2

Materials Development: The Process

2.1

INTRODUCTION

A three-step, tiered technology development process has been used in the U.S. Air Force (USAF) for years. It is taught at the Defense Acquisition University as part of the science and technology (S&T) management courses and instantiated in Department of Defense (DOD) and Air Force regulations.1 Air Force acquisition regulations assign responsibility for the execution of S&T, the assessment of technology readiness level (TRLs), and the negotiation of technology transition agreements. The majority of these responsibilities fall on the Air Force Research Laboratory Commander.2

Unfortunately, despite the fact that this three-step development process is instantiated in the planning and budgeting process, it rarely executes as published. Funding changes, advances or delays in moving to higher TRLs, and the dynamics of the technology-push–requirements-pull relationship result in each technology’s maturation path being different. In contrast to this notional model (further discussed in Section 2.4, below), what has actually occurred with respect to the technology development process cannot be well defined, differs from one case to the next, and, most importantly, changed substantially toward the end of the 1980s.

|

1 |

Air Force Instruction, AFI 63-101. Available at http://www.af.mil/shared/media/epubs/AFI63-101. pdf. Accessed July 9, 2009. |

|

2 |

Donald C. Daniel, Center for Technology and National Security Policy. 2006. “Issues in Air Force Science and Technology Funding.” National Defense University, Fort Lesley J. McNair, Washington, D.C., February. |

That change involved an increased emphasis on risk reduction and on decisions made by reliance on TRLs—considerations that now drive materials selection in engine developments (including demonstration engines) to the point that the insertion of new materials appears only tangentially in the objectives of engine test programs. Along with this paradigm shift, the evolutionary advance of traditional turbine materials, such as superalloys, has slowed. Engine designers have become averse to the increased risk of materials insertion, and so not only have once-widespread evolutionary materials and process discoveries decreased, but the funding for needed underlying developments has also been downplayed by the new paradigm change. This sentiment was expressed, for example, at the workshops leading to publication of the National Research Council (NRC) report Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems, which stated, “Workshop speakers unanimously identified risk aversion as a fundamental barrier to innovation and rapid technology transition.”3 This idea can be recast as follows: More stringent DOD guidelines with respect to required TRLs for incorporation of technology drive the engine OEMs (original equipment manufacturers) to proven low-risk technologies.4 At the same time, the path to quantum changes in advancements (discussed in Section 2.3, below) appears to point toward revolutionary classes of structural materials such as ceramic-matrix composites (CMCs) for which even less of a technology base is available. The lack of data for these materials predisposes risk-averse engine designers to avoid their use. These “structural” changes in the process for the development of new materials for propulsion have also been accompanied by a distinct change in the character of materials programs at U.S. universities.

All of these elements are crucial to the understanding of why things are as they are at the present time and what might be done to adapt to and perhaps improve the present state of advances in structural materials for propulsion. Understanding the notional process and what has actually occurred depends on understanding TRLs and funding definitions. These are discussed in Section 2.2, below, followed by a brief discussion in Section 2.3 of the critical role that materials development has played in advancing turbine engine performance. In Section 2.4, the nominal materials development process for propulsion materials is described. These sections are meant to place in better perspective the pre-1990s’ materials development “process”; Sections 2.5 and 2.6 then discuss how this process evolved in the changing 1990s’ environment into the present development process. Major programs that have contributed to advances in propulsion structural materials

are outlined in Section 2.7; these programs were started at the beginning of the paradigm shift in the process and continue to the present with the new demonstrator-engine program, the Versatile Affordable Advanced Turbine Engine (VAATE) Program. Section 2.7 ends with a discussion of the characteristics of successful materials development programs. Section 2.8 describes the common themes for successful materials development. Section 2.9 discusses the evolution of materials science and engineering programs at U.S. universities. Section 2.10 discusses the Air Force Office of Scientific Research (AFOSR). Finally, the chapter closes in Section 2.11 with a list of findings supported by the discussion in the chapter. These findings should be helpful in providing the context for Chapter 3, an assessment of the present state of materials development. As importantly, these findings form the starting point for Chapter 5, which presents discussion of and recommendations for a way forward.

2.2

TECHNOLOGY READINESS LEVELS AND RESEARCH AND DEVELOPMENT FUNDING

As mentioned above, a certain level of understanding of how risk is assessed and what types of funding are being used in DOD research and development (R&D) is needed for a discussion of the evolution of the process of materials development for propulsion. This section briefly describes these topics.

2.2.1

Technology Readiness Levels

Technology readiness levels are used by U.S. government agencies to define the level to which a technology has been developed and the concomitant risk associated with attempting to incorporate the technology into a development program. Readiness levels are also used in industry in one form or another, although the descriptions used by industry may differ from those used by the government. It is generally possible to align a company’s readiness level with the government’s definitions; when a TRL is mentioned in this chapter, an attempt is made to use the government’s definition. Even so, over the years TRLs have diverged slightly in definition between those of the DOD and of NASA. The definitions of the levels used by the DOD are given in Table 2.1.

2.2.2

Definition of DOD Defense Research and Development Funding

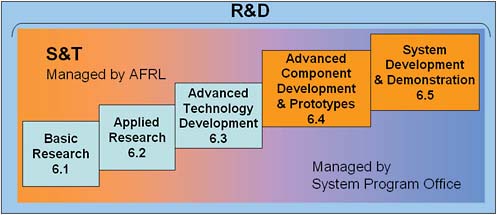

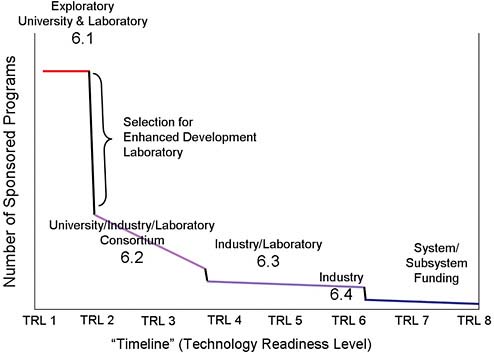

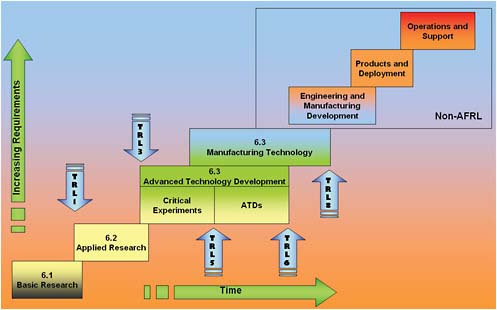

The DOD has 11 major force programs in which program 6 is for research, development, testing, and evaluation. Program 6 is further divided into five subcategories; see Figure 2.1. The subcategories for DOD research and development funding are referred to as 6.1, 6.2, and 6.3:

TABLE 2.1 Technology Readiness Levels in the Department of Defense (DOD)

|

Technology Readiness Level |

Description |

|

1. Basic principles observed and reported. |

Lowest level of technology readiness. Scientific research begins to be translated into applied research and development. Examples might include paper studies of a technology’s basic properties. |

|

2. Technology concept and/or application formulated. Invention begins. |

Once basic principles are observed, practical applications can be invented. The application is speculative and there is no proof or detailed analysis to support the assumption. Examples are still limited to paper studies. |

|

3. Analytical and experimental critical function and/or characteristic proof of concept. |

Active research and development is initiated. This includes analytical studies and laboratory studies to physically validate analytical predictions of separate elements of the technology. Examples include components that are not yet integrated or representative. |

|

4. Component and/or breadboard validation in laboratory environment. |

Basic technological components are integrated to establish that the pieces will work together. This is “low fidelity” compared to the eventual system. Examples include integration of “ad hoc” hardware in a laboratory. |

|

5. Component and/or breadboard validation in relevant environment. |

Fidelity of breadboard technology increases significantly. The basic technological components are integrated with reasonably realistic supporting elements so that the technology can be tested in a simulated environment. Examples include “high fidelity” laboratory integration of components. |

