5

Overall Assessment

This chapter presents an overall view of progress in the FreedomCAR and Fuel Partnership since the previous, Phase 2 review by the National Research Council (NRC, 2008). It delineates many of the major achievements made in each of the technical areas under investigation and also identifies the critical technical barriers that still need to be overcome. It also addresses the overall adequacy and balance of the Partnership by a review of and comments on the level of budgetary resources and effort being directed at each of the major budget line items. Finally, the committee’s concluding comments are presented.

MAJOR ACHIEVEMENTS AND TECHNICAL BARRIERS

Although there is evidence of steady progress in every technical area being pursued by the Partnership, there remain very formidable barriers to the mass-production of affordable hydrogen and fuel-cell-powered vehicles. Further, it is also becoming more obvious that major barriers can involve more than one technology. An example of this is the difficulty in arriving simultaneously at the emergence of the affordable, consumer-friendly fuel cell vehicles and the emergence of a widespread network of hydrogen refueling stations offering affordable hydrogen fuel. Even though the need for, as well as the difficulty in achieving, this simultaneous emergence has been well known from the beginning of FreedomCAR, most efforts were appropriately focused on advancing specific technologies. Clearly, without resolving the enabling technologies for the ultimate production of consumer-acceptable fuel cell vehicles and the production and distribution of affordable hydrogen, the simultaneous emergence issue would have been moot. Rigorous scenario modeling might serve to illuminate the simultane-

ous emergence problem by allowing the qualitative testing of alternate futures. The quantitative implications of these futures might be understood through simple and transparent spreadsheet models.

Advanced Combustion and Emissions Control

Higher efficiency and reduced emissions as compared to those associated with current internal combustion engine (ICE) vehicles will be very important to the success of biofuels, advanced hybrid electric vehicles (HEVs), and even plug-in hybrid electric vehicles (PHEVs). In addition, the use of hydrogen fuel in ICEs can offer an alternative for expanding the availability of hydrogen for refueling vehicles prior to the widespread distribution of fuel cell vehicles. There is also the potential for homogeneous charge compression ignition (HCCI) engines to provide even better combinations of efficiencies and emissions than either diesel or spark-ignited ICEs. Such advances can be implemented by a better understanding of fundamental processes, and such is the primary orientation of these efforts. However, almost all aspects of engine operation are being pursued by the Partnership.

Among the accomplishments in this area were the following:

-

The demonstration of a peak brake thermal efficiency of 43 percent for conventionally fueled and 45 percent for hydrogen-fueled ICEs has taken place. Engines with these efficiencies operating in hybrid vehicles could result in system efficiencies approaching those of fuel cell vehicles.

-

The development of a predictive model for spark-assisted HCCI combustion is complete. This could help lead to the elusive solutions for successfully controlling HCCI engines.

The fundamental research being performed by the advanced combustion and emission control (ACEC) technical team is generating the knowledge base necessary to identify how to optimize the combustion process at any operating condition. This understanding is being incorporated into detailed computational fluid dynamic (CFD) simulations, which in turn accurately replicate the experimental results with minimum adjustable numerical tuning (Ge et al., 2010).

Primary barriers include the following:

-

In all of these endeavors, the key barrier continues to be the need for detailed fundamental understanding of the chemical, thermal, and physical processes taking place within the power train and combustion system.

-

Also, as with almost all technologies being pursued, cost is a barrier. Specifically, the technical team has had difficulty specifically addressing its cost target. The team has assumed that the base engine cost will be

-

$20/kW and that the incremental cost for the technology improvements, which includes enhanced aftertreatment, will be $10/kW. The team has not been able to confirm these estimates with public domain data.

Electrochemical Energy Storage

Energy storage is essential for any type of vehicle that recovers part of the kinetic energy that would otherwise be lost to heat dissipation during braking (regeneration) and/or operates without the primary energy converter (e.g., ICE or fuel cell) for some or all of its operation; these vehicles would include HEVs, PHEVs, battery electric vehicles (BEVs), and hydrogen-fueled fuel cell vehicles (HFCVs). While there are many ways to store energy (flywheels, compressed air, elastomers, hydraulic springs, batteries, capacitors, etc.), the Partnership has focused on electrochemical storage—primarily batteries and to a lesser extent ultracapacitors. Batteries can serve as primary energy sources onboard the vehicles as well as being a means of recovering kinetic energy, unlike some of the other energy storage technologies that serve better as short-term power devices.

The emphasis on batteries is even greater with the Obama administration, which has announced a goal to “put 1 million plug-in hybrid cars—cars that can get up to 150 miles per gallon—on the road by 2015 …” (Satyapal and Davis, 2009). Conceptually, PHEVs are very similar to HEVs but require far more battery energy, enough to provide an all-electric-design driving range of (typically) 10 to 40 miles. At this time, versions of lithium-ion (Li-ion) batteries with different chemistries seem to be the most likely candidates, and these dominate most Partnership battery research activities.

