2

Overview of Agent Destruction Processes at Pueblo Chemical Agent Destruction Pilot Plant and Blue Grass Chemical Agent Destruction Pilot Plant

The Pueblo and Blue Grass Chemical Agent Destruction Pilot Plants (PCAPP and BGCAPP) will use neutralization technology instead of the incineration processes used at five other storage sites to destroy chemical munitions. Two other sites, Aberdeen, Maryland, and Newport, Indiana, at which chemical agents were stored only in bulk ton containers, used neutralization technology developed by the Army and have since completed destruction operations and been closed. In view of this, and in recognition of local public opposition to the use of incineration, Congress mandated that nonincineration technologies also be used to destroy the assembled chemical weapons stored at the Pueblo and Blue Grass sites (Public Laws 104-201 and 104-208). Neutralization involves the hydrolysis of chemical agent and energetics using hot water for mustard agent and alkali for nerve agents and energetics. BGCAPP will use neutralization followed by the treatment of the resultant hydrolysis products with supercritical water oxidation (SCWO). PCAPP plans to ship the energetics removed from the munitions for disposal offsite; it will use neutralization to destroy the mustard agent followed by biotreatment of the hydrolysate. These plants will be operated 24 hours a day, 7 days a week.

The processes planned for use at PCAPP and BGCAPP are described briefly below. These overview descriptions are not intended to delineate all of the waste streams and final products of the destruction processes. For example, most of the processes are batch operated and have sufficient buffer storage between unit operations. Rather, only those processes that will be discussed later in this report are described here, including those that will be used to exemplify aspects of process safety management. A more extensive description of the unit operations can be found in earlier National Research Council reports and on the Assembled Chemical Weapons Alternatives (ACWA) Web site.1 Tables 2-1 and 2-2 give the physical properties of the chemical agents that will be processed at PCAPP and BGCAPP. The munitions to be destroyed are depicted in Figures 2-1 through 2-5.

PCAPP PROCESS OVERVIEW

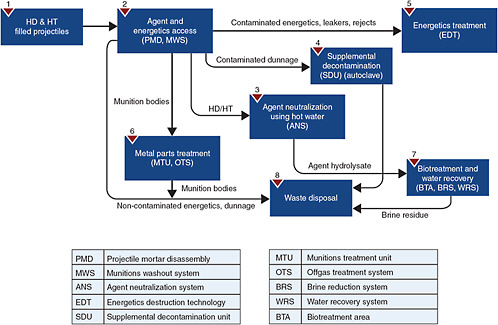

Unless otherwise noted, the material in this section is based on a presentation to the committee.2 The chemical munitions stockpile stored at the Pueblo Chemical Depot (PCD) consists only of artillery projectiles and 4.2-inch mortars containing mustard agent. The stockpile contents are shown in Table 2-3. The process flow chart for PCAPP is shown in Figure 2-6.

Pallets containing projectiles will be transported from the depot’s storage igloos to the munitions storage magazine (MSM) at PCAPP (first box in Figure 2-6). Because munitions can be transported only during daylight hours and in good weather, the accumulation

|

1 |

See, for example, Interim Design Assessment for the Blue Grass Chemical Agent Destruction Pilot Plant (2005) and Interim Design Assessment for the Pueblo Chemical Agent Destruction Pilot Plant (2005) at http://www.nap.edu/. The Assembled Chemical Weapons Alternatives Web site is at http://www.pmacwa.army.mil/. |

|

2 |

Joe Novad, Deputy Program Manager, U.S. Army Element, ACWA, “PCAPP Overview,” presentation to the committee on June 14, 2010. |