|

6. System/subsystem model or prototype demonstration in a relevant environment. |

Representative model or prototype system, which is well beyond the breadboard tested for TRL 5, is tested in a relevant environment. Represents a major step up in a technology’s demonstrated readiness. Examples include testing a prototype in a high fidelity laboratory environment or in simulated operational environment. |

|

7. System prototype demonstration in an operational environment. |

Prototype near or at planned operational system. Represents a major step up from TRL 6, requiring the demonstration of an actual system prototype in an operational environment, such as in an aircraft, vehicle or space. Examples include testing the prototype in a test bed aircraft. |

|

8. Actual system completed and “flight qualified” through test and demonstration. |

Technology has been proven to work in its final form and under expected conditions. In almost all cases, this TRL represents the end of true system development. Examples include developmental test and evaluation of the system in its intended weapon system to determine if it meets design specifications. |

|

9. Actual system “flight proven” through successful mission operations. |

Actual application of the technology in its final form and under mission conditions, such as those encountered in operational test and evaluation. In almost all cases, this is the end of the last “bug fixing” aspects of true system development. Examples include using the system under operational mission conditions. |

|

SOURCE: Reprinted from Department of Defense, 2006, Defense Acquisition Guidebook and Technology Readiness Levels, Washington, D.C. |

|

FIGURE 2.1 The 6.1 to 6.5 ladder: subcategories in Department of Defense program 6 for research, development, testing, and evaluation. SOURCE: Air Force Research Laboratory (AFRL).

6.1 basic research includes scientific study and experimentation to increase knowledge and understanding in science and engineering related to long-term defense needs. This research provides the foundation for technological improvements to warfighting capability.

6.2 applied research includes efforts to solve specific defense problems, short of major developments or demonstrations. This applied research category includes the development of components, models, and new concepts through in-house and industry efforts. Individual research programs often enable a variety of new systems and support a number of identified needs.

6.3 advanced technology development includes all efforts directed toward projects that have moved into the demonstration of hardware or software for operational feasibility. Experimental systems or subsystems are demonstrated in order to prove the technical feasibility and military utility of the approach selected. Advanced technology development (6.3) provides the path for the rapid insertion of new technologies or product improvements into defense systems.

Continued R&D efforts beyond 6.3 require special funding aimed at the development of engine demonstrators, specific engine component developments, or support of new weapon systems or subsystems.

2.2.3

Technology Readiness Levels and Funding Definitions

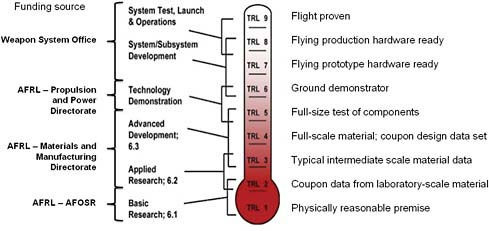

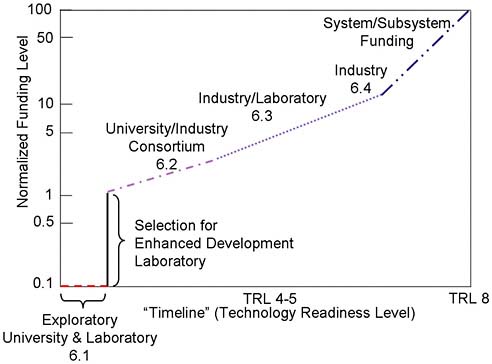

Technology readiness levels are aligned with funding levels in Figure 2.2. This alignment was provided by the Materials and Manufacturing Directorate of the

FIGURE 2.2 Alignment of technology readiness levels (TRLs) with funding levels as applied to materials for propulsion. NOTE: Acronyms are defined in Appendix F. SOURCE: Materials and Manufacturing Directorate of the Air Force Research Laboratory, October 2009.

Air Force Research Laboratory, applied to materials for propulsion, and is current as of this writing. When comparing the definitions of TRLs with the purported intent of the funding levels as seen in Figure 2.2, it is clear that this alignment is somewhat subjective and could be altered.

The subjectivity in defining research funding levels is clearly not limited to this particular case. In dealing with other directives within the government, the term “fundamental research” is used to cover a range of research levels and funding levels. In National Security Decision Directive 189 (NSDD 189), for example, “fundamental research” means basic and applied research in science and engineering, the results of which ordinarily are published and shared broadly within the scientific community, as distinguished from proprietary research and from industrial development, design, production, and product utilization, the results of which ordinarily are restricted for proprietary or national security reasons. Thus it is clear that the level of funding that can be interpreted as “fundamental research” is not restricted to 6.1 funding and can be the result of 6.2 and even 6.3 funding.

2.2.4

Technology Demonstration: Definitions of Milestones A, B, and C

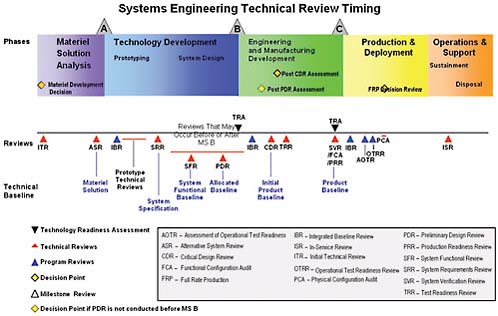

Once funding moves beyond 6.3 (see Figure 2.2) to support TRLs above 5 and 6 through technology demonstrations, the Defense Acquisition System uses the concepts of Milestones A, B, and C, which may be thought of as gates in a system development process. Concept development and refinement occur before

Milestone A, and further technology development to work out the concept occurs before Milestone B. Only after Milestone B does a program become an enterprise with dedicated funding behind it; the nature of systems engineering thus changes significantly after Milestone B. Figure 2.3 illustrates the milestones in conjunction with the technical review timing.

These milestones can also be aligned with TRLs. Milestone B occurs at approximately TRL 6. Recall that at TRL 6, any new material must be at the point where a representative or prototype component has been tested in a relevant environment and is ready to be made into an actual prototype to be tested in an actual system environment. Without providing an exact definition of Milestone B, it can be said that its focus is a demonstration of process maturity and component development. Milestone B generally marks the end of 6.3 programs, which start at TRL 3 or 4.

The major review for engineering acquisition at Milestone B is aimed at managing the risk for further development. This generally means that materials must be selected early in the process, because the use of new materials may require new designs and increase risk. By whatever process, a new material must have been matured to approximately TRL 5, bridging an ill-defined gap often described as the “valley of death.” The valley of death is associated with a disconnect between

FIGURE 2.3 Milestones A, B, and C for systems engineering review. SOURCE: Reprinted from Figure 4.3, Chapter 4, p. 39, of Interim Defense Acquisition Guidebook. Available at https://acc.dau.mil/dag.

technology development and successful application; it has been the subject of many books, studies, and discussions. The NRC report Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems discusses the issue extensively.5 Overcoming this barrier requires understanding the issues associated with it and devising strategies to be more successful in bridging the barrier. Much of the information in this report is applicable to the question of determining the adequacy of strategies for continued progress in developing materials for propulsion.

2.3

THE ROLE OF MATERIALS IN THE ADVANCEMENT OF PROPULSION TECHNOLOGY

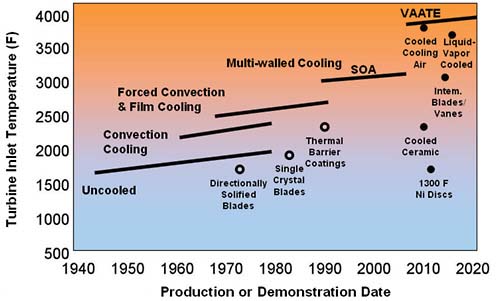

Although it goes without saying that materials technology, including the development of materials and the processes to turn these materials into engine components, has contributed significantly to the advance of propulsion technology over the past six decades, a brief discussion of this point may be helpful. The advent of new materials and processes (M&P), such as vacuum melting, high-strength titanium alloys, and superalloys, has enhanced materials performance, enabling increased turbine temperatures, rotor speeds, and engine thrust at ever-increasing engine efficiencies. This advance for high-pressure turbine airfoils is chronicled in Figure 2.4, which shows how materials improvements in concert with innovative turbine blade design advances have increased turbine inlet temperatures by a factor of two between 1940 and 2006. Complementary advances for structural titanium and superalloy rotor materials have enabled increases in rotor speed and thrust.

