There are many available technologies that can be applied to reduce the fuel consumption of trucks, but there are other ways of saving fuel that do not require any changes to vehicle or engine technologies. The overall fuel consumption of a truck fleet can be influenced significantly by the ways in which the vehicles are operated and maintained. Factors such as how close to full payload the trucks operate, whether they run on the most efficient routes, and even driver training can play a role in determining overall fleet fuel consumption. In addition, regulations can directly affect fuel consumption by constraining or promoting technology implementation and efficient operations. The infrastructure in which trucks operate also affects fuel consumption, through factors such as speed fluctuation and congestion. Electronic features can be added to the truck to modify the performance of the engine or vehicle in ways that can save fuel. All of these possibilities fall under the category of “efficient operations.”

The U.S. Department of Energy (DOE) and U.S. Department of Transportation (DOT) have recently proposed “efficient operations” as a new area for work under the 21st Century Truck Partnership (21CTP). Although no programs or work as yet have been initiated in the 21CTP in this new area of efficient operations, the committee’s statement of task charges the committee with examining and commenting on issues related to the 21CTP strategy. The 21CTP’s proposal for this new area is laid out in a February 2011 draft white paper, “Reducing Fuel Consumption in U.S. Trucking—A DOE-DOT Joint Study and Whitepaper” (DOE-DOT, 2011). In this draft, the two agencies explore opportunities to improve the efficiency of trucking operations. The paper focuses on two areas:

• Opportunities for joint research and development (R&D) effort between the DOE and the DOT, and

• Opportunities for modifying regulations (primarily DOT regulations) in ways that could permit more efficient operations.

This chapter provides the committee’s review of the identified opportunities for joint R&D. Because efficient operations is a new area for the 21CTP, the committee first offers its own review of the opportunities for reducing trucking fuel consumption by increasing the efficiency of operations, based on available literature and its own expertise. This information is provided as input to the DOE and DOT for their consideration as they revise the white paper and decide how to move forward in this area.

The committee notes that addressing freight fuel consumption requires a systems approach. Changes made to improve vehicle efficiency can have a negative impact on other aspects of trucking operations. For example, aerodynamic features may impede access to some loading docks. Also, changes made to vehicle specifications may have an effect on road wear or safety. The complete set of outcomes from a given proposed change must be evaluated in order to make good decisions about whether the change should be implemented.

Although it is beyond the purview of this committee to suggest changes to regulations, the committee offers its perspectives on R&D that would be needed in order to determine whether some of the commonly discussed changes to regulations would permit more efficient operations.

EFFICIENT-OPERATION OPPORTUNITIES

The objective of the draft white paper is as follows: “A key objective of this white paper is to identify specific opportunities and challenges with respect to advancing the state-of-the-art of truck fuel consumption and to highlight particular research needs that are seen as critical to maximizing the overall efficiency of freight movement and of trucks in general. It is proposed to develop a set of specific topics on which DOE, DOT and EPA (U.S. Environmental Protection Agency) can—and should—work together to further the goal of improved truck efficiency” (DOE-DOT, 2011, p.4).

Below, the committee has assembled a list of opportunities for more efficient truck operations. This list is by no means exhaustive, but it is intended to provide a survey of the opportunities available. As noted above, this information may be useful to the DOE and DOT as they revise the white paper and identify the highest-priority areas for joint R&D. It is indicated whether each item is covered in the current draft of the white paper.

1. Vehicle maintenance. Tire pressure has been shown to have a measurable effect on fuel consumption (NRC, 2010). This factor can be addressed by frequent, scheduled maintenance checks or by automated tire-pressure-maintenance systems that are mounted on the vehicle. In addition, factors such as axle alignment have an effect on rolling resistance and thus on fuel consumption (NRC, 2010). Axle alignment can be checked and adjusted as needed as a part of routine maintenance. As the diesel particulate filter (DPF) fills with ash, regenerations become more frequent, costing additional fuel consumption. Proper maintenance of DPFs can limit fuel consumption. Several other maintenance factors can affect fuel consumption. Maintenance practices vary widely, so some operators may have little to gain from improved maintenance practices, whereas others might see a significant benefit. The DOT-DOE white paper addresses the topic of trailer maintenance, noting that research into parasitic losses could help determine whether some type of maintenance regulations aimed at reducing fuel consumption would be useful (DOE-DOT, 2011, p. 7).

