The design and construction of a well are crucial to the safe exploration for and extraction of oil and gas resources. The process becomes more complex as the operating environment becomes harsher, as in deep, high-pressure, high-temperature wells drilled into the seabed beneath deep water. Macondo was such a well, with a total depth of more than 18,300 feet below sea level in slightly more than 5,000 feet of seawater. This chapter discusses changes that were made to the original Macondo well plan in response to geologic conditions encountered while drilling progressed. It then focuses attention on the approaches selected for temporary abandonment1 of the well given these conditions. The chapter provides findings and observations concerning a number of key decisions related to the design, construction, and testing of the barriers critical to the temporary abandonment process.2 At the end of the chapter, recommendations for achieving a more robust approach for implementing and verifying needed barriers are provided.

OVERVIEW OF THE MACONDO WELL PLAN

Macondo was an exploration well designed so that it could later be completed for production if sufficient hydrocarbons were found. The initial objective was to evaluate Miocene age formations expected to be found between 18,000 and 19,000 feet below sea level in about 5,000 feet of water. The original well plan was to drill to a total depth of 19,650 feet, but this was modified during drilling and the actual total depth was 18,360 feet, as discussed below. Before the well was drilled, design teams estimated pore pressures and strengths of geo-

____________________

1Temporary abandonment refers to a set of normal procedures used by rig personnel to secure a well after drilling has been completed, so that the rig, along with its blowout preventer and marine riser, can be moved from the well site. The Deepwater Horizon was to leave the Macondo well and another rig was to be used to prepare the well for production at some later time.

2Detailed descriptions of the overall sequence involved in constructing and testing the integrity of Macondo well barriers are provided in various reports listed in Box 1-1 of Chapter 1.

logic formations to create a design that included elements such as drilling procedures, drilling mud, drill bits, casing design, cement, and testing.

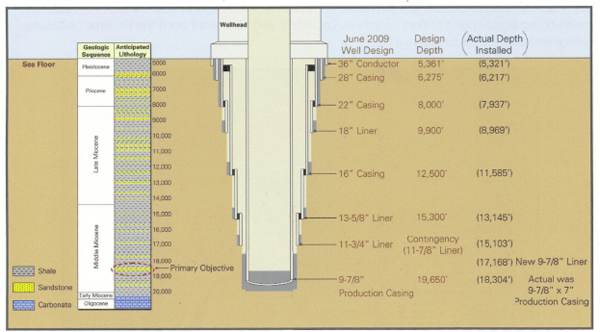

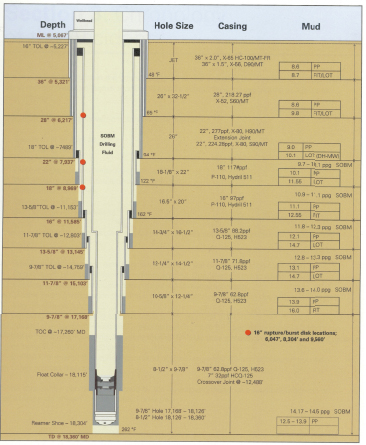

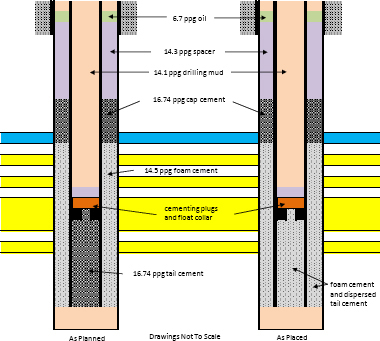

The original plan, shown in Figure 2-1, called for eight casing strings and liners (each consisting of steel casing segments that were screwed together), but the plan was modified to react to conditions that were encountered during drilling. Drilling ceased at 18,360 feet (a shallower depth than planned) and involved the use of a total of nine casing strings and liners, rather than the planned eight, including the final 9 ⅞- × 7-inch tapered production casing (sometimes referred to as a “long string”) as shown in Figure 2-2. The well was to be temporarily plugged and abandoned after the production casing was set and then completed for production at a later date.

The Macondo well presented a number of technical challenges to the drilling and completion teams, including the deep water, high formation pressures, and the need to drill through multiple geologic zones of varying pore and fracture pressures. In general, many of these problems can be anticipated, but some, such as pore and fracture pressure, are difficult to estimate in advance of drilling the well. This is especially true for the first well drilled in a new area, as was the case for Macondo. Thus, adaptation of the original well plan to the changing conditions encountered with depth when the well is drilled is not unusual. It is critical that the design be adapted to changing conditions with sufficient margins of safety to allow for further uncertainties that may be encountered during the operation.

Wellbore events that necessitated changes to the Macondo well plan included the following (BP 2010, 17-22):

1. Measurements showed that pore pressures were increasing at a faster rate than anticipated, combined with a period of lost circulation of drilling mud at 12,350 feet, indicating that the well could not be continued without setting protective casing. The 16-inch liner was set at 11,585 feet to seal off this section of the well. The setting depth of this liner was 915 feet shallower than planned.

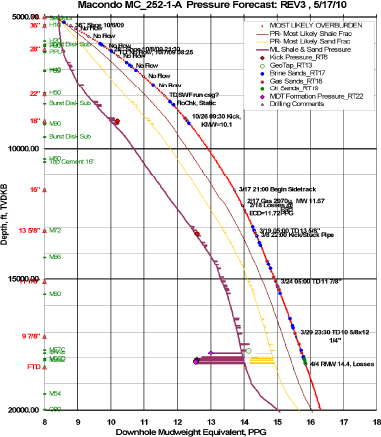

2. In the course of drilling at 13,250 feet, a kick occurred, and the lower annular blowout preventer (BOP) was closed in response. During well control operations, the drill string became stuck and was severed at 12,147 feet. The drill string and hole below 12,147 feet were abandoned, and subsequent well drilling deviated slightly to go around the abandoned materials left in the original hole. The 13 ⅝-inch liner was run at 13,145 feet, which was shallower than planned, to allow the well to be drilled safely past the higher-pressure reservoir that had been encountered. The 11 ⅞-inch liner was used at 15,103 feet to seal the reservoir and allow for the use of higher mud weights than had been anticipated. Mud weight was to be kept between the curves for pore pressure and fracture pressure, as shown in Figure 2-3.

