Technology Development and

Insertion for Sustainment

INTRODUCTION

This chapter addresses element 3 of the terms of reference (TOR), that is, “Determine if any modifications in technology efforts are required, and, if so, identify them and make recommendations regarding the technology efforts that should be pursued, because they could make positive impacts on the sustainment of the current and future systems and equipment of the Air Force.” Since its foundation, guided by the prescient words of Gen. Henry H. “Hap” Arnold, the U.S. Air Force (USAF) has demanded that technology development be a key element in providing the wherewithal to make the Air Force second to none in the world. Although the specific organizational structures have varied in response to changing times and needs, research and development (R&D) from the most basic, far-reaching scientific research through development, and on to testing and evaluation have been pursued with vigor.

Academic research, coupled with that of the Air Force laboratories and matured within Department of Defense (DoD)-funded programs and in industry, has led to the extraordinary array of technical marvels that patrol the air, cyberspace, and space domains in times of peace and war. Throughout the Air Force’s history, the results of much of this research effort have appeared in new systems, with emphases on immediate advancements in performance. Long-term durability was sought

and achieved over time through the application of refined technical understanding and the development and insertion of new materials and processes. New technology also found its way into the maintenance process through the introduction of refined detection apparatus and enhanced repair protocol. In an environment of rapid replacement of old systems with new ones, this strategy has been sustainable with modest maintenance costs. In the present and projected future, however, with limited new system procurement anticipated, a new strategy must govern the introduction of new technology and its impacts on sustainment of the warfighters’ requirements to carry out their assigned missions.

The combination of an aging fleet of aircraft with new aircraft whose technology has been primarily utilized to improve the performance of Air Force weapon systems has created a large sustainment cost problem for the Air Force. This problem has been made worse as the size of the Air Forces’ fleet has decreased and some aircraft, although small in overall numbers (e.g., the B-2), require a huge sustainment effort to keep them “mission ready.” Many examples illustrate how the injection of technology into an existing aircraft system has increased reliability and thereby greatly reduced the sustainment burden of the system (e.g., the F-100 engine required maintenance at 6,000 tacs vs. 4,000 tacs). That said, the non-recurring cost of injecting technology into existing aircraft may impede Air Force acceptance even when the life-cycle cost of not introducing that technology is greater. Although some Air Force technology initiatives have focused on reducing the Air Forces’ sustainment burden, in general technology development remains primarily focused on enhanced performance. In addition, programs that historically have been utilized to inject technology into the existing fleet have been weakened or no longer exist.

Although much of the new technology investment in the laboratory is originally targeted at new systems, it may find its way into existing systems. Maintenance depots are increasingly the locale for the insertion of this new technology into legacy systems and those under acquisition but in modification sequence. Sustainment will also continue to be an integral part of new system development as the Air Force focuses attention on its program of Integrated Life-Cycle Management (ILCM).

In this chapter, the implications of ILCM for the technology development and insertion processes will be explored; a broad survey of the array of relevant technologies identified; current technology development and transition processes described and analyzed; and suggestions made for improvement. The breadth of the technical areas and the broad charge outlined in the TOR preclude an in-

depth development of a proposed technical agenda; however, recent studies serve to complement this study with respect to comprehensive technical analyses.1,2,3,4,5

POLICIES AND GUIDANCE

The task of characterizing the current state of both the technology and institutional and management processes is a daunting one for an institution as complex as the Air Force and its many partners in system development. In addition, the study was conducted in an environment of rapid change in these processes within the DoD and the Air Force in particular. Fortunately, an array of recent related studies has provided background for the committee’s particular focus. In the next section, some of these studies will be briefly reviewed to set the stage for the drill-down to the specifics required by the TOR. The following statements regarding life-cycle affordability and sustainment reflect the current vision and responsibilities within senior Air Force leadership:

Science and Technology Program Tenets:

Demonstrate advanced technologies that address affordability by promoting efficiencies, enhancing the effectiveness, readiness, and availability of today’s systems, and addressing lifecycle costs of future systems.

S&T Program Priorities:

Priority 1.2: Improve the agility, mobility, affordability, and survivability of Air Force assets.

Priority 2.1: Improve the sustainment, affordability, and availability of legacy systems.

______________

1 Logistics Management Institute (LMI). 2009. Future Capability of DoD Maintenance Depots: Interim Report. LG901M1. December. Mclean, Virginia: LMI. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=be97f304-3d15-4e96-bc24-689f8cb6c633. Accessed February 20, 2011.

2 LMI. 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. McLean, Virginia: LMI. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc-47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

3 Vince Russo. “Greybeard Assessment of the Sustainment Technology Transition Process.” Presentation to the committee, February 7, 2011.

4 National Research Council (NRC). 2011. Research Opportunities in Corrosion Science and Engineering. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13032.

5 NRC. 2011. Materials Needs and R&D Strategy for Future Military Aerospace Propulsion Systems. Washington, D.C.: The National Academies Press. vailable at http://www.nap.edu/catalog.php?record_id=13144.

Priority 4.1: Be a trusted partner of the acquisition/sustainment community to assess technology maturity and enhance and accelerate technology transition.6

These priorities must be met within the more specific guidelines that define the acquisition process. Likewise, in AFI-63-101, the Air Force establishes definitions and assigns roles related to technology implications on ILCM. 7 Critical to the current discussion is section 1.4.5, where technology planning and insertion is defined as:

…the timely maturation and incorporation of relevant technology throughout the program life cycle to ensure an operationally effective and suitable system. Technology planning and the assessment of technology readiness levels include consideration of such factors as reliability, producibility, testability, sustainability and operational performance. Successful technology planning and insertion as part of program life cycle management results in higher fidelity time phased requirements with a more realistic schedule and improved cost estimates [emphasis added]. (p. 12)8

Responsibilities for senior leadership in the acquisition chain are clearly articulated. It is the Commander, Air Force Materiel Command (AFMC), who is tasked to “execute the AFMC Mission Assignment Process throughout the ILCM life cycle [and] establish management responsibilities and align the AFMC acquisition and sustainment infrastructure in support of approved missions/levels of service to achieve designated AF ILCM enterprise objectives” (section 2.19.8) and “plan and execute the S&T Program” (section 2.19.14). Interestingly, in defining the responsibilities for the Commander, Air Force Research Laboratory (AFRL), AFI-63-101 does not explicitly mention “sustainment,” even though execution of technology development and support of sustainment operations have long been a traditional responsibility of the Air Force science and technology (S&T) laboratories. The Air Force Chief Scientist recently released a 20-year vision document that describes the realm of the possible and dreamed for capabilities that should guide the Air Force’s technology development.9 Embedded in this document are statements that characterize leadership thinking about sustainment:

______________

6 Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology and Engineering. “Air Force Science and Technology Strategy.” Presentation to the Air Force Studies Board, November 16, 2010.

7 USAF. 2011. Air Force Guidance Memorandum to AFI 63-101, Acquisition and Sustainment Life Cycle Management Incorporating Through Change 3. March 22. Available at http://www.af.mil/shared/media/epubs/AFI63-101.pdf. Accessed April 10, 2011.

8 Ibid.

9 USAF. 2010. Technology Horizons: A Vision for Air Force Science and Technology During 2010-2030 (Volume I). May 1. Washington, D.C.: Office of the Chief Scientist of the Air Force.

Sustainment is essential to the Air Force mission. As legacy air platforms and other systems continue to be used throughout this period, and as new platforms and systems are introduced during this time, technologies to support improved sustainability or to reduce costs associated with sustainment will continue to be essential. (p. 35)

Expanding on this statement of intent, the report clarifies the role of the AFRL Commander by defining a list of actions required of the AFRL:10

2.1. Determine Alignment of Current S&T Portfolio with “Technology Horizons”

2.2. Identify Fraction of Portfolio to be Aligned with “Technology Horizons”

3.1. Identify Current Efforts Requiring Realignment or Redirection

3.2. Determine New S&T Efforts That Must Be Started (pp. 112-113)

Finding 5-1. The Air Force has recently assigned a higher priority to sustainment technology and has stated its intention to move to an ILCM strategy. Properly implemented, such a strategy implies sensitivity to sustainment in all technology development.

Finding 5-2. Implementation of ILCM is at various stages of development in organizations within the Air Force, but is not yet institutionalized in the research, development, testing, and engineering (RDT&E) system.11,12

TECHNOLOGY DEVELOPMENT AND TRANSITION

As suggested in Finding 5-1, to achieve ILCM, sustainment must be built into technology development at all stages. Although the detailed management issues will markedly vary depending on the specifics of the technology and the intended application (maintenance of legacy systems through to development of envisioned systems), broad underlying management issues govern the process of all technology development and transition within the DoD in general and the Air Force in particular. These processes have undergone frequent changes over the past decade or so and are in flux within the Air Force as this report is being written. A recent NRC report described these changing processes in great detail while constraining its focus to new systems. The NRC characterized the program it evaluated from

______________

10 USAF. 2010. Technology Horizons: A Vision for Air Force Science and Technology During 2010-2030 (Volume I). May 1. Washington, D.C.: Office of the Chief Scientist of the Air Force.