2. Packaging optimization. Some goods are shipped in bulk or with minimal packaging, but many products have extensive packaging. In the case of many consumer products, the size of the package can be several times the size of the actual product. Because trucks carrying these types of loads are typically filled by volume before reaching their maximum weight, a change in packaging can allow a given truck to carry substantially more product. This means that fewer loads are required to deliver the same amount of product, directly reducing both the number of trucks in operation and fuel consumption. Some companies, such as Walmart and a range of consumer-product manufacturers, have put considerable effort into packaging optimization, but there is still scope for improvement. This topic is addressed briefly in the DOT-DOE white paper (DOE-DOT, 2011, p. 1).

3. Load management optimization. This term describes efforts by trucking companies to ensure that trucks run as close to full payload as possible over the shortest distance needed to make deliveries. “Deadheading” (running empty on the way to pick up a load) needs to be minimized. Sophisticated software is used by many fleets to optimize pickup and delivery routes, both in terms of distance and in terms of maximizing vehicle capacity utilization. Because trucking is a low-margin business, competition places intense pressure on trucking companies to improve their load management. The difference between profitable operation and bankruptcy can be a few percent difference in average load factor. Over time, more companies are implementing ever-more sophisticated load-management systems. However, it must be recognized that there are instances in which a truck needs to run empty or with a very small load, or else a given customer cannot be served at all. This topic is addressed in the draft white paper (DOE-DOT, 2011, p. 14).

4. Routing optimization. Routing determination is normally done using the same system used for load management. The goal here is to select the most time-and fuel-efficient route, which may not always be the shortest distance. Factors that are considered include congestion (which varies by time of day), speed limits, the number of traffic signals or other situations requiring stops, and hills. Planned routing can also be adapted in real time during operation to take into account special conditions such as weather or accidents. As with load management, this is an area in which the industry is investing a significant amount of effort, so there is little if any productive role for agencies to play. One exception may be in the area of providing realtime information on road conditions in order to allow continuous optimization of routes, perhaps by the use of vehicle-to-infrastructure (V2I) communications. Such communications for fuel economy purposes are mentioned in the white paper (DOE-DOT, 2011, pp. 7-8). Another area of opportunity for the agencies is to develop and maintain a database that includes information on road restrictions, road construction, hazardous materials routes, preferred truck routes, and so on, so that the route-planning software used by trucking companies has up-to-date data to work with. This idea is not mentioned in the DOE-DOT white paper.

5. Supply-chain optimization. It is not unusual for a product to contain many individual components that are shipped from all over the world to a final assembly point before the final product is shipped to the customer. For example, raw materials or specialized components may be shipped from the United States to China, combined with other parts from many countries, and then shipped back to the United States for sale. Manufacturers consider the cost of shipping when they set up a supply chain, but shipping is only one of many costs that are considered. If the cost of shipping increases significantly (for example, during a spike in fuel prices), then companies may reconsider their supply chains, especially if the increase in shipping cost appears to be permanent. When companies choose supply chains that involve extensive shipping,

this results in higher fuel consumption, and more just-in-time shipping can lead to dramatically higher fuel consumption (for example, by favoring shipping by air or truck instead of by ship or train). The white paper addresses this topic (DOE-DOT, 2011, pp. 1-2).

6. Infrastructure improvements. Changes to increase road capacity and reduce congestion have a direct effect on truck fuel consumption. Congestion leads to more frequent speed changes and additional idling, both of which cost fuel.