TABLE 2-1 Physical Properties of Nerve Agents

|

Agent Characteristic |

GB |

VX |

|

Chemical formula |

C4H10FO2P |

C11H26NO2PS |

|

Molecular weight |

140.10 |

267.38 |

|

Boiling point (°C) |

150 (extrapolated) |

292 (extrapolated) |

|

Freezing point (°C) |

−55 |

≤51 |

|

Vapor pressure at 25°C (mm Hg) |

2.48 |

0.000878 |

|

Volatility at 25°C (mg/m3) |

18,700 |

12.6 |

|

Surface tension at 20°C (dynes/cm) |

26.5 |

32.0 |

|

Kinematic viscosity (cSt) |

1.28 at 25°C |

12.26 at 20°C |

|

Liquid density at 25°C (g/cm3) |

1.0887 |

1.0083 |

|

Solubility (g/100 g of distilled water) |

100; soluble in organic solvents |

5 at 25°C; best solvents are dilute mineral acids |

|

Heat of vaporization (cal/g) |

82.9 |

71.8 |

|

Heat of combustion (cal/g) |

5,600 |

8,300 |

|

SOURCE: NRC, 2005; Abercrombie, 2003. |

||

TABLE 2-2 Physical Properties of Mustard Agentsa

|

Agent Characteristic |

HD |

HTb |

|

Chemical name |

Bis (2-chloroethyl) sulfide or 2,2'-dichlorodiethyl sulfide |

Same as HD with 20 to 40 wt% agent T, bis[2(2-chlorethylthio) ethyl] ether |

|

Chemical formula |

C4H8Cl2S |

Not applicable |

|

Molecular weight |

159.07 |

188.96 (based on 60/40 wt%) |

|

Vapor density (relative to air) |

5.5 (calculated) |

6.5 (calculated based on 60/40 wt%) |

|

Boiling point (°C) |

218 (extrapolated) |

No constant boiling point |

|

Decomposition temperature (oC) |

180 |

165 to 180 |

|

Freezing point (°C) |

14.45 |

1.3 (measured as melting point) |

|

Vapor pressure at 25°C (mm Hg) |

0.106 |

7.7 × 10–2 (calculated based on Raoult’s law equation) |

|

Volatility at 25°C (mg/m3) |

9.06 × 102 (calculated from vapor pressure) |

7.83 × 102 (calculated from vapor pressure) |

|

Diffusion coefficient for vapor in air (cm2/sec) |

0.060 at 20°C (68°F) |

0.05 at 25°C (77°F) |

|

Flash point (°C) |

105 |

Flash point range 109 to 115 |

|

Surface tension (dynes/cm) |

43.2 at 20°C (68°F) |

44 at 25°C (77°F) |

|

Viscosity at 20°C (cSt) |

3.52 |

6.05 |

|

Liquid density at 25oC (g/cm3) |

1.2685 |

1.263 |

|

Solubility (g/100 g of distilled water) |

0.092 at 22°C (72°F); soluble in acetone, carbon tetrachloride, chloroform, tetrachloroethane, ethyl benzoate, ether |

Slightly soluble in water; soluble in most organic solvents |

|

Heat of vaporization |

|

Not available |

|

(Btu/lb) |

190 |

|

|

(J/g) |

82 |

|

|

Heat of combustion |

|

Not available |

|

(Btu/lb) |

8,100 |

|

|

(J/g) |

3,482 |

|

|

aMustard agents are labeled H, HD, and HT. The active ingredient in all these blister agents is bis(2-chloroethyl) sulfide, or (ClCH2CH2)2S. HD, called the distilled mustard, is nominally pure mustard agent. H, often called Levinstein mustard, was approximately 70% pure mustard agent and 30% impurities at the time of manufacture. However, the stored H mustard agent has deteriorated over time and its physical properties are highly variable. H is the only form of mustard agent stored at Blue Grass Army Depot. bOverall proportional composition of the mixture. HT is prepared by a chemical process that synthesizes the HT directly in such a way that it contains both the HD and T constituents without further formulation. SOURCES: Adapted from U.S. Army, 1988; Abercrombie, 2003; BPT, 2004. |

||

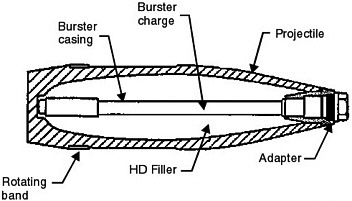

FIGURE 2-1 A 105-mm howitzer projectile. Some cartridges have been reconfigured and therefore will not have propellant in the box with the projectile. For those that still have propellant, there will be propelling charges in the box. SOURCE: Adapted from U.S. Army, 1977.

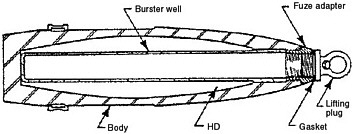

FIGURE 2-2 A 155-mm howitzer projectile. These projectiles have been separated from their propellant and stored. SOURCE: Adapted from U.S. Army, 1977.

