Uranium Mining,

Processing, and Reclamation

Key Points

• The choice of mining methods and processing parameters for uranium recovery depends on multiple factors that are primarily associated with the geological and geotechnical characteristics of a uranium deposit—its mineralogy and rock type, as well as a range of other factors.

• Uranium recovery from ores is primarily a hydrometallurgical process using chemical processes with industrial chemicals, with a lesser dependence on physical processes such as crushing and grinding.

• Mine design—whether open-pit or underground—requires detailed engineering planning that would include pit and rock stability considerations, as well as ventilation design to account for the presence of radon and other respiratory hazards.

• With the ore grades expected in Virginia, many of the technical aspects of mining for uranium would be essentially the same as those applying to other hard-rock mining operations. However, uranium mining and processing add another dimension of risk because of the potential for exposure to elevated concentrations of radionuclides.

• A complete life-cycle analysis is an essential component of planning for the exploitation of a uranium deposit—from exploration, through engineering and design, to startup, operations, reclamation, and finally to decommissioning leading to final closure and postclosure monitoring.

This chapter outlines the basic steps involved in mining, processing, and reclamation that might be suitable for uranium ore deposits in the Commonwealth of Virginia. For uranium ore deposits, the choice of mining methods and processing options is very deposit-specific and dependent on many variables such as the quality and quantity of the ore, the shape and depth of the ore deposit, site-specific environmental conditions, and a range of other factors. Accordingly, the description of how uranium mining is undertaken in this report is generalized and at a high level.

Open-pit mining and underground mining are the two types of mining that would be used to exploit uranium deposits in Virginia. These mining techniques can be used individually or combined; for example, many mines start as open-pit operations and continue as underground operations to follow a deposit deeper below the surface. This chapter presents a short overview of both mining methods, and the considerations involved in using them. A short description of the in situ leaching/in situ recovery (ISL/ISR) uranium mining technique and other uranium mining techniques are included for completeness, even though, based on current knowledge of known uranium occurrences in Virginia, ISL/ISR is unlikely to be applicable.

After the uranium ore is removed from the ground, it must be treated at a hydrometallurgical processing facility to remove impurities and produce yellow-cake. The specific type of hydrometallurgical process is also deposit-specific, dependent not only on the nature of the uranium mineral but also on the nature of the host rock as well as environmental, safety, and economic factors. Waste rock handling, tailings disposal, and final reclamation and closure are also discussed in this chapter because they are critical parts of a mine’s life cycle.

One overarching consideration throughout the entire mining, processing, reclamation, and long-term stewardship process is the need for meaningful and timely public participation throughout the life cycle of a mining project, beginning at the earliest stages of project planning. This requires creating an environment in which the public is both informed about, and can comment upon, any decisions made that could affect their community (see additional discussion in Chapter 7).

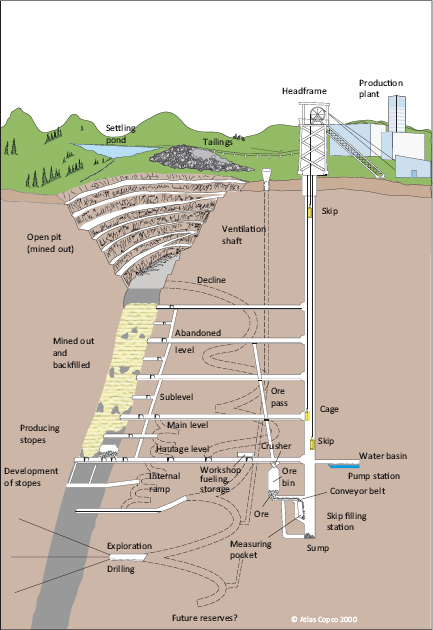

Based on the current understanding of uranium deposits in the Commonwealth of Virginia, extraction of uranium ore would use open-pit mining, or underground mining, or a combination of both (Figure 4.1). These general terms incorporate a large variety of design possibilities—there are as many methods of mining uranium as there are orebody sizes, shapes, and mineral constituents. The orebody size, location, orientation, rock quality, and the distribution of the valued minerals in it—along with site location and infrastructure—all play a part in the selection of the mining method and the overall plan for developing an orebody. Mines may range in size from very small underground operations, with considerably less than 100 tons of production per day, to large open-pits that move hundreds of thousands of tons of ore and waste per day. The descriptions of uranium occurrences in Virginia contained in the previous chapter indicate that most potential deposits will likely be hosted in a hard-rock setting, although geopolitical and market factors may in time enable uranium production as a byproduct of heavy mineral sand mining.

Underground Mining

Site-specific conditions, such as the depth of the ore deposit, its shape, surrounding geological conditions, and other factors, could result in the selection of an underground mining technique. In that case, the primary opening into an underground mine to provide access for people, materials, and equipment and to enable the ore to be brought to surface can be a shaft sunk vertically or on an “incline”; a “decline,” which is a ramp driven into the earth usually in a spiral fashion; or an “adit,” which is a horizontal opening driven into the side of a hill or mountain (Figure 4.1).

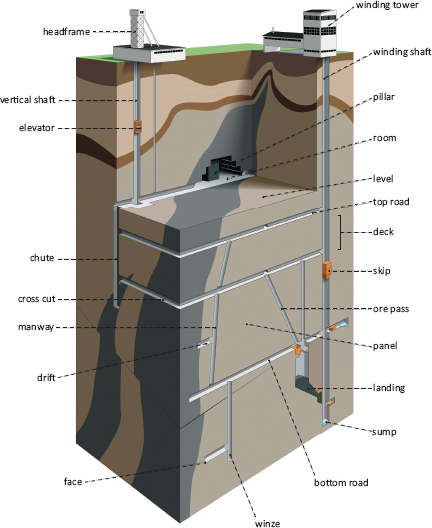

Both vertical and inclined shafts must be equipped with hoists and head-frames, which are the structures at the top of the shafts that enclose and operate the hoists used for transporting ore and mine personnel (Figure 4.2). Ramps usually spiral downward so that rubber-tired mobile equipment will have access to the mine. In some cases, ramps are driven in a straight line to accommodate conveyor belts. Horizontal or level mine workings are referred to as “crosscuts” and “drifts”; vertical access workings are referred to as “raises” or ”winzes.”

