Lightweighting Airborne Vehicles

2.1 CURRENT STATE OF LIGHTWEIGHTING IMPLEMENTATION AND METRICS

2.1.1 Drivers of Lightweighting

At the highest level, all aircraft designs are driven by performance, cost, and risk. The factors that affect each driver are these:

- Performance: thrust, weight, lift, and drag.

- Cost: research, development, test and evaluation (RDT&E); manufacturing; certification and qualification; and operations and support (O&S).

- Risk: safety, resource availability, technical maturity, and schedule.

Weight has been an important consideration in military and commercial aircraft design since the beginning of manned flight. It affects directly the amount of lift required to fly, which in turn affects the drag on the aircraft and therefore the thrust required to achieve the desired performance. Weight also has indirect impacts on the cost of the aircraft.

The importance of lightweighting for military aircraft depends on aircraft type. Table 2-1 relates the attributes shown previously in Table 1-1 to various military aircraft types. The three main attributes (functional capabilities, operational capabilities, and survivability) correspond roughly to the three parameters driving aircraft design as defined above (performance, cost, and risk), with some overlap. Trainers, fighters, and attack aircraft are included in the “fighter” category; primary military vehicles, tankers, and transports are included in “transports.” “Primary” and “secondary” assess the relative importance of these capabilities for aircraft design, and the numbers 1 through 3 rank the importance of the attribute for the aircraft type.

Military aircraft are driven by performance features (functional capabilities), which are strongly affected by weight. The O&S attributes of fuel consumption, maintainability, and the like are still primary design drivers for most aircraft and are related to weight in a lesser sense by virtue of fuel consumption and efficiency of the design. Thus, weight considerations are central to aircraft design.

Survivability is a design parameter for all military aircraft but a primary driver only for fighters, which sometimes depend on low observability to get to the target. It is not so important for unmanned aerial vehicles (UAVs) and remotely piloted aircraft (RPA) because, at least to date, they are not being used for first-strike operations.

TABLE 2-1 Lightweighting Attributes for Military Aircraft Systems

| Capability | Aircraft Type | Summary | |||||

| General Attributes |

Specific Attributes | Fighters | Transports and Bombers |

Helicopters | RPA / UAVs | Commercial Transports | Aircraft (Tactical and Transport) |

| Performance | Speed Maneuverability Payload Range Effectiveness |

Primary 1 |

Primary 1 |

Primary 1 |

Primary 1 |

Primary 2 |

Primary 1 |

| Operational Supportability | Fuel Consumption Maintainability Durability Reliability Repairability |

Secondary 3 | Primary 2 |

Primary 2 |

Primary 2 |

Primary 1 |

Primary 2 |

| Survivability | Ballistic Impact Explosion Damage Tolerance Observability |

Primary 2 |

Secondary 3 |

Secondary 3 |

Secondary 3 |

Secondary 3 |

Secondary 3 |

NOTE: RPA, remotely piloted aircraft; UAV, unmanned aerial vehicle.

However, at least two trends are forcing UAVs to become more reliable. When these aircraft begin to fly over populated areas, the potential for damage and injury to personnel on the ground when such aircraft fail in flight will be a concern. Moreover, the suite of sensors they carry is becoming increasingly expensive. UAV designers will need to begin paying as much attention to risk as designers of manned aircraft do. This risk tolerance must be traded off against the performance requirements for vehicles such as high-altitude, long-endurance (HALE) UAVs, where risk increases if design margins are reduced to achieve the lowest possible density, but flight over populated areas drives a desire for reduced risk. Generally speaking, lightweighting of military aircraft will therefore need to be done with an eye to retaining or improving survivability.

2.1.2 Historical and Current Lightweighting

Early work on composite and hybrid material systems in transport aircraft attempted to match their properties and design methods to those of aluminum. The results were nicknamed “black aluminum” structures, which ended up sacrificing many of the favorable characteristics of composites that had led to their adoption in the first place. For example, incorporating composites into structures originally designed for aluminum where transverse and shear stiffnesses had to be maintained meant that the tailored stiffness in bending of the composites could not be put to use.

Rotorcraft have also taken advantage of lightweight materials and structural concepts. Lightweight components for the engine and transmission housings have been studied but are not seeing widespread use today; however, lighter-weight materials and designs are finding their way into the airframe and the rotors of advanced rotorcraft.1 Composites with integral stiffening were examined in the NASA/Army-sponsored Rotary Wing Structures Technol-

________________

1 J.K. Sen and C.C. Dremann. 1985. “Design Development Tests for Composite Crashworthy Helicopter. Fuselage,” SAMPE Quarterly, Vol. 17, No. 1, October, pp. 29-39.

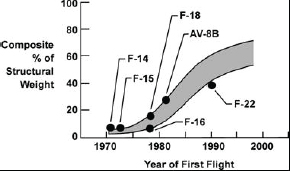

FIGURE 2-1 Composites in U.S. Fighter aircraft. SOURCE: C.E. Harris and M.A. Shuart. 2004. An Assessment of the State-of-the-Art in the Design and Manufacturing of Large Composite Structures for Aerospace Vehicles, NASA-Langley. Available at http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20040086015_2004090422.pdf.

ogy Demonstration (RWSTD) program.2 More recently, under Boeing funding3 composite rotor blades have been developed that offer significant cost savings compared with those previously developed for the AH-64 Apache attack helicopter. Rotorcraft development organizations have been among the first to develop and employ health monitoring systems as a means to ensure the integrity of advanced composite systems.4

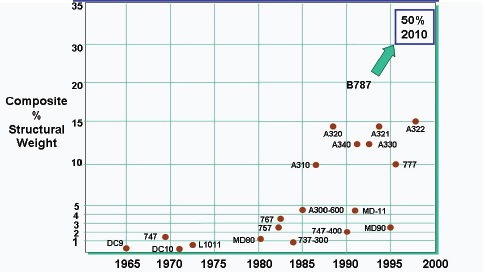

From 1970 to 2000, designers began to take advantage of the properties of resin matrix composites, which were introduced sequentially into the skins of the empennage (rear part or tail assembly), wings, and fuselages of military aircraft, as shown in Figure 2-1. After their successful implementation in military aircraft, these materials began to be introduced into commercial aircraft, as shown in Figure 2-2. Until recently, however, the cost of composite materials limited their application by commercial aircraft. Furthermore, the fuel savings that resulted from lighter weight were not sufficient to overcome the cost of the materials and the manufacturing processes.

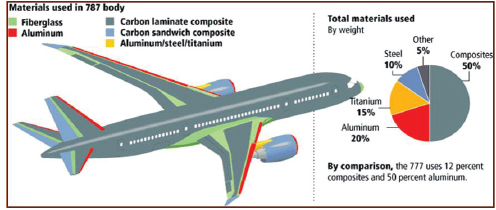

In the 1990s, manufacturing technologies for composite materials became more capable, less costly, and more pervasive, allowing production of parts around the world. At the same time, higher actual and predicted fuel prices made composites increasingly desirable for commercial aircraft. By the time the Boeing 787 was being developed, the costs of design, production, and operation allowed much greater use of composites in the airframe. This was aided by the use of advanced physics-based modeling and simulation for design, development and manufacturing.5

As materials analysis and fabrication methods continue to improve, composite materials are being employed extensively, not just for lightweighting but also to improve impact resistance and resistance to fire, damage, lightning strikes, ultraviolet (UV) degradation, moisture, and thermal degradation. Over time, experience has led to the preference for certain resin systems and fiber-sizing materials. Repair methods have been developed for composite structures and have been successfully used in both commercial and military applications.

________________

2 Shawn M. Walsh and Bruce K. Fink. 2001. “Achieving Low Cost Composite Processes through Intelligent Design and Control.” Presented at the RTO AVT Specialists’ Meeting, Low Cost Composite Structures, Loen, Norway. May 7-11. Published in RTO-MP-069(II).

3 Jian Li, P.H. Jouin, and A.S. Llanos. 2010. “Durability and Damage Tolerance Enhancement Feature and Life Prediction Methodology for the Apache Composite Main Rotor Blade (CMRB) Root-end Fitting,” American Helicopter Society 66th Annual Forum, Phoenix, Ariz., May 11-13.

4 Michael L. Basehore and William Dickson. 1998. “HUMS Loads Monitoring and Damage Tolerance: An Operational Evaluation.” Presented at the NATO RTO AV T Specialists Meeting, Exploitation of Structural Loads/Health Data for Reduced Life Cycle Costs, Brussels, Belgium, May 11-12. Published in RTO MP-7.

5 Göran Fernlund. 2008. “Reduction of Risk and Uncertainty in Composites Processing Using Process Modeling and Bayesian Statis tics.” Presented at the 13th European Conference on Composite Materials, Stockholm Sweden, June. Available at http://www.escm.eu.org/ECCM13_broschure.pdf.