Figure 2.4 also includes a projection of possible avenues to further enhance performance if materials advances continue, but it should be noted that at present the VAATE Program (discussed in Chapter 3) is not funded to develop components with the new materials concepts indicated on the figure. Today, the array of mate rials that are being used for propulsion or that may possibly be used in future systems is both vast and diverse, representing all classes of structural materials, including metal alloys, intermetallics, ceramics, polymer-matrix composites, metal-matrix composites, and ceramic-matrix composites. The fact is that turbo-machinery continues to depend predominantly on wrought or cast metallic alloys for the majority of engine components. The latter, nonmetallic materials clearly have the potential to contribute to future propulsion advances; however, the successful insertion of these advanced materials will depend on a thorough understanding of these emerging material classes and an acknowledgment of attendant manufacturing and durability risks.

FIGURE 2.4 The complementary contribution of materials advance and innovative design engineering on turbine inlet temperature increases over the past six decades. NOTE: Acronyms are defined in Appendix F. SOURCE: Information from a presentation to the committee by Charles Ward, Air Force Research Laboratory, January 2009. Approved for unlimited distribution: Public Affairs Case Number 88ABW-2009-0180.

Over the past six decades, continued advances in materials both enabled new Air Force systems with greater efficiency and performance and transitioned to U.S. aerospace companies, which continued to have competitive advantages. Now, however, continued investments by the Air Force and the DOD in the work needed to mature these new advanced materials to the point that they play a role in future engine advances6 appear to be downplayed. In general, this is because people appear to associate the need for continued advances in structural materials for propulsion systems with the expectations of new airframe programs in the Air Force—in this case there is a declining expectation, an expectation of fewer new airframe programs in the Air Force. However, this apparent association overlooks the role of advanced materials in upgrading existing engines. As an example, the benefits of continued technology insertion in fielded engines are well illustrated by the continued development of the PW100 and the GE110 engines. Technology insertion allowed these engines to have significant performance and durability

enhancements, resulting in the improved-performance engines that powered the F-15E and the later sections of the F-16 engine.

If materials development is to continue to play its historically demonstrated role in advancing engine performance, some enhanced investment will likely be needed. However, it is important to understand where this investment might best be placed, and this in turn depends on an understanding of the process that a new materials development goes through from concept to insertion.

2.4

THE NOTIONAL DEVELOPMENT PROCESS FOR PROPULSION MATERIALS FROM IDEA TO INSERTION

As discussed in Section 2.5, below, the introduction of new materials into a new or demonstration engine rarely follows the specified model. But regardless of whether or not the model is followed, it is important to discuss it because it is clear that funding plans are made under the assumption that this notional development plan will be followed. The time period from the point of the introduction of a new material idea to the point at which it is seriously considered for insertion into an engine involves a long-term process that can exceed 20 years. But rather than specifying time in years, it is easier here to describe a notional process with a “timeline” in TRLs. The notional timeline given in Figure 2.5 indicates a continuous maturation of a single material from a large number of initial candidates being nurtured at the 6.1, TRL 1 level of funding and readiness. In general, funding requirements at the lowest TRL level, even for a large number of good ideas, are small compared to the costs of insertion in the final stages of development of, by then, a single material. The funding requirements are also notionally described in Figure 2.6 as a companion to Figure 2.5. As one or a few of the ideas progress into further development, during which coupons are actually produced and property information is beginning to be obtained, the cost increases above the levels provided for all of the basic-concept materials. As larger scale-up occurs, representative geometries are reduced and spin tests and other tests are run on even fewer ideas, the costs escalate again, eventually rising to a level of risk that allows a single material to be matched against a conceptual design in pre-Milestone A, TRL 4 to 5 (see the discussion of milestones, above). Finally a Milestone B point is reached, and full-scale development begins.

It is difficult to ascribe actual years along the timeline axis in Figures 2.5 and 2.6, but Table 2.2 is helpful in this regard. Table 2.2 describes the nominal number of years required to bring a new material to the maturity level needed for insertion, depending on the level at which the material development starts. It is probably possible to match the “Development Phase” description in the table with a TRL level; however, for the purpose of this description, it is assumed that the TRL for the shortest development time is approximately TRL 5 or 6. At the longest devel-

FIGURE 2.5 Notional development technology readiness level (TRL) timeline.

opment time, the TRL level is approximately TRL 1. In this regard then, one can assume that the timeline extends to 20 years or more.

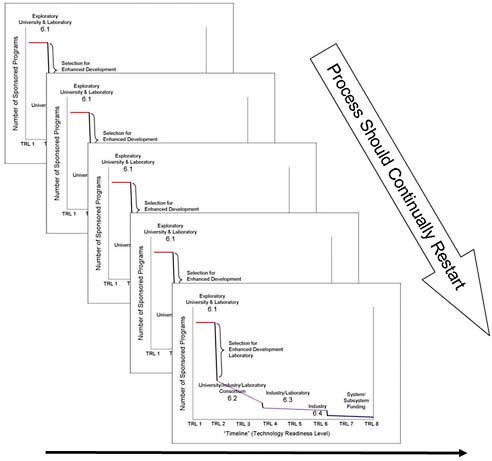

Section 2.5 describes how structural materials are actually brought into the engine development cycle and concludes that in order for quantum increases in performance to be made, new classes of materials beyond wrought or cast metallic alloys must be considered. If the notional process described in Figure 2.6 were to exist, however, ensuring a continuous flow of materials into new engine developments would require, as shown in Figure 2.7, that a new cycle for each new material or class of materials was reinitiated on a continuing basis.

2.5

THE HISTORICAL MATERIALS DEVELOPMENT PROCESS: HOW IT HAS ACTUALLY WORKED

Rather than closely following the prescribed process described in Section 2.4, the development and application of new propulsion structural materials have historically either opportunistically exploited novel and independent discoveries or have had programs established in order to use evolutionary developments in composition,

FIGURE 2.6 Notional funding profile for the eventual insertion of a new material.

TABLE 2.2 Typical Development Times for New Materials

|

Development Phase |

Development Time |

|

Modification of an existing material for a noncritical component |

2 to 3 years |

|

Modification of an existing material for a critical structural component |

Up to 4 years |

|

New material within a system for which there is experience |

Up to 10 years. Includes time to define the material’s composition and processing parameters. |

|

New material class |

20 to 30 years. Includes time to develop design practices that fully exploit the performance of the material and establish a viable industrial base (two or more sources and a viable cost). |

|

SOURCE: R Schafrik, GE Aircraft Engines, briefing presented at the National Research Council Workshop on Accelerating Technology Transition, Washington, D.C., November 24, 2003. |

|

FIGURE 2.7 Ensuring a continuous flow of materials.

microstructure, properties, and processing routes. Whether through opportunistic or concerted efforts, new materials were developed to solve known problems, to expand a material’s operational envelope, or even to enable new engine design concepts. Although all new M&P technology introduces some technical, budgetary, and scheduling risk to an engine program, those developments that represented revolutionary departures (i.e., the first application of a materials system or manufacturing process) have created the highest level of uncertainty. For these revolutionary materials, the materials developer too often struggles to anticipate reliably the potential for new-process-induced flaws, inherent materials defects, failure mechanisms, property balances, and manufacturing yield. An example of the struggles associated with such revolutionary developments is described in the case study in Section 2.5.1, below.

Early technical tools, team culture, and the management of M&P development were for decades relatively primitive compared to their counterparts today. Rather than following a formal structured process such as that described above, development was ad hoc, and it opportunistically exploited new ideas from universities (perhaps under 6.1 funding, as described in the notional process) but more often from promising M&P candidates derived from prior development programs and from innovation spawned and tested within independent research and development (IRAD) programs. Although cases may exist, it is worth noting that the committee was unable to find an example of a 6.1-funded material that could be tracked through continuous development to an engine insertion. Historically, materials research was usually performed by a team that included engine manufacturers, material-forging companies, and casting suppliers, all having well-staffed research departments and facilities and vibrant, ongoing research programs. Activities being carried out in universities under 6.1 funding were generally thought of as providing properly trained researchers for the workforce rather than providing the early development or discovery of candidates for continued maturation by the industry.

