3

Combustion and Cyberinfrastructure

OVERVIEW

Combustion has been a scientific and engineering discipline for hundreds of years. The chemical and physical aspects of the field are well known. Today’s central challenges for combustion research are, in principle, easily summarized. Revolutionary changes are needed in the way that fuels are converted into work and heat to significantly reduce carbon dioxide (CO2) and other emissions into the atmosphere while at the same time significantly increasing combustion efficiency so as to make fuels last longer.

Most combustion systems are based on technologies that are very old; gasoline and diesel engines were invented more than 100 years ago. Although they have been improved and refined continuously, they continue to emit toxic chemicals and greenhouse gases, especially CO2. Factory burners, boilers, and other industrial combustion systems are based on even older technology and still produce carbon black (soot) along with toxic chemicals and CO2. To the extent that these systems rely on petroleum—which is the case for most transportation, in particular—they are using up a limited resource that by some estimates will be largely depleted in 50 to 100 years (U.S. EIA, 2007). Thus, it is essential to improve the efficiency with which they use that resource. At the same time, indications are that the world cannot tolerate another hundred years of the toxic emissions and global warming currently produced through petroleum combustion (U.S. Global Change Research Program, 2009). Mere tinker-

ing with extremely mature engine and burner technologies will not solve existing combustion problems. A fundamental change in the way that combustion is studied will be required to meet these societal goals. Unfortunately, combustion is a complex problem involving enormous ranges of temporal and spatial scales and a wide range of disparate disciplines. Historically, these different disciplines have studied different aspects of the combustion problem independently, with relatively loose coupling between disciplines. Traditionally this decoupling has been particularly acute between the communities dealing with the detailed characterization of molecular properties and the large-scale continuum modeling community that is focused on the complexities of modeling turbulent flows. This decoupling has arisen primarily because the tools to bridge the gap between molecular properties and turbulent flows were not available.

Two developments in recent years that have had major impacts on progress in science and engineering have been laser diagnostics and high-performance computing (HPC). Used together, these two technologies have accelerated the pace of research and development (R&D) in many important fields, including combustion research, where they offer the potential to bridge the gap between different disciplines that study different facets of the combustion problem. Laser diagnostics have made it possible to examine combustion systems at the molecular level and in complex physical systems where in situ observations had not been possible. For example, it is now possible to probe turbulent flames experimentally in ways that elucidate turbulent-flame structure in detail both spatially and temporally. In addition, time-resolved velocity fields and two-dimensional planar images of flame markers to capture the interaction of a flame with turbulent flows can now be measured.

Computational combustion is quite well established (Westbrook et al., 2005), but it is only within the past decade that HPC has progressed to the point that detailed simulations of the physical and chemical structure of combustion have become possible. Modeling a wide range of two-dimensional combustion problems has now become relatively routine. It has even become possible recently to model turbulent flows at the laboratory scale with detailed chemical kinetics and transport (Puduppakkam et al., 2009). This knowledge is essential in exploiting the information obtained by sophisticated observations and optical diagnostics to bring together the different communities working on combustion and to help effect the necessary revolution in combustion science.

However, to realize this potential and to achieve significant advances, a much more coherent approach to simulations and data management than exists today is needed. Currently, most combustion investigators work independently or as part of small research groups, each of which develops its own simulation tools and has access primarily to its own

data. Every group saves experimental and computational data in its own style and format, and many groups develop their own software tools in their own idiosyncratic manner. For example, almost every chemical kinetics group in the world has developed its own submechanisms for the oxidation of hydrogen, methane, propane, and other fuels, rather than each contributing to a collective kinetics model that can be revised by everyone and used by everyone. The only significant exception occurred when a common kinetic mechanism was developed: the GRIMech (Frenklach, 2007) mechanism for methane and natural gas combustion (see Appendix A in this report), assembled by a team of kinetics experts from multiple research groups and optimized exhaustively using results from many experimental studies. That reaction mechanism was responsible for an enormous number of excellent subsequent studies and provided a thoroughly tested research tool that was used worldwide. GRIMech played a significant role in unifying the community before funding to support continued development of the mechanism was lost.

Another example of a community-wide resource was the CHEMKIN family of combustion software tools developed at the Sandia National Laboratories in Livermore, California (see Appendix B in this report). For many years, CHEMKIN provided a valuable common resource worldwide that was used in countless computational combustion studies. The CHEMKIN software tools were particularly important because a combustion researcher could walk into any combustion facility or office in the world and immediately be capable of carrying out modeling studies of simple zero- and one-dimensional combustion problems, since the software tools were the same everywhere.

HOW INDIVIDUAL RESEARCHERS WOULD BENEFIT FROM A COMBUSTION CYBERINFRASTRUCTURE

As has been found in other scientific and engineering disciplines, the coordination of computer software tools, data storage, formats, and protocols can be extremely effective in increasing dramatically the rate of progress in a given field. A well-designed cyberinfrastructure (CI) applied to combustion is a means of enabling this coordination. Among the features of a cyberinfrastructure that would immediately be very helpful would be common repositories and/or registries for experimental and computational data, which would make data sets available to any researcher. The establishment of collaborative groups working to produce, improve, and maintain these common data sets would lead to more accurate and robust models for chemical kinetics, molecular transport, radiation parameters, and thermochemical databases. Similar collaborative groups working at the continuum level would lead to better models for turbulence and other

submodels needed for simulating realistic combustion systems. In addition, a suitably designed CI would facilitate interchange among the different disciplines that would serve as a catalyst to change fundamentally the way that combustion research is pursued. Communication of robust and well-validated software tools and databases from developers to users would also be greatly facilitated, and improvements made by one group or individual would immediately be available to many other researchers. As discussed in Chapter 2, the existence of a community CI facilitates such interaction.

A HIERARCHICAL APPROACH TO COMBUSTION MODELING

The starting point for computer simulations of gas-phase combustion is the compressible Navier-Stokes equations, which describe the conservation of mass, momentum, and energy in a compressible fluid. For combustion applications, this system is augmented with additional chemical species equations that describe the transport and reactions of the chemical components in the gas. To examine even a simple laboratory problem such as a steady laminar Bunsen flame, a detailed description of the properties of the gas under consideration must be developed. The thermodynamic behavior of the gas and the chemical kinetics that describes the burning process must be characterized. Also needed are transport properties that specify the viscosity and thermal conductivity of the fluid as well as inter-species diffusive processes. In addition, radiative heat transfer properties are needed to capture accurately the thermal environment of the flame.

For more realistic combustion systems, it is necessary to introduce additional complexity to the model. Most practical combustion devices operate in a turbulent environment; consequently, even for gaseous combustion, one must deal with the complexities of turbulent flows. Many systems, such as internal combustion engines or jet engines, burn liquid fuels instead of gaseous fuels. Such fuels are introduced into the system as a spray, requiring a treatment of multiphase effects. Other types of systems use particulate fuels, such as pulverized coal in a coal-fired burner or solid fuels in a rocket. The formation of soot during the combustion process introduces additional multiphase effects.

