3

Materials Development Assessment

The availability of critical materials for propulsion systems and innovative manufacturing processes and capacity have been key elements in creating and maintaining U.S. preeminence in military aircraft capabilities and have contributed significantly to the U.S. engine manufacturers’ competitiveness in the global market.1 The first six sections of this chapter provide assessments of the following: Section 3.1, the materials development process used for structural materials research and development (R&D); Section 3.2, the organizations in the Air Force Research Laboratory (AFRL) addressing materials R&D; Section 3.3, materials research and databases; Section 3.4, the importance of materials to the three types of propulsion needed for U.S. Air Force (USAF) missions; Section 3.5, the current global activities in propulsion structural materials; and Section 3.6, the past, present, and planned activities of the AFRL in propulsion structural materials. Sections 3.7 and 3.8 present, respectively, the findings and recommendations of the committee related to its materials development assessments.

3.1

DEVELOPMENT PROCESS FOR STRUCTURAL MATERIALS RESEARCH AND DEVELOPMENT

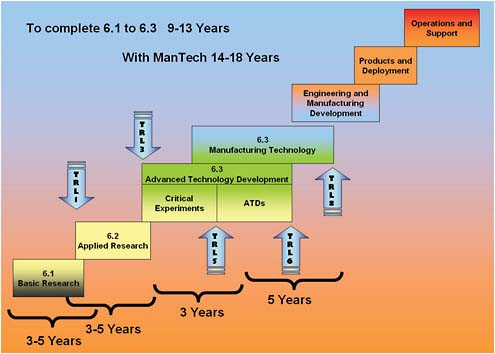

The Air Force’s science and technology (S&T) process is illustrated in Figure 3.1. Basic research (6.1), applied research (6.2), and advanced technology

FIGURE 3.1 Air Force science and technology program. NOTE: Acronyms are defined in Appendix F.

development (6.3) constitute the parts of the S&T program that are managed by the AFRL. The S&T program seeks new ways of accomplishing tasks of military value and developing the underlying scientific and engineering principles involved. Individual S&T projects are not directed at developing new operational weapons systems, although they may support such development by solving specific problems. The 6.3 Manufacturing Technology (ManTech) element is the program of the Air Force that anticipates and closes gaps in manufacturing capabilities for the affordable, timely, and low-risk development, production, and sustainment of defense systems. The elements above 6.3 are the Air Force’s Acquisition Program, managed by the system program offices.

Within the S&T program, basic research (6.1) is the systematic study directed toward greater knowledge or understanding in science and engineering of the fundamental aspects of phenomena and/or observable facts consistent with the Air Force missions, but without practical application of that knowledge and understanding. Applied research (6.2) is systematic study to gain the knowledge or understanding necessary to determine the means by which a recognized and specific need may be met; these efforts attempt to determine and exploit the potential

of scientific discoveries or improvements in technology such as new materials, devices, methods, and processes. Advanced technology development (6.3) includes all efforts that have moved into the development and integration of hardware for large-scale or field experiments and tests. Advanced technology development demonstrates the viability of applying existing technology to new products and processes in a general way.

If a new material followed the exact path illustrated in Figure 3.1, a 6.1 program would last on average about 3 to 5 years, a 6.2 program would last about 3 to 5 years, and a 6.3 advanced technology development program would last about 3 years. The total S&T effort would thus be around 9 to 13 years. This time period assumes that no major issues would result in program delays; such issues could easily add several years to the process. If a ManTech program were factored into the process, the total time could easily reach 14 to 18 years or longer. It is possible that the Air Force S&T steps shown in the figure could be skipped altogether if a strong industry development effort completed the technology base work with internal funds. The nature of the work would remain the same, but would be funded by industry.

For noncritical components, materials that have already transitioned into a system and are subsequently modified typically require much less time for reinsertion than for the original development effort. In general, the 6.1 step is eliminated for reinsertion. The “tweaked” material may start at the late 6.2 or early 6.3 stage. In such a case, the time to transition into a system may be as short as 3 to 5 years.

For critical components, materials that have already transitioned into a system and are subsequently modified would also likely see the 6.1 step eliminated. The modified material may also start at the late 6.2 or early 6.3 stage. The 6.3 stage could be longer for critical than for noncritical applications owing to additional testing. In such a case, the time to transition may be as short as 5 years of S&T or as long as 8 years, especially if requalification is required.

Figure 3.1 is useful for illustrating the various elements of the S&T program and their relationships to the system customer (the three program elements in the upper-right-hand corner) and the various TRLs for each stage. However, a material’s transition path, in which a new composition or process transitions sequentially from one totally isolated or independent element to another, as shown in Figure 3.1, does not represent the actual technology transition path that most materials and processes follow. There is no consistent formal path for a material’s transition from basic research to applied research to system development to ManTech. For a new material, the S&T elements represented in Figure 3.1 could be working on complementary, parallel paths, with multiple programs in each. As the maturity level increases, including in production, work at an earlier stage may be necessary to address an unforeseen issue. This cyclical nature of materials transition is not unusual and in many cases is a known element of risk for high-performance applications. Modification of an existing material could require that multiple pro-

gram elements (upper right, Figure 3.1) also be pursuing parallel, complementary paths. In all cases, continuous interaction among the program elements must take place for the transition to be timely and successful.

3.2

ORGANIZATIONAL ENTITIES OF THE AIR FORCE RESEARCH LABORATORY

The Air Force Office of Scientific Research (AFOSR), the Materials and Manufacturing Directorate, and the Propulsion and Power Directorate are the organizational entities that handle the development of new materials and their introduction into propulsion systems. The AFOSR manages the basic research investment (6.1 in Figure 3.1) and is a part of the AFRL. The AFOSR fosters and funds basic research within the AFRL, domestic universities, and industry laboratories to support USAF needs. Research managers seek to create revolutionary scientific breakthroughs, enabling the Air Force and industry to produce world-class, militarily significant, and commercially valuable products using technical guidance from the AFRL and requirements of the Air Force; research managers also ensure the transition of research results to support USAF needs.

The Materials and Manufacturing Directorate performs comprehensive research and development activities to provide the Air Force with new and improved materials, processes, and manufacturing technologies. Its activities span 6.1, 6.2, and 6.3. The directorate receives 6.1 funds from the AFOSR for intramural research and has its own 6.2 and 6.3 budget elements for materials R&D and manufacturing technology. The directorate explores new materials, processes, and manufacturing technologies for use in aerospace applications, including aircraft, spacecraft, missiles, rockets, and ground-based systems, along with their structural, electronic, and optical components. Areas of expertise in this directorate include thermal protection materials, metallic and nonmetallic structural materials, nondestructive inspection, materials used in aerospace propulsion systems, electromagnetic and electronic materials, and laser-hardened materials. The directorate provides real-time materials operating problem solutions and failure analysis, along with support to Air Force weapons system acquisition offices and maintenance depots, to solve materials-related concerns and problems. The directorate plans, executes, and integrates advanced manufacturing technology programs and affordability initiatives that address manufacturing process technologies, computer-integrated manufacturing, and excellence through design for producibility, quality, cost, and the use of commercial processes and practices for military needs. The Air Expeditionary Forces Technologies Division, located at Tyndall Air Force Base (AFB), Florida, addresses environmental issues and provides materials expertise for airbase assets such as runways and infrastructure. The directorate also manages the Air Force Corrosion Control Program Office at Robins AFB, Georgia; the Air Force

Nondestructive Inspection Office at Tinker AFB, Oklahoma; and the Air Force Advanced Composites Office at Hill AFB, Utah.

The Propulsion and Power Directorate provides a complete spectrum of advanced propulsion technologies for the nation’s military services. The directorate has its own 6.2 and 6.3 budget elements. Its 6.3 funds are the principal source of funding for transitioning new materials to promote application of these technologies to military systems for an aerospace force for advanced aircraft, weapons, and space electrical power system technologies and to advance concepts for advanced air-breathing, rocket, and space propulsion. In addition, the directorate designs and analyzes advanced propulsion concepts and promotes the application of advanced propulsion science and technology to military and commercial systems; assists operational commands and air logistics centers in resolving field problems; and coordinates and participates in joint propulsion science and technology programs with other Air Force Materiel Command, USAF, and Department of Defense (DOD) organizations, NASA, other government agencies, other countries, industry, and academia.2

The following sections describe the current and planned approaches and activities of the major contributors addressing Air Force needs in the materials area.