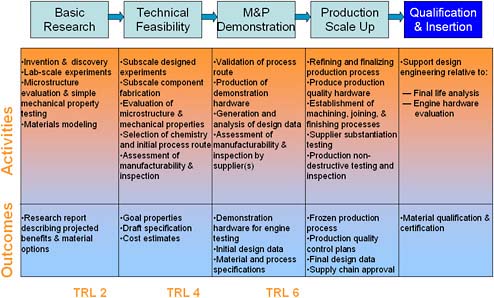

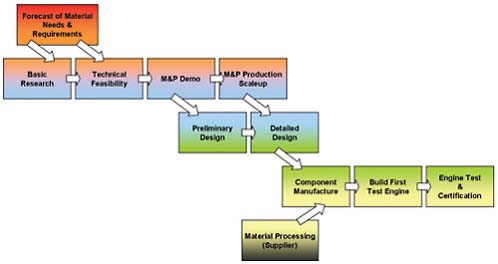

Regardless of the exact path, the fundamental development steps were the same as those of any other engineering discipline, then as now. These steps include the following (Figure 2.8):

-

Basic research and invention—laboratory experimentation to explore and evaluate new materials and processing concepts;

-

Technical feasibility assessment—subscale M&P implementation to refine the material architecture, evaluate processibility, and provide initial evaluation of material properties;

-

M&P demonstration—full-scale M&P implementation to validate the process route, assess manufacturing issues, and generate design data curves; and

-

Production scale-up—finalizing of manufacturing processes and making production-quality hardware for design data and material qualification engine testing.

Historically, the first two stages of development lacked formal guidelines and “tollgates” and instead depended largely on the experience, knowledge, and development style of the principal investigator. Prior to 1985 there were few computational tools except for chemical thermodynamics and PHACOMP methods (PHACOMP is a sigma phase prediction tool)7 that the development team could apply to help guide development. Instead, development depended on an iterative,

|

7 |

SUPER PHACOMP carries the NASA case number MFS-26164. It was originally released as part of the COSMIC collection. See http://www.openchannelfoundation.org/projects/SUPER_PHACOMP. Accessed May 3, 2009. |

FIGURE 2.8 Description of the steps, activities, and outcomes in the materials development process.

NOTE: M&P, materials and processes.

empirically driven, experimental plan which produced property data that distinguished success from failure.

The final development step (production scale-up) included material qualification, insertion, and support for fielded hardware. The qualification requirements for a material depended on both the material and the type of engine component targeted for insertion. Considerations in determining requirements included the impact of component failure on engine operation and flight safety, prior experience with the material in other components or engines, the prior history for similar materials and manufacturing processes, the quantity and quality of materials data, and the maturity of as-manufactured and in-service nondestructive inspection methods.

The committee notes that the TRLs listed along the bottom of Figure 2.8 indicate the approximate point in the materials development process where a TRL would fall, even though almost no TRL language was used in the development cycles in the early years. Because the materials development process steps remain essentially the same today, TRLs are included in Figure 2.8.

Early materials development, prior to the 1990s, was performed with only limited interaction with the other engineering disciplines. Following the receipt of materials requirements from the design engineering department, the materials department, in concert with suppliers, iteratively developed and characterized the

M&P and ultimately delivered specifications, drawing notes, and materials property design data curves to its engineering customer. During development, interactions among engineers across disciplines were limited, and confined to periodic reviews except when serious problems arose. In this climate, ineffective communication between disciplines and the absence of standard development processes too often caused a misunderstanding of materials requirements, misjudgment of insertion risks, and non-uniform development approaches, methods, and decision-making processes. In the early days, aerospace engine manufacturers developed and produced many capable engines, usually under the direction of highly experienced managers whose careers started in engineering and spanned the entire history of the evolving modern turbine engine.

The engine development cycle originally depended largely on component and engine testing to improve and validate engine designs, including constituent materials and processes. This make-or-break approach required a long (8 to 12 year) engine development cycle, involved a number of development engines and spin pit and component test rigs, and was costly; however, the cycle provided time for materials development and afforded ample opportunity for early materials evaluation during development-engine testing. For example, a designer could include a rainbow wheel of different turbine blade designs and materials in a test engine and assess their relative merits by evaluating features such as coating condition, tip erosion, leading-edge and tip cracks, and dovetail wear. The materials and engine development cycles were largely in sync unless either was delayed because of unexpected risks that had materialized. It should be noted, however, that development periods of approximately 10 years for materials mean that although the candidate materials were new to the engine being developed, they were materials for which there had been experience (see Table 2.1). According to Figure 2.8, this places the candidate materials at approximately TRL 4, which means that by whatever nonspecific route, the candidate materials had been developed to TRL 4.

Even with an 8- to 10-year horizon and some confidence that the materials choice at the start seemed promising, the level of insertion risk for any materials choice always increases during the course of a materials development program. For this reason, at the early stages, the development team had a number of materials and process options, but as development progressed, ultimately all but one option was discarded on the basis of the property data and processing findings generated during subscale trials. However, the subsequent materials processing scale-up, the generation of complete mechanical property design data curves, and the implementation of the full suite of component manufacturing operations too often uncovered materials issues and deficiencies that required further development. Coming late in the product development cycles, these surprises disrupted engine building and testing, caused engine design revisions, and required iterative processing trials that collectively affected both cost and schedule.

It is, of course, true that a prudent development plan requires that any new material must have a backup that keeps the engine design viable should the new material solution fail; however, if there was a completely acceptable, tried-and-true material backup available that had the same advantage as the new material and/or process offered, the backup would be the primary candidate. In the present climate, there are too few funds to develop the material and process for the primary new-material solution, let alone to carry along a backup.

2.5.1

Case Study: Powder Metallurgy “As-HIP” Superalloys

The following case study clearly changed the paradigm within the company involved for evaluation of the importance of considering risk in inserting new materials. This case and others like it throughout industry were studied by engine manufacturers and the government, leading to a new emphasis on risk aversion and the use of integrated product development teams (IPDTs).

The development of aerospace materials has offered up many lessons over the past 50 years, and all too often these lessons have come the hard way—particularly those associated with the development of revolutionary materials. Whether they break new ground in composition or in processing, revolutionary materials usually promise significant advancement in materials capability and engine performance. But such materials also pose higher risks and often present processing and manufacturing-infrastructure challenges. This case study recounts the development of powder metallurgy (PM) turbine components consolidated using hot isostatic pressing (HIP).

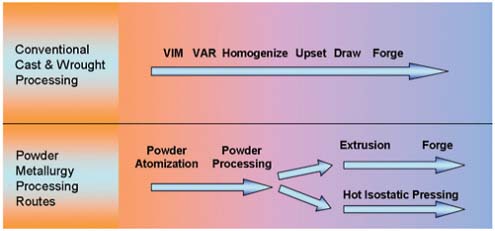

In the 1960s, the advance of turbine technology encountered what seemed to be a materials roadblock. Turbine designers wanted higher-temperature and stronger superalloys to increase turbine temperature and rotational speed, reduce the number of turbine stages, and thereby gain improved turbine efficiency and performance. But stronger, more highly alloyed superalloys exhibited excessive ingot segregation and both poor hot workability and cracking when manufactured using conventional cast and wrought processes (Figure 2.9).

In 1968, materials engineers at Federal Mogul and Pratt and Whitney demonstrated that powdered metal superalloy processing was viable and that it could achieve mechanical properties equivalent to those of traditional cast and wrought materials.8,9 The main idea behind this advance was sound—the atomization of a

FIGURE 2.9 Comparison of typical steps used for conventional cast and wrought processing and powder metallurgy processing of aerospace superalloys. NOTE: Acronyms are defined in Appendix F.

superalloy melt produces a fine, rapidly solidified powder, having less elemental segregation. But developers needed to find a consolidation process that produced the best combination of materials properties and manufacturing cost. Initial candidates included HIP consolidation either followed by forging, extrusion, and more forging, or used directly from HIP consolidation, so-called as-HIP, to directly produce a shaped compact (see Figure 2.9). The latter option, as-HIP, promised the added cost benefits of streamlined consolidation and near-net-shape compacts that required less machining; for these reasons it was selected by several engine programs for production rotor hardware. In retrospect, the expectations of improved mechanical properties and significant manufacturing cost savings may have overshadowed the perception of risks associated with the product introduction of nonforged rotor as-HIP components made by a nascent PM manufacturing base. Were as-HIP promises too good to be true?