FIGURE 2-3 A 4.2-inch mortar cartridge. The 4.2-inch mortar cartridges will be reconfigured as will be the projectiles. Most 4.2-inch cartridges will also be defuzed. SOURCE: Adapted from U.S. Army, 1977.

of munitions in the MSM allows for round-the-clock operation at PCAPP. From the MSM, munitions will be moved to the unpack area in the enhanced reconfiguration building (second box in Figure 2-6). If the projectiles contain bursters,3 they will be moved to the reconfiguration room, where the bursters will be removed by the linear projectile and mortar disassembly (LPMD) machine (described later in this chapter) without disturbing the burster well that seals in the chemical agent. Uncontaminated energetics will be sent offsite for processing. Leaker and reject projectiles will be disposed of using an explosive destruction technology, without disassembling the munition (fifth box in Figure 2-6).4 The reconfigured projectiles (that is, those whose bursters have been removed) will then be transported robotically along a long corridor to the agent processing building in munition transfer carts.

|

3 |

A burster is an explosive charge, the purpose of which is to burst the munition casing and disperse the chemical agent within. |

|

4 |

A leaker is a munition that has leaked. A reject is a munition that for any reason cannot be disassembled. These munitions will be destroyed by an explosive destruction technology without removing them from their outer protective overpack, reducing the risk of exposing personnel or the environment to agent. For more information on explosive destruction technology, see the NRC reports Review of International Technologies for Destruction of Recovered Chemical Warfare Materiel (2006) and Assessment of Explosive Destruction Technologies for Specific Munitions at the Blue Grass and Pueblo Chemical Agent Destruction Pilot Plants (2009). Both are available at http://www.nap.edu. |

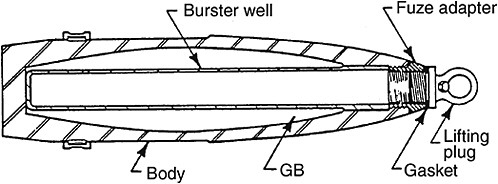

FIGURE 2-4 An 8-inch projectile. The 8-inch projectiles at BGAD do not contain any energetic materials. SOURCE: U.S. Army, 1983.

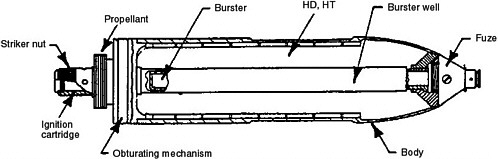

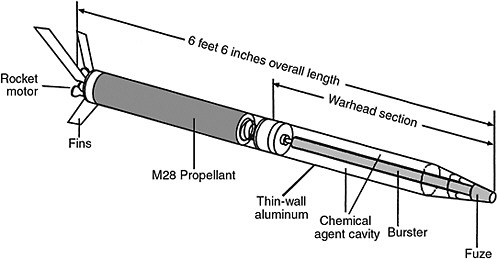

FIGURE 2-5 An M55 rocket. SOURCE: Beth Feinberg, Office of the Program Manager for Alternative Technologies and Approaches, presentation to the Committee on Review and Evaluation of the Army Chemical Stockpile Disposal Program, March 28, 2001.

In the agent processing building, the shells, still containing the burster well, will be moved on trays to the munition washout system (MWS) (second box in Figure 2-6). A robot will take a projectile from a tray and place that projectile into a cavity access machine in an inverted position. In the cavity access machine, an arm will dislodge the burster well by ramming it into the shell to expose the agent. The agent will then be drained and the interior of the shell washed using a high-pressure water wand. The chemical agent removed from the munition will then be transferred to the agent neutralization system, where it will be neutralized (third box in Figure 2-6). (Agent neutralization is described after the BGCAPP process description later in this chapter.) Hydrolysate will not be transferred from the agent neutralization system until it has been analyzed and verified that agent destruction is complete. The hydrolysate produced from the neutralization of mustard agent contains mostly thiodiglycol, which is biodegradable. The hydrolysate will thus be transferred to and treated in immobilized-cell bioreactors, where bacteria will feed on the thiodiglycol that is the prime

