Additive Manufacturing Technologies: Technology Introduction and Business Implications

BRENT STUCKER

University of Louisville

INTRODUCTION

Additive manufacturing (AM) technologies have finally hit the mainstream. After 25 years of development as “rapid-prototyping” techniques, the industry is transforming into a manufacturing-focused enterprise. Today, when you walk the trade show floors and attend industry conferences, there are more than just engineers and manufacturers walking around. You also bump shoulders with investment bankers, venture capitalists, and do-it-yourself enthusiasts. A recent National Geographic video has gone viral on the Internet, showing the potential for 3D printing of a crescent wrench. So many people have seen the video and forwarded its link via email that some recipients assumed it must be a viral hoax, and snopes.com (the email hoax-tracking website) had to confirm the reality of “3D printing.” Within the past year the Economist, the New York Times, Standard &Poor’s, Wired magazine, and others have all written about 3D printing techniques.

So what is the hype all about? Many believe additive manufacturing is revolutionary and has the potential to transform manufacturing in the same way that Web 2.0 transformed cyberspace (the transition of the Internet to user-driven content, such as Facebook, Twitter, LinkedIn, etc.). As consumers begin to see the potential for creating their own manufactured goods using additive manufacturing, Factory 1.0 (production of physical goods by companies and manufacturing experts) will transform to Factory 2.0 (production of physical goods by consumers), thus permanently transforming the manufacturing landscape.

ADDITIVE MANUFACTURING

Additive manufacturing techniques are a collection of manufacturing processes that join materials to make physical 3D objects directly from virtual 3D computer data. These processes typically build up parts layer by layer, as opposed to subtractive manufacturing methodologies, which create 3D geometry by removing material in a sequential manner. In 2009, after more than 20 years of confusing terminology, the ASTM International F42 Committee on Additive Manufacturing Technologies defined additive manufacturing as the “process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies.” These technologies were also called rapid prototyping, direct digital manufacturing, solid freeform fabrication, additive fabrication, additive layer manufacturing, and other similar technology names over the years. In the technical community, an international consensus has coalesced around the use of “additive manufacturing,” whereas in the popular press the technologies are known as “3D printing.”

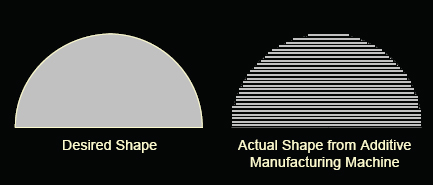

Every existing commercial AM machine works in a similar way. First a 3D computer-aided design (CAD) file is sliced into a stack of two-dimensional planar layers. These layers are built by the AM machine and stacked one after the other to build up the part (Figure 1). Today, there are seven different approaches to AM, and dozens of variants of these approaches. As most of these approaches were first patented in the late 1980s and early 1990s, in many cases the fundamental process patents have expired or are expiring soon—thus opening up the marketplace for significant competition in a way that was impossible over the past 20 years due to intellectual property exclusivity.

The remainder of this paper provides an overview on the seven different approaches to AM, followed by a discussion of the business trends and opportunities afforded by AM techniques. The breakdown of AM processes into the following seven categories is based upon the work of the Terminology Subcommittee of the ASTM F42 committee. At the time of the writing of this paper this categorization is being balloted, and thus the final names of these categories are subject to change as the standards-development consensus process proceeds.

Material Jetting

Material jetting is the use of inkjet printers or other similar techniques to deposit droplets of build material that are selectively dispensed through a nozzle or orifice to build up a three-dimensional structure. In most cases these droplets are made up of photopolymers or wax-like materials to form parts or investment casting patterns, respectively. These processes are truly 3D-printing machines, as they use inkjet and other “printing” techniques to build up three-dimensional structures.

FIGURE 1 Layered approach to AM.

Photopolymers are useful materials for material jetting because they transform from a liquid to a solid in the presence of light. Photopolymers can be tuned to cross-link and harden in response to different wavelengths of light, and for AM they typically transform in the visible or ultraviolet wavelength ranges.

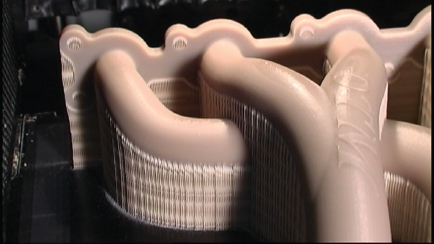

Material-jetting techniques often use multiple arrays of printheads to print different materials. The most common reason for printing two materials is for one of the materials to be used as the “build” material, while the second material is used as a “support” material. For 3D geometry that includes channels, voids, or overhanging structures, a support must be built below any overhanging surfaces (as droplets have to land on something to keep them in a fixed location; see Figure 2). When a secondary support material is used, a water-soluble material is commonly used so that the supports can be removed by immersing the part in a water-based liquid.