FIGURE 2-1 Original wellbore architecture planned for Macondo well. Source: BP 2010, p. 16. Reprinted with permission; copyright 2010, BP.

FIGURE 2-2 Final wellbore architecture for Macondo well. Source: BP 2010, p. 19. Reprinted with permission; copyright 2010, BP.

3. The 9 ⅞-inch casing (originally planned as the production casing) was used as a liner at 17,168 feet to drill the final section of the well safely, where the use of higher mud weights was expected in continuing the well to the planned depth of 19,650 feet.

4. During drilling at 18,250 feet, severe lost circulation of drilling mud occurred. This problem was solved by the use of mud containing material designed to stop lost circulation and by a reduction of mud weight from 14.3 to 14.1 pounds per gallon (ppg). The lower mud weight should not have been needed at this depth on the basis of the original plan and was an indication that pore pressure and fracture pressure in part of this interval were considerably less than had been anticipated.

FIGURE 2-3 The four curves (moving from right to left) represent overburden stress, fracture gradients in the shale and sands, and pore pressure in the Macondo well. Depth and diameter values on the y-axis correspond to the final well bore architecture shown in Figure 2-2. The equivalent mud weight (EMW), expressed in pounds per gallon (ppg), must be higher than the pore pressure to avoid flow from the well and lower than the fracture gradient to prevent accidental hydraulic fracturing. Note the small separation between the values at depths below 18,000 feet. Source: BP unpublished report, July 26, 2010.3 Reprinted with permission, BP.

5. The well was drilled to 18,360 feet, and after 5 days of logging to make a detailed record of the geologic formations, it was determined that hydrocarbon-bearing reservoirs of sufficient quality existed to warrant completion of the well for production at a later time. According to the BP accident investiga-

____________________

3BP Post-Well Subsurface Description of Macondo well (MC0252_1BP1) v3. July 26, 2010.

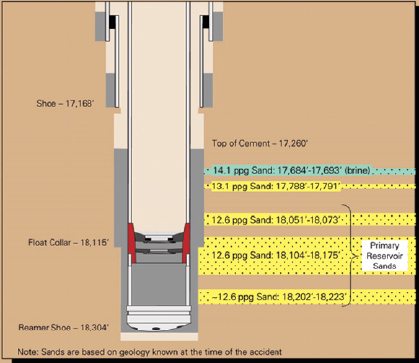

tion report, the well analysis indicated that there were in fact several reservoirs open in the wellbore with decreasing pore pressure with depth, as shown in Figure 2-4. The hydrocarbon reservoirs had pore pressures equivalent to a range of 12.6 to 13.1 ppg. A reservoir containing salt water that had a pore pressure equivalent to 14.1 ppg was also exposed in the wellbore. As discussed below, the difference between the mud weight needed to prevent flow of salt water and the mud weight above which reservoir fracture could occur was only 0.2 ppg. Recent reports in the press have indicated that a thin gas sand was present above the salt water bearing zone shown in Figure 2-4 and have questioned the possible contribution of this sand to the blowout. The committee has seen no evidence indicating that flow occurred upwards in the annulus between the production casing and the reservoirs (see discussion below). Also, the presence of the high-pressure salt water sand created the same completion problem referenced above as would have been created by the presence of a high-pressure gas sand. Therefore, the presence or absence of the gas sand is expected to have had no material effect on the cause of the blowout.

FIGURE 2-4 Variation of pore pressure in the open hole section of the Macondo well expressed in pounds per gallon. Source: BP 2010, p. 54. Reprinted with permission; copyright 2010, BP.

To continue drilling to the planned final depth of 19,650 feet, the reservoirs that had been discovered with decreasing pore and fracture pressures with depth (Figure 2-4) were to be sealed with the 9⅞- × 7-inch combination casing string and cement. However, because the hole diameter that could be drilled below the 7-inch casing was considered too small to be practical, the well was terminated at 18,360 feet.

The challenge then was to install the production casing and pump the cement into the well without causing additional lost circulation. This was achieved on the basis of reports from the rig that no lost circulation occurred during casing and cementing operations (BP 2010, 23).

Once the casing and cementing operations were concluded, the focus moved to the installation and testing of the integrity of the wellhead seals and testing of the integrity of the cement, and then to completion of the temporary abandonment process.

Beginning of Hydrocarbon Flow That Led to the Blowout

As part of the temporary abandonment process, a negative pressure test was used to indicate whether a cement barrier and other flow barriers had isolated formation fluids from the wellbore. To conduct the test, rig personnel purposely reduced the hydrostatic pressure inside the well. If the barriers were effective, there should be no flow into the well (or pressure buildup) from the formation during the test. After deciding (incorrectly) that the negative pressure test indicated that the barriers were effective, rig personnel continued with the temporary abandonment process. The annular BOP was opened, and seawater was circulated down the drill pipe and up the casing and marine riser to the surface. Seawater displaced the mud from the marine riser and from the well to a depth of 8,367 feet (measured from the rig). This had the effect of reducing the hydrostatic pressure in the well below the reservoir pressure. Because the cement and mechanical barriers did not have sufficient integrity (as discussed below), hydrocarbons began to flow from the formation into the well.

Summary Finding 2.1: The flow of hydrocarbons that led to the blowout of the Macondo well began when drilling mud was displaced by seawater during the temporary abandonment process.

Misinterpretation of Cement Integrity Test Results

The negative pressure test was attempted three times, as described in the BP accident investigation report (BP 2010). The initial test was flawed because

the annular BOP did not seal and allowed 50 barrels (bbl) of heavy 16-ppg spacer fluid—made up of lost circulation material (LCM)—to flow back into the well below the BOP. This was recognized by rig personnel, and the closing pressure on the annular BOP was increased to make a seal. At the end of this first test, the drill pipe pressure was 273 pounds per square inch (psi) and the kill line pressure was zero with both lines shut in.