7. Intelligent transportation systems (ITSs). A wide range of features and technologies falls under the term “ITS.” These include driver information systems that can provide warning of accidents or congestion and suggest alternative routes. They can involve demand-management features that restrict access to highways prone to congestion. ITSs also include optimization of traffic-signal operation that can increase capacity, reduce congestion, and reduce speed fluctuation, all of which reduce fuel consumption. “On demand” traffic-signal switching using vehicle presence detection for control is increasingly used to reduce wait times (and fuel consumption due to idling) at stops. Changes such as traffic-signal optimization are particularly attractive, because no road construction or change to the vehicle fleet is needed for all vehicles on the route to benefit. Other ITS applications include ramp metering to reduce congestion, electronic on-road toll collection, automated electronic screening such NORPASS and PrePass for weight and safety inspections, credential checking and border clearance, among others (NRC, 2010, pp. 168-171). These applications can save fuel by reducing congestion and eliminating the need for starting and stopping. ITSs can include vehicle-to-vehicle (V2V) communication as well as V2I communication. ITS features that require V2V or V2I communication will take time to implement, because not all vehicles will have the required systems onboard. However, in many cases the overall traffic flow will benefit even if only a portion of the vehicles involved are actively using ITS. The white paper addresses ITS issues (DOE-DOT, 2011, pp. 7-9).

8. Driver training. In order to obtain a commercial driver’s license (CDL), drivers of commercial vehicles go through more rigorous training than is required for drivers of light-duty vehicles. The primary focus of this training is safety, which misses an opportunity to train drivers in how to operate their trucks in the most fuel-efficient manner. Some truck fleets do have their own driver-training programs. These programs usually go beyond CDL requirements, and often fuel efficiency is part of this training. In some cases, engine and truck manufacturers work directly with fleet operators to help them provide the best possible information to drivers. However, at this time, there is no standardized curriculum for this kind of training, and many drivers do not receive any fuel efficiency training at all. Also, it is unclear how far such training could be standardized, in view of the many manufacturer-specific features and characteristics that drivers need to understand. Driver training is mentioned in the introduction of the white paper, but is not discussed in any detail. However, the white paper does suggest that research into aspects of driver behavior that might affect the fuel-saving performance of specific driver management features (see item 9 below) would be useful (DOE-DOT, 2011, pp. 12-13).

9. Driver-management features. Engine and vehicle manufacturers have developed a wide range of control features aimed at encouraging (or forcing) drivers to operate in a way that reduces fuel consumption. Driver-management features are not discussed in the white paper in any detail, but they offer significant potential for fuel savings. Examples of these features include the following:

a. Progressive shift. This feature reduces the maximum engine speed available in the lower gears, which forces the driver to shift to a higher gear earlier than he or she might otherwise choose. Cummins offers a more sophisticated version of progressive shift called load-based speed control. The control algorithm estimates the vehicle mass and the grade and adjusts the engine-speed governor to be appropriate for the vehicle load.

b. Gear-down protection. At cruising speed, it is typically possible to operate in more than one gear. For example, it may be possible to run at 65 mph in both 9th and 10th gears with a 10-speed transmission. The gear-down protection algorithm reduces the maximum vehicle speed that can be attained in 9th gear, forcing the driver to shift to the more economical 10th gear if he or she wants to run at 65 mph. With gear-down protection, the lower gears are reserved for conditions that require their use, such as climbing hills or coming up to cruising speed.

c. Road-speed governors. Virtually every truck sold today includes a road-speed governor, but the use of the governor and the governor setting are left up to the owner. The road-speed governor limits cruising speed. Because fuel consumption increases with cruising speed, the use of a governor saves fuel. Note that there are tradeoffs: to the extent that speed is reduced, trip times will increase. This will lead to a need for more trucks to deliver the same quantity of freight per day. Speed governors also have no effect on fuel consumption when other constraints such as congestion or road conditions limit vehicle speed so that it is at or below the speed-governor setting (NRC, 2010). Many owners of large fleets set their road speed governors in the range of 62 to

67 mph. Most owners of smaller fleets and most owner-operators do not use road-speed governors. The Owner-Operator Independent Drivers Association has registered strong objection to the regulation of road-speed governor settings, citing safety concerns caused by differential car-truck speeds.

