6

Vehicle Technology Directorate

INTRODUCTION

The Vehicle Technology Directorate (VTD) was reviewed by the Panel on Air and Ground Vehicle Technology of the Army Research Laboratory Technical Assessment Board (ARLTAB). The directorate has four divisions, three of which are aligned with the key scientific disciplines of mobility: Propulsion, Autonomous Systems, and Mechanics; the fourth division is the Vehicle Applied Research Division (VARD). VARD provides an early assessment of evolving technologies to aid the directorate’s investment decisions and to ensure that all technologies required for a class of vehicles are covered, and in general it increases the research productivity of the entire VTD. In addition, two Collaborative Technology Alliances (CTAs) are an integral part of the directorate. The directorate leads the Robotics CTA and participates in the Micro Autonomous Systems and Technology CTA, acting as the point of contact for the Micromechanics Center (led by the University of Maryland). All divisions of VTD and portions of the CTAs were reviewed by the panel.

Appendix A shows the staffing profile for VTD (see Table A.1). The assessment below reflects visits by the Panel on Air and Ground Vehicle Technology to the VTD sites at NASA Glenn Research Center on July 13-16, 2009, and at the Army Research Laboratory (ARL) facilities at Aberdeen Proving Ground, Maryland, on June 8-11, 2010.

CHANGES SINCE THE PREVIOUS REVIEW

Many changes have occurred in VTD in both manpower and research as well as its location since the previous ARLTAB report.1 The directorate is benefiting from leadership that has seized the opportunity

presented by the consolidation required by the 2005 Base Realignment and Closure (BRAC) decision to develop and motivate a unified team around a research portfolio focused on the critical Army need of ground and air vehicles, with a current focus on relatively small vehicles. Although the hiring of new team members and the transition of the research portfolio from a focus on large, helicopter-type vehicles to a focus on the smaller ground and air vehicles have not been completed, there has been much progress on both of these issues in the past 2 years.

Currently three of the four VTD divisions are located at Aberdeen Proving Ground, and the fourth is in the process of locating there. In addition, VTD has in place a Memorandum of Understanding with NASA for the 11 VTD staff members who will remain at the NASA Glenn Research Center or the NASA Langley Research Center. This Memorandum of Understanding gives VTD the advantage of having access to unique facilities and personnel at the two NASA sites. At Aberdeen Proving Ground, construction is under way to house VTD personnel and corresponding research laboratories. The new building is scheduled for occupation in time to meet the date mandated by BRAC.

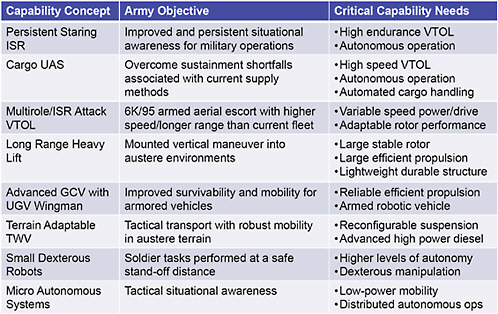

During this 2009-2010 review period, the most far-reaching change to VTD has been the development and staffing of VARD. The creation of this new division is in direct response to concerns expressed by ARLTAB in its previous report.2 That report urged VTD to maintain a systems focus as it instituted changes in its location, personnel, and research portfolio over the 2009-2010 period. With respect to its research portfolio, VARD has used integrated systems analysis to define eight capability concept (CC) vehicles that address defined Army objectives and critical capability needs (see Figure 6.1). VTD management is in the process of aligning its research portfolio to address the technologies required to meet the requirements of the eight capability concept vehicles.

ACCOMPLISHMENTS AND ADVANCEMENTS

Significant technical transition has been achieved by the divisions and several programs during the past 2 years. The status of these accomplishments and advancements is discussed below.