In the second test after increasing the closing pressure on the BOP, the drill pipe pressure increased to 1,250 psi. The drill pipe was opened and the pressure decreased to zero after flowing out more water than was necessary to account for mud compressibility. The drill pipe pressure should not have built up between tests, but this could have been attributed to the heavy mud leaking past the annular BOP. The mud volume that flowed out beyond what was necessary to account for mud compressibility should have made this test a failure, despite the drill pipe pressure having bled to zero.

With the drill pipe shut in, the kill line was chosen for the third test. It was opened, and it flowed out between 3 and 15 bbl of water and was shut in. During this time the drill pipe pressure slowly built up to 1,400 psi and stabilized.

The kill line was confirmed to be full of water and then reopened. It flowed out a small volume, and then flow out of the kill line ceased. The open kill line was monitored for 30 minutes with no pressure and no flow. Possible reasons for this are the following: the kill line may have been plugged by the LCM spacer, the pressure might have been equalized by the flow of the dense spacer into the kill line, or the correct valves for the kill line may not have been opened during this final test. The drill pipe maintained 1,400 psi.

Rig personnel focused on the fact that no flow was coming out of the kill line instead of addressing the implications of the shut in pressure having built up on the drill pipe. After some discussion on the rig, the negative test was deemed a success. However, the pressure buildup actually meant that the test had failed. The explanation used on the rig was an erroneous theory referred to as the “bladder effect” (see BOEMRE 2011, 95). The term, as used in the industry, is unrelated to the situation faced during the negative pressure test.

At this point the annular preventer was opened. When this was done, the marine riser was still full of 14-ppg mud and 16-ppg LCM spacer, which was sufficient to offset the reservoir pressure. Circulation of seawater was continued, displacing the mud from the riser and steadily decreasing the hydrostatic pressure inside the well. As mentioned above, when the hydrostatic pressure from the seawater and mud became less than the reservoir pressure, the well began to flow. Hydrocarbon flow into the well from the reservoir was not detected by the rig crew during this time, although there were indications that it was occurring. Among the indications were the following: (a) the flow of fluids pumped out of the well was larger than the flow being pumped in and (b) the drill pipe pressure gradually increased over time after accounting for changing pump rates (see BP 2010, Figure 8, p. 93).

Summary Finding 2.2: The decision to proceed to displacement of the drilling mud by seawater was made despite a failure to demonstrate the integrity of the cement job even after multiple negative pressure tests. This was but one of a series of questionable decisions in the days preceding the blowout that had the effect of reducing the margins of safety and that evidenced a lack of safety-driven decision making.4

Approach Chosen to Complete the Well and Prepare for Temporary Abandonment

According to the BP accident investigation report (BP 2010), the final open hole section of the well contained several reservoirs with decreasing pore pressure with depth. As shown in Figure 2-4, the largest pore pressure was estimated at 14.1 ppg in a salt water–bearing reservoir, and the lowest was estimated at 12.6 ppg in the hydrocarbon-bearing reservoir. The largest pore pressure required that the mud weight be at least this high to prevent salt water flow from the reservoir. The fracture mud weight was just above 14.2 ppg, as evidenced by lost circulation at 18,260 feet (see BP 2010, 17–18, and Figure 2-3). This caused the margin of safety between the equivalent circulating density (ECD),5 shown in Figure 2-3 as an equivalent mud weight, and the fracture mud weight to be very small. The operations associated with pumping cement into the annulus without fracturing one of the lower-pressure reservoirs were therefore difficult.

The completion approach chosen was to cement the production casing by using primarily foamed cement with a density low enough that the fracture pressure in the well was not exceeded. The placement of cement is always a potentially problematic operation, and if it is unsuccessful it can leave channels or pathways for fluid movement outside the casing. If the fracture pressure is exceeded while the cement is pumped, all or part of the cement can be lost to the fracture, greatly reducing the volume of cement available to isolate the well from high-pressure reservoirs. As explained below, foamed cement is more difficult to mix and place at the bottom of a well than is un-foamed cement. The foamed cement does not establish the strength of the base cement used to mix the foam, which can increase the potential for cement cracking. Furthermore, cementing hardware, such as the backflow valves used in the float collar or centralizers on the outside of the casing, is subject to failure. Hardware failure can lead to flow pathways through the cement and into the casing.

____________________

4Various questionable decisions are discussed in this chapter. Also see discussions in BOEMRE (2011), Chief Counsel (2011), DHSG (2011), and Presidential Commission (2011).

5ECD is a parameter that reflects the pressure that a column of fluid exerts when it is circulating. It is a function of the density of the fluid and the friction pressure in the annulus required to circulate.

Summary Finding 2.3: The reservoir formation, encompassing multiple zones of varying pore pressures and fracture gradients, posed significant challenges to isolation using casing and cement. The approach chosen for well completion failed to provide adequate margins of safety and led to multiple potential failure mechanisms.

Pumping Sequence of Cement Slurries for the Macondo Well

The primary function of cement is to provide the first barrier to flow from the formations into the wellbore or to flow between individual formations exposed in the wellbore. In addition, the cement stabilizes the wellbore wall and supports the steel casing. Cement slurries are often heavy, with densities around 16.4 ppg. Use of a high-density slurry is not a problem so long as the density of the slurry, along with the density of the mud, does not create a pressure in the well that exceeds the fracture pressure of exposed reservoirs. Cement slurries that are dense have a high fraction of cement in the mixture and develop excellent strength over fairly short intervals of time. This type of slurry can be adjusted by using a variety of additives to perform at the conditions found at the bottom of a given well.

For the Macondo well, the concern was to use a combination of cements with an average density sufficiently low that the open well would not be hydraulically fractured. As indicated by the experience during drilling, the density that would cause a fracture was about 14.3 ppg.