11 Committee Meeting 2, Wright-Patterson Air Force Base, Dayton, Ohio, December 7-9, 2010.

12 Committee Meeting 4, Air Force Research Laboratory (AFRL), Tech Edge Innovation and Collaboration Center, Dayton, Ohio, February 7- 8, 2011.

March to August 2010 as one in need of serious attention. Several quotes reflect the NRC’s concerns:13

None of the many Air Force presenters to the committee was able to articulate a USAF level, integrated science and technology (S&T) strategy, nor could they identify a single office with authority, resources, and responsibility for all S&T initiatives across the Service. Instead, there appears to be an assortment of technology “sandboxes,” in which various players work to maximize their organizational self-interest, as they perceive it. In such a system, optimization will always take place at the subunit level, with less regard for the health of the overarching organization. (p. 7)

Among the most critical resources are robust processes, from the very conception of a program. For both government and industry, well-defined and well-understood work processes in all phases of program management are essential to successful technological development. Repeatedly during the study, evidence was presented that within the Air Force some of these processes have been diluted in significant ways in the past decade and are only now beginning to be reinvigorated. (p. 29)

Previous studies suggest that the Air Force needs to do more effective planning in the earliest stages of programs, when ultimate cost, schedule and technical performance are most malleable, and thus most readily influenced. Recently, the Kaminski Report addressed this aspect directly, highlighting the need for systems engineering and the importance of the role that systems engineering plays in the major systems acquisition process.14 It also persuasively made the case for a return to the days of Development Planning, describing how prior to 1990 the Air Force used Development Planning to assess and integrate the various acquisition stakeholder communities, to include especially combat commands, the Air Force Research Laboratory, and acquisition Product Centers. According to the Kaminski Report, the use of Development Planning, coupled with systems engineering, resulted in the delivery of needed capability to the warfighter in a timely and affordable manner. In addition to Development Planning, there exist two other significant tools in the quest for clear, realistic, trade-off tolerant, stable, and universally understood requirements. These tools are the once-effective ATCs [Applied Technology Councils], in which warfighting commands, acquisition and logistics organizations, and laboratories managed the linkages between operational requirements, technology development, and systems acquisition—with the added benefit of the interpersonal relationships that developed, as well as the face-to-face communications which ensued. The third tool is the establishment and disciplined use of measures of technological readiness, so that only when a technology is well-defined and demonstrated does it make the transition from the laboratory world to become part of a major system acquisition program. (p. 44)

The NRC’s 2008 report, supported by extensive benchmarking from successful

______________

13 NRC. 2011. Evaluation of U.S. Air Force Preacquisition Technology Development. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13030.

14 NRC. 2008. Pre-Milestone A and Early-Phase Systems Engineering. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12065.

technology development and transitions then in place in the United States Navy, United States Army, the Defense Advanced Research Projects Agency, and several industrial concerns, focused attention on the “three R’s”: requirements, resources, and the right people. It is worth repeating the definitions of these guiding principles because they frame the discussion of the current state of sustainment technology at the close of this chapter:

1. Requirements—clear, realistic, stable, trade-off tolerant, and universally understood;

2. Resources—adequate and stable, and including robust processes, policies, and budgets; and

3. The Right People—skilled, experienced, and in sufficient numbers, with stable leadership. (p. 3)15

As dramatic testimony to the fact that the Air Force S&T strategy and implementation are currently in flux, many of the issues raised in the 2011 NRC report had already begun to be addressed by the Air Force at the time of its final publication, and other issues are being addressed by this report. Nonetheless, much remains to be done. In 2010, the Deputy Assistant Secretary of the Air Force (Science, Technology, and Engineering) outlined many of these changes to strategy, development planning, and prioritization by a process similar to the Applied Technology Councils (ATCs) and workforce development. These topics will be reviewed later in this chapter with specific focus on their implications to the development and insertion of sustainment technologies.16

Finding 5-3. The Air Force is in the early stages of instituting a focused management approach and of developing plans with requirements, resources, and right people designed to succeed within the ILCM strategy.

TECHNOLOGY AREAS RELEVANT TO SUSTAINMENT

Defining Sustainment Technology Needs

Technology may influence sustainment of the fleet in many ways. These span the range of problem identification and repair of legacy systems to the development of new materials with longer projected lifetimes. Sustainment technology includes those technological advances that, when inserted on an aircraft or aircraft subsystem, produce improvements in the performance life and or maintenance of the

______________

15 NRC. 2011. Evaluation of U.S. Air Force Preacquisition Technology Development. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13030.

16 Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology and Engineering. “Air Force Science and Technology Strategy.” Presentation to the Air Force Studies Board, November 16, 2010.

aircraft or aircraft sub-system. Sustainment technology may be inserted on aircraft engines, airframe structures, sensors, weapon systems, electronics, hardware, and software. Also included are technologies and advanced processes and practices that include improved forecasting, lean processes and practices, manufacturing, diagnostic and prognostic tools and procedures, personnel education and training, and integrated databases. Too often, technology development programs characterized as “sustainment” are exclusively those targeted at legacy system vehicles, when in fact important sustainment technology opportunities in support of ILCM, including long-term research on underpinning science, may be found throughout the lifecycle. Chapter 4 addresses sustainment of software, while this chapter focuses primarily on vehicles and engines.

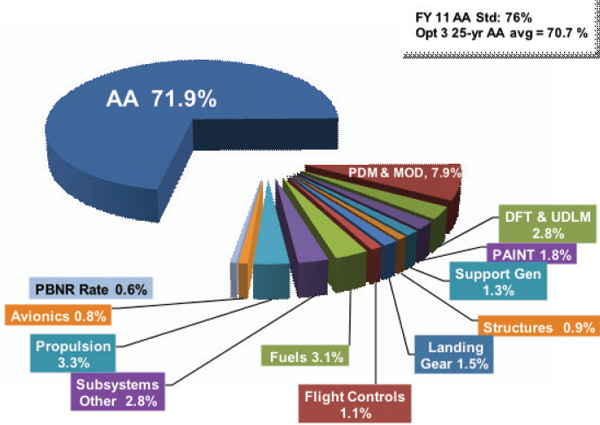

In the vehicle and engine areas alone, there is a broad array of relevant technical applications and finite available resources, and a process for their prioritization are required. Recently compiled statistics, shown in Figure 5-1, from the Air Force

FIGURE 5-1

Total possessed hours for the KC-10 system. AA, aircraft availability; DFT, depot field team; PDM, programmed depot maintenance; MOD, modification; UDLM, unscheduled depot-level maintenance. SOURCE: Fran Crowley, Director, Air Force Fleet Viability Board. “AF FVB Feedback for the Air Force Studies Board.” Presentation to the committee, December 7, 2010.

Fleet Viability Board might be considered as input to such a prioritization process. Issues limiting aircraft availability (AA) in the most recent year studied were classified into the several technical root-cause categories listed.

It may be presumed that significant technology fixes might be developed to improve some of the identified issues, but it is clear that no single “fix” will by itself dramatically affect availability of this particular aircraft. Although the S&T community has often been called upon and in many cases has assisted in the development of such point fixes, the preferred strategy is to develop information about issues that are pervasive across platforms and focus development on technologies likely to impact broadly across the fleet. Accomplishments in one such area, high-cycle fatigue, are described in Box 5-1.