VTD’s most far-reaching accomplishment in the past 2 years has been the development by VARD of the eight capability concepts. These eight CCs cover the Army’s objectives and critical capability needs, make a clear statement of VTD’s vision to meet the Army’s needs, and serve as a clear guideline for individual researchers to align their research to these needs. The CCs also allow VTD management to prioritize research that will impact more than one CC and to determine quickly if its portfolio of research is sufficient to meet the technology requirements of the capability concepts. The focus provided by the CCs will serve as a valuable yardstick for VTD as it continues its efforts to develop an excellent research portfolio in the new focus area of small autonomous air and ground vehicles. Because VTD is in the process of changing to the capability-concept-driven research portfolio, the discussion below is organized to present the status of the research and progress of an example capability concept and related general accomplishments.

Examples of the Persistent-Staring-Vehicle Capability Concept

The goal of VTD’s research portfolio for the persistent-staring-vehicle capability concept is to reduce the weight by a factor of two and increase the time on station by a factor of five relative to a referenced vehicle. VTD’s research portfolio for this capability concept includes a pressurized-structure vehicle, powered by advanced internal combustion engines, ceramic engine components, flash-vaporized Jet

FIGURE 6.1 The mobility capability concepts approach of the Vehicle Technology Directorate. NOTE: Acronyms are defined in Appendix D. SOURCE: Mark Nixon, Vehicle Technology Directorate, “VTD Overview,” Presentation to the panel, Aberdeen Proving Ground, Maryland, June 8, 2010.

Propellant 8 (JP-8) fuel injectors, a ducted fan with diffusing exit contours, and an autonomous control system. Systems analysis by VARD has demonstrated that if this research portfolio were successful, the performance goal of the persistent-staring-vehicle capability concept would be achieved.

Preliminary investigations have identified ultrahigh-molecular-weight polyethylene as a material having the weight and strength characteristics necessary to meet the goals for a pressurized-structure vehicle. Plans are in place to characterize this material in different structural forms and to construct prototype air vehicles with the material. The construction of a test stand to evaluate the vehicle and its propulsion requirements is planned for FY 2011. The pressurized-structural-vehicle concept appears promising, but a materials expert should be engaged to ensure that the selected materials are robust under exposure to chemicals, ultraviolet radiation, and other relevant battlefield conditions.

Research is underway to develop a computational fluid dynamics (CFD) design system for ducted fans and diffusion exit passages. Both of these technologies are utilized to improve the thrust efficiency and reduce the power requirements relative to the reference vehicle. CFD analysis has produced design shapes for the fan airfoil profiles, and continuing CFD analysis is in the process of defining an optimum fan diffuser exit duct. A fan center body should be included in the design space to ensure that the CFD design system for diffusion exhaust ducts will work for all fan-drive systems.

Both nutating and Bonner advanced internal combustion engines are under development through Small Business Innovation Research (SBIR) funding. These engines, if successful, would increase the

horsepower-to-weight ratio and improve fuel economy relative to the referenced persistent-staring-vehicle power plant. Both of these engine types are currently at the prototype stage, but neither has demonstrated the achievement of its design goals. These engine configurations are of interest because of their novelty and the enthusiasm of their proponents within VTD. However, both the nutating and Bonner engines have remained at the prototype stage over the past 2 years, and the VTD researchers have made little progress toward their design goals. These engine concepts may never reach their design goals, particularly in sizes that are of interest to VTD. Therefore, both the thermodynamic and combustion analysis of the two engines should be done to ensure that these concepts can meet VTD’s goals.

Research with respect to utilizing bulk ceramic components in the combustion or rotor sections of engines is being conducted. Bulk ceramic or ceramic composites will be required in engines that achieve JP-8 combustion in small volumes and engines that operate at very high pressure ratios. Both of these areas are of great interest to VTD, and therefore research in this area should be conducted. However, the approach adopted in the current program is a continuation of long series of work performed at the NASA Glenn Research Center. Moreover, the approach taken in this project is not addressing the basic problems that are limiting bulk ceramic application. Therefore, it can be seen by the panel that this approach will not advance the state of the art and will not succeed, and so this work should be refocused or discontinued. For example, the Wankel rotor chosen for this study would appear to be a poor choice. It does not take advantage of the high-temperature capabilities of ceramics, and it requires a metal-to-ceramic joint that will prove difficult to achieve. It is also a complex shape, which will prove difficult to fabricate to the required tolerances and will be subject to residual stress problems. Neither the success nor the failure of this project will prove anything, simply because of the small sample size.

