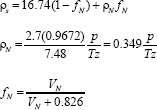

Δp = po – pi

where

Δp = pressure differential [pounds per square inch (psi)];

po = pressure outside the casing at the bottom (psi), assumed equal to reservoir pressure of 11,892 psi, which is a pore pressure of 12.57 pounds per gallon (ppg) at the bottom of the reservoir at 18,212 feet (true vertical depth); and

pi = pressure on the inside above the cement (psi).

![]()

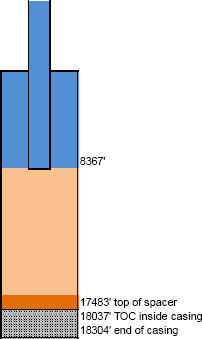

Here the differential is into the casing. The cement is treated as a solid that does not transmit hydrostatic pressure but that must be strong enough to withstand the pressure differential across it. The top of the cement inside the casing is based on the assumption that 2.8 barrels of foam cement flowed back into the casing when the pressure was bled off at the end of the cement job.

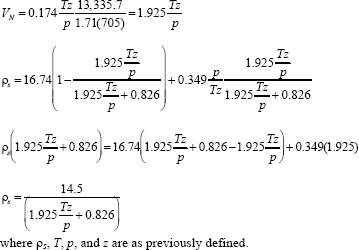

2. Foam quality calculations:

Foam cement: The purpose in this case is to reduce the bottom hole (in situ) density of the slurry from 16.74 ppg to 14.5 ppg. The bottom hole pressure is the hydrostatic pressure of 14 ppg mud or 13,321 pounds per square inch gauge (psig) at 18,304 feet. The static bottom hole temperature is 245°F.

![]()

where

where

γN = specific gravity of nitrogen (compared with air),

p = pressure (pounds per square inch absolute),

z = gas deviation factor (dimensionless), and

T = temperature (degrees Rankine = 460 + degrees Fahrenheit).

So, for every in situ gallon of slurry there will be 0.174 gallon of nitrogen mixed with 0.826 gallon of base 16.74-ppg cement slurry. Thus, the in situ foam quality is 17.4 percent. Note that the Chevron tests used a 13 percent quality foam, which corresponds to the weight fraction of nitrogen necessary to create a 14.5 ppg density foam at atmospheric conditions. Therefore, more nitrogen is required to create the same density foam at the much higher pressure and temperature of the bottom of the Macondo well.

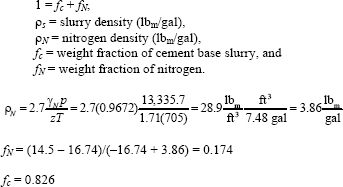

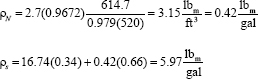

At the mixer at the surface, the slurry is blended and pumped at about 600 psig. The volume of nitrogen introduced to 0.826 gallons of base cement is the in situ volume increased through the real gas law.

![]()

This is added to 0.826 gallon of base cement. Thus, for every 1 gallon of base cement, 1.94 gallons of N2 at 600 psig is required. This is a 66 percent quality foam.

The density of the foam slurry at the mixer will be as follows:

The previous equations and results can be combined to obtain an equation for the density of the slurry at any depth with a corresponding pressure, temperature, and gas deviation factor.