The pumping sequence of fluids for cementing the Macondo well was designed as follows to reduce the ECD during the cementing job to prevent a hydraulic fracture from being created:

- 7 bbl of 6.7-ppg oil,

- 72 bbl of 14.3-ppg spacer,

- 5.26 bbl of Class H cement mixed at 16.74 ppg,

- 47.75 bbl of N2–Class H foam cement with bottom hole density of 14.5 ppg,

- 6.93 bbl of Class H cement at 16.74 ppg,

- 20 bbl of 14.3-ppg spacer, and

- 857 bbl of 14.1-ppg mud displacement (calculated).

The first four fluids were to be pumped down into the casing and up into the annulus. Fluid 5 was to be left in the shoe track. Fluids 6 and 7 were to displace the leading fluids to the float collar6 (see Figure 2-5). The end of the casing was to be at 18,304 feet, measured from the rig floor.

____________________

6The bottom section of the casing in the Macondo well, called the “shoe track,” was a section of casing about 189 feet long with a reamer-guide shoe at the bottom and a dual-flapper float collar on top.

FIGURE 2-5 Planned cement location and likely cement location after pumping. Source: Committee.

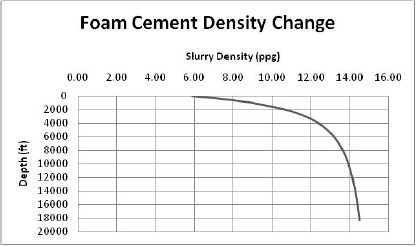

To make a foamed cement slurry that has a density of 14.5 ppg at the bottom of the well, the foam quality7 had to be 17.4 percent at bottom hole conditions of 245°F and 13,321 psi (see Appendix D for the calculations).8 At the surface, where the conditions in the mixer were about 600 psi and 60°F, the foam quality had to be 66 percent, producing a foamed slurry of about 6 ppg, to allow for the substantial compression and heating that were to occur as the foam was pumped to the bottom of the well. (For reference, freshwater has a density of 8.33 ppg.) Figure 2-6 shows the calculated foam density versus depth.

____________________

The purpose of the float collar is to stop wiper plugs from falling farther down the casing string and to prevent cement slurry pumped into the annular space around the casing from flowing up the casing.

7Foam quality is the volume fraction of gas in a given volume of foam expressed as a percent.

8There is some discrepancy as to what the bottom hole temperature might have been when the cement was placed (circulating temperature). In this analysis, however, sufficient time is assumed to have elapsed such that the wellbore had returned to the static temperature.

FIGURE 2-6 Calculated foam density versus depth during pumping. Source: Committee.

Once mixed, the foam was immediately pumped into the well, where pressure and temperature increased with depth, changing the foam quality and slurry density all the while. The shear associated with fluid movement down the inside of the pipe would act to break up large bubbles, which immediately reform as smaller bubbles so long as agitation is taking place.

The last of the cement (tail cement) was to be un-foamed Class H plus retarder and other standard additives. This slurry was mixed at a density of 16.74 ppg and was intended to remain inside the shoe track. As such it was meant to provide a high-quality, high-compressive-strength flow barrier inside the shoe track at the bottom of the casing. When this slurry was pumped, it was immediately on top of and in contact with the 66 percent quality foam cement that had a density of about 6 ppg near the surface. The heavier slurry, being on top of the foam cement slurry, was gravitationally unstable and thus could have fallen into the lighter foam. The tail cement might have fallen all the way through the foam, unless it was stopped by viscous forces, or it might have mixed with the foam and changed the quality of the foamed cement. In either event, the tail cement slurry remaining inside the shoe track at the end of pumping would be dispersed in the foam and would not retain its intended composition; that is, there would be no concentration of dense tail cement inside the casing as originally planned (see Figure 2-5, right side).

Finding 2.4: The sequence of fluids used to cement the Macondo well included a low-density foamed slurry followed by a dense un-foamed tail slurry. The foam cement was designed to have a density of 14.5 ppg at the bottom of the well, but at the surface, where the foam was

mixed, the density was extremely light at around 6 ppg. The tail slurry had a density of 16.7 ppg. Because of the extreme density imbalance, the heavy tail cement on top of the foamed cement would have been gravitationally unstable near the surface, and it probably fell into and perhaps through the foamed slurry. This would have had the unintended effect of leaving a tail slurry containing foamed cement in the shoe track at the bottom of the casing rather than leaving the heavy, un-foamed tail cement.

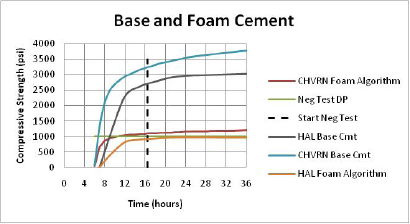

Compressive Strength of Foamed Cement and Un-foamed Cement

The properties of Class H cement are well known. The properties of foamed cement are not well known and not easy to measure because of the compressibility of the foam. In principle, the compressive strength of foamed cement should be less than the compressive strength of un-foamed Class H cement, given the same curing conditions and additives. Testing has shown this to be true. The compressive strength of foamed cement has been shown to be approximately 35 percent of that of Class H base cement under the same curing conditions (Gardner 2010). Testing done by Chandler Engineering (Sabens and Maki 2002) has shown that foamed cement begins to establish compressive strength at about the same time as the base cement (Class H in this case), but the strength of the foam continuously lags that of the base cement as curing time increases. Accepting these trends as representative, the committee created Figure 2-7 to show the compressive strengths of the various cement slurries. The Chevron (Protocol 1) and Halliburton base slurry curves are taken from the laboratory testing done on those two un-foamed slurries.

FIGURE 2-7 Uncontaminated cement compressive strength tests (DP = differential pressure). Source: Committee.

The curves for the two foamed cements are not from direct measurement but assume that the foamed cement compressive strength is reduced according to the foam protocol used in the Chevron test software (by a factor of approximately 35 percent).