This complexity means that a wide range of disciplines are needed to study combustion, which in turn has led to significant specialization within the field. Researchers developing chemical kinetic mechanisms, for example, will have expertise in quantum mechanics, computational chemistry, spectroscopy, and a number of zero- and one-dimensional experimental techniques, but they are unlikely to be experts in turbulent fluid mechanics or multiphase flow problems. Similarly, researchers with expertise in turbulence modeling or multiphase systems may have

expertise in the development of sophisticated numerical algorithms but are unlikely to have any expertise in the development of chemical mechanisms or transport properties. Progress in each of these specialties would be more rapid and targeted if each of those communities had ready access to the best data, models, and software from the other specialties.

Historically, the linkages between the different subfields of combustion have been fairly weak. In particular, the linkages have been minimal between researchers investigating fundamental molecular-level properties such as kinetics and transport and researchers studying continuum behavior of flames. This historical structure of the field reflects the types of tools available to combustion scientists. Simulation capabilities for modeling reacting flows for most problems were limited to relatively simple (e.g., one- or two-step) chemical mechanisms that approximate (often poorly) the basic energetic and flame-propagation properties; computations of realistic flames with detailed kinetics were simply not feasible. Over the past decade, the advent of HPC and advances in numerical algorithms have changed this, and it is now feasible to simulate realistic turbulent flames with detailed kinetics for simple fuels (Chen, 2011; Lu and Law, 2009). Moreover, new quantitative diagnostic methods are being developed at all scales (Kohse-Hoinghaus et al., 2005), from individual reactive encounters, to controlled molecular ensembles, to in situ studies inside combustion chambers. As these measurement techniques are improved, much better characterization of detailed flame and ignition behavior will provide the data needed for the accurate validation of new simulation capabilities.

The changes in the tools available for studying combustion—combined with the need to address the challenges posed by developing cleaner, more efficient systems for new, alternative fuels—are driving a need to change the way that combustion research is being done.

COMBUSTOR CONFIGURATIONS

Practical combustion devices are usually complex systems in which the actual chemical reactions are only one part. To predict and evaluate combustor performance using a computer model, all of the processes that contribute to the overall system must be understood and included in the model, ideally with well-quantified fidelity. For safety concerns, fuel is almost always stored separately from the oxidizer, and they are not mixed at the molecular level until they are about to be burned. Therefore, the mixing of fuel and oxidizer either at the engine process level or within the flame structure is an essential process in the full combustion system, and in many cases the overall performance of the combustion system depends on the details of this mixing. Fuels may be initially in the gas, liquid, or

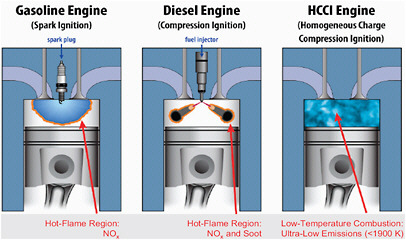

FIGURE 3.1.1 Internal combustion engine concepts. BOX 3.1 Current and Future Internal Combustion Engine Concepts In a typical gasoline engine, a premixed fuel-air mixture with just enough air to burn all of the fuel injected is compressed and spark-ignited (SI) at a specified, optimal time. The high temperature resulting from the stoichiometric combustion leads to significant NOx formation. However, the NOx, along with other pollutants formed, can largely be removed by the three-way catalyst aftertreatment system on all SI engines on the road today. The power output (load) of an SI engine is controlled by restricting (commonly called throttling) the amount of air drawn into the engine and injecting correspondingly less fuel. Overall, the throttling and low compression ratio of an SI engine result in a significantly less fuel-efficient engine than a diesel engine. In part, the lower efficiencies can be overcome with more recent developments that use direct injection of gasoline into the cylinder to eliminate the throttling losses. This option adds substantial flexibility toward ultralean combustion but at the expense of more challenging exhaust gas aftertreatment systems. Direct injection can also be an enabler for homogeneous charge compression ignition (HCCI) engine technology, a new combustion strategy under investigation that approaches the high fuel efficiency of a diesel engine while producing very low NOx and soot emissions—so low that there is the potential to meet the 2010 emissions standards without exhaust aftertreatment. As in an SI engine, fuel and air are premixed; however, combustion is started by a compression-ignition process similar to a diesel engine. Many challenges exist for this promising ultraclean combustion strategy before use in high-efficiency engines can be achieved. The challenges include robust methods of controlling the timing of ignition for optimal performance, expanding the usable load range, controlling the engine through transients, and determining the optimal fuel characteristics. Overcoming these challenges, especially in a diversified-fuel-source future, requires a vastly improved science base around the fundamentals of fuel ignition, combustion, and emission formulation chemistry, and fuel spray and turbulent fuel-air mixing processes, all at the high temperature and pressure conditions relevant to engines. These engine types are shown in Figure 3.1.1. SOURCE: Adapted from www.er.doe.gov/bes.reports/files/ReproCTF_rpt.pdf. |

solid phase, so fuel and air mixing can be a multiphase process. If the fuel is introduced into the combustion system in the liquid phase, such as in a diesel engine, then the combustion simulation must include a treatment of a liquid fuel spray and its vaporization and subsequent mixing with air. If the fuel is a solid particulate, a multiphase entrainment model is needed to characterize the system.

The combustible fuel and oxidizer mixture must then be ignited, and different practical devices accomplish this ignition in different ways. In some cases, such as diesel or homogeneous charge compression ignition (HCCI) engines, ignition is produced by the compressive heating of the reactants, whereas in other systems such as a gasoline engine, a spark or other ignition system is employed. These concepts are illustrated in Box 3.1. Once the fuel and oxidizer have been ignited, chemical reactions convert them into chemical products, and many different types of combustion can be encountered. Overall combustion can take place by means of nearly simultaneous fuel oxidation as in HCCI engines, but in most cases, combustion occurs through the propagation of flames. Some engines, such as spark-ignited gasoline engines, feature premixed flames, and other systems, including diesel engines and aircraft gas turbine engines, combine features of premixed and non-premixed flames—the latter being the central feature of most industrial burners. Reciprocating engines, found in most internal combustion engines, operate as repetitive time-dependent systems in a cyclically changing environment, whereas turbines used in aircraft and for power generation and industrial burners are statistically stationary turbulent flames (see Box 3.2) in which oscillation instabilities related to acoustic flame interactions are important phenomena. Each type of combustion system or flame requires its own solution algorithms, models, and data analysis.