Unlike cast and wrought processing of highly alloyed superalloy compositions (such as Rene ’95), early as-HIP development yielded fully dense, crack-free component pre-forms that exhibited good mechanical properties. The superalloy powder for these as-HIP, near-net-shape compacts was produced using laboratory-scale gas-atomization equipment operated by highly skilled research technicians. However, as production rates ramped up, production equipment scaled up and relocated to the factory floor, and the low cycle fatigue (LCF) test database grew in size, engineers became concerned about the cleanliness of the as-HIP product. They observed that the lives of LCF test bars were controlled by anomalous defects of four types: voids, discrete chunky ceramics, ceramic agglomerates, and reactive

agglomerates that decorated prior powder-particle boundaries (PPBs).10 More troubling, the population of LCF test-bar lives was bimodal, with a significant short-life subpopulation composed of test bars for which LCF failure initiated at larger defects, usually located at or near the surface of the test bar. Moreover, mate rials engineers found that although the size of most defects was limited by the powder screen size, PPB defects were considerably larger. These engineers postulated and then demonstrated that PPB defects originated from reactive exogenous material (e.g., rubber, iron oxides, and vacuum grease) that had contaminated the powder prior to HIP thermal processing.11 Upon HIP processing, reactive contaminants decomposed, generating gaseous products that decorated the surrounding powder surfaces and reduced interparticle strength upon compaction.

Concerned but not deterred, engine manufacturers and supplier engineers under took process-improvement programs and instituted additional quality controls. Recognizing that the size of melt-related oxides and those reactive contaminants that were introduced prior to powder screening were related to screen size, powder was screened to a finer, 150 mesh size. Also, engineers scoured powder production and handling facilities in order to identify and then remove sources of reactive contaminants. Numerous sources were identified, such as elastomer O rings in gas-line valves and fittings, gaskets, oxides from weld debris inside powder transfer lines and storage containers, fibers from wipes used to clean handling equipment, and particulate matter distributed by means of factory air-handling equipment. Even as improvements were made to address these problems, other efforts involved introducing strict cleaning protocols, implementing clean-room facilities, and heating powder to volatilize organic contaminants.12

Quality control (QC) enhancements were no less scrupulous. Powder lots were tested using water elutriation to gauge cleanliness, large-bar LCF testing was added as a QC requirement for powder-blend qualification, and “HIP’ed” compacts were inspected using high-resolution ultrasonic methods. Meanwhile, materials and design engineers were busy assessing the impact of cleanliness on the cyclic life of PM rotor hardware. The bimodal life distribution of LCF bars introduced new challenges in defining statistically valid minimum LCF curves, and the defect sensitivity of PM superalloy elevated the importance of fatigue-crack growth testing and the statistical determination of defect size distributions. Design engineers concurrently developed probabilistic lifing methods based on fracture mechanics to complement classical LCF life-prediction methods. Also, extensive spin pit testing was carried

out to validate component lifing methods and to assess the volumetric scaling of associated defect distributions.

By the late 1970s, suppliers and engine-manufacturer engineers had been fully exposed to the technical risks of as-HIP superalloy technology and the challenges of concurrently building powder metallurgy manufacturing capability while production was underway. Through painstaking efforts, suppliers had improved powder cleanliness and engine-manufacturer engineers had learned to manage the quality and life of as-HIP components. Meanwhile, the cost of as-HIP products soared because of extensive quality testing, more tightly controlled processing, and the lower yield of 150 mesh powder. But a most important question remained unanswered: Could an engine manufacturer successfully manage the risk of powder cleanliness—particularly the risks associated with reactive PPB defects?

In 1980, an F-18 aircraft, powered by two GE404 engines, crashed at Farnborough, United Kingdom; the crash was attributed to the failure of an as-HIP Rene ’95 low-pressure turbine disk.13 Although the cause of failure could not be determined because critical disk fragments were never recovered, clearly the disk failure and resulting F-18 crash heightened the perceived risk of as-HIP superalloy cleanliness and defect intolerance, and so began the end of the as-HIP superalloy processing. The final abandonment of as-HIP prompted the urgent development of several alternative superalloy technologies as replacements.

This case study of the abandonment of as-HIP superalloy technology provides an opportunity to learn several lessons. Foremost, an underestimation of the risks associated with the insertion of not-well-understood materials processed in novel ways can have catastrophic consequences. The potential problems created by what is not known can easily outweigh the confidence that one gains from what is known. The harmful consequences following the events recounted above included design and manufacturing disruption, urgent activity to develop replacement technologies, and the emergence of distrust of the traditional materials development process. Indeed, in the aftermath of this accident, the development of alloys, such as Rene ’88 damage tolerant and direct age IN718, as well as the application of isothermal forging as the preferred PM processing route for PM disk materials, proved to eliminate the as-HIP problem and also dvanced turbine materials technology significantly. But unfulfilled material promises, such as that described in this case study, also taught a generation of young design engineers and managers to avoid new materials technology lest they be ambushed by similar problems with the next new material.

The longer-range consequences for future propulsion materials are clouded by the competitive fallout of the 1980s engine wars, the 1990s economic downturn in the propulsion business, and the resulting reduction of the overall aerospace engineering workforce. These latter years saw lower aerospace materials development,

|

13 |

For further information, see http://ammtiac.alionscience.com/about/. Accessed August 11, 2009. |

lower governmental and industrial investment in structural materials, and a waning interest in aerospace careers by materials engineering university graduates. Shortcomings such as those demonstrated by this case study probably also contributed to the institution of risk-abatement efforts such as those represented by formal engine development processes and the institution of TRLs. These methodologies require a level of proof for all new technologies before engineers can commit the technologies to the start of production.

2.5.2

Simultaneous Development

Up to this point in Chapter 2, materials development has been presented as a progression toward increasing materials maturity and a concomitant decrease in insertion risk (i.e., increasing TRL). This progression is the basis of the notional devel opment process represented in Figures 2.5 through 2.7. This progression toward maturity is also evident in the Air Force’s S&T program (Figure 2.10). The basic research (6.1), applied research (6.2), and advanced technology development (6.3) elements discussed above constitute the Air Force’s S&T program. Also shown is “6.3 Manufacturing Technology,” which represents the Air Force’s ManTech Program. Unless the engine developments are for demonstration engines

FIGURE 2.10 The science and technology program of the U.S. Air Force. NOTE: Acronyms are defined in Appendix F.

as in the Integrated High Performance Turbine Engine Technology (IHPTET) Program discussed below, the program elements in the non-AFRL portion of Figure 2.10 are the Air Force’s Acquisition Program, managed by the system program offices. Also shown in Figure 2.10 are the TRLs expected at the successful completion of the work in the various stages.

This development process, as discussed below in Section 2.6, forms the basis for the Air Force’s research and development program. On paper it seems to present a logical framework, and it illustrates the various elements of the S&T program and their relationships to the system customer (program elements in the non-AFRL portion of Figure 2.10) and the various TRLs for each stage. But in the case study described in Section 2.5.1, development did not follow the model path shown in Figure 2.10, in which a new composition or process transitions sequentially from one totally isolated or independent element to another. As suggested in the case study, this progression in maturity is not successive with time. In fact, there is no formal transition or handoff from basic research to applied research, as discussed in the notional process, and then on to system development and then to ManTech.

For a new material, the S&T and ManTech elements might be operating simultaneously, with multiple programs in each. As shown in the case study in Section 2.5.1, as the maturity level of M&P increases, and even into production, work at lower TRLs may be necessary to address an unforeseen issue. This cyclical nature of materials transition is not unusual and in many cases is a known element of risk for high-performance applications.