3.2.1

Research Funding and Directions at AFRL

The Air Force Research Laboratory exists to eliminate gaps in technology in order to address today’s needs and to reshape tomorrow’s Air Force. The longer-term focus is on the future needs of the Air Force.

The AFRL consists of 10 technical directorates, including the AFOSR:

-

AFOSR, located in Arlington, Virginia;

-

Air Vehicles Directorate, at Wright-Patterson AFB, Ohio;

-

Directed Energy Directorate, at Kirtland AFB, New Mexico;

-

Human Effectiveness Directorate, at Wright-Patterson AFB, Ohio;

-

Information Directorate, at the Rome Research Site, New York;

-

Materials and Manufacturing Directorate, at Wright-Patterson AFB, Ohio, and Tyndall AFB, Florida;

-

Munitions Directorate, at Eglin AFB, Florida;

-

Propulsion and Power Directorate, at Wright-Patterson AFB, Ohio, and Edwards AFB, California;

-

Sensors Directorate, at Wright-Patterson AFB, Ohio; and

-

Space Vehicles Directorate, at Kirtland AFB, New Mexico;

|

2 |

See http://www.wpafb.af.mil/afrl/rz/. Accessed September 11, 2009. |

Funding of the directorates is divided between short- and long-term needs, with the emphasis on the long term: 80 percent of funding is for long-term activities.3 The AFRL responds to the immediate needs of the warfighter by moving staff around as needed to solve short-term issues.

Funding priorities and levels have changed over the years with the changes in the geopolitical world, the economy, and the mission and vision for the AFRL. For example, engineering funding for USAF was cut by approximately 70 percent in the late 1980s and by a further 20 percent in the early 1990s, resulting in a considerable loss of capabilities. The AFRL directorates have not been subject to the same level of engineering reductions as other Air Force functions;4 however, these reductions have resulted in some increased workloads within the laboratories, as the product centers in the Air Force now look to the AFRL or to the engine contractors or suppliers for solutions.

Research and development at the AFRL is organized in Focused Long Term Challenges (FLTCs),5 described in Chapter 2 of this report, and 70 to 75 percent of the funding is for tasks held within the FLTCs. The remainder of the funding at the laboratories is for “discovery,” or low technology readiness level, less-directed work aimed at longer-term issues. Discovery does include 6.1, low 6.2, and some engineering research.

Discovery includes the 6.1 funding received from the AFOSR; generally, approximately 20 percent of AFOSR’s funding goes to the AFRL and constitutes approximately 50 percent of the discovery budget.6 Most of the remainder of the discovery budget is early 6.2 funding and comes from the directorate budgets. The splits and focus of the discovery money vary by directorate and are set by the priorities of the directorate. In addition to the above sources, there is a special Laboratory Director’s fund of approximately $1 million per year. There is an open competition throughout the AFRL for grassroots ideas, with awards of between approximately $50,000 and $100,000 per year for selected projects.

Technology pull comes from the FLTC roadmaps and associated plans. Technology push comes mainly from the discovery activities and Laboratory Director’s funding; an example is the modeling of materials and materials behavior that is being explored with discovery funding.

The FLTCs are divided into near-, mid-, and far-term research and development. The customers and technology providers are intertwined in defining the FLTC goals. Management is done by a matrix method, with each FLTC being assigned to a directorate, which pulls in expertise from other relevant directorates to flesh out priorities and build roadmaps. A single directorate may thus support six to eight FLTCs. Materials, especially high-temperature materials, are important in a number of the FLTCs, and the Materials and Manufacturing Directorate is involved with nearly all of the FLTCs to some degree. The Materials and Manufacturing Directorate has management responsibility for the sustainment FLTC. The sustainment FLTC has a focus on long-term operation and evolutionary progress.7

The Materials and Manufacturing and the Propulsion and Power Directorates work quite closely together on common interests. The use of a joint workshop to set the priorities and provide input to the roadmaps is discussed elsewhere in this report. One of the materials and propulsion workshop sessions led to approximately 25 new ideas for materials. Some priority was given to these ideas, and efforts have been made to obtain the required funding.

Each FLTC may have many roadmaps for individual elements of the particular challenge. Roadmaps have “owners” and often include unfunded programs; however, nothing can be added or subtracted without the permission of the owner. These unfunded lines are for technology developments that are identified as being necessary to meet long-term goals but for which there is no funding identified. In general, the FLTCs are ambitious and are underfunded, although they provide a driving force and an interdependent, long-term plan. FLTCs are reviewed regularly and changed as appropriate. Recently, the AFRL has been presenting the FLTCs to industry groups to educate them and to identify areas for collaboration.

There is a balance in research efforts between the AFRL and industry. The situation has changed over the years, with the large prime contractors becoming increasingly more reliant on the suppliers to do research and development. The prime contractors act as integrators, passing some of the materials development work to their suppliers, which puts financial stress on the supplier. Often the result is that incremental changes are possible but revolutionary changes are difficult.

The importance for a project of reaching Milestone B or TRL 6 needs to be emphasized. The milestone is difficult to define exactly, but the focus is on the demonstration of process maturity and component development. Milestone B generally marks the end of 6.3 programs, which start at TRL 4 or 5. The engineering acquisition major review at Milestone B is aimed at managing risk for future development; the effect of this setup is that materials must be selected early in the

process, because the use of new materials may require new designs and increase risk later in the process. Further discussion of risk and the associated valley of death is presented in Chapters 2, 4, and 5, but these topics are mentioned here as they are integral to the FLTC and planning process.

3.2.2

Air Force Office of Scientific Research

Basic research investments for USAF are managed by the AFOSR. As a part of the AFRL, AFOSR’s technical experts foster and fund research within the AFRL, universities, and industry laboratories to ensure the transition of research results to support USAF needs. Following are five general focus areas:

-

Aero-structure interactions and control;

-

Energy, power, and propulsion;

-

Complex materials and structures;

-

Space architecture and protection; and

-

Thermal control.

The current AFOSR basic research program is divided into three directorates. Research on aerospace propulsion materials is funded primarily through the Aerospace, Chemical, and Materials Science Directorate under 12 topical areas.8 The area most relevant to propulsion systems is topical area (7): High Temperature Aerospace Materials (HTAM). As stated in an Air Force BAA, “The objective of basic research in HTAM is to provide the fundamental knowledge required to enable revolutionary advances in future Air Force technologies through the discovery and characterization of high-temperature materials (nominally temperatures above 1000ºC), including ceramics, metals, [and] hybrid systems including composites.”

Current research under HTAM includes fundamental research on high-temperature materials, focused on understanding combined mechanical behaviors such as strength and toughness as a function of thermal and acoustic loads. For example, the program includes exploratory research on refractory materials systems such as molybdenum and niobium silicides, borides, and boro-silicides that includes studies of phase equilibria, thermal stability, coating methodology, oxidation, corrosion, and mechanical behavior. These types of programs represent long-term, high-risk investments in the development of revolutionary high-temperature materials for propulsion, which are likely to lead to “revolutionary” as opposed to “incremental” advances in the temperature limits of engine operation.

Although the AFOSR has a broad portfolio that is relevant to future propulsion needs, further analysis of the AFOSR portfolio could be useful in order to

|

8 |

See http://www.wpafb.af.mil/AFRL/afosr/. Accessed May 6, 2009. |

determine its topical breakdown with respect to the development of new materials at the lower TRLs and how to best coordinate activities with the Materials and Manufacturing and the Propulsion and Power Directorates and obtain inputs from the warfighter. The analysis could consider whether the research portfolio is sufficiently broad to build the desired knowledge base and to train the number of future scientists and engineers needed to address the challenges that lie ahead. In addition, the further analysis should consider the internal investment in materials research through the AFRL and potential interactions with efforts funded by other agencies such as the Office of Naval Research (ONR) and NASA.