Material jetting is capable of printing multimaterial and gradient-material structures. Applications of multimaterial parts range from parts with controlled hardness and flexibility to parts with differing electrical properties in various regions to tissue-engineered structures with different biological properties in different regions of the part.

Binder Jetting

Binder-jetting techniques also use nozzles to print material, but instead of printing with the build material, the printed material is “glue,” which holds powder together in the desired shape. A binder-jetting process starts by first depositing a thin layer of powder. A printhead is then used to print a glue pattern onto the powder, thus forming the first layer. A new layer of powder is deposited and glue is printed again. This pattern is repeated until the part is completed.

FIGURE 2 Thermojet wax manifold. Note the supports.

Two benefits of binder jetting are its speed and its lack of need for secondary support materials. Since the majority of the volume of the part is made up of the powder material, only a small fraction of the volume of the part needs to be deposited from the printheads. As a result, a layer can be formed very quickly (using arrays of printheads)—often in a matter of seconds. The powder that surrounds the part being formed will naturally act as a support for any subsequent overhanging geometries, and no secondary support materials are necessary.

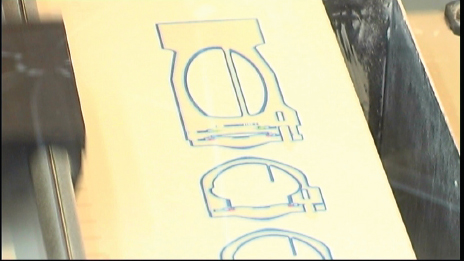

The only commercially available full-color 3D printing machines are binderjetting machines. A binder-jetting machine can be set up in such a way that a complete color spectrum can be printed layer-by-layer. This enables assembled parts to be produced in the intended colors (for marketing purposes) and for graphics, labels, and other visual features to be directly printed onto a part as it is being produced (Figure 3).

Photopolymer Vat

Photopolymer vat processes involve selective curing of predeposited photopolymers using some type of light source. Stereolithography, the first patented and commercialized AM process, works by scanning a laser across the surface of a vat of photopolymer. A platform is raised to just one layer thickness below the surface of the liquid. The laser scans the first cross-sectional layer, attaching the layer to the platform. The platform is lowered within the vat one layer thickness

FIGURE 3 ZCorp 3D printed layer. Glue is printed inside the blue contours of the part layer. Color figure available online at http://www.nap.edu/catalog.php?record_id=13274.

(and material flows over top of the previously formed layer, or is formed over the previous layers using a blade or deposition device), and the process repeats until the part is completed. Photopolymer vat techniques give some of the best accuracies and surface finishes of any AM process.

Some photopolymer vat technologies have been developed to use digital light processing projectors to project an image of the layer on the surface of the vat, thus cross-linking the photopolymer and converting the entire layer from a liquid to a solid simultaneously.

Photopolymer vat technologies require a support network to be built for overhanging structures, otherwise these structures are subject to breaking or deforming. These supports are made from the same material that the part is made from, so these supports must be cut away after the part is completed.

Material Extrusion

The largest installed base of AM techniques is based upon material extrusion. Material-extrusion machines work by forcing material through a nozzle in a controlled manner to build up a structure. The build material is usually a polymer filament that is extruded through a heated nozzle—an automated version of the hot-glue gun used for arts and crafts. After a layer of material is deposited by the nozzle onto a platform, the platform either moves down or the nozzle moves up, and then a new layer of material is deposited.

In instances where two nozzles are installed in a machine, one of the nozzles is typically used to deposit a water-soluble support material. Three or more nozzles are sometimes used in machines designed for tissue-engineering research, so that scaffolds and other biologically compatible materials can be deposited in specific regions of the implant.

The simplicity of material-extrusion machines makes them suitable for in-office and home environments. Today, thousands of inexpensive extrusion machines, ranging in price from $700 to $3,000, are sold each year to do-ityourself enthusiasts, small companies, educational institutions, and hobbyists. This proliferation of low-cost AM machines is a major reason for the current mainstream interest in 3D printing.

Powder Bed Fusion

Powder-bed-fusion machines work in a manner similar to binder jetting; however, instead of printing glue onto a layer of powder, thermal energy is used to melt the powder into the desired pattern. In most machines a laser is used to melt polymer or metal powders to build up three-dimensional objects. Another common variant is the use of an electron beam to melt metal powders.