FIGURE 2-2 Composites in commercial transport aircraft. SOURCE: Charles E. Harris, James H. Starnes, Jr., and Mark J. Shuart. 2001. An Assessment of the State-of-the-Art in the Design and Manufacturing of Large Composite Structures for Aerospace Vehicles. NASA-Langley. Available at http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20040086015_2004090422.pdf.

2.1.3 Current State of Metrics

Until recently, weight was used directly in calculating aircraft costs at the conceptual design stage. Military and commercial data dating back to 1935 had been used to develop and refine an understanding of the relationship between cost and weight for “built-up” aluminum structures. Translating weight into cost worked well until about 1970, when composite structures began to see greater application in military aircraft.6

Composite materials offer great potential for weight savings at the same time that they lead to improved performance for military aircraft and lower operating costs for commercial aircraft. However, metrics are not available to compare those benefits with the significantly increased production costs. The aluminum-based cost models are not valid for composites, and the uncertainty surrounding costs became greater in the late 1990s, when stealth materials were introduced in military aircraft such as the B-2 (Figure 2-3) to reduce radar signatures.

The higher costs of composites had less to do with raw material costs than with the need to fabricate parts in expensive autoclaves using tooling that was unique for each part and each design. Projecting the costs of aircraft that incorporated composite materials meant developing very detailed cost models that incorporated the cost of tooling and layup and reflected the complexity of the parts and of their fabrication. It has taken a long time for such tools to become standardized in the aerospace industry, and they still are not as well validated as the cost models for metallic structures had been.7,8

The assessment of risk is a crucial metric for advanced technology. Risk drives cost and schedule as program managers attempt to achieve the weight and cost advantages of advanced technologies while reducing the risk

________________

6 K. Zhou, C. Radcliff, T. Lenzm, and J. Stricklen. 1999. “A Problem Solving Architecture for Virtual Prototyping in Metal to Polymer Composite Redesign,” Proceedings of the DETC’99: 1999 ASME Design Automation Conference. September 12-15, Las Vegas, Nev.

7 S.A. Reseter, J.C. Rogers, and R.W. Hess. 1991. “Advanced Airframe Structural Materials: A Primer and Cost Estimating Methodology.” R-4016-AF. RAND.

8 Han P. Bao, 2002. “Process Cost Modeling for Multidisciplinary Design Optimization.” NASA Grant NAG-1-2195. Norfolk, Va.: Old Dominion University. June.

FIGURE 2-3 Composite applications for the B-2 highlighted the need for new validated cost models. SOURCE: Available at http://www.aviationexplorer.com/Stealth_Principles_What_Makes_Stealth_Aircraft_Work.html.

that technology maturation will lag, thus delaying the schedule and increasing the costs of implementation. While the relationship has been understood for a long time, only recently have tools become available that allow risk to have the same visibility as cost and performance (weight) in the manager’s evaluations.

2.2 BARRIERS AND KEYS TO SUCCESS

Because aerospace applications, especially vertical lift vehicles like rockets and helicopters, can justify higher costs for materials that reduce their weight, cost is not as great a barrier as it is for land and sea applications. Developers will not seek to achieve lower weight without appropriate cost and risk assessments, but the more serious barriers to lightweighting in aircraft relate to technology and management. These barriers include the need for (1) new materials; (2) new manufacturing processes and equipment; (3) systems engineering approaches to handling the multiple demands placed on materials and structures by aircraft applications; (4) more rapid insertion processes that include advanced physics-based modeling and reduce the test burden; and (5) less risky transition methods that account for all the requirements of the new air vehicles.

2.2.1 Timelines for Materials Development

The development of composite material and of its associated manufacture take much longer than the design cycle for new systems.9 As a result, manufacturers often use existing materials and manufacturing systems for which data exist rather than emerging materials and manufacturing systems that are promising but unproven.

________________

9 C.R. Saff, G.D. Hahn, J.M. Griffith, R.L. Ingle, and K.M. Nelson. 2005. “Accelerated Insertion of Materials—Composites.” 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference. April.

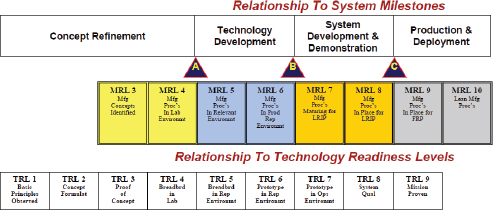

FIGURE 2-4 MRL relationships. SOURCE: Jim Morgan. 2006. “Manufacturing Readiness Levels (MRLs) for Multi-Dimensional Assessment of Technology Maturity,” presented at the Air Force Research Laboratory Seminar/Workshop on MultiDimensional Assessment of Technology Maturity. Fairborn, Ohio. May 9-11. Available at http://www.dtic.mil/cgi-bin/GetTRDoc?Location=U2&doc=GetTRDoc.pdf&AD=ADA507087.

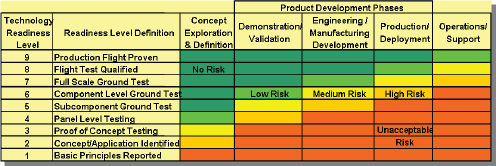

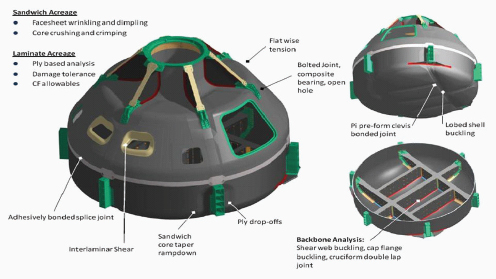

A material is considered application-ready at technology readiness level (TRL) 6,10 when manufacturing scale-up and fabrication trials are complete and typical design values are in hand. The TRL scale measures the maturity of a technology’s performance. The corresponding manufacturing scale of maturity is the manufacturing readiness level (MRL).11 MRLs were developed to assess the manufacturing maturity of a technology or product and the plans for its future maturation; to provide a common language to convey risk; and to understand the manufacturing risk associated with producing a weapon system or transitioning a technology into a weapon system application. The relationship between TRLs and MRLs and system acquisition milestones is shown in Figure 2-4. System manufacturers can begin to consider a material during the conceptual and preliminary design phases, but once the product goes to detailed design, the materials must be locked in for that design unless special provisions are made to keep the door open. Even that must be curtailed at the engineering and manufacturing development stage, when testing for “allowables”12 is done to develop data for materials in their as-fabricated condition for final design. (See the section “Materials Properties and Testing” in Chapter 1.)

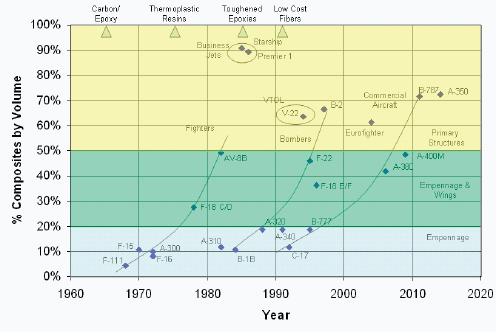

Strong demand for lighter materials is driven by their performance payoff. As shown in Figure 2-5, each new composite material has been introduced gradually. As the materials and their manufacturing processes mature and their capabilities are demonstrated, they begin to account for a growing portion of each aircraft type. New materials are used first in hardware that is not flight-critical, then in empennage structures, then in wings (where their payoff is usually greatest) and in other primary structures (fuselage skins and substructures).

As shown in Figure 2-5, new materials are often first introduced in fighters, where performance is the main consideration, then in business jets and rotorcraft, then in the larger bombers, and, finally, in commercial aircraft. It takes 5 to 10 years from the availability of a new material to its introduction into aircraft empennage surfaces, depending on how quickly manufacturing processes can be developed that enable low-cost fabrication of parts;

________________

10 See Chapter 5 of this report for a list of the DoD’s nine TRL levels; level 9 is the successful use of a system in mission operations.

11Manufacturing Readiness Level (MRL) Handbook, version 2.01, July 2011. Available at http://www.dodmrl.com/MRL_Deskbook_V2.01.pdf provides best practices for MRL.

12 “Design allowables are statistically determined material property values derived from test data. They are limits of stress, strain, or stiff ness that are allowed for a specific material, configuration, application, and environmental condition.” See p. 361 in ASM Handbook, Vol. 21, Composites, 2001. ASM International.

