3

Vehicle Subsystems

The long-range goals of the FreedomCAR and Fuel Partnership—to transition to a transportation system that uses sustainable energy resources and produces minimal criteria or net carbon emissions on a life-cycle or source-to-wheels basis—are extremely ambitious. The difficulties are compounded when the additional constraints associated with the Partnership are imposed: energy freedom, environmental freedom, and vehicle freedom. These goals and associated constraints effectively eliminate the continued simple evolution of the gasoline-fueled internal combustion engine (ICE) vehicle as a possible answer. “Sustainable energy resources” and “energy freedom” both suggest non-petroleum-based alternative fuels or electricity. The emphasis on “net carbon emissions” and “environmental freedom” suggests that carbon dioxide (CO2) and other emissions from the production and consumption of alternative fuels or electricity should be reduced, through highly efficient processes, to minimize adverse environmental effects. Finally, “vehicle freedom” implies that the fuel and onboard energy conversion systems should not limit the options and choice that buyers expect to have available in their personal vehicles. These goals, if attained, are likely to require new transportation energy carriers (fuel[s] and/or electricity) utilized in more efficient power plants in lighter vehicles having reduced power requirements and equivalent utility and safety.

This chapter discusses the vehicle systems technology areas that the Partnership is addressing in its research and development (R&D) programs, which include the following: (1) advanced combustion, emission control, and fuels for ICEs; (2) fuel cells; (3) hydrogen storage on the vehicle; (4) electrochemical energy storage or technologies for storing electricity onboard a vehicle; (5) electrical propulsion systems; and (6) materials for reducing the weight of the vehicle. The

reader is referred to the presentations from the Partnership to the committee on the various technical areas: these can all be found in the project’s public access file, available through the National Academies Public Access Records Office. Chapter 4 will address issues associated with hydrogen and biomass-based fuels.

ADVANCED COMBUSTION, EMISSIONS CONTROL, AND HYDROCARBON FUELS

Introduction

Steady progress is being made in the advancement of power plants that rely on energy carriers other than liquid hydrocarbon (HC) fuels. However, one unique characteristic of mobility applications is that the energy being supplied to the power plant needs to be carried around with the vehicle. As weight and volume are important parameters in vehicle design and function, it is critical to have the highest possible energy per unit of mass and per unit of volume within the vehicle’s fuel system. Here, the fuel system includes all aspects of carrying the energy on the vehicle—that is, the fuel tank or containment system (battery pack, or hydride material) and supporting structures are included in this weight and volume assessment. On this basis, liquid HC fuels are very effective energy carriers for mobility systems.

Using the metrics of energy density (watt-hour per liter [Wh/L]) and specific energy (watt-hour per kilogram [Wh/kg]) of a vehicle’s complete fuel system highlights differences compared to conventional vehicles and the challenges of implementing alternative energy carriers to mobility systems. When one makes these comparisons, it is important to consider not only the energy density of the vehicle’s fuel system but also the efficiency of converting the energy carried on the vehicle to motive power (power that causes motion) at the wheels of the vehicle.

Liquid HC fuels have very high energy density and specific energy relative to batteries and hydrogen systems, but the efficiency of the ICE is typically lower than that of systems using electric motors and power electronics and fuel cell systems. Thus the concentrated effort to improve the engine and power-train efficiency is easily understood. However, the energy density and specific energy of liquid HC fuels is so great that even considering these efficiency differences, a typical vehicle carrying a liquid HC will have significantly higher capability than that of an electric or hydrogen-powered vehicle in terms of deliverable work to the wheels per unit of mass and volume of vehicle energy storage onboard the vehicle.

For example, comparing an ICE with an efficiency of 40 percent to a hydrogen fuel cell vehicle (HFCV)1 with an overall power-train efficiency of 65 percent results in a work capacity of the liquid-fueled ICE vehicle that is approximately

4.5 times higher per unit of volume of “fuel storage” and approximately 4 times higher per unit of mass of “fuel storage” than those of the HFCV. It seems likely that there will be certain applications, such as extended operation at higher loads or very long range transport, that will favor using a liquid HC as the on-vehicle energy carrier.

In addition, as new power plants with alternative energy carriers are developed, produced, and introduced into the market, there will be a significant time delay associated with their market penetration. As noted in Chapter 1, in the United States the vehicle fleet turnover in recent years is estimated to be about 15 years.2 Consequently the turnover time for completely new vehicle architectures to achieve significant market penetration will be measured in multiple decades (Bandivadekar et al., 2008; Weiss et al., 2000). During this transition the dominant power plant for mobility systems will continue to be ICE vehicles fueled with a hydrocarbon fuel (e.g., gasoline, diesel fuel, or biofuel).3

Consequently, it is important to maintain an active ICE and liquid fuels R&D program at all levels: industry, government laboratories, and academia, to expand the knowledge base to enable the development of technologies that can reduce the fuel consumption of transportation systems powered by ICEs. The near-term introduction of such technologies into existing production facilities will reduce the growth in transportation petroleum use during a transition to alternative power plants and power-train configurations. This is the focus of the Partnership’s advanced combustion and emission control (ACEC) technical team.

The overarching goals, technical targets, and program structure of the ACEC technical team are basically the same as reported in the Phase 2 review of the program (NRC, 2008). The technical team has established the following technical engine target goals for 2010:

-

Engine peak brake thermal efficiency (BTE): 45 percent

-

Nitrogen oxides (NOx) and particulate matter (PM) emissions: Tier 2 Bin 5 (T2B5)

-

Power-train cost: <$30/kW

The general focus of the ACEC technical team’s work to achieve these targets continues to be lean-burn, direct-injection engines for vehicles fueled by diesel, gasoline, and biofuel or other alternative fuels, provided appropriate carbon emission mitigation is accomplished during their production. Within this broad area specific foci include the following:

-

Low-temperature combustion (LTC)

-

Control

-

Expanding the load range

-

Coupling to fuel characteristics

-

Transient operation

-

Combustion mode switching

-

-

Aftertreatment

-

Diesel particulate filter (DPF) modeling

-

Lean NOx traps

-

Selective catalytic reduction (SCR) NOx reduction

-

Potential catalyst identification for HC NOx catalysis

-

-

Tool development

-

Improved computational fluid dynamic (CFD) capabilities

-

Improved diagnostics capabilities

-

Comparison of CFD and experiment

-

In this quest, all aspects of the engine and power train are under investigation. Individual subsystems and processes, such as injection systems, turbochargers, combustion chamber system optimization, the enhanced use of alternative combustion processes (such as low-temperature combustion) and exhaust-gas energy recovery, are actively being investigated. All aspects of the engine operation are being pursued. The electrification of auxiliaries, matching the engine operation to the fuel characteristics, and reducing friction through advanced lubricants are subjects of investigation. Advanced sensors and total power-train system optimization will be enablers for integrating alternative combustion processes into the engine operational map. This will enable optimal matching of the engine and the exhaust aftertreatment systems. In addition, improvements in the aftertreatment systems, particularly lean NOx systems, will be a critical component of meeting the technical team’s targets. Current exhaust-gas aftertreatment systems increase fuel consumption. More effective exhaust emission systems will have a double benefit. They will reduce the fuel consumption associated with their use, and they will allow the engine to be tuned differently with an attendant increase in efficiency.

Hydrogen-fueled ICEs have also been investigated. Such technology could allow a broader use of hydrogen within the transportation system and thus allow the implementation of a hydrogen infrastructure while chemical-electric conversion power plants penetrate the market. However, the hydrogen-fueled ICE vehicle will have similar energy density and specific energy constraints as those of an HFCV, described above.

In all these endeavors, the key hurdle continues to be detailed fundamental understanding of the chemical, thermal, and physical processes taking place within the power train and combustion system.

Good progress is being made by the ACEC technical team in meeting the technical targets. A peak thermal efficiency for an ICE of 43 percent has

been achieved. A peak engine efficiency of 45 percent has been achieved for a hydrogen-fueled ICE. The operational range for LTC has been enhanced through active cylinder valve actuation and intake boosting. The technical team reported achieving engine loads of 16 bar (1.6 MPa) indicated mean effective pressure (IMEP) with homogeneous charge compression ignition (HCCI) using a combination of exhaust-gas recirculation (EGR) and intake boost. Additional sensing devices are being developed and integrated into the engine cylinder and power train that facilitate better control of the in-cylinder conditions and power-train energy flow management, which is a necessity for the integration of LTC operation into the engine map.