A well-known nonpropulsion materials technology maturation that made intentional use of this “simultaneous process” is the development of advanced composites. Early work showed that significant weight savings, fatigue resistance, and corrosion resistance were possible with advanced composites (i.e., laminated anisotropic fiber-reinforced materials containing high-strength and high-stiffness fibers in a polymer matrix, which was a new technology at the time). Included in this class of materials were both thermoset and thermoplastic matrix mate rials, and carbon/graphite, boron, aramid, and E-glass fibers. To take advantage of what this class of materials had to offer in as short a time as possible, programs in each of the program elements shown in Figure 2.10 were underway at the same time (ca. the late 1960s, 1970s, and early 1980s): 6.1 programs in mechanics, 6.2 programs in materials and process development, and 6.3 programs in design and data; ManTech programs for producibility; and industry IRAD (not shown in Figure 2.10). In addition, there were near-term application opportunities such as the F-15, F-16, B-1, F-18, F-117, B-2, and others. While each program element shown in Figure 2.10 could benefit from efforts made in the others, the unique focus of each gave these programs a level of independence that allowed them to run simultaneously and still be very effective. The 6.1 mechanics programs were not focused on a specific material but rather on the overall class of materials. The 6.3 programs were

materials-specific and as such relied on the 6.2 work and/or industry efforts to provide the materials. The 6.2 work on improved materials, processes, and tools relied on government and industry efforts for new approaches as well as for the transition of the new technology.

The overall “class of materials effort,” with “specific materials efforts,” allowed fundamental tools, new M&P data, and producibility to be worked on at the same time. This simultaneous process proved to be quite effective in reducing risk and achieving timely transitions.

2.6

THE EVOLVING MATERIALS DEVELOPMENT PROCESS

Although the traditional steps undertaken during M&P development are still used today, the landscape in which materials developers’ work has undergone significant changes. Some of these changes, which include technical, programmatic, and cultural elements, have increasingly challenged the M&P development process, have increased the risk associated with materials insertion, and have even led some engine designers and now even government-sponsored demonstration-engine programs to de-emphasize the deployment of new materials. Other changes have aided the materials and engine developers.

In this changing environment, the cycle time gap between the product and materials development represents the largest challenge to materials development and insertion. Figure 2.11 shows the relationship between materials and engine

FIGURE 2.11 Relationship and conceptual timeline between materials engineering, engine design, and manufacturing activities during component development. NOTE: M&P, materials and processes.

development. Since the mid-1980s, the emergence and evolution of computer codes for design analysis have allowed the design engineer to use computation to eliminate a significant number of engine and component tests. Also, the application of structured engine development processes, integrated product development teams, and computer-based optimization have reduced the number of engine design iterations, further expediting the engine development cycle and in the process widening the cycle gap between the materials development cycle and the engine-development cycle.

Although engineers benefit from IPDTs and structured materials development processes, materials development activities remain highly dependent on costly and time-consuming experiments, processing trials, and mechanical property testing. Some modest gains in cycle times have been achieved, but the cycle time gap is now measured in many years. For example, the development of a new material can take as long as 20 years depending on the material of the targeted material class (see Table 2.1). In contrast, engine development can now take as little as 2 years for a derivative engine and perhaps 6 to 8 years for an engine based on an all new turbine core.

Also, materials development differs from the design activities during engine development in several important ways. While both demand creativity, the development of a new material is more dependent on the vagaries of invention and discovery and is confounded by a plethora of materials science and processing mechanisms that often compete, are nonlinear, and are difficult to describe or predict mathematically. Simply stated, there is a fundamental knowledge and technology gap separating the mechanical and materials engineering disciplines. This gap has exacerbated the associated development-cycle time gap and produces technical and programmatic risks that together create uncertainty and impede the development and insertion of new materials.

Resolution of the development-cycle gap is confounded by a number of other changes that have taken place within the propulsion community, including reduced investment in new M&P and increased reliance on emerging materials systems for future propulsion gains. Historically, the dominant approach used by engine manufactures to ensure a reliable stream of new materials has been to maintain active internal materials research in strategic areas and leverage research undertaken by universities, national laboratories, and throughout the materials supplier base. Prior to the 1990s, there was a vibrant climate for such research, but more recently much supplier-based development has been sharply curtailed, internal engine-manufacturer materials research funding has been reduced and earmarked to address nearer-term needs, and fewer university researchers are dedicated to structural materials. Therefore, in contrast to earlier times, there are now fewer materials choices, and less technical information is available on which to base materials development decisions.

Also, some materials engineers believe that the capability of workhorse super-alloy and titanium alloys is nearing exhaustion and that further evolutionary change in their chemistry and processing is likely to yield only modest advances. In the absence of computational tools to identify superior alloy compositional spaces more effectively, these skeptics are likely correct. But in the meantime, the drive to improve engine performance (higher temperatures and light weight) has rightly focused more materials research and development on intermetallics and composites such as the ceramic SiC-reinforced SiC system. But, these alternative materials systems may actually increase the development-cycle gap and pose additional schedule and insertion risks associated with the immaturity of the supplier base and uncertainties associated with materials defects, manufacturing flaws, and limited knowledge of failure modes and other durability issues for these newer, less-mature classes of materials.

Conversely, materials development has also been aided by several changes in the propulsion engineering culture, including the adoption of IPDTs and the establishment of formal product development cycles and TRLs. Also, the long-standing traditional, ad hoc materials development approach could not be effectively sustained as the aerospace propulsion industry matured, engine products proliferated, and competition, both domestic and global, intensified. Consequently, aerospace engine manufacturers began to introduce structure and discipline into development methodologies, including those used to establish new materials. Each engine manufacturer took different routes, but they typically included methods such as continuous improvement, concurrent engineering by IPDTs, and formal product (and materials) development. This approach has also been adopted by the government in awarding new development and demonstration contracts.

The implementation of IPDTs created cross-disciplinary teams armed with team methods and decision-making tools for increasing the immediacy and effectiveness of communications, the consideration of competing viewpoints, and decisions that integrate knowledge from the full spectrum of stakeholders. Some engine manufacturers even embedded IPDT concepts through organizational structures that enhanced their execution, such as with centers of excellence. The institution of formal product- and materials-development processes further enhance materials development by imposing structured processes to ensure that standardized best-development methods are uniformly applied across an organization. These processes typically include development steps that list and describe required development activities, engineering methods, risk analyses, and best practices that must be systematically followed during the development of a new material or product. A management team usually oversees the IPDT executing the development and ensures that the process is followed and that required efforts at tollgates are accomplished prior to a transition to the following development stage. These tollgates typically either closely follow or duplicate the government-developed TRLs

and milestones that define the interim technical requirements and preconditions necessary for advancing to the subsequent product development stage.

In the end, the cycle gap in materials development and engine development and the increasing emphasis on risk aversion imposed by TRL and milestone tollgates have led to the near disappearance of introducing revolutionary new materials into new engine development. This cycle gap and the lack of funding prior to the demonstration-engine level are the basis for the reference above to the valley of death (Section 2.2.4). In turn, this de-emphasis on introducing new materials has led to fewer job openings for materials people in engine manufacturing and supplier-based jobs and a general dismantling of facilities. These developments have also had an effect on materials programs at U.S. universities.

2.7

THE ROLE OF LARGE PROGRAMS IN THE DEVELOPMENT OF MATERIALS AND PROCESSES

The evolving nature of the materials development process described in Section 2.6 has had a dramatic effect on the funding of materials development within new engine development programs. This evolving effect can be seen by examining programmatic objectives that at first did not take into account the consequences of design-cycle accelerations, of risk aversion, and of the use of IPDTs with respect to the eventual de-emphasis on introducing new materials and processes into demonstration programs. Since about 1986, there has been a change in the amount and purpose of funding above the 6.3 level made available within the DOD for R&D in materials and processes for demonstration engines. After that date many of the types and purposes of materials development became tied to specific programs. This “directed funding” led large amounts of productive activity to move materials to higher TRLs. Major programs that became the drivers were as follows: National Aerospace Plane–Materials and Structures Augmentation Program (NASP-MASAP), High Speed Civil Transport–Enabling Propulsion Materials (HSCT-EPM) Program, Integrated High Performance Turbine Engine Technology (IHPTET), Integrated High Payoff Rocket Propulsion Technology (IHPRPT), and Versatile Affordable Advanced Turbine Engine Program. These programs provided the rationale and focus for new materials, defined the goals that had to be met, and often provided the opportunity to demonstrate new materials in a relevant environment (TRL 6). But the reduced funding in these demonstration programs and the adaptation of the resulting fewer engines and risk aversion have led to much smaller amounts of available funds for the transitioning of materials up the TRL ladder.