Among the accomplishments are the following:

-

Three Li-ion battery chemistries classified by the cathode material, including (1) lithium nickel, cobalt and aluminum; (2) lithium iron phosphate; and (3) lithium manganese spinel and a carbon anode, have been developed and tested for HEV applications. Since the Phase 2 review, there has been improvement in discharge and regenerative pulse power rating, calendar life as measured by accelerated testing, and increased cycle life. This applies to all three of the chemistries discussed. Laboratory data indicate that energy and power density requirements for HEVs will be met. With only Daimler having a production HEV with Li-ion batteries, the real cost is still unknown. However, recent announcements about the Nissan Leaf indicate that the cost and durability for a BEV, which is a much tougher application, may be within reach.

-

Safety is an important factor in the design of the battery. To determine safety, the Partnership has conducted extensive abuse testing, including mechanical (crushing, perforation, and shock), electrical (external shorting, overcharging, and overdischarging), and thermal (over-temperature

-

from external and internal sources). The three Li-ion chemistries were tested at both the cell and battery-pack level in an attempt to access their readiness for use and to improve their design and manufacturability.

Barriers include the following:

-

The system battery cost for an HEV is still very high, about twice the target of $500.

-

For the PHEV battery research, the Partnership has followed multiple paths of developments, also using different materials and designs to optimize performance, life, and cost. At present none of the battery chemistries meets the performance, life, or cost goals for 2012 requirements.

Electrical Propulsion and Electrical Systems

BEVs, HEVs, PHEVs, and fuel-cell-powered vehicles have in common a dramatic increase in electrical and electronic components as compared to those in conventional ICE vehicles. All of these vehicles are completely or partially electrically driven. Therefore, the performance and costs of components such as electric drive motors and power electronics are major factors for a range of advanced vehicles.

The Partnership has appropriately focused on key technical areas that are precompetitive, with the objective of long-term reductions in size (volume and weight) and cost. To accomplish this, emphasis has been on better packaging, cooling, materials, and devices.

Among the accomplishments for power electronics are the following:

-

Good progress is being made on a scalable inverter. The concept for a scalable inverter is that it can easily be scaled to meet different power levels. This is a cost-shared contract provided by DOE that runs from October 2007 through March 2011, with Delphi as the project lead contractor.

-

The Partnership is investigating a new process for making silicon carbide (SiC) on silicon substrates. SiC devices are better than those based on doped silicon since they operate at higher temperatures and have faster switching times. Potentially they lead to smaller and more efficient power electronics.

-

Successful experiments for a novel approach using direct backside cooling for the thermal management of power electronics have been conducted. More effective thermal management can lead to reduced weight and volume as well as an increase in life.

Some key accomplishments toward better permanent magnet electric drive motors are as follows:

-

The design of a 30 kW continuous (55 kW peak) motor is making good progress. Key objectives are for scalable motors to meet the very tough performance specifications and the use of novel soft magnetic material with a tripling of resistivity enhancement, and some specific accomplishments within this project are these:

-

Motor design. Two rotor and two stator concepts have been developed and analyzed in detail.

-

Low-loss soft magnetic materials. Bulk amorphous alloy compositions were identified as well as a kilogram-scale production by gas atomization. Also, a novel microstructure developed to enhance resistivity and magnetic properties, including composite soft magnetic material with doubling of resistivity enhancement, was demonstrated. Some cost and performance issues remain with these materials. Thus, while the materials are not satisfactory replacements for current materials, simply developing such low-loss materials is an important accomplishment.

-

Low-loss permanent magnet materials. Using a hydrogen-based route for processing the high-energy-density magnet materials used in electrical machines, the project has demonstrated a novel composite microstructure to minimize eddy current losses and seems very promising.

-

-

Other accomplishments include the apparently successful testing of a new compressor expander motor (CEM) for fuel cell vehicles. The CEM project incorporates a high-speed drive (165,000 rpm) with a fairly low projected cost. The motor is a permanent magnet brushless motor based on a design at Honeywell for motors in excess of 200,000 rpm. Although details of the motor and motor controller are proprietary, the motor controller and motor are reported to have efficiencies of greater than 90 percent and greater than 93 percent, respectively, for a combined efficiency near 85 percent, which is truly remarkable at such speeds and frequencies.

Among the remaining significant barriers are the following:

-

Permanent magnet motors still require rare-earth materials that are available from only a few countries and could become scarce and expensive or could become political or national security issues.

-

Induction motors, while much less expensive and requiring no exotic materials, do not yet achieve efficiency levels sufficiently high for most vehicle (e.g., BEVs or PHEVs) drive motor applications.

-

While much progress is being made on power electronics, silicon devices are still exclusively used. Perhaps in the future, cost-effective SiC devices capable of operating at higher temperature and faster will be developed, but there are not yet affordable options for higher-temperature and/or faster electronics.