In every important combustion system, the hot gas products transfer heat to do useful work, either by moving a piston or turbine blades or by heating a working fluid such as water in a boiler or furnace. In some large-scale systems, such as furnace combustion, building fires, and wildfires, radiation constitutes an essential long-range mode of heat transfer, and as such it must be included in the simulation. Furthermore, not all of the fuel in a combustion reaction is converted to chemical products such as CO2 and H2O, and incomplete fuel consumption is a primary source of carbon monoxide and other toxic emissions from combustion. In addition, the high temperatures produced by combustion convert molecular nitrogen (N2) into oxides of nitrogen (NOx), which are main components of photochemical smog. In some combustors, the incomplete or inefficient mixing of fuel with oxidizer can lead to the production of soot, which is produced by means of a complex sequence of chemical reactions that starts with gaseous species and steadily build larger molecules until they

|

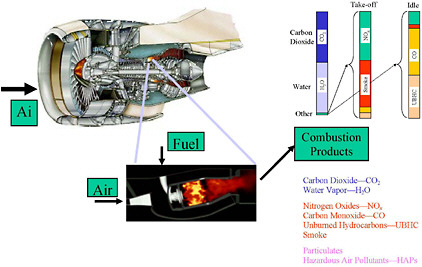

BOX 3.2 Aircraft Emissions Produced by Combustion of Fuel and Air Proposed high-efficiency engines will have combustors that must operate at extreme pressures (~50 atmospheres) and inlet temperatures (~950 K). Few facilities with necessary flow rates are available for testing such hardware and are very expensive to operate. Combustor modeling has assisted significantly in the design of recent-generation engines and can be expected to be even more critical at the extreme conditions in cycles of high-efficiency engines. To enable such modeling, accurate simulations of phenomena such as fuel injection, spray and vaporization, fuel and air mixing, mixing and combustion in swirling and jets in-cross flows, heat transfer, fuel chemistry, and heat release rates in flows with Reynolds numbers on the order of 106 are required. Such capabilities are needed to ensure proper combustor performance by enabling quantitative predictions of flow splits and pressure drops, liner temperatures, exit temperature profiles at high power, emissions (gaseous and particulates) at various power settings, ignition, pre-ignition and altitude relight, lean blow-off, and acoustics. Furthermore, fuel effects need to be simulated—or experimentally validated—to ensure safe operation with new synthetic fuels. Testing new combustor designs through the use of advanced and validated modeling methods leads to significant savings. The operation of such an engine is shown in Figure 3.2.1.  FIGURE 3.2.1 Turbine engine combustion. |

become so large that they become solid-phase particles. In some cases, such as in industrial furnaces, soot at an intermediate stage in the combustion process is a good thing, enhancing radiative heat transfer from the burning gases to the surfaces of the combustor where heat transfer to a working fluid is the goal of the combustion process prior to its subsequent oxidation. In other cases, such as in diesel engines, soot is harmful and contributes to emissions of air pollutants.

MODELS, SUBMODELS, AND REDUCTIONS

One goal of combustion simulation is to provide system designers with a suite of simulation tools that can solve the relevant equations for all of the physical and chemical processes in an integrated model with quantified uncertainty. This full-system model thus has to include submodels for each of the processes that contribute to the performance of the combustor. Since the interactions between these subprocesses determine the overall performance of the combustor, each submodel must include the appropriate level of detail to be able to supply the overall model with enough information to simulate those interactions. The fidelity of the submodels needs to be categorized, and the impact of uncertainty in submodels on the overall simulation needs to be assessed. Some subprocesses do not contribute to every type of combustor; for example, in many gasoline-fueled, spark-ignition engines, the fuel is prevaporized prior to entering the combustion chamber, so a spray evolution submodel is not required. However, a spray submodel is essential for the simulation of combustion in a diesel engine, in which the liquid diesel fuel is injected directly into the combustion chamber and must vaporize before it can be burned.

Most practical combustion systems operate in a turbulent environment. Thus, a full-system model for a combustor is usually based on an underlying computational fluid dynamics (CFD) framework for turbulent flow that provides sufficient spatial resolution to describe the overall combustion process. In most cases, the physical combustor has a complex geometry, so this CFD framework must describe enough geometrical detail, usually in a fully three-dimensional setting. This geometric complexity can include the following:

-

Fluid flows through moving intake and exhaust valves or through an injector,

-

Swirling flows intended to enhance mixing between fuel and air,

-

Flames propagating from spark plugs across a combustion chamber,

-

Explosions occurring within some portions of a combustion chamber, and

-

Radiation across a burner from a flame to tubes carrying secondary fluid to be heated.

The combination of three spatial dimensions and sufficient spatial resolution for each important subprocess often requires a very large computational grid, which leads to high computational costs. Each model for the subprocesses involved also can require extensive amounts of detail and therefore computer capacity. Since full-system detailed combustion models are prohibitively expensive for general use, the most common approach for full-system models is to combine simplified submodels for each of the important processes involved in a given combustion application. A balance is usually necessary, trading computational detail in each submodel against the need for an efficient computer solution, often combining many simulations at lower fidelity with a few simulations at higher fidelity to help bound uncertainties.

The starting point of a model for a combustion system is the description of the molecular properties of the fluids in the system. The physical and chemical parameters in a typical combustion model cover wide ranges, and the characteristics of these data are one of the primary reasons for the development of a CI for combustion. In particular, combustion systems cover temperature ranges from room temperature to levels of 3000 K in the products of fuel and oxygen flames, and from very low pressures of a few torr in laboratory flame studies to hundreds of atmospheres of pressure in diesel engines and some types of detonations. There can be many thousands of different chemical species when a hydrocarbon fuel is being burned, and each species has physical and chemical properties that are often complex functions of temperature and pressure. These include physical parameters such as equations of state, specific heat, heats of fusion and vaporization, ionization potentials and other spectroscopic quantities, frequency-dependent radiative opacities, molecular diffusivities, and others, as well as chemical parameters including elementary reaction rates with other species, with their activation energies and A-factors, heats of formation, and many other parameters.