Generally, orebodies are either vein type, massive, or tabular in shape, and both the shape and ore thickness influence the mining method used. Vein-type orebodies usually dip steeply, and this steepness can be used during mining with the ore being allowed to fall to lower levels to an extraction accessway (Figure 4.3). Uranium orebodies are often narrow and irregular. The strength of the ore material and the surrounding host rocks, as well as the ore grade and the distribution of the ore, influences the ore removal method. Mined openings may be either supported or self-supported. Some supported openings are held up

FIGURE 4.2 Underground mine headframe and hoist room. SOURCE: Photograph courtesy Richard Cummins/SuperStock.

by backfill, that is, waste rock or aggregate placed in the openings shortly after they are mined out. Others are held up by timber, metal supports, concrete, rock bolts, or a combination of methods. The different techniques for underground mining have very specific names—cut and fill, drift and fill, shrinkage stoping, and block caving—and they are described below in very general terms based largely on ILO (2006):

Cut and fill mining is used in steeply dipping or irregular ore zones, where the mineral deposit is contained in a rock mass with good to moderate stability. Cut and fill mining removes the ore in horizontal slices starting from a bottom cut and advances upward, allowing the stope boundaries to be adjusted to follow irregular mineralization. This permits high-grade sections to be mined selectively, leaving low-grade ore in place. Access to the ore zone is by “ramping down” from a crosscut, and then holes are drilled in the rock face followed by blasting with explosives. After the ore is removed from the “cut,” the resulting space is backfilled with waste rock or tailings, but with enough space left open to mine the next slice. Although cut and fill mining is relatively expensive, it minimizes ore loss and ore dilution.

Drift and fill mining is similar to cut and fill, but is used where the ore zone is too wide for a single cut. As with cut and fill mining, ore is removed after

FIGURE 4.3 Underground mine with vertical shaft. SOURCE: Reproduced with the permission of QA International (http://www.qa-international.com from the book, “The Visual Dictionary” ©QA International 2003. All rights reserved).

blasting, and the resulting space is packed with fill material. With drift and fill mining, after completion of the first drift, a second drift is driven adjacent to the first. Additional drifts are developed until the ore zone is mined out to its full width, after which a second cut is started on top of the first cut.

Shrinkage stoping is a mining method that can be used for steeply dipping orebodies. Ore is extracted in horizontal slices, starting at the stope bottoms and advancing upward. Most of the blasted rock remains in the stope to provide a working platform for the miner drilling holes in the roof, and and it also serves to keep the stope walls stable. Because blasting increases the volume of the rock by about 60 percent, some 40 percent of the ore is drawn at the bottom during stoping in order to maintain a working space between the top of the blasted rock and the roof. The remaining ore is removed after blasting has reached the upper limit of the stope. Shrinkage stoping allows mining that is very selective, but one disadvantage is that there is a delayed return on capital investment because most of the ore stays underground until mining of the stope is completed.

Room and pillar mining is commonly done in flat or gently dipping ore-bodies. Room and pillar mining accesses an orebody by horizontal drilling advancing along a multifaced front, forming empty rooms behind the producing front. “Pillars” of rock are left between the rooms for support to keep the roof from caving. The usual result is a regular pattern of rooms and pillars, with their relative size representing a compromise between maintaining the stability of the rock mass and extracting as much of the ore as possible. In some room and pillar mines, once the rooms are mined out the pillars can be mined, starting at the farthest point, allowing the roof to collapse. This allows the ore contained in the pillars to be accessed.

Block caving is a large-scale mining method that is used to mine massive orebodies with specific characteristics that enable gravity to do part of the work. Preparation for block caving requires long-range planning and extensive initial development involving a complex system of excavations beneath the orebody. An “undercut” is mined under the orebody, and cavities are excavated to serve as repositories for caving rock to be collected. The orebody is drilled and blasted above the undercut, and ore is removed through the accessway. Because of the characteristics of the orebody, material above the first blast area falls into the collection areas. As ore is removed from the collection areas, subsequent caving provides steady availability of ore. Extensive rock bolting and concrete lining are required to keep the openings intact, and if caving stops and removal of ore continues, a large void may form that can have the potential for a sudden and massive collapse.

Ground Control in Underground Mining

Ground control—the prevention of rock collapse into a mined cavity—is an integral part of mine design to ensure a safe underground working operation.

Ground control design requires consideration of many factors, such as rock type, groundwater inflow, geological features, deposit shape and size, and others. Ground control may be as simple as leaving adequate support columns during the mining operation, or may involve more complex systems that use cemented backfill to infill voids. Methods also include the use of “rock bolting” and screens for stability, and shotcrete (i.e., a spray-on cement mixture) may be used to stabilize loose rock.