TABLE 2-3 Chemical Weapons Stockpile Stored at PCD

|

Munition |

Agent Fill |

Quantity |

|

155-mm projectiles M110 |

HD |

266,492 |

|

155-mm projectiles M104 |

HD |

33,062 |

|

105-mm cartridge M60 |

HD |

383,418 |

|

4.2-inch mortar M2A1 |

HD |

76,722 |

|

4.2-inch mortar M2 |

HT |

20,384 |

|

SOURCE: NRC, 2001. |

||

constituent of the mustard hydrolysate and convert the hydrolysate compounds to water, carbon dioxide, and sludge that will contain compounds of chlorine and sulfur originating from the mustard (seventh box in Figure 2-6). It is also anticipated that this sludge will contain mercury owing to previous experience with the contamination of mustard agent with mercury at other stockpile sites that contained mustard agent. The Program Manager for Assembled Weapons Alternatives (PMACWA) is working on procedures to address the anticipated presence of mercury.

The projectile bodies are meanwhile placed in other trays and moved to the munitions treatment unit (sixth box in Figure 2-6), where they will be decontaminated at 1000°F for over 15 minutes before being released. The munitions treatment unit is a long muffle furnace with a conveyor that will slowly move projectile bodies from one end to the other as they are heated.

FIGURE 2-6 PCAPP process flow chart. SOURCE: Joe Novad, Deputy Program Manager, U.S. Army Element, Program Manager for ACWA, “PCAPP Overview,” presentation to the committee on June 14, 2010.

TABLE 2-4 Chemical Weapons Stockpile Stored at BGAD

|

Munition |

Agent Fill |

Quantity |

|

115-mm rockets M55 |

GB |

51,716 |

|

115-mm rockets M55 |

VX |

17,733 |

|

115-mm rocket warheads M56 |

GB |

24 |

|

115-mm rocket warheads M56 |

VX |

6 |

|

155-mm projectiles M121/A1 |

VX |

12,816 |

|

155-mm projectiles M110 |

H |

15,492 |

|

8-inch projectiles |

GB |

3,977 |

|

SOURCE: NRC, 2005. |

||

BGCAPP PROCESS OVERVIEW

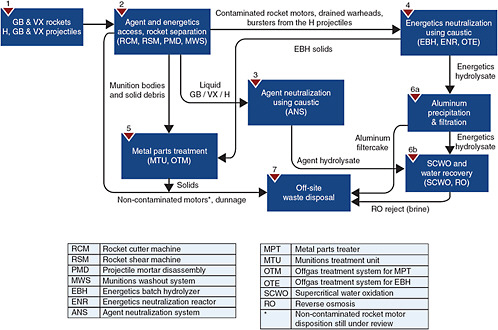

Unless otherwise noted, the material in this section is based on a presentation to the committee.5 The chemical munitions stockpile stored at the Blue Grass Army Depot (BGAD) is smaller but far more diverse than that at PCD. It contains both rockets and projectiles and the chemical agents H (mustard), GB (sarin), and VX. Consequently, the process for destroying the munitions in the BGAD inventory is more complex than that for the munitions at PCD. The contents of the stockpile stored at the BGAD are shown in Table 2-4, and the flow chart for the destruction process is shown in Figure 2-7.

Rocket Processing

Because the M55 rockets, which contain about 19 pounds of a two-base propellant and 10 pounds of nerve agent, pose the highest storage and processing risks, they will be destroyed first. The rockets will be transported from the igloos into the unpack area, where personnel will remove them from the pallets (first box in Figure 2-7). If agent is detected outside the shipping and firing tube, the rocket is returned to storage until it and other leaking rockets are disposed of. After being removed from their pallets, the rockets, still contained in their fiberglass shipping and firing tubes (SFTs), will be placed on a conveyor and moved to the explosion containment vestibule and onto the rocket cutting machine (second box in Figure 2-7). First, the propellant motor section at the back end will be separated from the rocket warhead in two stages by cutting through the SFT and rocket body with a pipe cutter-like device. The first cut is only deep enough to cut open the SFT so that it can be removed. The second cut will be deep enough to breach the outer body of the rocket, allowing the warhead and motor sections to be separated. Uncontaminated propellant sections and the warhead’s SFT sections will be shipped offsite for disposal. Contaminated propellant sections and SFT sections will be sent to the energetics neutralization process for treatment (fourth box in Figure 2-7).