For most applications, particularly those involving the modeling of a three-dimensional turbulent-flow, high-fidelity characterization of the fluid properties is not computationally feasible (see Box 3.3). For example, rather than using a chemical kinetic reaction model with 1,000 chemical species, a reduced chemistry model with perhaps 10 to 50 species needs to be used. The challenge is that it can be difficult for such a reduced chemistry model to reproduce the important features from a thousand-species chemistry model. Fortunately, extensive research in model reduction for chemical systems has shown that such reductions can be defined that are reasonably accurate and comprehensive within extensive parametric

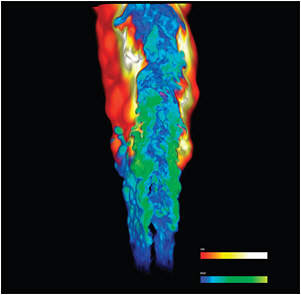

FIGURE 3.3.1 Direct simulation of a turbulent jet flame. BOX 3.3 Stabilizing a Lifted Autoignitive Turbulent Jet Flame in a Heated Co-flow as Revealed by Direct Numerical Simulation When a jet flame is lifted from the burner by increasing the fuel or surrounding air co-flow velocity, the flame can stabilize without a physical element to use for stabilization, and a lifted jet flame is generated. The flame can exist over a range of jet velocities until a critical velocity is reached and the flame blows out globally. Figure 3.3.1 shows a direct numerical simulation of a typical laboratory combustion configuration corresponding to a (small) turbulent, premixed, methane-air, slot Bunsen flame. The chemical model includes 12 reactive species and the computational domain is decomposed into 200 million cells. Lifted flames are found in practical applications such as industrial burners for power generation, in which a lifted jet flame is utilized to reduce damaging thermal stresses to the nozzle material by minimizing contact between the flame and the nozzle. Lifted flames are also found in stratified combustion—for example, in direct injection gasoline engines, diesel engines, and gas turbines—where the fuel and oxidizer streams are partially premixed prior to combustion. The position downstream of a fuel injector where a diesel fuel jet establishes a flame, the so-called stabilization point, influences the degree of premixing between the cold fuel and the heated air prior to combustion, which, in turn, affects the combustion and soot formation processes downstream. For example, soot levels decrease as the fuel and air streams are better mixed upstream of the stabilization point and can even be eliminated if sufficient premixing has occurred upstream. In a heated |

|

co-flow, the stabilization point is highly sensitive to the ignition quality of the fuel. For example, in a diesel jet flame the composition of the cool flame ignition intermediates and low-temperature heat release rate may help to stabilize the flame. However, cool flame chemical kinetics is relatively slow and may be modulated by turbulent strain and mixing. Therefore, fundamental knowledge of the mechanism by which a turbulent lifted flame stabilizes in a hot environment of vitiated gases will lead to the development of predictive models for the design and optimization of fuel-efficient, clean-burning combustion devices. SOURCE: See http://vis.cs.ucdavis.edu/~yuho/combustion/HO2+OH_8k.png. Accessed February 18, 2011. |

ranges of operation (Lu and Law, 2009). Furthermore, reduced models can be patched together as operating conditions change, to provide even more realistic overall simulations.

There is, in fact, an entire discipline of mechanism reduction for chemical kinetics. Some of these approaches use an elementary approach by just removing chemical species and elementary chemical reactions that are relatively unimportant, whereas other, more complex approaches take advantage of the fact that strong coupling exists between the evolution equations for groups of chemical species (Prager et al., 2009; Liang et al., 2009; Hughes et al., 2009; Bykov and Maas, 2009). Other interesting approaches precompute representative chemical solutions and then save the answers, which can then be retrieved while carrying out a larger simulation, thereby saving the time required for the costly kinetics equations. The same concept of precomputing the expensive parts of a larger simulation has been used to simulate classes of turbulent flames, which can be visualized as a complex mixture of microscopic laminar flamelets. One can precompute an entire library of laminar flamelets and save the results, then retrieve the relevant flamelets from the library while simulating a turbulent flame as a superposition of these microscopic laminar flamelets (Pope, 1997). A combustion CI could provide optimal access to existing results and kinetic rate data, which would accelerate the optimization process and enable individuals in this community to provide better research tools to others. At the present time, this type of progress is extremely slow, proceeding through journal publications and conference meetings, with little or no central, common collection of relevant results and synthesis of results into widely useful common models.

From this discussion, it is apparent that database requirements vary from subcommunity to subcommunity. Databases required for kinetics modeling are tens of megabytes, whereas those for direct numerical simulation (DNS) calculations for complex geometries with modest kinetic submodels are already into the terabyte range—and they are only expected to grow.

In addition to the complexities of chemistry, fluid flow in most practical combustion systems is highly turbulent. In fact, turbulent flows are observed in many reactive noncombustion systems in nature, including the atmosphere, in the oceans, and in stars such as the sun. Turbulence modeling is thus a feature of many types of system simulations. In chemically reactive combustion systems, turbulence is essential because it increases the overall rates of fuel and oxidizer mixing and combustion, making it possible to burn a large amount of fuel in a short period of time to produce the power that is needed by various types of engines and burners. Turbulence is very difficult to predict and model, since it is a stochastic, highly variable phenomenon; descriptions of the reactive flow over an enormous range of spatial and temporal scales are required.

Historically, turbulence has been modeled by making a series of approximations (Peters, 2000; Poinsot and Veynante, 2005), averaging the characteristic turbulent fluctuations over time and space intervals that have been made progressively smaller as the capacities of computers have permitted over the years. An important current target of combustion modeling research is direct numerical simulation (see Box 3.3) of turbulent reacting-flow phenomena. For a given problem specification in terms of flow geometry and the choice of kinetics and transport models and other processes, DNS approaches fully numerically resolve all of the turbulent and flame scales in space and time. DNS calculations do not require models for turbulence; turbulent phenomena are handled directly by solving the Navier-Stokes equation so that deterministic physical and chemical predictions can replace probabilistic descriptions of spatial and temporal fluctuations, which require closure assumptions that are frequently intuitively posited. Needless to say, such direct numerical simulations require enormous computer resources to simulate even small and greatly simplified systems, and they present unique challenges for simulations as described in Box 3.3 and in Appendix C in this report. They nevertheless provide trustable insights that are available in no other way. In addition to chemical kinetics and turbulent flow, other areas amenable to study using a combustion CI include, but are not limited to, surface chemistry and catalysis and condensed-phase phenomena.

In conducting full-scale practical combustion simulations, however, it is not possible to resolve all of the scales needed to represent turbulence.

For practical systems, some type of model for turbulence is required. There are a variety of approximations, such as Reynolds-averaged Navier-Stokes (RANS) simulation and large-eddy simulation (LES) (see Box 3.4). RANS approaches, which are the traditional workhorse for engineering design simulations, attempt to capture the temporal average of a turbulent flow. LES approaches currently being developed are based on spatially filtering and incorporating a model for subgrid processes at finer scales than that of the filter. Typically, RANS is much less expensive than LES but offers less fidelity. Hence, there is a trade-off in the initial choice of turbulence modeling approach.

In nonreacting fluid flows, the choice of turbulence model depends on the fluid dynamical scales to resolve and the scales that require modeling. For reacting flows, the issues related to turbulence modeling are far more complex. Every subprocess that is being modeled in a combustion simulation requires a subgrid model for describing how that process interacts with turbulence. A model for mixing of fuel and oxidizer prior to combustion is needed. Models for turbulence-chemistry interaction are needed to represent flame behavior in a turbulent environment. When multiphase and radiation are important processes, submodels for their interaction with turbulence are also required.