To maximize the gains in reducing fuel consumption and emissions, every aspect of the ICE power train and aftertreatment system must be optimized for every operating condition in the vehicle’s duty cycle. This requires accurate control and manipulation of all engine control parameters for each operating condition. The fundamental research being performed by the ACEC technical team is generating the knowledge base necessary for the identification of how to optimize the combustion process at any operating condition. This understanding is being incorporated into detailed CFD simulations, which in turn accurately replicate the experimental results with minimum adjustable numerical tuning.

The predictive capabilities of the current CFD codes are very good. In fact, the codes are now being used to guide experiments and, more importantly, to identify the combination of engine control parameters that will optimize the engine and power-train performance at different operating conditions, including the use of different combinations of fuels. This is a significant technical accomplishment.

The simulation currently being used is KIVA III, developed by the U.S. Department of Energy (DOE). KIVA is an open-source-code program, which allows researchers to incorporate new understanding directly into the code for any aspect of the thermophysical processes occurring within the engine: for example, improved kinetic schemes for different fuel types, or new submodels that more accurately represent liquid fuel-combustion chamber surface interactions can be implemented into the code and then exercised for more detailed predictions of combustion results. However, KIVA III is more than 10 years old and lacks important, modern numerical technologies such as parallel computing. Having an up-to-date, open-source-code CFD program for researchers to use is a critical aspect of achieving the improvement potential of the ICE and aftertreatment power trains.

To conduct such a program successfully requires close coordination among industry, government laboratories, and academia. The ACEC technical team continues to do a good job with this close coordination. The organizational structure of the team’s activities involves memoranda of understanding (MOU) between companies and government laboratories, working group meetings, regular intergroup reviews, and an annual peer-reviewed research meeting. The technical team’s responses to the recommendation of the previous review were good (DOE, 2009c).

The energy companies continue to be engaged, and the program of Fuels for Advanced Combustion Engines (FACE), organized under the Coordinating Research Council (CRC), is supplying an important database on the impact of fuel characteristics on engine-emission processes and alternative combustion process facilitation.

The technical team has had difficulty specifically addressing its cost target. The team has assumed that the base engine cost will be $20/kW, and the incremental cost for the technology improvements, which includes enhanced aftertreatment, will be $10/kW. The team has not been able to confirm these estimates with public domain data. Consequently, it has adopted a strategy of determining the technical feasibility of the power train and aftertreatment system, and from there it will work on reducing costs by system improvements (i.e., reduce engine-out emissions, maximizing use of LTC, improving aftertreatment robustness to poisons and thermal degradation, reducing precious metal content).

Funding

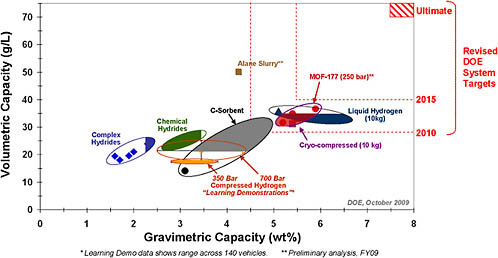

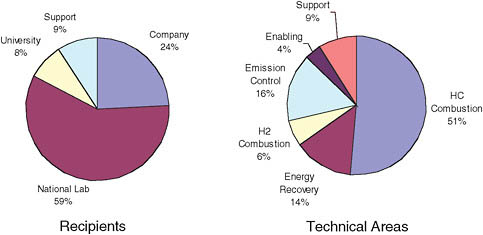

The FY 2009 funding level for the ACEC technical team was $25.4 million, with the requested level for FY 2010 being $27 million: the funds appropriated for FY 2010 were $34 million. A breakdown of how the FY 2009 funding was dispersed among different organizations and technologies is shown in Figure 3-1.

Adjustments and New Issues

Since the National Research Council’s (NRC’s) Phase 2 review of the FreedomCAR and Fuel Partnership research program (NRC, 2008), changes in the country’s energy situation have occurred. The biofuels program has grown significantly. Estimates that up to 30 percent of U.S. liquid HC energy could be displaced by domestically produced biofuels have appeared in the literature.4 A genetically modified alga has attracted attention as a way to enhance the recycling of power plant’s CO2 emissions into a viable transportation fuel.5 The prospect of enhanced electric storage capacity has spurred the interest in plug-in hybrid electric vehicles (PHEVs). And, new, more stringent emission regulations for NOx and PM are scheduled to go into effect after 2010. All of these will impact the ACEC program.

The ACEC technical team has acknowledged these changes and addressed them in its future plans. For example, the team is now engaged in fundamental combustion, emission, and kinetic studies of fuel derived from biomass. This work

|

4 |

See for example <http://www.altdotenergy.com/2009/02/sandia-gm-study-finds-large-scale-biofuel-is-sustainable/>. |

|

5 |

See for example <http://www.exxonmobil.com/Corporate/energy_climate_con_vehicle_algae.aspx>. |

FIGURE 3-1 DOE advanced combustion engine research and development funding, FY 2009. SOURCE: Advanced Combustion and Emission Control Technical Team, Presentation to the committee, August 4, 2009, Southfield, Michigan.

is aimed at understanding the fundamental changes that occur in ignition and emission-formation processes when different compounds, such as methyl esters that are found in biofuels, are used in the engine. The auto-ignition characteristics of many oxygenates, which occur naturally in biofuels, may offer advantages in expanding the range of low-temperature combustion or in expanding the optimal-efficiency regions in engine maps.

The new emission standards will require that the vehicle emission target will need to be changed from Tier 2 Bin 5 to Tier 2 Bin 2. With this change will come new challenges in lean NOx aftertreatment, specifically mitigating the impact of sulfur poisoning and the associated degradation of the system performance that occurs with repeated desulfurization.

Pending fuel economy standards will impact the vehicle mix as the on-the-road light-duty vehicle fleet turns over. Vehicles will become smaller and lighter. Thus the requirements for the engines and power trains will change. For example, the optimal engine for a PHEV will be significantly smaller than the engines typical in vehicles today. All of these changes will force an evolution in engine and power-train design, and consequently, the optimal power-train configuration, operating scenario, and fuel characteristics will also evolve. It is likely that the operational targets for the engine and power train will become more fluid.

To the committee the foregoing considerations raised the question of whether system-level modeling could be used as a tool to evaluate the optimal power train, engine map, and fuel characteristics for different scenarios of vehicle, power train, and fuel mixes as the energy market and government regulation evolve.

Recommendations

Within the scope of the FreedomCAR and Fuel Partnership objectives, the funding level and work allocation for the continued development of the ICE and vehicle electrification seem appropriate. The ACEC technical team is doing a good job of maintaining a close and constructive working relationship with the stakeholders within the vehicle and energy community. It is critical for the technical team to maintain this collaboration and to look for ways to make it even stronger.

The largest barrier to implementing advanced combustion, aftertreatment, and fuel technologies continues to be an insufficient knowledge base. Not only topic-specific understanding but also an understanding of the system-level interactions among the energy carrier, the energy release process, and the final emission cleanup are critical to continued improvement of the ICE power train.6 Continued close collaboration between the DOE and industry is necessary to allow newly developed technologies to transition into the industrial laboratories and to lead to the identification of new areas where enhanced understanding will be the most beneficial.

Recommendation 3-1. The DOE should continue to support financially, be active in, and work to further enhance the collaborations among the national laboratories, industry, and academia in order most effectively to direct research efforts to areas where enhanced fundamental understanding is most needed to improve internal combustion engine and aftertreatment power-train performance.

Recommendation 3-2. The DOE should continue to support the development and dissemination of the open-source-code computational fluid dynamics program KIVA. This tool is critical to integrating the new understanding of combustion and emission processes into a framework that allows it to be used to guide further research and identify fuel and engine operating conditions that will maximize reductions in fuel consumption over the entire operating range of the engine.

