Appendix G

Regulations and Voluntary Use of Hearing Protection Devices

Both industrial workers and military personnel, the largest users of hearing protection devices (HPDs), are governed by regulations. In fact, regulation is a major reason the use of HPDs has proliferated. This appendix reviews the history of these regulations, focusing on the laws that affect the majority group (i.e., U.S. workers).

OSHA GENERAL INDUSTRY AND CONSTRUCTION REGULATIONS CIRCA 1971

OSHA—General Industry

The Occupational Safety and Health Administration (OSHA) Noise Standard for General Industry (29 CFR 1910.95(a)) specifies: “Protection against the effects of noise exposure shall be required when the sound levels exceed those shown in Table G-16 when measured on the A-scale of a standard sound level meter at slow response.” Table G-16 specifies a 90-dB(A) time weighted average (TWA) “criterion level” for an 8-hour exposure, including a 5-dB exchange rate between increased noise exposures and allowable exposure durations per day. So, for example, 95-dB(A) TWA is allowed for 4 hours, 100-dB(A) TWA is allowed for 2 hours, and so on, with a not-to-exceed 140-dB peak sound pressure level for impulsive or impact noise.

29 CFR 1910.95(b)(1) further states: “When employees are subjected to sound exceeding those listed in Table G-16, feasible administrative or engineering controls shall be utilized. If such controls fail to reduce sound levels within the levels of Table G-16, personal protective equipment shall be provided and used to reduce sound levels within the levels of the table.” Thus, this first OSHA regulation, via the words “shall be utilized,” required that feasible administrative or engineering controls take priority over hearing protection. However, a significant weakness was that the word “feasible” was not defined specifically in terms of technical, economical, or other criteria. This left room for industries to claim infeasibility.

Nevertheless, only if engineering or administrative controls fail to reduce noise to within the limits of Table G-16 are hearing protectors to be relied on under OSHA (1971b). Thus, in the earliest OSHA general industry regulations, HPDs were regulated as an augmentation to, and not a replacement for, administrative or engineering noise controls. In practice, however, HPDs are relied on in many industrial plants as the first line of defense against noise hazards to workers’ hearing, which violates the letter of the OSHA law.

OSHA—Construction

The law for construction work, 29 CFR 1926.52, cites Table D-2 (a duplicate of Table G-16) for exposure limits; it also includes the same statement about administrative and engineering controls having priority over HPDs (OSHA, 1971a). However, the construction regulation in 29 CFR 1926.101 has additional stipulations: (a) “Whenever it is not feasible to reduce the noise levels or duration of exposures to those specified in Table D-2, Permissible Noise Exposures, in 1926.52, ear protective devices shall be provided and used.” (b) “Ear protective devices inserted in the ear shall be fitted or determined individually by competent persons. (c) Plain cotton is not an acceptable protective device” (OSHA, 1971b). Subparts (b) and (c) may be a slight improvement over the general industry standard. However, overall, the construction standard became much weaker because it was never updated, as the general industry standard was.

OSHA GENERAL INDUSTRY—HEARING CONSERVATION AMENDMENT CIRCA 1983

The Hearing Conservation Amendment significantly improved the original OSHA noise standard by specifying that a multifaceted hearing conservation program is required when daily TWA noise exposures exceed 85 dB(A) (equivalent to a 50 percent noise dose; OSHA, 1983). The priority

of engineering and administrative noise controls remained; in addition to other facets of a hearing conservation program (including noise monitoring, employee notification, audiometric testing, worker training, access to information and training materials, and exposure and audiometric recordkeeping), the amendment specified the use of HPDs in more detail.

Perhaps the most significant addition, at 29 CFR 1910.95(i), was (1) that “employers shall make hearing protectors available to all employees exposed to an 8-hour time-weighted average of 85 decibels or greater at no cost to the employees. Hearing protectors shall be replaced as necessary” and (2) that “employers shall ensure that hearing protectors are worn: (i) by an employee who is required by paragraph 1910.95(b)(1) of this section to wear personal protective equipment [i.e., mandatory HPD use at exposures equal to or greater than 90 dB(A) TWA] and (ii) by any employee who is exposed to an 8-hour TWA of 85 decibels or greater, and who” has not had a baseline audiogram, or who has experienced a standard threshold shift (as defined by OSHA). In addition, employers were required, under paragraph 3, to provide “a variety of suitable hearing protectors” for the employee to select from; under paragraph 4 to provide training in the use and care of all hearing protectors; and under paragraph 5 to ensure proper initial fitting and supervision in the correct use of all hearing protectors. Finally, in part (j) the amendment specified computational procedures for evaluating HPDs for adequacy of protection in specific noise exposures, with the requirement that the protected exposure levels be brought to less than or equal to 90-dB(A) TWA, or to less than or equal to 85-dB(A) TWA if the worker has experienced a standard threshold shift.1

