Assessment of Current

Sustainment Investments,

Infrastructure, and Processes

INTRODUCTION

This chapter addresses element 1 of the terms of reference (TOR), that is, “Assess current sustainment investments, infrastructure, and processes for adequacy in sustaining aging legacy systems and their support equipment.” This chapter also sets the stage for other chapters about the importance of the funding that significantly impacts the sustainment of systems over the entire life cycle. Sustainment investments are found in multiple elements of the Air Force budget in part because of the fact that sustainment cuts across all aspects of weapon system life cycles.

The Air Force faces a number of sustainment challenges, including aging of aircraft systems, rapid advances in technology, and increasing costs. As noted in Chapters 1 and 2, the Air Force does not have a clearly articulated definition of sustainment or high-level sustainment goals. Instead, most leaders involved in sustainment-related activities define their goals only in terms of achieving an availability metric at the platform level. There was not a clear understanding of the source of the availability requirement for each platform or of the relationship between aircraft availability and cost by platform or across the entire enterprise.

AIR FORCE INVESTMENT PROCESS RELATING TO SUSTAINMENT

Department of Defense (DoD) and Air Force budgeting and funding are institutionalized processes that respond to national needs in terms of strategies and doctrines and include the functional activities of operation and maintenance

(O&M), procurement, research, development, testing, and evaluation (RDT&E), and military construction that have either a direct or indirect relationship to sustainment. The O&M portion of the budget is usually associated with sustainment because it is within this realm that the most visible activities associated with the metric of aircraft availability are funded. It also is in this budget area that investments in depot maintenance, some hardware procurement, logistics, and, in some cases, contract logistics support are made.

The procurement phase of weapon system programs has historically been driven by cost and performance parameters that are established in the concept, or pre-Milestone A, phase in Defense Acquisition Board (DAB) decisions, when program budgets are established on a cost-benefit basis. Only recently, as exemplified by the Air Force memorandum “Present a Competitive Acquisition Strategy at Each Program Milestone,” has the Air Force stressed the importance of incorporating sustainment considerations into all phases of the acquisition process.1 The importance of addressing sustainment early in the acquisition process cannot be over-emphasized and was a subject raised repeatedly during the study. Consider the following quotes from the 2009 DoD Weapon System Acquisition Reform Product Support Assessment:

Acquisition processes pay too little attention to supportability and consistently trade down-stream sustainability for required capability or program survival. Some Program Managers assert that “logistics is their only discretionary account”, making it a frequent target for inevitable resource reductions. In acquisition decision reviews, sustainment is often relegated to the back-up charts. Hampered by functionally stove-piped organizational structures and lacking life cycle management qualifications in their diverse workforce, the logistics community fails to achieve effectively integrated and affordable Warfighter operational readiness. Instead, it remains focused on managing commodities, parts, and services.2 (p. 7)

Product support, vital to both acquisition and logistics, has been treated as the stepchild of both functions. The acquisition community has neglected it, and the logistics community seems mismatched to effectively perform its demanding scope.3 (p. 7)

______________

1 DoD. “Present a Competitive Acquisition Strategy at Each Program Milestone.” A Memorandum from Air Force Service Acquisition Executive David M. Van Buren to Senior Air Force Personnel. January 14, 2011. Washington, D.C.: Office of the Assistant Secretary. Available at https://acc.dau.mil/CommunityBrowser.aspx?id=433566. Accessed March 23, 2011.

2 DoD. 2009. DoD Weapon System Acquisition Reform Product Support Assessment. Washington, D.C.: Office of the Secretary of Defense. November, p. 7. Available at https://acc.dau.mil/adl/en-US/328610/file/47489/DoD%20Weapon%20System%20Acquisition%20Reform%20PSA_19%20NOV_Final.pdf. Accessed March 22, 2011.

3 Ibid.

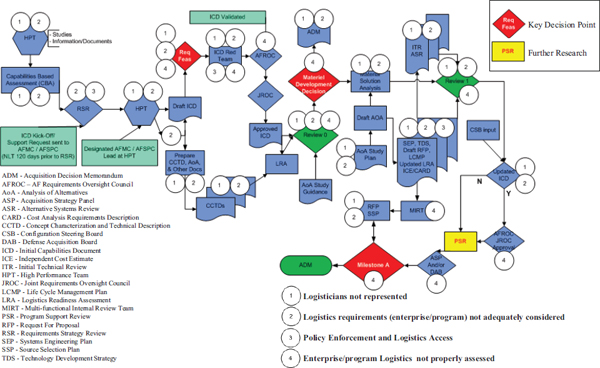

The Air Force is attempting to put in place new acquisition processes—for example, giving the logistics community a seat at the table earlier in the acquisition process.4 The Air Force Logistics Requirements Traceability (LRT) process is intended to “ensure that life cycle logistics is addressed at every step from the lab to the requirements to the design and testing to the manufacturing and delivery process.”5 The white circles in Figure 3-1 show activities leading up to Milestone A, where there is currently inadequate logistics representation or assessment. As part of the LRT process, a set of standard work, tools, and templates is being developed to ensure that logistics requirements are addressed and tracked over the complete lifecycle.