The strength test results for the base slurry are all from a nondestructive compressive strength tester that measures the speed of sound through the sample as it sets. The interval transit time of sound through the sample is proportional to the compressive strength of the sample. The relationship between compressive strength and interval transit time is established by comparing the strength of samples determined by crushing tests. However, the end points of these tests were not compared with crushing tests. Therefore, the differences in the test results could be due to variation in the cement or variation in the programmed strength-to-transit-time relation.

Figure 2-7 shows the time at which the negative pressure test was started after cement slurries were pumped into the Macondo well. The figure also shows a differential pressure of about 999 psi that was created between the reservoir pressure and the reduced hydrostatic pressure inside the casing during the negative test (see Appendix D for the calculation). Figure 2-7 indicates that the foamed cement using the Chevron data would have just barely established the strength required to resist crushing under the differential pressure imposed by the negative test, assuming that the cement was not contaminated or altered by other events. The foamed cement using the Halliburton base data and the foam algorithm would not have achieved sufficient compressive strength. The positive pressure test9 of the casing that was performed before the negative pressure test would not have affected the cement because the cement plugs within the well would have supported this increased pressure.

Another area of concern is contamination of the slurry as it is pumped into the well. The compressive strength of cement can be degraded if the slurry is contaminated by other fluids. Chevron conducted compressive strength tests of the base cement (un-foamed) with various amounts of synthetic oil-base mud contamination. On the basis of the values obtained at the critical 16.4 hour time of the negative test, the compressive strengths with mud contamination are shown in Table 2-1.

By applying the foam compressive strength algorithm mentioned above, the effect of mud contamination on base cement compressive strength was used to estimate the effect of mud contamination on the strength of foamed cement. Table 2-1 shows that as little as 5 percent mud contamination reduces the foam compressive strength to less than the 999-psi pressure differential created during the negative test. On the basis of the general relationship illustrated by the Chevron data and the assumption of the foam algorithm, if mud contamination ex-

____________________

9A positive pressure test was used to assess the integrity of the production casing and other mechanical barriers by intentionally increasing the pressure within the production casing. Because pressure inside the well remained constant during the test period, rig personnel determined that the test was successful.

ceeded 10 percent, the foamed cement would not have established sufficient strength to withstand the negative test after 48 hours of curing. Mud contamination of cement is a real possibility in the annulus if the mud is not completely removed before the cement is placed, and it is a possibility in the shoe track if any spacer flows past the top wiper plug, which is intended to separate the cement slurry from other fluids.

Finding 2.5: Foamed cement that may have been inadvertently left in the shoe track would likely not have developed the compressive strength of the un-foamed cement, nor would it have had the strength to resist crushing when the differential pressure across the cement was increased during the negative test.

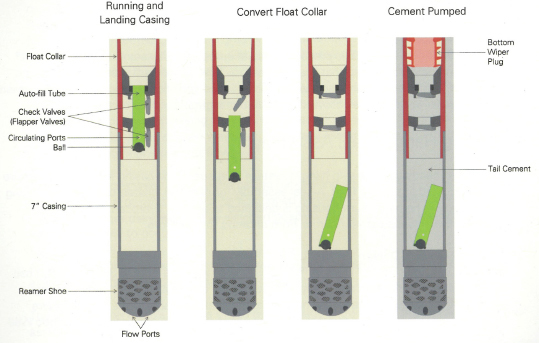

Float Collar with Flapper Valves and Differential Fill Tube

The float collar had two flapper-style backflow valves that were held open by a differential fill tube, as shown in Figure 2-8.

The differential fill tube allows mud to flow back into the casing as it is run into the well. Once the casing is in place, the differential fill tube is pumped out of the flappers and allowed to fall to the bottom of the shoe track. The flappers can then close and prevent fluids from flowing into the casing from the outside. If fluids are pumped down the inside of the casing, the flappers will open and allow fluid circulation from the inside of the casing to the outside, for example, during cementing operations. The shoe track below the float collar is made up of several joints of 7-inch casing with a ported reamer shoe10 on the bottom.

TABLE 2-1 Chevron Data to Illustrate the Effect of Mud Contamination on Cement Compressive Strength

| 16.4 Hour Comprehensive Strength (psi) | ||

| Mud % | Base Cement | Foam Algorithm |

| 0 | 3,261 | 1,100 |

| 5 | 2,518 | 850 |

| 10 | 2,379 | 803 |

| 15 | 1,412 | 476 |

| 20 | 1,013 | 342 |

| 25 | 308 | 104 |

____________________

10A ported reamer shoe is a perforated piece of equipment used to guide the casing toward the center of the hole as it is lowered into the well.

FIGURE 2-8 Float collar with flapper valves and differential fill tube. Source: BP 2010, p. 71. Reprinted with permission; copyright 2010, BP.

Once the casing was in place in the Macondo well, initial circulation could not be established until 3,142 psi of pump pressure was applied. This suggests that the shoe track was plugged with foreign material when it was run into the well. The practice of allowing mud to fill the casing by flowing up through the differential fill tube is a time-saving step that would not be needed if the casing were filled with mud from the top as it is run, a much slower process but one that reduces the possibility of debris entering the casing.

Several factors pointed to the probable failure of the flapper valves in the float collar. Once circulation was established, the pump rate never exceeded 4 barrels per minute (bpm), when at least 5 bpm was needed to shear the differential fill tube holding the flapper valves open. This indicates that the flapper valves likely remained open. Another possibility is that sufficient debris remained inside the shoe track to prevent the tube from falling out of the floats but allowing the ball to be pumped out the end of the tube. A third possibility is that the flappers in the valves were damaged when the higher pressure cleared the plug in the casing.