3.2.3

Materials Lab: Materials and Manufacturing Directorate

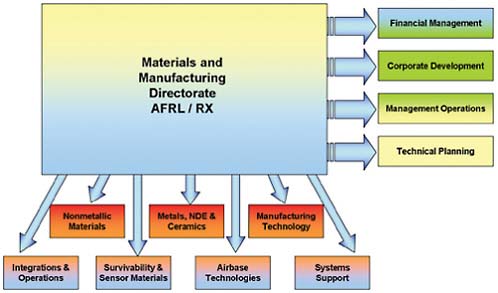

The Materials and Manufacturing Directorate, or the Materials Lab as it is often called, is one of the AFRL’s 10 directorates. It performs comprehensive research and development activities to provide new or improved materials, processes, and manufacturing technologies for USAF. The directorate integrates industry requirements with an execution program providing advanced manufacturing processes, techniques, and systems for the timely, reliable, high-quality, economical production and sustainment of Air Force systems. The directorate’s areas of expertise include thermal protection materials, metallic and nonmetallic structural materials, nondestructive inspection, materials for aerospace propulsion systems, electro magnetic and electronic materials, and laser-hardened materials. Figure 3.2 presents the directorate’s organizational chart.

The directorate addresses the sustained need for metals development currently and into the future, through the Metals Branch of the Metals, Ceramics and NDE [Nondestructive Evaluation] Division. The primary focus of the research is on high-temperature metals; it is aimed at service temperatures in the range from 650ºC to 1500ºC. The most general objective of the Metals Branch is to establish and maintain leadership in metals technologies for Air Force systems. For the foreseeable future, the group is focused on research in the following areas:

-

Materials damage prediction for turbine engine materials,

-

Computational tool development,

-

Advanced turbine disk materials, and

-

Thin gage/honeycomb structure for thermal protection systems.

The objective of the Metals Branch is to understand, develop, and transition metallic materials with high specific strength and stiffness along with other functional properties for use in existing, advanced, and conceptual aerospace systems for USAF. The technical program is implemented through an integrated extramural and intramural program. The extramural program is conducted through contrac-

FIGURE 3.2 Organizational chart of the Air Force Research Laboratory’s Materials and Manufacturing Directorate (AFRL/RX). SOURCE: From http://www.ml.afrl.af.mil/orgchart.html.

tual arrangements with aerospace companies and academic institutions. The intramural program is conducted in the facilities of the Materials and Manufacturing Directorate. Technical collaborations with other organizations in the United States and abroad are also pursued. The technical program consists of efforts in four areas: materials damage prediction for turbine engine materials, computational tool devel opment, advanced turbine disk materials, and thin gage/honeycomb structure for thermal protection systems.

The Materials and Manufacturing Directorate receives some 6.1 funds from the AFOSR for intramural research. Within the directorate’s own 6.2 and 6.3 budget elements, its scientists and engineers explore new materials, processes, and manufacturing technologies. With a host of modern material analysis laboratories, the directorate performs research on thermal protection materials, metallic and nonmetallic structural materials, nondestructive inspection, materials used in aerospace propulsion systems, electromagnetic and electronic materials, and laser-hardened materials. It also provides real-time operating problem solutions and failure analysis, along with support to Air Force weapons system acquisition offices and maintenance depots, including work on advanced manufacturing technology programs and affordability initiatives. Materials Lab activities address environmental issues, and lab activities through the Air Expeditionary Forces Technologies

Division, located at Tyndall AFB, Florida, provide materials expertise for air base assets such as runways. The Materials Lab also manages the Air Force Corrosion Control Program Office at Robins AFB, Georgia; the Air Force Nondestructive Inspection Office at Tinker AFB, Oklahoma; and the Air Force Advanced Composites Office at Hill AFB, Utah.

The historic model described in Figure 3.1 continues to frame the current approach for Air Force propulsion materials development.9 Several organizational and programmatic changes over the past few years have changed the materials development environment, resulting in changes in this decade compared with the previous several decades. These changes include a significant reduction in applied research in other agencies working on propulsion materials technology, and a contract focus for the materials work on the Integrated High Performance Turbine Engine Technology (IHPTET) Program (and the Versatile Affordable Advanced Turbine Engine [VAATE] Program that has replaced it).10 Also, the level of funding available for propulsion has been reduced as a result of a diffusion of focus due to the increased diversity of the Air Force mission(s) in recent years.11

The historic model has also been modified to some extent on the contractor’s side in recent years. The current business model gives suppliers more responsibility for component manufacturing process development and more involvement in the details of the design. Several of the engine manufacturers have reported a deterioration in some of the supplier base with respect to addressing propulsion materials as the pressures for more short-term profitability have increased in the supplier base.12 The propulsion industry has undergone some restructuring in recent years that has had an effect on materials development in the United States. Pratt and Whitney has consolidated its material activities from its Florida R&D facility into the East Hartford, Connecticut, operation,13 resulting in a reduction of the total number of materials scientists and engineers. The Rolls-Royce acquisition of Allison Engine Company generated the Liberty Works that is focused exclusively on military technology, while Honeywell has purchased the parent company of Allied Signal Propulsion. The committee could not make an assessment of the impact of these changes relative to meeting U.S. military needs, although the changes are significant enough to be noted here.

Another factor affecting the overall level of materials R&D is the reduced number of new weapons systems in development along with the reduced quantity of buys and the reduced number of competitive 6.3 demonstrators, as also noted in Chapter 2. The reduced number of new propulsion systems in development does not directly dictate that there will be a reduced new materials development effort, since history has shown materials advances to be a significant contributor to upgrades for current systems and an important factor in maintaining a U.S. competitive edge in weapons system capabilities.14 The reduction in the number of technology demonstrators in the IHPTET historical model, which had three large competing demonstrators, to the current level in the VAATE Program has reduced the opportunity to bring new talent into the field. These reductions are directly related to the quantity of the investment available for materials-related R&D. These reductions have a dual effect on the production of materials advances: they lead to fewer and less diversified ideas and approaches being pursued and to a loss of the competitive atmosphere among contractors. Compounding this effect is the reduced investment in new materials through Materials and Manufacturing Directorate research found in these demonstrators.15

Other issues that were raised during the committee’s visit to Wright-Patterson AFB on May 27, 2009, included a reduced emphasis on traditional propulsion materials technology at the level of the Director, Defense Research and Engineering (DDR&E), compared to the support for the area in the 1980s and 1990s; the reduced emphasis is due to the increase in missions to which the Office of the Secretary of Defense (OSD) is responding to today. This reduced emphasis is reflected in the projected 6.2 funding levels for future propulsion programs as shown in the National Research Council report A Review of United States Air Force and Department of Defense Aerospace Propulsion Needs.16 Also, some concern was expressed by AFRL personnel that the 6.1 research work supported by the AFOSR was not as closely linked to the propulsion needs as it had been in the past. It was noted by the committee during the May visit that this work needed to be more far-term and that it should not be too closely linked to requirements, but needs to be free to deal with more creative advances in materials science and engineering. It was pointed out during the visit that several of the major materials advances (e.g., gamma titanium aluminides) were the direct results of competition among contractors (Pratt and Whitney, GE, and Allison) and that the recent action that narrowed

VAATE-type technology demonstrators down to a single contractor demonstrator will significantly diminish competition-driven advancements.

During their visit to Wright-Patterson AFB in May 2009, committee members were presented with an overview of the integrated planning process that involves each of the AFRL lab directors being assigned to lead one of eight Focused Long Term Challenge areas (e.g., the director of the Materials and Manufacturing Directorate is responsible for the sustainability area). These challenge area teams are staffed with cross-functional personnel from other directorates who help make the directors and members aware of USAF challenges. The teams also include members from the AFRL planning group who are responsible for structuring the planning and budgeting document for the entire AFRL. The directors of the Materials and Manufacturing and the Propulsion and Power Directorates had recently organized a Propulsion Mate rials Workshop that resulted in signs of improved communications and coordination between the two directorates. The committee views this as a very positive move, but observed that there was not representation from the AFOSR, the user commands, or the systems program offices and that these workshops were not institutionalized as regularly scheduled events.

3.3

MATERIALS RESEARCH AND DATABASES

3.3.1

Basic Research

Fundamental research supported by the AFOSR is not tied to specific platforms or systems but is designed to build a knowledge base that may be relevant to desired long-term capabilities (i.e., 20 to 30 years in the future). As stated in Chapter 2, the current AFOSR broad agency announcement17 describes research opportunities that are consistent with the capability-based planning approach. Research related to materials for propulsion applications is described in several of the programs within the research portfolio, including the High Temperature Aerospace Mate rials Program.