As noted in a recent article, “… while attention is typically focused on the initial cost of procuring a weapon system, sustainment spending actually accounts for most of the total lifetime cost of ownership. Sustainment is critical from a mission and readiness perspective. When sustainment is optimized, weapon systems perform better, spend less time under repair, and remain in use longer, thus delaying the need for their replacement.” 6

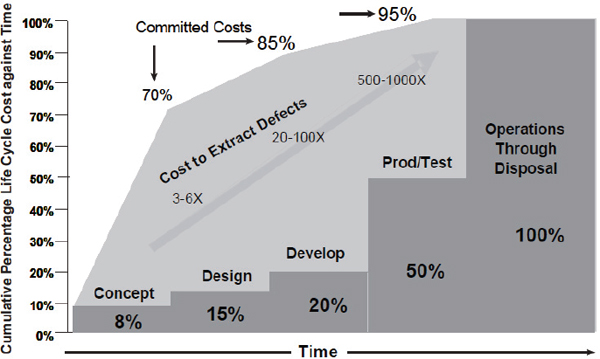

From a life-cycle cost perspective, early consideration of sustainment as part of a comprehensive approach to systems engineering is critical. As shown in Figure 3-2, only a small fraction of the overall life-cycle budget is spent during the concept development phase of a program; however, by the time that phase is completed approximately 70 percent of the life-cycle cost of the program is committed. Based on a statistical analysis performed on DoD projects, the Defense Acquisition University reports that by the time 20 percent of the life-cycle cost has been spent more than 80 percent of the life-cycle cost has been committed. Early involvement by the sustainment community offers the maximum opportunity to leverage its insights and experience to impact life-cycle costs.

All of the appropriate stakeholders, including acquisition, technology, and logistics, are at the table when DAB decisions are made.7 During the execution of the acquisition process, the Air Force must more fully consider, and plan for, long-term sustainment as a critical component of weapon system acquisition

______________

4 Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters United States Air Force. 2011. Expeditionary Logistics for the 21st Century. November 3.

5 Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters United States Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

6 Rick Conlin and Jim McIntosh. 2010. Collaborative Management Will Improve Weapon System Sustainment. Army Sustainment 42(5):55-59. Available at http://www.almc.army.mil/alog/issues/SepOct10/collaborative_mgmt.html. Accessed March 23, 2011.

7 DoD. Defense Acquisition Guidebook. Section 10.2, p. 479. Available at https://dag.dau.mil/Pages/Default.aspx. Accessed May 16, 2011.

FIGURE 3-1

Pre-Milestone A Defense Acquisition Board activities showing inadequate logistics involvement. SOURCE: Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

FIGURE 3-2

Life-cycle cost commitment. SOURCE: INCOSE Systems Engineering Handbook Version 3, June 2006.

decisions. Efforts such as LRT will be helpful to moving meaningful sustainment considerations to earlier in the acquisition process; however, the Air Force must strengthen its own leadership to properly maintain a balance between capability and lifecycle sustainment costs.

As described in detail in Chapter 2, the Air Force’s sustainment strategy is founded on the concept of developing an Integrated Life Cycle Management (ILCM) enterprise, and it has already established an ILCM Executive Forum. This forum has been charged to ensure that sustainment considerations are fully represented as part of the development process for new weapon systems, as mandated in DoD Instruction 5000.02 and DoD Weapon System Acquisition Reform Product Support Assessment.8,9

The Air Force’s research and development (R&D) activities are conducted in the Air Force Research Laboratory (AFRL), which primarily focuses on technology

______________

8 To review the DoD Instruction 5000.02, see https://acc.dau.mil/CommunityBrowser.aspx?id=332529. Accessed May 4, 2011.

9 DoD. 2009c. DoD Weapon System Acquisition Reform Product Support Assessment. November. Washington, D.C.: Office of the Under Secretary of Defense for Acquisition, Technology and Logistics. Available at https://dap.dau.mil/career/log/blogs/archive/2010/01/28/implementation-ofdod-weapon-system-acquisition-reform-product-support-assessment-psa-recommendations.aspx. Accessed November 22, 2010.

for new weapon systems in the concept stage or early development stage. During the course of the study, the committee identified some history of technology transition from the Air Force Research Laboratory to the operational fleets to provide solutions to near-term problems arising from (1) new requirements and (2) upgrades to sustain the fleet readiness and to reduce sustainment costs through improvements in repair techniques. These functions, however, have not been a priority for the Air Force. Chapter 5 describes some of the major technology transfer successes and will discuss how the process and intensity of technology transfer and sustainment-related investments have been insufficient.

Military construction investments and the portion of the O&M budget that supports facility maintenance are vital to the sustainment mission, because adequate facilities are required to support the new and evolving system requirements and to address normal obsolescence and deterioration from use. The Base Realignment and Closure (BRAC) Act that consolidated the Air Logistics Centers (ALCs) provided some modernization and replacement, but the significant ages of some of the facilities require attention. Legislation defines a minimum level of funding to be directed to depot maintenance functions.10

Finding 3-1. The Air Force acquisition process has emphasized (1) initial acquisition cost estimates; (2) promised achievement of key performance parameters; and (3) optimistic support costs estimates, without adequately addressing longer-term sustainment considerations that drive most of the total lifecycle costs.

CURRENT RESOURCES AND INVESTMENTS

Through 2007, the Air Force experienced a significant reduction in funding for O&M, a key driver of the sustainment enterprise. Several factors contributed to this reduction, including contingency operations, increasing fuel costs, aging aircraft spares requirements, costs associated with BRAC actions, and lost savings due to congressional restrictions on retirement and divestment of legacy aircraft. Several important factors put pressure on the Air Force’s ability to manage an aging fleet. Specifically, from 1988 through 2008, personnel costs increased 57 percent, while personnel end strength decreased 8 percent.11 Furthermore, the cost to operate aircraft rose 179 percent while aircraft inventories declined. These rising costs put pressure on the Air Force’s ability to modernize the fleet because procurement

______________

10 For additional information on the BRAC and also how the legislation consolidated the ALCs, see http://www.globalsecurity.org/military/facility/brac.htm. Accessed May 2, 2011.