Recommendation 3-3. The advanced combustion and emission control technical team should engage with the biofuels research community to ensure that the biofuels research which the team is conducting is consistent with and leverages the latest developments in the field of biofuels R&D.

Recommendation 3-4. As the vehicle mix within the on-the-road light-duty vehicle fleet is likely to change with the implementation of the new fuel economy standards, the advanced combustion and emission control technical team should

interface with the system modeling technical team to make sure that their research programs are consistent with the changing demands for the optimal matching of the engine operational regimes, power management, and emission control that will be imposed on the internal combustion engine and hybrid power trains as the vehicle characteristics evolve.

FUEL CELL SUBSYSTEM

The fuel cell power-generation subsystem—containing the fuel cell stack and its balance of plant (BoP) consisting of the supporting air and fuel supply, thermal management, and controls—is arguably the most complex and challenging element of the entire hydrogen-fueled vehicle. As this technology is not yet fully developed, advancements are needed to meet the established efficiency, durability, lifetime, and cost targets. Although there are multiple approaches and engineering configurations under development by the original equipment manufacturers (OEMs; the automobile manufacturers), the burden of successfully accomplishing all advancements by any one organization is challenging, since much of the effort is high-risk and demands the assignment of critical resources.

The Department of Energy has been proactive in providing fuel cell R&D support for the precompetitive scientific and engineering initiatives that are high-risk and enabling by providing funding to appropriate organizations such as universities, national laboratories, and the private sector. In many cases involving private-sector developers, R&D activities have the added benefit that the initiatives may lead to supply chain development. Such support has been available through the open solicitation process for nearly 8 years under this current program (FreedomCAR and Fuel Partnership) and a number of years prior in forerunner efforts such as the Partnership for the Next Generation of Vehicles (PNGV). The recent years have witnessed funding activities on fuel cells through multiple DOE organizations, including the Office of Energy Efficiency and Renewable Energy (EERE), Basic Energy Sciences (BES), the Small Business Innovation Research (SBIR) office, and more recently, with coordinated efforts with the National Energy Technology Laboratory (NETL) and the National Renewable Energy Laboratory (NREL). During this period, multiyear development programs have resulted in awards in support of fuel cell R&D efforts. In this program alone, the 8 years of funding has resulted in three cost-shared solicitations, resulting in many R&D contracts ranging from early programmatically focused efforts, to “go/no-go” milestone-based R&D. As a result of these programs, the core technology has advanced in such areas as fuel cell membranes, catalysts, operating modes, durability, lifetime, and the scientific evaluation of the factors limiting performance (e.g., gas quality), to name a few, while projected costs have continually decreased. The activities have been coordinated directly by the fuel cell technical team organized under the FreedomCAR and Fuel Partnership Executive Steering Group (ESG).

With respect to this review, since FY 2007 approximately $140 million (see Figure 3-2) has been appropriated in total to support the attainment of the fuel cell technology roadmap R&D (DOE, 2009a) objectives so that the Partnership’s chances of meeting the 2010 targets and the 2015 commercialization-readiness decision goal are enhanced. In order for this decision to be reasonably made (i.e., for the OEMs to decide by 2015 whether or not to initiate the next steps in the process of developing commercially viable vehicles based on a hydrogen fuel cell power-generation subsystem), much of the technology must be demonstrated to be operational in vehicles, or at least it must be significantly beyond laboratory scale. The attainment of, or progress toward, 2010 targets, as shown in Table 3-1 for selected fuel cell stack targets, can also be considered as a measure of progress of the program. The 2010 goals assessment is also a measure of ascertaining whether the R&D topics initially deemed to be the highest priority are still appropriate. In such cases, the DOE go/no-go decision-making process can be and is employed. The committee’s assessment is that the fuel cell technical team is well coordinated and is aligned with respect to the achievement of the goals and the longer-term, high-risk technology challenges, especially as the OEMs are now road testing prototype HFCVs.

In light of the prior funding of this program as reported in this review period (2007-2009) and the advancements reported to the committee, at the time of this assessment the success of the program could have been put in jeopardy as a result

FIGURE 3-2 Fuel cell budget, FY 2007 through FY 2009 (in millions of dollars per year). SOURCE: C. Gittleman (GM) and K. Epping Martin (DOE), “FreedomCAR Fuel Cell Technical Team,” Presentation to the committee, August 4, 2009, Southfield, Michigan.

TABLE 3-1 Selected Fuel Cell Stack Targets and Progress

|

|

Currenta |

2010 Target |

2015 Target |

|

Lifetime (hr) |

1,977 |

|

5,000 |

|

Catalyst loading (mg/cm2) |

0.15 |

0.30 |

0.15 |

|

Efficiency at 25% rated power |

59%b |

60% |

60% |

|

Projected system costs (500,000 units produced per year; $/kW) |

~60-70 |

45 |

30 |

|

Power density (W/L) without storage |

224 |

|

325 |

|

Specific power (W/kg) without storage |

406 |

|

325 |

|

a As reported to the committee at its August 4-5, 2009, meeting and by S. Satyapal, DOE, Hydrogen Program Overview, Annual Merit Review and Peer Evaluation Meeting, May 18, 2009, Washington, D.C. Available on the Web at <http://www.hydrogen.energy.gov/pdfs/review09/program_overview_2009_amr.pdf>. b Based on laboratory results from 3M and not full-size modules. |

|||

of the zeroing of the primary budget line items related to the fuel cell development activities (in the FY 2010 administration’s budget request). If vehicle fuel cell development is to continue, such funding must remain intact and must be directed at the R&D that can help enable OEMs to develop the complete vehicle fuel cell power-generation subsystem. More specifically, as stated in its recommendations, the committee believes that technologies needed for vehicle fuel cell systems—and not just fuel cells for stationary, auxiliary power, or portable applications—should be pursued. Vehicle fuel cell requirements can be, and usually are, different and more challenging with respect to cost, reliability, and manufacturability when compared to the other nonvehicle applications. Furthermore, continued funding, especially of the high-risk concepts, will help facilitate next-generation technologies.

The fuel cell stack is composed of layers of catalyzed proton-conducting membranes and electrode assemblies (MEAs) that react supplied hydrogen fuel with oxygen from the air. The MEAs must operate under all environmental conditions and have nearly turnkey operating characteristics. The continued refinement of prior generations of the MEAs is a major issue, as neither the earlier nor current versions have been shown to meet simultaneously the 2015 targets for performance, lifetime, reliability, and cost. However, significant progress has been and continues to be made, as evidenced by field and laboratory testing. Table 3-1 presents selected fuel cell stack targets, the current status, and the progress against such targets as reported by the DOE and the Partnership. Even with such data, complicating the comprehensive understanding of the status of the fuel cell technology is the fact that the OEMs have their own respective (proprietary) fuel cell activities and engineering approaches, which may or may not be synchronized with the DOE-funded development efforts. With that said, what has been reported is that, overall, the OEMs have shown increased power density for the fuel cell stack and BoP, while at the same time the packaging and operating modes have become quite sophisticated. Manufacturing aspects of the power-generation

subsystem have yet to become a serious focus partly because of the continuing evolution of the technology (i.e., capital funding for fixed assets is not prudent when the technology may still change). Yet, selected subcomponent suppliers have prototype manufacturing capability today that would meet near-term demand. A noteworthy comment on significant achievements since the previous review is that, while almost every major target has been met in one form or another, they have unfortunately been in separate initiatives and not from a collective, single source. Although it is not definitive that the 2015 targets are achievable by the year 2015, the promising results to date indicate that they could be.

As the DOE programs address precompetitive R&D, it is important to point out again that the OEMs have their own proprietary engineering programs and are not obligated to incorporate DOE-funded developments and technologies into their units. As a result, aside from the open reporting of such performance data and improvements, the contributions of the publicly funded programs and the degree to which the results impact the success of the OEMs related to efficiency, durability, lifetime, and cost are not known with certainty.