The HTAM Program18 clearly identifies both air-breathing and rocket propulsion systems as application areas of interest. The program emphasizes several aspects of materials research, including the discovery of new materials with superior performance above 1000ºC, microstructural evolution at elevated temperatures, and materials behavior under combined loadings (e.g., mechanical and acoustic).

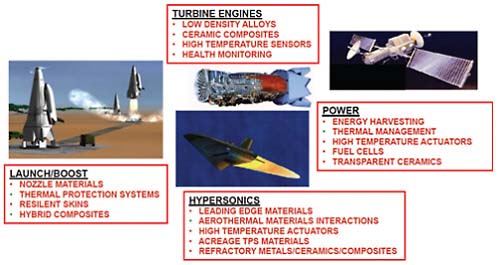

Potential propulsion applications addressed by the HTAM Program are shown in Figure 3.3. Technology areas either funded currently or over the past 10 years

|

17 |

See AFOSR BAA-2008-1. Available at http://www.wpafb.af.mil/AFRL/afosr/. Accessed March 8, 2009. |

|

18 |

Document AFD-080612-188. |

FIGURE 3.3 Description of future applications and the impact of high-temperature materials. SOURCE: Reprinted from Document AFD-080612-188, available at http://www.wpafb.af.mil/shared/media/document/AFD-080612-188.pdf.

for metals and ceramics research show an emphasis on materials for engines and nozzles (more than 80 percent) with some funding also directed toward skins. The HTAM Program appears to be well aligned with the needs for future propulsion systems. The Polymer-Matrix Composites Program focuses on the use of polymer-matrix and carbon-fiber-reinforced materials and appears to be aligned to directly address future needs that are related to propulsion systems. The program encourages both experimental studies and computational approaches for matrix resins, fibers, plies, and laminates. The use of multiscale modeling is a specific area of interest.

Although the AFOSR has a broad portfolio that is relevant to future propulsion needs, further analysis needs to be conducted to determine if the amount of the current investment is appropriate. The analysis should consider whether the research portfolio is sufficiently broad to build the desired knowledge base and to train the number of future scientists and engineers needed to address the challenges that lie ahead. In addition, the further analysis should consider the internal investment in materials research through the AFRL and potential interactions with efforts funded by other agencies such as the ONR and NASA.

Complementing the AFOSR materials science activities and coordinated with these activities is the work at the Office of Naval Research. Relevant to the committee’s statement of task (see Appendix A) are the ONR initiatives that support

university-based research related to aerospace propulsion. The ONR S&T program generally supports basic and applied research and advanced development in the physical sciences and engineering, materials and processing, and environmental quality that enable enhanced performance, affordability, and reliability for future and legacy Navy and Marine Corps systems and platforms.

The Sea Warfare and Weapons Department (Dept. 33), under the Code 332 High Temperature Materials Program, has continuous thrusts to develop higher-temperature materials to meet future naval challenges and capability requirements for future aircraft and shipboard gas turbine engines, hypersonic vehicles, and critical missile components.19 Reliable high-temperature materials are also needed to improve engine efficiency and decrease maintenance costs. Much of the work supported under this topic is currently focused on the development of thermal barrier coatings (TBCs) for turbine-engine applications. Efforts in this area concentrate on thermal stability, high-temperature phase equilibria, bond coating materials (e.g., platinum intermetallics), degradation of coatings by stress and corrosion, environmental contamination, delimitation, rumpling, and other mechanisms. Some work on new materials such as refractory silicides and borides is also supported.

The current ONR effort seems to be reasonably well coordinated with the AFOSR effort, with a division of tasks to avoid redundancy. The ONR effort supports the broader mission to develop advanced materials for aerospace propulsion, but it is rather focused and quite limited in scope. Once again, further analysis is recommended to determine whether the amount and breadth of this work are adequate to meet future military needs and to ensure that the U.S. military is at the forefront in the development of revolutionary propulsion technology. As with the case of the AFOSR, the training of future scientists and engineers in this critical technology area should be a key consideration in this analysis.

Other government agencies that provide broad-support basic research in high-temperature aerospace materials include the U.S. Department of Energy (DOE) through its High Temperature Materials Laboratory (HTML) at the Oak Ridge National Laboratory (ORNL). The HTML is a national user facility designed to support the development of advanced materials. It is sponsored by the DOE Office of Transportation Technologies in the Office of Energy Efficiency and Renewable Energy.

Through HTML, researchers from U.S. industries, universities, and government agencies have access to hands-on assistance from a skilled staff and to a number of sophisticated, often one-of-a-kind, instruments or facilities for materials characterization. The 64,500-square-foot building houses six user centers, which are clusters of specialized equipment designed for specific types of property measurements. The HTML also has a neutron beam-line facility at the high flux

isotope reactor (HFIR) at the ORNL and a synchrotron beam line at the National Synchrotron Light Source at the Brookhaven National Laboratory.

This type of user center provides access for university groups to a broad range of facilities for the characterization of structure, phase equilibria, thermo chemistry, and mechanical properties of materials at elevated temperatures. This critical resource provides university research with unique tools and facilities to support high-temperature materials development.

The extreme temperature and environmental stability requirements posed by aerospace propulsion systems and the substantial technological payoff for materials improvements have acted as a strong “pull” and have provided much of the driving force for fundamental research on high-temperature metals, alloys, ceramics, and composites. The scientific knowledge base that underlies the development of advanced aerospace propulsion materials is highly multidisciplinary. Heat transport, atomic transport, high-temperature corrosion and oxidation, deformation, fracture, and fatigue are among the complex phenomena involved in the performance of high-temperature materials in the extreme environment of turbine engines and rocket propulsion systems. Current state-of-the-art incumbent materials, their processing and manufacturing technologies, and the engineering know-how surrounding these materials were not developed for their own sake, but rather to meet the needs created by advancing propulsion systems; they are the result of decades of materials research and practical engineering experience.

To meet the materials needs and requirements for the next generation of advanced propulsion systems requires highly skilled scientists, mostly at the PhD level, trained in disciplines mentioned above, as well as a pipeline of evolving materials solutions and strategies to enhance the present capabilities.

Fundamental research is needed; however, investing in a broad portfolio is not enough. Mechanisms are needed by which promising results can be selected for the further support of more applied research and/or development to bridge the so-called valley of death between academic research and real-world applications. (Further discussion of risk and the associated valley of death is presented in Chapters 2 and 4.)

The committee reviewed the relationship between AFOSR interactions with the Materials and Manufacturing Directorate in implementing this transition of the technology and concluded that additional coordination would significantly improve the process of recognizing material transition opportunities and accelerating these to higher TRLs.

3.3.2

Applied Research and Materials Demonstrations and Development

As discussed in detail above, the time and effort required to introduce a new conventional (Ti-, Ni-, Co-, or Fe-based) alloy into aircraft engines typically take

approximately 5 to 20 years. Precise timing depends on the degree of departure that the new alloy represents from the current alloy and the availability of significant industrial-base manufacturing capabilities, as well as on whether an application window of opportunity exists. Established design practices, materials and process understanding, and industrial procedures are the results of experience gained in successfully designing, using, and producing materials. New alloys represent an opportunity to learn what portions of established practices are no longer applicable to the new material. Since all materials have their advantages and disadvantages, the convergence of design practices and materials and processing knowledge is a fundamental requirement for the successful engineering application of materials.

As shown in Table 3.1, the Air Force funding planning line for Materials for Structures, Propulsion, and Subsystems submitted to Congress to support this type of work shows a reduction from the fiscal year (FY) 2007 level to the FY 2008 level; in future years there might be an increase. The committee recognizes that the final funds appropriated by the congressional process may differ from the amount requested, since it has been common for Congress to add funds for earmarked programs that are not in the focused R&D plan; however, the committee understands that Table 3.1 represents Air Force planning for Materials for Structures, Propulsion, and Subsystems.