11 United States Airforce (USAF). 2007. U.S. Air Force FY08 President’s Budget. February. Available at http://www.saffm.hq.af.mil/shared/media/document/AFD-070212-012.pdf. Accessed April 15, 2011.

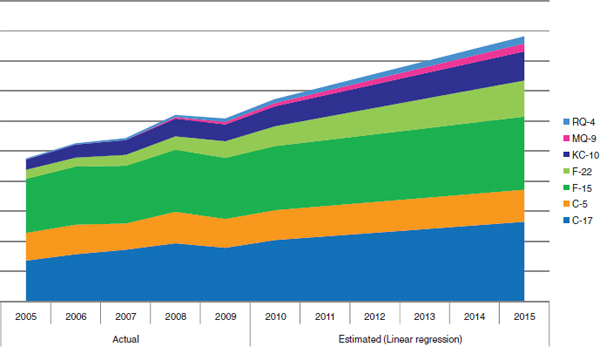

FIGURE 3-3

Weapon system sustainment growth for selected programs. SOURCE: Debra K. Tune, Principal Deputy Assistant Secretary of the Air Force for Installations, Environment and Logistics, Office of the Assistant Secretary of the Air Force for Installations, Environment and Logistics. “Developing the Right Product Support Concepts for the Future.” Presentation to the committee, October 20, 2010.

funding as a percentage of Air Force Funding declined 19 percent over a 22-year period.12 Figure 3-3 highlights this sustainment growth for selected weapon systems. Growth in sustainment costs for these systems is the result of increasing costs and increasing aircraft inventories in some cases.

These funding pressures have left the Air Force with an aging fleet that requires more funds to operate at viable levels that meet aircraft availability targets. However, with the submission of the Fiscal Year (FY) 2012 President’s budget, it seems unlikely that the Air Force will receive the resources necessary to significantly improve the viability of its fleet. Further funding reductions will be taken from the sustainment O&M accounts in the form of efficiencies as the Administration works to save $1.1 trillion over the next 10 years to ease deficit concerns. The Secretary of Defense (SECDEF) has outlined the savings proposed by the Military Departments, and the Air Force’s proposal totals $34 billion from 2012 to 2016. Some of these savings will come from the sustainment enterprise as indicated by the SECDEF’s

______________

12 Ibid.

statement that the Air Force would “improve depot and supply chain business processes to sustain weapon systems.”13

Finding 3-2. It is uncertain that the efficiencies envisioned in the FY2012 budget can be achieved. If these efficiencies do not come to pass, sizable impacts to fleet readiness should be expected.

The Air Force Budget for FY2012 totals $119 billion (the “Blue” budget),14 which represents a decrease of almost $600 million from FY2011 levels. The O&M appropriation, a critical component of sustainment funding, decreases by more than $500 million, despite the increasing requirements for aircraft sustainment. It was widely reported that the Air Force needed an additional $7 billion to fund 82 percent of the sustainment requirement over the next 5 years. This funding level was not affordable, so the Air Force conducted a total review and prioritization of remaining requirements. The result of this review was a $4 billion increase in funding, coupled with $3 billion in efficiencies within the sustainment enterprise, enabling the Air Force to fund 84 percent of the requirement over the next 5 years.

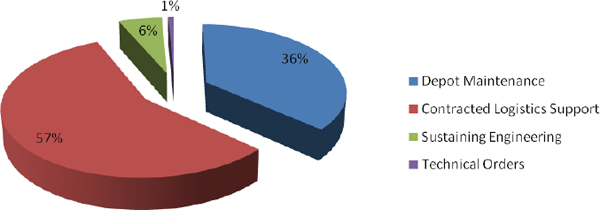

The Air Force weapon system sustainment (WSS) budget for FY2012 is $9.7 billion, or 69.7 percent of the full requirement. It consists of four primary components: (1) depot maintenance, (2) contractor logistics support (CLS), (3) sustaining engineering, and (4) technical orders. Funding levels (excluding funding for Overseas Contingency Operations), and the percentage of the requirement that is funded, for each of these areas is as follows:

- Depot Maintenance ($3.8 billion, 75 percent)—Includes major overhaul and/or rebuild of parts, assemblies, subassemblies and end items, manufacture of parts, technical assistance, software maintenance, and storage.

- CLS ($5.4 billion, 69 percent)—Includes contract support for a program, system, training system, equipment, or item used to provide all or part of the sustainment elements in direct support of an approved sustainment strategy to include operations.

- Sustaining Engineering ($0.4 billion, 48 percent)—Includes engineering efforts required to review, assess, define, and resolve technical or supportability deficiencies revealed in fielded systems, products, and materials.

- Technical Orders ($0.1 billion, 60 percent)—Includes user friendly, techni-

______________

13 Briefing: “Secretary’s Efficiency Initiatives: Follow-up to Jan 6 Speech by Secretary Gates.”

14 United States Air Force FY2012 Budget Overview, SAF/FMB, February 2011.

FIGURE 3-4

Components of the Air Force weapon system sustainment portfolio. SOURCE: Data provided by Major General Alfred Flowers, Deputy Assistant Secretary for Budget, Office of the Assistant Secretary of the Air Force for Financial Management and Comptroller.

cally accurate, and up-to-date technical data at the point of use that is acquired, sustained, distributed, and available for all users.15

Figure 3-4 highlights the relative amounts of each of the four areas listed above in the WSS program.