After separation, the rocket warhead will be transferred to the rocket shear machine in the explosive containment room (second box in Figure 2-7). The warhead will be punched on its top and bottom and the agent drained out. The warhead cavity will then be washed out with a high-pressure water system to remove residual agent as well as any gelled or crystallized material that may have formed during storage. The drained warhead will then be sheared into segments in the rocket shear machine. If the rocket warhead cannot be separated from its SFT, it will be processed while it is still in the SFT. Any rockets where agent is detected before punching and draining are returned to storage to await the disposal of leaking rockets.

The chemical agent drained from the warhead will be sent to the agent collection system and put into holding tanks until processed. The wash water from rinsing the warhead will be sent to another holding tank that is used for spent decontamination solution. From the holding tanks, the chemical agent and wash water are sent to an agent neutralization reactor (ANR), where the chemical agent will be neutralized (third box in Figure 2-7). The resulting hydrolysate will then be sent through the SCWO units for further treatment, reducing the products to water, carbon dioxide, and salts, before being released for disposal (box 6b in Figure 2-7). The neutralization process is described in more detail below.

Each rocket segment that was cut in the rocket shear machine will be dropped into a bucket as it is sheared. These parts will include the burster and the fuze. The buckets will then be transported to the energetics batch hydrolyzer (EBH) room (fourth box in Figure 2-7) (BPBGT, 2009a). The three EBHs are large rotating vessels that have discontinuous helical flights that are used to mix the components as the EBH rotates. Indeed, an EBH can be thought of as the drum on a cement mixer. Once in the EBH room, a robot will pick each bucket up and raise it to a platform near the top of the EBHs. A second robot will then move the bucket from

FIGURE 2-7 BGCAPP process flow chart. SOURCE: Joe Novad, Deputy Program Manager, U.S. Army Element, Program Manager for ACWA, “BGCAPP Overview,” presentation to the committee on June 14, 2010.

the platform to an EBH, into which the contents are dumped.

Prior to the addition of metal parts and energetics, the EBHs will be filled first with water and next with 50 percent caustic, to reach a concentration of 39.5 percent caustic, and will then be heated. After processing the metal parts and energetics for the specified time, the direction of rotation of the EBH drum will be reversed, lifting the metal parts out of the EBH and dropping them onto the vibrating screen belt of a horizontal conveyor. Any liquid passes through the screen and is collected. When this operation is completed, the rotation speed of the vessel will be increased, allowing the liquid to be removed from the EBH through a wire screen that catches any remaining solids.

The metal parts from the EBH will then be sent to the metal parts treater, where they will be decontaminated by heating them to over 1000°F for more than 15 minutes (fifth box in Figure 2-7). The metal parts can then be sent offsite for recycling or to a landfill (seventh box in Figure 2-7). The hydrolysate from the EBHs will be sent to the three energetics neutralization reactors, where it will be analyzed for presence of agent and energetic material (fourth box in Figure 2-7). The contents will remain in the energetics neutralization reactors until it has been verified that any energetics and agent have been neutralized. The hydrolysate from the EBHs will then be sent to the three SCWO units to reduce it to water, carbon dioxide, and salts (box 6b in Figure 2-7) (BPBGT, 2009b). It is anticipated that the solid wastes resulting from mustard hydrolysis will contain mercury owing to previous experience with the contamination of mustard agent with mercury at other stockpile sites that contained mustard agent. PMACWA is working on procedures to address the anticipated presence of mercury.

Projectile Processing

Projectiles will be processed differently from rockets. They will be unpacked manually and conveyed into an explosive containment room where the bursters will be removed by the two LPMD machines (second box in Figure 2-7). The munition bodies, still containing their burster wells, will then be moved to the munitions washout station. The process from this point on will be identical to the process at PCAPP, described above, except that the hydrolysate will be sent to the SCWO units instead of bioreactors for treatment.

NEUTRALIZATION OF CHEMICAL AGENT

The chemical agent at both sites will be treated by chemical neutralization. The agent will first be collected in the agent collection system, where it will be stored in holding tanks until it is moved to an agent neutralization reactor (ANR). The ANR will be a continuously stirred vessel where the hydrolysis reaction will be taken to completion.