Fuel Cells

Fuel cells are considered to have the potential for being the most efficient means of converting hydrogen fuel to useful power for vehicles. As such, they have been from the beginning of the program until very recently a primary focus of the FreedomCAR and Fuel Partnership. Progress has been steady, with an increase in almost every performance metric and a decrease in projected costs between each review. Even so, this technology is not yet fully developed, and additional advancements are needed. A noteworthy comment on significant achievements since the last review is that while almost every major target has been met in one form or another, they have so far been in separate initiatives and not from a collective single source.

Among notable achievements are these:

-

Demonstrated stack lifetimes in on-road vehicles have increased from approximately 1,250 hours to 1,977 hours. With the goal of 5,000 hours, this represents a significant achievement since the Phase 2 NRC (2008) review.

-

Single-cell and short-stack tests at the laboratory scale have demonstrated (using accelerated test protocols) much longer run times (3M Company, 7,200 hours) that, if demonstrated in vehicles under realistic on-road conditions, would meet or exceed the goals of the Partnership.

-

Two separate DOE-funded studies, with independent oversight by industry experts, have concluded that at volumes of 500,000 units per year, the cost per kilowatt for the fuel cell subsystem including the fuel cell and balance of plant (BoP) will be approximately $60-$70/kW. These figures are still more than two times higher than the target but significantly lower than the $107/kW presented during the Phase 2 review.

-

The development of a membrane with double the conductivity and reduced in-plane swelling as compared to Nafion membranes (DOE, 2008).

-

The development of improved non-invasive methods for visualizing water distribution inside fuel cells.1

Technical barriers that still remain include the following:

-

For the fuel cell stack the technical barriers are the membrane and electrode life and cost. Neither cost nor durability targets have been met with a single technology.

-

Previously, most cost-reduction efforts have been directed to the stack. However, the projected stack cost is now down to approximately the

|

1 |

See DOE Annual Merit Review Meeting, May, 2009. Available on the Web at <http://www.hydrogen.energy.gov/annual_review09_proceedings.html>. |

-

projected cost of the BoP. Consequently, to reach cost targets there must be appreciable reductions in BoP costs, which will probably require significant simplifications to the system.

Onboard Hydrogen Storage

Onboard hydrogen storage is a key enabler for fuel-cell-powered vehicles. A specific goal of the program is a vehicle driving range of greater than 300 miles between refuelings while simultaneously meeting vehicle packaging, cost, and performance requirements as well as those related to life-cycle issues, energy efficiencies, and safety with consideration of the possible environmental impact of implementing various hydrogen storage technologies.

The availability (or lack thereof) of an effective, affordable technology for onboard hydrogen storage was, and continues to be, a likely major issue in the ultimate decisions to mass-produce fuel cell vehicles. At the time of the Phase 2 report (NRC, 2008), only compressed hydrogen (and a few vehicles using liquid hydrogen) onboard storage systems had been utilized for Partnership experimental vehicles. The same is still true as this report is written.

Shortly before the Phase 1 report (NRC, 2005) was written, the Partnership had formed three new centers of excellence (COEs) for hydrogen storage. In the Phase 2 report (NRC, 2008), it was noted that the Chemical Hydrogen Storage COE had made significant progress in identifying materials with increased hydrogen storage capacity. The COEs have now investigated more than 350 candidate storage materials. Of those investigated, more than two-thirds (68 percent) have been discontinued, with about one-third still under investigation.

An additional center of excellence, the DOE Hydrogen Storage Engineering COE, was also established in the interim since Phase 2, to focus on systems issues that complemented the materials-oriented issues addressed by the other COEs. Another significant change by the Partnership since the Phase 2 report was to change (lower) the 2015 targets for system gravimetric density (hydrogen [H2] storage weight/system weight from 9 percent to 5.5 percent) and volumetric density (kilowatt-hours of H2 per liter of storage system volume, from 2.7 to 1.3). The system fill-time target was increased from 2.5 minutes for 5.0 kg H2 to 3.3 minutes for 5.0 kg H2.

Key achievements made since the Phase 2 NRC review include the following:

-

A no-go decision made for vehicle hydrogen storage during the Phase 2 review was to discontinue applied research and development (R&D) in pure, undoped, single-walled carbon nanotubes based on the fact that they were not able to meet storage target of 6 wt% close to room temperature (2006).

-

A no-go decision was made for sodium borohydride onboard vehicular hydrogen storage (2007).

-

A down-select decision was made on chemical hydrogen storage materials (2008). Of 120 materials and classes of materials examined to date, 15 percent were selected for continued study.

-

Metal hydride materials were down-selected. Of 74 materials investigated to date, 40 have been selected for further work.

-

The Hydrogen Sorption COE has investigated 160 materials, and 35 percent are still in the COE’s inventory. A down-select report is in preparation.

-

Overall progress in system capacity is reported to have increased 50 percent since 2007.

Barriers remain formidable for onboard hydrogen storage. Specifically:

-

The only complete system that has been successfully demonstrated in vehicles (other than a few liquid hydrogen demonstrations) is compressed hydrogen gas, which seems unlikely to meet any of the Partnership cost or performance targets.