Flash-vapor fuel injector configurations for JP-8 fuels are under development. This research includes the modification and testing of an existing fuel injector, the design and testing of a new injector, and in FY 2011 the engine testing of the final selected injector. The burning of JP-8 in all power plants has been defined as a key Army technology goal. The current programs are demonstrative in nature and may lead to some short-term use of JP-8 in some platforms, but given the key technology, classification work needs to be done in the more basic areas of burning JP-8 in small volumes with small residence times. This is a critical research area for VTD—that is, as pressure ratios increase and the size decreases for engines burning JP-8, there is a clear need for fuel injectors of this type. The approach underway does not have a high probability of success; however, this problem is so important that the program should continue, but it should be carefully coordinated with similar work underway in other parts of the Army and in other services. In fact, because of the importance of this research area to VTD, the directorate should commit increased resources to it.

Research to develop control systems that effectively combine manned and unmanned vehicles into an effective, safe, coordinated team is underway. The proposed approach is to use an object-oriented mapping decision process to learn both the types of action that a human would take and the proper control response of the teamed unmanned vehicle. This approach was poorly justified and is not recommended. A better approach might be to provide a set of initial rules of perception and control to the unmanned vehicle and then allow the vehicle to learn and adapt to the unique characteristics of a particular human pilot. More attention should be paid to the challenge of inferring the intention of the human and to how the approach should be formulated to address this key issue.

General Accomplishments

The Vehicle Technology Directorate continues to perform good work and to make progress in its historic focus area of helicopters and helicopter-size engines while increasing its research in smaller,

robotic-type systems. Two examples of good work in the helicopter area are the demonstration of the active twist of a helicopter rotor and variable-speed turbine design. Design and analytical studies have indicated that active rotor twist could increase the maximum gross takeoff weight of a helicopter by 10 to 15 percent. A full-scale design of the active rotor twist concept, complete with control concepts, was completed in FY 2010 and is to be transitioned to NASA and the Boeing Company for manufacturing and testing in late FY 2011. The variable-speed turbine research is aimed at developing turbine airfoils that will maintain the near-constant efficiency of a gas turbine from the design takeoff rotor speed to the cruise and near-loitering condition at 50 percent rotor speed. The analytic results of this research show that turbine blades that hold constant efficiency over this speed range are possible and would increase turbine efficiency at cruise or near-loitering condition by greater than 3 percent. This increase in efficiency would greatly improve helicopter time on station or mission radius. Cascade verification testing of this type of turbine airfoils for losses over the turbine operating range is planned in FY 2011.

In the newer area of smaller air and ground robotic systems, significant advancements have been made by the Robotics Collaborative Technology Alliance. This program continues to be a well-organized and well-executed effort that brings together a consortium of personnel from industry, academia, and government. VTD has two major roles in this CTA—the first is to manage the overall effort, and the second is to test the results of the program. To date, this effort has produced completely autonomous vehicles that have attempted to navigate real-world terrain littered with many obstacles. In addition, this CTA has demonstrated progress in human recognition by an autonomous vehicle in a prototypical complex urban environment. The CTA process continues to demonstrate a great leveraging of Army Research Laboratory money and other resources.

VTD has also made progress in staffing and technical demonstrations in the microrobotics area. This area is now staffed with new investigators who are conducting state-of-the-art studies of the mechanics and function of very small, flapping-winged vehicles. This is groundbreaking research that will have great promise once it is fully staffed and the research portfolio is fully developed. In the robotics area, the overall plan is to build up the robotics activities and to add more people. VTD management did not present a vision describing how the internal robotics research projects are chosen. The articulation of that vision is still a work in progress, as ARL is trying to develop a crosscutting problem but does not have control of all the funds that would be involved. The danger is that the effort will end up pursuing only the technologies that reflect the expertise and interest of the investigators. ARL should pursue strategic planning to design the overall technical objectives of this program so that more-directed hiring can take place. ARL is in need of a critical mass of individuals working in particular areas of robotics that fit into this larger vision. ARL currently lacks a critical mass of technology leaders in robotics. It has a critical need for technical leaders who can provide vision and guidance in the robotics area as well as technical mentorship of the new Ph.D. researchers.