Although the Air Force considers these categories to be the components of weapon sustainment, there are other costs that should be mentioned within the context of sustainment. Specifically, the categories of depot-level reparables and consumable supplies should be considered when viewing sustainment in the larger construct. These costs, which are key components of the Air Force flying hour program, comprise an additional $2.6 billion in sustainment costs. Additionally, the cost of labor at the three ALCs totals nearly $2 billion.16 Adding these costs to the WSS portfolio brings overall sustainment spending in FY2012 to $14.3 billion, nearly 32 percent of the Air Force O&M budget.17

______________

15 Scott A. Haines, Colonel, USAF. Capabilities-based Resourcing for Air Force Weapon System Sustainment. Air Force Journal of Logistics. Vol XXXIV, Numbers 1 and 2, Annual Edition. Available at http://www.aflma.hq.af.mil/shared/media/document/AFD-101122-029.pdf. Accessed August 18, 2011.

16 Cost of labor includes pay/salaries. It is not intended to be fully burdened with medical, retirement costs, among other factors.

17 Department of the Air Force, FY 2012 Budget Estimates, February 2011, Operation and Maintenance, Vol II.

AIR FORCE SUSTAINMENT INFRASTRUCTURE

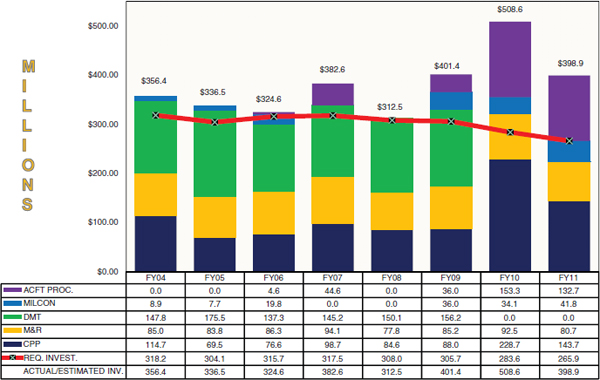

Infrastructure issues have a direct impact on the ability of the Air Force to sustain its weapon systems. As Figure 3-5 shows in the row entitled “Actual/Estimated Inv,” the Air Force investments in depot maintenance production/facilities and equipment were approximately $3 billion over the past 8 years.

The Air Force is actually exceeding the requirements of 10 U.S.C. § 2476, which requires that 6 percent of the annual revenue be invested in the physical facilities and infrastructure that perform the work. Yet the facilities are neither optimized nor in some cases suitable for present and future needed capabilities. For example, 1950s-era engine test stands that are marginally serviceable due to obsolete and nonsupportable instrumentation and fixtures are still being used, and computers in the B-2 Weapon System Support Center Software Integration Laboratory are no longer supported by the original manufacturer or sub-tier vendors. In addition, there is a lack of availability of engine test stands to accommodate the F119 engine

FIGURE 3-5

Investments in the Air Force maintenance infrastructure. SOURCE: Debra K. Tune, Principal Deputy Assistant Secretary of the Air Force for Installations, Environment and Logistics, Office of the Assistant Secretary of the Air Force for Installations, Environment and Logistics. “Developing the Right Product Support Concepts for the Future.” Presentation to the committee, October 20, 2010.

for the F-22, the F117 engine for the C-17, and the engines for the planned new tanker fleet.

There is tremendous capability at the ALC facilities. In some cases the capabilities exceed what is expected for local maintenance requirements and border on full-scale manufacturing. Some of this is needed, but in a modern facility with modern digitalized technologies, redundancy in the sense of manufacturing capability is not widely needed. Improved planning in response to requirements, flexible manufacturing concepts with a focus on maintenance and repair capabilities, and integration of appropriate repair and maintenance technologies would allow the Air Force to find efficiencies and improve costs.

More than 100 aircraft were in for some type of maintenance or repair at Warner-Robins Air Logistics Center (WR-ALC).18 Significant numbers were being worked outdoors, where they were subjected to numerous weather impacts. In addition, the aircraft were affected by a less-than-optimal production environment because of distance from parts and lighting, among other factors. These conditions do not generally exist in the top-performing echelons of industry but seem to be taken for granted by the Air Force to meet production needs. The workforce accomplishes the work despite the impediments and possesses a terrific “can do” attitude; however, the work is not necessarily efficient, and resources may not be effectively allocated to meet the work volume.

There is significant degradation of base infrastructure. Aging facilities have potential for catastrophic loss of heating, cooling, power, and other utilities systems that are essential for production. Although these disruptions occur from time to time at all Air Force installations, in the depot production environments, where work center revenue accrual may be in the hundreds of thousands of dollars per day and millions over the center, the impact is real, immediate, and measurable.

Investment in Infrastructure

The Ogden (OO-ALC), Oklahoma City (OC-ALC), and WR-ALCs were established in 1940, 1941, and 1943, respectively.19 Over the years, the ALCs have expanded their support to address the changing needs of the military. The ALCs provide support to long-standing platforms as well as to newer platforms that contain advanced technologies. Newer methods of repair and maintenance are often required to support these newer platforms. Reorganization of the maintenance and test areas is required to provide efficiency in returning the platforms to service. The facilities must be upgraded to ensure effective service.

______________

18 The committee visited WR-ALC on January 5-6, 2011.

19 For more information, see http://www.hill.af.mil/library/factsheets/factsheet.asp?id=5830. Accessed May 16, 2011.

TABLE 3-1 Comparison of the Needed Maintenance Costs Versus the Budgets

|

|

||

| Millions of Dollars | ||

|

|

||

| Base | Needs | Budget |

|

|

||

| Tinkera | >985 | 32-55 |

| Odgenb | >800 | 4 |

| Warner-Robinsc | 4-5 | |

|

|

||

aFloyd Craft, Director, 547th Propulsion Maintenance Squadron. “Engine Test Cell Strategy.” Presentation to the committee on January 12, 2011.

bMajor General Andrew E. Busch, Commander, OO-ALC. “Ogden ALC Mission Briefing.” Presentation to the committee on January 31, 2011.

cBrigadier General Lee K. Levy, II, Commander, 402nd Maintenance Wing. “402 MXW Perspective to the Air Force Studies Board.” Presentation to the committee on January 6, 2011.