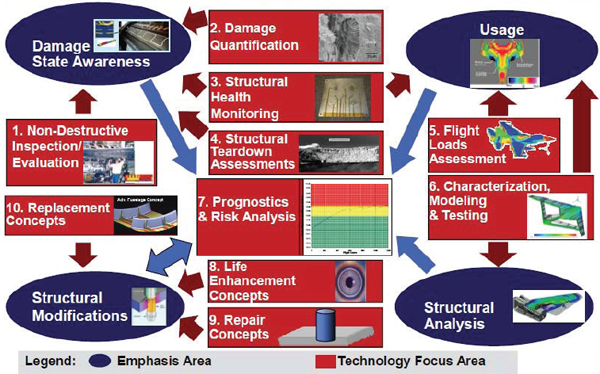

In identifying such pervasive technology areas, the S&T community is aided by programs managed within the Aeronautical Systems Center (ASC): for example, the Aircraft Structural Integrity Program (ASIP), the Engine Structural Integrity Program (ENSIP), the Functional Systems Integrity Program (FSIP), and the Engine Component Improvement Program (CIP). CIP also has a history of assisting transitions of sustainment technology, but in recent years has done little of this because of significant budget cuts. With input from the ALCs, appropriate program offices, industry, and the Air Force and other DoD S&T community, these programs continue to identify technology needs, share accomplishments in regular conferences, publish standard practices, and in the best of circumstances influence the identification of priorities for funding by one or more entities. Figure 5-2 depicts one of the key areas addressed by ASIP; the committee was informed that laboratory work is under way at various levels of intensity in each of the areas indicated in the figure.17

The interaction of the AFRL with these integrity programs is explored further below, but in the present context, it is worth noting that many of these integrity programs have a long history (ASIP was initiated in 1958) and represent a significant resource for identifying “needs” to be addressed. Translating this list of needs into funded “requirements” is a complex process involving many other players. These several independent improvement programs identify opportunities in their own spheres, but no comprehensive sustainment technology plan currently exists within AFRL. In its 1997 report exploring the elements that would be expected in such a plan, the NRC presented a template that might be used as AFRL reexamines its sustainment portfolio:

1. Develop an overall strategy that addresses the Air Force aging aircraft needs

2. Recommend and prioritize specific technology opportunities in the areas of

______________

17 Pam Kobryn. “Aircraft Structural Integrity Program (ASIP).” Presentation to the committee, February 7, 2011.

BOX 5-1

High-Cycle Fatigue (HCF)

The solutions to the HCF problem that plagued the Air Force for nearly a decade could not have been possible without the contributions of the Air Force S&T community.

The combination of high frequencies (up to 1,000 Hz), millions of cycles, and low amplitudes can result in HCF.1 The presence of manufacturing defects or Foreign Object Damage (FOD) provide sites from which cracks can grow as a result of many millions (or billions) of cycles at stresses well below the yield strength of the material.2 FOD provides the source of initiation of the crack. HCF provides the method of propagation. If not detected in time, the end result is catastrophic failure of the component. Combining HCF conditions with the increasingly higher performance provided by advanced materials and designs exacerbated the phenomenon.1

From 1995 to 2003, HCF was the major contributor to the failure of components in military gas turbine engines.3 Studies of the rates of Air Force mishaps over a period of 15 years showed that more than 50 percent resulted from HCF. Similar data for the United States Navy showed that more than 40 percent of mishaps resulted from HCF. Also during this time HCF began to appear in commercial engines to a lesser extent than in military engines but with severe consequences to the manufacturer’s development programs and revenue service for airlines.1 HCF affected virtually all engine components and many of the materials. It impacted not only engine reliability and safety of flight, but also sustainment, requiring increased field inspections and depot maintenance and reduced aircraft availability.

This problem became so pervasive that a major program was initiated to solve it. The AFRL began the HCF Initiative with the strategy of developing the tools and techniques to change the basis of HCF design from empirically based to physics based and then to demonstrate and transition these tools to the industry design systems. The Initiative consisted of seven action teams: Materials Damage Tolerance, Component Surface Treatment, Passive Damping Technology, Forced Response Prediction, Component Analysis, Aeromechanical Characterization, and Instrumentation. Engine demonstrations were an eighth action team, but as the engine demonstrators supported the overall Integrated High Performance Turbine Engine Technology program, they were eventually not counted in the HCF Initiative.1

The impact of the HCF Initiative on current and development engines was enormous. The field engine inspection workload for HCF was reduced by more than 90 percent, and the proportion of engine mishaps resulting from HCF was reduced from 54 to 7 percent, far exceeding the HCF program goal of 50 percent.1 Further, these same tools became enabling technologies for the next generation of high-performance jet engines, including the F-135 engines for the F-35 Joint Strike Fighter. Without these tools and methods, the development programs would likely have encountered many unexpected difficulties with the accompanying delays and cost growth.1

______________

1Theodore Nicholas. 2006. High Cycle Fatigue, A Mechanics of Materials Approach. London, UK: Elsevier.

2Danny Eylon, University of Dayton, personal communication.

3B.A. Cowles. 1996. High cycle fatigue in aircraft gas turbines—an industry perspective. International Journal of Fracture 80:147-163.

FIGURE 5-2

Condition-based maintenance as part of the Aircraft Structural Integrity Program. SOURCE: C.A. Babish IV, “ASC/EN.” Presentation at Panel Session Kick-Off, 2008 ASIP Conference.

• fatigue, corrosion fatigue, and stress corrosion cracking

• corrosion prevention and mitigation

• nondestructive inspection

• maintenance and repair

• failure analysis and life prediction methodologies18

The 1997 NRC report described in great detail the state of the art of all of the above and suggested 49 specific technical recommendations. This report was well received by the Air Force and was influential at the time in determining not only the research agenda, but also the strategies for inserting technology into practice. This report offers an appropriate template for the sustainment tasks ahead for

______________

18 NRC. 1997. Aging of U.S. Air Force Aircraft: Final Report. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=5917. Accessed November 22, 2010.

AFRL, described more recently in Technology Horizons19; namely, a comprehensive examination of needs and opportunities that will guide investment strategy within the S&T arena. This process of developing an investment strategy is currently under way, assisted by a panel assembled by the Air Force Scientific Advisory Board (AFSAB) and charged with tasks including some that are in many ways similar to those performed by the Ageing Aircraft Study in the 1990s. The results of the AFSAB study will be briefed to the Air Force in June 2011.

Long-Term Research

In any discussion of technology, it is important to note the role of long-term research. Long-term (“basic” or “fundamental”) research in the technical areas identified in the current report have been funded over the years by many agencies including the National Science Foundation, Department of Energy, National Institutes of Standards and Technology, Federal Aviation Administration, and others, but a great deal of the specific focus on Air Force-related problems has come from efforts of the Air Force Office of Scientific Research (AFOSR), the Office of Naval Research, Army Research Office, and the National Aeronautics and Space Administration. The following sections summarize the results of several key studies that explore the status of these support S&T areas.

Corrosion

Corrosion, broadly defined as atmospheric degradation of materials, is ubiquitous. Although rarely causing catastrophic failure to systems because it is found and repaired, corrosion adds to sustainment costs and extended depot time. Any improvements in corrosion resistance in new materials, mitigation and/or detection in old materials, repair technology, and life prediction promise to be money saving and enabling of fleet readiness. The subject of corrosion and its interaction with mechanical degradation received significant attention in the 1997 NRC report discussed above, and was attacked with some vigor by the Air Force in the years immediately before and after that report’s release. In recent years, corrosion is no longer the center of Air Force or other federal agency attention, even though significant new tools and opportunities for understanding corrosion have matured in related fields of science and engineering. In 2010, the NRC released a broadly based study on Research Opportunities in Corrosion Science and Engineering

______________

19 USAF. 2010. Technology Horizons: A Vision for Air Force Science and Technology During 2010-2030. Volume I. AF/ST-TR-10-01-PR. May 15. Available at http://www.af.mil/shared/media/document/AFD-101130-062.pdf. Accessed May 25, 2011.

(ROCSE), outlining the needs and opportunities in this important field. Quoting from this report:

There are many forms of corrosion, and while some are well understood at the macro level, complex interactions among the different forms are yet to be fully clarified. Further, at the detail level there is often relatively poor understanding of corrosion mechanisms, which makes it technically difficult to devise cost-effective engineering solutions to predict, avoid, and mitigate corrosion damage. These difficult problems have often been put on hold in favor of short-term, empirical fixes, but now appears to be an opportune time to readdress complex questions with new techniques. Advances in characterization (using, among other techniques, transmission1 and scanning electron microscopy, micro- and nanometer electrochemical probe methods, synchrotron beam lines and lasers, x-ray, and neutron spectroscopy and combinations of these methods for simultaneous information gathering) and computation and modeling (first principle, molecular dynamics, multiscale modeling, and informatics) have dramatically broadened the array of tools available.

ROCSE recommends that all federal agencies develop and carry out a targeted plan for corrosion research. It is anticipated that near-term impacts on corrosion mitigation and management may be achieved, and that long-term effects will be seen in the development of new materials with less need for such costly repair.

Propulsion Materials

The relative ease of re-engining offers unique opportunities for technology insertion into aging systems. Although the principal drivers for such engine replacements are reductions in fuel costs and/or improvement in performance, reduced sustainment costs may also be an immediate consequence of re-engining. A 2006 NRC report broadly looked at all DoD aerospace propulsion needs and focused on how technology may improve performance, specifically thrust-to-weight and fuel consumption.20 Although it gave very little direct attention to sustainment, the NRC noted that the further development and insertion of new materials such as superalloys, composites, and ceramic matrix composites that have longer life, increased fatigue resistance, and improved temperature resistance would impact sustainment. Specific recommendations relevant to the current study include:

3-1. To accelerate the development of new engine technologies, the Air Force gas turbine S&T funding should be increased significantly, from approximately $100 million annually to a level that reflects buying power at the time when the F-15 and F-16 engines were being developed. Top priority should be given to overcoming the technology barriers that will have the largest impact on future weapons systems:

______________

20 NRC. 2006. A Review of United States Air Force and Department of Defense Aerospace Propulsion Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=11780.