OPPORTUNITIES AND CHALLENGES

The continued realignment, redefinition, and repositioning of VTD to meet the BRAC requirements as well as its focus on small air and ground autonomous vehicles offer VTD great opportunities to build an organization staffed with excellent researchers who are conducting research focused on critical Army needs.

The standing up of VARD is a first important step to ensuring that VTD is focused on critical Army needs. The challenge now is to ensure that the work of each researcher supports one or more of the directorate’s eight capability concepts. In addition, the VTD management team needs to ensure that all

of the technologies required for each capability concept are being developed within VTD or elsewhere in the total research community.

By concentrating VTD personnel at Aberdeen Proving Ground, many good early-career and other new researchers are being added in several technology areas. The VTD management challenge is to mentor and guide these individuals to ensure that their research is state of the art and is focused on critical Army needs. This is particularly challenging because many of VTD’s new technologies are concentrated in the technology areas for smaller autonomous vehicles instead of in VTD’s historic focus area of technologies for large helicopter-type vehicles.

The power per unit of weight produced by JP-8 combustion is approximately two orders of magnitude greater than that produced by battery or electric power. Therefore, the time on station and the range of many of the smaller robotic vehicles would be greatly enhanced by JP-8 combustion in small engines. VTD currently is conducting research into JP-8 fuel injection and is carrying out some research on the operation of current small engines with JP-8. However, this is an area of research that could affect many of the VTD capability concepts and that cuts across many ARL areas. Therefore, this area should be elevated to a major area of concentration for VTD.

For example, VTD should focus on the combustion of liquid fuels in small volumes—that is, in volumes of a cubic centimeter to a few cubic centimeters. Since the energy per unit of mass achievable from common hydrocarbon fuel is more than an order of magnitude greater than what can be achieved with batteries, an attempt to develop efficient and stable combustors of smaller volume could have very great payoffs for small autonomous air and ground vehicles. Also, there can be some improvement over batteries through the use of liquid-fueled (e.g., using methanol or even reformed JP-8) fuel cells. Fuel cells probably will not reach the same power-to-weight ratios as those possible with combustors, because fuel cells rely on surface reactions whereas combustion uses reactions in the open volume. The large amount of internal surface area in fuel cells implies more solid material in a given volume and therefore tends to make fuel cells heavier. Batteries rely on the exchange of charged particles at surfaces and are heavier due to the same surface-intensive cause. In the research on combustion in small volumes, it should not be assumed that the scaling down of processes from large combustors is the logical approach. A critical evaluation of why a process works well at larger scales is urged, as well as some innovation.

The panel commends VTD for its utilization of unique facilities and personnel at the NASA Glenn and the NASA Langley Research Centers. Its challenge, however, is to integrate the research and researchers from these two NASA sites effectively into the VTD organization, with its focus on critical Army needs. This is particularly problematic because many of the NASA personnel have been conducting the same research for many years. On the one hand, for example, the research areas of ceramic components for gas turbines, coatings for small engines, and foil bearings have been ongoing for a long time and have little or no expected use in Army systems. On the other hand, the research conducted by the NASA personnel on compressor-tip-injection stall control is state of the art, but unfortunately it did not find use in the Versatile Affordable Advanced Turbine Engines (VAATE) Program.

The proper balance of analytical work or computer simulation and experimentation in a research portfolio is always difficult. In-house, VTD has more personnel who are capable experimenters than it has capable computation and simulation people. In several research areas VTD has reached out to universities to add computation and simulation to complement good internal experimental research. The compressor-tip-injection stall control work is an example of this combination of experimental and computer simulation. Ensuring that the proper balance is maintained in all research areas is both a challenge and an opportunity for VTD management.