d. Smart cruise control. Cruise control helps the vehicle maintain a constant speed when road conditions permit, and reduces driver effort. Cruise controls can be developed with features that help save fuel. For example, cruise control can allow small speed fluctuations that permit the engine to operate at its most efficient load point a higher percentage of the time than would be the case if precise speed control were the goal. There are also cruise-control systems that automatically adjust truck speed to maintain a safe distance from the vehicle ahead. A more recent example is the introduction by Daimler Trucks of predictive cruise control. This feature works with a Global Positioning System (GPS) unit to adjust cruise speed based on speed limits and terrain. The truck may speed up before climbing a hill, for example. Tuning of these algorithms has to balance driver acceptance and fuel-savings potential. For example, drivers might object if large speed fluctuations around the set point selected by the driver are used by the cruise-control algorithm.

e. Driver reward systems. Features are available to track aspects of driver performance that can affect safety and fuel consumption. Some of these systems can be programmed to provide the driver with a direct financial interest in reducing fuel consumption by awarding bonuses for fuel-sensitive driving styles. Some of the rewards are determined in real time by algorithms in the engine-control module, such as access to higher engine power and torque (and possibly even a change in the speed-governor setting) when the vehicle is being operated in a fuel-efficient manner. The goal of these systems is to provide drivers with an incentive to operate in a fuel-efficient way, by sharing some of the fuel cost savings with the driver.

10. Barriers to the application of fuel-saving technology. As the white paper notes, several technologies that could save fuel run into regulatory constraints. Examples in this category include the following:

a. DOT mirror regulations specify the size, number, and locations of mirrors. Mirrors are a significant source of vehicle aerodynamic drag, and the replacement of mirrors with a system of cameras and in-cab displays has been proposed. These vision systems could not only save fuel but also could improve safety by reducing or eliminating blind spots. However, regulations would need to change to allow use of camera-based systems. This issue is addressed by the white paper (DOE-DOT, 2011, p. 6).

b. The aerodynamic skirts used on trucks today do not extend to cover the drive axles of tractors or the trailer axles. The reason for this is that if skirts are built around existing axles, the truck may violate regulations governing maximum width. Other aerodynamic improvement features, such as boat-tails, can run into issues with length regulations at the local level, even when operators are granted a federal exemption. This issue is addressed by the white paper (DOE-DOT, 2011, p. 5).

c. Weight limits discourage the use of heavy fuel-saving features such as auxiliary power units (APUs) or aerodynamic devices, especially on vehicles that frequently run at or near the maximum weight limit. In these cases, the fuel-saving feature directly reduces the load-carrying capacity of the truck, which defeats the purpose of the fuel-saving feature. This issue could be addressed by providing a weight allowance (i.e., an increase in legal weight) for vehicles with specific fuel-saving features. This issue is not mentioned in the white paper.

d. Federal vehicle-size and -weight regulations have not changed since 1983. These regulations prevent the use of high-productivity vehicles, including long combination vehicles (often called, respectively, HPVs and LCVs). HPVs involve greater freight volume or weight than is allowed under existing regulations. Current regulations forbid the use of HPVs in many areas, regardless of whether safety and road damage considerations are adequately addressed in the vehicle design. Some very large fuel savings are possible if regulatory barriers to the appropriate use of HPVs are removed (see the section “Fuel-Saving Opportunities from Efficient Operations” in this chapter, as well as Table 9-2). For example, a bill has been introduced in Congress that would allow weights of up to 97,000 lb, compared to the current limit of 80,000 lb, for trucks using a 6th axle.1 In addition to saving fuel, the use of HPVs could reduce truck vehicle miles traveled (VMT), congestion, accident rates, shipping costs, driver shortages, and road damage by combining longer and heavier vehicles with appropriate operational restrictions and performance requirements. Certain trailer and dolly configurations are inherently more stable than others, providing opportunities to upgrade braking and stability-control requirements. The white paper has a discussion of some options for heavier vehicles (DOE-DOT, 2011, pp. 13-15),

_____________________

1 The Safe and Efficient Transportation Act., S. 747, was introduced on April 6, 2011. The proposed legislation is available at http://www.gpo.gov/fdsys/pkg/BILLS-109s747is/pdf/BILLS-109s747is.pdf.

but the range of options considered is limited, and options to increase the allowable volumetric capacity of trucks are discussed in a very limited way (DOE-DOT, 2011, p. 15).

e. As noted in previous chapters, the EPA and the National Highway Traffic Safety Administration (NHTSA) have implemented fuel-consumption and greenhouse gas (GHG) regulations for trucks. So far, these regulations are aimed only at engines and at vehicles (tractors in the case of tractor-trailer vehicles). Trailers were left out of the regulations because some trailer manufacturers are small businesses. However, the trailer can have a significant effect on both the aerodynamic drag and the rolling resistance of a tractor-trailer vehicle. The idea of expanding the EPA/NHTSA regulations to include trailers is not discussed in the white paper.