FIGURE 2-5 Timelines for the introduction of composite materials into aircraft. Of the two circles, the first links the business jets, and the second indicates the single rotorcraft to separate them from the other aircraft shown. SOURCE: Developed based on information in (1) R.B. Deo, J.H. Starnes, and R.C. Holtzwarth, “Low-Cost Composite Materials and Structures for Aircraft Applications,” paper presented at the RTO AVT Specialists’ Meeting on Low Cost Composite Structures, Loen, Norway, May 7-11, 2001, and published in RTO-MP-069(II); (2) M. Buckley, “An Introduction to Composites at Airbus,” presented at HYBRIDMAT 4, 2007, available at http://www.adcom.org.uk/downloads/3D Preform Technologies for Advanced Aerospace Structures.pdf; and (3) C. Harris and M. Shuart, “An Assessment of the State-of-the-Art in the Design and Manufacturing of Large Composite Structures for Aerospace Vehicles,” NASA Langley Research Center, April 2001. Available at http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20040086015_2004090422.pdf.

about 10 years from fighters to bombers; and then another 10 years from bombers to commercial aircraft. The transition from empennage structures (tail surfaces) to primary structures is about 10 to 15 years.

2.2.2 System Engineering for Multifunctional Design

Multifunctional Structures

Components and structural elements that serve multiple functions offer the potential to lighten a structure. One way to achieve multifunctionality is through functionally graded materials that have properties and material constituents on one surface that differ from those on another surface, or are stratified through the interior of a part. There are a number of common examples, such as alclad aluminum, which provides corrosion protection for the base aluminum; or interlaminar toughened epoxies like those used in the 787, which provide impact damage resistance to composite systems. Hybrid materials like GLARE13 that marry conventional aluminums with high-

________________

13 R.C. Alderliesten. 2007. “On the Available Relevant Approaches for Fatigue Crack Propagation Prediction in Glare.” International Journal of Fatigue. Vol. 29, Issue 2, pp. 289-304.

strain glass-fiber-based systems can provide significant increases in damage tolerance for aluminum. The goal of graded materials has always been to build a material with graduated properties so that it meets different requirements in different locations within the material of component part.

Multifunctionality also encompasses “intelligent material” design, using either inherently smart materials or composites designed with multifunctional attributes. Examples of such materials are conductive polymers and high-temperature-resistant ceramic materials. Combinations of metallic and ceramic materials that protect the metal with a high temperature resistant coating while retaining the strength and toughness of the metal have been attempted for years. Similarly, inorganic and organic hybrid materials offer “designed” thermal and electrical conductivity and improved mechanical properties. While they have not yet reached maturity, nanoparticle technologies may offer the breakthrough required to make these kinds of materials a reality.

While progress has been made in the use of lightweight composites that are resistant to fire and tolerant of impact damage, there are other barriers to their use. Protection from electromagnetic effects (EME) is still an add-on system that is assumed not to carry loads, but because it strains along with the wing skin materials and has stiffness, it does carry a portion of the loads.14 Burn-through criteria now set the minimum gage for composites more often than do the loads. That is, the time to burn through a composite fuselage skin panel can define the required thickness of the material. Thus, improving fiber, resin, or sizing materials is insufficient without also addressing burn-through.

To overcome these challenges to the use of composites, methods to predict their properties accurately will have to be developed. Testing will then be used not to characterize the materials, but to verify that they are behaving as predicted. The predictive capability cannot be limited to the simple geometries of the coupon and element tests—it must also be capable of predicting the performance of highly complex shapes, structures, and components not only under expected service conditions, but also under the worst case loading expected for off-nominal flight conditions.

Design for Durability

Today’s aircraft structures must meet a host of durability requirements while still carrying loads and being capable of deflections that shed loads and enhance the aerodynamic performance of the aircraft. Durability issues include burn resistance, damage resistance, EME tolerance, and resistance to UV degradation, chemicals, moisture, and extreme temperatures. Aluminum is affordable and has an excellent set of properties under these conditions that, until recently, made it the material of choice for large transport aircraft.

Some successes have been achieved by a new approach to the design of structures such as wings, which would have not been possible with aluminum. For in-plane loads, composite laminates having more than 25 percent of the fibers running in the load-carrying direction have much greater resistance to fatigue damage than do metallic structures. Thus, good composite designs offer better durability than good metallic designs. Because composite materials allow for tailoring the twist of a wing as it bends under airflow, it has been possible to achieve better aerodynamic performance.15 This tailoring has been used on X-29, F/A-18, and 787 aircraft to achieve better performance at lower weight. And only in recent years have the tools required to predict loads and perform these design and analyses been generally available to aircraft design teams.

2.2.3 Shorter Insertion Time for New Technologies

If allowables for composites must be determined based on testing, it would be beneficial to focus it on the means of the properties and not on their distributions, which take hundreds of tests to determine. The ability to predict strength based on material parameters such as resin make-up, fiber properties, sizing capabilities, variability of processing parameters, and so on might significantly reduce the amount of testing needed for composite materials. This is discussed further later in this chapter in the section on ICME for composite materials. One ele-

________________

14 R. Jones. 1998. Mechanics of Composite Materials. 2nd Edition. Materials Science & Engineering Series.

15 M.J. Patil. 1997. “Aeroelastic Tailoring of Composite Box Beams.” Georgia Institute of Technology. Published through the American Institute of Aeronautics and Astronautics.

ment of the ICME approach is the Advanced Mean Value Algorithm,16 which requires only 10 or fewer specimens to accurately determine the mean of the property distribution.17 If the expected variation in properties is known from chemistry and mechanics, the allowables could be determined much more rapidly and from far fewer tests.

Another way of hastening the determination of allowables will be the development of semi-empirical approaches to predicting the strength of a composite material for a wide range of geometries, layups, and loadings. Today’s methods for doing this are of two kinds. One is focused on using laminated plate theory18 to convert the data from element tests to pseudo-lamina in situ properties, then applying them to structural strength predictions. This works well when the loads are applied in plane and when the damage state of concern is the same as that incorporated in the test. Whenever these conditions are violated, which happens all too often, additional tests are required to validate the more difficult details of the design. It can be very difficult for these tests to recreate the load or damage conditions of concern because the structure being modeled is so complex.

The second method19 used is to intrinsically model the structure, including the layup, the geometry, the damage, and the loadings and perform a damage tolerance analysis on it. In general, this takes a very detailed finite element model, far more detailed than those normally used to predict internal load and strain distributions. Often because of the damage, loading, or geometry, these analyses must be performed using nonlinear methods, which increase run times and the complexity of interpretation. Such models cannot be run for every condition the aircraft might undergo: Because they are simply too complex and too time-consuming to validate and perform, they are run only for the most critical or complex cases.

A third possible way of surmounting the test barrier is to use existing tests and data to cover new materials, as was done using the Advanced General Aviation Transport Experiments (AGATE) process for general aviation vehicle design20 and the Composite Materials Handbook 17 (CMH-17) methods for shared data.21

2.2.4 Accelerating the Transition from Laboratory to Product

The difficulty of bringing a new technology to the marketplace has been dubbed the Valley of Death, because so many promising technologies die before they are used in products. The Valley of Death occurs when technology is developed to some extent, and then a search begins for applications. Since the key requirements of candidate applications were not taken into account during the technology development process, oftentimes the development has to restart. Aircraft are no exception, and the difficulty of this transition inhibits the greater use of lightweighting technologies.

If technology is developed in response to a defined need, there is no Valley of Death. Therefore, the key to truly accelerating technology transition is to create a mechanism for technology pull. Advanced technology demonstrations (ATDs) are one strategy used by DARPA and the military services to provide the pull required to transition technology from the laboratory to deployable vehicles. Their purpose is “a demonstration of the maturity and potential of advanced technologies for enhanced military operational capability or cost effectiveness. ATD are identified, sponsored, and funded by Services and agencies.”22

Here, DARPA has had a number of successes. However, the process is flawed when the prototype aircraft are given limited operational assignments after meeting only a few design requirements—i.e., before they are battlefield-ready. As described in the second part of Section 2.5.2, the Predator and Global Hawk Unmanned Aerial Vehicles were ATDs that were deployed in Iraq and Afghanistan. Their ability to persist over targets and deliver

________________

16 Y.T. Wu, H.R. Millwater, and T.A. Cruse. 1990. “Advanced Probabilistic Structural Analysis Method for Implicit Performance Functions.” AIAA Journal, Vol. 28, No. 9, pp. 1663-1669. September.

17 E.J. Gumbel. 2004. Statistics of Extremes. Mineola, New York: Dover Publications.

18 C. Kassapoglou. 2010. Review of Classical Laminated Plate Theory. Published online at http://onlinelibrary.wiley.com/doi/10.1002/9780470972700.ch3/summary.

19 E.J. Gumbel. 2004. Statistics of Extremes, Mineola, New York: Dover Publications.

20 For more information on the AGATE shared database process, see http://www.compositesworld.com/articles/agate-methodology-proves-its-worth. Last accessed October 19, 2011.