VTD has several research efforts in the prognostics and diagnostics area. This body of research is aimed both at decreasing injuries to personnel inside a vehicle when the vehicle is under attack and

at lowering vehicle maintenance cost. This is an area of demonstrated Army need that exists now and will exist far into the future. The definition of a new capability concept of a vehicle health monitoring system and focusing of all research efforts will ensure that the VTD portfolio contains all necessary technologies to achieve this capability concept.

VTD testing and field demonstrations of autonomous vehicles and their interactions with terrain and humans are very important. VTD’s Fort Indiantown Gap facility in Pennsylvania is well equipped to conduct this type of research. However, some of the results from recent tests of experiments suggest that the design of the tests and analysis of the data gathered are a challenge for VTD. VTD personnel should develop expertise in the design and conduct of robotics experiments.

There are emergent areas and opportunities for VTD in engineering in mesoscale and bio-inspired systems. These scales represent an opportunity for VTD to take a leadership role. Moreover, this scale of system is likely to be compatible with a multitude of systems for the soldier—for example, squad- or platoon-level reconnaissance assets employing new concepts for air and ground vehicles.

There is a need for the modeling of vehicle systems at VTD. The results of good models, such as performance prediction and scalability studies, seemed absent in many of the projects presented to the panel. Robotic platforms and air vehicles need modeling to enable understanding of performance limits and optimization of platform parameters. Modeling is also critical to system design; good models are the key to insight into the underlying physics, from which meaningful functional and performance metrics can be developed and understood.

VTD should consider undertaking an effort in the following emerging technology areas: mesoscale power sources, such as small fuel cells and gas turbines; the analytical modeling of physical processes such as combustion; and simulators for the training of operators of remotely piloted air and ground vehicles.

High energy density power systems will be a disruptive technology in future Army vehicles. Therefore, VTD should develop and sustain its capability to take a leadership role in some classes of the Department of Defense small engine initiatives. VARD will be of great help in determining in which classes VTD should have the natural leadership role. In order to decide where natural leadership roles exist, VTD should carefully define classes of small engines. For example, a characterization of classes might be as follows: (1) gas turbines: from 3,000 to 10,000 shaft horsepower (hp); (2) internal combustion engines: from 2 to 50 hp; (3) electrical engines: from 0.1 to 10 hp; and (4) hybrid power systems. For example, one area of research that deserves consideration is power sources for baseball-size vehicles. The energy per unit of mass achievable from common hydrocarbon fuel is more than an order of magnitude greater than what can be achieved with batteries. Thus an attempt to develop efficient and stable combustors of smaller volume (a cubic centimeter to a few cubic centimeters) for these baseball-size vehicles could have significant payoffs for small autonomous air and ground vehicles. The number of engine classes needed by the Army and the enabling technology required will exceed the resources of VTD. However, careful selection of primary leadership classes and classes in which VTD needs to leverage the work of other government agencies and industry is the information needed to make the Army an intelligent buyer and will be of great use in focusing VTD’s efforts.

The materials science and technology area is of particular importance to VTD. Addressing the need to develop this area requires that personnel embedded in VTD collaborate with others at ARL, universities, and other laboratories. The new VTD laboratory and the embedded capabilities of the Weapons and Materials Research Directorate can be utilized to attract new researchers, faculty, and students for summer internship programs and develop existing personnel in this vital area.

OVERALL TECHNICAL QUALITY OF THE WORK

The Vehicle Technology Directorate has established the tradition of a research approach that successfully applies analytical tools and experimental techniques in a controlled environment to hardware-based problems of various scales. In many areas, VTD research is contributing to both fundamental and applied levels of technology. In addition, many examples exist of the work of VTD fulfilling both current and future Army needs. Over the past 2 years, a continuum of evidence demonstrating higher-quality research has evolved. The BRAC decision to consolidate VTD at Aberdeen Proving Ground, coupled with VTD management’s evolving focus on Army needs, is increasing the quality of the VTD research portfolio. The establishment of eight capability concepts that embody clearly defined future Army needs is a clear example of VTD focus as it moves from research emphasis on helicopter-type vehicles to research emphasis on smaller, autonomous robotic vehicles. The capability concepts approach also improves the quality of the research portfolio by allowing VTD management to ensure that all of the research needed to support each capability concept is underway by the technical community either inside or outside VTD. The recognition that a crawling-bug-type vehicle needs to be added to the Micro Autonomous Vehicle Capability Concept is a clear example of management’s understanding of the Army’s need in this research area. In a similar manner, the capability concepts approach allows VTD to prioritize research so that research impacting several capability concepts can be moved forward, or research that does not apply to any capability concept might be redirected or stopped. The combustion of JP-8 fuel in a very small volume is an example of a crosscutting technology area that would impact several capability concepts, and it is therefore a high-priority research area.