Each of these submodels tries to represent very complex phenomena that are beyond the capabilities of existing computing. Thus, the improvements that are made with each advance in computing enable the inclusion of important phenomenology that was previously neglected. Such improvements are not simply incremental refinements but capture important details that require greater computing power. As more of the relevant phenomena can be directly captured in a simulation, fewer effects need to be incorporated in a subgrid model, resulting in higher-fidelity simulations. In addition, a fundamental reason for continually improving the submodels is so that the state-of-the-art versions can be used to evaluate coarser approximations. Highly refined models serve a critical role for running sensitivity analyses that contribute to the understanding of what phenomenology, and at what degree of precision, must be retained when a submodel is incorporated into a larger model to calibrate the fidelity of coarser models and estimate their associated uncertainties.

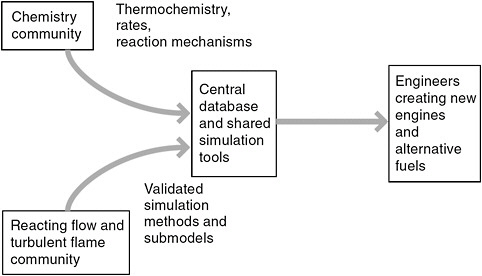

The researchers developing new fuels and combustion systems need to be able to simulate the behavior of proposed new devices and products under a wide range of operating conditions, in order to properly assess and improve the designs. Each of these simulations requires as inputs chemistry data relevant to the fuel of interest and some reacting-flow submodels (e.g., for turbulent mixing and radiative heat transfer). Thus, at a minimum the CI needs to carry information “up the scales,” in the direction shown in Figure 3.1. Ideally the CI would enable feedback that

|

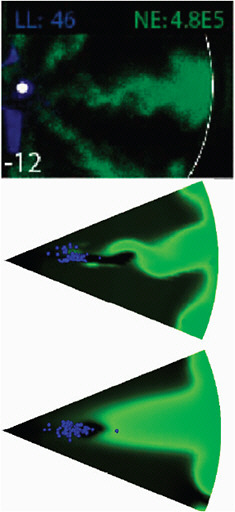

BOX 3.4 Large-Eddy Simulations Computer simulations that are targeted for engineering applications require turbulence models. This is especially true for the complex flows that occur inside the cylinders of internal combustion (IC) engines. The next generation of turbulence modeling is called large-eddy simulations (LES). This name emphasizes the fact that the simulations can capture more of the important large-scale flow features than previous modeling approaches could. A generic name for these large-scale features is an “eddy,” which qualitatively describes a swirling motion that is characteristic of turbulent flows. Thus, LES models offer enhanced representations of turbulent eddies and therefore better predictive capabilities. This is illustrated in Figure 3.4.1. There are several requirements for LES: faster computers, improved numerical algorithms, and improved physical models. Faster computers are required so that more detail can be incorporated into the simulations. This requirement is progressively overcome with the rapid increase in computer capabilities. The requirement for more accurate, next-generation physical models involves more effort. The purpose of these models  FIGURE 3.4.1 Snapshot showing combustion around one liquid fuel jet (injection from left to right) in a heavy-duty diesel engine. The top figure shows the experimental results, with the combustion displayed in green and the liquid fuel in blue. The middle figure shows an LES simulation of the same process, and the bottom figure shows a simulation using previous-generation turbulence modeling Reynolds-averaged Navier-Stokes (RANS) simulation. Note that LES captures the wavy structure of the combustion region, whereas RANS lacks resolution and shows only a smeared region for the combustion. |

|

is to represent the effects of small eddies—eddies that are too small to be captured in the simulation but still impact the large-scale dynamics. A key feature of LES models is that they feature low dissipative errors and thereby achieve higher fidelity for the large-scale flow dynamics. Relatively simple LES models have been successfully developed for simple flows. However, for IC engines, with the added complexity of liquid fuel sprays and combustion, the models need to be more sophisticated. This is usually achieved with additional modeling variables and increased complexity. SOURCE: Adapted from www.er.doe.gov/bes.reports/files/ReproCTF_rpt.pdf. |

could carry information “down the scales” as well. This would allow simulations at the continuum level to be used for the verification of chemical mechanisms. Sensitivity analysis and uncertainty quantification at coarser scales can be used to identify research needs at finer scales. Integrating information flow across the scales would represent a fundamental change in combustion research. The proposed combustion CI can build on

FIGURE 3.1 The cyberinfrastructure will collect the information and submodels needed by engineers to simulate novel combustion systems and alternative fuels under all operating conditions.

existing multiscale research. Two examples are multiscale simulations of nanoparticle formation from combustion sources (Viola and Voth, 2005) and flamelet modeling of turbulent combustion in which parameterized solutions from simple laminar flames are used to model the small-scale processes in turbulent flames (Peters, 1984).

DATA AND DATA FLOW

All of the data discussed above, spanning the range of conditions encountered in combustion systems, need to be made available to the combustion research community. However, it is frequently difficult to find all the data that one needs, and in some cases there can be quality-control problems. Although there have been data representation efforts—such as the representation of kinetics data at the Chemical Kinetics Database on the Web at kinetics.nist.gov, and the representation of molecular properties at the National Institute of Standards and Technology Chemistry WebBook at webbook.nist.gov—some data are very sparse or unavailable, because experimental measurements can be difficult or unrewarding. In addition, some data, both experimental and computational, are not sufficiently well characterized to meet the needs of the larger combustion community. However, the CI alone will not be sufficient. The community must pay attention to data reuse, including that of metadata, documentation, standards, and registries.

Species-Based Data

A common core of physical and chemical data is required for most combustion applications. These include specific heats, entropies, and enthalpies of formation; molecular transport coefficients; heats of fusion and vaporization; and other quantities that are specific for each individual chemical species involved in kinetic mechanisms, which are used to evaluate macroscopic variables such as the equations of state. Other species-specific quantities of importance include ionization potentials, radiative opacities and cross sections, and other spectroscopic parameters. Some data needs are specific to particular submodels, whereas others are needed for almost every submodel. For example, radiative opacities affect only the propagation of radiation within a combustor, but specific heats and pressures are needed for all cases. These data are determined in a variety of ways, and some can be provided by more than one physical model (Ritter and Bozzelli, 1991; Muller et al., 1995). Most thermochemical data are based on the “bond additivity” approach of Benson (Benson, 1976), which conceptually builds a molecule by combining all of the

contributions from the atoms in the molecule and the bonds between them. However, these “groups” are evaluated in different ways, which result in similar but not identical values. There is a common data format for the results, based on a convenient approach from the Department of Defense’s Joint Army-Navy-NASA-Air Force (JANNAF) tables (McBride et al., 1993). Almost every computational combustion researcher in the world uses thermochemical data tabulated in the JANNAF format, which is a good example of how standardization provides significant economies of time and effort. However, there is at present no ongoing effort to provide convergence of the various chemical models that generate JANNAF data into a single, consensus set of thermochemical data.