Available funds are not sufficient to keep up with the needs of maintaining, repairing, and updating old facilities and for providing new capabilities. At the 402d Maintenance Wing at WR-ALC, the average building age is 29.4 years with the oldest building being 68 years. At OC-ALC the buildings date back to the 1940s, and many of the original systems are still in place. A comparison of the cost of needed maintenance versus the budgets is shown in Table 3-1.

The maintenance needs shown in Table 3-1 illustrate the disparity that exists between the resources (budget) available for infrastructure maintenance and the perceived needs for infrastructure maintenance. These requirements are those that are foundational to maintaining infrastructure and include plumbing, electrical, and HVAC systems as well as the pavements, buildings, and test stands. There are concerns about catastrophic events in which failure of any of these systems could have an adverse impact on the bases’ missions. Insufficient maintenance and upgrades can result in failures that are not easily repaired, resulting in delays to making airplanes available. Although OC-ALC has leased an updated, former General Motors facility, it is used primarily for manufacturing, component repairs, and parts replacement and not for testing. The test facilities are old and cannot be utilized with the newer platforms that are a part of the future plans of the base. The facilities’ layouts are also an important consideration. Although the ALCs have applied some amount of lean practices to optimize rate and flow, the facilities must be correctly aligned to allow for this optimization.

The bases have accepted more and different work because of movement of work from other bases, but this desire for flexibility creates challenges, because current facilities that are inadequately maintained can be taxed by new test fixtures, equipment, and methods. Newer platforms often contain new technologies, and the facilities must be updated to accommodate repair and maintenance technologies

that can support these platforms. This may not be possible with the current facilities because of the aged power, plumbing, and other systems. In short, the investment in facilities maintenance is not adequate to accommodate current workloads and to address future needs.

Ground Equipment

Ground support equipment typically includes all implements, tools, and devices (mobile or fixed) required to inspect, test, adjust, calibrate, appraise, gage, measure, repair, overhaul, assemble, disassemble, transport, safeguard, record, store, or otherwise function in support of a platform, either in the research and development phase or in an operational phase. Different equipment is used to assess, repair, or provide maintenance, and test for the quality of operational outcomes. Although the ground equipment tends to be old, it is adequate to provide these functions for current needs. However, the equipment will not be adequate to perform new work that is planned for the ALCs, such as an increase in new testing for the C-17 at OC-ALC.20

Finding 3-3. Several critical plant and equipment investments will be needed in the near future. Without these investments, the Air Force will not be able to fully support current and future organic workloads, and thus will face longer periods of CLS with the inherent 10 U.S.C. § 2466 ramifications.

Recommendation 3-1. The Air Force should continue funding depot plant and capital equipment and, at the same time, be guided by focused analyses to ensure that constrained funding is provided to the most critical sustainment needs to avoid future support impacts and to meet 10 U.S.C. considerations.

CURRENT AIR FORCE SUSTAINMENT PROCESSES

The following section provides a broad review of Air Force sustainment processes. Some of these processes are addressed in detail elsewhere in this report. Covered in this chapter, however, are workforce,21 acquisition, the supply chain, maintenance processes, resourcing efforts, Fleet Viability Board efforts, logistics

______________

20 Floyd Craft, 547th Propulsion Maintenance Squadron director. “Engine Test Cell Strategy.” Presentation to the committee on January 12, 2011.

21 Workforce is defined in this report as the policies, procedures, and issues affecting the development and retention of the knowledge and skill sets needed by the labor force to maintain existing systems and to be ready to maintain future systems.

support processes, Expeditionary Logistics for the 21st Century (eLog21), and obsolescence and diminishing manufacturing sources.

Workforce

This section discusses knowledge and skill sets, engineering staff focus, and personnel allocation. The ALCs expressed concern about present-day workforce knowledge and skill sets and the ongoing retirements of many senior employees. At one of the ALCs, the average employee has only 5 years on the job.22 Across the sustainment enterprise and particularly at the ALCs, a number of active recruitment and knowledge retention actions are ongoing, such as recruiting personnel from nearby career and technical education (CTE) schools, arranging with state technical training agencies, and chartering senior employees to mentor junior employees. In this way, long-term skills and experience are passed on to supplement and fuse with new techniques/approaches learned at the CTE schools.

Harvesting and maintaining knowledge and lessons learned might be further improved by making information-sharing systems, such as SharePoint, available on the shop floor. Knowledge accumulation, editing, and distribution would, of course, need to be addressed when implementing these systems. Continued use of formal training programs is another useful investment, especially as technology insertions occur. These observations are consistent with the Air Force Maintenance Strategic Plan.23

At the same time, there are real concerns with the evolution of CLS platforms to organic support, such as where the technical workforce will come from an era of constrained workforce levels and new technology introduction. The belief is that the workforce applied to current legacy systems will easily transition to the newer platforms or support concepts. This may be more theory than reality in practice. In addition to airframe and other logistics issues, questions exist regarding software sustainment over the lifetime of a weapon system.24

Finding 3-4. At the current time, the ALCs are doing an adequate job of personnel recruitment and knowledge retention. However, long-term concerns exist as retirements increase and systems move from CLS to organic support.