The OSHA Hearing Conservation Amendment greatly impacted the requirements for hearing protection, and the numbers of HPDs supplied in occupational settings dramatically increased as a result. Although engineering or administrative controls were still required for TWA exposures above 90 dB(A), the amendment provided, at no cost to workers, a selection of HPDs to everyone exposed to 85-dB(A) TWA or above. The 5-dB(A) difference between the 90-dB(A) OSHA “criterion” level imposed as a result of OSHA (1971) and the 85-dB(A) OSHA “action” level imposed as a result of the 1983 OSHA Hearing Conservation Amendment defined an exposure window wherein thousands of workers who had not been protected by law were now to be supplied with a selection of suitable HPDs.

In this sense the new 85-dB(A) TWA action level was a major step forward in protecting workers against the hazards of noise exposures; however, the OSHA Hearing Conservation Amendment should not be understood as an indication that HPDs are preferable to engineering noise controls, which do not require human intervention to protect workers’ hearing and prevent noise-induced hearing loss.

DATA AND LABELING REGULATIONS

Labeled Versus In-Field Attenuation Performance

The labeling of HPDs has been the subject of debate for more than two decades, much of it about the differences between on-package EPA-required attenuation data and the actual protection provided for users in the field (Berger and Casali, 1997; Casali and Robinson, 2003). To comply with OSHA (1983) and other applications, the adequacy of an HPD for a given noise exposure is determined by subtracting, in a prescribed way, the attenuation data required by the U.S. Environmental Protection Agency (EPA) from the TWA noise exposure for the affected worker (see OSHA, 1983, Appendix B: Methods for Estimating the Adequacy of Hearing Protector Attenuation).

Attenuation data are obtained from psychophysical real-ear-attenuation-at-threshold tests at nine 1/3-octave bands with centers of 125 to 8,000 Hz performed on human listeners; the signed, arithmetic difference between thresholds with the HPD and without it constitutes the attenuation at a given frequency. Both the spectral attenuation statistics (means and standard deviations) and the broadband single-number noise reduction rating (NRR), which is computed there from, are provided, and either of them can be used to estimate HPD adequacy for a given exposure, per OSHA (1983) Appendix B.

Labeled ratings are the primary means by which end users compare different HPDs and determine if they will provide adequate protection and OSHA compliance in a given noise environment. Therefore, the accuracy and validity of label ratings are very important.

Current EPA-Required Labeling and Cited Test Standards

The labeling of hearing protectors is controlled by EPA via federal law per 40 CFR Part 211, Subpart B, which was promulgated in September 1979 and remains in effect as of this writing. This section of the law applies to “any device or material, capable of being worn on the head or in the ear canal, that is sold wholly or in part on the basis of its ability to reduce unwanted sound that enters the user’s ears” (40 CFR Part 211, Subpart B). Unfortunately, the law references an outdated, superseded ANSI standard (1974) for obtaining the real-ear attenuation of threshold data on which the EPA label, which includes an NRR, is based.

The data on HPD packaging are obtained under optimal laboratory conditions with properly fitted protectors worn by trained, well-practiced human subjects. However, numerous research studies (e.g., Berger et al., 1998; Berger and Casali, 1997; Park and Casali, 1991) have shown that the “experimenter-fit” protocol and other aspects of the EPA-

required test procedure do not represent the conditions under which HPDs are selected, fitted, and used in the workplace. Therefore, the attenuation data used in the octave band or NRR formulas are highly inflated and cannot be assumed to represent the protection achieved in the field.

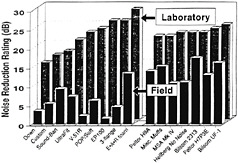

Figure G-1 shows the results of a review of research studies in which manufacturers’ on-package NRRs (in the background) were compared against NRRs computed from actual subjects using HPDs in field settings (in the foreground). Clearly, there are large differences between laboratory and field estimates, especially for earplugs (Berger, 2003). HPD consumers must take this difference into account when selecting protectors.