-

System weight and volume are too high for meeting the 300-mile vehicle driving range across a wide spectrum of vehicle platforms. Basically no suitable storage material has been identified and developed.

-

The system cost is too high and needs to be able to compete with petroleum-based fuels. Cost areas include materials of construction and manufacturing methods and balance-of-plant components.

-

Charging time (refueling) for material storage must meet consumer expectations. Storage capacity and rates of sorption and release need to be better understood and improved (the 2015 target is 3.3 minutes for 5 kg H2 charge).

-

The charging or discharging of hydrogen to a storage tank or material can be an energy consumer (requiring heating or cooling), which impacts the overall system efficiency.

-

Systems issues need to be considered in addressing thermal management, durability and operability, hydrogen quality, containment vessels, dispensing technologies, and system life-cycle assessment and prediction.

-

Codes and standards are needed for the entire system and for all interfaces.

-

A better understanding of hydrogen sorption (physisorption and chemisorption) and desorption processes is needed.

-

The cost of high-quality carbon fibers for high-pressure storage tanks needs to be reduced.

Materials

Reducing the mass of a vehicle will simultaneously reduce the required power for a given performance and increase fuel efficiency. Thus fuel cells and/or batteries (for fuel cell vehicles) and/or ICEs as well as batteries (for HEVs or PHEVs), power requirements, weight, volume, and cost of power plants can all be reduced with reduced vehicle mass.

Although there is undoubtedly some potential for mass reduction through design optimization using conventional materials, the automotive manufacturers have had mass reductions as priority goals for decades. This suggests that additional significant mass reductions are likely to be achieved through materials and corresponding fabrication changes. Among materials with the most promise are high-strength steel, aluminum, magnesium, and composites. With these, as well as other alternative materials, the biggest barrier is making components affordable as well as lighter.

Among materials, accomplishments of note are these:

-

A project conducted for the possible substitution of magnesium for some aluminum components. This project was completed in September 2009. The mass reduction achieved was 29 percent for the magnesium components and 7.8 percent for the engine subsystem, which exceeded the weight savings goal. Although over the cost target, the outcome was judged as demonstrating that magnesium was both technically feasible and potentially cost-effective in some applications.

-

The development of textile-based carbon-fiber precursors that could help lower the production costs of carbon fibers.

-

The design and development of a vehicle magnesium front end.

-

The development of better engineering property tools for tailored polymer composite structures.

-

The development of a structural composites underbody.

The major barrier to using alternative materials to reduce vehicle mass is cost:

-

The technology is available to replace many vehicle components with lighter alternatives. However, all alternative materials to date use base materials and/or production processes that are significantly more costly than are current materials and processes.

Fuel Infrastructure Technologies

The production, distribution, and delivery of affordable hydrogen is obviously essential if hydrogen is to become a widespread fuel available for refueling millions of fuel cells or other hydrogen-fueled vehicles. Even though relatively

large quantities of hydrogen are produced in the United States (and the rest of the world), very little is distributed and used as vehicle fuel.2 Consequently, there is virtually no effective infrastructure in place for large quantities of vehicle fuel. Thus, the Partnership R&D projects include essentially all phases necessary to develop a complete hydrogen vehicle fuel infrastructure.

Some of the more notable of the achievements are as follows:

-

An analysis of infrastructure materials availability was completed, identifying key materials and their respective availability for an infrastructure for up to 10 million vehicles by 2025.

-

A resource-availability analysis was completed that considered especially water and electrical energy.

-

A refinement of a source-to-wheels analysis for better projecting both energy and emissions associated with various complete hydrogen pathways was made.

-

A study on the feasibility of using glass fiber composite tanks to deliver cold hydrogen gas to refueling stations was completed.

-

National and regional workshops involving hydrogen fuel station developers along with code officials were convened. The result was a Web-based information compendium to meet the needs and recommendations of the developers and authorities having jurisdiction. This is important because there are hundreds of federal, state, and local codes that developers must comply with to build widespread hydrogen refueling stations.

The primary barriers to hydrogen production, delivery, and refueling stations are given below:

-

Costs for long-term hydrogen production with low or zero CO2 emissions are a major issue. In the near term, natural gas can be used as a feedstock for producing relatively low cost hydrogen with relatively low CO2 emissions, but the long-term availability of natural gas is not assured. For the long term, low-cost hydrogen with low to zero CO2 production using non-fossil-fuel feedstocks is necessary, supplemented by coal if carbon capture and storage (CCS) technology is successfully developed. Long-term use of electrolysis depends on a substantial reduction of CO2 emissions from the generation of grid electricity, which also is not assured.

-

Delivery has many issues to be resolved better, including capital costs for pipelines, compression, and on-site storage; efficiency for compression and for liquefaction; and the maintaining of hydrogen quality acceptable for fuel cells.

-

There is a need for comprehensive codes and standards.