• Compressor discharge temperature limits,

• Turbine inlet temperature limits,

• High-temperature, high-heat-sink fuels for thermal management,

• Lightweight structures, and

• Signature control….

3-3. DoD should restore gas turbine S&T funding under the Versatile, Affordable, Advanced Turbine Engine (VAATE) program to the original planned level. VAATE should address the primary risk areas necessary to advance jet engine technology, which include a robust engine demonstrator program and key producibility challenges….

3-5. DoD should reinstate an engine model derivative program (EMDP) to speed the transitioning of technology to the legacy fleet to improve safety, reliability, and affordable readiness for DoD. An earlier EMDP demonstrated its utility and value for the current fleet of engines, most of which were developed spirally through this program or similar programs in the commercial sector [emphasis added]….

3-9. DoD should invest in several critical technologies that will impact all types and classes of propulsion systems: high-temperature materials, including high-temperature blade/vane materials and coatings; high-temperature and high-heat sink fuels; lightweight structures; and accurate analytical modeling.

Integrated Computational Materials Engineering

Introduction of new materials into the design space presents one of the greatest opportunities to enhance sustainment through longer projected system life. Additional drivers for materials substitution include enhanced performance and, increasingly, issues of availability of scarce alloying elements (rare earths and others) and environmental concerns (e.g., elimination of corrosion-inhibiting chromates from paints). In recent years, engineering practice, aided by an array of computational tools, has shortened the design to manufacture time while new materials development has lagged behind. Constrained by a largely empirical strategy for development and testing, new materials are frequently “not ready” for inclusion in the designer’s portfolio and are always considered the “material of the future.”

Recent developments, building on years of basic research in fundamental understanding, computation, and experimental technology, have led to a new paradigm for materials development, Integrated Computational Materials Engineering (ICME). When properly exploited, ICME shortens the time and dramatically reduces the cost of new materials development. A recently released NRC report (the “ICME report”) reviews the history of these developments, describes the current state of the art, and lays out an agenda for further R&D. Properly implemented, ICME promises rapid development of new materials with the same or better properties, at the same or lower cost as substitutes with availability threatened by

environmental concerns or specialty alloy requirements, and in adequate time to address these pressing concerns as legacy or new systems demand modification. Expanded efforts in ICME-enabled materials development are now in place in all three service laboratories, targeted at issues specific to each service’s needs, and supported by state-of-the-art understanding of science, including that required to extend useful life in service. In summary, science and engineering developments offer opportunities to reduce cost and extend useful life for both legacy and future systems.

Finding 5-4. Targeted technology development and insertion have long been critical elements in addressing sustainment needs within the Air Force. Advances in the underlying sciences continue to offer new opportunities for development of technologies that would support the Air Force goal of ILCM. Several independent improvement programs identify opportunities in their own spheres, but no comprehensive sustainment technology plan currently exists within AFRL.

Addressing the development and transition of technology requires a robust system of prioritization, establishment of requirements, proper resourcing, and an adequate workforce to execute planned programs. The following section discusses the specifics of these elements within the Air Force technology development and transition process, beginning with a brief review of recent years.

AIR FORCE SUSTAINMENT TECHNOLOGY

Overview

Sustainment technology that is inserted on aircraft and aircraft sub-systems involves several developmental centers/organizations including AFRL Technical Directorates (TDs) and industry original equipments manufacturers (OEMs). Because an OEM possesses first-hand manufacturing knowledge, its relationship with the aircraft or aircraft sub-systems is strong, creating an advantage in developing sustainment technology that is relatively easier to insert into the aircraft and aircraft sub-systems. OEM-driven block upgrades and product improvements of aircraft and aircraft sub-systems include programmed developments of sustainment technology. These types of sustainment technology development may continue over an extended portion of the aircraft life cycle.

The control of insertion of sustainment technology into aircraft and aircraft sub-systems may involve several stakeholders including industry OEMs, Air Combat Command (ACC), Air Mobility Command, AFMC, ASC, and the Air Logistics

Centers (ALCs). Once the technology is developed to a Technology Readiness Level (TRL) of 6 or higher within an AFRL TD, the System Program Office (SPO), OEM, and/or the ALC may control the insertion of sustainment technology. The age of the aircraft or aircraft sub-system is an important variable in determining which organization has authority to order sustainment technology insertion. In this complex system with many players), trust and respect between the supply side (AFRL TDs, OEMs, SPOs) and support side (ALCs) are critical for effective and efficient decision making to insert sustainment technology. However, success depends not only on trust and respect but also on well-defined strategies and processes.

Within the Air Force, the AFRL TDs are the primary source for the development of sustainment technology. The following sections discuss the recent history of sustainment development within the AFRL, in addition to the often-changing strategy and processes in which it has been lodged during the past decade.

Historical Background

The Air Force S&T program has undergone many organizational changes since the creation of the Air Force. The current organization, the Air Force Research Laboratory, evolved from several individual labs that had strong historical linkages with different centers and commands, driven largely by their specific technology focus and by geographic proximity. Many of these linkages continue to this day and constitute an important element in identifying the technology agenda and transition pathways. Twenty-five years ago, the Air Force S&T program was housed in 13 labs plus the Rome Air Development Center in New York.21 In 1990, these 13 labs, plus Rome, were reorganized into four major laboratories—Armstrong Laboratory, Phillips Laboratory, Rome Laboratory, and Wright Laboratory.22 These four “superlabs” were aligned with four Air Force product centers—Wright Laboratory with the Aeronautical Systems Center, Phillips Laboratory with the Space and Missiles Systems Center, Armstrong Laboratory with the Human Systems Center, and Rome Laboratory with the Electronics Systems Center. Each superlab had missions and investments supporting these centers as well as other parts of the Air Force.

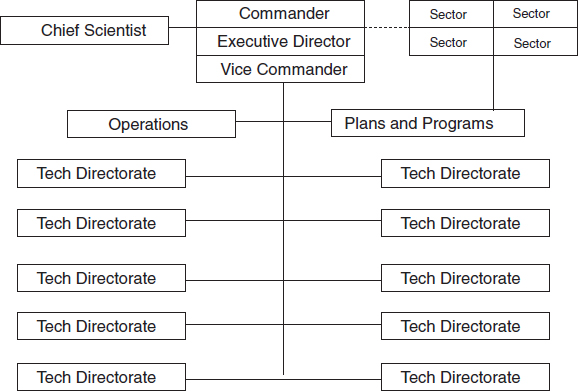

The formation of AFRL in 1997 consolidated all of the Air Force S&T efforts into a single organization reporting to the AFMC commander. The new organization, consisting of key headquarters (HQ) functions and 10 technology directorates, one of which is the AFOSR, is shown in Figure 5-3.

AFRL’s website describes its mission as “leading the discovery, development and integration of affordable warfighting technologies for America’s aerospace

______________

21 Robert W. Duffner. 2000. Science and Technology, The Making of the Air Force Research Laboratory. Maxwell Air Force Base, Alabama: Air University Press. November. p. 12.

22 Ibid.

FIGURE 5-3

Early notional organizational structure of the Air Force Research Laboratory. SOURCE: Robert W. Duffner. 2000. Science and Technology, The Making of the Air Force Research Laboratory. Maxwell Air Force Base, Montgomery, Alabama: Air University Press.

forces. It is a full-spectrum laboratory, responsible for planning and executing the Air Force’s science and technology program. AFRL leads a worldwide government, industry and academia partnership in the discovery, development, and delivery of a wide range of revolutionary technologies. The laboratory provides leading-edge warfighting capabilities keeping our air, space and cyberspace forces the world’s best.” 23 To support this mission, AFRL develops an investment strategy, delineating its emphasis areas, including near-, mid-, and long-range technologies. The eight TDs are responsible for discovering, developing, and transitioning the technologies required by this strategy. Out of necessity, the strategy changes with time. World events, emergence of revolutionary technologies, and Air Force strategic changes can impact the S&T strategy. The TDs’ technology programs change to keep pace with the current strategy.

Customer interface was a strong headquarters focus during AFRL’s initial startup. As shown in Figure 5-3, an early construct of AFRL had sectors—representing major customer focus/investment areas—led by Colonels, interfacing directly with the Commander. Six sector offices—Aeronautics, Space and Missiles, Com-

______________

23 Available at http://www.afrl.mil. Accessed May 4, 2011.

mand and Control, Human Systems and Logistics, Weapon Systems, and Modeling and Simulation—eventually were formed within AFRL. The sectors’ focus was three-fold: customer interface via a single point of entry, integration across TDs, and investment strategy. To assist with customer interface, AFRL representatives served as collocates in the major commands (MAJCOMs). These representatives reported to their various sector chiefs. Even though the intent was that the sectors would be a single point of entry, customer technology transition processes were numerous, diverse, and spread across each of the TDs.