“Proposed” Revisions for Labeling and Cited Test Standards

ANSI Working Group S12/WG11 developed a new testing standard, ANSI S12.6-1997(R2002), which includes both a “Method A” provision for experimenter-supervised fitting of an HPD and a “Method B” provision for self-fitting of the HPD and with test subjects who have not been trained. The new standard has much improved experimental controls and human factors protocol over the current standard. Nevertheless, even though the Method B (subject-fit) testing protocol has been experimentally demonstrated to yield attenuation data that are more representative of those achievable under workplace conditions (Berger et al., 1998), as of this writing it appears that Method A (experimenter-supervised fit) is likely to be adopted by EPA for a revised regulation.

EPA has given notice (see EPA Docket OAR-2003-0024) in public workshops and presentations of a plan to revise the 1979 labeling regulation, in conjunction with the requirement to replace ANSI S3.19-1974 with the current ANSI standard to obtain passive attenuation data along with a new means of broadband rating. This rating is likely to be called the single-number rating, even though it will probably provide a range of values. This differs from NRR, which provided a single number.

FIGURE G-1 Comparison of hearing protection device NRRs by device type: manufacturers’ laboratory data versus real-world “field” data. Adapted with permission from Berger (2003), Fig. 10.18, p. 421.

The proposed regulation is also likely to include elements of another testing standard, ANSI S12.42 (ANSI, 2004), to enable physical, microphone-based testing in real ears and acoustical test fixtures; this will enable comprehensive testing of active noise cancellation, as well as certain other HPD types that are currently not amenable to the 1979 EPA regulation for labeling and thus cannot currently be marketed as hearing protectors. Elements of ANSI S12.68 (ANSI, 2007) are also likely to be added to prescribed methods of estimating protected exposure levels under HPDs. At the time of this writing, none of the details of the proposed EPA revised labeling regulation had been finalized. For updates the reader should go to www.regulations.gov (docket number: EPA-HQ-OAR-2003-0024).

REFERENCES

ANSI (American National Standards Institute). 1974. Method for the Measurement of Real-Ear Protection of Hearing Protectors and Physical Attenuation of Earmuffs. ANSI S3.19-1974. New York: ANSI.

ANSI. 2004. Microphone-in-Real-Ear and Acoustic Test Fixture Methods for the Measurement of Insertion Loss of Circumaural Hearing Protection Devices. ANSI S12.42-1995(R2004). New York: ANSI.

ANSI. 2007. Methods of Estimating Effective A-Weighted Sound Pressure Levels When Hearing Protectors Are Worn. ANSI S12.68-2007. New York: ANSI.

Berger, E.H. 2003. Hearing protection devices. Pp. 379–454 in The Noise Manual, Revised 5th Ed., edited by E.H. Berger, L.H. Royster, J.D. Royster, D.P. Driscoll, and M. Layne. Fairfax, VA: American Industrial Hygiene Association.

Berger, E.H., and J.G. Casali. 1997. Hearing protection devices. Pp. 967–981 in Encyclopedia of Acoustics, edited by M. Crocker. New York: John Wiley.

Berger, E.H., J.R. Franks, A. Behar, J.G. Casali, C. Dixon-Ernst, R.W. Kieper, C.J. Merry, B.T. Mozo, C.W. Nixon, D. Ohlin, J.D. Royster, and L.H. Royster. 1998. Development of a new standard laboratory protocol for estimating the field attenuation of hearing protection devices, Part III: The validity of using subject-fit data. Journal of the Acoustical Society of America 103(2):665–672.

Casali, J.G., and G.S. Robinson. 2003. Augmented Hearing Protection Devices: Active Noise Reduction, Level-Dependent, Sound Transmission, Uniform Attenuation, and Adjustable Devices—Technology Overview and Performance Testing Issues. EPA Docket OAR-2003-0024. Washington, DC: U.S. Environmental Protection Agency.

Casali, J.G. 2006. Sound and noise. Pp. 612–642 in Handbook of Human Factors, 3rd Ed., edited by G. Salvendy. New York: John Wiley.

OSHA (Occupational Safety and Health Administration). 1971a. Occupational Noise Exposure (Construction Industry). 29 CFR 1926.52. Federal Register.

OSHA. 1971b. Hearing Protection (Construction Industry). 29 CFR 1926.101. Federal Register.

OSHA. 1983. Occupational Noise Exposure; Hearing Conservation Amendment; Final Rule. 29 CFR 1910.95. Federal Register.

Park, M.Y., and J.G. Casali. 1991. A controlled investigation of in-field attenuation performance of selected insert, earmuff, and canal cap hearing protectors. Human Factors 33(6):693–714.