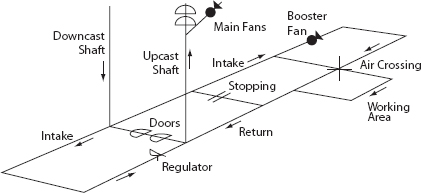

Ventilation in Underground Mining

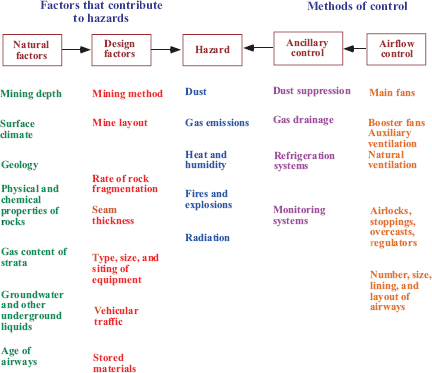

Ventilation is a critical consideration for all underground mining. Adequate ventilation is required to provide fresh air to miners and to reduce exposure to gases, products of combustion, dusts (including siliceous material), heat and humidity, radioactive gases and solids, and diesel gases and particulate matter. For many hazardous components, ventilation is used to first dilute contaminants to a safe level, and then to remove them. The most common method for ventilation in the subsurface is by airflow from the surface produced by large fans. Underground booster fans can also be used to ventilate specific areas of a mine (e.g., Figure 4.4).

The design of a major underground ventilation and environmental control system is a complex undertaking (Figure 4.5). It requires a systems engineering approach that encompasses the entire mining process, to ensure that the consequences of changes in the mining techniques and size of the mine, and other factors, are accounted for in the control system design and operation.

FIGURE 4.4 Schematic diagram showing a simple mine ventilation system. SOURCE: McPherson (1993); with permission from Springer Science and Business Media.

FIGURE 4.5 Multiple factors interacting in the creation and control of hazards in a subsurface environment. SOURCE: McPherson (1993); with permission from Springer Science and Business Media.

Open-Pit Mining

Compared with underground mining, an open-pit mine is usually less expensive. Unlike underground mining, equipment size is not restricted by the size of the opening to the mine and consequently open-pit mining can take advantage of economies of scale, using larger and more powerful shovels and trucks. Ore production is generally faster in open-pit mines, and lower costs per ton for the mined ore means that lower grades of ore can be mined economically. Open-pit mines do not require the extensive mine ventilation of underground mines, because generally there is sufficient air movement without ventilation equipment. Air monitoring for radon is usually carried out in case there is an atmospheric air inversion; however, these are usually short-lived, and mine operations are reduced in these instances. Air inversions may also be relevant for other exposures, for example, diesel vapors and particulates.

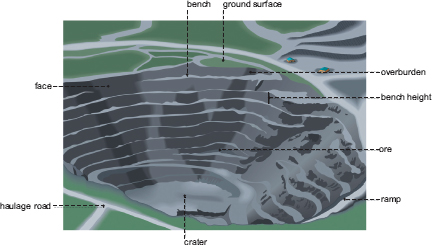

Open-pit mining is appropriate when the ore is near the surface, particularly if the ore deposit is relatively large and there is little overburden. There are several important design considerations for open-pit mines. First, the open-pit walls need to be constructed and angled so that they are strong enough to support a safe slope. Second, the depth to the ore will dictate how much waste overburden will need to be mined before production can begin. And third, the size of the first “bench” of any open-pit mine (Figure 4.6) must be planned carefully, as each successive bench will be smaller than the last one and, consequently, the dimensions of the initial bench will dictate the depth of the final open-pit.

The stripping ratio—the ratio of the amount of waste rock that has to be mined to the amount of ore mined—is a critical element for deciding the economic feasibility of exploiting a particular ore deposit with open-pit or underground mining. In most cases, this stripping ratio is high for the first bench, and decreases steadily for each successive bench. Obviously, an open-pit mine will only be economically feasible if the cost of mining the waste rock does not exceed the value of the ore.

Ore Recovery in Underground and Open-Pit Mining

Ore recovery involves a number of steps that are common to both open-pit and underground mining. The first step is to drill a pattern of small holes in the rock and the ore using electric or compressed-air hydraulic drill “jumbos.”

FIGURE 4.6 Typical open-pit mine structure. SOURCE: Reproduced with the permission of QA International (http://www.qa-international.com from the book, “The Visual Dictionary” ©QA International 2003. All rights reserved).

Explosives are loaded into the holes, and then detonated to break the rock. Commonly, nitroglycerine dynamites and ANFO (i.e., a mixture of ammonium nitrate fertilizer and fuel oil) are used as blasting agents. The blast is initiated by a high explosive blasting cap, usually with a primer.

Once the ore has been fragmented by blasting, and a suitable time interval has elapsed to allow safe reentry based on explosive gas dissipation, the ore is loaded into either trucks or rail cars to be transported to the processing area. In some cases, initial ore processing (often crushing) occurs underground or in the open-pit, followed by transportation for further processing via a conveyer belt system. After an underground area has been mined out, it is often necessary to backfill it with some waste material—this can occur immediately, or it can be delayed until the stope is completely mined out.

For safety reasons, large blasts in underground mines are usually set off electrically from the surface once all underground workers have reached the surface of the mine, usually at the end of a work shift. This precaution also limits exposure to the dust and fumes caused by a blast, because the ventilation system can flush the underground atmosphere before the next shift goes underground.

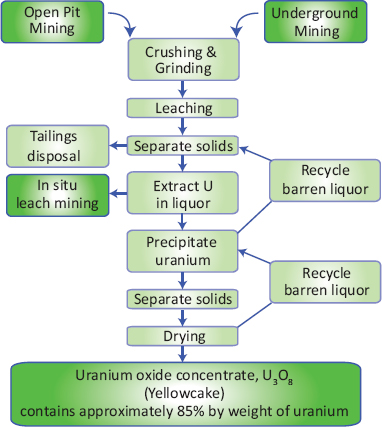

A hydrometallurgical process is used to produce uranium from uranium ore, using chemicals and solutions to extract the uranium from the ore matrix. The process is complete when the final uranium product, known as yellowcake, is produced in a sufficient high purity (typically 75 to 85 percent U3O8) so that it can be used in the remainder of the nuclear fuel production cycle.

There are four major process routes for uranium processing—conventional agitation leach, recovery as a byproduct, heap leaching, and ISL/ISR. This section provides an overview of these options, with emphasis on the conventional agitated leach process. In situ recovery is briefly discussed for the sake of completeness, but is not evaluated in detail because, as noted previously, it is unlikely to be appropriate for use in Virginia. Also for completeness, this section will briefly describe byproduct recovery.