11. Vehicle specification. Purchasers of new trucks have the opportunity to select a vehicle specification that is optimized to achieve a good combination of productivity and low fuel consumption. There are many features that buyers can select from, including engine type, power rating, transmission type, wheelbase, axle ratio and number of drive axles, tire type, aerodynamic improvement features, lightweight features such as aluminum wheels, and so on. Because profit margins in trucking are normally very small, there is intense interest from larger trucking companies in choosing the best possible vehicle specification for their application. Vehicle specification tools are a key technology for controlling operating costs, including fuel consumption.

a. Truck-specification tools have been developed by both vehicle and engine manufacturers. These tools can be quite sophisticated, allowing comparison of various vehicle specifications on a huge variety of routes, with any load specified by the customer. A wealth of detail is available, such as data to answer a question like this: “How many times would the driver need to shift gears on a run from Chicago to Los Angeles?” The primary use of the specification tools, however, is fuel-consumption optimization. These tools are widely used by larger trucking companies but are often not used or not fully taken advantage of by smaller fleets and by owner-operators. In many cases, this may be a result of a lack of awareness of how the tools can help, but in other cases the buyer lacks the information on loads and routes that is required to feed the tool. There are some limitations to these tools: many trucks are used to carry widely varying loads over their lifetime, so it may not be practical to specify a truck with a narrow focus on the first use. Trucking companies generally specify trucks with resale value as one of the parameters that they consider. There may be an opportunity for the agencies to encourage the more widespread use of existing vehicle-specification tools. These tools are not discussed in the white paper.

As the list above makes clear, a wide variety of technologies, training practices, and regulatory changes falls under the umbrella term “efficient operations.” All of the items listed above have some potential for saving fuel, and some of them have potential to save a substantial amount of fuel—as much as vehicle technologies that may cost tens of thousands of dollars per truck. The cost of efficient operations technologies can range from several thousand dollars per vehicle to actual cost reductions. For example, HPVs are more expensive on a per truck basis but less expensive on a unit freight capacity basis.

FUEL-SAVING OPPORTUNITIES FROM EFFICIENT OPERATIONS

As noted in the draft white paper as well as in an earlier NRC (2010) report, the data that would be needed to quantify the possible fuel savings in some of the areas above are sparse or do not exist. This is especially an issue when the potential savings depend strongly on the details of drive cycles. The white paper proposes R&D and testing to develop some of the needed data. In this section, the committee uses data available in the literature to quantify some of the fuel-saving opportunities available for features discussed above. This assessment should be useful to the DOE and DOT as they set R&D priorities for efficient operations.

Much of the data listed below references the NRC (2010) report titled Technologies and Approaches to Reducing the Fuel Consumption of Medium- and Heavy-Duty Vehicles, which in turn references a wide variety of sources. In this section, the term “fuel savings” means fuel consumption in units of gallons per 1,000 ton-miles or per cube-mile. Note that the fuel savings quoted below are typically determined for a specific operating condition and are not likely to be representative of the savings potential possible for trucks operating under a wide range of conditions. It is common practice to evaluate a fuel-saving technology under the operating condition for which it provides the largest benefit.

Tire Underinflation and Axle Misalignment

The NRC (2010) report referred to above estimates that the effect of running with all tires underinflated by 20 percent is a 2 to 3 percent increase in fuel consumption. Typical inflation pressures for tractor-trailer tires are 100 to 120 psi. Thus a tire that is 20 percent underinflated would be 20 to 25 psi below the recommended inflation pressure. Inflation pressures for medium-duty trucks vary but typically fall between those for light-duty and heavy-duty vehicles.