Assessment of the Program and Key Achievements

Results reported from the recently funded activities indicate that the current fuel cell subsystem program is making significant progress, yet the successful attainment of the 2015 targets will not be known for some time. However, the attainment of the 2010 targets will be a very positive indicator of future success. Key achievements highlighted by the DOE and made since the Phase 2 review (NRC, 2008) are primarily performance- and cost-related: in particular, fuel cell stack technology tested under realistic on-road operating conditions. Demonstrated stack lifetimes in on-road vehicles have increased from operating times of approximately 1,250 hours to 1,977 hours.7 With the goal of 5,000 hours, this represents a significant achievement since the Phase 2 NRC review. Furthermore, single-cell and short-stack tests at the laboratory scale have demonstrated (using accelerated test protocols) much longer run times (3M Company, 7,200 hours)8 that, if demonstrated in vehicles under realistic on-road conditions, would meet or exceed the goals of the Partnership. Larger-scale stack performance and on-road testing will help to validate the laboratory data and determine the ultimate value to the program.

Cost (reduction) is the other area where significant advancements have been reported. The cost assessment of a fuel cell power plant is difficult to make, since the stack and BoP materials and system technology are still evolving.

|

7 |

See DOE’s Annual Merit Review on the Web at <http://www.hydrogen.energy.gov/annual_review.html>. |

|

8 |

See DOE’s 2009 Annual Merit Review, presentation by S. Satyapal, on the Web at <http://www.hydrogen.energy.gov/pdfs/review09/program_overview_2009_amr.pdf>. |

Furthermore, such component costs are not benefiting from established volume manufacturing operations at this time. To complicate the assessment of future cost further, the fuel cell stack is dependent on the platinum metals markets and on ever-changing global metals markets dynamics. In making cost projections, the assumptions are many and in some cases are based on still-unproven laboratory-phase performance. Although the results are encouraging, the same conclusion that was reached in the Phase 2 review (NRC, 2008) still holds: the cost projections are highly dependent on many unknowns and must have greater resolution in the forthcoming period. However, two separate DOE-funded studies, with independent oversight, have concluded that at volumes of 500,000 units per year, the cost per kilowatt for the fuel cell subsystem, including the fuel cell and BoP, will be approximately $60-$70/kW (Satyapal, 2009; James and Kalinoski, 2009; Sinha et al., 2009). These figures are still over two times higher than the target, but significantly lower than the $107/kW presented during the Phase 2 review. The projected cost is split nearly evenly between the stack and the BoP. Furthermore, within these cost assessments it was pointed out that platinum and membrane costs are still significant hindrances to stack cost reduction (currently active areas of DOE-funded efforts). Both stack and BoP cost reductions are required in order to achieve the $30/kW target. It was suggested by the cost studies that system simplification is essential to reduce the BoP cost.

Another measurement of progress is the number of granted patents related to FreedomCAR technology which have been derived from DOE funding. Such a metric is indicative of technology that is in the marketplace today or is available for commercialization. It impacts the fuel cell developers as well as the supply chain. As reported in a Pacific Northwest National Laboratory (PNNL) report prepared for the DOE on the patents originated from the Hydrogen, Fuel Cells and Infrastructure Technologies (HFCIT) program (DOE, 2009d), of the 144 patents, 70 have been issued since 2002 when the FreedomCAR program was initiated. Such patents have been awarded to universities, the private sector, and the national laboratories, and they represent inventions in all segments of the technology.

A particular subcomponent impacting the fuel cell cost and lifetime is the membrane and electrode assembly. Catalyst quantities required to support the hydrogen and oxygen reaction also contribute to both metrics. The lower catalyst loadings, although attractive from a cost perspective, introduce a greater risk of negatively impacting performance. The lower the catalyst loadings, the greater the potential impact on performance. Loadings as low as 0.2 mg/cm2 have been reported in full-size modules, yet the direct impact on life is not clear at this time. The ability to achieve less than 20 grams of precious metal per 80 kW stack has been verified in the laboratory but has not yet been demonstrated in a vehicle. Progress in other MEA areas has been mixed. Current membranes have a greater degree of robustness but are still impacted by secondary reactions, which can lead to chemical attack and therefore failure. Newer, lower-cost membrane development activities have been funded in recent years, and although the results of such

work look promising, it is unclear if they will lead to significant improvements in stability, life, and cost.

Overall, within this last period of activity and considering that the results available for assessments stem from 2001-2008 activities, much progress has been made in key areas. However, the coordination of the program (targets) by the fuel cell technical team could be reevaluated in some areas, such as the following:

-

The system being modeled by the Argonne National Laboratory (ANL) and used for costing efforts by the two cost contractors is not equivalent to the system expected to be under test for the 2010 goals assessment or the 2015 commercialization-readiness decision. Even though the DOE uses the system model principally for the purpose of costing and not system performance, the model should be representative of the actual system. As a specific example of the disparity, the costing was performed using a two-stack configuration, although even in the 2010 goals-assessment configuration it is expected that there will be a single stack.

-

On-road vehicle operation and performance trials have proven to be invaluable in uncovering unanticipated problems and verifying operation, and yet there is no plan to continue the funding for this activity.

-

As the majority of on-road vehicles were tested in moderate climates, additional assessments of performance in all-weather conditions are needed to provide additional insight into the viability of the current technology path.

Significant Barriers and Issues That Need to Be Addressed

The barriers remaining for the fuel cell subsystem R&D program are both programmatic and technical. Programmatic issues relate to the coordination and execution of the high-risk research in order that the solicitation timing and content address updated requirements of the Partnership.

Technical barriers that still remain for the fuel cell stack are membrane and electrode life and cost. Both areas must remain the focus of the next round of solicitations. Further, as indicated in the preceding discussion on cost, system simplification is essential to cost reduction.

Response to Phase 2 Recommendations

The Partnership addressed and concurred with the majority of the recommendations from the National Research Council’s Phase 2 review (DOE, 2009c; NRC, 2008). In some instances the FY 2009 DOE budget reflects such recommendations, and the Partnership continued to be proactive in specific areas highlighted in the Phase 2 report. In particular, the focus on advanced membranes and

catalysts to address the cost, reliability, and durability challenges is reflected in the current budget.

Appropriate Federal Role

The committee believes that federal funding for fuel cell activities is appropriate and that it remains extremely important, especially for the high-risk-related technical barriers. The need will be reduced, however, as the OEMs move closer to a commercialization phase and as the companies lock in designs for their engineering solutions. New concepts, cost-reduction R&D, and alternative engineering approaches must remain the focus of the DOE funding, especially for the development of next-generation technologies. This is especially important because numerous subsystems are interrelated. Furthermore, supply chain R&D and manufacturing concepts might require funding for the high-risk initiatives.

As the number of potential vehicle fuel cell manufacturers has been reduced in the current (2009) time frame, it is extremely important to maintain continuity and commitment regarding fuel cell technology from the perspective of the United States. As European and Asian car manufacturers are announcing fuel cell vehicle commercialization target dates in the 2015 time frame, the role that the DOE plays in supporting the FreedomCAR and Fuel Partnership has become even more critical.

Conclusions and Observations

Technology has advanced since the NRC Phase 2 review, and it is progressing even in spite of the current economic and automotive industry challenges. Together with the DOE, the OEMs with their proprietary engineering advancements have reported significant on-road achievements toward the 5,000-hour reliability and durability target. Although it is difficult to assess the specific technologies adopted by the OEMs, and the origins of the technologies, the degree of success is apparent.

The core stack technology advancement appears to be one of the most significant achievements reported to date. Although the current approach is very promising, there is a risk that down-selection of any one specific technology might be premature. Backup and secondary approaches must be in place, especially with respect to the high-risk elements.

Results to date indicate that most of the 2010 fuel cell performance targets are going to be met. The attainment of the majority of the 2015 targets is still difficult to predict.

The coordination of activities between the fuel cell technical team members and the DOE appears functional and focused. Yet, because of the nature of the DOE multiyear funded solicitation process and the rapid advancements by the OEMs, there can be a divergence of the currently funded efforts and the fuel cell subsystem R&D needs.

Recommendations

Recommendation 3-5. As the auto companies begin to down-select technologies for fuel cell vehicles, they must focus their limited R&D resources on development engineering for the platform selected and move into the competitive (as distinct from precompetitive) arena. The only way that alternative fuel cell systems and components can receive sufficient attention to mitigate the overall program risk is for the precompetitive program, sponsored largely by the DOE, to support them. Thus, the DOE should increase its focus on precompetitive R&D related to both the fuel cell stack and the balance of plant—the other components of the fuel cell system required for successful operation, such as controls, fuel storage, instrumentation, and so forth—to develop alternatives to the down-selected technologies.