21 For more information on composite properties, see http://www.compositesworld.com/columns/shared-composite-material-property-databases. Last accessed October 19, 2011.

22 Information on ATDs is available at http://dap.dau.mil/glossary/pages/1414.aspx. Last accessed October 19, 2011.

small, accurate weapons was valuable to the war effort, but because of the limited design requirements, these UAVs failed to meet normal reliability and supportability goals typical for fielded aircraft.23

2.3 LIGHTWEIGHTING OPPORTUNITIES FOR AIRCRAFT

Although the aircraft industry has been seeking lightweight structures for more than 100 years, there are still a surprisingly large number of opportunities to reduce weight through exploiting emerging technologies to refine materials, manufacturing, design, and configuration.

2.3.1 Opportunities in Materials

It was recognized 20 years ago that high strain-to-failure graphite fibers would be relegated to research laboratories unless high strain-to-failure resins were developed simultaneously. Today, several promising materials could someday produce better, lighter structures.

Carbon Fiber Development

As shown in Figure 2-6, the use of carbon-fiber composites for lightweighting in commercial and military airplanes has grown since the early 1970s. The success of these composites illustrates the need for parallel development of a wide range of ancillary technologies (such as sizing [a chemical coating] for fibers, tooling for the system, and manufacturing processes for the application) and their eventual convergence.

These developments took many years, and each needed sustained support. For instance, although high-strength carbon fibers made from polyacrylonitrile (PAN) were first created in the 1960s by Aksanti in Japan and then in the Royal Aircraft Establishment (RAE) at Farnborough in 1963, the applications at that time, such as in sports equipment, were structurally non critical and did not take full advantage of fiber compositing. Similarly, the resins available early on in composite development had lower strain to failure than the fibers themselves, again limiting the performance capabilities of fiber composites. In parallel, successful implementation has also required extensive investments in the educational, industrial, and research infrastructures, both here and abroad.

The DARPA Advanced Structural Fiber program24 seeks to increase fiber strength and stiffness by reducing defects in the fibers through advanced processing and by applying atomic control on a massive scale. Before such fibers can achieve meaningful weight savings, resins will need to be developed that can carry the fibers well and without microcracking.25

Each development related to composite materials has lent a capability for the aircraft. Durable epoxies have led to lightweight structures with high stiffness. Thermoplastics, while initially hard to fabricate, became an enabler for toughened systems that have allowed more damage tolerance. Thermoplastics have also provided better compatibility with high stiffness and strain fibers to enable very low thickness to chord wings for fighters and bombers. Eventually, low-cost fiber made it affordable to introduce composites into commercial aircraft. Chemistry- and physics-based analytical approaches of integrated computational materials engineering (ICME) are replacing much of the testing done in the 1980s and 1990s. These approaches could reduce the time it takes to put new multifunctional materials to work in aerospace applications.

Alternative Composite Polymers

Work in the 1980s showed that thermoplastic resins offered much higher durability than conventional epoxy resins. At that time, however, thermoplastic resins were comparatively expensive, sensitive to degradation when

________________

23 E. Bone and C. Bolkholm. 2002. “Unmanned Aerial Vehicles: Background and Issues for Congress.” Report for Congress, Order Code RL3187. April. Available at http://www.fas.org/irp/crs/RL31872.pdf.

24 For information on DARPA’s Advanced Structural Fiber program, see http://www.darpa.mil/Our_Work/DSO/Programs/Advanced_Structural_Fiber_(ASF).aspx. Last accessed October 19, 2011.

25 H.G. Chae and S. Kumar. 2008. “Materials Science: Making Strong Fibers.” Science, Vol. 319, Issue 5865, pp. 908-909.

FIGURE 2-6 Multidisciplinary approach to carbon fiber development.

exposed to aircraft fluids, and difficult to work with because their processing takes place at very high temperatures. Instead of using thermoplastics outright, researchers used toughened epoxy resins to gain some of the strain-to-failure and toughness characteristics that the systems then lacked.

Today, pultrusion26 and other ways of injecting thermoplastic resins into parts have progressed to the point where interest in such materials is growing. If these new processes overcome the barriers to the use of thermoplastics and are accompanied by new approaches to solvent sensitivity, the strain-to-failure, durability, and damage tolerance of thermoplastics could improve dramatically.

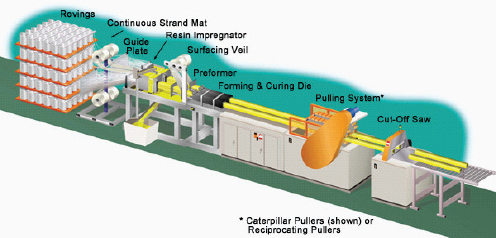

One of the main attractions of pultrusion is its simplicity of tooling and low labor requirements. At first glance, pultrusion appears to be a straightforward process: reinforcing fibers are saturated with a thermosetting resin matrix and pulled through a heated die, as shown in Figure 2-7. It turns out that successful pultrusion requires excellent control of the staging temperatures and the tension in the system, as well as control of the state of the material as it is pulled through the process in order to achieve the desired results. It is, in short, more of an art than it appears.

Nano- and Multifunctional Materials

Damage in aluminum—for example, cracks or dents—becomes evident before it limits structural performance. Less accessible areas inspected frequently enough to prevent cracks of critical size from forming.

________________

26 Pultrusion is a continuous molding process for composite materials that mechanically aligns long strands of reinforcements for a composite material and then passes them through a bath of thermosetting resin. The coated strands are then assembled by a mechanical guide before the curing process. More recently, pultrusion has been used with thermoplastic matrices such as polybutylene terephthalate (PBT) either by impregnating the glass fiber with powder or surrounding it a sheet of the thermoplastic matrix, which is then heated to fuse the polymer and fibers. From “Putting It Together—the Science and Technology of Composite Materials.” Australian Academy of Science. 2000. Available at http://www.science.org.au/nova/059/059glo.htm and http://www.acmanet.org/pic/products/description.htm.

FIGURE 2-7 Pultrusion, a potentially simple process for manufacturing composites. SOURCE: Pultrusion Industry Council. Available at http://www.acmanet.org/pic/products/description.htm. Courtesy of Strongwell.

Impacts that would produce damage that could be easily seen on aluminum structures do not visibly damage the new composite structures.27 Composites can delaminate internally after a low-impact load without any sign of delamination on the surface of the part. Designers of the Boeing 787 have gone a long way toward remedying this concern by using interply toughening and designs that accommodate large impacts without inducing damaging the structure. Research is also under way to explore the use of nanoparticles in the resin as one way of enhancing interply toughening.

An aluminum structure provides a second function: It serves as an electrical shield around the structure that conducts rather large currents without excessive heating or resistance. It forms a virtual Faraday cage around the structure that protects fuels from sparking and prevents lightning from entering the structure. Carbon fiber composites do not provide this function: Although carbon fibers conduct electricity, epoxy resins do not. The epoxy insulates the carbon from electrical sources, a composite structure must be shielded with another system to provide the same levels of spark and EME shielding that aluminum structures provide. Currently, EME shielding for composites is provided by add-on systems that are either placed on the skin or incorporated into the skin as woven wire. Use of carbon nanoparticles in the matrix resin is being explored as a mechanism to significantly increase the electrical conductivity of composites, particularly in out-of-plane directions. Successful design of these nanoreinforced materials could provide adequate EME shielding without the add-on wire mesh.

The potential improvement offered by nanotechnologies based on carbon nanoparticle enhancements to resins (Figure 2-8) has been proven at laboratory scale. However, this approach must be thoroughly explored and rigorously verified to ensure that it meets all of the aircraft’s requirements. If the approach is successful, nanotechnologies could be used to create a single, multifunctional, integrated material system that improves on the damage resistance and EME protection that are today provided by multiple systems.

Hybrid Materials

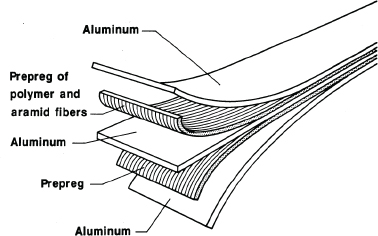

Hybrid materials could provide some of the benefits of multifunctional materials at relatively low cost— lower even than the cost of composite materials. Hybrid materials, particularly metal-fiber laminates (shown in

________________

27 Available at http://www.boeing.com/newairplane/787/design_highlights/.

FIGURE 2-8 Multiscale modeling of nanocomposite materials. SOURCE: T.S. Gates, G.M. Odegard, S.J.V. Frankland, and T.C. Clancy. 2005. “Computational materials: Multi-scale Modeling and Simulation of Nanostructured Materials,” Composites Science and Technology, Vol. 65, pp. 2416-2434. Reprinted with permission from Elsevier.