ADEQUACY AND BALANCE OF THE PARTNERSHIP

In two previous reports (NRC, 2005, 2008), the committee reviewed the funding for the FreedomCAR and Fuel Partnership and the allocation of that funding, both between hydrogen-related and non-hydrogen-related activities and between technologies perceived to be nearer-term and longer-term technologies. Generally speaking, the committee concluded in those earlier reports that the balance between technologies and between near and long term was appropriate. Major shifts in emphasis and funding have occurred over the past 12 months, and those shifts are explored in this section.

Since the beginning of the FreedomCAR program, and even earlier during the Partnership for a New Generation of Vehicles (PNGV) program, the NRC reviews have recommended government support emphasizing long-term, high-risk, high-payoff technologies. It was, and is, the view of the committee that this is an appropriate expenditure of government resources. However, current economic conditions, including the need for government support to prevent the collapse of two major automobile manufacturers, influence what the committee and the government consider “appropriate.” It is still believed by the committee that support for long-term technologies such as the enablers for hydrogen to become a viable transportation fuel and the fuel cell R&D leading to affordable hydrogen fuel-cell-powered vehicles is very important and should be continued. Nonetheless, the committee agrees with government support for possible nearer-term technologies, especially those that could transfer some of the required transportation energy from petroleum to biofuels or to the electric power grid.

Historically, hydrogen-related activities represented approximately 70 percent of Partnership research and funding. This emphasis was consistent with the recommendations of the NRC report The Hydrogen Economy: Opportunities, Costs, Barriers, and R&D Needs (NRC/NAE, 2004) and the U.S. Department of Energy (DOE) report Hydrogen Posture Plan: An Integrated Research, Development and Demonstration Plan (DOE, 2004). It was also consistent with continuation of President Bush’s commitment of $1.7 billion over 5 years (FY 2004 to FY 2008, the first 5 years of the Partnership). However, early in 2010, coincident with a new administration in Washington, D.C., all funding requests for hydrogen-related activities for vehicles were withdrawn. The stated reasons for this were that in order to achieve commercialization of hydrogen fuel cell vehicles, four major breakthroughs were required: namely, the sustainable production of hydrogen, effective distribution, onboard storage, and robust, reliable, low-cost fuel cells. It

was apparently believed by the administration that the simultaneous achievement of these challenging tasks was highly unlikely in the 10- to15-year time frame, and consequently resources were redeployed to nearer-term activities.

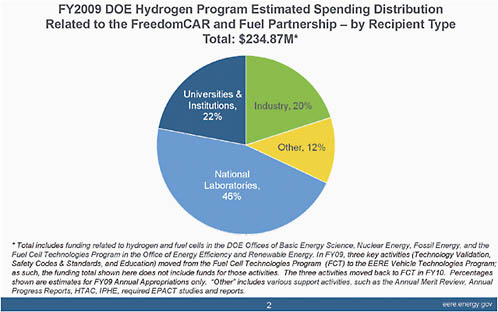

Although the committee agrees that these four challenges to the deployment of HFCVs are indeed huge, it believes that the other two possible pathways to achieving the ultimate Partnership goals—namely, vehicles using biofueled ICEs and highly electrified vehicles (PHEVs and BEVs)—also face major challenges, and research on all three pathways deserves continued stable funding for the immediate future (see Appendix B, the committee’s Interim Letter Report). Congress reached the same conclusion and reinstated most funding for hydrogen-related Partnership activities for FY 2010. The resulting FY 2010 funding for such activities is shown in Table 5-1. Figure 5-1 provides an estimate of the distribution of funding for the Hydrogen Program for FY 2009.

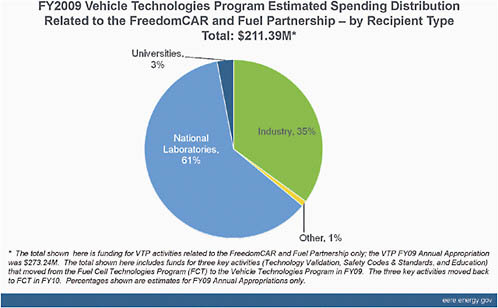

The companion Partnership activities under the general heading of the Office of Vehicle Technologies (VT) program continued to be adequately funded and in fact, the VT program, including similar activities in the separate 21st Century Truck Partnership, grew from $242 million in FY 2009 to $311 million in FY 2010, a 29 percent increase. This is illustrated in Table 5-2. (Note that the FY 2009 total is overstated by $31 million due to a one-time re-binning of three items normally included in hydrogen funding.) Figure 5-2 provides an estimate of the distribution of funding from the VT program in FY 2009.

The end result of these major swings in funding is that the hydrogen and fuel cell portion of the program currently represents some 50 percent of total funding, compared with roughly 70 percent in earlier years and 60 percent in FY 2009. Although the committee believes that a higher proportion of the funding could very justifiably be devoted to hydrogen and fuel cell activities, the nearer-term projects to which the majority of funding is now allocated are nevertheless well worthwhile, and much of that activity, such as improved batteries, more efficient electrical components, and lighter-weight materials, would also potentially benefit fuel cell vehicles in the future.