Recommendation 3-6. The DOE should incorporate more of the advanced, most recent, nonproprietary OEM system configuration specifications in the various systems and cost models for fuel cell power plants. Systems configurations no longer demonstrated to be optimal should be abandoned in favor of best proven technology.

Recommendation 3-7. The DOE should establish backup technology paths, in particular for stack operation modes and stack components, with the fuel cell technical team to address the case of current technology selections determined not likely to meet the targets. The DOE should assess which critical technology development efforts are not yielding sufficient progress and ensure that adequate levels of support for alternative pathways are in place.

Recommendation 3-8. The DOE, with input from the fuel cell technical team, should evaluate, and in selected cases accelerate, the timing of the “go/no-go” decisions when it is evident that significant technological progress has been made and adopted by the OEMs.

ONBOARD HYDROGEN STORAGE

Background

Onboard hydrogen storage is a key enabler for fuel-cell-powered vehicles. The primary focus of the hydrogen storage program within the FreedomCAR and Fuel Partnership is to drive the development and demonstration of commercially viable hydrogen storage technologies for transportation and stationary applications. A specific goal of the program is a vehicle driving range of greater than 300 miles between refuelings while simultaneously meeting vehicle packaging, cost, and performance requirements. The program also includes life-cycle issues, energy efficiencies, safety, and the environmental impact of the applied hydrogen storage technologies.

The primary focus of the program is exploratory materials concepts for onboard storage with the potential to meet the long-term goals. Issues for high-pressure tanks that may have nearer-term application and can benefit from exploratory research are also included. Concepts developed in this program could potentially benefit all hydrogen storage applications.

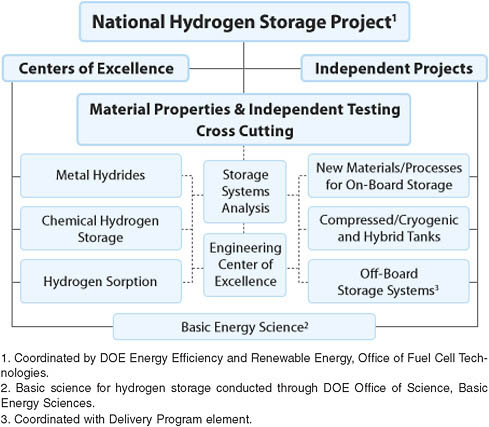

The work of the onboard hydrogen storage program is organized in four centers of excellence (COEs): the Chemical Hydrogen Storage COE, the Hydrogen Sorption COE, the Metal Hydrides COE, and the Hydrogen Storage Engineering COE (see Table 3-2 and Figure 3-3). In 2009, DOE-funded activities in hydrogen storage, including Office of Science Basic Energy Sciences awards, were carried out at 41 universities, 15 companies, and 14 federal laboratories. The hydrogen storage technical team and the DOE provide guidance for the work of the COEs. The program also includes several independent projects that are not associated with any of the COEs (see Figure 3-3). The hydrogen storage technical team is a joint technical team with participants from both the automotive and the fuel industries.

The four COEs and the independent projects constitute the framework of the National Hydrogen Storage Project (see Box 3-1 and Figure 3-3). The independent research projects explore promising hydrogen storage materials and concepts, off-board hydrogen storage for hydrogen delivery, the standardized testing of hydrogen storage properties, and analyses of life-cycle cost, energy efficiency, and environmental impact for hydrogen storage systems.

The EERE hydrogen technology budget appropriation for hydrogen storage was $59.2 million in FY 2009, which was 36 percent above the FY 2008 appropriation ($43.5 million) for applied hydrogen storage research (see Table 3-3). The FY 2010 EERE appropriation for hydrogen storage is $32.0 million. This reduced funding versus FY 2009 will meet existing grant commitments but provides no new starts. The BES budget within the Office of Science also included support of Basic Energy Research Needs for the Hydrogen Economy ($38.3 million in FY 2009). Novel materials for hydrogen storage were a high-priority area for BES funding, receiving $8.0 million in FY 2008 and $9.0 million in FY 2009.

Hydrogen storage has been an R&D priority for the DOE for less than a decade. The committee believes that continued activity with adequate R&D funding should be provided for material-based storage in order to increase the marketability of HFCVs. New focus and funding should be given to compressed-gas storage in order to meet near-term needs for hydrogen storage.

Current Status Vis-à-Vis Goals and System Targets

The physical storage of hydrogen on vehicles as compressed gas (and to a lesser extent liquid hydrogen) has emerged as the technology path for the early introduction of HFCVs. The hydrogen storage capacity of tanks is performance limiting for some vehicle architectures, but hydrogen storage overall is not a

TABLE 3-2 Centers of Excellence (COEs) Project Focus and Participating Organizations

|

COE |

Project Focus |

Organizations |

|

Center of Excellence on Chemical Hydrogen Storage |

New chemical hydrogen storage materials and regeneration processes, including ammonia borane, ionic liquids, heteroatom containing organics, catalytic processes, and new concepts for hydrogen release and spent-fuel regeneration. |

Los Alamos National Laboratory, Pacific Northwest National Laboratory, Intematix Corporation, Millennium Cell, Northern Arizona University, Pennsylvania State University, Rohm and Haas, Inc., University of Alabama, University of California-Davis, University of Missouri, University of Pennsylvania, University of Washington, US Borax |

|

Center of Excellence on Hydrogen Sorption |

High surface area sorbents including metal-carbon hybrids, boron-carbon materials, metal organic frameworks, nanohorns and fibers, conducting and porous polymers; modeling and mechanistic understanding |

National Renewable Energy Laboratory, Air Products and Chemicals, Inc., California Institute of Technology, Duke University, Lawrence Livermore National Laboratory, National Institute of Standards and Technology, Oak Ridge National Laboratory, Pennsylvania State University, Rice University, University of Michigan, University of North Carolina, University of Pennsylvania |

|

Center of Excellence on Metal Hydrides |

Light-weight complex hydrides, destabilized binary hydrides, intermetallic hydrides, modified lithium amides, and other advanced onboard reversible hydrides |

Sandia National Laboratories-Livermore, Brookhaven National Laboratory, California Institute of Technology, General Electric, HRL Laboratories, Intematix Corporation, Jet Propulsion Laboratory, National Institute of Standards and Technology, Oak Ridge National Laboratory, Savannah River National Laboratory, Stanford University, University of Hawaii, University of Illinois at Urbana-Champaign, University of Nevada-Reno, University of Pittsburgh/Carnegie Mellon University, University of Utah |

|

Hydrogen Storage Engineering Center of Excellence |

Energy challenges associated with developing low-pressure material-based hydrogen storage systems for enabling onboard storage of hydrogen for fuel-cell-powered vehicles and for achieving customer expected driving range and performance. (Includes systems integration, prototype development, and systems analysis.) |

Savannah River National Laboratory, Pacific Northwest National Laboratory, United Technologies Research Center, Los Alamos National Laboratory, NASA Jet Propulsion Laboratory, National Renewable Energy Laboratory, General Motors Company, Ford Motor Company, Oregon State University, Lincoln Composites, Inc. |

|

SOURCE: DOE (2009a), Section 3.3, Hydrogen Storage. |

||

FIGURE 3-3 Structure of the National Hydrogen Storage Project. SOURCE: Reprinted from DOE (2009a).

TABLE 3-3 Office of Energy Efficiency and Renewable Energy Budget Appropriations for Hydrogen Storage, FY 2007 through FY 2010 (millions of dollars)

|

Fiscal Year |

Appropriation ($ millions) |

|

2007 |

33.7 |

|

2008 |

43.5 |

|

2009 |

59.2 |

|

2010 |

32.0 |

|

SOURCE: A. Sudik, F. Bavarian, and N. Stetson, Hydrogen Storage Joint Technical Team, Presentation to the committee, August 5, 2009, Southfield, Michigan. |

|

“blocking” technology for vehicle introduction. The storage capacity of current tanks does not meet the long-term goals, but it may be adequate for some applications for which the cost can be justified. Thus, research aimed at significantly higher hydrogen storage capability needs to be kept as a research objective. Materials-based storage at the level required to meet all program targets is considered theoretically achievable, yet no material has been identified that meets all of the targets. These results are promising but will not be achieved without adequate funding, which is required to continue to make progress and to attract outstanding scientists and engineers to this line of research. All targets (weight, volume, efficiency, cost, packaging, safety, refueling ability, etc.) must be met simultaneously. The discovery and development of materials for onboard hydrogen storage remain high-technical-risk R&D in need of research attention and government funding.