Large-scale component or rig tests and engine demonstrators have been an important part of the historical U.S. material development process (6.1, 6.2, and 6.3 funding) and transition to use in propulsion systems.20 While the Air Force lead military demonstrator programs have been the most productive, it is appropriate in the context of the statement of task for this report to recognize that the NASA High Speed Civil Transport Program and several other NASA programs have made significant contributions to U.S. applied materials research and development. Included in these developments are contributions to the advancement of superalloy turbine disk materials, thermal barrier coatings, single-crystal blade alloys, gamma TiAl, and ceramic-matrix composites for combustion liners, discussed in Chapter 2.

The close linkage of military applied materials development and demonstrator programs dates back to the Advanced Turbine Engine Gas Generator programs of the 1970s. The linkage became more focused under the DOD coordinated Integrated High Performance Turbine Engine Technology Program that ran from 1988 through 2005. This program had clear technology goals without being tied to a specific mission. In the IHPTET Program, materials advances were considered necessary to meeting the goals and were an integral part of the effort, with funding as part of the demonstrator programs. This program produced significant advances

TABLE 3.1 U.S. Air Force Propulsion-Related Materials Budget Items: Actual (FY 2007 and FY 2008) and Estimated (FY 2009 and FY 2010) (in US$ millions)

|

|

FY 2007 Actual Cost |

FY 2008 Actual Cost |

FY 2009 Estimated Cost |

FY 2010 Estimated Cost |

|

Total program element |

151,438 |

175,040 |

188,152 |

127,957 |

|

6201SP: Space Materials Development |

25,728 |

36,012 |

28,963 |

0.000 |

|

624347: Materials for Structures, Propulsion, and Subsystems |

70,723 |

65,942 |

83,446 |

82,625 |

|

624348: Materials for Electronics, Optics, and Survivability |

26,687 |

26,068 |

35,703 |

27,087 |

|

624349: Materials for Technology for Sustainment |

21,550 |

28,912 |

29,223 |

14,312 |

|

624915: Deployed Air Base Technology |

6,750 |

18,106 |

10,817 |

3,933 |

|

SOURCE: Propulsion-Related Materials Budget, PB 2010 Air Force RDT&E Budget Item Justification, May 2009, PE 0602102F Materials, 3600-Research, Development, Test and Evaluation, Air Force/BA2—Applied Research. |

||||

in the areas of wrought gamma TiAl, SiC/SiC ceramic-matrix composites, high cycle fatigue, and titanium- and organic-matrix composites.

The Versatile Affordable Advanced Turbine Engine Program was initiated in 2005 as a follow-on to the IHPTET Program21 and is scheduled to run through 2017. The program has strong ties to mission goals and an acknowledgment of material needs. However, traditional materials research was excluded from the program due to concern about schedule risks. Some company proprietary work was included as competitive positioning by the contractors. Advanced materials demonstrations based on work from previous programs include advanced nickel disk alloys, the application of material-behavior-and-life-prediction methods, and ceramic and ceramic-matrix composite materials. The two demonstration components of VAATE are the Advanced Versatile Engine Technology (ADVENT) Program, with a goal of reaching TRL 6 in 2012, and the Highly Efficient Embedded Turbine Engine (HEETE) Program, with a goal of TRL 6 by 2016. The original plan for HEETE includes some materials R&D, but only in the last phase and only with a very limited insertion plan.

Since initiation of the VAATE Program, the Materials and Manufacturing and the Propulsion and Power Directorates have held a series of workshops to better define the materials requirements for the range of propulsion options defined by the Air Force as a result of the FLTC planning. An example of this planning is

summarized in the International Traffic in Arms Regulations (ITAR)-controlled report provided to the committee.22 It appears that that report has served to define key materials R&D activities that will, with appropriate funding, leverage future propulsion capabilities. It also appears that this planning was specifically directed toward trying to make the normal annual funding in the Materials and Manufacturing Directorate available for developing some material to put into the HEETE engine, as discussed below.

3.3.3

Current and Planned Demonstrator Engine Programs

The funds recently awarded to the ADVENT Program will result in a TRL 6 engine-demonstration project by 2012. Owing to time constraints, ADVENT will only use materials that have already been demonstrated in a component or rig test—that is, materials must have reached TRL 5 prior to being used in the ADVENT demonstrator engine. This type of engine-demonstration program is important to furthering the use of advanced materials in future propulsion systems; however, it does not provide an opportunity to develop new or even improved materials. The HEETE Program plan is currently aligned with the materials development plan and will provide transition opportunities for new materials, provided that they have reached sufficient maturity, TRL 4 or 5, by the time they are transitioned.

The VAATE Program is a collaborative effort in which the DOD community, NASA, and the DOE and the major engine manufacturers and weapon system contractors come together under the auspices of the OSD to share knowledge of their individually funded efforts related to gas turbine engine technology. It is a mechanism for cooperation and potential collaboration, not a “program” in the sense of a single funded entity.

The AFRL Materials and Manufacturing Directorate and the ONR have participated in the VAATE Program since its inception, and both organizations have funded materials development efforts at the engine manufacturers that advance the state of the art of turbine engine materials. Traditionally, the AFRL Propulsion and Power Directorate has also funded 6.3 materials-related efforts as an integral part of engine-demonstrator programs.

From a materials perspective, such efforts are narrowly focused on making components for a given engine and in some cases are best regarded as “technology pushes” rather than as steps for the orderly insertion of a new material. While such efforts may increase the TRL of a material, they do little to advance the manufacturing readiness level (MRL); so while an engine demonstration incorporating a

new material shows the material to have a capability (i.e., because of high-enough TRL), it may not be ready for insertion into a new or a legacy engine system because of the inability to produce the material on a sustainable scale. For example, a proper manufacturing base may not be available—the component was probably manufactured once in a model shop environment. Recall the following:

-

TRLs provide a common language and widely understood standard for

-

Assessing the performance maturity of a technology and plans for its future maturation, and

-

Understanding the level of performance risk in trying to transition the technology into a weapon system application,

-

-

Whereas MRLs provide a common language and standard for

-

Assessing the manufacturing maturity of a technology or product and plans for its future maturation, and

-

Understanding the level of manufacturing risk in trying to produce a weapon system or transition the technology into a weapon system application.

-

TRL 1 through 6 and MRL 1 through 6 are related, whereas MRL 7 and 8 are seen as comparable with TRL 7, MRL with TRL 8, and MRL 10 with TRL 9.23

In addition, developmental engine tests are not planned to demonstrate the full-life performance of components, leaving the question of the long-term durability of materials in an aggressive environment unanswered.

Current materials development within the Air Force and the engine manufacturers as assessed by the Materials and Manufacturing Directorate is categorized in Table 3.2, including the 6.3 type of demonstrations noted above. It should be said that a portion of detailed materials work by the engine manufacturers is considered proprietary, and it is difficult to determine the depth of the efforts.

3.3.4

Materials Database Availability

The global engine producers generate a significant quantity of materials property data in support of materials development and insertion, in accordance with military customer and civil certification agency requirements. Wider access to materials property data for advanced materials would provide property benchmarks for materials developers, enable researchers to develop and validate property models, and eliminate the cost of redundant testing. A widely accessible database of

TABLE 3.2 Assessment by the Air Force Research Laboratory’s Materials and Manufacturing Directorate of Current Materials Activities

materials property data similar to that available to other scientific and engineering communities in other areas of research would serve to accelerate materials research and academic training.

Some industry data are available to the materials community at large. For example, data for well-established materials are cataloged in the Military Handbook,24 whereas data from DOD contract reports can be acquired from the Advanced Materials, Manufacturing, and Testing Information Analysis Center. This latter organization is chartered by the DOD to serve as a repository for materials and manufacturing reports as well as to analyze and disseminate technical information for advanced materials.25 Despite these resources, however, the materials community does not have access to the most important and recent industrial materials property data for advanced propulsion materials.

|

24 |

DOD. 1998. Military Handbook: Metallic Materials and Elements for Aerospace Structures, MIL-HDBK-5H. |

|

25 |

See http://ammtiac.alionscience.com/about/. Accessed July 7, 2009. |

Engine manufacturers have limited incentive to share their extensive property data for these materials, for legal, financial, and competitive reasons, as outlined below:

-

Materials data for the most advanced materials generated by the U.S. engine companies are often export-controlled and subject to ITAR (e.g., data for powder metallurgy disk alloys).