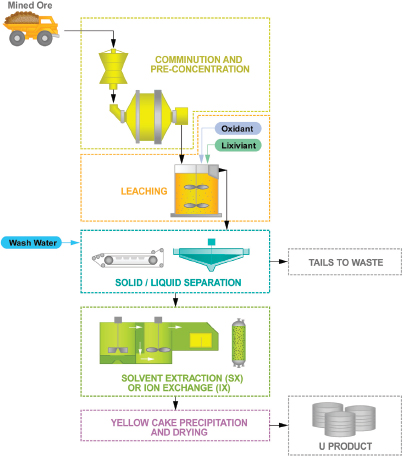

A simplified schematic for uranium processing is shown in Figure 4.7, outlining the main unit processes required to produce the final high-purity uranium concentrate. There are variations within each unit process as required by the specific uranium ore being processed and the availability of specific chemicals and equipment.

Process Choice

Although the steps for recovery of uranium from ore can be shown simply (Figure 4.7), the actual choice of the final processes is complex and requires careful advance planning, analysis, and design. As with all decisions about the

FIGURE 4.7 Uranium processing flow diagram showing the unit process steps, from ore produced by an open-pit or underground mine through to yellowcake production. SOURCE: WNA (2010b).

suitability of a particular ore deposit for mining suitability, a range of economic, social, and environmental issues are critical. The following primary considerations dictate process choice (El-Ansary and Schnell, 2010):

• Mining method

• Type of deposit

• Size of deposit

• Mineralogy of the ore

• Uranium grade

• Geographical location

• Climate

• Required production capacity

• Regulations and permitting

• Workforce availability and qualifications

• Deposit and country history

• Commodity volatility

• Capital cost

• Operating cost

• Schedule

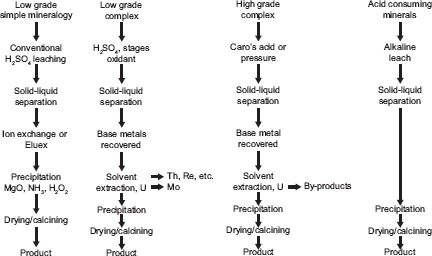

Extensive planning, testing, and analysis of the ore and the surrounding rock are required as the first stage in process selection; in general, the type of ore—whether low or high grade, or whether it is a simple or complex mineralogy—can provide a first-order indication of processing options (Figure 4.8).

General Uranium Mineralogy

While the mining method for a particular uranium ore deposit will be determined by the type and size of the deposit, the choice of process will be primarily determined by the ore type and uranium mineralogy. For the ore, the host rock will have the highest influence on process choice except in the case of very-high-grade deposits (+5 percent U3O8); as noted in the previous chapter,

FIGURE 4.8 General overview of process selection based on ore characteristics. SOURCE: IAEA (1993); with permission of the International Atomic Energy Agency.

such high-grade deposits are not anticipated in Virginia. The host rock will be the primary determinant of the type of uranium leaching, either alkaline using a carbonate solution (sodium carbonate and sodium bicarbonate mixture) or acid (normally sulfuric acid; other acids are very rarely used). The quantity of acid or carbonates consumed, combined with the associated process costs, will determine the final process choice.

The nature of the host rocks plays a major part in the design of the sequence of processing steps—the flowsheet (Lunt et al., 2007). The presence of carbonate minerals in sufficient quantity to cause acid consumptions of greater than about 75 to 100 kg per tonne of ore leached is likely to be the deciding factor in favor of carbonate leaching. Generally, using an acid leaching process has advantages in terms of circuit simplicity and offering a greater range of purification options compared with alkaline leaching. However, each situation is evaluated on its own merits. In summary, the ultimate process route selection is influenced by the following (Lunt et al., 2007):

1. The concentration of uranium in the ore, with higher grade material being able to tolerate higher acid consumptions without having to contemplate alkaline leaching

2. The more rapid kinetics of the acid leach over carbonate digestion for the same ore type, which has ramifications on the leaching step and also on the degree of comminution (size reduction, usually by grinding or crushing) required, where acid leaching may not require such a fine grind

3. The presence of valuable byproducts in the ore and the ability of either flowsheet to recover these species economically

4. The price of the reagents themselves and the relative transportation costs

5. Choice of purification step in acid leaching, which is wider than that of alkaline leach circuits, the options for acid circuits including solid ion exchange (fixed bed, continuous countercurrent, resin-in-pulp, and the carousel) and SX (mixer-settler and pulsed column), and possibly combinations of IX/SX

Although ore or rock characteristics govern the overall leach process choice, between alkaline or acid leach, the specific uranium mineralogy must also be considered. Uranium occurs in a very large number of minerals because of its large ionic radius and its two valence states. Uranium minerals occurring in ore deposits (as described in Chapter 3) belong to the following general groups:

• Oxides, which represent by far the most common group of uranium minerals in ore deposits

• Silicates, which are second in importance, and occur in significant concentration in sandstone-hosted deposits

• Titanates, which mostly occur in some sodium-metasomatism related uranium deposits

• Vanadates, which essentially occur in calcretes

• Phosphates, carbonates, oxyhydroxides, arsenates, and other hexavalent uranium minerals, which generally occur as alteration products of other primary uranium minerals, and accordingly are called secondary uranium minerals.

Despite the very large range of uranium minerals that can occur, the most common uranium minerals exploited are uraninite and pitchblende, carnotite, coffinite, brannerite, and torbernite (Table 4.1).