The targets and timing for the onboard hydrogen storage program were revised since the Phase 2 review to reflect the knowledge gained from real-world vehicle experience and the vehicle weight and space appropriate for market penetration. The revised targets assume that the vehicle architecture will change between gasoline ICE and HFCVs. The newly revised hydrogen storage targets are shown in Table 3A-1 in the annex at the end of this chapter.

The overall objective for hydrogen storage remains unchanged except for the targets: vehicle performance across vehicle models with acceptable driving range, packaging, and cost, while meeting all safety requirements. Hydrogen storage capacity and cost are key parameters for initial materials evaluation. The revised targets are as follows:

-

By 2010, develop and verify onboard hydrogen storage systems achieving (old targets) 2 kWh/kg (6 weight percent [wt%]), 1.5 kWh/L, and $4/kWh; (new targets) 1.5 kWh/kg (4.5 wt%), 0.9 kWh/L (28 g/L).

-

By 2015, develop and verify onboard hydrogen storage systems achieving (old targets) 3 kWh/kg (9 wt%), 2.7 kWh/L, and $2/kWh; (new

-

targets) 1.8 kWh/kg (5.5 wt%), 1.3 kWh/L (40 g/L). (See “Annex to Onboard Hydrogen Storage” at the end of this chapter.)

Since the Phase 2 review, more than 350 materials approaches for hydrogen storage were investigated, of which 68 percent have been discontinued and 32 percent are still under investigation. Twenty-one hydrogen storage patents were issued. To date no material for onboard hydrogen storage has been identified that meets the full set of 2015 targets. These system targets are listed in the annex to this chapter.

Milestones achieved since the Phase 2 NRC (2008) review include the following:

-

The no-go decision made for vehicle hydrogen storage during the Phase 2 review was to discontinue applied R&D in pure, undoped, single-walled carbon nanotubes based on the fact that they were not able to meet the storage target of 6 wt% close to room temperature (2006).

-

A no-go decision was made for sodium borohydride onboard vehicular hydrogen storage (2007).

-

The Multiyear Research, Development, and Demonstration Plan was developed for the years 2005-2015 (2007).

-

A Hydrogen Storage Engineering Center funding opportunity was announced (2008).

-

The down-select decision on chemical hydrogen storage materials was made (2008). Selection criteria were established (e.g., gravimetric capacity, potential to regenerate onboard, regenerable, acceptable phase change, H2 release rate materials stability, endothermic release, H2 release temperature). Of 120 materials and classes of materials examined to date, 15 percent were selected for continued study.

-

Metal hydrides materials were down-selected. Selection criteria were established based on the potential to meet 2010 technical targets. Of 74 materials investigated to date, 40 have been selected for further work.

-

The Hydrogen Sorption COE has investigated 160 materials, and 35 percent are still in its inventory. A down-select report is in preparation.

-

The announcement of the Hydrogen Storage Engineering COE (2009) was made. This COE will address system integration and prototype development in coordination with the materials centers. It was awarded to the Savannah River National Laboratory (SRNL).

-

An H-Prize competition notice was issued for “Breakthrough Advances in Materials for Hydrogen Storage” (DOE, 2009b). A single amount of $1 million will be awarded for the development of an onboard hydrogen storage material that meets or exceeds a set of performance targets specified in the competition announcement. This prize creates an incentive for the R&D community outside the conventional grant process.

-

A DOE hydrogen program solicitation was issued for R&D for onboard vehicular hydrogen storage to support the COE or as independent projects (2008).

Assessment of Progress and Key Achievements

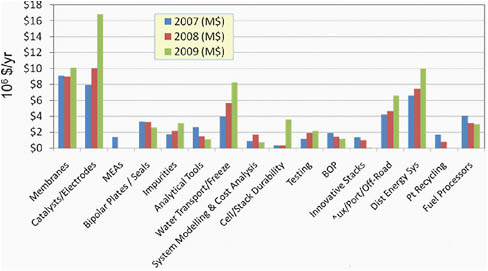

The current status of promising hydrogen storage materials is shown in the composite Figure 3-4. Hydrogen storage is shown together with the new targets (volumetric and gravimetric capacity only). Figure 3-4 shows results for the three groups of hydrogen storage materials: complex hydrides, chemical hydrides, and carbon sorbents. Data given here show that all three material groups fall short of the 2015 system targets for both volumetric and gravimetric capacities, but with best results demonstrated for the carbon sorbents.

The current candidate storage materials under investigation for the three classes of materials—reversible metal hydrides, chemical storage materials, and hydrogen sorbents—are listed in Box 3-2.

Information for physical storage is shown in Figure 3-4 for both ambient and cryo-based systems. Data are shown for 350 and 700 bar (ca. 35 MPa and 70 MPa) compressed hydrogen. In the nearer term, ambient physical storage provides a means for advancing the integrated hydrogen fuel cell system development and gaining experience while the materials storage approach is developed further. The ambient systems (the current and simplest configuration) are targeted for the early introduction of the vehicle test fleets.

Expensive “aerospace quality” carbon fiber is needed in the construction of the onboard pressure vessel for hydrogen for HFCVs. Such fibers provide the necessary high strength and lightweight characteristics. The DOE currently has several efforts to reduce the cost of carbon-fiber pressure vessels. Included in these efforts is the use of melt spinning in place of the currently used solution spinning of the PAN (polyacrylonitrile) feedstock. Another project that has promise for cost reduction is the hot-melt processing of PAN. Quantum Technologies is also being funded to reduce the cost of compressed storage by manufacturing process optimization. Also, a carbon-fiber pilot line facility is being funded with American Recovery and Reinvestment Act (ARRA) of 2009 funds at the Oak Ridge National Laboratory to lower the processing and feedstock costs for aerospace-quality fibers.

Two reports, one on cryo-compressed hydrogen (ANL, 2009) and one on compressed hydrogen (TIAX, 2009), released in late 2009, project that the cryo-compressed tank as modeled will meet the gravimetric targets for hydrogen storage but not the volumetric targets. For the compressed hydrogen study, the 350 and 700 bar (ca. 35 MPa and 70 MPa) tanks as modeled will meet the gravimetric targets but none of the volumetric and cost targets. These projections include the balance of plant.

Although the storage density is a critical parameter, all of the targets (weight, volume, efficiency, cost, packaging, safety, refueling ability and time, etc.) must

|

BOX 3-2 Current Candidate Hydrogen Storage Materials Under Investigation

|

|||||||||

be met simultaneously. None of the approaches (neither material-based nor physical storage) meets the combined targets. The program approach of using the Hydrogen Storage Engineering COE to fabricate and evaluate complete vehicle-ready test systems is an excellent technique for selecting the most viable material configuration. The material and physical storage results to date (obtained in a short time) as well as the Hydrogen Storage Engineering COE are promising with respect to the attainment of the 2015 objectives.

Also of note, the DOE Vehicle/Infrastructure Demonstration Program reported having achieved an HFCV range of 196 to 254 miles. The highest HFCV range reported to date (estimated to be 431 miles on a single full tank of compressed gas from Toyota) is the result of a field evaluation for a fuel cell hybrid vehicle. This field test included data analysis by NREL and SRNL through a collaborative research and development agreement (CRADA).

Highlights of Technical Accomplishments

Several significant technical accomplishments have been achieved, as follows:

-

Overall progress in system capacity is reported to have increased 50 percent since 2007.

-

Systems analysis of hydrogen storage options has been accomplished (Argonne National Laboratory).

-

Areas have been identified for materials-based and physical/compressed storage-system cost reduction (TIAX LLC).