Axle misalignment caused by suspension maladjustment produces a slip angle, which increases rolling resistance. This effect increases with the square of the slip angle. NRC (2010) estimates the effect as an approximately 0.1 percent increase in fuel consumption for an average slip angle of 0.1 degree, and 0.4 percent increase for a slip angle of 0.2 degrees. Other studies have assessed the extent of tire underinflation in the field, such as a Federal Motor Carrier Safety Administration (FMCSA, 2005) report, but the committee is not aware of studies on the extent of axle misalignment to be found in the field. The FMCSA (2005) report says that only 44 percent of all tires checked had inflation pressures on all tires within 5 psi of the target value, and about 7 percent of tires were off by 20 psi or more. There is also a lack of data about other areas, such as the extent to which fuel consumption needed for DPF regeneration increases as miles accumulate.

Packaging

As noted in item 2 above in the committee’s list in the section “Efficient-Operation Opportunities,” packaging can significantly affect the cost of shipping a product, as well as the fuel consumed in shipping. Some products have packages that are several times larger than the product itself, which results in trucks running with the trailer full (capping the number of products that can be shipped in a single load), but well below the legal weight limit. Walmart has been working for more than 10 years now to use sustainable packaging materials by reducing the size and the energy and natural resources needed to produce packaging. Its target, as stated in its 2010 Sustainability Report, is to reduce total packaging by 5 percent from 2008 to 2013 (Walmart, 2010). The report does not specify whether this reduction is in the amount of packaging material or in the volume of packages, or whether some other metric is being used. Although the fuel savings from modified packaging of certain products can be substantial, the committee is not aware of any published research that quantifies the potential overall fuel-consumption opportunity in this area.

Load Management, Routing Optimization, and Supply-Chain Optimization

The benefits of load management and routing optimization can be substantial. However, this is an area of intense competition among trucking companies as well as among suppliers of logistics software and systems. As far as the committee is aware, there is no published research that quantifies the overall fuel-saving opportunity. The same comments apply to supply-chain optimization, except that in this case, manufacturers and distributors are also part of the overall picture.

Infrastructure Improvements

Infrastructure improvements (road expansion and construction) are the subject of intense debate. For a given volume of traffic, congestion causes increased fuel consumption, and the increase can be dramatic. A truck may consume twice the fuel in urban traffic that it consumes traveling the same distance on an uncongested road. However, congestion also affects demand. As congestion becomes intolerable, road users find other ways of moving freight (alternative routes, night operations, etc.), or they may simply give up (which has the effect of limiting economic growth). Therefore, there is debate over whether new or expanded roads save fuel, or whether they lead to increased traffic and thus higher fuel consumption.

Intelligent Transportation Systems

As the draft white paper (DOE-DOT, 2011) notes, ITS programs have historically been driven largely by safety concerns. There has been limited research to quantify the fuel-saving opportunities available through ITSs, or even to explore all the ways in which ITSs could be used to save fuel. The white paper discusses the potential fuel savings from ITSs primarily in relation to the avoidance and mitigation of congestion, because concepts such as route management are dealt with elsewhere. The NRC (2010) report estimates the fuel-saving potential of ITSs in the 2015-2020 time frame as 8 to 15 percent. This figure includes some technologies that are described elsewhere in this chapter, such as predictive and adaptive cruise control, as well as other ITS technologies such as predictive control of hybrid systems, use of electronic tow bars, and real-time route optimization.

The white paper asserts that research on V2V and V2I communications is the most critical aspect of the ITS program, and that this work is crucial for obtaining significant improvements in fuel consumption, not just safety. The paper states, “With the magnitude of potential energy savings, it is important that DOE and DOT work very closely in this domain so that the magnitude of energy savings is not overlooked and research and applications development is sufficiently funded for assuring the maximum benefits in fuel savings, in addition to safety” (DOE-DOT, 2011, p. 8). Given the 8 to 15 percent potential energy savings estimated for ITSs (NRC, 2010), the committee concurs with the high importance of determining fuel savings as part of any project that involves ITS-related technologies. Further, the potential for ITS technologies to reduce fuel consumption would seem to argue for the development of one or more goals by the 21CTP.