Figure 2-9), offer greater damage resistance than composites at half the cost. If cost or damage tolerance are large enough drivers to justify a weight penalty, hybrid materials can offer good damage resistance at an affordable price.

Airbus is using fiber-metal laminates and has invested heavily in bringing the technology to maturity and to a price that makes it affordable for its A-380. Whether that price will work for smaller aircraft is unknown. Hybrid materials offer some of the benefits of the multifunctional material systems, but not all. While GLARE and ARALL are commercial products, many others with different design drivers are being developed that promise still lower cost with very little penalty in other properties.

Metals with Improved Properties

Although composites offer the most potential for lightweighting, advanced metallic materials could also meet the needs of advanced vehicle applications, as shown in the example of a lightweight aluminum-lithium alloy in Section 2.5.2.

2.3.2 Opportunities in Manufacturing

Automated, Additive Manufacturing for Multifunctionality

Years ago, aircraft were almost entirely made from formed sheet products and were “built up” by fastening the products mechanically. Once high-speed machining became linked to digital design drawings, parts could be fabricated without the limitations of sheet products. More intricate substructures (e.g., bulkheads, spar, ribs, and frames) became possible that could perform more functions (carry loads, carry current, provide grounding for electronics, and so on) more efficiently than mechanically attached sheet products could do. The same advances were achieved for lightweight composite materials and structures, from hand-laid-up sheet skins and simple parts (doors, flaps, and so on) to more intricate resin-transfer-molded products for ribs, frames, and other structures. Composite materials provide benefits beyond lighter weight in that they are formed by “laying up” materials—

FIGURE 2-9 Hybrid fiber-metal laminates offer superior damage resistance. SOURCE: R.C. Alderliesten. 2005. Fatigue Crack Propagation and Delamination Growth in Glare. Delft, The Netherlands: Technical University of Delft Press.

that is, manufactured additively instead of by machining away materials, facilitating the design of materials for multifunctionality.

Recently, additive manufacturing techniques have been developed for metallic materials, notably aluminum and titanium. These techniques make it possible to go straight from the design to the fabrication of parts using systems very much like the three-dimensional printers that heat particles of material and lay them up using a laser to guide and fuse the particles. This technology allows the laying up of multiple materials, layer by layer, in particular locations so as to create specific properties and capabilities in at different places in the part. Maturation of this technology will likely create entirely new ways to design and fabricate multifunctional structures.28

The same additive manufacturing technology is potentially applicable to composite parts to permit the tailoring of properties at specific points to achieve multifunctionality. The technology imposes some constraints on the designs: For example, using a material of a given stiffness in one section of the part and a less stiff material in another section would cause distortion.

Non-traditional laminates that are not limited to 0°, +45°, –45°, and 90° plies but that may have other orientations to maximize the bending and twisting capability of the airfoil or the shear and pressure capability of a fuselage are now part of the design space made possible by new automated layup techniques. Fiber steering29 to reduce strain concentrations is another capability made possible by these techniques.

Reducing the Number of Parts

The ability to produce large parts with complex geometries (such as curved spars) in composite materials would make it possible to have simpler structures requiring fewer fastened parts. Instead of kicks and joints in these structures, simpler joints could be used or perhaps none at all, as shown in Figure 2-10, where the substructures flow into one another seamlessly. However, the tools required to design and analyze such structures do not yet

________________

28 “Rapid Technologies & Additive Manufacturing (RTAM),” Society of Manufacturing Engineers, 2011. Available at http://www.sme.org/cgi-bin/getsmepg.pl?/communities/rpa/rpahome.htm&&&SME&.

29 Fiber steering is a method of constructing fiber-reinforced composites that allows the unidirectional fibers to be aligned along curvilinear paths. See “Fiber Steering for Laminated Composites,” Adoptech. Available at http://www.adoptech.com/fibersteering/main.htm.

FIGURE 2-10 Airfoil manufactured as a single piece (no joints). SOURCE: Photo courtesy of BlueSwarf LLC, available at http://blueswarf.com/ProductCart/pc/viewContent.asp?idpage=150.

exist, and more experimentation is required to reduce the risk of this approach and to determine the capabilities that such structures might have.

Long, discontinuous fiber systems have been developed that offer the ability to drape and form parts with unidirectional properties in which the primary axes of the fiber can change radically without much loss in stiffness or strength. Simpler substructures seem to be on the verge of viability,30 requiring only work to develop the capability to design and analyze them.

Larger Tools for Unitized and Integral Structures

Larger and more complex tooling is required to support the fabrication of larger and more complex shapes. Some of these tools have been demonstrated for prototype parts but are not durable enough for a production program that maintains the surface quality of the parts. Such tooling currently uses (low-cost) composite structures, thus averting mismatches between the coefficient of thermal expansion (CTE) of the tooling and that of the part being produced.

Bonding, Welding, and Fusing Assemblies

An alternative to larger, more complex tooling is to divide parts into smaller pieces and assemble them by bonding, welding, or fusion. Bonding was a method used more in the mid-20th century than today, although light aircraft with bonded structures have been flying for years. Of course, load intensities and strain levels have increased markedly in today’s structures since that time and the properties required for bonds and weldments are near the limit of what can be produced. In addition, today’s certification criteria require mechanisms to arrest bond delaminations, or redundant structures to carry loads, in case these joints fail without having given any outward sign of failure.

________________

30 J. Pepin. 2011. “The Promise of Fiber Reinforced Thermoplastics: Pepin Associates’ DiscoTex® Enables Lightweight, Recyclable Parts.” Thomas News, Inc. June. Available at http://news.thomasnet.com/companystory/The-Promise-of-Fiber-Reinforced-Thermoplastics-Pepin-Associates-DiscoTex-Enables-Lightweight-Recyclable-Parts-847832.

Weldments have historically been assigned knockdown factors (i.e., a reduction in design value) to account for the effects of heat on the material in the weld. Friction stir welding has not eliminated heat-affected zones but has demonstrated the ability to provide near-pristine properties for them. There was some concern that the loss of corrosion inhibitors in a heat-affected zone might cause earlier corrosion in the weld, and testing has shown that the knockdown factor can be as high as 28 percent.31,32 However, the strength knockdown factors are in about the same range as for specimens not having fatigue testing. Moreover, results in Europe discount this corrosion behavior.33 Single-lap shear joints with double-pass welds show remarkable joint efficiency, far greater than any mechanical joints.34

High-Speed Precision Machining

Precision digitally driven machining has permitted significant weight reductions by reducing the minimum gages permitted by the manufacturing process. For example, years ago machining could provide only 0.04-in. thicknesses at the tolerances required for aerospace structures. The advent of high speed machining made it possible to maintain even closer tolerances and achieve a 0.02-in. minimum gage in places where frame members are lightly loaded. The weight savings afforded by these advances are almost free of cost, since digital process now routinely go from drawings to completed parts. The savings can amount to 5 percent of the overall structural weight.

2.3.3 Opportunities in Design

Trading Off Materials and Manufacturing Processes at the System Level

Product design currently begins with conceptual design at the system level. It defines the system, then the vehicle, then the assembly process, then the structure, and finally the parts. Materials and manufacturing methods are traded off against one another and defined at the part level. It is difficult to trade off materials and manufacturing processes at the point of conceptual design and system definition.

There are no clear metrics that link tradeoffs at lower levels to those at the vehicle or system level. Even though cost and weight are obviously traded off at the part level, determining the payoff of these tradeoffs at the system level requires weighting the payoffs throughout the system. The payoff is greater at the conceptual design stage, where weight savings can affect the overall size of the vehicle. Tradeoffs later in the design process at lower levels have much less effect if the size of the vehicle cannot be changed.

Multifunctional Parts

One of the best ways to achieve a lightweight vehicle is to ensure that as the substructure for a vehicle is being defined, no part is performing fewer than two functions. This approach represents a change in the focus of multidisciplinary design. For example, the structure can take loads and provide support for systems or support for doors. Bulkheads can support wings and still have the carry-through ability to carry loads under live fire. A structure may be able to perform three functions without additional weight—it may, for instance, carry fuselage loads, support a door, and carry electrical return currents.

________________

31 Ibid.

32 M. Czechowski. 2004. “Slow-Strain-Rate Stress Corrosion Testing of Friction Stir Welded Joints of Al-Mg Alloys.” Achievements in Mechanics and Materials Engineering. 12th International Scientific Conference. Warsaw: Polish Academy of Science.

33 J. Pepin. 2011. “The Promise of Fiber Reinforced Thermoplastics: Pepin Associates’ DiscoTex® Enables Lightweight, Recyclable Parts.” Thomas News, Inc. June. Available at http://news.thomasnet.com/companystory/The-Promise-of-Fiber-Reinforced-Thermoplastics-Pepin-Associates-DiscoTex-Enables-Lightweight-Recyclable-Parts-847832.