Chemical Databases

A central component of a combustion simulation is the submodel for combustion chemistry. For coupled chemical kinetic models, one differential equation must be solved for each chemical species in the reaction mechanism, and these differential equations are coupled through their mutual chemical reactions. While a hydrogen oxidation mechanism may be as small as 8 to10 species and is relatively easy to solve numerically, a mechanism for the important diesel reference fuel n-hexadecane (n-C16H34) can include 2,100 chemical species and 8,300 individual chemical reactions (Westbrook et al., 2009). Since chemistry submodels, especially those that compute overall rates of reaction and heat release, can include hundreds or thousands of different chemical concentrations, these databases can be extremely large.

Each chemical species adds a new differential equation to the overall combustion model; consequently, as the complexity of the chemical model grows, it can easily dominate the computational cost for a simulation. One approach to dealing with this chemical complexity is to reduce the dimensionality of the system. For example, for large kinetics models, many simulations are made on simplified, one-dimensional spatial grids that have several hundred spatial zones where large chemical mechanisms can be treated numerically. The best example of such one-dimensional models is the premixed laminar flame, which is widely used to study combustion kinetics for many fuels. Many other numerical studies, including a large variety of ignition problems as well as studies of oxidation in jet-stirred reactors and flow reactors, can be carried out under spatially homogeneous (i.e., single zone) conditions with no significant sacrifice of chemical generality.

Although these types of simulations can provide important insights into the behavior of the kinetic model, more realistic combustion simulations cannot treat a complex fuel with a comprehensive chemical mech-

anism. Thus, this chemical complexity motivates a need for reduced mechanisms, where the trade-off of using a simpler mechanism versus its reduced cost is well characterized. The CI must provide not only comprehensive mechanisms for a given fuel but also a hierarchy of reduced mechanisms for which the trade-off of fidelity versus computational complexity is well characterized.

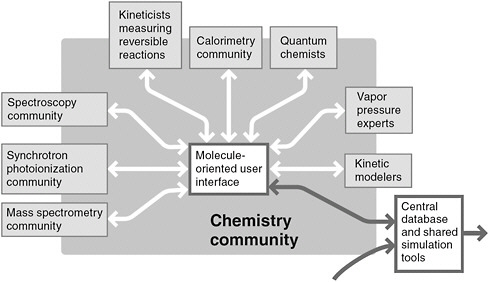

The data needed to develop the high-fidelity chemical kinetics models represent a synthesis of data from a broad range of disparate sources. For example, the molecular enthalpies needed to simulate the combustion of an alternative fuel are extracted by combining information from spectroscopy, calorimetry, synchrotron photoionization, vapor pressure, reversible reaction kinetics, and mass spectrometry experiments with the results of quantum mechanical calculations. Each of those types of data is generated by different research communities, whose members attend different conferences and publish in different journals. When a new enthalpy value is reported, it is often discovered that there is a need to supplement previous measurements or calculations using new techniques in order to improve the precision or resolve technical issues with the older data. The CI needs to gather and disseminate all these disparate types of information, and therefore it must develop interfaces that are useful for each of the subcommunities in addition to the tools that facilitate the integration of these heterogeneous data (see Figure 3.2).

The combustion community is broken up into disparate subcommunities, each specializing in different types of data and methods. Combustion chemistry requires data from all of these communities. The CI will need to interface with many different subcommunities and handle very heterogeneous data. Because of the quantity and variety of data, data-curation services will be an important component of the combustion CI. These services maintain data integrity and enable data discovery, retrieval, and use over time through a range of activities for identification, selection, authentication, representation, preservation, and other processes that span the entire life cycle of data from production to archiving and reuse.

Continuum-Based Data

At its core, combustion is the synthesis of chemistry and fluid mechanics. The previous subsection discussed the role that the CI could play in enhancing progress at the molecular level. A CI could play a similar role at the continuum level, unifying the efforts of different research groups working on different aspects of the problem and providing a framework for dramatically improving the flow of information.

Broadly speaking, there are essentially three subcommunities whose research focuses on combustion at the continuum level. One of those sub-

FIGURE 3.2 Expanded view of the chemistry community block from Figure 3.1.

communities consists of experimentalists whose research spans a range of problems, from simple laminar flames such as diffusion flames or vortex-flame interaction, to idealized turbulent flames in a laboratory setting, to in situ measurements in a realistic combustor.

The second of these subcommunities consists of researchers who develop and apply simulation methodology to study flame behavior at the continuum scale using a “first principles” approach; namely, solving the reacting Navier-Stokes equations. At the forefront of this subcommunity is a small number of research groups whose work focuses on harnessing the most powerful supercomputers to perform large-scale direct numerical simulations of turbulent flames. However, this subcommunity also includes groups using DNS approaches for less demanding turbulent-flame simulations as well as groups studying laminar-flame phenomena computationally.

The third subcommunity, whose efforts focus on continuum modeling, includes the groups that focus on the development of approaches to turbulence and combustion modeling and the application of those models to the simulation of realistic combustors. As with the other subcommunities, this group also spans a broad range of activities, ranging from those researchers developing high-fidelity LES approaches that capture significant features of a turbulent flow in detail, to researchers focused on improving the fidelity of simplified RANS-type approaches to full-

system simulations, to engineers applying these tools as part of the design cycle to develop new combustion systems. A focal point of current LES efforts is the development of “multiregime” subgrid models for mixing and combustion that automatically treat the existence of mixed modes of combustion prevalent in advanced combustors operating at high pressure and low temperature, and in dilute conditions to maximize fuel efficiency and minimize emissions. For example, mixed combustion modes can include partially premixed flame propagation into low-temperature autoigniting mixtures for which traditional, purely premixed or purely non-premixed combustion models do not apply. Experimentation in these adverse environments is limited, and high-fidelity simulation is providing complementary data required to understand and model these complex combustion regimes. These regimes operate near combustion limits where intermittent phenomena—extinction, ignition, flammability limits—result in low-Damköhler-number flames and ignition phenomena characterized by strong sensitivities to variations in fuel chemistry and properties. Hence, there is demand for simulations that can differentiate fuel effects in fundamental “turbulence-chemistry” interactions encountered in practically relevant environments.

The CI requirements for the continuum community share a number of the issues with the infrastructure for molecular properties discussed above. The system would need to support a diverse set of data from a broad range of sources and to provide tools to facilitate the comparison of data from different sources. One example in this context would be tools for the direct comparison of experimental and simulation data. These types of comparisons would range from detailed comparison of laser measurement of nitrogen oxides (NOx) in a diffusion flame, to a statistical comparison of local flame wrinkling in a turbulent premixed flame. Another type of comparison that would be required is the ability to perform comparisons between different types of models at different scales and fidelity. For example, the infrastructure should provide the ability to calibrate the fidelity of a coarse-grained turbulence model by comparing it with high-fidelity DNS data. For some of the data, quality issues are also important. For example, an experiment may not be adequately calibrated for it to be quantitatively compared to a simulation. Similarly, standards of validation and verification are needed to ensure the quality of simulation flame data. The committee believes that tools already developed by the combustion community, such as model versus data comparison tools developed by PrIMe,1 will be made available to the combustion CI.