In the case of polymer powders, the powder surrounding the part being built makes possible the creation of complex three-dimensional objects without supports. However, for metal powders, the thermal shrinkage of metal parts during solidification causes the parts to warp; supports are used to attach the part to a thick metal baseplate to maintain the accuracy of the parts and restrain them from warping. These metal supports are machined off after the part is completed.

Powder-bed-fusion machines are the most commonly used AM machines for the creation of end-use parts for highly engineered products. Polymer and metal parts made using these techniques are becoming widely used in aerospace, defense, and other highly engineered systems.

Directed Energy Deposition

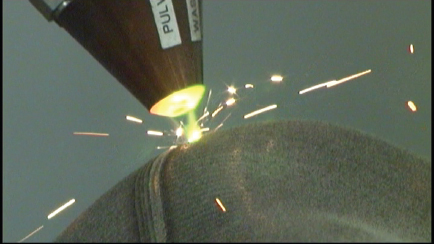

Directed-energy-deposition machines melt material with a laser or other energy source as material is being deposited. These machines work similarly to material-extrusion machines except that, instead of melting the material with a nozzle, the wire or powder feed material is melted as it is being deposited onto a part (Figure 4).

In order to make parts with overhangs, directed-energy-deposition systems need to use either a five-axis deposition system (so that material can be deposited from any orientation) or a secondary support material. Because these systems are typically used to make metal parts or metal-ceramic composite structures, any supports that are used require machining to remove them.

Directed-energy-deposition processes are used primarily to add features

FIGURE 4 Trumpf machine depositing metal from powder (across a curved surface).

to an existing structure (such as adding strengthening ribs onto a plate) or for repair of damaged or worn parts. In most cases these processes are used to build up metal structures, and thus they are commonly referred to as metal-deposition AM machines.

Sheet Lamination

Sheet lamination techniques work by cutting and stacking sheets of material to form an object. This approach has been used with paper, plastic, and metal sheets to build up wood-like, plastic, and metal parts, respectively. A binder is typically used to bond paper and plastic sheets, whereas welding (either thermal brazing or welding, or ultrasonic welding) or bolting of sheets together is typically used for metals. Additionally, sheet lamination has been used with ceramic and metal green tapes (e.g., powder held together by a polymer binder in the form of a sheet of material) to build up structures that are later fired in a furnace to achieve a dense part.

Hybrid and Direct-write AM

In some instances multiple AM techniques are combined within the same machine or AM is combined with subtractive techniques such as computer numerical control milling or laser cutting. For instance, by combining a simple

horizontal milling head into a material-jetting machine, Solidscape has created a popular line of high-precision wax printing machines with layer thicknesses of 0.0005 in. that are heavily used in the jewelry industry to create wax patterns for custom jewelry.

Several AM techniques have been modified to work at a small scale to deposit passive electronic structures (conductors, insulators, resistors, antennas, etc.). These techniques are often known as direct-write techniques and, for instance, use electronic “inks” that contain nanoparticles or other additives that result in electronic properties after drying, thermal decomposition, or other post-treatment. By combining direct-write techniques with other AM techniques it becomes possible to create multifunctional 3D-embedded electronic structures on a layer-bylayer basis that combine structural, thermal, electronic, and other functions into a single component.

BUSINESS IMPLICATIONS OF AM

AM has made a significant impact on manufacturing design over the past 25 years as rapid-prototyping techniques. The ability to create three-dimensional objects directly from CAD data allows designers to print out 3D representations of their designs for form, fit, and functional testing during the design process. This reduces the time needed to prototype new designs and enables more optimized designs to propagate through to manufacturing, catching errors before committing to costly mass-production tooling and assembly lines.

The layer-by-layer approach of AM is particularly well suited for highly complex geometries, including geometries with internal passageways, undercuts, and features that are difficult or impossible to make using traditional manufacturing techniques. For small, highly complex objects, AM powder-bed-fusion processes are sometimes cheaper than injection molding for volumes of parts approaching 100,000 components. However, the larger the part or the simpler its geometry, the more cost-effective traditional manufacturing processes become, compared to AM.

AM is well suited for parts with complex geometries that are made in low volumes or for personally customized geometries. For instance, AM is used today in many aerospace systems, including the Space Station, microsatellites, F-18 fighter jets, Boeing 787 aircraft, and more, and for custom dental aligners and hearing aids. AM techniques are commonly used as assembly jigs and fixtures by BMW and others to enable more ergonomic, accurate, and quick assembly of automobiles.

One of the key benefits of AM techniques is that there is no tooling or specialized hardware needed for any individual component. Each and every part can be unique from the part created just before or after it. A manufacturer can thus distribute AM machines near to the point of assembly or to the end customer, dramatically changing the logistics and distribution models for manufacturing rather than concentrating manufacturing where tooling is located. Since AM

involves little human involvement to create a part, there is no longer an incentive to offshore manufacturing to a region of low-cost labor. As a result, onshoring is the standard for AM.