-

Data on engine life are highly competition-sensitive. Engine manufacturers have a disincentive to convey materials property data to competing manufacturers—particularly creep, fatigue, and hold-time low cycle fatigue (LCF) data that directly relate to calculated component life limits.

-

Engine life management depends on materials property data that are relevant to a company’s lifing methods and the processing used to produce specific engine hardware. Although material property testing is conducted to American Society for Testing and Materials (ASTM) standards, engine manufacturers often institute additional control to regulate specimen geometry, machining (surface condition and residual stress), and test protocols.

-

Shared materials property data from the wider materials community offer limited value to engine manufacturers. Without direct knowledge of material pedigree and control of testing, engine companies subject themselves unnecessarily to legitimate legal liability if data generated by the materials community are proved to be erroneous or inappropriate. Engine makers are fully committed to both flight safety and the financial risk of inappropriate engine warranties.

These legitimate industry concerns need to be balanced against the benefits of data sharing. There appears to be an appropriate level of controlled cooperative programs26 among engine manufacturers, materials and component suppliers, and external materials scientists that could reduce the cost and time to develop material property data for advanced materials.

3.4

MATERIALS CONTRIBUTION TO CURRENT AND EMERGING PROPULSION SYSTEMS

3.4.1

Turbine Engines

For more than 50 years, materials have been the major enabler for the evolution of aircraft turbine engines. At the very beginning of powered flight, the Wright brothers depended on a revolutionary new material, aluminum, for the

performance of their engine.27 Whittle28 and von Ohain,29 inventors of jet propulsion, depended on steel for their engines. Today’s modern turbine engines depend on high-performance materials such as nickel-based superalloys, thermal barrier coatings, and advanced composites for their exceptional performance.

Engineers have learned over the years that improvements in gas turbine engines require improvements in service temperatures. Increased temperature capability can be achieved through the development of new and improved materials as well as through innovative designs, with both materials and designs dependent on advanced processing techniques. Improved temperature capability allows higher turbine inlet temperatures, resulting in increased thermodynamic efficiency and improved performance.

A key performance figure of merit is the ratio of thrust to weight. Developments in advanced materials have been the major contributor to the unparalleled growth in the thrust-to-weight ratio in gas turbine engines. For example, the substitution of Ti- and Ni-based superalloys for steel was a major evolutionary step. More recently, the introduction of advanced ceramic-matrix composites (CMCs), with their improved specific properties, has resulted in further increases in the thrust-to-weight ratio of low-bypass turbofan engines. Similarly, improvements in specific fuel consumption, also dependent on thermal efficiency, have been realized with the use of advanced materials processes. Within the past decade, the DOD’s IHPTET Program for low-bypass turbofan engines has demonstrated thrust-to-weight improvements on the order of 60 percent, to approximately 9:1. A significant portion of this improvement can be attributed to the use of higher-temperature superalloys and CMC materials in the engine hot section and polymeric composites for fan casings. The engine weight reductions arise not only from material density reductions but also from the reduction in core engine size enabled by the higher temperatures. Similarly, a reduction in specific fuel consumption, which is also dependent on improved thermal efficiency, has been realized with the use of advanced materials and processes.

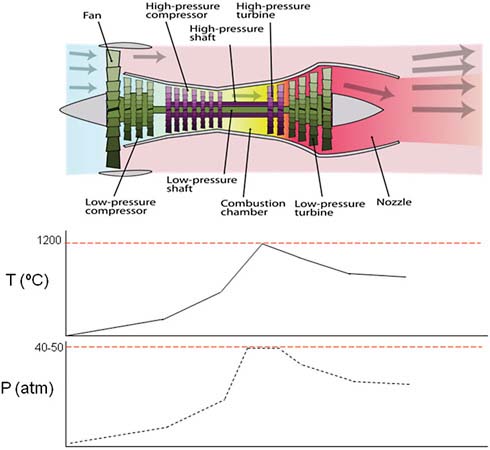

A diagram of a typical turbofan jet engine is shown in Figure 3.4, with the key components identified. As shown in the associated graphs on the figure, temperature and pressure dramatically increase from left to right in the engine, with maximums occurring in the area of the combustion chamber and high-pressure turbine (HPT). Today’s engines see temperature extremes from ambient temperature in the front of the engine to values of 1000ºC or higher in the HPT. Similarly,

|

27 |

See http://www.nasm.si.edu/wrightbrothers/fly/1903/engine.cfm. Accessed April 2, 2009. |

|

28 |

Frank Whittle. 1981. Gas Turbine Aero-thermodynamics: With Special Reference to Aircraft Propulsion. Elmsford, NY: Pergamon. |

|

29 |

Jacob Neufeld, George M. Watson, Jr., and David Chenoweth. 1997. Technology and the Air Force: A Retrospective Assessment. Darby, Pa.: DIANE Publishing. |

FIGURE 3.4 Cross section of a turbofan engine and the related temperature (T) and pressure (P) values along the engine. SOURCE: Reprinted from “Turbofan” at http://en.wikipedia.org/wiki/File:Turbofan_operation.svg.

pressures can increase to 40 to 50 atm in the HPT. The materials and their associated processes will accordingly change with their location in the engine to provide the necessary thermal stability.

Looking at the materials as a function of location in the engine is a useful approach to showing how materials have contributed to dramatic improvements in propulsion. Three major sections of the engine are considered here: (1) the fan or low-pressure compressor (LPC), (2) the high-pressure compressor (HPC), and (3) the turbine and combustor.

Fan or Low-Pressure Compressor

As shown in Figure 3.4, the fan or LPC section of the engine is cooler and operates at lower pressures than is the case with succeeding sections. For several years, Ti alloys have been the materials of choice for fan blades and cooler sections of the compressor. Use temperatures as high as 350ºC to 400ºC have been achieved. Replacement of steel by Ti resulted in improved specific properties such as strength and fatigue, which in turn produced improved performance and reliability. Advanced processes (such as diffusion bonding and electron-beam welding) coupled with improved properties of Ti alloys also enabled design changes such as large hollow fan blades and welded construction blisks. In recent years, carbon-fiber-reinforced organic-matrix composites have been used in fan blades, also reducing weight and improving performance.

High-Pressure Compressor

The HPC, as shown in Figure 3.4, is subject to much higher temperatures and pressures than those to which the fan and LPC are subject. Typically, the HPC is where the designers transition to higher-temperature materials. To keep pace with the desire of designers to increase performance, Ti alloys have been improved steadily over the years. For example, alloys such as IMI 834 are useful to temperatures of 600ºC to 650ºC. As HPC temperatures have increased, Ni-based super-alloys have replaced Ti-based alloys in many areas. Even though superalloys result in a weight penalty, they provide higher temperature capability, allowing higher compression ratios and improved performance.

Turbine and Combustor

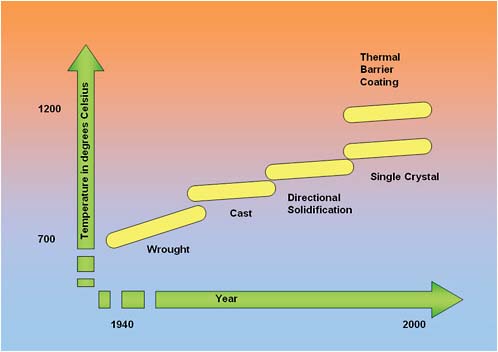

The turbine and combustor sections of the engine are the hottest, as shown in Figure 3.4, and are historically the domain of Ni-based alloys. The temperature capability of these alloys has progressed steadily over the years, shown in Figure 3.5. The evolution in temperature capability of blades has resulted from improvements in alloy composition and processing, from wrought, to conventionally cast, to directionally solidified, to single-crystal blades. Wrought nickel alloys replaced steel alloys, allowing higher temperature and improved performance. Going to a casting process provided a temperature increase of about 100ºC due to the ability to incorporate cooling channels as well as higher creep resistance due to larger grain size. Directional solidification (DS) eliminated transverse grain boundaries, providing another increase in use temperature, once again due to improved creep resistance. Most recently, single-crystal blades eliminated grain boundaries altogether, resulting in improved creep resistance and, in turn, another incremental increase in use tempera-

FIGURE 3.5 Increase in operational temperature (T) of turbine components, 1940 to 2000. SOURCE: Data from U. Schulz, C. Leyens, K. Fritscher, M. Peters, B. Saruhan-Brings, O. Lavigne, J. Dorvaux, M. Poulain, R. Mevrel, and M. Caliez. 2003. “Some Recent Trends in Research and Technology of Advanced Thermal Barrier Coatings,” Aerospace Science and Technology 7:73-80.

ture. Beyond the capabilities afforded by the alloys and their associated processes, the utilization of thermal barrier coatings provided another 100ºC or so increase in temperature capability. Yttria-stabilized zirconia and other TBCs reduce the heat transfer from the flame to the substrate. Because of their porosity, TBCs require the use of an oxidation-resistant coating (such as NiAl) between the TBC and the substrate.