As noted in Chapter 3, uranium in nature is generally found in the U4+ and U6+ oxidation states within the large variety of different uranium-containing mineral species. During uranium processing, the uranium is solubilized with the use of acids (normally sulfuric acid) or in an alkaline form (normally a carbonate or hydroxide form). The sulfate or carbonate requires the uranium to be in the UVI oxidized state, which normally requires the addition of an oxidant in the leaching stage to improve overall metal content. The oxidants most commonly used are oxygen, hydrogen peroxide, sodium chlorate, or manganese dioxide.

Uranium Occurrence in Nature

Uranium in nature occurs over a very wide range of concentrations (Table 4.2). For a uranium occurrence to be considered as a feasible and economic ore deposit, it must be of sufficient size and be amenable to mining and processing. Worldwide, conventional uranium production is from ores that range from very

TABLE 4.1 Chemical Constituents of the Main Uranium Minerals

|

Primary Uranium Minerals |

||

|

Uraninite |

UO2.x |

|

|

Pitchblende |

UO2.x (x = 0.2-0.6) |

|

|

Coffinite |

U(SiO4)1-x(OH)4x |

|

|

Brannerite |

(U, CA, Y, CE)(Ti, Fe)2O6 |

|

|

Davidite |

(REE)(Y, U)(Ti, Fe3+)20O38 |

|

|

Thucholite |

Thorium- and uranium-bearing organic material |

|

|

Secondary Uranium Minerals |

|

|

Autunite |

Ca(UO2)2(PO4)2·8-12 H2O |

|

Carnotite |

K2(UO2)2(VO4)2·1-3 H2O |

|

Gummite |

A mixture of uraninite and secondary uranium minerals of variable composition |

|

Seleeite |

Mg(UO2)2(PO4)2·10 H2O |

|

Torbernite |

Cu(UO2)2(PO4)2·12 H2O |

|

Tyuyamunite |

Ca(UO2)2(VO4)2·5-8 H2O |

|

Uranocircite |

Ba(UO2)2(PO4)2·8-10 H2O |

|

Uranophane |

Ca(UO2)2(HSiO4)2·5 H2O |

|

Zeunerite |

Cu(UO2)2(AsO4)2·8-10 H2O |

TABLE 4.2 Range of Uranium Concentrations in Ore Deposits and in Earth

|

Grade |

Concentration (ppm U) |

|

Very high-grade ore (Canada), 20% U |

200,000 |

|

High-grade ore, 2% U |

20,000 |

|

Low-grade ore, 0.1% U |

1,000 |

|

Very low-grade ore (Namibia), 0.01% U |

100 |

|

Granite |

4-5 |

|

Sedimentary rock |

2 |

|

Earth’s continental crust (average) |

2.8 |

|

Seawater |

0.003 |

SOURCE: Schnell (2009).

high grade (20+ percent U3O8 in Canada) to very low grade (0.01 percent U3O8 in Namibia), with most world uranium deposits in the 0.05 to 0.5 percent uranium concentration range.

As noted in Chapter 3, it is highly unlikely that there will be deposits with grades in excess of 1.0 percent uranium in Virginia. In addition, contamination of ore deposits with selected toxic metals, in particular arsenic, is also not expected in Virginia. For uranium grades of 0.05 to 0.5 percent, a typical process would be conventional underground or open-pit mining followed by crushing, grinding, tank leaching, solid-liquid separation, a solution purification step, and final precipitation of a concentrate. In the 0.05 to 0.5 percent uranium grade range, there is limited requirement for special precautions—beyond standard engineering practice—except for general dust control, ventilation for radon emissions, and a minor amount of nonradon radiation protection. For higher-grade uranium ores, additional controls are required targeting gamma radiation, and ores with specific toxic metal contamination (in particular arsenic) require other types of control.

Ore Pretreatment or Beneficiation

A process step that may precede conventional agitation leaching and possible heap leaching is ore pretreatment, or “beneficiation,” in order to reduce the quantity of ore that will require chemical treatment. Beneficiation involves separating some of the host rock from the uranium-bearing mineral. This type of beneficiation can result in lower capital and operating costs, and may be a relevant option for lower grade deposits such as those that are likely to occur in Virginia. Generally, very few operations have used flotation or beneficiation processes that concentrate the uranium mineral by removing gangue constituents, because the value of the uranium losses is commonly higher than processing the whole ore. Flotation, gravity separation and other beneficiation processes that separate the uranium minerals from the gangue are tested during project planning, and in

some cases economic benefits can be realized. This is possible because, in many deposits, the uranium mineralization is found in fissures or cracks within the rock, rather than being disseminated through the rock as is often the case with other metal mineralization.

Conventional Agitation Leach

Uranium is highly soluble as a sulfate in sulfuric acid, and as a carbonate in alkaline solution in the U6+ valence state. If it occurs in the U4+ state it must oxidized before becoming soluble; this is a two-step reaction, with a chemical oxidant first used to oxidize iron, for example, from the ferrous Fe2+ to the ferric Fe3+ state, and in turn the oxidized iron causes oxidation of the uranium from U4+ to U6+ (Merritt, 1971).

The use of an agitated leaching process is the most common type of uranium processing, and is the one most likely to be applied to deposits in Virginia. The choice between an acid leaching process or alkaline leaching process is dependent on the ore and gangue and the uranium mineralogy. Extensive testing, economic studies, and environmental considerations will decide the final process choices.

The first step in the agitated leaching process is to finely grind the ore (typically to about 300- to 500-micron size) in a water–slurry mixture. The ore slurry is thickened to a higher density (about 50 percent solids), and then forwarded to a series of stirred tanks where the leaching takes place. Acid and oxidants are added—for acid leaching, temperatures of 50°C to 60°C are used, whereas alkaline leaching requires a higher temperature of 90°C to 95°C. The tanks can be at normal atmospheric pressure or pressurized. Acid and a suitable oxidant (e.g., oxygen, hydrogen peroxide, sodium chlorate, or manganese dioxide) is added to oxidize U4+ to U6+. The acid is the lixiviant—or liquid solution—that dissolves the metal in the U6+ sulfate form. Alternatively, a mixture of sodium carbonate and sodium bicarbonate can be used if the ore gangue has a high acid consumption. The choice of a carbonate or acid leaching route is based on the consumption of each chemical by the ore matrix or host rock, reagent availability, and environmental and economic considerations. The choice of oxidant is based on many of the same considerations as the choice of lixiviant.