CI support for continuum data also presents some significant and

|

1 |

See www.primekinetics.org. Accessed December 3, 2010. |

unique challenges. The basic issue is that of the sheer volume of data associated with high-fidelity simulations. Time-dependent direct numerical simulations of turbulent flames being performed today are able to model billions of spatial zones for relatively simple gaseous fuels using either detailed or reduced chemical mechanisms. Typically, detailed mechanisms for hydrogen, syngas, or methane can be incorporated in DNS, whereas reduced mechanisms for larger hydrocarbon and oxygenated fuels—for example, n-heptane, di-methyl ether, butanol—accurately representing low-, intermediate-, and high-temperature kinetics at pressure (i.e., transporting approximately 30 to 80 reactive species) are required for feasibility in DNS on petascale supercomputers. These simulations currently generate data sets measured in the hundreds of terabytes and are only expected to increase in size over time. The data are characterized by velocity, temperature, and dozens of reactive scalar composition fields and additional hundreds of terabytes of particle data used to aggregate Lagrangian statistics in a turbulent flow. The generation of these data sets represents a significant computational investment on the world’s largest supercomputers and, in many cases, is the only means of providing comprehensive temporally and spatially resolved validation data for model development. Hence, it would be extremely valuable to make these data sets available to the larger modeling community. Providing community access to this type of data raises a number of questions. Should there be an effort to collect such data at a central site, or should data be distributed, with individual data sets remaining at the facilities where they are generated? What types of tools are needed to catalog and access these data? If the data are not centralized, how does one deal with the security issues? What standardized file input/output formats and application programming interfaces are needed to facilitate extensible postprocessing and visualization software that operate on subsets of the data?

Similar to the GRIMech effort in kinetics, there has been one noteworthy example of an effort to organize a subset of the continuum combustion community, the Turbulent Nonpremixed Flame (TNF) Workshop. The TNF Workshop, organized in 1996 by Rob Barlow from the Sandia National Laboratories, is an open international collaboration of approximately 100 experimentalists and computational researchers focused on non-premixed and stratified turbulent flames. The TNF Workshop has established an Internet library of well-documented flames that are appropriate for model validation and for comparison of experimental data and modeling results. Although the TNF Workshop is limited to certain classes of flames and has not addressed the issues of providing community access to full-simulation data sets, it has served as a focal point for the community and is viewed as making a significant contribution to the study of

non-premixed and, more recently, stratified turbulent flames. Thus far the scale of the experimental data is sufficiently small that data access, movement, and processing do not significantly hinder progress. The addition of high-fidelity simulation benchmark data and their comparison with experimental and RANS and LES models will require additional CI to accommodate the sheer volume of the simulated data.

Data Flow

All of the subcommunities involved in developing and verifying the molecular properties needed by the combustion community are in the chemical sciences, so they all communicate in a common scientific “language,” and they all could be served by similar molecule-oriented user interfaces. Similarly, the different types of groups studying turbulent flames are from the fluid dynamics community and could be served by interfaces specific to their detailed research needs. However, the combustion CI must also facilitate information transfer between more disparate communities, and in some cases it would be appropriate to develop different interfaces for different communities. In particular, researchers studying continuum-level phenomena will require a substantially different interface to the chemical databases than that required by researchers studying kinetics of a particular molecule.

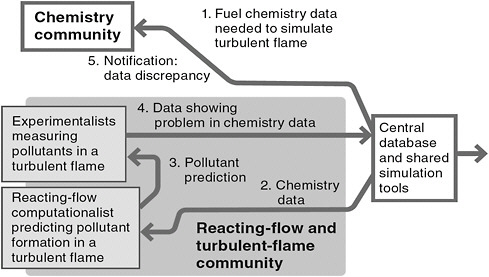

Another key ingredient is the need for the data flow in both directions. For example, researchers studying a turbulent flame may notice that there is a large discrepancy in the simulation predictions of a particular pollutant under certain reaction conditions, suggesting that something may be wrong with the chemistry model. The CI should allow for the rapid communication of this information back to the chemistry community (see Figure 3.3).

There is very strong data dependency in the combustion R&D system: a change in one number can require changes in many other numbers at all levels of the system. A dramatic illustration of this problem was the recent discovery that the published enthalpy of formation of OH was incorrect (Ruscic et al., 2001). This enthalpy number had been used to determine the enthalpies of many other species over the years, all of which need to change, and virtually every combustion simulation ever constructed is sensitive to this number, and so must be corrected (Ruscic et al., 2005). In the absence of a CI, all of these thousands of corrections must be performed by hand—a process expected to take many years. Clearly the new CI must correct this deficiency of the present information flow, making it practical to update the databases and the combustion simulators quickly whenever new information becomes available.

FIGURE 3.3 The cyberinfrastructure should facilitate forward and backward information flow between different communities, driving improvements in critical data and submodels.

The choice of enthalpy data in the examples above is just for illustrative purposes. There are many other types of data needed for combustion simulations, and most have similar issues (e.g., they are derived from heterogeneous sets of measurements and calculations; their numerical values are interdependent with other quantities; they necessitate information flow across disciplinary boundaries).

The development of submodels for many other processes could also be accelerated if coordinated partnerships, common data formats, and common software tools were available and used widely. Today, problems such as soot inception, growth, and oxidation are being pursued by many independent, individual groups, with minimal interconnection. Radiation transport in combustion devices, turbulence modeling, and many other data-rich submodels have the same characteristics as those outlined above. For example, the accessibility of detailed DNS data sets to the community developing turbulence models could greatly accelerate the development, validation, and verification of those models. The overall rate of progress toward solutions can be much faster, and the community can develop better capabilities with coordinated projects that are built

around a centralized data-management and software tools core. This approach has never been attempted at this scale in the field of combustion, although in the few cases where this type of activity was pursued at a much reduced scope, it was very successful. Examples are PrIMe and CHEMKIN (see Appendix B in this report).

Cyberinfrastucture: A New Mode of Organization for a Community-Level Vision in Combustion Research

A CI-enabled combustion community will evolve in a two-tier framework organized into three quasi-homogeneous subcommunities (the fuel and chemistry research community, the reacting-flow and flame research community, and the industrial R&D community) under the umbrella of a superstructure for community-level coordination (see Figure 3.1).