The DOE budget request for FY 2011 was submitted to Congress in February 2010. The committee strongly urges the DOE to maintain hydrogen-related funding at no less than the current level. Furthermore, this hydrogen activity should emphasize the most urgent needs to support a 2015 commercialization decision—namely, onboard storage, vehicle fuel cells, and distributed fueling. Not only is continued emphasis required to enable a robust 2015 decision, the fundamental objective on which the Partnership was founded, it is also precisely this type of high-risk/high-payoff research that is most appropriate for the use of public funds to augment private-sector spending.

Although not strictly comparable since the budget categories are somewhat different, the FY 2011 budget request is delineated in Table 5-3. Of course, it will be up to Congress as to where the final budget levels for FY 2011 end up. Also, Table 5-3 only provides estimates by the DOE of how the funding may

TABLE 5-1 Fuel Cell Technology and Related DOE Hydrogen Funding, FY 2009 and FY 2010 (in thousands of dollars)

|

Office/Activity |

FY 2009 |

FY 2010 |

|

Hydrogen Production and Delivery R&D |

10,000 |

15,000 |

|

Hydrogen Storage R&D |

59,200 |

32,000 |

|

Fuel Cell Stack Component R&D |

62,700 |

62,700 |

|

Technology Validationa |

See footnote a |

13,097 |

|

Transportation Systems R&D |

6,600 |

3,201 |

|

Distributed Energy Systems R&D |

10,000 |

11,410 |

|

Fuel Processor R&D |

3,000 |

171 |

|

Safety, Codes and Standardsa |

See footnote a |

8,839 |

|

Educationa |

See footnote a |

2,000 |

|

Systems Analysis |

7,713 |

5,556 |

|

Manufacturing R&D |

5,000 |

5,000 |

|

Market Transformation |

4,747 |

15,026 |

|

Total EERE |

168,960 |

174,000 |

|

Fossil Energy |

26,400b |

|

|

Nuclear Energy |

7,500 |

0 |

|

Science |

38,284 |

~38,284d |

|

DOE Total |

241,144a |

~237,284 |

|

a Under the Vehicle Technologies budget in FY 2009; the FY 2009 total noted for Fuel Cell Technology funding and related DOE Hydrogen funding does not include the three EERE Fuel Cell Technology activities moved to the Vehicle Technologies program in FY 2009. The DOE total including those activities is $272,633,000. b Does not include funding for program direction. c Includes coal to hydrogen and other fuels. Fossil Energy also plans $50 million for SECA in FY10. d Exact funding for hydrogen- and fuel-cell-related projects to be determined. The Office of Science also plans approximately $14 million for hydrogen production research in the Office of Biological and Environmental Research in FY 2010. Projects in the Office of Basic Energy Sciences can be found on the Web at <http://www.hydrogen.energy.gov/pdfs/review09/2_kung_2009_amr.pdf>. SOURCE: Submission to the committee by DOE, December 7, 2009. |

||

be distributed, as noted in the footnotes to the table. Nevertheless, it does show continuing efforts on, among other activities, fuel cells for vehicles.

While these changes in hydrogen funding were taking place during 2009, another major initiative influencing Partnership goals emerged. That was the American Recovery and Reinvestment Act (ARRA) of 2009 (Public Law 111-5) and its massive funding of advanced technologies under the umbrella of economic stimulus. This expenditure is entirely separate from FreedomCAR and Fuel Partnership funding, but such initiatives as $1.5 billion for lithium-ion battery manufacture, $500 million for electric-drive component manufacturing, and $400 million for transportation electrification are clearly relevant to advanced development activities within the Partnership. The large ARRA expenditures

TABLE 5-2 Vehicle Technologies Program Funding, FY 2009 Appropriation and FY 2010 Estimate (in thousands of dollars)

|

Activity |

FY 2009 FreedomCAR Appropriation |

FY 2009 Total |

FY 2010 FreedomCAR Estimate |

FY 2010 Total |

|

Hybrid Electric Systems |

125,709 |

125,709a |

140,960 |

145,733 |

|

Advanced Combustion Engines |

25,427 |

40,800 |

33,990 |

57,600 |

|

Materials Technologies |

28,256 |

39,903 |

38,355 |

50,723 |

|

Fuels Technologies |

13,195 |

20,122 |

11,534 |

24,095 |

|

Technology Integration |

2,700 |

46,704a |

3,500 |

33,214 |

|

Total |

195,287 |

273,238 |

228,339 |

311,365 |

|

a In FY 2009, the DOE transferred three activities from the Fuel Cell Technologies program to the Vehicle Technologies program. Technology Validation (FY 2009: $14,789) was included in Hybrid Electric Systems activity; Education (FY 2009: $4,200) and Safety, Codes, and Standards (FY 2009: $12,500) were included in Technology Integration. All three activities moved back to the Fuel Cell Technologies program in FY 2010. SOURCE: Submission to the committee by the DOE, December 7, 2009. |

||||

could, at least temporarily, affect the appropriate levels of funding within the Partnership budget. The DOE should examine this and consider reallocations if warranted. Furthermore, late in 2009 (October 26), the DOE released a list of the first 37 approved research projects, totaling $151 million, under the Advanced Research Projects Agency-Energy (ARPA-E), a creation of the America Competes Act of 2007 (Public Law 110-69). On December 7, 2009, Energy Secretary Steven Chu announced a second round of funding amounting to $100 million for such projects. The total funds available for these ARPA-E projects are $400 million, drawn from the ARRA.3