Additional critical materials in key components include cobalt alloys in the combustor and high-strength steels in shafts and the use of cast gamma TiAl in low-pressure turbine (LPT) blades. TiAl provides higher specific properties such as high-temperature strength and stiffness, resulting in improvements in such areas as fuel consumption.

Summary and Future Directions for Turbine Engines

The near-term future no doubt promises fewer transition opportunities than were available in the past for the development of new materials or for the improve-

ment of current materials, owing to the military sector’s lack of planned new systems and the commercial sector’s focus on cost and risk. Where opportunities do appear, thrust-to-weight ratio and specific fuel consumption will continue to be two key measures of advanced engine performance. These will be integrated with the desire to reduce cost throughout the development, application, and sustainment cycle.

3.4.2

Scramjet Engines

Desired future DOD capabilities that include aspects of prompt global strike, extending the vertical limit of the battlefield, and responsive access to space30 have driven interest in developing flight vehicles capable of sustained flight at Mach 5 or higher (i.e., the hypersonic regime). Hypersonic flight represents a revolutionary advance in capabilities. However, revolutionary advances in the propulsion systems are required to enable this technology. For reusable hypersonic flight vehicles, airbreathing propulsion systems offer the promise of combining high specific impulse (thrust normalized by the amount of fuel burned) with speeds of Mach 5 to 10 or higher.31 This section focuses on supersonic combustion ramjets, typically shortened to scramjets, as a potential enabling technology for hypersonic propulsion. In the end, scramjets will likely be one component of a combined-cycle propulsion system that includes some other engine (e.g., rocket or turbine-based) to accelerate to the speed at which scramjets can operate efficiently, which is above about Mach 5.

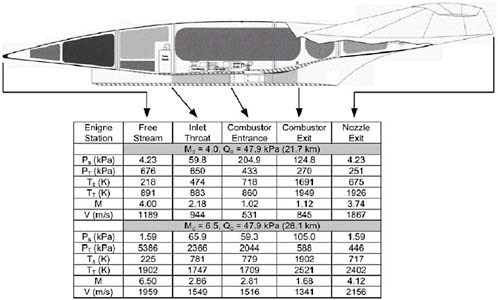

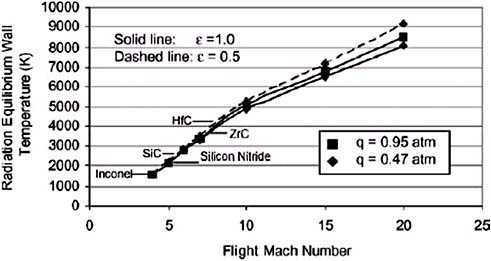

As discussed in the Section 3.4.1, turbine engines have a series of complex, rotating parts such as those used to compress the air used for combustion. In contrast, scramjets use the kinetic energy of the vehicle to compress air as it enters the engine (Figure 3.6). This makes scramjet designs conceptually simple, as shown by the schematic cross section of a hypersonic flight vehicle in Figure 3.6. One of the main challenges in scramjets is the extreme temperatures encountered during operation.32 Relatively modest speeds by hypersonic standards result in temperatures over 2000ºC for the engine inlet cowl, fuel injection areas, and the exit nozzle (Figure 3.7). Possible designs of the hottest areas of the engine require novel materials or approaches to deal with the temperatures and heat loads.

The extreme temperatures associated with scramjet propulsion are beyond the operating regime for materials used in conventional propulsion applications. Using engine cowl inlets as an example, some of the concepts that are being

|

30 |

U.S. Air Force Strategic Plan, available at http://www.airforcestrategynet.mil/. Accessed March 2009. |

|

31 |

T.A. Jackson, D.R. Eklund, and A.J. Fink. 2004. “High Speed Propulsion: Performance Advantage of Advanced Materials,” Journal of Materials Science 39(19):5905-5913. |

|

32 |

D.M. Van Wie, D.G. Drewry, Jr., D.E. King, and C.M. Hudson. 2004. “The Hypersonic Environment: Required Operating Conditions and Design Challenges,” Journal of Materials Science 39(19):5915-5924. |

FIGURE 3.6 Schematic illustration of a hypersonic flight vehicle showing the cross section of the scramjet and temperatures of various points on the vehicle. SOURCE: Reprinted with permission from T.A. Jackson, D.R. Eklund, and A.J. Fink. 2004. “High Speed Propulsion: Performance Advantage of Advanced Materials,” Journal of Materials Science 39(19):5905-5913.

FIGURE 3.7 Predicted temperatures at the stagnation point of the leading edge of an engine cowl with a radius of one inch. SOURCE: Reprinted with permission from T.A. Jackson, D.R. Eklund, and A.J. Fink. 2004. “High Speed Propulsion: Performance Advantage of Advanced Materials,” Journal of Materials Science 39(19):5905-5913.

explored to accommodate the extreme temperatures and heat loads include actively cooled refractory metals and passive ultrahigh-temperature ceramics.33 Actively cooled metal designs are used in the first demonstration engines because known refractory metal alloys are available and can be machined to shape. However, later generations of engines will likely incorporate advanced ceramic components, as these offer the promise of decreased design complexity due to the elimination of cooling channels, reduced weight due to lower bulk densities, and improved environmental stability. Hybrid designs that incorporate ceramic coatings into metallic systems have also been proposed as a method to take advantage of the manufacturability of metallic components and the superior thermal stability of ceramics.34

To date, scramjet development has largely been limited to computer- generated design and ground-based demonstrators. Two significant programs warrant discussion here to highlight the current status of hypersonic propulsion. First, the X-43 demonstrator was flight-tested in March 2004. Images of the X-43 are shown in Figure 3.8. The X-43 was flown to 40,000 feet by a B-52, dropped, and accelerated by a solid rocket booster.35 After reaching approximately Mach 10, a hydrogen-fueled scramjet was ignited for approximately 10 seconds to demonstrate engine operating principles. At the time of this writing, a consortium that includes the Boeing Company and Pratt and Whitney Rocketdyne is developing the X-51a Waverider concept as part of an effort funded by the Defense Advanced Research Projects Agency (DARPA) and managed by the Propulsion and Power Directorate of the AFRL.36 In flight tests scheduled for the spring of 2010, the vehicle was to be accelerated from Mach 4.5 to Mach 6 by a hydrocarbon-fueled scramjet. Three additional tests were then scheduled at 4- to 6-week intervals following the initial test. Although these short-duration tests can use expendable materials for engine components, further development and longer-duration flights will require the use of more robust designs and materials in future vehicles. Fundamental research is needed to identify new candidate materials, and concurrent materials development is needed to transition new or existing materials into these demanding applications.

|

33 |

S.R. Levine, E.J. Opila, M.C. Halbig, J.D. Kiser, M. Singh, and J.A. Salem. 2002. “Evaluation of Ultra-High Temperature Ceramics for Aeropropulsion Use,” Journal of the European Ceramic Society 22:2757-2767. |

|

34 |

C.A. Steeves, M.Y. He, and A.G. Evans. 2009. “The Influence of Coatings on the Performance of Structural Heat Pipes for Hypersonic Leading Edges,” Journal of the American Ceramic Society 92(9):553-555. |

|

35 |

See http://www.aerospace-technology.com/projects/x43/. Accessed June 2009. |

|

36 |

See http://www.boeing.com/defense-space/military/waverider/index.html. Accessed June 2009. |

FIGURE 3.8 (Left) Artist’s rendering of the X-43 hypersonic flight demonstrator and (right) image of an actual vehicle during assembly. SOURCE: Images downloaded from the NASA Image Exchange Server, http://nix.nasa.gov/.