In either acid or alkaline leaching, the ore slurry—with the uranium in solution—requires the separation of the solids from the uranium-containing liquid. This is commonly performed using filters (horizontal belt, pressure, or drum filters) or a series of thickeners or decanters. In both cases, the slurry is washed with acidified water for the acid leach process, or water only in the case of the alkaline leach option, in what is termed countercurrent decantation. The washed solids, now referred to as tailings, are generally neutralized with lime or other alkaline material if acid leaching of the ore was employed to extract the uranium. The tailings are then forwarded to a tailings impoundment facility for storage.

The clear liquid containing the uranium in solution is further purified using a solvent extraction or ion exchange technology. After uranium removal, the solution—known as “raffinate” or “barren solution”—is recycled back to the filters or decantation process. The concentrated, purified uranium solution (referred to as “pregnant solution” or “eluate”) is advanced to a precipitation stage using hydrogen peroxide, magnesium oxide, or sodium hydroxide. The resultant uranium precipitate is then filtered or centrifuged, dried or calcined, and packaged into suitable drums for shipping. All processing plants maximize solution and reagent recycling to reduce cost and environmental effects. A typical conventional agitation leaching process is illustrated in Figure 4.9. The final yellowcake product

FIGURE 4.9 Typical conventional agitated leaching process. SOURCE: Courtesy of Zeyad El-Ansary, AMEC Minproc Ltd.

is normally packaged in an IP2-approved drum containing 400 to 500 kg of concentrate. All yellowcake product and uranium-containing material has strict accountability controls and is only shipped to other licensed facilities.

Although the specific uranium processing method that might be used for an ore deposit in Virginia would be dependent on the specific situation, some of the parameters that would need to be considered for a modern conventional agitated leaching operation, and a typical set of basic design criteria, are shown in Table 4.3.

Modern uranium processing operations have very strict mine-plant-product accounting practices to control the process and ensure an accurate accounting of recovery and production. Metallurgical accounting occurs daily, with a monthly balance and reconciliation, and is supported by a chemical laboratory that must be certified and have external check analysis systems.

In Situ Recovery (ISL or ISR)

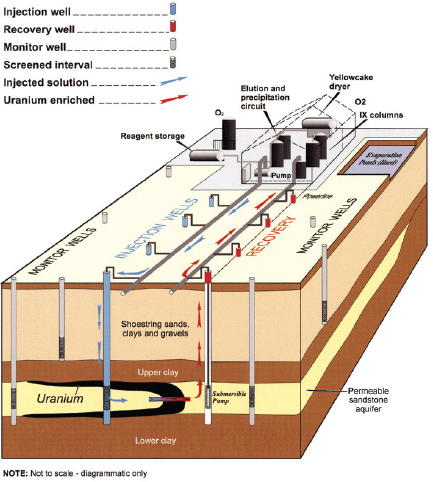

In situ leaching (ISL), also known as solution mining, or in situ recovery (ISR) in North America, involves leaving the uranium ore in the ground, and recovering the uranium by dissolving it from the uranium-bearing minerals by injecting carbonated solution or mild acid and pumping the leached uranium in a pregnant solution to the surface where the metal can be recovered (Figure 4.10). Consequently, there is little surface disturbance and no tailings or waste rock generated. However, the orebody needs to be permeable to the liquids used and located so that the process does not contaminate groundwater away from the orebody (WNA, 2010a).

Uranium ISL uses the native groundwater in the orebody, which is fortified with a complexing agent, a mild alkaline solution (used in the United States) or weak sulfuric acid (used outside the United States), and in some cases the addition of an oxidant. It is then pumped through the underground orebody to recover the uranium by leaching. Once the pregnant solution is returned to the surface, the uranium is recovered in much the same way as in any other uranium processing plant.

The ISR method requires that the ore deposit rock structure be permeable (commonly sandstone) and have an underlying impermeable confining layer (such as a clay) beneath the mineralization. This method has been applied in the United States (e.g., in Wyoming and Texas), but as described in Chapter 3, the geological setting in Virginia is unlikely to be appropriate for this type of process.

Heap Leaching

Heap leaching occurs when ore containing uranium is piled in a heap and fluid is distributed over the surface to leach metal from the heap over a period of months. Heap leaching has been applied successfully for production of copper,

TABLE 4.3 Typical Uranium Mine and Processing Plant Design Criteria That Might Be Applicable to an Ore Deposit in Virginia