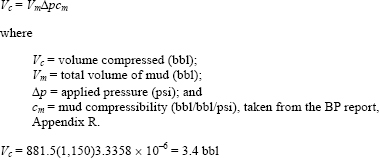

After the cement was pumped, spacer followed by mud was pumped. The plug bumped on the float collar after 881.5 bbl of total displacement, about what was expected, and the plug was bumped with 1,150 psi of additional pressure above the circulating pressure (BP 2010, 23). After bumping the plug, the pressure was bled off and 5 bbl of drilling mud was flowed back out of the well. The volume necessary to account for fluid compression is shown in the following equation:

Thus, the expected flow out of the well to relieve the pressure trapped above the plug was only 3.4 bbl, and the additional 1.6 bbl that flowed out can only be attributed to flow through the flapper valves. Flow from the well ceased, and the floats were considered closed. If the valves were in fact open, the differential pressure across the flapper valves would have been very small after the trapped pressure was bled off and equalized after the small volume of flow back through the floats. The fact that more volume flowed back before flow ceased than was necessary to account for fluid compression should have been a sign—although a subtle one—that the flapper valves were likely open.

Failure of the flapper valves would have provided a possible pathway for reservoir fluids to flow inside the casing and up to the surface. Had it been suspected that the flapper valves were not closed, the well probably would have been shut in and monitored for a time sufficient for the cement to set.

Finding 2.6: Evidence available before the blowout indicated that the flapper valves in the float collar probably failed to seal, but this evidence was not acted on at the time.

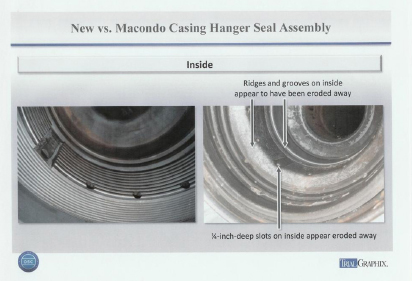

Probable Path of Hydrocarbon Flow

Identification of the probable hydrocarbon flow path up the Macondo well can provide insights for well design considerations to enhance the safety of drilling operations. Pictures of the long string casing hanger that was recovered, shown as Figure 2-9, indicate that hydrocarbon flow was up the inside of the casing, because the inside of the hanger showed signs of fluid erosion while the outside did not. However, under the correct circumstances, flow could have been up the annulus. Because the lockdown sleeve was not installed, the margin of safety against the potential for flow up the annulus was reduced.

There are alternative possibilities for the point of entry into the casing. As discussed above, the most likely possibility appears to be the combination of weak cement inside the casing and leaking flapper valves in the float collar. Another option would be for a split to have formed in the casing at some point. A review of the casing design and the pressure to which the casing was subjected

makes this possibility unlikely. In addition, the closing cementing plug was displaced to the top of the float collar with the correct volume of fluid and held pressure when the plug landed on the float collar. This would not have occurred had a split formed in the casing above the float collar.

Finding 2.7: On the basis of photographic evidence, it appears that flow was up the inside of the casing, because the inside of the hanger showed signs of fluid erosion while the outside did not. However, not installing a lockdown sleeve left a potential for flow up the annulus.

Good Cementing Practice

Industry practices that have been shown to provide the best chance for quality cement jobs are based on numerous principles (Smith 1990):

• Once casing is in the well, circulate at least one annular or one casing volume, whichever is larger. This is done to ensure (a) that no debris is inside the casing that might plug the float collar or shoe and (b) that the open hole section is stable, has no hydrocarbon flow entering the borehole, and is free of debris before cementing. The circulation also improves the likelihood of good bonding of the cement to the surfaces of the borehole and pipe by removing stagnant mud along with any debris.

FIGURE 2-9 View inside casing hanger. Source: Presidential Commission 2010, Slide 118.

This type of circulation was not done completely at the Macondo well to reduce the possibility of exceeding the fracture pressure because of unforeseen pressure surges. This decision by BP also cut down on the time spent circulating. Failure to perform the minimum circulation could leave debris inside the casing or annulus that may plug it. Any hydrocarbons in the annulus may result in a well control problem.

• Centralize the casing in the hole. This helps to prevent mud-filled channels in the cement by preventing the casing from being closer to one side of the hole than another. Failure to achieve good centralization increases the likelihood that mud-filled channels will be left in the cement, which can become flow pathways. A high gas flow potential indicates that gas may percolate through the cement as it sets and provide flow pathways through the cement.

Whether the casing was adequately centralized in the Macondo well is not clear, although the final computational simulation by Halliburton suggested that a gas flow potential existed. The simulation was run to obtain an optimal number and placement of centralizers onto the production casing. The simulation was flawed in that it did not use the most accurate data set available from the well. The best practice for centralizer placement is to use the results of the simulation, if it has used the most accurate well data. Some confusion about the number and placement of the centralizers and the accuracy of the final simulation appears to have occurred. A final simulation on the basis of the most accurate well data followed by a discussion of the results to make a decision on the final centralizer placement would have been prudent.

• Use a float collar and a guide or float shoe on the casing. The floats are valves that prevent backflow from outside the casing.

A float collar with two float valves in it was used in the Macondo well. A reamer shoe rather than a float shoe was used so that the differential fill tube could be installed in the float collar. The use of a float shoe in addition to the float collar would have increased the redundancy and thus the margins of safety.

• The casing should be reciprocated or rotated during the cement placement. Casing movement tends to help keep the mud moving ahead of the spacer and cement and tends to force cement to flow into pathways that might otherwise be bypassed.

This could not be done for the Macondo well because of the design choice of using the long string of casing. The long string casing hanger must be set into the wellhead when the casing reaches bottom to avoid its becoming stuck and losing the ability to place the casing hanger into the wellhead. Once the hanger is in the wellhead, the casing cannot be moved. Had a liner been used with a rotating liner hanger, it would have been possible to rotate the casing during cementing.

• Use a mud flush to remove the mud ahead of the cement. Surfactants are necessary for oil-base mud to reverse wettability on casing and hole wall, and they were used.

• Use enough cement to fill the desired hole volume plus excess to make up for hole washout and mud cake contamination. This was probably achieved, at least to the standards of the Minerals Management Service (MMS). However, it could not be verified because cement bond logging was not used.

• Where possible, achieve turbulent flow in the annulus, at least for the mud flush. Turbulent flow tends to help keep the mud moving ahead of the cement. Turbulent flow probably did not occur because of the low pump rate used.