For mustard neutralization, hot water will be used. Caustic will be added to neutralize the HCl that forms and to maintain the pH at 10.5 until the hydrolysis is completed (BPT, 2010). Caustic will be used to neutralize GB and VX agent. First, water is added to the ANR. Then the prescribed amount of 50 percent caustic is added. The final caustic concentration will be different for GB and VX. Finally, agent from the holding tanks will slowly be added to the ANR (BPBGT, 2009c). The contents will be both continuously stirred and recirculated to ensure good mixing and a complete reaction.

FIRST-OF-A-KIND PROCESS EQUIPMENT

Since the processes for chemical agent and munitions destruction to be used at PCAPP and BGCAPP are new, several pieces of process equipment that have never been used before have been included in the design of these two pilot plants. These pieces of process equipment are referred to as first of a kind (FOAK). The pieces of FOAK equipment the committee believes are the most likely to pose challenges to operations at PCAPP and BGCAPP are briefly described in Table 2-5. Because they embody new technologies or novel applications of existing technologies these FOAK items are at greater risk of having problems with respect to functionality, reliability, availability, and maintainability and may therefore require adjustments ranging from procedural modifications to varying degrees of redesign as they are developed, tested, and integrated into actual agent processing operations.

The LPMD is one of the pieces of FOAK equipment to be used at both PCAPP and BGCAPP. While it had previously undergone testing on simulated equipment test hardware (SETH) munitions, it had not been tested on actual chemical munitions.

Because the remaining stockpile being destroyed at the Anniston Chemical Agent Disposal Facility (ANCDF) contains mustard agent and projectiles, as does the stockpile to be destroyed at PCAPP, and similar issues relating to age of munitions can therefore be expected at both sites, PCAPP established a test project at ANCDF to evaluate the reliability, operational efficiency, and safety of the LPMD.

To date, LPMD testing at ANCDF has revealed a number of design and operational problems that would have considerably impacted systemization at PCAPP. For example, the munitions reject rate of the process was found to be significantly higher than had been anticipated (1.3 percent actual versus 0.01 percent expected). Thus far, 164 specific LPMD operating criteria have been reviewed, and 20 documented lessons learned will be applied to the design and operation of the system at PCAPP. Additionally, more than 110 significant code changes have been identified during testing at ANCDF.6 The committee believes that based on the LPMD experience, similar difficulties can be expected with other FOAK equipment as systemization progresses.

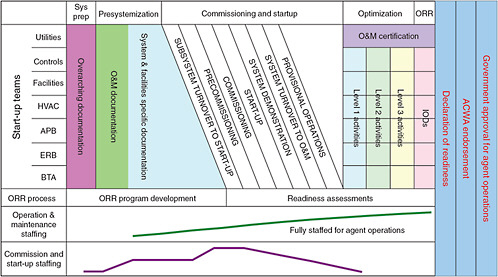

SYSTEMIZATION

PCAPP and BGCAPP will both undergo preoperational systemization prior to starting actual agent disposal operations. Both facilities will follow a progression of steps that consist of the installation of process equipment, integration of process equipment, and demonstration of overall plant operation using surrogates instead of actual chemical agent. During this phase of the project, the systems used to operate the plant will be tested and configured. Systemization involves progressive testing, from a component basis to a subsystem basis to a system demonstration on surrogate munitions to bring each system to its fully

TABLE 2-5 First-of-a-Kind Equipment and Processes That Could Pose Significant Challenges for PCAPP and BGCAPP

|

FOAK Equipment |

Site(s) |

Function |

Notes |

|

Rocket cutting machine (RCM) |

BGCAPP |

To separate rocket motors from the warhead. |

This is an entirely new piece of equipment. |

|

Linear projectile mortar disassembly (LMPD) machine |

BGCAPP PCAPP |

To disassemble projectiles and mortars and remove their bursters. |

This is a new unit that replaces the PMD machine used at the baseline incineration sites operated by CMA. |

|

Munitions washout station (MWS) |

BGCAPP PCAPP |

To remove the burster well from projectiles, drain the chemical agent, and wash out any agent residues. |

This is an entirely new piece of equipment. It replaces the PMD machine used at the baseline incineration sites operated by CMA. |

|

Energetics batch hydrolyser (EBH) |

BGCAPP |

To neutralize energetics and any chemical agent in the metal parts of the rockets and fuzes from projectiles. |