|

Item |

Range or Alternative |

Range or Alternative |

Units |

|

Deposit |

|||

|

Resource tonnage |

5 to 20 |

Million tons of ore |

|

|

Resource grade |

0.05 to 0.20 |

% U3O8 |

|

|

Uranium content |

20 to 50 |

Million lbs U3O8 |

|

|

Ore depth from surface |

Surface to 1,000 |

Feet |

|

|

Deposit area |

50 to 100 |

Acres |

|

|

Mine |

Open-pit mine alternative |

Underground mine alternative |

|

|

Depth |

Surface to 500 |

300 to 1,000 |

Feet |

|

Open mine/strip ratio |

3 to 10 |

0.5 to 2 |

Tons waste to tons ore |

|

Underground dilution |

5,000 to 50,000 |

1,000 to 20,000 |

Tons waste to tons ore |

|

Daily mined tonnage |

1,000 to 10,000 |

500 to 5,000 |

Tons ore plus tons waste per day |

|

Daily ore mined |

Tons per day |

||

|

Plant |

Acid leaching alternative |

Alkaline leaching alternative |

|

|

Daily tons of ore |

1,000 to 10,000 |

1,000 to 10,000 |

Tons per day |

|

Leach recovery |

90 to 95 |

80 to 85 |

% |

|

Grind size |

35 (0.02) |

65 (0.01) |

Mesh (inch) |

|

Leach temperature |

120 to 135 |

190 to 205 |

Degrees Fahrenheit |

|

Leach time |

8 to 12 |

48 to 96 |

Hours |

|

Slurry solids |

40 to 60 |

40 to 60 |

% solids |

|

Acid consumption |

80 to 200 |

— |

Pounds per ton |

|

Oxidant |

O2, H2O2, Na2C1O3 |

O2 or air |

|

|

Carbonate concentration |

— |

30 to 50 |

Gram per liter |

|

Carbonate consumption |

— |

5 to 10 |

Pounds per ton |

|

Bicarbonate concentration |

— |

7 to 12 |

Gram per liter |

|

Bicarbonate consumption |

— |

2 to 10 |

Pounds per ton |

|

Purification |

Solvent extraction or Ion exchange |

Direct precipitation or ion exchange |

|

|

Precipitation |

H2O2 |

NaOH and then H2O2 |

|

|

Final product |

UO4 or U3O8 |

UO4 or U3O8 |

|

|

Tailings treatment |

Lime neutralization |

Wash tailings for solution recycle |

|

FIGURE 4.10 Typical ISR installation. SOURCE: With permission from Heathgate Resources Pty Ltd.

most notably in Chile and the western United States (Schnell, 1997), and for gold operations in South Dakota, Montana, Nevada, and many other parts of the world. Recovery of uranium by heap leaching is less common, with acid heap leaching used in Hungary (NEA/IAEA, 2000) and and alkaline heap leaching process used in Namibia (Schnell, 2010). Heap leaching today is applied to crushed ores, and modern heaps are designed to prevent ground contamination using a minimum of double containment, groundwater monitoring, and diversion channels. The advantage of heap leaching is that the ore does not need to be finely ground, water

consumption is low, and remediation is simplified, avoiding tailings impoundment. The leached residue can be returned to the mine or covered with suitable material in place. Heap leach is limited to ores with low clay content, and the process requires long leach times and has relatively low metal recovery.

Byproduct Uranium Recovery

Byproduct uranium recovery occurs when other metal production, such as gold, copper, or nickel, is the primary product and uranium is recovered as a minor byproduct. This may be done to recover uranium for its own sake, or undertaken when the uranium has to be removed for product purity or environmental reasons, for example, in the production of phosphoric acid fertilizer, or copper production such as with the Olympic Dam deposit in Australia.

Unconventional Resources

Uranium may be recovered from tailings from old uranium operations, or tailings from other metal operations. Generally speaking, these sources are currently not economically viable because of low concentrations and high processing costs, but they may have future production potential.

Virginia’s environmental conditions make it almost certain that a mine—whether underground or open-pit—will be wet, and water will need to be removed and managed. Water removed from a mine or excess water that cannot be recycled within a processing plant must be treated to meet environmental requirements. Treatment will be dependent upon the uranium recovery process, chemicals used, and ore contaminants. Typically, treatment will be a multistep process that will neutralize the effluents, precipitate any metals, and diminish the uranium and radium content.

Water management within a mining project starts with a characterization of all potential water sources, possible usage, and possible contamination issues. This includes a site water balance analysis, including a plant water balance analysis, that assesses not just water flows and water quality but also identifies water recycle options. This water balance analysis would consider seasonal variations, and consider the use of cutoff berms, stormwater ponds, and possible evaporation ponds, all based on a probable-maximum-precipitation analysis with a suitable safety margin.

Water recovered from mining activities gets into the mine as groundwater, and this would either be discharged or used for plant operations. Contaminated mine water requires solids removal, either in settling basins or by use of filtration systems. In some cases, contaminated mine water may contain minor quantities

of metals that could require other technologies for treatment, for example, reverse osmosis or nanofiltration. After treatment, mine water is either discharged, recycled to plant operations, or sent for additional treatment.

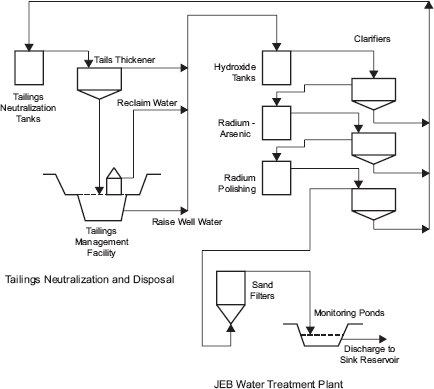

Process effluents are internally recycled to minimize water usage and conserve process chemicals. Typical plant water usage will be on the order of 0.5-2.0 m3 of water per ton of ore. Process or plant effluents require treatment to neutralize any chemicals, precipitate any dissolved metals, and precipitate radium. A multistep process is usually applied (e.g., Figure 4.11), first coagulating or precipitating heavy metals, neutralizing acids, or adjusting pH and then precipitating radium with barium chloride. The water treatment process can be followed by additional “clarification” or “polishing” steps using clarifiers, sand filters, and possibly reverse osmosis. The final selected treatment is dependent upon the plant

FIGURE 4.11 Example of multistage water treatment flowsheet showing treatment for metal content and radium and including pH adjustment with associated clarification as well as real-time monitoring of water quality before discharge. SOURCE: Schnell and Thiry (2007).

process, type of ore treated, and chemicals employed. In Canadian operations, for example, the final treated effluents are discharged into holding ponds, where they are analyzed to ensure that the treated effluents meet environmental objectives before release.