Many transition processes involved relationships that existed prior to the AFRL’s formation, especially with the product centers. Some were the direct result of the TD’s geographical proximity to a major Air Force unit, such as the proximity of several AFRL TDs to ASC. Many resulted from the TD’s direct interface with its customers, in some cases supported with major 6.3 programs. Many were the result of strong ties to industry, such as that of the Propulsion Directorate to engine companies. Many “transition programs” lacked formal agreements or documents that identified key performance parameters or that put critical resources in place to ensure the transition. The formation of the sectors was one way to improve the transition process and take some of the customer interface/integration workload off of a hard-pressed staff.

A good example of informal relationships with a sustainment focus may be found in the programs of the Systems Support Division in the Materials and Manufacturing Directorate. This division maintained the expertise and facilities to do quick reaction support to urgent Air Force sustainment issues. This division also had collocated engineers in each of the major SPOs, such as F-22 and C-17, to identify issues and bring S&T solutions to the needed sites. Customers would frequently go directly to the quick reaction team or use the collocated engineer as a point of entry to directorate personnel and technologies. The division also housed program offices—corrosion, non-destructive evaluation, and composites—at each of the ALCs. Other TDs also had their own informal structures, often involving collocated personnel at major stakeholders’ offices. In essence, a network was in place to provide a multitude of sustainment solutions.

When AFRL was established, its technology portfolio was as diverse as its TDs, spanning basic research, new materials, advanced propulsion, sensors, and human resources. Within this diverse portfolio, however, sustainment was a significant part of the investment strategy and transition focus. The Aeronautics Sector had sustainment as a major part of its portfolio. Four TDs—Materials and Manufacturing, Propulsion, Air Vehicles, and Human Effectiveness—had major sustainment investment areas. Each TD had numerous examples of successful transitions that impacted sustainment cost/aircraft availability. The sectors were key participants in many of these successful transitions. Two TDs, Materials and Manufacturing and Air Vehicles, jointly manned/resourced an aging aircraft office whose mission was

to call increased attention to aging aircraft issues with technology solutions. This office was closely aligned with an aging aircraft office in ASC, which was formed shortly after the release of the 1997 NRC report.24 A special 3600 Program Element (PE) was created specifically for the aging aircraft function. Eventually this PE was transferred to the ASC aging aircraft office, where it became a key source of funds to facilitate the technology transition of sustainment-related technologies to the ALCs. The office was also strongly supported by the ASIP personnel in ASC. In those early years, the aging aircraft offices, the Aeronautics Sector, and the ALCs had substantial collaborations that produced significant advances for Air Force weapon system sustainment. Many technologies transitioned through this collaboration, including those related to paints/coatings, wiring, corrosion control, composite repair, and composite patches.

The FY2000 S&T plan for AFRL shows sustainment as a key emphasis area, supported by the Aeronautics Sector, the relevant TDs, and an aging aircraft office. The 1997 NRC report was a key reference for the 2000 plan.25,26 Even though the plan is more than a decade old, sustainment was already recognized as a major developing need, forecasted to increase dramatically in importance over the coming years to maintain air worthiness for aircraft being used past their anticipated service life. The plan also recognized that sustainment was not just an aging issue. Advanced systems entering the inventory frequently created sustainment issues, such as low observable (LO) maintainability, which required new inspection and repair concepts. However, the level of emphasis that sustainment would receive was to wax and wane in the next decade as S&T strategy and processes changed.

Changing Strategies and Processes

2000-2002

Shortly after AFRL’s creation, the Air Force S&T investment strategy experienced a change in emphasis that had a major effect on sustainment. The 2000 strategy called for, among other things, a migration of focus from aero to space, development of enabling technologies, and identification of an Integrated Technology Solutions (ITS) strategy to address high-priority warfighter needs.27 The goal of the ITS strategy was to mesh the technical efforts of multiple TDs into Integrated

______________

24 NRC. 1997. Aging of U. S. Air Force Aircraft: Final Report. Washington, D.C.: The National Academy Press. Available at http://www.nap.edu/catalog.php?record_id=5917.

25 Ibid.

26 USAF. The Air Force Science and Technology Plan Fiscal Year 2000. Available at http://www.wslfweb.org/docs/st_plan00final.pdf. Accessed May 5, 2011.

27 USAF. The Air Force Science and Technology Plan Fiscal Year 2000. Available at http://www.wslfweb.org/docs/st_plan00final.pdf. Accessed May 5, 2011.

Technology Thrusts (ITTs), providing a synergistic laboratory solution. Each ITT contained several Integrated Technology Thrust Programs (ITTPs) supported by programs in the TDs. One of the initial six ITTs was aircraft sustainment. Within this ITT were four ITTPs directed at aging aircraft structures, LO maintainability, HCF, and turbine engine durability. 28 Each ITTP supported a documented critical warfighter operational need as defined in the Air Force Modernization Planning Process (AFMPP) and needed to align with Air Force core competencies.29

The enabling technologies strategy was implemented through programs in the individual TDs. Several sustainment-related enabling technology programs were being implemented in the TDs during this time period. For example, materials and manufacturing had LO maintainability, paint, aging aircraft, HCF, pollution prevention, and nondestructive evaluation (NDE); air vehicles had aging aircraft; and propulsion had HCF, to name a few. Transition of the technology being developed under the Enabling Technology efforts was accomplished through arrangements set up by the TDs or by the TDs combined with the sectors.

Clearly, sustainment was a major emphasis area for the AFRL during this period, and successes were numerous. A particularly noteworthy success was the solution of the HCF fatigue problem (see Box 5-1), which affected virtually every fighter aircraft engine in the Air Force inventory. The combination of outstanding technical expertise and leadership, TD programs, ITTs, and partnerships with industry led to the successful solution of this major showstopper.

2002-2004

During 2002-2004, Long-Term Challenges and Short-Term Objectives were identified to support Air Force Vision 2020.30 A Short-Term Objective had to address compelling Air Force requirements, have strong user support, and attain its objectives within 5 years at a TRL of 6. There were eight Short-Term Objectives, with one being sustaining aging systems.31 One of the areas recommended for increased emphasis at the applied research level was Integrated Vehicle Health Management (IVHM) directly impacting sustainment. IVHM uses a systems approach and is designed to detect and diagnose the condition of an air vehicle to determine the usable safe operating life and/or the need for any maintenance actions. Within this system, using a strictly Condition-Based Maintenance (CBM) approach versus a Programmed Depot Maintenance (PDM) approach would be a major capability

______________

28 Ibid.

29 Ibid.

30 Don Daniel. “AF S&T Investment Strategy and Funding.” Briefing to NDIA, February 12, 2002. Available at http://www.dtic.mil/ndia/2002science/daniel.pdf. Accessed May 6, 2011.

31 Ibid.

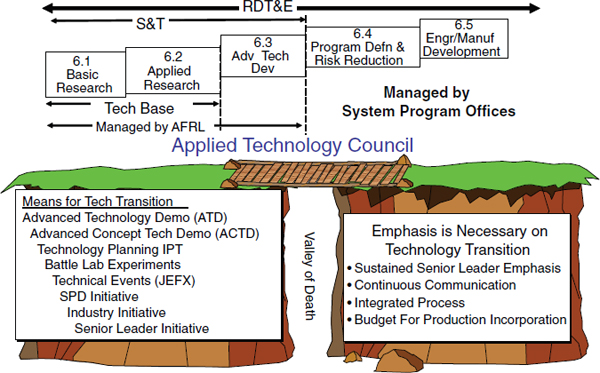

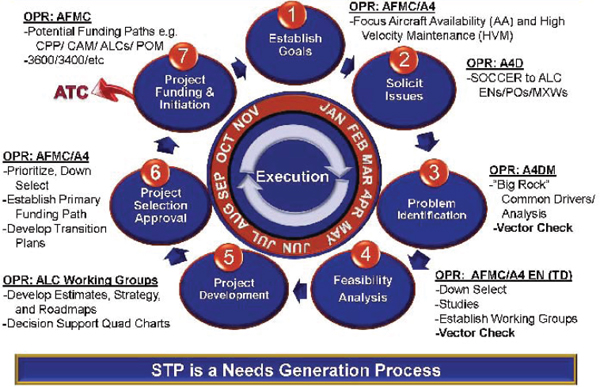

FIGURE 5-4

The Applied Technology Council (ATC) was designed to link the S&T community with the user community. SOURCE: Major General Paul D. Nielsen, Commander, Air Force Research Laboratory. “AFRL Overview Briefing.” May 2003.

afforded the sustainment community with positive aircraft availability results. Key technologies for development were sensing methodologies, signal processing, and prognostics. New initiatives were identified that had major implications on next-generation warfighting capabilities, such as information technology, biotechnology, nanotechnology, space technology, and directed energy. New, revolutionary technologies aimed at sustainment were not in this mix.32

The major process change during this time period was the creation of the ATCs. The ATCs were organized to address the many difficulties that were severely hampering the transition of technologies from the AFRL to its customers. In many cases, funding shortfalls, funding reallocations, requirement changes, shortfalls in key performance parameters, and personnel changes occurred without the knowledge of key stakeholders. These pitfalls were viewed as the “valley of death” between the S&T community and the user community and are schematically represented in Figure 5-4.