34 L. Cederqvist and A. Reynolds. 2001. “Factors Affecting the Properties of Friction Stir Welded Aluminum Lap Joints.” Welding Journal, Vol. 80, Issue 12, pp. 281S-287S.

Curved Parts

Early finite element routines and simplified analysis techniques dealt with structures in only two planes. Forming techniques, formed-in-place structures, and formable composites have made it possible to produce much more complicated structures that bend and turn through three dimensions that can be joined along straight load paths. This allows a structure to carry loads in the most efficient manner. Moreover, joints in simpler structures are easier to design, install, and maintain.

2.3.4 Opportunities in Configuration

Effects of New Materials and Manufacturing Processes on Configurations

An aircraft can be made lighter by changing the configuration itself. Not only can its size be changed, but also its shape. Many such reconfigurations have been successful—for example, the wings of the X-29, the nose of the 787, the shaping of the F-22 wing-to-body join, the lifting body, blended-wing X-45, and the blended-wing X-37 were all made possible by composite materials and the ability to fabricate them to carry loads and serve other functions. See Section 2.5.4.

Effects of Materials and Manufacturing on Configuration Tradeoffs

Manufacturing capabilities for composite and metallic parts are rapidly becoming more flexible. The question is whether these capabilities can be traded off at the conceptual design stage to decrease aircraft size and at the same time increase aircraft efficiency. Quantification of the tradeoffs is the goal of a current study at the Georgia Institute of Technology,35 sponsored by Boeing. Researchers are developing systems-level metrics and ties to lower-level part definition parameters that could allow new manufacturing capabilities to be better exploited in new designs. After only a year, the project had already made significant progress in linking preliminary design parameters to lower-level metrics for materials and manufacturing processes.36

Reducing the Cost of Composite Materials

The Composites Affordability Initiative (CAI) was a joint project of the Air Force Research Laboratory, Office of Naval Research, and five aerospace companies that focused on reducing the risk of using advanced composite materials in aircraft. The program succeeded in lowering the cost of composite structures, which made greater weight reductions affordable, but it was not directly focused on lightweight materials or design. In fact, lighter weight often lost out to lower cost in the CAI program. The demonstration performed on a low cost wing for X-45C saved very little weight but cut the cost of the wing by 20 to 50 percent, primarily by reducing assembly time and using a bonded substructure approach.37 The savings in cost and weight were demonstrated in the Air Force Research Laboratory (AFRL) Advanced Composite Cargo Aircraft (ACCA) program, which proved that in addition to the weight savings afforded by composites, “composite technologies are real game changers in reducing design and manufacturing costs and extending the life and reducing the maintenance costs over traditional metallic aircraft structures.”38

________________

35 J. Ceisel and Z. Liu. 2008. “Manufacturing Influenced Design (MInD),” Aerospace Systems Design Laboratory. Atlanta: Georgia Institute of Technology. Available at http://www.asdl.gatech.edu/Advanced_Concepts.html.

36 Z. Liu, P. Witte, J. Ceisel, and D. Mavris. 2011. “An Approach to Infuse Manufacturing Considerations into Aircraft Structural Design.” Technical paper, Society for the Advancement of Materials and Process Engineering (SAMPE), presented at SAMPE 2011, Long Beach, Calif. May.

37 J. Russell. 2001. “Composites Affordability Initiative.” AMMTIAC Quarterly, Vol. 1, No. 3. Available at http://ammtiac.alionscience.com/pdf/AQV1N3_ART01.pdf.

38 “Lockheed Martin Conducts Successful Flight of AFRL’s Advanced Composite Cargo Aircraft,” PR Newswire, June 2, 2009. Available at http://www.prnewswire.com/news-releases/lockheed-martin-conducts-successful-flight-of-afrls-advanced-composite-cargo-aircraft-61979512.html.

System-Level Metrics by Which Materials and Manufacturing Can Influence Configuration

Some of the metrics used in the Georgia Tech study—for example, part count, process steps, density, stiffness, and sizing—are not unique to the study. But some of them have provided surprises in the way they influence system-level metrics. For example, when initial composite designs that used isotropic composites were compared, it was found that these provided little or no benefit to the system on a cost for weight basis until quite a large number of aircraft had been assembled. This had always been believed to be the case, and the study has provided accurate, traceable cost and weight values that demonstrate it. The processes developed to weight metrics at the system level in order to trade off materials and manufacturing processes at that level have proven to be remarkably successful in forecasting capabilities, weight, and cost. The processes for weighting metrics also provide a measure of the risk inherent in new designs so that engineering managers can control the risk to acceptable levels.

2.4 LONG-TERM CHALLENGES IN LIGHTWEIGHTING AIRCRAFT

2.4.1 Identifying Future Threats and Their Implications for New Materials

Given the 10 years it takes to transition a material from the test tube to the point where its design properties have been demonstrated,39 it is important that the Department of Defense (DoD) look at least 20 years into the future to define potential threats and identify the capabilities that might be needed to develop materials to counter those threats. Materials cannot be developed and matured within the typical 5-year aircraft development cycle and must be under development long before aircraft definition takes place. Moreover, even at the conceptual design phase, aircraft manufacturers cannot justify looking at materials that have no well-defined and demonstrated properties or manufacturing history behind them. New materials must be always in the pipeline where they are being refined to provide capabilities that mesh with the strategic needs of the armed forces.

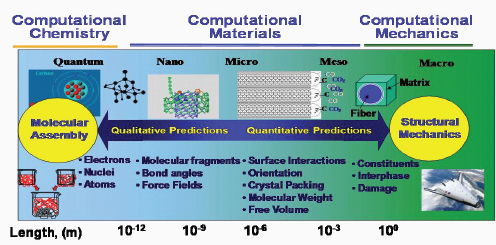

The long timeline for materials development also underscores the need for integrated computational materials engineering (ICME) to bring the synthesis and fabrication of new resins into the digital age. Recent years have seen significant progress in understanding how different chemical structures affect the chemical, electrical, and mechanical properties of resins. Advances in computational chemistry may make it possible to design the molecular structure of the resin to meet structural and other requirements for a given application. The science of materials processing will be an integral part of this endeavor, ensuring that the desired section thicknesses and shapes can indeed be fabricated from the designer resins.

2.4.2 Incorporating New Materials and Manufacturing Processes in Conceptual Design Through Systems Engineering Approaches

Incorporating new materials and manufacturing processes in conceptual design calls for predicting the as-manufactured properties of these materials. Too often, laboratory-based properties have been used that do not match the as-manufactured properties of the material. It is here that computational materials engineering that accounts for processing at scale can help.

At the conceptual design stage, manufacturers are able to accept some risk as they consider new materials and technologies, but these must be within 2 or 3 years of maturity in order to be ready by the start of engineering, manufacture, and design definition.40 Because this window of opportunity is so narrow, it is crucial that a suite of new materials and technologies ready for insertion into new designs be available. This readiness can be achieved only by sustained investment in candidate materials and manufacturing technologies.

This requires that materials, processing, tooling, and manufacturing all be part of the integrated product development team from conceptual design through detail design. Historically, these experts are brought into the

________________

39 C.R. Saff, G.D. Hahn, J.M. Griffith, R.L, Ingle, and K.M. Nelson. 2005. “Accelerated Insertion of Materials—Composites.” AIAA Paper 2005-2165. Available at http://pdf.aiaa.org/preview/CDReadyMSDM2005_970/PV2005_2165.pdf.

40 Ibid.

team at the detailed design stage, but to enable them to have a positive impact on cost and schedule they should be on the team from the beginning of concept development.

As a design matures, manufacturers are less able to accept the risk of using unproven materials or processes. At preliminary design review (PDR), it is too costly and time-consuming to redesign the product and test the fall-back technologies to bring them to the level of maturity they must have for the later stages of development. Figure 2-11 shows this increasing risk as a function of the design cycle for aircraft. Note that once an aircraft is in production, its certification is based on the materials and processes used to manufacture it; the cost to switch materials in primary structures at that point is often far too high to justify the gains.

Conceptual design is the stage where a manufacturer investigates new materials and manufacturing concepts and determines their payoff for new designs. But decisions on materials and manufacturing processes at this stage are difficult because payoffs are determined at the part level, not at the vehicle level. Research is how to determine payoffs at the preliminary and conceptual design trades when the parts, and ultimately the components, have not yet been defined. Linking these part-level benefits to vehicle-level metrics is the focus of this research.