-

MB12H12 effects on borohydride reversibility have been studied (NASA Jet Propulsion Laboratory [JPL], California Institute of Technology, and General Electric).

-

Alane regeneration has been achieved by means of adduct (Brookhaven National Laboratory).

-

Ammonia borane regeneration efficiency and yields have improved (COE on Chemical Hydrogen Storage).

-

Hydrogen binding energy on adsorbents has been increased (University of California, Berkeley; University of California, Santa Barbara; and Texas A&M).

-

Improved hydride kinetics by means of carbon aerogel scaffolds has been achieved (HRL Laboratories, LLC; and Lawrence Livermore National Laboratory).

-

A subscale prototype has been developed for NaAlH4.

-

A full-scale prototype has been developed for cryo-compressed hydrogen storage.

Significant Barriers and Issues That Need to Be Addressed

The hydrogen storage program has good recognition of the many technical needs and challenges that it faces. The following is a compilation of these issues:

-

Those common to all storage approaches

-

System weight and volume: Too high for meeting the 300-mile range across a wide spectrum of vehicle platforms. Basically no suitable storage material has been identified and developed.

-

System cost: Needs to be reduced compared with petroleum. Cost areas include materials of construction and manufacturing methods, and balance of plant components.

-

Charging time (refueling) for material storage: Storage capacity and rates of sorption and release need understanding and improvement (goal is 3 minutes for 5 kg charge).

-

Energy efficiency: Charging and discharging of hydrogen to a storage tank or storage material can be an energy consumer (requiring heating and/or cooling), which impacts the overall system efficiency.

-

Systems issues: Thermal management, durability and operability, hydrogen quality, containment vessels, dispensing technologies, and system life-cycle assessment and prediction need to be addressed.

-

Codes and standards: Needed for entire system and for all interfaces.

-

Safety: Issues related to hydrogen storage (see Recommendations 2-2 and 3-10).

-

-

Reversible materials-based systems (reversible onboard)

-

Hydrogen sorption (physisorption and chemisorption) and desorption processes: Understanding of these processes is needed.

-

Reproducibility of performance: Needs to be demonstrated.

-

-

Chemical hydrogen storage systems (typically regenerated off-board)

-

Regeneration process: Process cost, efficiency, environmental impact.

-

By-product/spent material removal: Important issues to be addressed.

-

-

Pressurized hydrogen storage tanks

-

The cost of high-quality carbon fibers: Needs to be reduced.

-

Technical tasks have been established that address each of these issues.

Future Plans

The newly organized Hydrogen Storage Engineering COE has taken on the coordination of the engineering aspects of material-based hydrogen storage systems. This center plans crosscutting hydrogen storage activities organized across six areas: performance analysis, system modeling, enabling technologies, materials operating requirements, transport phenomenon, and subscale prototype construction and testing and evaluation. Given the fact that the completion dates for the other three COEs and a number of independent projects fall within FY 2010, this COE will have a critical role in capturing the progress for a sustained activity during any transition period.

Target dates have been appropriately set for technology down-select decisions:

-

A complete analysis of onboard storage options for 2010 and 2015 targets was scheduled for 2009 as well as a decision point on advanced carbon-based materials and a down-select for chemical hydrogen storage approaches for the 2010 targets.

-

A decision on reversible metal hydride R&D is scheduled to be made in the fourth quarter of 2010 as well as a decision point on chemical hydrogen storage R&D.

-

The down-select for onboard reversible hydrogen storage materials and for chemical hydrogen storage approaches with the potential to meet 2015 targets is set for the fourth quarter of 2013.

-

Complete laboratory-scale prototype system and evaluation against 2015 targets is scheduled for the fourth quarter of 2015.

Future plans include continued R&D on breakthrough hydrogen storage materials with increased emphasis on engineering analysis, a broadening of the effort to include all of the targets (versus just the capacity targets), and increased coordination between the basic and applied activities. Early market applications will

receive increased emphasis. The hydrogen storage technical team will continue to monitor and leverage globally activities on hydrogen storage. In order to address the fuel storage needs of and to set priorities for fuel cell applications, the EERE plans to conduct a Request for Information (RFI) and a workshop during FY 2010.

Response to Recommendations from the Phase 2 Review

The DOE agreed with most of the recommendations from the Phase 2 review (DOE, 2009c; NRC, 2008). It did not address in the response the safety implications of relying on compressed-gas storage in the interim period. Compressed-gas tank safety needs further attention. The FY 2009 budget appropriation allowed the program to be supported at a high level for continuing and new R&D activities. The program has been managed to balance resources—for example, to cut storage approaches without potential and to down-select approaches with the most potential. The Hydrogen Storage Engineering COE is a timely use of resources and fits well with the other COEs. The real-world experience with pressurized tanks is providing information on R&D issues. The DOE (2009c) stated in the response that the issue of materials for pressurized tanks is being addressed in other parts of the program and in future solicitations. In response to the recommendation for a strong basic research portfolio, it was noted that BES held a contractors’ meeting for principal investigators funded on projects related to the Partnership in conjunction with the DOE Hydrogen Program Annual Merit Review and Peer Evaluation Meeting in 2006 and again in 2009. Hydrogen basic research is well funded in the FY 2009 program, and new concepts will continue to be supported.

Appropriate Federal Role

The federal sponsorship of the hydrogen storage activities within the FreedomCAR and Fuel Partnership is an appropriate federal role. The research work supported is high-risk and potentially important for meeting national energy and emission objectives. This sponsorship has significantly stimulated research and aided the advancement of the field through its support of a significant number of qualified researchers, providing focus on common goals, maintaining communications among participants, and peer review of results.

Recommendations

Recommendation 3-9. The centers of excellence are well managed and have provided an excellent approach for organizing and managing a large, diverse research activity with many participants at various locations. Measures should be taken to continue research on the most promising approaches for onboard hydrogen storage materials. The complete documentation and communication of

findings should be undertaken for all materials examined for the completed R&D. Furthermore, in view of the fact that the hydrogen storage program has been in place for less than a decade, the Partnership should strongly support continuing the funding of basic research activities. Public domain contractor reports should be available through links on the DOE EERE Web site.

Recommendation 3-10. Research on compressed-gas storage should be expanded to include safety-related activities that determine cost and/or weight, such as validation of the design point for burst pressure ratio at beginning of life and end of life and evaluation of Type 3 versus Type 4 storage vessels. Furthermore, finite-element modeling of stresses and heat flow in fires, investigative work on wraps (i.e., translation efficiency), and analysis of applicability of compressed-gas storage to specific vehicle types would be beneficial.

Recommendation 3-11. The high cost of aerospace-quality carbon fiber is a major impediment to achieving cost-effective compressed-hydrogen storage. The reduction of fiber cost and the use of alternative fibers should be a major focus for the future. Systems analysis methodology should be applied to needed critical cost reductions.

Recommendation 3-12. The hydrogen storage program is one of the most critical parts of the hydrogen/fuel cell vehicle part of the FreedomCAR and Fuel Partnership—both for physical (compressed gas) and for materials storage. It should continue to be funded, especially the systems-level work in the Hydrogen Storage Engineering COE. Efforts should also be directed to compressed-gas storage to help achieve weight and cost reduction while maintaining safety.

Recommendation 3-13. The time for charging the hydrogen storage material with hydrogen (refueling time) is a program goal (3 minutes for a 5 kg charge). Concepts beyond materials properties alone should be explored to meet this challenge for customer satisfaction, and will require coordination with the areas of production, off-board storage, and dispensing.

Recommendation 3-14. There should be an effort to anticipate hydrogen storage material property and performance requirements that will place demands on developed systems—for example, purity and response to impurities, aging and lifetime prediction, and safety in adverse environments. Linkage between the hydrogen storage and production and delivery activities should receive attention.

Recommendation 3-15. The search for suitable onboard hydrogen storage materials has been broadly based, and significant progress is reported. Nonetheless the current materials are not close to the long-range goals of the Partnership. Onboard hydrogen storage R&D risks losing out to near-term applications for

future emphasis and funding. The management of a long-term/short-term joint portfolio should be given consideration.