As indicated in Figure 5-4, there were many paths for technology transition, but

______________

32 Major General Paul D. Nielsen, Commander, Air Force Research Laboratory. “AFRL Overview Briefing.” May 2003.

they required the emphasis areas shown on the right to successfully navigate the valley. To achieve this emphasis, ATCs were established as semi-annual meetings of the AFRL Commander, the Product Center Commander, and the Vice Commander of the receiving MAJCOM. It was through this process that technology “needs” as seen from the AFRL perspective would become technology “requirements” as seen from the warfighter perspective. The primary outputs of the ATCs were programs or groups of programs commissioned as Advanced Technology Demonstrations (ATDs) by the senior leadership of the three entities noted. ATDs were binned in four categories:

- Category 1: MAJCOM/Agency supports and has programmed required funding for transition (6.4 and beyond) within the Future Years Defense Program (FYDP)

- Category 2A: MAJCOM/Agency supports and is committed to identify transition funding in the next programming cycle

- Category 2B: MAJCOM/Agency supports but is not currently able to Program Objective Memorandum(POM) for transition

- Category 3: Warfighter does not support33

Each round of an ATC was focused on a specific MAJCOM, with ATC #6 focused on AFMC. Four Category 1 ATDs that supported sustainment were commissioned from ATC #6:34

- Bonded Repair Capability Enhancements

- Corrosion Effects on Structural Integrity

- Advanced Aircraft Corrosion Protection

- Advanced Non-destructive Evaluation (NDE) for Aging Systems

A further ATD on LO maintainability was established in the ATC with ACC. In addition to the ATDs, the TDs continued to support sustainment through their individual programs, quick reaction capabilities, and collocated engineers. However, their level of support was dramatically reduced in the aging aircraft area. Largely because of budgetary pressures, the AFRL and ASC eventually closed their aging aircraft offices.

______________

33 Major General Paul D. Nielsen, Commander, Air Force Research Laboratory. “AFRL Overview Briefing.” May 2003.

34 Mike McMillan. “Air Force Technology Transition and Modernization.” Briefing to JTEG, 2001.

2005-2009

The next major change in strategy and process centered around the creation of Focused Long-Term Challenges (FLTCs). During the 2005-2009 timeframe, the S&T program was strongly influenced by the demands of the 21st century environment. The Global War on Terrorism (GWOT), cyber warfare, and precision strike, to name a few, were major drivers not envisioned in earlier years. The S&T program was also under continuing pressure to be more innovative and forward thinking, especially with the GWOT changing strategies and tactics. These mounting pressures resulted in the AFRL creating an “integrated capability-based planning and programming” approach. Also during this timeframe the Air Force adopted a new technology vision that AFRL had already embraced: Anticipate, Find, Fix, Track, Target, Engage, Assess—Anything, Anywhere, Anytime (AF2T2EA4).35 This technology vision provided a link to the Air Force’s capabilities-based planning and Capability Review and Risk Assessment (CRRA) process. The S&T program was binned in three time-phased groupings:36

- Rapid Reactions—technology options for immediate warfighter needs

- ATDs—technology options that meet near-term needs

- FLTCs—technology options for innovative capabilities for future needs

The planning and implementation of the FLTC process and portfolio became a primary emphasis of AFRL during this period. Eventually, this concentrated effort produced eight FLTCs. One of these—FLTC #8: Affordable Mission Generation & Sustainment—was the home of sustainment technologies for the future Air Force. These long-term programs were aimed at innovative capabilities: Provide Real-time Total System Health Status; Predict Any System’s Mission Capability; Proactively Maintain Readiness; Design for Integrated System Life Cycle Management & Intrinsic Reliability; and Autonomously Reconfigure Systems for Any Damage Condition.37

The substantial investment in time and resources that went into the planning and implementation of FLTCs, along with the strategic shift to longer term investments, resulted in a decreased emphasis on many program areas including sustainment. TD individual programs and established ATDs made up the major part of the sustainment portfolio. The influence of the FLTC process was evident in that the focus of sustainment programs within the S&T plan was moving toward

______________

35 Leo J. Rose. April 2008. Air Force Research Laboratory’s Focused Long Term Challenges. Air Force Research Lab, Eglin Air Force Base, Florida, Munitions Directorate.

36 Ibid.

37 USAF. The Air Force Science and Technology Plan Fiscal Year 2000. Available at http://www.wslfweb.org/docs/st_plan00final.pdf. Accessed May 5, 2011.

Condition Based Maintenance—a program that would “enable total state awareness” and “eliminate time-phased maintenance.”38 One of the TD programs that continued to support the sustainment area was the Materials and Manufacturing Directorate’s Air Force Manufacturing Technology Program (ManTech). Some of the many successful ManTech programs directed at sustainment are documented in Box 5-2.

ManTech programs such as Lean Depot Repair (LDR); Aerial Multi-Axis Platform (AMP), aimed at the de-paint process in the depots; Enhanced MAUS (Mobile Automated Ultrasonic System) Inspection Capabilities, aimed at improving the MAUS’ detection capabilities; and the upcoming HVM program were all directed at improving flow time and reducing cost at the ALCs.39 Lean Sustainment was an earlier ManTech program that produced the foundation on which the lean programs, such as LDR, were built. By the end of this period, the ATC process within AFMC had gone into somewhat of a holding pattern, resulting in no new ATDs being commissioned. In its place, a new process had been established for coordinating the needs of the developers and users of technology intended for sustainment. This Sustainment Technology Process:

… provides a systematic repeatable method for identifying sustainment needs starting with requirements generation, going through validation, execution, transition, and ending with implementation. This process creates a strategic partnership between the Science and Technology (S&T) provider and the sustainment and acquisition communities to address sustainment technical opportunities, solution planning and programming. While this process is primarily focused on technology improvements within AFMC Centers, it will also be an avenue for MAJCOMs to identify sustainment technology needs that are of concern to both.40

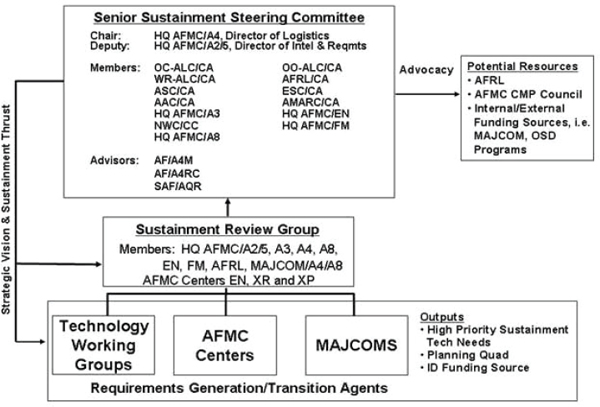

The process is shown in Figure 5-5. The process leads to a meeting of the Senior Sustainment Steering Committee, headed by the AFMC/A4; indications are that this process has not been achieving its goals. Although stating otherwise, the complex effort to bring all of these parties together was not designed to establish requirements and ensure resources for transition across the “valley of death.” Rather, as indicated clearly in Figure 5-5, it was to provide “advocacy” to those organizations controlling the resources. Efforts by such organizations as ASIP to identify technology “needs” could find no clear path through which to translate those needs into funded “requirements.”

______________

38 Kathy Stevens. “Air Force Sustainment Science & Technology.” Presentation at the CTMA 2009 Symposium, March 30-April 2, 2009, Detroit, Michigan.

39 Ibid.

40 AFMC Guidance Memorandum 61-101, January 27, 2007.

BOX 5-2

ManTech Success Stories

Organization

The ManTech program is chartered by U.S.C. Title 10, section 2521 and implemented by DODD 4200.15. The purpose of the program is to enable a robust industrial base for affordable warfighter weapon systems, and provide advanced manufacturing capabilities to multiple weapon systems. The goals of the program are to reduce acquisition and sustainment costs; reduce cycle time for technology transition, manufacturing, and repair; and improve quality, productivity, and business practices. The program focuses investments on those beyond the normal risk for industry and system program offices. ManTech directly supports administration, Congressional, Secretary of Defense and Secretary of the Air Force industrial base policies. Within the Air Force, program management responsibility is assigned to Air Force Materiel Command (AFMC), with execution performed centrally by the Manufacturing Technology Division, Materials & Manufacturing Directorate, Air Force Research Laboratory (AFRL/MLM).