Often an optimized conceptual design presents a “mixed-material” solution in which one set of materials is used to achieve certain requirements and another material is used to meet other requirements. In an optimized design these materials obviously need to work hand-in-hand to meet all of the objectives. A mixed-material design increases complexity due to property discontinuities, leading to possible joining issues and the potential for corrosion. Also, available design software is incapable of modeling the behavior of mixed materials effectively, especially when they have different joint designs and bonds. An optimized systems design approach has to accommodate this complexity. The materials industry does not yet support this approach, so the application would likely be developed at the integrator. Development of tools that can support mixed-material solutions would aid the design and optimization process for lightweighting significantly.

2.4.3 Accelerating Insertion by Reducing Testing Requirements for Composite Structures

Development of “allowables” for composite materials that may have a great variety of layups—and thus properties at any point in a structure—is crucial for effective design with such materials. In the past, designs had to meet strain cutoffs that were determined by the capabilities of the matrix. As matrix capabilities improved through toughening mechanisms, strain allowables were based on notched and damaged elements to ensure some level of damage tolerance in the structure. Allowables that include damage are very difficult to develop by test. Unlike for metallic structures, there are no proven, rapid methods to link the structural capabilities of undamaged composites to those of damaged composites. Although analysis methods for damage tolerance in composites have come a long way, there is still a long way to go before it will be possible to rapidly analyze and predict the behavior of composites under any given geometry, layup, or loading. Until this capability is developed, manufacturers will be forced to rely on extremely time-consuming testing of all composite configurations or fall back on more conservative (strain-limited) allowables. Research is needed to refine and further develop methodologies for analyzing progressive failure in different composite systems.

2.4.4 Application of ICME to Composite Materials

ICME, described in Chapter 1, could dramatically improve composite structural analysis in aircraft systems. Great progress is being made in applying ICME to develop materials for aircraft. Many first-level models to predict the behaviors of the today’s materials have been developed, and some elements of ICME, such as chemical modeling of resins, are already being used to develop the materials needed for tomorrow. However, much more must be done to provide the rapid, accurate, and reliable prediction methods for composite materials that would reduce the enormous amount of testing required to design aircraft today.

The electrochemical modeling capabilities of the medical industry have been used and modified to accurately

FIGURE 2-11 Technical immaturity raises risk. SOURCE: C.R. Saff, G.D. Hahn, J.M. Griffith, R.L. Ingle, and K.M. Nelson. 2005. “Accelerated Insertion of Materials—Composites,” AIAA Paper 2005-2165. Available at http://pdf.aiaa.org/preview/CDReadyMSDM2005_970/PV2005_2165.pdf.

capture the characteristics of the resin systems used in composites. The models can predict cure temperatures and the stiffness, toughness and strength of the resin systems, all of which facilitate the application of ICME.41

The processing of composite materials can be modeled to a degree—specifically, the interaction of tools with the composite laminates and parts can be examined. These models are used to assure good consolidation of the parts, as well as uniform heating and cooling rates to ensure that the part does not warp or warps only minimally when it is removed from the tool. The complex manufacturing plan of the 787 would not have been so successful without these tools.

Although the capability to apply these tools to predict the performance of composite materials is being worked on, the capability remains elusive. Today, industry still finds it difficult to predict composite performance from constituent properties. Designers must rely on semiempirical methods for predicting the strength of a laminated composite once its constituent properties are determined.

New analytical models are also needed to predict the strength of composites based on their geometry, layup, manufacturing processes, and damage condition. Such models would cut down on the number of tests needed to develop allowables so they are no more burdensome than the tests for metallic materials. Just being able to predict laminate strength properties from constituent materials would be a remarkable breakthrough in analysis capability. However, it is not a simple thing to accomplish: Industry has spent millions of dollars but made only a little headway.

2.4.5 Transition via Advanced Technology Demonstrations

ATDs must be developed using a systems engineering approach that takes into account all requirements (including those based on anticipated threats) for similar operational systems.42 Determining requirements and defining them in terms of system performance requirements is the first step in any systems engineering approach to problem solving. Some past ATDs (see, in Section 2.5.1, Predator and Global Hawk) were promising but could not meet the warfighter’s expectations when fielded. This shortcoming resulted from not having a clear a path from the early prototypes to a partly or fully operational vehicle.

There must be a clearly defined path to take what was initially demonstrated in the ATD and turn it into

________________

41 Stephen Christensen, Andrea Browning, and Jon Gosse. 2011. “Computational Methods for New Materials Development: The ’Atoms to Airplanes’ Concept.” Presented at the 1st World Conference on ICME. Seven Springs, Pa. July. Available at http://www.programmaster.org/PM/PM.nsf/ApprovedAbstracts/643383E358B992ED852577D50083D5D1?OpenDocument.

42 For more information on ATDs, see http://www.fas.org/man/dod-101/army/docs/astmp/c1/P1E2.htm. Accessed October 19, 2011.

a certified, operational system, making use of the ATD demonstration data to minimize the additional testing needed to certify the operational system. A good ATD begins with a fully defined set of operational requirements and objectives, designs the vehicle to meet those, and determines which of the requirements must be dropped for expediency and which functions will be demonstrated and which will not. At the conclusion of an ATD project there must be a plan to provide the functionalities missing in the demonstrator in future vehicles, first for limited operation and then for full operational capability.

2.5 EXAMPLES OF LIGHTWEIGHTING IN AIRBORNE VEHICLES 2.5.1 Unmanned Aerial Vehicles

Lightweighting in UAVs of All Sizes

The speed and weight of unmanned aerial vehicles (UAVs) cover a broad range, broader, in fact, than manned vehicles. They extend from hand-held micro-UAVs to large solar-powered loiter devices, to Mach 10 hypersonic vehicles, and on to vehicles as large as a 737.

UAVs: A Variety of Lightweighting Techniques and Requirements

The smallest UAVs must be very lightweight in order to fly, and larger or faster UAVs use light-weighting for meeting various performance requirements. Strategies under development have included air breathing engines, solar power, adaptation of automotive fuel cells, model airplanes, UAV wings based on insect wings, and others.

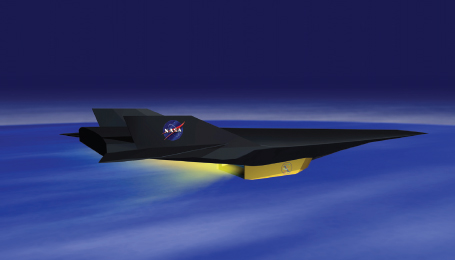

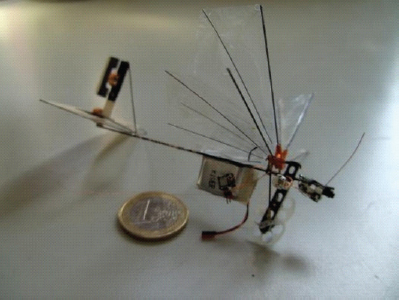

These vehicles use lightweighting in very different ways. The Mach 10 X-43 scramjet (Figure 2-12) uses very high density materials to achieve high thermal gradients without thermal protection. Its air-breathing engine reduces weight by making it unnecessary to carry large oxidizer tanks, thus allowing a heavier pay-load or higher speeds. 43 High-altitude long-endurance (HALE) vehicles (Figure 2-13) use very low density materials because they have so little battery power with which to achieve very high altitudes and must sustain those high altitudes using solar power and batteries alone.44 Even the tiniest aircraft, such as the bioinspired Delfly (Figure 2-14), must be kept very light—it weighs only 3 grams and extends 10 cm from wing tip to wing tip—in order to fly on a peanut-size power source.45 Its flapping wings were modeled after dragonfly wings, which achieve stiffness and strength by being highly corrugated.46 Other sources of ideas for making future UAVs lighter include developing a propulsion system based on automotive fuel cell technology47 and emulating the lightweighting strategies of model airplanes.48

Deployment of Predator and Global Hawk from Advanced Technology Demonstration Program

The unmanned aerial vehicles (UAVs), Predator and Global Hawk, were deployed in Iraq and Afghanistan after being designed and validated through the ATD program. The foreshortened requirements of ATDs demonstrate the capability of the platform but omit testing with respect to the specific battlefield requirements and usage to

________________

43 “X-43A raises the Bar to Mach 9.6,” NASA News, Sept. 2, 2010. Available at http://www.nasa.gov/missions/research/x43-main.html; A. Brown, “X-43A Captive Flight Succeeds, Air Launch Next,” NASA Dryden Research Center X-Press, Vol. 48, Issue 8, Sept. 30, 2004.

44 “Helios Prototype Solar-Powered Aircraft,” NASA Dryden History, Nov. 3, 2009. Available at http://www.nasa.gov/centers/dryden/history/pastprojects/Helios/index.html.