Driver Training and Management

Driver training and driver management features have significant potential for saving fuel. According to the NRC (2010, p. 175) report, several case studies report fuel savings from 1.9

to 17 percent for driver-training programs. Generally, there is more opportunity for savings in urban and congested environments than there is for savings on the open road. Large fleets often develop their own driver-training programs, many of which include fuel-efficient driving techniques. Smaller fleets and owner-operators typically do not have driver-training programs. Driver-management features also vary in their effects based on operating conditions. Progressive shift algorithms are useful in urban driving but make little difference in long-haul operation. Conversely, cruise control is not used in urban driving but can contribute to fuel savings on the open road. Studies reviewed in the NRC (2010, p. 126) report show benefits of 1 to 5 percent for predictive cruise control, depending on the vehicle and duty cycle.

Road-speed governors are discussed in the NRC (2010, pp. 166 ff.) report. Vehicles that currently run at 70 mph would see fuel savings of 7 to 10 percent by running at 60 mph, and vehicles slowing from 65 to 60 mph would save 3.5 to 5 percent. However, there are disadvantages to lower speeds that must be carefully considered before any mandatory road-speed governor setting is implemented. Road-speed governors could include the use of GPS devices or wireless systems that would change the governor setting based on local speed limits and road conditions.

Aerodynamic Features That Exceed Width or Length Limits

A report by the Truck Manufacturers Association (NETL, 2007) shows that replacing mirrors with cameras has the potential to reduce fuel consumption at high-speed cruise by up to 3 percent, depending on the type of mirrors being replaced. The committee is not aware of any studies estimating the potential benefit from tractor and trailer skirts that extend over the drive axles and trailer bogies, but the value is likely to be a few percent.

Size and Weight Limits

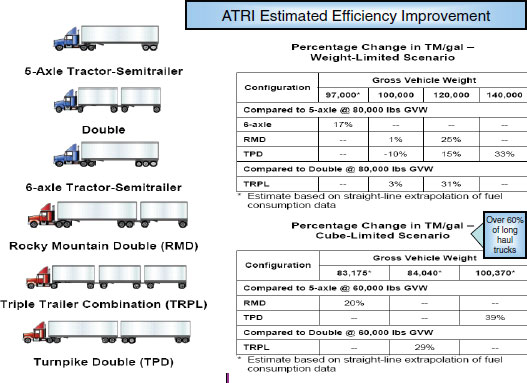

The NRC (2010, p. 163) report discusses the effects of size and weight limits. Fuel savings of up to 13 percent and truck VMT reductions of up to 23 percent are projected, depending on the nature of regulatory changes. The American Transportation Research Institute (ATRI) estimated potential fuel savings of up to 25 percent for weight-limited trucks (grossed-out) and 28 percent for volume-limited trucks (cubed-out) (ATRI, 2008). In Figure 9-1, reproduced from the ATRI report, the metric used is ton-miles per gallon, which is a fuel economy metric. The changes in fuel consumption are smaller, but still significant.

The topic of longer and heavier vehicles (called high-productivity vehicles or long combination vehicles by different authors) raises public concern about safety, so it is essential that discussion and research are based on high-quality data rather than on emotional arguments. The authors of a study of Canadian experience with LCVs (Regehr et al., 2009) concluded: “An analysis of the safety performance of LCVs relative to other types of articulated trucks operating on Alberta’s rural LCV network revealed that, from a collision rate perspective, LCVs as a group had better safety performance than other articulated trucks….” The conclusion is intensified considering that, for a fixed quantity and density of freight transported by articulated trucks, each LCV replaces 1.5 to 2 standard 5-axle semitrailers, which, over the same period, had higher collision rates than those of LCVs. In this sense, LCVs operating in Alberta in this period provided increased freight productivity and reduced the number of collisions that would have occurred if standard configurations had been used to haul the same freight. The longest and heaviest LCV in the CSC (2003) study, the turnpike double, had the best safety record of any articulated vehicle.

A recent report from the Organization for Economic Cooperation and Development (OECD), Moving Freight with Better Trucks (OECD, 2010), provides an insight into the good safety performance of LCVs. According to the report, many LCV configurations are more dynamically stable than typical truck configurations used on the road today. This makes it easier for a driver to control an LCV in difficult high-speed maneuvers and in strong crosswinds. In addition, regulations limiting LCV operation to specific roads and conditions, along with rules requiring additional driver qualifications, appear to improve LCV safety. The OECD report is the most comprehensive review of the opportunities and challenges of LCV implementation of which the committee is aware. Results from Europe, Australia, Canada, and the United States are all considered in this report.