To facilitate this transformation and to promote the fast, wide, and deep adoption of a CI by combustion researchers, it is envisioned that some of the current stakeholders of the research community will play an increasingly important leadership role. One such stakeholder is the Combustion Institute (www.combustioninstitute.org). The Combustion Institute is the premier international scientific society in combustion. With approximately 2,000 full-time members, it promotes the field of combustion science by organizing meetings, both national (the biennial U.S. National Combustion Meeting) and international (the biennial International Combustion Symposium), and by helping manage the premier journal publications in combustion science.

The Combustion Institute can play a pivotal role by providing the technical expertise, the integrity, and the legitimacy that an effort to build and sustain such a CI will require when interacting with funding agencies, individual researchers, and external communities. The Combustion Institute can work at the U.S. national level (through the joint U.S. sections of the Combustion Institute) or at the international level and thereby provide international coordination, should wide-scale CI efforts also be developed in Europe and/or Asia (in fact, the Combustion Institute can presumably promote the emergence of additional CI efforts in Europe and Asia). Finally, and perhaps more importantly, the Combustion Institute can further develop, articulate, and help promote the vision of a new combustion research community empowered by a community-wide CI. Other institutions that could undertake this role include the National Center for Supercomputer Applications at the University of Illinois at Urbana-Champaign and the National Institute of Standards and Technology.

REFERENCES

Benson, S.W. 1976. Thermochemical Kinetics. 2d ed. New York: Wiley.

Bykov, V., and U. Maas. 2009. “Problem Adapted Reduced Models Based on Reaction-Diffusion Manifolds (REDIMS).” Proceedings of the Combustion Institute, Vol. 32, pp. 561-568.

Chen, J.H. 2011. “Petascale Direct Numerical Simulation of Turbulent Combustion—Fundamental Insights Towards Predictive Models.” Proceedings of the Combustion Institute, Vol. 33, pp. 99-133.

Frenklach, M. 2007. “Transforming Data into Knowledge—Process Informatics for Combustion Chemistry.” Proceedings of the Combustion Institute, Vol. 31, pp. 125-140.

Hughes, K.J., M. Fairweather, J.F. Grifiths, R. Porter, and A.S. Tomlin. 2009. “The Application of QSSA via Reaction Lumping for the Reduction of Complex Hydrocarbon Oxidation Mechanisms.” Proceeding of the Combustion Institute, Vol. 32, pp. 543-552.

Kohse-Hoinghaus, K., R.S. Barlow, M. Alden, and J. Wolfrum. 2005. “Combustion at the Focus: Laser Diagnostics and Control.” Proceeding of the Combustion Institute, Vol. 30, pp. 89-123.

Liang, L., J.G. Stevens, and J.T. Farrell. 2009. “A Dynamic Adaptive Chemistry Scheme for Reactive-Flow Computations.” Proceedings of the Combustion Institute, Vol. 32, pp. 527-534.

Lu, T.F., and C.K. Law. 2009. “Toward Accommodating Realistic Chemistry in Large Scale Computations.” Progress in Energy and Combustion Science, Vol. 35, pp. 192-215.

McBride, B.M., S. Gordon, and M.A. Reno. 1993. “NASA Thermodynamics Database.” NASA Technical Memorandum 4513. Cleveland, Ohio: Lewis Research Center, NASA.

Muller, C., V. Michel, G. Scacchi, and G.M. Come. 1995. “THERGAS: A Computer Program for the Evaluation of Thermochemical Data of Molecules and Free Radicals in the Gas Phase.” Journal of Chemical Physics, Vol. 92, pp. 89, 1154-1178.

Peters, N. 1984. “Laminar Diffusion Flamelets in Non-Premixed Turbulent Combustion.” Progress in Energy Combustion Science, pp. 319-339.

Peters, N. 2000. Turbulent Combustion. Cambridge, United Kingdom: Cambridge University Press.

Poinsot, T., and D. Veynante. 2005. Theoretical and Numerical Combustion. Philadelphia, Pa.: R.T. Edwards.

Pope, S.B. 1997. “Computationally Efficient Implementation of Combustion Chemistry Using in Situ Adaptive Tabulation.” Combustion Theory Modelling, Vol. 1, pp. 41-63.

Prager, J., H.N. Najm, M. Valorani, and D.A. Goussis. 2009. “Skeletal Mechanism Generation with CSP and Validation for Premixed n-heptane Flames.” Proceedings of the Combustion Institute, Vol. 32, pp. 509-518.

Puduppakkam, K.V., L. Liang, C.V. Naik, E. Meeks, and B. Bunting, 2009. Modeling of a Gasoline HCCI Engine Using Model Fuels. Society of Automotive Engineers Publication SAE-2009-01-0669. Warrendale, Pa.: Society of Automotive Engineers.

Ritter, E.R., and J.W. Bozzelli. 1991. “THERM: Thermodynamic Property Estimation for Gas-Phase Radicals and Molecules.” International Journal of Chemical Kinetics, Vol. 23, pp. 767-778.

Ruscic, B., D. Feller, D.A. Dixon, K.A. Peterson, L.B. Harding, R.L. Asher, and A.F. Wagner. 2001. “Evidence for a Lower Enthalpy of Formation of Hydroxyl Radical and a Lower Gas-Phase Bond Dissociation Energy of Water.” Journal of Physical Chemistry A. 105(1):1-4.

Ruscic, B., J.E. Boggs, A. Burcat, A.G. Scaszar, J. Demaison, R. Janoschek, J.M.L. Martin, M.L. Morton, M.J. Rossi, J.F. Stanton, P.G. Szalay, P.R. Westmoreland, F. Zabel, and T. Berces. 2005. “IUPAC Critical Evaluation of Thermochemical Properties of Selected Radicals, Part I.” Journal of Physical Chemistry Reference Data, Vol. 34, pp. 573-656.

U.S. EIA (U.S. Energy Information Administration). 2007. U.S. Crude Oil, Natural Gas, and Natural Gas Liquids Reserves, 2006 Annual Report. DOE/EIA-0216. Washington, D.C. November.

U.S. Global Change Research Program. 2009. Global Climate Change Impacts in the United States. New York, N.Y.: Cambridge University Press.

Viola, A., and G.A. Voth. 2005. “A Multi-Scale Computational Approach for Nanoparticle Growth in Combustion Environments,” in High Performance Computing and Communications, Vol. 3726, pp. 938-947, Book Series: Lecture Notes in Computer Science, L.T. Yang et al. (eds.). Berlin/Heidelberg: Springer.

Westbrook, C.K., Y. Mizobuchi, T. Poinsot, P.A. Smith, and J. Warnatz. 2005. “Computational Combustion.” Proceedings of the Combustion Institute, Vol. 30, pp. 125-157.

Westbrook, C.K.,W.J. Pitz, O. Herbinet, H.J. Curran, and E.J. Silke. 2009. “A Comprehensive Detailed Chemical Kinetic Mechanism for Combustion of n-Alkane Hydrocarbons from n-Octane to n-Hexadecane.” Combustion and Flame, Vol. 156(1), pp. 181-199.