45 G.C.H.E. de Croon, K.M.E. de Clerq, R. Ruijsink, B. Remes, and C. de Wagter. 2009. “Design, Aerodynamics, and Vision-Based Control of the DelFly.” International Journal of Micro Air Vehicles, Vol. 1, No. 2, pp. 71-97.

46 S.R. Jongerius and D. Lentink. 2010. “Structural Analysis of a Dragonfly Wing.” Experimental Mechanics. Vol. 50, No. 9, pp. 1323-1334. Oct. 26. Available at http://www.delfly.nl/Jongerius%20and%20Lentink%202010%20Dragonfly.pdf.

47 J.R. Wilson. 2003. “UAVS: A Worldwide Roundup.” Aerospace America, June. Available at http://www.aiaa.org/aerospace/Article.cfm?issuetocid=365.

48 A. Noth, W. Engel, and R. Siegwart. 2006. “Design of an Ultra-Lightweight Autonomous Solar Airplane for Continuous Flight.” Available at http://infoscience.epfl.ch/record/97588/files/FSR05_Sky-Sailor.pdf.

FIGURE 2-12 X-43A Scramjet after separation from Pegasus booster. SOURCE: NASA Dryden Research Center Photo Collection, available at http://www.dfrc.nasa.gov/Gallery/Photo/X-43A/Large/ED04-0082-4.jpg.

which they would be exposed. Now that these UAVs are fielded, limitations in their design capabilities with respect to battlefield needs are becoming apparent. Still, their ability to persist over targets and deliver small, accurate weapons to minimize collateral damage have been valuable, and these capabilities more than compensate for their shortcomings (e.g., performance problems under varying weather conditions).

ATDs: Adequate Testing with Rapid Transition to Production

The problems with the Predator and Global Hawk on the battlefield suggest that more testing of ATDs could improve battlefield readiness. However, the performance of these UAVs also shows that the ATD program is, on balance, an effective way to deploy systems with new capabilities.

2.5.2 Super Lightweight Tank for the Space Shuttle, using Aluminum-Lithium

To place the International Space Station modules in orbit, the weight of the space shuttle had to be significantly reduced.49 The successful development of a new super lightweight tank (SLWT) to replace the lightweight tank (LWT) provided 50 percent of the performance increase required for the shuttles to reach the International Space Station.

The weight reduction achieved was made possible by the development of the 2195 aluminum-lithium alloy. When work on the new alloy began, there was a strong bias against aluminum-lithium (Al-Li) alloys because the previous generation of aluminum-lithium alloys (2090 and 8090) had demonstrated poor fracture toughness. This toughness issue was overcome by a new formulation and new processing technologies. This produced an alloy— Al-Li 2195—with improved properties and a lower density than the 2219 alloy previously used for the external tank of the shuttles and reduced the weight of the external tank by 7,500 lb (3,402 kilograms). For comparison, the SLWT weighs 36,123 lb, the LWT weighs 43,623 lb, and a Standard Weight Tank weighs 52,589 lb.

The lithium in Al-Li 2195 made the initial welds of the external tank far more complex. The repair welds

________________

49 For more information, see “Analysis of International Space Station Vehicle Materials on MISSE 6,” available at http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20100033233_2010034433.pdf. Last accessed October 19, 2011.

FIGURE 2-13 NASA’s HELIOS, a type of high-altitude long endurance (HALE) vehicle. SOURCE: NASA Dryden Research Center Photo Collection, available at http://www.nasa.gov/centers/dryden/images/content/105841main_helios.jpg.

FIGURE 2-14 TU delft–Delfly. SOURCE: Used with permission of www.DelFly.nl; available at http://www.delfly.nl/?site=Publications&menu=&lang=en.

were difficult to make and the joints in the external tank had much lower strengths. In an effort to mitigate the increased production cost and regain the mechanical properties of the earlier Al 2219 external tank, the project began researching alternative welding techniques. The friction stir welding process produces a joint stronger than the fusion arc welded joint and has only three process variables to control: rotation speed, travel speed, and pressure, all of which are easily controlled. The fusion weld, in contrast, has to control many process factors, such as purge gas, voltage and amperage, wire feed, travel speed, shield gas, and arc gap. The increase in joint strength, combined with the reduction in process variability, provides an increased safety margin and a high degree of reliability for the external tank. Shuttle external tank weights are compared in Table 2-2.

SLWT: New Materials and Processes Go Hand in Hand

Advanced processing methods must often be used for the advanced materials used for light-weighting. When fundamental alloy development, advanced processing, and design are addressed together, it allows consideration of tradeoffs and thereby improves the final design.

The successful development of aluminum lithium 2195 illustrates what can be accomplished when fundamental alloy development is integrated with processing and design. The addition of Ag to the alloy promoted a distribution of the T1 phase in the micro-structure that gave good transverse strength, which had been the weak strength direction in earlier generation Al-Li alloys 2090 and 8090. Solving the transverse strength problem allowed this alloy to be used to fabricate section thicknesses required for the shuttle external tank. Friction stir welding also contributed to the success of this allocation as noted above.

2.5.3 Using Aeroelastic Tailoring of Composite Wings to Enable Higher Maneuverability

X-29 Wings

The thin forward swept wing of NASA’s X-29 (Figure 2-15) can be achieved only with tailored composite wing skins. Such a wing improves maneuvering performance because the ailerons are not “washed out” by wing bending at high angles of attack as they are on rear swept wings. The wings still provide the sweep required to achieve supersonic flight.

X-29, F/A-18, 787: Advantages to Composite Wings

Composites offer bending torsion relationships that allow tailoring wing bending to achieve lightweight designs with better performance. The significant laminate tailoring to achieve the necessary stiffness in torsion offers performance characteristics that cannot be achieved any other way.

The composite wings of the X-29 were designed to achieve flutter-free flight in the forward swept configuration. “State-of-the-art composites permit aero-elastic tailoring, which allows the wings some bending but limits twisting and eliminates structural divergence within the flight envelope (i.e., deformation of the wing or breaking off in flight).”50

FA-18 E/F Wings

The FA-18 E/F is a much larger aircraft than its predecessor, the FA-18 C/D. Its larger size was enabled by IM-7 fibers and the toughened resin systems required to exploit the additional strain and strength capability of those fibers (without being limited by resin strains to failure). The toughened resin allowed the strengths after impact damage to remain near those of open holes and thus not drive the design to an overly conservative strain level. The additional stiffness of the fibers made an expanded wing planform possible without a comparable increase

________________

50 Federation of American Scientists. 2010. “The X-29.” Website of the Federation of American Scientists. Available at http://www.fas.org/programs/ssp/man/uswpns/air/xplanes/x29.html. Last accessed December 7, 2011.

TABLE 2-2 Space Shuttle External Tank Weights

| Component | Weight (lb) | |||

| Standard Weight Tank |

Lightweight Tanka |

Super Lightweight Tankb |

||

| 1 Structure (LO2 and LH2 tanks, intertank) | 52,589 | 43,623 | 36,123 | |

| 2 Thermal protection (external foam, misc.) | 5.959 | 4,823 | 4,823 | |

| 3 Propulsion (feed. vent, pressure systems) | 2,951 | 2,951 | 2,951 | |

| 4 Power (cables, supports) | 372 | 372 | 372 | |

| 5 Controls | 0 | 0 | 0 | |

| 6 Avionics (instrumentation and supports) | 68 | 68 | 68 | |

| 7 Environment | 0 | 0 | 0 | |

| 8 Other (orb., SRB attachment, misc.) | 6,676 | 5,954 | 5,954 | |

| 9 Growth | 0 | 0 | 0 | |

| 10 Non-cargo (unusable and reserve LO2 and LH2) | 8,209 | 8,209 | 8,209 | |

| TOTAL | 76,824 | 66.000 | 58,500 | |

aWeight reduction made in structure and SRB attachments.

bReplace major portion of Al2219 components in lightweight tank with Li Al 2195 alloy.

SOURCE: Prepared with information in the NASA paper Super Lightweight Tank—A Risk Management Case Study in Mass Reduction. Available at http://www.nasa.gov/externalflash/irkm-slwt/Text%20Case/SLWT%20RM%20Case%20Study%20Accessible%20Version.pdf.

in wing thickness. The fibers also provided enough outer wing torsional stiffness to maintain the aerodynamic shaping of the very thin wing.

787 Wings

The Boeing 787 uses composites to tailor its wings, allowing much more efficient cruise flight than had been possible with the earlier metallic wings. These tailored wings, which have raked wing tips, have been designed to optimize cruise performance, and they bend more than conventional wings. To maintain torsional stiffness for the outer wings and still provide the required bending stiffness, such a wing has a highly tailored layup along its span.

2.5.4 Commercial Aircraft Applications

Extensive Use of Composites in the Boeing 787