2.7.1

Major Program Pushes in Materials

The following section describes some of the major program efforts that have been made in materials.14

National Aerospace Plane—Materials and Structures Augmentation Program, 1988-1991

The goal of the National Aerospace Plane Program was to develop an experimental aircraft, the X-30, to explore the entire hypersonic-velocity flight range. Other objectives included the support of future national security, civil applications, and a reduction in the costs of space launch. According to the NASP mission statement quoted by President Ronald Reagan in his 1986 State of the Union address, NASP would “by the end of the next decade, take off from Dulles Airport and accelerate up to 25 times the speed of sound, attaining low earth orbit or flying to Tokyo within 2 hours.”15 Given the demanding conditions of flying a vehicle from a horizontal take-off to Mach 25 and using hydrogen as the fuel, materials were identified by the Defense Science Board as one of six critical technologies.

The Materials and Structures Augmentation Program under NASP was a 46-month effort begun in March 1988. It was funded at $136 million through the NASP Joint Program Office (JPO). A materials consortium was formed and managed by the NASP JPO and an industry executive steering committee. Companies also shared both completed and current industry research and development (IR&D) on a voluntary basis. The consortium focused on developing producible processes for a range of relevant materials (see list below). The development of an advanced supplier base was a critical part of the program, as the team focused on establishing materials and structural designs that met the requirements of the vehicle and the mission. The program was canceled before a demonstration vehicle was built, but the stable funding over 4 years, albeit abruptly ended, enabled significant advances in many materials classes that were to a lesser extent picked up by other programs and other means. Relevant materials advances from the NASP Program are listed below:

-

Titanium aluminide development and processing,

-

Titanium matrix composites,

-

Carbon-carbon,

-

Coatings for refractory alloys, and

-

High-conductivity materials.

|

14 |

The information in Section 2.7.1 was provided to the committee by Charles Ward, Air Force Research Laboratory, May 2009. |

|

15 |

Ronald Reagan, 1986 State of the Union address. |

High Speed Civil Transport—Enabling Propulsion Materials Program, 1990-1999

The High Speed Civil Transport was going to be a next-generation supersonic passenger jet, flying 300 passengers at greater-than-Mach-2 speeds at a ticket price of no more than comparable, slower flights. The program was initiated in 1990 and terminated in 1999. Again, materials were acknowledged to be critical for the success of the program, and the Enabling Propulsion Materials Program was created and funded at $40 million to $45 million per year (total: $280 million to $315 million). This stable and significant level of funding over approximately 9 years resulted in very significant advances over a broad range of materials classes, as seen in the following list:

-

Superalloy disk materials—ME-3, ME-16, and LSHR;

-

Thermal barrier coatings (TBCs), especially low thermal conductivity TBCs;

-

Single-crystal blade alloy—EPM 102 (MX4, PW1497);

-

Gamma TiAl, particularly casting process development;

-

Ceramic metal composites for combustor liners—SiC/SiC;

-

Environmental barrier coatings for Si-based ceramics; and

-

Dual microstructure/property heat treatment for disks.

It should be noted that the HSCT-EPM Program began in the early stages of the transition in the materials development process and was associated with a development program that was expected to take a decade or more. Depending on the level of readiness, such a long development horizon assumed that the material and demonstrator cycle times would not be far out of sync.

NASA Transitions

NASA does not classify its programs using the terminology employed by the DOD (i.e., 6.1, 6.2, 6.3, and so on), but its effort appears to have been primarily 6.2 in nature. Both the NASP-MASAP and the HSCT-EPM Programs were very important in pulling materials technology forward to meet the very demanding goals of high-speed flight. But neither program was associated with an engine or a vehicle demonstration effort, so that insertion of the materials that were developed into actual systems had to await the formulation of new programs, military or commercial, that needed new materials capability. This lack of demonstrator engines hampered transitions of these materials out of the 6.2 level, but at least it moved select materials upward on the TRL ladder; this was particularly important to the IHPTET Program, discussed below.

A number of the materials technologies that were investigated in the NASA programs are now in service, but they have required significant additional invest-

ment to bring them to fruition—that is, other programs picked up where the NASA program left off with at least a promise that investments in moving things farther up the TRL ladder would lead to a payoff in terms of a higher probability of insertion. For example, gamma TiAl is scheduled to be used by General Electric as low-pressure turbine blades on its GEnx (GE next-generation) engine, which will power the Boeing 787 and Boeing 747-8 aircraft. This is the first large-scale use of this material on a commercial jet engine; it has not yet been designed into a military engine. Similarly, the new superalloy disk materials, ME-3 and ME-16, are only now finding their way into newly designed engines.

Integrated High Performance Turbine Engine Technology Program, 1988-2005

The IHPTET Program began in 1988 and was driven by phased goals related to the performance of gas turbine engines, the ultimate goal being a doubling of the performance (thrust to weight) for military engines. The program was built around a series of time-phased engine demonstrators that allowed for the timely insertion of technology. The program was jointly funded by the DOD and industry, with the total government expenditure being $2.2 billion (total program funding, not including materials). The materials effort was funded separately, with the Air Force materials budget contributing approximately $6 million per year and the Navy materials budget approximately $4 million per year. Again, the IHPTET Program was begun in the early stages of the changes in engine-design paradigm shifts and materials cycles were started early in the program, rightly assuming that their cycle development would be in sync with the demonstrators developed in the program. Materials development was acknowledged as an enabling technology to meet the objectives of the program. Because of the importance placed on materials in the program, the sharing of pre-competitive knowledge was part of the early stages of the program; it allowed for the sharing of materials information that might have come from IR&D-funded projects, which placed materials at higher-than-6.1 levels at the beginning of their consideration under the IHPTET umbrella.

The IHPTET Program also provided the rationale for new materials—recall comments at the beginning of Section 2.5 indicating that materials and process developments were driven to solve known problems, to expand a material’s operational envelope, or even to enable new-engine design concepts. As such, the IHPTET Program set the goals that new materials had to meet and, importantly, provided the opportunity to demonstrate new materials in a relevant environment (TRL 6). More than 40 demonstrator engine tests were conducted over the full length of the IHPTET Program. These demonstration opportunities inherent in the IHPTET Program cannot be overemphasized. While both the NASP-MASAP and the HSCT-EPM Programs were very important in pulling materials technology forward to meet the very demanding goals of high-speed flight, neither program

was associated with an engine or a vehicle demonstration effort. The insertion of the materials that were developed into actual systems had to await the formulation of new programs, military or commercial, that needed the capabilities inherent in the new materials. By contrast, the insertion of technologies developed under the IHPTET Program can be readily traced to their successful demonstration. Following are materials advances from the IHPTET Program:

-

Advances in wrought gamma TiAl alloys,

-

Advances in SiC/SiC composites,

-

High cycle fatigue of titanium, and

-

Organic matrix composites.

Integrated High Payoff Rocket Propulsion Technology Program, 1995-Present

The Integrated High Payoff Rocket Propulsion Technology Program, which began in 1995, is a collaborative effort initiated by the DOD, NASA, and industry. The primary objective of IHPRPT is to double rocket propulsion capability by 2010. Because materials were recognized as critical to the success of the technology goals, an IHPRPT Materials Working Group (IMWG) was chartered by the IHPRPT Steering Committee in February 1997. The IMWG is composed of representatives from various NASA, DOD, and industry organizations. AFRL’s Materials and Manufacturing Directorate first received funding for participation in the IHPRPT Program in 2001 and began conducting research and development efforts designed to address specific material and component concerns. Unlike the funding for the IHPTET Program, the funding for the IHPRPT Program has not been straightforward and has been somewhat disconnected from the program, leading to an unstable funding environment for materials research.