ELECTROCHEMICAL ENERGY STORAGE

Introduction

Electrochemical energy storage technologies, batteries, and ultracapacitors are critical to the advancement of the FreedomCAR and Fuel Partnership’s long-term goals. Significant improvement in their performance can result in battery electric vehicles (BEVs), one of the ways to meet the Partnership’s goal of “energy freedom, environmental freedom, and vehicle freedom.” The FreedomCAR and Vehicle Technologies (FCVT) program (now renamed the Vehicle Technologies [VT] program), has supported the advancement of batteries and ultracapacitors from the beginning as a key to developing hybrid electric vehicles (HEVs). Also, before a hydrogen fuel infrastructure is fully developed, plug-in hybrid electric vehicle (PHEV) and BEV technologies, which would compete with hydrogen fuel cell vehicles, may offer a transitional means to improve fuel efficiency and emissions reduction. Since the success of HFCVs is not assured, this transition role could turn out in many cases to be a more permanent scenario.

In 2006, in response to the President’s Advanced Energy Initiative, the FCVT program began the development of PHEVs, or extended-range electric vehicles. In contrast to conventional vehicles or HEVs, PHEVs are able to drive on electric power alone for some distance, depending on the electric battery storage capacity. PHEVs thus need more advanced batteries and electric power components than HEVs need. Electric energy storage technologies have taken on an even greater importance in the past year due to the priorities of the new administration to “put 1 million plug-in hybrid cars—cars that can get up to 150 miles per gallon—on the road by 2015, cars that we will work to make sure are built here in America.”9 Furthermore, corporate average fuel economy (CAFE) standards were increased 40 percent to a national fuel economy standard of 35 miles per gallon (mpg) by 2020 (the Obama administration is targeting 2016 rather than 2020). This increase provides a regulatory incentive to increased HEV and PHEV production.

In 1999, HEVs were first introduced in the United States, and their market penetration continued to grow through 2007. In 2008, their sales decreased with the general decrease in all auto sales. Overall the number of HEVs sold has increased 271 percent from 2004 to 2008—from 84,000 to 312,000 vehicles—yet this represents only about 2.5 percent of the new vehicles sold in 2008. The number of models available has also increased from 5 in 2004 to 18 in 2008. All of the HEVs available use a nickel metal-hydride (NiMH) battery, and the DOE has been involved in the advancement of this technology since the 1990s. However, the

|

9 |

See, for example, <http://www.whitehouse.gov/agenda/energy_and_environment/>. |

NiMH battery will not meet the long-term FreedomCAR electrochemical energy storage goals for HEVs of a 15-year life with 25 kW pulse power and a cost of $500 by 2010. Thus, the Partnership, through the VT program, is focused on the development of lithium-ion (Li-ion) batteries for HEVs. Major improvements of Li-ion technology are one key requirement for the economic mass production of competitive PHEVs, HFCVs, and BEVs. Li-ion-powered BEVs began production in 2008 with the introduction of the Tesla Roadster powered by 6,800 cells sized for commercial electronics. (Tesla is an expensive sports car that does not meet the target goals of the Partnership.) In addition, a large number of auto companies have announced their intention to launch HEVs, PHEVs, and BEVs using Li-ion batteries in the next few years.

The VT program, in collaboration with the United States Advanced Battery Consortium (USABC), manages the electrochemical energy storage technology program with a goal of the advancement of battery technologies, to the point that the program partners are encouraged to introduce hybrid and electric vehicles with large market potential. Technology development is undertaken by battery manufacturers, DOE national laboratories, and universities, and by awards through the SBIR program. The effort is composed of three subactivities: (1) Battery Technology Development is involved in battery system module development, including design and fabrication specifications, testing procedures, cost modeling and recycling studies, and technology assessment and the benchmark testing of various battery systems; (2) Applied Battery Research focuses primarily on improving the understanding of failure and life-limiting parameters, including safety and abuse tolerance, of the Li-ion system that currently is closest to meeting the technical goals; and (3) Long-Term Battery Research addresses the fundamental understanding of specific electrochemical systems for Li-ion batteries and the development of newer couples with a potential for higher power and energy density.

The Partnership’s budget for electrochemical energy technologies has increased as the importance of PHEV battery development has increased. The budget was increased from $24.4 million in FY 2006 to $40.8 million in FY 2007, with a significant increase primarily for PHEV batteries. It was again increased to $48 million in FY 2008 and to $69 million for FY 2009. The FY 2009 budget included $15 million for HEV systems, $38 million for PHEV systems, and $16 million for exploratory R&D. The budget request for FY 2010 is for $78 million. Also, full battery system development is done in collaboration with the USABC through competitive subcontracts that are at least 50 percent cost-shared.

In addition, the Advanced Research Projects Agency-Energy (ARPA-E) of the DOE continues to fund several projects on energy storage technologies for both stationary and vehicular applications. The focus of these projects is primarily to develop high-energy-density batteries. Furthermore, fundamental research projects on electrochemical energy systems are funded by the BES. The VT pro-

gram contributes about $2 million to the BES for this effort. The BES focuses on long-term needs, such as a basic understanding of materials, interfacial charge transfer, and the development of tools and processes for the design of new materials. Although the BES mandate on energy storage is broader and longer term, it works in close coordination with the VT program to advance the energy storage needs for automotive applications.

Of the 312,000 HEVs sold in 2008, only 31,000 (10 percent of total HEV sales) were manufactured by the three U.S. auto companies, whereas Toyota Prius sales comprised about half of the total sales of HEVs. In order to accelerate the manufacture and deployment of electric vehicles, batteries, and related power components here in America and to create thousands of jobs in these technologies, 48 new advanced battery and electric drive projects of $2.4 billion were funded under the ARRA. Of these funds, $1.5 billion in grants is for producing batteries and their components and expanding battery-recycling capacity. Although the ARRA funding is short term for the purpose of establishing a manufacturing base and primarily increasing employment, it has the potential of influencing continued research and development of advanced batteries into the future.

Until 2007, the FCVT program was primarily involved in the development of high-power electrochemical energy storage systems for HEVs. Since 2007, the FCVT program has expanded the electrochemical energy storage activity to include PHEVs. The goal is to develop vehicles that would allow a 40+ mile electric range, enough to satisfy about 70 percent of the daily commuting travel in the United States. These vehicles operate in both modes—electric-only (as in a BEV) and electrical/mechanical (as in an HEV)—and the battery can be recharged from a standard electric outlet. The VT efforts for PHEVs are directed at developing higher-energy batteries that meet the targets (see Table 3-4) established by the DOE and USABC for commercial viability. In addition, it continues to pursue research activities toward even-higher-energy batteries for BEV applications.

Program Status and Assessment

Lithium-ion battery technologies hold promise of achieving the long-term goals of high power, energy, and other performance requirements for HEV and PHEV applications at lower anticipated costs than those for other battery systems. Thus, the Partnership is correctly focused on the development of these technologies while it continues to benchmark competing battery technologies and encourages research on higher-energy chemistries for BEV applications.

Three Li-ion battery chemistries classified by the cathode material, including (1) lithium nickel, cobalt, and aluminum; (2) lithium iron phosphate; and (3) lithium manganese spinel and a carbon anode have been developed and tested for HEV applications. Sufficient progress has been made on these chemistries that they meet or exceed most of the 2010 performance goals listed in Table 3-4. Since the Phase 2 review, there has been improvement in discharge and regen-

TABLE 3-4 Target Characteristics for Hybrid Electric Vehicle Batteries for 2010

|

Characteristics |

Unit |

Status in 2009 |

Minimum Goal |

Maximum Goal |

|

10 s discharge pulse power |

kW |

29.5 |

25 |

40 |

|

10 s regenerative pulse power |

kW |

35.3 |

20 |

35 |

|

Available energy |

Wh |

780 |

300 |

500 |

|

Efficiency |

% |

>90 |

90 |

90 |

|

Cycle life |

Cycles |

200,000 |

300,000 |

300,000 |

|

Calendar life |

Years |

15 |

15 |

15 |

|

System cost at 100,000/yr |

$ |

1,035 |

500 |

800 |

|

Maximum system weight |

kg |

36.5 |

40 |

60 |

|

Maximum system volume |

Liter |

35 |

32 |

45 |

|