Equally important to the overall sustainment activities is the engineering staff for depot maintenance support. A common issue for the three ALCs relates to

______________

22 Major General Bruce A. Litchfield, personal communications to committee members on January 11, 2011.

23 USAF. 2008 Air Force Maintenance Strategic Plan.

24 Software sustainment is discussed in considerable detail in Chapter 4.

engineering support for the depot maintenance repair lines. Engineering support is provided by the program offices and the commodity management offices. The engineering staff in these offices has conflicting priorities between depot support, evaluations of field requests, requests for manufacturing first article tests, and so on. In fact, engineering disposition for issues on the aircraft, engine, and commodity repair lines is delayed from time to time with the attendant impact to production schedules. Engineering resources are constrained as part of the O&M-funded manpower baseline and often don’t reflect workload needs. Interestingly, the United States Navy reported that these issues are nonexistent at its Fleet Readiness Centers.25 Although the Navy’s engineering staff supports the same type of function, the leadership recognizes and prioritizes support to the maintenance operations.

As manpower resources were constrained over the past several years, the Air Force eliminated Combat Logistics Support Squadrons at the ALCs, an action with unintended consequences. These squadrons provided deployable military maintenance specialists to perform depot-level tasks at field locations. Since the squadrons’ elimination, qualified civilian rather than Air Force military craftsmen are now deployed to perform the depot-level tasks. One depot maintenance supervisor explained that this change has created her most pressing challenge: although she has a full complement of specialists, many are temporary or contract employees who have backfilled the skilled workforce. The learning curve for these new employees has been high, and times to complete tasks have been higher than they should be, which has routinely impacted the schedule.26

Finding 3-5. The ALCs have a great demand for engineering support. At the same time, the engineering staffs have conflicting priorities.

Recommendation 3-2. The Air Force should establish clear priorities for engineering activities and consider examining lessons learned and the applicability of the Navy model of workforce issues.

Acquisition

A key message repeated by Air Force officials is that sustainment must be considered at the outset of the acquisition life cycle. During the acquisition process, a systems view of the platform with a definition of the total life cycle is required to accurately reflect realistic requirements. Lessons learned from current plat-

______________

25 Captain Fred Melnick et al., Fleet Readiness Center Southwest, Roundtable Discussion, March 29 2011.

26 OC-ALC program managers, personal communications with committee members on January 11, 2011.

forms can increase accuracy of predicted sustainment needs relative to scheduled maintenance. Moreover, documented findings and trends related to aging aircraft, condition-based maintenance, exposures to extreme environments, and product disposal can provide a more accurate picture of the processes and costs related to the acquisition process. As pointed out earlier in this chapter, Figure 3-1 highlights the gaps with respect to the consideration of logistics in the early planning of programs. Further, long-term sustainment needs are often minimized early in the acquisition process in favor of performance or shorter-term financial considerations. Early involvement of sustainment personnel at multiple points before Milestone A will allow for more accurate planning and budgeting of sustainment needs.

Finding 3-6. Currently, sustainment resource planning is not adequately planned and budgeted for during the acquisition process.

Supply Chain

From the purest standpoint, the supply chain refers to the complete cycle of acquiring the raw material to produced goods; the manufacturing, stocking, and storage of the produced goods; transportation to locations of needs; resupply efforts; maintenance activities on these items; disposition after consumption; condemnation; and so on. In this particular discussion, the supply chain is confined to the spare parts available to users and to the approaches for obtaining products and services (i.e., contractor-operated or organic processes).

The organic supply chain processes are those activities that are supported by the Air Force and the DoD, including the ALCs and the Air Force Global Logistics Support Center (AFGLSC). The AFGLSC is the principal manager of the Air Force supply chain, and the Defense Logistics Agency is organic to DoD. Many organizational and process changes have been associated with these organizations over the past six years. These changes and the degrees of success are covered in considerable detail in Chapter 4 because they directly involve resourcing of the ALCs.

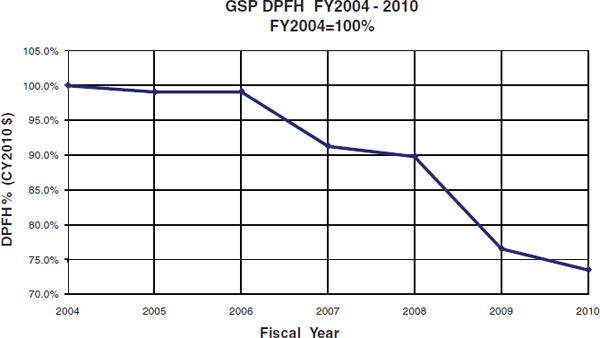

The committee observed several examples of very effective and reasonably efficient contractor-operated supply chains. For example, in its partnership with Boeing for C-17 lifecycle support, the Air Force has retained limited core depot maintenance capability and maximized the use of the contractor support and supply system, which has led to a significant reduction in cost per flight hour as highlighted by Figure 3-6.

Such partnerships are in line with DoD Instruction 5000.02: “Support Concepts for new and modified systems shall maximize the use of contractor provided, long term, total life logistics support that combines Depot Level maintenance along

FIGURE 3-6

Dollars per flight hour (DPFH) for the C-17 FY2004-FY2011. SOURCE: Gustavo Urzua, The Boeing Company. Personal communication with the committee on May 19, 2011. NOTE: The data portrayed are based on the Boeing contract with the Air Force and include profit and full award fee and are a performance-based logistics yearly contract for labor and material.

with wholesale and selected materiel management functions.”27 The Air Force and the contractor have a shared infrastructure that reduces organic sustainment footprints, promotes Air Force partner access to the international C-17 infrastructure, generates opportunities for robust exchange agreements (spares, equipment, Tech Data), and minimizes the size and cost of spares pools.