All ore mining produces waste rock that must be managed. This rock can be either waste that may produce acid mine drainage (AMD), due to the presence of sulfides, or it may be clean or stable waste that can be placed on the surface without special consideration. AMD waste is generally stored on an engineered pad to control water drainage, and is either returned to the mine as backfill or placed in an open containment pit at the end of mining. Such a containment pit may also have an engineered cover to prevent influx of water and oxygen to reduce the risk of acid mine water runoff.

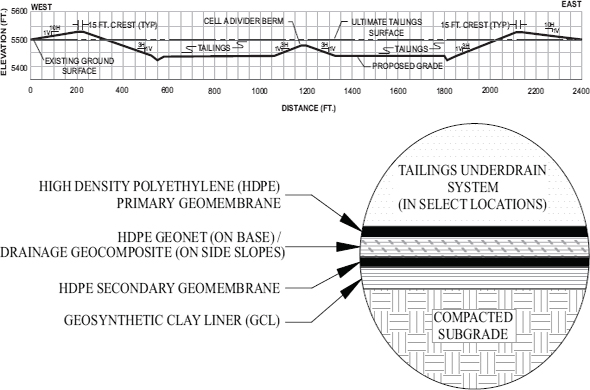

The solid waste remaining after recovery of uranium in a processing plant are the tailings, consisting of everything that was in the ore except the extracted uranium. The main radioactive materials remaining are those from the uranium decay series, mainly thorium-230 and radium-226. Tailings are typically neutralized and thickened to reduce water content and then pumped to an impoundment facility. One concern for tailings impoundments is the potential for release of radon gas, and impoundments are monitored to ensure that radon does not pose a hazard. Radon can be controlled by limiting the amount of tailings exposed during operations by maintaining only small parts of an impoundment cell open at any one time, or by use of a water cover.

The characteristics of tailings impoundments have undergone many changes in recent decades. Historically, tailings were generally deposited in aboveground dam impoundments or in natural ground low points, with minimal treatment. In most cases, tailings are now impounded in purpose-built lined cells, placed in a mined-out pit, or sent to an engineered facility. Modern mines have tailings neutralization systems that use lime—together with other additives such as barium chloride—to stabilize radium content and prevent metal contaminants from causing environmental contamination.

The purpose-built lined pit or system of tailings cells has been adopted as the current practice in the United States. This is combined with a final cover to stabilize the tailings and prevent future contamination (Figure 4.12). For acid leach plants, all tailings need to be neutralized before disposal.

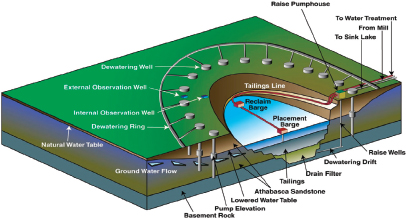

An alternative to the tailings cell design is to use in-pit disposal, where the tailings are placed in a designed open pit that allows the tailings to become less permeable than the surrounding rock, and a French drain prevents groundwater from entering the tailings mass (Figure 4.13). The tailings are placed subaqueous to prevent dust and to protect workers from potential radiation exposure. For final closure, the tailings mass is required to be below the surrounding ground

FIGURE 4.13 Schematic showing an in-pit tailings disposal system. SOURCE: AREVA Resources Canada, Inc.

level, and an engineered cover is installed to prevent contamination and stabilize the area.

Although reclamation and closure have always been considered during mine development, current practice has advanced to the point where the reclamation and closure plan is an important element for any mine’s ultimate success. Reclamation and closure are planned during the earliest stages of the project, and encompass the initial gathering of comprehensive baseline environmental data, developing detailed cost of closure estimates, through to the actual implementation of the reclamation plan to ultimately trigger bond release (Feige, 2008). These plans consider all disturbances associated with the mine and processing plant areas. Closure activities may involve some postclosure water treatment where a treatment facility is required, and long-term sampling is undertaken.

Modern mine practice is to carry out continuous rehabilitation during the life of an operation. Appropriate reclamation and closure are guaranteed by a bond to ensure that sufficient resources are available should the operating company fail prior to final reclamation and closure. It is difficult to envision and describe all postclosure requirements, but modern practice is to review risks and assess opportunities to reduce final closure impacts early in the project design phase. Such impacts encompass not only technical and environmental issues, but also socioeconomic issues such as future site use.

The committee’s analysis of mining and processing activities that might apply if uranium mining and processing were to take place in Virginia has produced the following findings:

• The choice of mining techniques and processing parameters for uranium recovery depends on multiple factors that are primarily associated with the geological and geotechnical characteristics of a uranium deposit—its mineralogy and rock type, as well as a range of other factors. Additional parameters that require consideration are the location and depth of the deposit, whether the location is in a positive or negative water balance situation, as well as a range of environmental and socioeconomic factors. Consequently, a final design would require extensive site-specific analysis, and accordingly it is not possible at this stage to predict what specific type of uranium mining or processing might apply to ore deposits in Virginia.

• Uranium recovery from ores is primarily a hydrometallurgical process using chemical processes with industrial chemicals, with a lesser dependence on physical processes such as crushing and grinding.

• Mine design—whether open-pit or underground—requires detailed engineering planning that would include pit and rock stability considerations, as well as ventilation design to account for the presence of radon and other respiratory hazards.

• With the ore grades expected in Virginia, many of the technical aspects of mining for uranium would be essentially the same as those applying to other hard-rock mining operations. However, uranium mining and processing add another dimension of risk because of the potential for exposure to elevated concentrations of radionuclides. Hard-rock mining varies significantly from soft rock mining, such as coal or sand/gravel mining.

• A complete life-cycle analysis is an essential component of planning for the exploitation of a uranium deposit—from exploration, through engineering and design, to startup, operations, reclamation, and finally to decommissioning leading to final closure and postclosure monitoring. Each of these steps requires wide-ranging stakeholder interaction and communications.