Finding 2.8: Because of the choice of the long string of production casing, it was not possible to reciprocate or rotate the casing during the cementing operation. Casing movement tends to help remove any mud left in the path of the cement and force the cement into pathways that might otherwise be bypassed. The minimum circulation of mud was not achieved in this well, which would have been helpful in removing stagnant mud and debris from the annulus. Thus, the possibility of mud-filled channels or poor cement bonding existed.

Cement Bond Log

Whether to run a cement bond log was up to the discretion of the operator because MMS rules did not require a bond log if no lost circulation occurred during cementing operations. The decision was made not to run a cement bond log because no lost circulation had been noted during cementing operations. The design of the well placed the top of the float collar above the bottom of the deepest reservoir, so even had a log been run it could not have been run deep enough to examine the condition of the cement across all of the productive zones. The top of the cement and the cement quality in the annulus above the float collar could have been determined if the software necessary to evaluate the foam cement was on board.

Finding 2.9: No cement bond log was run to investigate the condition of the cement. The well design placed the float collar above the bottom of the deepest reservoir and would have prevented the log from investigating the lower sections of the well in which cement had been pumped.

Onshore Oversight

No person in authority (from BP onshore management or a regulatory agency) was required to review critical test data such as the results of the nega-

tive test. Had this been a requirement before operations could continue, the negative pressure test data might have been questioned and additional testing conducted that would have exposed the problem of reservoir communication with the well. The real-time data from the rig were being recorded but not monitored on shore. Even with the negative test having been accepted, subsequent data showing that the reservoir and well were in communication might have been discovered by personnel on shore in time to take the appropriate control action.

Finding 2.10: Although data were being transmitted to shore, it appears that no one in authority (from BP onshore management or a regulatory agency) was required to examine test results and other critical data and render an opinion to the personnel on the rig before operations could continue.

Alternative Well Completion Techniques for Temporary Abandonment

Alternative cement types or completion styles were available for use at the Macondo well. When personnel on the rig encountered a low margin of safety between the ECD and the fracture pressure, the safest approach would have been to plug the bottom open portion of the well and use the geologic data to design a replacement well. The replacement could have been a new well entirely or a sidetrack out of the lower portion of the existing well. Had a higher margin of safety between the ECD and the fracture pressure been required, this is the option that most likely would have been chosen. A redesign of the completion could also have provided sufficient depth below the producing formations so that the cement bond log could examine the presence and quality of the cement throughout the productive interval.

A sufficient margin of safety should be used for the ECD while fluids are circulating so that even with unforeseen pressure surges or rate and fluid property fluctuations, the possibility of fracturing is reduced. This is especially important during cement jobs in which only small cement volumes are used because the entire cement volume could be lost to a fracture.

ECD is a function of the density of the fluids and the friction pressure in the annulus required to circulate. Thus, the fluid properties, pipe-to-hole dimensions, and pump rate have an influence. There are no standards for this margin of safety, but one possible standard is to use a safety (kick) margin of 0.5 ppg, as referenced by several authors (Bourgoyne et al. 1991; Aadnoy et al. 2009). The authors define that safety margin in the same manner as an ECD margin of safety is defined in this report: as the difference between the mud weight that

would create a fracture and the ECD used. The ECD margin of safety discussed here does not obviate the need for other good drilling and completion practices to help avoid a kick or blowout.

Summary Observation 2.1: While the geologic conditions encountered in the Macondo well posed challenges to the drilling team, alternative completion techniques and operational processes were available that could have been used to prepare the well safely for temporary abandonment.

Missed Opportunity to Discover Hydrocarbon Flow

Data presented in the BP accident investigation report (BP 2010, 93) indicate that drill pipe pressure increased to 1,400 psi during the last of the negative pressure tests. The increase in the drill pipe pressure at that time should have been a clear indication that hydrocarbons might be flowing into the well. The rig personnel explained the pressure increase by using an erroneous theory termed the “bladder effect.”

Observation 2.2: Had an attempt been made to bleed off the drill pipe pressure at the end of the negative test, the communication with the reservoir would likely have been discovered.

Instability of the Foamed Cement

Foam is inherently unstable, and the extent to which it is stable is sensitive to its chemical makeup and the environment to which it is exposed. To make a foamed cement slurry that has a density of 14.5 ppg at the bottom of the well, the foam quality must be 17.4 percent at bottom hole conditions of 245°F and 13,321 psi. At the surface, where the conditions in the mixer are about 600 psi and 60°F, the foam quality must be 66 percent, producing a foam of about 6 ppg, to allow for the substantial compression and heating that will occur as the foam is pumped to the bottom of the well.

As foam is pumped into the well, where pressure and temperature increase with depth, the foam quality and slurry density change all the while (see discussion earlier in the chapter). Also, the shear associated with fluid movement down the inside of the pipe would act to break up large bubbles, which immediately reform as smaller bubbles so long as agitation is taking place. The foam cannot be considered stable in all of these conditions.

However, a chemical blend and surfactants were used on the rig in an attempt to make the foam stable at bottom hole conditions of the Macondo well—at least long enough for the slurry to set.

After the blowout, static tests were performed under laboratory conditions on a foam cement slurry similar to the one pumped into the Macondo well. Analysts observed settling of cement and breakout of nitrogen from the foamed cement exposed to atmospheric pressure. The tests were not carried out at bottom hole conditions. Therefore, it is impossible to say whether the foam was stable at the bottom of the well.

Observation 2.3: The results of a variety of static tests of foamed cement mixed at 14.5 ppg and exposed to atmospheric pressure call into question the stability of the foam, because settling of cement and breakout of nitrogen were observed in these tests. The tests were not performed at conditions that existed during pumping or at the bottom of the well and therefore cannot be considered as representative of the foam during displacement or at bottom hole conditions.