Finding 3-7. Collaborative partnerships with contractor-operated supply chains have resulted in improved efficiencies and lowered costs.28

Maintenance Processes

Maintenance processes consist of field and depot activities that allow the platforms to be ready for service. Maintenance activities include scheduled maintenance as well as unplanned repair or replacement activities. Both scheduled and

______________

27 DoD. 2008. Operation of the Defense Acquisition System. December 8. http://elastic.org/~fche/mirrors/www.jya.com/dodi/dodi-5000-02.pdf. Accessed August 18, 2011.

28 This topic is discussed extensively in Chapter 4.

unscheduled maintenance can be diverse and complex because of the age and variety of platforms and the conditions to which these platforms are exposed. Maintenance activities can range from simple to complex replacements/repairs to complete fabrication, manufacturing, and installation of complex parts. Maintenance is a key element to the aircraft availability metric.

Challenges to maintenance include inadequate planning, part shortages, and increased turn time, all of which can occur with planned maintenance and thus necessitate unscheduled work and inefficiencies. However, these challenges can be exacerbated by conditions such as aging platforms, unplanned damage, and new technologies that can result in discoveries of new and/or unexpected types of damage requiring extensive or yet-to-be identified technologies to be repaired or maintained.

Additionally, a lack of synchronization between field and depot activities, programmed depot maintenance cycles, stove-piped processes, and general maintenance execution can contribute to not attaining the target aircraft availability. A common and centralized data collection system would allow the ALCs to standardize processes and share technical data, best practices, and lessons learned, which would help to streamline and standardize processes for maintenance and repair.

Finding 3-8. There is no centralized database to document technical activities, best practices, and lessons learned to enhance knowledge management and process improvement.

High Velocity Maintenance (HVM) is one example of Air Force efforts to improve depot maintenance processes. The HVM methodology has been considered and adopted in some areas to improve maintenance performance, reduce flow days, and reduce field-level maintenance. Additionally, the benchmarking of commercial companies and the application of best practices and lean processes are being implemented to streamline maintenance activities. Different lean tools are applied as needed to decrease the time to delivery.29,30

Resourcing Processes

The Air Force has a complex, thorough, and highly participative resourcing process for funding its requirements. Following the direction and guidance of the Office of the Secretary of Defense (OSD), the Air Force assembles its current

______________

29 Steve Walker. “High Velocity Maintenance (HVM).” Presentation to the committee, January 12, 2011.

30 Captain Tyler B.L. Schroder. “F-22 High Velocity Maintenance Program Review.” Presentation to the committee, January 7, 2011.

and future budgets in a Future Years Defense Program (FYDP) that summarizes resources (funding, manpower, and forces) as approved by the Secretary of the Air Force (SECAF) and OSD. The FYDP also reports Planning, Programming, Budgeting, and Execution decisions and funding for the next six fiscal years.

The Air Force programming process is essentially the first step to assembling the information and resources necessary to create a budget. The resources and force structure are aligned in a Program Objective Memorandum (POM) that reflects Air Force priorities. At this point in the process, all fiscal resources are fungible, which means they can be realigned between programs and appropriations as needed to fund priorities as outlined by Air Force leadership. During the course of this study, the committee learned of issues and challenges related to the “color of money,” that is, not having the money in the right appropriation for spending on a project or program. Although this misappropriation may be a constraint during the fiscal year of execution, it can be largely mitigated during the POM process. Funding issues that arise during the budget year of execution can often be resolved by the Air Force reprogramming process, whereby the Service seeks congressional approval to realign resources between appropriations to fund critical high-priority shortfalls, thereby resolving many color of money issues.

Within the WSS enterprise, the Air Force has implemented a Centralized Asset Management (CAM) system that consolidates resources previously managed by the operational commands. Fiscal resources have been realigned from the operational commands to Air Force Materiel Command (AFMC), are managed at the enterprise level, and include the funding for spare parts, depot-level maintenance, sustaining engineering, technical orders, and aviation fuel.

The CAM program offers several benefits to AFMC and the Air Force. Prior to its implementation, major commands were often faced with difficult decisions related to O&M funding shortfalls in base support, communications, real property maintenance, and many other areas of base activity. As a result, commands would often defer inducting aircraft or engines, previously funded for depot work, and elect to spend those resources on other high-priority shortfalls. Centralizing this funding now provides AFMC with the ability to more effectively manage WSS, scheduling, and work flow. Over time, this process will improve the sustainment levels within the Air Force.

Fleet Viability Board

The Fleet Viability Board provides technical assessments of aging aircraft to both the SECAF and the Chief of Staff of the Air Force (CSAF). Viability is defined as “It can do what we need it to do, when we need it to do it, at a price we are willing

to pay.”31 The metric used is the cost per available aircraft or the sum of the modification costs plus the operation and support (O&S) costs per available aircraft. The Fleet Viability Board does not believe that current sustainment investments, infrastructure, and processes are adequate to sustain aging legacy systems and their support equipment because of competition for funding and the short-term view of sustainment. It has recommended that changes be made to contract types to ensure visibility of costs and the deployment of health monitoring technologies.