Some high-quality technical work at VTD is clearly an important contribution to the overall technical community. For example, the compressor-tip-injection stall control work that couples experiment data and computational fluid mechanics is state of the art and will enable the industrial design community to improve gas turbine fuel economy and reduce compressor stall. In a similar manner, the windage work in high-speed gear systems is state of the art and promises to improve gearbox efficiency across a wide range of vehicles. The bearing work offers real increases in power transfer per pound of weight in a large range of geared systems. The 3,000 to 10,000 shaft hp gas turbine (VAATE) program has well-defined metrics; leverages technology development across the Army, Air Force, Navy, NASA, and industry; and, if successful, will enable several classes of new Army vehicles. In all of these areas, VTD is aware of and is leveraging a wide range of government, industry, and university research to achieve the needs of the Army. Clearly there needs to be more work like the examples given above if VTD is going to meet all of its requirements with limited resources.

The VTD research in microautonomous systems is groundbreaking work. The researchers involved in this work are of high quality. The development of a complete portfolio of work in this area and the addition of new team members will improve the focus of this work.

Several areas within VTD are not focused clearly on the Army’s highest priorities or are of lower quality than desired:

-

The foil bearings, small-engine coating, and ceramics programs need to be examined for relevance to the VTD mission and possibly refocused or eliminated.

-

The burning of JP-8 fuel in all power plants has been defined as a key Army technology. The current programs are demonstrative in nature and may lead to some short-term use of JP-8 in some platforms, but given the importance of this key technology, classification work needs to be done in the more basic areas of burning JP-8 in small volumes with brief residence times. This effort

-

would benefit from being carefully coordinated with similar work underway in other parts of the Army and other services.

-

The limiting of equipment maintenance and downtime for unexpected failures is a critical Army need. There are two paths to achieving the desired results: (1) the embedding of sensors to detect impending failures so that action can be taken before the next mission, or (2) the conduct of statistical analysis based on mission usage to determine when to take maintenance action. The current programs are based on the embedded-sensor approach; however, many sensors are less reliable than the equipment that they are attempting to measure, and “low-hanging fruit” from the statistical method is available. Therefore, the research efforts on prognostics and diagnostics should investigate both methods.

-

Electric power vehicles will be more commonplace in the future Army. Therefore, VTD should have programs or develop influence and awareness of high energy density for electrical motors, batteries, power conditioning, and control of electric drive trains.

VTD efforts to encourage personnel to participate in conferences, publications, committees in the technical community, and other professional interactions are commendable. Contact with other funding agencies, investigators, and professional societies are essential for VTD to maximize the results of its efforts. Opportunities exist for VTD to increase the awareness of and leverage activities of other agencies and offices; VTD should continue its emphasis in this area. Metrics for success with respect to such opportunities need to be constantly examined in terms of strategic technical goals, objectives, and expectations. VTD presented some very positive results from this activity; for example, the drive train activity includes collaborations with universities in the production of papers, analyses, and experiments. The facilities and intellectual resources of NASA should continue to be utilized as Army representatives in those activities leverage NASA work and capabilities.

The organizational research model of the CTAs is commendable. This model allows the best personnel of industry, academia, and ARL to collaborate on research areas of great interest to the Army. The Robotics CTA is continuing to do state-of-the-art work. The testing and demonstration areas at Fort Indiantown Gap are capable of ensuring that the results of the CTA meet Army needs; however, the current quality of robotic test design needs to be upgraded.