Potential for Cement Contamination

The lead slurry pumped into the Macondo well was made up of 5.26 bbl of un-foamed Class H cement and was in contact with the spacer and any mud that was not successfully moved out of the annulus once it was pumped out the end of the casing. The small volume of lead cement was designed to provide a high-strength cap between the spacer and mud that was ahead of and above the slurry and the foamed cement that was following and below. The small volume of lead cement may have been contaminated by either the spacer or the drilling mud from the annulus above the lead slurry or by mixing with the trailing foam slurry. Any contamination of the lead slurry would reduce the compressive strength of the cement once it set.

Observation 2.4: The pumping sequence of cement slurries and other fluids used for cementing the Macondo well subjected the volume of the lead cement slurry to contamination by the spacer or mud that was placed ahead of it. If it was heavily contaminated, the slurry would not have established a cement cap with the compressive strength of uncontaminated cement.

Possible Path of the Blowout and Implications for Well Construction

Had the blowout occurred up the annulus rather than inside the casing, the various liner tops and the rupture discs in the 16-inch liner would have been exposed to high pressure. A liner top or the rupture discs could have failed and allowed flow to exit the annulus and flow into a formation outside the well. This would have resulted in a downhole blowout rather than the surface blowout that

occurred. The shallowest possible escape point would have been 7,937 feet had a rupture disc and the top of the 18-inch liner failed (see Figure 2-2). This is about 2,937 feet below the ocean floor. Depending on the flow rate, pressure, and formation type, flow at this point might find a pathway to the ocean floor and cause a breach outside of the well. Therefore, a more robust design from a downhole blowout point of view would be to lower the possible point of escape from the wellbore to a deeper point where eventual breaching at the seafloor is impossible or at least very unlikely. This could be done by running a deeper casing string as a long string rather than as a liner and sealing it in the wellhead.

Observation 2.5: Had the path of the blowout been up the annulus, a liner top or the rupture discs could have failed and allowed flow to escape the well into a shallow formation. This would result in a down-hole blowout that could breach at the seafloor under the correct conditions. Future well construction could avoid this possibility by running one of the deeper casing strings back to the wellhead where it can be sealed. For example, in this well the 13 ⅝-inch liner could have been run back to the wellhead. This would protect the shallower liner tops and rupture discs from potential exposure to high pressure from flow up the annulus from a deeper reservoir.

Use of the Long String Production Casing

The use of the long string of production casing has already been cited as a reason the casing could not be reciprocated or rotated during cementing operations. One alternative to using the long string is to run a production liner on the drill pipe. The liner is suspended or hung several hundred feet up inside the previous casing, in this case the 9 ⅞-inch drilling liner that had been set at 17,168 feet. Cement is then pumped though the drill pipe and liner to fill up the desired annular volume. Often cement can be circulated to the top of the liner, which may create a seal at the top of the liner. If cement cannot be or is not circulated to the top of the liner, a cement squeeze is performed at the liner top where cement is forced into the annular space between the liner and the previous casing to form a seal at the top of the liner. A liner top packer that forms a mechanical seal at the top of the liner can also be deployed to replace or supplement the cement seal. The liner top is tested with a positive and a negative test in a manner similar to the testing of the long string to demonstrate wellbore isolation from the formations outside the liner. Because of the short length of the liner, it is also possible that the differential fill tube used in the float collar could have been omitted, removing one possible failure mechanism for the float equipment.

A major difference between testing of the liner top and testing of the long string is the reduced likelihood of other operations that can confuse the interpretation of the test being carried out at the same time. In addition, should the liner

top show signs of a leak, the well is still substantially full of drilling mud near the bottom of the well, and the drill pipe is in a better position, near the bottom of the well, to control the leak and begin repair operations.

Observation 2.6: The use of a production liner rather than the long string could have allowed for the use of a rotating liner hanger to improve the chances of good cement bonding; allowed for the use of a liner top packer to add a barrier to annular flow near the bottom of the well; allowed for the omission of the differential fill tube, which would remove a potential failure mechanism for the float collar; potentially made the negative test simpler to conduct and interpret; and configured the well to better control and repair a leak in the liner by leaving the well filled with drilling mud to a greater depth and by placing the drill pipe at a greater depth in the well during the test.

Margins of Safety

Summary Recommendation 2.1: Given the critical role that margins of safety play in maintaining well control, guidelines should be established to ensure that the design approach incorporates protection against the various credible risks associated with the drilling and completion processes.

Recommendation 2.2: During drilling, rig personnel should maintain a reasonable margin of safety between the ECD and the density that will cause wellbore fracturing.

There is no standard for this margin of safety. As a guide until a reasonable standard is established, industry should design the ECD so that the difference between the ECD and the fracture mud weight is a minimum of 0.5 ppg. In the event that a sufficient margin of safety cannot be maintained, the open section of the well should be plugged and alternative drilling or completion methods used in which the required safety margin can be maintained. Additional evaluations and analyses should be performed to establish an appropriate standard for this margin of safety.

Verifying Barrier Integrity

Summary Recommendation 2.3: All primary cemented barriers to flow should be tested to verify quality, quantity, and location of cement. The integrity of primary mechanical barriers (such as the float

equipment, liner tops, and wellhead seals) should be verified by using the best available test procedures. All tests should have established procedures and predefined criteria for acceptable performance and should be subject to independent, near-real-time review by a competent authority.

This includes the timing of the start and the magnitude of the pressure tests compared with the amount of time needed for strength development of the cement, the results of the pressure tests, verification that the flapper valves have closed and the other mechanical seals are holding, and evaluation of cement bond logs.

Well Design Review

Recommendation 2.4: The general well design should include the review of fitness of components for the intended use and be made a part of the well approval process.

For example, the review should consider alternatives to the use of a series of two cement slurries that will be gravitationally unstable during placement in the well and potentially result in a slurry that does not achieve the desired compressive strength. The review should also consider the use of a differential fill device because the use of this device in the Macondo well appears to have contributed to the failure of the flapper valves to perform their intended function.

Well Construction Practice

Recommendation 2.5: Generally accepted good operational or best practices should be used in the construction of the well. Such practices would ensure that the most accurate well data are passed from the operator to the various contractors for use in simulations and design and that the results are considered by all parties before implementation.