Although many of the recipients of the ARPA-E funding are also participants in the FreedomCAR and Fuel Partnership, and staff from the two DOE program offices responsible for the Partnership assisted in the review of relevant ARPA-E proposals, these activities are not directly within the purview of Partnership leadership or this committee. However, they represent a substantial commitment of public funds to R&D and to the commercialization of technologies of major interest to the Partnership. Without passing judgment on the relative merits of all these ARRA and ARPA-E projects, it must be noted that, taken together, they overwhelmingly favor the “enhanced electrification of vehicles” pathway rather than either of the other two potential avenues, noted above, to the Partnership’s (and the nation’s) transportation energy goals. Indeed, a total of about $2.4 billion has been invested in battery manufacture, power electronics, and transportation electrification as well as $400 million for ARPA-E programs. These efforts are

|

3 |

Details of these initial awards may be found on the Web at <http://arpa-e.energy.gov>. |

TABLE 5-3 Estimate of DOE’s Congressional Budget Request for FY 2011 FreedomCAR and Fuel Partnership (FCFP) Activities

|

FY 2011 Budget Structure |

FY 2011 Request ($000)a |

FCFP Estimateb ($000) |

|

Vehicle Technologies |

|

|

|

Batteries and Electric Drive Technologyc |

120,637 |

120,637 |

|

Vehicle and Systems Simulation and Testingd |

44,328 |

39,127 |

|

Advanced Combustion Engine R&D |

57,600 |

35,900 |

|

Materials Technology |

50,723 |

38,355 |

|

Fuels Technologies |

11,000 |

5,500 |

|

Outreach, Deployment, and Analysise |

41,014 |

3,500 |

|

Vehicle Technologies Program Total |

262,265 |

243,019 |

|

Hydrogen and Fuel Cell Technologies |

|

|

|

Fuel Cell Systems R&Df |

67,000 |

67,000 |

|

Hydrogen Fuels R&Dg |

40,000 |

40,000 |

|

Systems Analysis |

5,000 |

5,000 |

|

Market Transformationh |

9,000 |

9,000 |

|

Manufacturing R&D |

5,000 |

5,000 |

|

Technology Validation |

11,000 |

11,000 |

|

Hydrogen and Fuel Cell Technologies Total |

137,000 |

137,000 |

|

aAll numbers in the Request column include SBIR/STTR. b Numbers indicate unofficial, “ballpark” estimates only and are based solely on prior-year splits for activities supporting the FreedomCAR and Fuel Partnership, 21st Century Truck Partnership, and “other” activities. All estimates are subject to change. c In the FY 2011 DOE budget request for Vehicle Technologies, the Batteries and Electric Drive Technology (BEDT) subprogram contains all of the activities of the former Hybrid Electric Systems subprogram, except for Vehicle and Systems Simulation and Testing (VSST). The proposed budget structure change gives batteries and electric/hybrid vehicles a dedicated budget line, while separating the crosscutting and non-electric/hybrid activities that are included in VSST. dIn the FY 2011 DOE budget request for Vehicle Technologies, the Vehicle and Systems Simulation and Testing (VSST) activity, which in prior-year budgets had been included in the former Hybrid and Electric Systems subprogram (now the Batteries and Electric Drive Technologies subprogram), has been elevated to a subprogram in order to make budget line items more transparent and meaningful. e In the FY 2011 DOE budget request for Vehicle Technologies, the Technology Integration subprogram has been renamed Outreach, Deployment, and Analysis to better reflect the subprogram’s activities. f In the FY 2011 DOE budget request for Hydrogen and Fuel Cell Technologies, the Fuel Cell Stack Component R&D, Distributed Energy Fuel Cell Systems, Transportation Fuel Cell Systems, and Fuel Processors R&D key activities have been consolidated into a new Fuel Cell Systems R&D subprogram. g In the FY 2011 DOE budget request for Hydrogen and Fuel Cell Technologies, Hydrogen Fuel R&D encompasses R&D for fuel-cell-compatible fuel production, delivery, and storage. h In the FY 2011 DOE budget request for Hydrogen and Fuel Cell Technologies, a structure change consolidates the previous Safety and Codes and Standards and Education activities with early-market activities in the Market Transformation subprogram, although funding for educational activities is deferred in FY 2011. SOURCE: Submitted to the committee by the DOE, February 2, 2010. |

||

not in the Partnership but are supportive, so their loss would probably slow significantly, but not directly jeopardize, the existing Partnership programs.

