|

Mercury |

|

Mariner |

FWD |

NA |

26 |

30 |

39 |

NA |

NA |

NA |

NA |

$22,650 |

|

Mercury |

|

Mariner |

FWD |

NA |

23 |

27 |

36 |

NA |

NA |

NA |

NA |

$23,660 |

|

Mercury |

Split |

Mariner Hybrid |

4WD |

NA |

37 |

37 |

37 |

NA |

4.1 |

10.7 |

5.8 |

$31,840 |

|

Mercury |

|

Mariner |

4WD |

NA |

24 |

28 |

35 |

NA |

3.3 |

10 |

6.4 |

$24,400 |

|

Mercury |

|

Mariner |

4WD |

NA |

22 |

26 |

33 |

NA |

3 |

7.9 |

5.2 |

$25,410 |

|

Make |

Type |

Model |

Drive |

Volume |

Official EPA (unadjusted mpg) |

EPA Test |

Acceleration (Consumer Reports) |

Edmund’s MSRP |

||||

|

Trunk |

City |

Comb. |

Hwy |

Car Weight |

0 to 30 mph, sec. |

0 to 60 mph, sec. |

45 to 65 mph, sec. |

Price |

||||

|

Chevrolet |

Parallel |

Malibu Hybrid |

FWD |

15 |

33 |

39 |

48 |

3875 |

4.1 |

10.3 |

6.9 |

$25,555 |

|

Chevrolet |

|

Malibu |

FWD |

15 |

27 |

33 |

43 |

3750 |

3.4 |

9.4 |

7 |

$21,605 |

|

Chevrolet |

|

Malibu |

FWD |

15 |

23 |

28 |

40 |

NA |

3 |

8.1 |

5.1 |

NA |

|

Lexus |

Split |

RX 400h Hybrid |

2WD |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

NA |

|

Lexus |

|

RX 350 |

2WD |

NA |

20 |

22 |

25 |

4250 |

NA |

NA |

NA |

$37,700 |

|

Lexus |

|

RX 350 |

2WD |

NA |

20 |

22 |

25 |

NA |

NA |

NA |

NA |

NA |

|

Lexus |

Split |

RX 400h Hybrid |

4WD |

NA |

NA |

NA |

NA |

NA |

2.9 |

7.4 |

4.6 |

NA |

|

Lexus |

|

RX 350 |

4WD |

NA |

22 |

26 |

32 |

4500 |

NA |

NA |

NA |

$39,100 |

|

Lexus |

|

RX 350 |

4WD |

NA |

22 |

26 |

32 |

NA |

2.7 |

7.3 |

4.8 |

NA |

|

Lexus |

Split |

GS 450h Hybrid |

RWD |

9 |

28 |

31 |

35 |

4500 |

2.5 |

5.9 |

3.9 |

$56,550 |

|

Lexus |

|

GS 350 |

RWD |

13 |

24 |

28 |

37 |

4000 |

NA |

NA |

NA |

$45,000 |

|

Lexus |

Split |

LS 600h L |

AWD |

12 |

25 |

27 |

30 |

5500 |

NA |

NA |

NA |

$106,035 |

|

Chevrolet |

Split |

Tahoe Hybrid |

RWD |

NA |

27 |

28 |

30 |

6000 |

NA |

NA |

NA |

$50,455 |

|

Chevrolet |

|

Tahoe |

RWD |

NA |

15 |

19 |

27 |

6000 |

NA |

NA |

NA |

Premium |

|

Chevrolet |

|

Tahoe |

RWD |

NA |

17 |

20 |

27 |

5500 |

NA |

NA |

NA |

$39,315 |

|

Chevrolet |

Split |

Tahoe Hybrid |

4WD |

NA |

27 |

28 |

30 |

6000 |

3.9 |

9.6 |

5.5 |

$53,260 |

|

Chevrolet |

|

Tahoe |

4WD |

NA |

15 |

18 |

26 |

6000 |

3.4 |

9 |

5.7 |

$41,025 |

|

Chevrolet |

Split |

Silverado Hybrid |

RWD |

NA |

27 |

28 |

30 |

NA |

NA |

NA |

NA |

$38,020 |

|

Chevrolet |

|

Silverado |

RWD |

NA |

17 |

21 |

27 |

5500 |

NA |

NA |

NA |

NA |

|

Chevrolet |

|

Silverado |

RWD |

NA |

18 |

21 |

27 |

5000 |

NA |

NA |

NA |

$26,915 |

|

Chevrolet |

Split |

Silverado Hybrid |

4WD |

NA |

27 |

28 |

30 |

NA |

|

|

|

$41,170 |

|

Chevrolet |

|

Silverado |

4WD |

NA |

17 |

20 |

27 |

5500 |

|

|

|

NA |

|

Chevrolet |

|

Silverado |

4WD |

NA |

18 |

21 |

27 |

5250 |

3 |

7.9 |

5.1 |

$30,065 |

|

GMC |

Split |

Yukon Hybrid |

RWD |

NA |

27 |

28 |

30 |

NA |

NA |

NA |

NA |

$50,920 |

|

GMC |

|

Yukon |

RWD |

NA |

15 |

19 |

27 |

NA |

NA |

NA |

NA |

Premium |

|

GMC |

|

Yukon |

RWD |

NA |

17 |

20 |

27 |

NA |

NA |

NA |

NA |

$39,970 |

|

GMC |

Split |

Yukon Hybrid |

4WD |

NA |

27 |

28 |

30 |

NA |

3.9 |

9.6 |

5.5 |

$53,730 |

|

GMC |

|

Yukon |

4WD |

NA |

17 |

20 |

27 |

NA |

3.4 |

9 |

5.7 |

$41,765 |

|

GMC |

Split |

Sierra Hybrid |

RWD |

NA |

27 |

28 |

30 |

NA |

NA |

NA |

NA |

$38,390 |

|

GMC |

|

Sierra |

RWD |

NA |

17 |

21 |

27 |

5500 |

NA |

NA |

NA |

NA |

|

GMC |

|

Sierra |

RWD |

NA |

18 |

21 |

28 |

NA |

NA |

NA |

NA |

$26,915 |

|

GMC |

Split |

Sierra Hybrid |

4WD |

NA |

27 |

28 |

30 |

NA |

NA |

NA |

NA |

$41,540 |

|

GMC |

|

Sierra |

4WD |

NA |

17 |

20 |

27 |

NA |

NA |

NA |

NA |

NA |

|

GMC |

|

Sierra |

4WD |

NA |

18 |

21 |

27 |

6000 |

3 |

7.9 |

5.1 |

$30,065 |

|

Dodge |

Split |

Durango Hybrid |

4WD |

NA |

25 |

27 |

30 |

NA |

NA |

NA |

NA |

$45,040 |

|

Dodge |

|

Durango |

4WD |

NA |

17 |

20 |

26 |

NA |

2.8 |

7.4 |

5.2 |

NA |

|

Chrysler |

Split |

Aspen Hybrid |

4WD |

NA |

25 |

27 |

30 |

NA |

NA |

NA |

NA |

$45,270 |

|

Chrysler |

|

Aspen |

4WD |

NA |

17 |

20 |

26 |

NA |

2.8 |

7.4 |

5.2 |

NA |

|

Cadillac |

Split |

Escalade Hybrid |

2WD |

NA |

27 |

28 |

30 |

NA |

NA |

NA |

NA |

$73,135 |