Requirements and Planning

Technical requirements, priorities, and investment planning are developed in partnership with AFRL, Air Force program executive officers (PEO), ALCs, major commands, and industry. Technology transition requirements are identified and developed in partnership

with AFRL. Acquisition and sustainment requirements are identified and developed through integrated product teams in each customer “sector”: aeronautical; sustainment; armament; directed energy; command, control, intelligence, surveillance, and reconnaissance; and space. Key criteria for investment decision are warfighter capability

impacts, pervasive system applications, and stakeholder implementation commitment. Requirements and plans are coordinated and approved by HQ AFRL, HQ AFMC, and SAF/AQR.

C-17 Landing Gear Doors

An increase in failure rates for C-17 main landing gear doors has become a major contributor to reduced mission capability of the aircraft. The AFRL Materials and Manufacturing Directorate and Air Vehicles Directorate, in cooperation with The Boeing Company, have successfully developed and implemented a durable composite C-17 main landing gear door that resolves the C-17s number one airframe maintenance problem, saves more than $6 million in life cycle costs, and increases mission readiness days by 90 per year. A result of the Composites Affordability Initiative (CAI) C-17 technology transition demonstration program, the new main landing gear doors incorporate several advanced manufacturing technologies and an improved design that will increase reliability by 40 percent.

Turbine Engine Components

Historically, methods for predicting the life of gas turbine engine rotor components have resulted in a conservative estimate of useful life. The “retirement for cause” program developed, integrated, and deployed advanced inspection and life-estimating technologies that are in use today at Oklahoma City Air Logistics Center permitting longer service life for many safety-critical, high-value components on the F-15, F-16, B-1B, and B-2.

This program—a collaboration between Air Force ManTech, materials S&T, and logistics centers—is also credited with enhancing safety, increasing inspection throughput, and introducing damage tolerance and probabilistic concepts-of-life management for engines. The program has realized more than $1 billion in cost savings. A related ManTech effort, Engine Rotor Life Extension, is currently working to create and implement the technology to further extend the life of these components and address the more complex rotor geometries of advanced engines for the F/A-22 and F-35, for an additional projected $550 million in savings.

Lean Depot Repair

The Lead Depot Repair project was established to determine whether lean methods could be adapted to the depot repair environment. Air Force ManTech partnered with Warner-Robins Air Logistics Center to revolutionize the programmed depot maintenance lines for F-15 and C-5 aircraft, reducing cycle time and cost. As a result, critical warfighting assets are more quickly moved from maintenance to fully operational status. Specifically, on-time return of C-5 aircraft increased from 25 percent in FY 2000 to 100 percent in FY 2004. The average flow time for depot maintenance on C-5s at the Air Mobility Command was reduced from 339 days in FY 2000 to an average of 240 days in FY 2004. On-time return of F-15 aircraft increased from 12 percent to 80 percent between FY 2000 to 2004. As a result, 22 additional F-15s (the equivalent of an additional squadron) were freed for operational use. Due to the success of this effort, lean depot practices are rapidly expanding across DOD, including Army arsenals and depots, Navy air depots, and shipyards.

______

SOURCE: Extracted verbatim from Defense Science Board Task Force on The Manufacturing Technology Program: A Key to Affordably Equipping the Future Force. February 2006.

Summary of Recent History

The past decade has seen significant accomplishments in the development and transition of technologies that have increased aircraft availability and reduced sustainment costs. During the same period, the Air Force S&T system has seen many changes in strategy and processes, each one initiating some new programs and disrupting others, leading to less than optimum use of limited resources. Unfortunately, at the end of this period, the process to transition sustainment technology into funded requirements was broken.

Finding 5-5. The Air Force Materiel Command has a strong cadre of highly qualified researchers in AFRL and applied engineering talent in the ALCs. Historically, AFMC has made major contributions to the development and transition of technology in support of sustainment.

FIGURE 5-5

Air Force Materiel Command (AFMC) sustainment technology process. SOURCE: AFMC Guidance Memorandum 61-101, January 27, 2007.

Finding 5-6. In recent years, because of (1) frequent changes in management; (2) weakened processes for establishing requirements; and (3) reduced availability of resources, the Air Force Material Command talent base has not been optimally engaged in finding solutions to critical cost, schedule, or performance sustainment issues.

TRANSITION TO THE FUTURE

The Air Force appears to be addressing the severe criticisms of its S&T process.41 It has done so in the context of rising sustainment costs that refocus attention on the potential for investment in technology to effectively increase aircraft availability and/or reduce sustainment costs. Addressing these challenges in parallel, the

______________

41 Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering. “Air Force Science and Technology Strategy.” Presentation to the Air Force Studies Board, November 16, 2010.

Air Force has adopted a strategy of ILCM and instituted new processes to manage the S&T portfolio. The following section discusses the current state of this transition under the headings of the three R’s: requirements, resources, and right people.

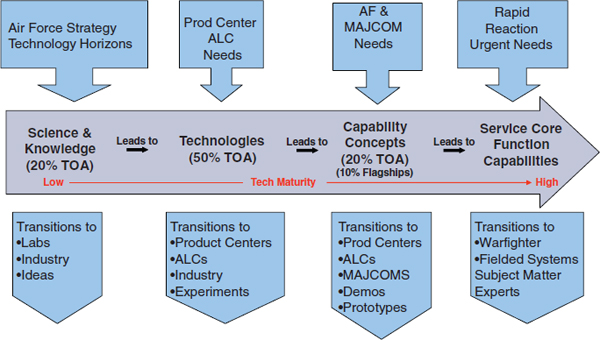

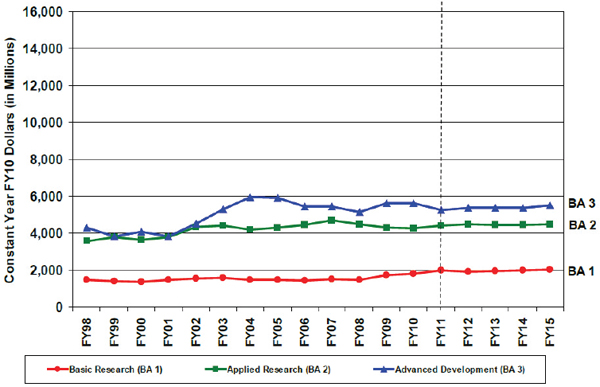

Requirements

Guidance for establishing requirements in sustainment technology development are now to be drawn from the Air Force Science and Technology Strategy 2010, described earlier in this chapter. Sustainment, one of eight areas targeted for increased emphasis, will be planned along with other areas according to the approach sketched in that document (see Figure 5-6). This oversimplified diagram describes the development of technology as a linear feed-forward process, neglecting the important feed-back of information and experience that often energizes early-stage development. Nevertheless, it is a convenient planning structure.

FIGURE 5-6

Air Force Research Laboratory (AFRL) approach to S&T. SOURCE: General Norton A. Schwartz, Chief of Staff, United States Air Force, and Michael B. Donley, Secretary of the Air Force, “Air Force Science and Technology Strategy 2010.”

Quoting Air Force Science and Technology Strategy 2010, the four stages in this process are42

Science and Knowledge

Science and knowledge are the foundation of the Air Force S&T Program and the cornerstone of the future force. Based on visions of the future established by Air Force leadership, Air Force scientists and engineers identify, nurture, and harvest the best basic research to transform leading-edge scientific discoveries into new technologies with substantial military potential. These technologies transform the art-of-the-possible into the near-state-of-the-art and offer new and better ways for the acquisition community to address far-term warfighter needs.

Technologies

Air Force scientists and engineers continually interact with warfighters to understand their capability needs. The Air Force S&T Program addresses these needs by leading and harnessing innovation across service laboratories, government agencies, industry, and academia. These efforts mitigate risk and create the foundation for new capability concepts.

Capability Concepts

Senior representatives from Headquarters Air Force, MAJCOMs, Centers, and Air Force Research Laboratory (AFRL) will work together to define a balanced set of capability concepts that support known warfighter needs and mitigate risk from emerging threats. The highest-priority capability concepts are designated as Air Force “Flagship Capability Concepts (FCCs).” These FCCs address validated capability gaps and increase Air Force leadership’s visibility into the Air Force S&T Program.

Service Core Function Capabilities

The Air Force’s investment in S&T ensures the infusion of revolutionary and evolutionary S&T-enabled capabilities that are needed to maintain air, space, and cyberspace dominance. The Air Force S&T Program will address the needs identified in each of the twelve Service Core Functions (SCFs). Each of the MAJCOMS has one or more SCFs. Sustainment is housed in Agile Combat Support, AFMC’s SCF.