3.4.3

Rocket Propulsion

As with turbine engines and scramjets, rocket engine performance is driven by the materials used in the construction of the engine. Also as with turbines, designs that use cooling mechanisms are critical to engine performance.

Even though the specifics of operation are different, both solid rocket motors (SRMs) and liquid rocket engines (LREs) have many components in common. Both have propellant cases/tanks, combustion chambers, throats, and nozzles. One major difference is that liquid rockets require pumps to inject the fuel ingredients into the combustion chamber. These pumps represent one of the most demanding materials applications.

Solid Rocket Motor Materials

In a solid rocket engine, a solid fuel-oxidizer mixture (such as ammonium perchlorate and aluminum) is stored in a case, with the combustion taking place inside the case. The reaction of the mixture produces high-temperature gases that pass from the case through a throat and into a nozzle where they expand, producing thrust.

Case Materials

SRM cases have been fabricated from both metallic and composite materials. In the case of metallic materials, steel, titanium, and aluminum alloys have been used. Steel alloys offer excellent mechanical properties, processability, and afford-

ability. Aluminum and titanium alloys offer high specific mechanical properties, which result in weight savings, which in turn translate into increased vehicle payloads or increased range. However, titanium is a relatively high cost material. Composite materials offer even greater weight savings compared to the metals because of their very high specific properties. Composite systems such as glass and carbon fibers have been used as candidate systems to reduce weight and increase performance.

Solid Rocket Motor Nozzle Materials

The materials used to manufacture SRM nozzles generally fall into the following groups: structural materials; housing and nonstructural materials, such as adhesives; sealants and greases; thermal insulating materials; and ablative materials. The lower-temperature housing or case materials are discussed above. The nonstructural materials are subjected to high temperatures.

Up to 200ºC to 260ºC, materials such as aluminum alloys and fiberglass-resin composites can be used. These materials systems have high strength-to-weight ratios, excellent corrosion resistance, and cost-effective manufacturing methods. High-strength steels may be used for thin skin sections operating at higher temperatures.

From 200ºC to about 1100ºC, higher-temperature iron-based, iron-nickel-based, nickel-based, cobalt-based, and iron-nickel-cobalt chromium-based super-alloys may be used.

Above 1100ºC, high-temperature refractory alloys such as molybdenum, columbium, tantalum, and tungsten provide property retention up to 2200ºC. Above 2200ºC, graphite and pyrolytic graphite may be used.37

Liquid Rocket Engine Materials

In a liquid rocket engine, a fuel (such as hydrogen or kerosene) and an oxidizer (such as liquid oxygen) are stored in tanks or “bottles” and, on demand, are pumped into a combustion chamber where they mix and react. The reaction produces high-temperature gases, which pass through a throat and into a nozzle where they expand, producing thrust. Gas temperatures in the chamber may exceed 3300ºC, while gas temperatures in the nozzle may range from 1600ºC to 2800ºC. A combination of high-performance materials and cooling schemes is required for engine performance. These temperatures are too extreme for conventional aerospace materials; therefore engines must employ some type of active cooling scheme.

|

37 |

See, for example, http://www.fas.org/man/dod-101/sys/missile/docs/RocketBasics.htm. Accessed June 2009. |

To provide for coolant flow, the walls of the combustion devices are constructed of tubes or channels. During operation, coolant is pumped through the tubes or channels to keep the materials stable within their temperature limitations while this process is also serving to preheat the propellants.

Tank Materials

Common tank materials have included aluminum, stainless steels, titanium alloys, and, more recently, high-performance organic-matrix composites. In recent years the trend has been to materials that offer mass reductions, which translate into greater launch loads or increased fuel capacity. The magnitude of the mass reductions sought can only result from the use of materials with high specific properties, such as aluminum alloys and composites. In addition to light weight, aluminum offers advantages such as imperviousness to fuel leakage, corrosion resistance, and excellent fracture toughness. It is also amenable to emerging manufacturing operations such as friction stir welding. Composites offer the potential for the greatest mass reduction of all of the materials. However, in many designs, the use of an inner liner is required to prevent a loss of fuel or oxidizer and to prevent potential reactions with the propellant materials.

Combustion Chamber and Nozzle Materials

Gas turbine engine combustion processes take place at relatively lower temperatures, resulting in reduced efficiency. In addition, turbine engines use air as an oxidant. Air contains a relatively small amount of oxygen, which dilutes the reaction and lowers the combustion temperatures. Both the combustion inlet temperature and the combustion exit temperature directly affect the thermal efficiency of a gas turbine engine. The efficiency of the combustion process is nearly 100 percent in modern gas turbine engines in that the available heat release of the fuel is fully achieved. The combustor exit temperature is controlled by diluting the combustion products with air that bypasses the combustion zone. Any air used for dilution or used as a coolant either in the combustor or the turbines limits the amount of air available for combustion and represents an engine system inefficiency. The availability of higher- temperature materials would reduce the required dilution and coolant air and improve the overall turbine engine system efficiency. Since rocket engines have none of these limitations, temperatures approaching 3300ºC can be achieved. Such temperatures can far exceed the melting points of the combustion chamber and nozzle materials themselves; therefore, it is critical that these mate rials be prevented from degrading to the point of failure. Cooling techniques, such as the propellants being passed through tubes around the combustion chamber or nozzle, are employed to give longer nozzle

and chamber life. This cooling technique allows rocket engines to use more common construction materials such as aluminum, steel, nickel, or copper alloys. For example, the space shuttle’s nozzle consists of 1,080 tapered stainless steel tubes that are brazed together and then brazed to an outer structural jacket made of a nickel-based super alloy. During operation, hydrogen coolant flows through the tubes to keep the nozzle materials from exceeding their melting points.

It is also possible to use uncooled nozzles that are fabricated from ablative materials. Ablative nozzles represent some of the earliest designs, in use since the 1950s. Ablative nozzles are typically constructed from composite materials of phenolic resins with various reinforcements.

The materials of choice for combustion devices in large liquid-fueled rocket engines have historically been stainless steels, nickel-based superalloys, and copper alloys. These materials are selected for their high strength and high thermal conductivity for coping with stresses and extreme thermal environments. Since these alloys also have high densities (8-9 g/cm3), their use is associated with a weight penalty.

The space shuttle main engine combustion chamber consists of an inner copper liner with 390 milled cooling channels that run axially the length of the liner. The cooling channels are closed out with a layer of electro-deposited nickel, and then an outer structural jacket made of a nickel-based superalloy is welded in place. During operation, hydrogen coolant flows through the slotted channels in the high-conductivity copper liner to keep the component cool.

3.4.4

Summary and a Look at Future Directions for Rocket Propulsion

A key future direction for rocket propulsion is to reduce the weight of the rocket engines. Lighter engines and launch vehicles would allow heavier payloads at lower costs. Innovative cooling concepts and advanced materials will help enable reductions in weight. One potential materials approach to lighter weight is the replacement of conventional high-density engine alloys with lightweight, high-specific-strength ceramic composites, such as SiC/SiC (silicon carbide fibers with silicon carbide matrices). Many materials and manufacturing issues will need to be addressed for these emerging materials to be a viable engineering approach.

The technical challenges for new materials are also accompanied by market challenges. Simply put, fewer opportunities are available for the insertion of new materials in rocket propulsion because future plans are limited by orders-of-magnitude fewer systems and fewer flights compared to those in the past. Further, as in the case of the gas turbine engines, even fewer transition opportunities are likely owing to the military sector’s lack of new rocket and launch systems.

3.5

GLOBAL COMPETITIVENESS

3.5.1

The Committee’s Approach to Assessment

The U.S. military and industry have been successful over the past 60 years in maintaining the military superiority and commercial competitiveness of aerospace systems, with few exceptions. Propulsion systems technologies have contributed heavily to this position, and the committee has reviewed on a comparative basis both the programmatic and investment strategies that have contributed to these advantages. Much of the past history is highly anecdotal and is subject to various interpretations; therefore the committee has made some observations based on experience, but it has relied largely on published information in making an assessment of the current and future U.S. global competitiveness.