Versatile Affordable Advanced Turbine Engine Program, 2005-2017

The ongoing VAATE Program is the follow-on program to IHPTET; the program appears similar to the IHPTET Program in that it has very concrete goals, both technology goals and cost goals. But from a materials point of view, the resemblance is superficial. VAATE is a capability-based program; engine goals are subservient to system and platform goals. Improved engine performance is important but is no longer the major selling point of the program. In the present environment, fuel efficiency, not performance, is the main driver behind the current program centerpiece: the Advanced Versatile Engine Technology (ADVENT) demonstrator engine. It should be noted that some of the materials development efforts left over from the IHPTET Program due to the cancellation of IHPTET Phase III were picked up by VAATE. These included, for example, the upcoming demonstration of

the second vane row in the high-pressure turbine of the F-136 engine core, a joint program between Rolls-Royce and General Electric, which is sponsored under the VAATE umbrella. Other materials insertions planned for IHPTET Phase III were considered too high risk to be undertaken in VAATE, however. Also, some materials insertions through the VAATE Army Turboshaft Program continue; however, these do not constitute new materials work but rather engineering and process efforts aimed at continuing some of the insertion plans left over from the cancellation of IHPTET Phase III.

Another major difference between the IHPTET and VAATE Programs is the much smaller number of demonstrators that are currently planned during the VAATE Program. This means that the transition of materials into engines will be highly constrained by the timetable of the few available demonstrator engines. This situation has already impacted the planned materials development programs: to ensure transition, the planned Air Force materials programs have become highly focused. Their timing is critical: any schedule delays may mean that these programs will be irrelevant to the VAATE Program. Since VAATE is an ongoing program, more specifics will be covered in the Chapter 3, which deals with the present materials-development environment.

2.7.2

Discussion

It is clear that national programs prior to the VAATE Program provided not only incentive and direction but also periods of robust and stable funding for materials and processes research and development. In addition, the IHPTET Program in particular provided demonstrator engines that were specifically identified as placeholders for demonstrating new materials. Although those materials were not part of the IHPTET Program funding directly, IHPTET’s expecting new materials to transition into IHPTET and setting the requirements for these developments led to concomitant funding from DOD materials programs to be transitioned into the demonstrator engines, and this in turn furnished a rationale for continuing the materials program funding. The importance of the availability of engines to test new materials cannot be overstated. In VAATE—the program that replaced IHPTET—materials development, although stated as one of its goals, does not have a separately funded materials and processes funded line. Not only are there fewer demonstrator engines and thus few transition opportunities, but the availability of these demonstrators for use as new materials demonstrators is also at present unfunded; currently these demonstrators appear in the program milestone charts as unfunded placeholders. What is clear is that VAATE has no specific performance objectives that require new materials. In the VAATE Program, even though it is an engine-demonstrator program, the new paradigm of risk aversion and IPDTs has come to full maturity.

This situation presents a quandary regarding where the incentive to develop new materials for propulsion lies within the Air Force Research Laboratory. The role of Focused Long Term Challenges (FLTCs) is discussed in Chapter 3; briefly, FLTCs enable the AFRL to describe future capabilities and help develop a technological path that can shape the future Air Force. The FLTC process provides the planning construct to define future priorities by describing the problems needing to be addressed as opposed to the specific technology solutions to be pursued. However, in terms of the development of new materials for propulsion, the FLTCs give little support for the level of materials development funding at the 6.3 level and beyond that was present under the IHPTET Program. Without the pull for new mate rials provided in new development engines from the AFRL’s Propulsion and Power Directorate and acquisition and program offices, there exists little support for the infusion of funds into new materials for propulsion within the AFRL’s Materials and Manufacturing Directorate. Given the competing materials interests within the Materials and Manufacturing Directorate, it is inevitable that funds for structural materials development for propulsion applications will languish. IHPTET itself did not stand alone, having depended on the availability of materials brought to high 6.2 levels from other national programs such as the NASA HSCT-EPM Program. At present there are essentially no engine-specific structural material programs being funded in or outside the DOD targeted on advancing 6.1 materials to high 6.2 level.

2.8

COMMON THEMES FOR SUCCESSFUL MATERIALS DEVELOPMENT

The successful development of any technology requires a number of events or factors plus the long-term involvement of management, researchers, and users. The role of the visionary that will continually champion the progression of the material up the TRL ladder is especially important, as technology needs change, applications and partners disappear and appear, and funding stops and starts. The development of new or advanced materials currently requires extensive amounts of time and money. It is critical to implement approaches to make the development more efficient.

2.8.1

AFRL’s Identification of Important Elements

Listed below are what the AFRL considers to be the three major elements for success in a materials technology program.16 This list is then expanded with elements from other sources, but it is clear that AFRL’s list is based on its belief that a successful materials program must be associated with a concomitant engine- or aircraft-development program. In other words, the AFRL mind-set appears to be

that a materials development program cannot be successful without the pull of a new engine- or aircraft-development program. Thus, its three major elements for success start with the umbrella engine/aircraft development program.

-

The engine/aircraft development program itself must be well defined and must have specific end-point objectives, which are clearly articulated in the program’s mission statement.

-

Concomitant with a clear mission statement is a clear acknowledgment of the need for material advances in order to fulfill the goals of the program.

-

A sufficiently funded companion materials development program is tied to the goals of the overall engine/aircraft development program—that is, a commitment to fund materials development is part of the larger technology development program.

In their discussion of these elements of success before the committee, AFRL staff members17 gave as an example of a successful materials-advancing program the 1988-1991 National Aerospace Plane Program. They cited each of the major elements listed above and repeated here:

-

NASP mission statement—“By the end of the next decade, take off from Dulles Airport and accelerate up to 25 times the speed of sound, attaining low earth orbit or flying to Tokyo within 2 hours.”

-

Acknowledgment of materials need—The Defense Science Board identified materials as one of six critical technologies for system development of the national aerospace plane.

-

Commitment of funding—The NASP Materials and Structures Augmentation Program, with stable funding of approximately $125 million, was created.

Although many believed that the NASP Program was unsuccessful in that it was ended abruptly without meeting its goals, the presenters pointed to the fact that NASP’s companion materials development program, MASAP, was successful in advancing the state of the art of propulsion mate rials. In Section 2.7.1, see the discussion of the NASP Program and in particular the materials advances made in the MASAP and used by the propulsion materials community as the basis for further developments. It should be noted that AFRL’s list of the three elements of a successful materials maturation requires that materials candidates be available at high 6.2 levels.

2.8.2

Other Common Themes of Successful Materials Developments

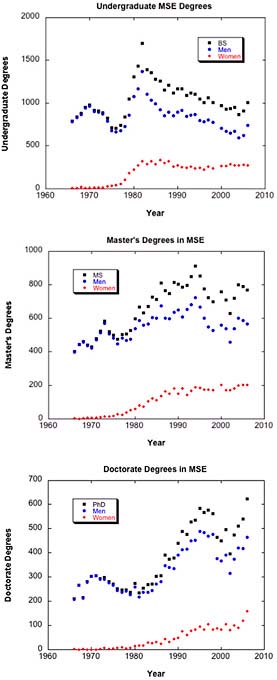

It is clear that AFRL’s focus in identifying its three elements of success is tied to major pulls in either system developments or demonstrator engines. But as indicated in tracing the history of various large programs, it is clear that the environment has changed. The present mind-set holding that new engines are not needed because new major systems are not on the horizon ignores the opportunities of enhancements afforded by new materials that can be exploited in re-engineering and upgrading existing aircraft, as stated earlier. Further, the fact that military propulsion materials developments migrate into the nation’s commercial engine manufacturing base keeps U.S. engine companies competitive on the world market. In each of the programs mentioned in Section 2.7, materials that developed to higher TRLs had a legacy; they did not materialize out of thin air. The present section discusses the elements that keep materials candidates progressing through a string of programs.