This is an entirely new piece of equipment. |

|

Metal parts treater (MPT) |

BGCAPP |

To decontaminate projectile bodies and secondary waste by heating to over 1000°F for more than 15 minutes. |

This is an entirely new piece of equipment. |

|

Munitions treatment unit (MTU) |

PCAPP |

To decontaminate projectile bodies and secondary waste by heating to over 1000°F for more than 15 minutes. |

This is an entirely new piece of equipment. |

|

Supercritical water oxidation (SCWO) |

BGCAPP |

To treat agent and energetics hydrolysates before releasing them for final disposal. |

This is an entirely new piece of equipment and process. |

|

Immobilized-cell bioreactors (ICBs) |

PCAPP |

To treat mustard hydrolysate before releasing it for final disposal. |

This is an entirely new piece of equipment and process. |

operational design function. Systemization provides an opportunity to train operators and to integrate plant systems and processes with a trained workforce and appropriate documentation. This ensures that each of the systems functions properly before a Declaration of Readiness is issued, Army endorsement is obtained, and governmental approval to begin agent operations is granted. The steps in systemization, along with the staffing levels, are shown in Figure 2-8.

Finding 2-1. Because of the unique nature of the processes at the Pueblo Chemical Agent Destruction Pilot Plant and the Blue Grass Chemical Agent Destruction Pilot Plant and the extensive use of first-of-a-kind equipment, the use of both leading and lagging process safety metrics will be important in achieving the congressional mandate to safely destroy the chemical weapons stockpiles at the respective sites. Systemization affords an excellent opportunity to implement and evaluate leading and lagging process safety metrics.

Recommendation 2-1. During systemization, the Program Manager for Assembled Chemical Weapons Alternatives should develop and implement extensive process safety metrics that can be evaluated for relevance and utility. Metrics that are found to be meaningful should be carried forward to operations. While

FIGURE 2-8 Overview of the systemization process. SOURCE: Joe Novad, Deputy Program Manager, U.S. Army Element, Program Manager for ACWA, “PCAPP Overview,” presentation to the committee on June 14, 2010.

both leading and lagging metrics should be developed and implemented to the extent possible, both the Pueblo Chemical Agent Destruction Pilot Plant and the Blue Grass Chemical Agent Destruction Pilot Plant should emphasize developing leading metrics to guide them in process safety management.

REFERENCES

Abercrombie, P.L. 2003. Physical Property Data Review of Selected Chemical Agents and Related Compounds: Updated Field Manual 3-9 (FM 3-9), ECBC-TR-294, September. Edgewood, Md.: U.S. Army Edgewood Chemical Biological Center.

BPBGT (Bechtel Parsons Blue Grass Team). 2009a. System Design Description for Rocket Handling System (RHS), Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) Project, rev. 5. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPBGT. 2009b. System Design Description for Energetics Neutralization System (ENS), Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) Project, rev. 5. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPBGT. 2009c. System Design Description for Agent Collection and Neutralization, Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) Project, rev. 6. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT (Bechtel Pueblo Team). 2004. Initial Design for the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) Project, Rev. A—redacted for release to the NRC, January 16. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2010. System Design Description (SDD) for Agent Collection and Neutralization System No. B04, Rev. 002. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

NRC (National Research Council). 2001. Analysis of Engineering Design Studies for Demilitarization of Assembled Chemical Weapons at Pueblo Chemical Depot. Washington, D.C.: National Academy Press.

NRC. 2005. Interim Design Assessment for the Blue Grass Chemical Agent Destruction Pilot Plant. Washington, D.C.: The National Academies Press.

U.S. Army. 1977. Army Ammunition Data Sheets: Artillery Ammunition, Guns, Howitzers, Mortars, Recoilless Rifles, Grenade Launchers, and Artillery Fuzes (FSC 1310, 1315, 1320, 1390), TM 43-0001-28, April. Washington, D.C.: Headquarters, U.S. Army.

U.S. Army. 1983. Final Demilitarization Plan for Operation of the Chemical Agent Munitions Disposal System (CAMDS) at the Tooele Army Depot, Utah, June. Aberdeen Proving Ground, Md.: U.S. Army Toxic and Hazardous Materials Agency.

U.S. Army. 1988. Chemical Stockpile Disposal Program Final Programmatic Environmental Impact Statement. Aberdeen Proving Ground, Md.: U.S. Army Chemical Materials Agency.