One particularly good opportunity for AM techniques is in the area of spare part production. If an out-of-production component is needed, a scanning technique can be used to capture the geometry of a broken part, modifications can be made to the CAD file, and a replacement part can be printed out. This is increasingly being used by people who restore automobiles, aircraft, defense systems, and other machines that were designed and built decades ago for which there are no CAD drawings or tooling available to make a replacement part and/or where the original manufacturer is no longer in business.

PERSONAL MANUFACTURING

AM is today where personal computing was in the late 1970s and early 1980s. AM is starting to move from the “mainframe” manufacturing arena into the “personal” manufacturing arena. In 2010, more than 5,978 “personal” AM machines were sold (all material-extrusion machines, most of which are sold for between $700 and $1,500), as compared to an estimated 6,164 other AM systems. In 2007, when personal AM machines first became available, only 66 personal AM machines were sold compared to 4,938 other AM systems (Wohlers, 2011). Thus, even though mainframe AM systems are growing at a respectable rate, the personal AM market has grown explosively. From an economic standpoint, as personal AM machines are sold at a cost of between 0.1 and 10 percent of the cost of other AM machines (with a commensurate lack of speed, accuracy, materials flexibility, etc.), the personal market is still a small portion of the overall AM market. However, explosive growth has caught the eye of many investors and companies, who are starting to make plans to enter the market.

ENTREPRENEURSHIP

A comparison of 3D printing to 2D printing is commonly used to understand the potential for AM. For 2D printing, there is a relatively stable mix of high-volume printers (e.g., newspapers, magazines, advertisements, etc.), medium-volume printers (e.g., digital photocopiers), and low-volume printers (e.g., laser and inkjet printers). In the same way that a consumer can purchase a mass-produced poster, print their own photos at Walmart, or use their own inkjet printer at home, 3D printing will likely be used by major manufacturers in factories, local suppliers in neighborhood 3D print shops, and within peoples’ homes in the near future.

For AM, entrepreneurial opportunities include the development of new AM machines, supplying AM-produced components to major manufacturers, printing designs for consumers, selling unique designs for people to print at home, and more.

Thus, AM offers entrepreneurs the opportunity to develop new hardware, software, and services that either supplant existing products or introduce completely new products. For instance, entrepreneurs have started companies that develop and sell personal AM machines (www.makerbot.com), provide web portals for designers and consumers to sell and buy parts (www.shapeways.com; i.materialise.com), provide customized dental aligners (www.aligntech.com), sell unique artistic (www.bathsheba.com) and consumer products (www.freedomofcreation.com), and more.

AM enables designers and entrepreneurs to start selling products without their own brick-and-mortar infrastructure. This is a new paradigm in manufacturing. Instead of requiring investors to provide startup capital, a creative person can create and sell unique goods without ever buying a manufacturing machine or paying for the development of a mold or tool. This means that the barrier to market for entrepreneurial activity in AM is very low and the distinguishing factor between successful and unsuccessful entrepreneurs may often have more to do with their ability to create marketing momentum through social media than their ability to secure venture capital or other financing. This means that entrepreneurs who are creative and understand the capabilities, benefits, and limitations of AM will have an edge over others.

CONCLUSIONS

AM technologies have the potential to create a new type of industrial revolution. AM is moving far beyond rapid prototyping in many industries. In the same way that the Internet has democratized the creation and distribution of information, AM has the potential to democratize the creation and distribution of physical goods. The ability to create customized, geometrically complex parts without tooling lowers the barriers for entrepreneurial activity and gives designers never-before-available opportunities for optimized design. Today AM is crossing the barrier from a specialized set of manufacturing and design tools into the regime of “personal” manufacturing. Those who are able to capitalize upon new business models involving physical goods might very well be the “Internet billionaires” of the future.

SUGGESTED SOURCES FOR FURTHER INFORMATION

Gibson, I, D.W. Rosen, and B. Stucker. 2010. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing. New York: Springer (an engineering textbook).

Rapid Prototyping Journal, Emerald Publishing (the leading AM-related journal, in its 16th year of publication).

Solid Freeform Fabrication Symposium proceedings (the premiere academic conference on AM since 1990). All papers are available for download at http://utwired.utexas.edu/lff/symposium/.

Wohlers Report 2011: Additive Manufacturing and 3D Printing State of the Industry. 2011. Fort Collins, Colo.: Wohlers Associates (a detailed industry analysis, updated annually).

www.additive3d.com (the well-known “Castle Island” website. Its terminology is a bit dated, but it has a lot of information for people who are new to the industry.)