In summary, although the committee understands the continued shift in the Partnership’s funding and focus away from HFCVs and toward PHEVs and BEVs, the committee believes that in order to enable the fundamental “commercialization decision in 2015,” future hydrogen-related funding should, at a minimum, be maintained at the current level. Furthermore, the committee’s charter does not extend to ARRA and ARPA-E oversight, but it is very apparent, and of some concern, that the overwhelming majority of those relevant activities are devoted to only one of three possible pathways to achieving the nation’s ultimate transportation energy goals.

Finally, in prior reports, the committee has expressed concern over the inclusion of congressionally directed activities (also knows as “earmarks”) in DOE funding authorization for the Partnership. It is worth noting that in the FY 2010 appropriations for the DOE, Congress included many congressionally directed projects for the Office of Energy Efficiency and Renewable Energy totaling about $292 million. The DOE tentatively identified approximately $40 million of congressionally directed projects as part of the Fuel Cell Technologies or Vehicle Technologies Programs. However, Congress also appropriated additional funds specifically to support the earmarks and, as a result, the DOE-managed Partnership funding was not affected. The committee regards this as a very positive development.

CONCLUDING COMMENTS

Overall, the goals and operations of the FreedomCAR program, and then the FreedomCAR and Fuel Partnership, have changed somewhat since the creation of the FreedomCAR program in January 2002, due primarily to the balance between nearer-term and longer-term activities shifting more toward nearer-term activities. Especially considering the current economic and political issues associated with massive petroleum imports, as well as the change in administration with understandably different priorities, the committee finds such a shift to be appropriate. However, the committee also believes that an important function of the government is to support longer-term high-risk, potentially high-payoff technology developments, such as vehicle fuel cells and hydrogen as a vehicle fuel, and as such that these activities should be continued. The serious challenges that the nation faces with fuel supplies and the environment will not likely be solved with short-term solutions alone.

In terms of achievements and barriers, there has been considerable progress in most areas between Phases 2 and 3 of the National Research Council reviews just as there was between Phases 1 and 2. In some portions of the program, such as efforts toward projected fuel cell cost reductions, the results since the program began in 2002 have been very significant. In other areas, such as efforts to find

onboard hydrogen storage technologies more viable than compressed-gas tanks, solutions are still elusive. In a few cases, such as materials to allow important vehicle weight reductions, technologies are lesser barriers than costs. Indeed in virtually every area being pursued within the program, projected costs continue to be major issues.

From an organizational standpoint, the committee believes that the FreedomCAR and Fuel Partnership government/industry collaboration is working well and that such precompetitive collaborations should be continued. Evidence that it is working well can be seen in the activities by and accomplishments of the technical teams, which is the heart of the Partnership. Cost and performance targets have been established in every technical area, and steady progress is noted in essentially all of them. There is, however, at least one major failing of the Partnership, the effectiveness of the Executive Steering Group (ESG). This group, composed of vice-presidential-level executives from each of the Partnership companies and the Assistant Secretary of Energy for EERE, has not met in more than 2 years. This is a problem area that should be corrected. The government involvement seems appropriate and well managed, and the government/industry technical teams have worked well to develop reasonable technical and cost goals, which have been updated when necessary. Overall, the FreedomCAR and Fuel Partnership is a very ambitious program; there is a good chance that, within the life of the program, some of the key targets will never be met. However, this program with its goals and long-term collaborations is, in the opinion of the committee, very much in the nation’s interest.

REFERENCES

DOE (Department of Energy). 2004. Hydrogen Posture Plan: An Integrated Research, Development and Demonstration Plan. Washington, D.C.: U.S. Department of Energy. Available on the Web at <http://www.eere.energy.gov/hydrogenandfuelcells/pdfs/hydrogen_posture_plan.pdf>.

DOE. 2005. Multi-Year Research, Development and Demonstration Plan: Planned Program Activities for 2005-2015. Section 2.3, Domestic Resources for Hydrogen Production. Washington, D.C.: Office of Energy Efficiency and Renewable Energy. Available on the Web at <http://www1.eere.energy.gov/hydrogenandfuelcells/mypp/>.

DOE. 2008. “FreedomCAR and Fuel Partnership 2008 Highlights of Technical Accomplishments.” Available on the Web at <http://www1.eere.energy.gov/vehiclesandfuels/pdfs/program/2008_fcfp_accomplishments_rpt.pdf>.

Ge, H.-W., Y. Shi, R.D. Reitz, and W. Willems. 2010. “Engine Development Using Multi-Dimensional CFD and Computer Optimization.” SAE Paper 2010-01-0360.

NRC (National Research Council). 2005. Review of the Research Program of the FreedomCAR and Fuel Partnership, First Report. Washington, D.C.: The National Academies Press.

NRC. 2008. Review of the Research Program of the FreedomCAR and Fuel Partnership, Second Report. Washington, D.C.: The National Academies Press.

NRC/NAE (National Research Council/National Academy of Engineering). 2004. The Hydrogen Economy: Opportunities, Costs, Barriers, and R&D Needs. Washington, D.C.: The National Academies Press.