Logistics Support

Of the many processes that are used to sustain Air Force weapon systems, logistics support is overarching and vitally important, but often under-recognized. In part, logistics support includes the processes associated with engineering data, engineering drawings, technical orders, spare part provisioning, cataloging, and others. Without the successful execution of these and other activities, the WSS would grind to a halt. The committee placed logistics support in the category of too important to ignore but too detailed to cover in depth under the terms of this report. However, the committee recognizes that it is entwined in WSS. The decisions that occur very early in a weapon system’s life cycle affect logistics support processes, such as re-procurement, day-to-day supply, and maintenance support, over the remainder of the system’s life cycle and determine success or failure as well as costs. Logistics support processes are precisely among the key processes that are impacted when decisions are made for various support concepts. Consequently, when decisions makers arrive at major milestones, the sub-elements of logistics support must be considered. Simply put, early decisions should be made with full understanding of their long-term costs and implications.

eLog21

eLog 21 is a transformational campaign aimed to drive improvements to Air Force logistics support and WSS. This umbrella effort consists of multiple logistics transformation initiatives and primarily aims to increase equipment availability and reduce operations and support costs. It addresses the fact that future budgets will remain flat or decrease, resulting in calls for more “efficiencies.” It relies heavily on process tools such as LEAN and Six Sigma and introduces a Logistics Enterprise Architecture (LogEA) as a roadmap, which provides an authoritative source to define both operational and systems approaches to Air Force logistics. eLog21 defines and aligns the organizational vision, mission, goals, objectives, and processes

______________

31 Fran Crowley, Director, Air Force Fleet Viability Board. “AF FVB Feedback for AF Studies Board.” Presentation to the committee on December 7, 2010.

with information technology initiatives. It established the aforementioned ILCM Executive Forum and aids in the integration of Air Force acquisition and logistics policy. It aims to ensure that life-cycle logistics are addressed at every step from the lab, to the requirements, to the design and testing, to the manufacturing and delivery process. It explores innovative technologies and incorporates a number of product support initiatives.

In addition to the LogEA roadmap, the Expeditionary Combat Support System (ECSS) is a key underpinning of eLog21. ECSS represents a standardization of sustainment processes at every level and uses an Enterprise Resource Planning tool to implement and enforce the approved rule set. ECSS is discussed further in Chapter 4, but it is worthwhile to note here that the Air Force estimates that 240 legacy systems will be replaced by ECSS. The Air Force has spent $897 million through FY2010 on ECSS, expects to spend an additional $2.71 billion on investment through FY2017, and will see a total life-cycle cost of $5.1 billion through FY2027.32 ECSS is clearly a major Air Force investment in the future.33 Phase I of ECSS development and deployment has been challenging, and the program is at risk, but the need for ECSS or its equivalent is undeniable.

Finding 3-9. eLog21 shows promise in driving improvements to Air Force logistics support and WSS. The campaign deserves full visibility and should be the direct responsibility of the sustainment commander.34

Obsolescence and Diminishing Manufacturing Sources

Obsolescence and diminishing manufacturing sources are two conditions that can affect the production and sustainment of the platforms. Obsolescence is defined as the process or condition by which a piece of equipment becomes no longer useful. It can also mean that the form and function are no longer current or available for production or replacement/repair. Introduction of new technologies may cause older technology to become less supportable because of diminished availability of parts and suppliers. Obsolescence must be resolved before the process of dealing with Diminishing Manufacturing Sources and Material Shortages (DMS/ MS) occurs, especially if the system is still in production.

DMS/MS is loss or impending loss of the last known manufacturer or supplier

______________

32 Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. Personal communication to the committee, May 23, 2011.

33 Government Accountability Office. 2010. DoD Business Transformation: Improved Management Oversight of Business System Modernization Efforts Needed. October. Available at http://www.gao.gov/products/GAO-11-53. Accessed May 16, 2011.

34 eLog21 is discussed in greater detail in Chapter 2.

of raw materials and other critical components for production or repair/replacement parts. As the weapon systems’ service lives are extended, the loss of supply chain and manufacturing capability are an increasing concern. During the course of the study, Air Force leaders repeatedly emphasized the importance of managing obsolescence and DMS/MS.35,36

Ultimately, both obsolescence and DMS/MS will result in the inability to provide parts or components to the weapon systems, which poses a risk to readiness. Performance Based Logistics (PBL) is an important obsolescence mitigation strategy. DoD Instruction 5000.02 states, “The PM shall employ effective Performance-Based Life-Cycle Product Support (PBL) planning, development, implementation, and management. Performance-Based Life-Cycle Product Support represents the latest evolution of Performance-Based Logistics. Both can be referred to as ‘PBL.’ PBL offers the best strategic approach for delivering required life cycle readiness, reliability, and ownership costs.”37 Because this process is performance-based and focuses on weapon system availability and lowering costs, it can be accomplished organically, through suppliers, or a combination thereof. PBL tackles the problem of aging by instituting incentives between the government and the weapon system manufacturer to ensure that support providers continuously modernize and improve their systems and methods of support.

CONCLUDING THOUGHTS

This chapter has addressed the sustainment investments, infrastructure, and processes that are currently in place. Investments in sustainment have not met the challenges of supporting an aging, highly stressed fleet. Current acquisition practices do not consider sustainment early enough in the planning process. The ALCs function adequately, but they are not optimized for current and future needs. Investments in infrastructure, personnel, and ground equipment are needed for optimization. Activities such as eLog21 and HVM are aimed at improving processes for maintenance.

______________

35 Sue Lumpkins, Deputy Director of Logistics, Office of the Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters United States Air Force. “Air Force Studies Board Sustainment Study.” Presentation to the committee, October 20, 2010.

36 Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgetary Considerations Related to Sustainment.” Presentation to the committee, October 21, 2010.

37 DoD. 2008. Operation of the Defense Acquisition System. December 8. http://elastic.org/~fche/mirrors/www.jya.com/dodi/dodi-5000-02.pdf. Accessed August 18, 2011.