As noted earlier in this chapter, technology development for sustainment should be found at every stage identified in Figure 5-6, but it is primarily in Technologies that transitions to the ALCs are identified, while both ALCs and MAJCOMs are called out as recipients in Capability Concepts. The planning process for sustainment within Technologies is primarily the responsibility of AFRL, demands close cooperation with the ALCs and programs such as ASIP, ENSIP, and FSIP in identifying priorities, and is endorsed by higher-level validation within AFMC. As this report is being written, this planning process has not yet been completed, although extensive pre-planning is evident. During 2010, AFRL commissioned a study by a

______________

42 General Norton A. Schwartz, Chief of Staff, United States Air Force, and The Honorable Michael B. Donley, Secretary of the Air Force. Air Force Science and Technology Strategy 2010.

distinguished group, seeking its advice on priorities and process.43 During 2011, AFRL will be further aided by the results of the AFSAB study on sustainment that is under way in parallel to this current study and mentioned earlier in the chapter. Anticipating a successful planning process, the Air Force has already committed to an increase in funding for this area. This planned increase of funds is consistent with statements by the Greybeards that the present effort is underfunded, but until the planning process is complete, no judgment can be made about its adequacy to address the need. Also uncertain at this time are the specific process changes that may accompany this technology development plan and how priorities and funding will be made available for transition to ALCs and industry.

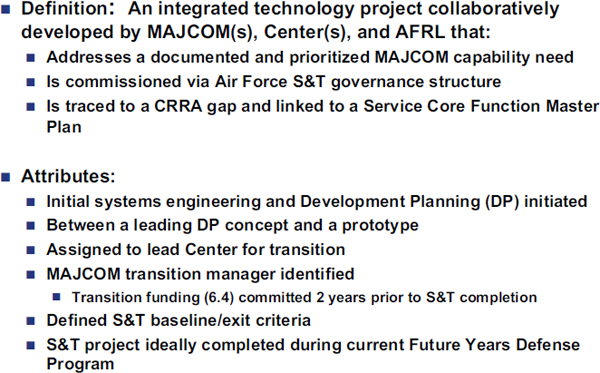

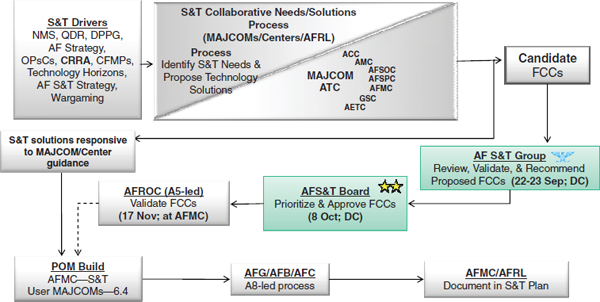

The planning that leads to Capability Concepts supporting the MAJCOMs is carried out as part of AFRL’s Integrated Planning and Programming (IPP) process.44 This “five body” integrated process, involving the TDs, a Capabilities Council, a Capabilities Working Group (CWG), an IPP Council, and the Commander, was developed to ensure a balanced S&T investment portfolio that addresses near-to far-term warfighter needs. The CWGs are responsible for managing customer-AFRL interface, gathering needs, and translating those needs into S&T projects that will deliver the desired capabilities. There is a CWG for each MAJCOM and its associated SCFs, and each CWG is chaired by a senior leader in the AFRL. In the case of sustainment, the AFMC CWG addresses AFMC’s SCF of Agile Combat Support, which includes sustainment needs along with those of several other areas. This CWG is chaired by the Director of the Materials and Manufacturing Directorate of AFRL. Two organizational paths now exist for high-level validation and transition of sustainment technology development within AFRL: (1) selection at the Air Force Requirements Oversight Council (AFROC) in which a very few Capability Concepts are identified as Air Force Flagship Capability Concepts (FCCs) and, more commonly, (2) identification as Advanced Technology Development (ATD) programs through the Advanced Technology Council accessed via the Sustainment Technology Process.45 The Capability Concepts/AFROC process identifies high-priority candidates that may be designated as FCCs. The definition, characteristics, and attributes of FCCs are shown in Figure 5-7.

Organized within AFRL, these candidate FCCs then follow the process shown in Figure 5-8 to become FCCs. In the first FCC submission under this new strategic management approach (completed in November 2010), AFRL submitted several

______________

43 Vince Russo. “Greybeard Assessment of the Sustainment Technology Transition Process.” Presentation to the committee, Dayton, Ohio, February 7, 2011.

44 Personal communication between C. Browning and Dr. James Malas, AFRL/XP.

45 USAF. 2011. Sustainment Technology Process. Personal communication from Claudia Kropas-Hughes, Deputy Chief, Technology Transition Division, AFMC/A5S, to the committee, May 4, 2011.

1FIGURE 5-7

Definition and attributes of Flagship Capability Concepts (FCCs). SOURCE: Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology and Engineering. “AF Science and Technology Strategy.” Presentation to the Air Force Studies Board, November 16, 2010.

FCC candidates, and the Air Force S&T Board recommended that the following projects be selected as FCCs:46

- High Velocity Penetrating Weapon (HVPM)

- Responsive Reusable Boost for Space Access (RBS)

- Selective Cyber Operations for Tech Integration (SCOTI)

- Low Observable (LO) Maintainability

- Adaptive Versatile Engine Technology (ADVENT)

- Selectable Effects Munitions (SEM)

- Next Gen C2 and Operations for remotely Piloted Aircraft (RPA)

From this list, the AFROC selected the top three candidates.47 The sustainment candidate, LO Maintainability, did not make the cut during this cycle. However it was characterized as an excellent program and will continue to support its prime

______________

46 Major General Ellen Pawlikowski. “AFRL Overview to the Electronic Engineering Steering Group.” January 2011.

47 Ibid.

FIGURE 5-8

S&T planning process producing Flagship Capability Concepts (FCCs). SOURCE: Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering. “AF Science and Technology Strategy.” Presentation to the Air Force Studies Board, November 16, 2010.

customer, ACC. The other candidate programs will likewise continue to be worked by AFRL and its partners as Capability Concepts. This is certainly the highest visibility given to a sustainment technology program in recent memory and reflects well on the Air Force’s commitment to reemphasize this important area. The second and more common transition path for sustainment technologies will lead to the AFMC/ATC via the Sustainment Technology Process. This process, identified earlier in Figure 5-5, has now been revisited and converted into the seven-step process depicted in Figure 5-9.48

This process was roughly at step 4 when this report was being written and is expected to lead to recommendation to the AFMC/ATC in 2012. In lieu of completion of the process this year, AFMC/A4 has identified HVM as the sustainment candidate for consideration by the AFMC/ATC scheduled for August 2011.

______________

48 USAF. 2011. Sustainment Technology Process. Personal communication from Claudia Kropas-Hughes, Deputy Chief, Technology Transition Division, AFMC/A5S, to the committee, May 4, 2011.

FIGURE 5-9

Newly revised sustainment technology process. SOURCE: Claudia Kropas-Hughes, Deputy Chief, Technology Transition Division, AFMC/A5S, personal communication to the committee, May 4, 2011.

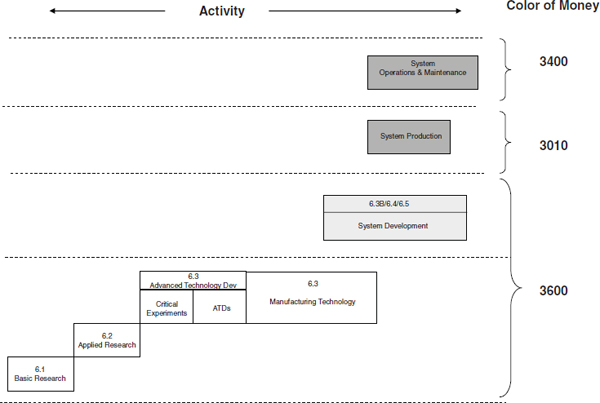

Resources

Adequate and timely funding are key factors in any successful technology transition process. Funding issues affecting the sustainment technology transition process are (1) the restrictions placed on use of funds associated with each category of the “technology for sustainment” process: development, implementation, and maintenance; (2) the amount of funds in these categories required to support the work needed; and (3) the timing of the available funds. Funds are broken out by appropriations and are often referred to as “colors of money.” There are several colors of money within the Air Force, but three are strongly tied to the “technology for sustainment” processes. Figure 5-10 illustrates the funding categories for the Air Force S&T program, along with those of the acquisition and operation and maintenance (O&M) programs, in addition to the various colors of money that house these program elements.

Their specified functions prohibit use of funds in any category for reasons other

than those allowed by statutes. If funding for any stage in the technology transition shown in Figure 5-6 is inadequate, then it is difficult to cover the deficiency with funds from another color or level.