Longer, heavier trucks require an increase in power in order to maintain existing levels of vehicle performance (acceleration rates and speed on grades). This increase in power can be accommodated to some extent with existing truck technology, but large changes in weight, such as with turnpike doubles, would result in lower vehicle performance. The impact of lower speeds on other traffic could be minimized by restricting or preventing the operation of these vehicles on routes where traffic flow becomes an issue. There may also be value in setting minimum power-to-weight ratio requirements for longer and heavier trucks, to limit the potential for impeding traffic flow.

Road wear and damage are known to be controlled by contact (Hertz) stress. Relative fatigue damage of pavement is approximately a fourth-power function of axle load, which is related to contact stress (FHWA, 2000). As a result, vehicle weight and the distribution of that weight over the tire contact patches are critical factors in determining the durability of road surfaces. LCVs typically have lower weight per axle than do current trucks, which allows these vehicles to provide reduced road surface wear, compared to conventional trucks.

The fuel-saving potential of high-productivity vehicles makes the removal of barriers to their use one of the most powerful fuel-saving tools available. In addition, the economic benefits obtained by higher-productivity vehicles could be used to support the addition of safety technologies that would improve the acceptability of these larger vehicles. Currently, the major barriers to HPVs are (1) regulatory limits on vehicle size and weight, and (2) lack of adequate data and experience on which to base analyses of benefits and drawbacks. Before 1983, states had almost complete freedom to regulate truck length and weight. In 1983, Congress passed legislation that standardized the trailer length limit at 53 ft and the maximum weight at 80,000 lb. The 1983 legislation “grandfathered” in state regulations that had previously allowed vehicles longer or heavier than provided for in the 1983 national standard, but no additional states are allowed to set standards above the federal limits. Also, states with grandfathered length or weight limits (see Table 9-1) cannot increase these limits. This prevents neighboring states from standardizing their regulations on anything beyond the federal limits or the limits that applied in the states in question before 1983. Twenty U.S. states have pre-1983 regulations that allow a wide range of vehicle lengths and weights, while the remaining 30 states are denied the option of longer or heavier vehicles by the 1983 law. Table 9-1 shows the regulations for the states. The diversity of these regulations means that trucks complying with different state standards can only be used for intrastate commerce, which greatly reduces the fuel-saving potential of HPVs in the United States.

Canada, Australia, and Scandinavian countries have extensive experience in the operation of trucks that are longer and heavier than traditional American trucks, and their experience, in addition to that of some U.S. states, can be drawn upon by the DOT and DOE in analyzing the effects of using these vehicles in the United States (see Appendix H in this report). The European Union (EU) is now considering an increase in maximum truck weight and length from 40 to 60 metric tons (88,000 lb to 132,000 lb) and from 16.5 to 25 meters (54 ft to 82 ft) as a measure to reduce both greenhouse gas emissions and fuel consumption (Die Zeit, 2010). If this change is implemented, it would effectively extend the current Scandinavian regulations across Europe. There may be opportunities for joint research with European regulators, and perhaps even standardization of some regulatory requirements. This would allow manufacturers that sell trucks in both the United States and the EU to use a single design for both markets. Current designs of trucks for use in the United States and those for use in the EU diverge widely, driven primarily by different regulatory requirements.

Given President Obama’s emphasis on energy security, the DOE and DOT, working with the Congress, should consider the recommendations of the NRC’s Transportation Research

TABLE 9-1 Maximum Truck Size and Weight Limits for 13 of 20 States Subject to the ISTEA Freeze

| State | Truck Tractor and Two Trailing Units | Truck Tractor and Three Trailing Units | Othera | ||

| Length (ft) | Weight (lb) | Length (ft) | Weight (lb) | Length | |

| Colorado | 111 | 110,000 | 115.5 | 110,000 | 78 |

| Idaho | 95 | 105,500 | 95 | 105,500 | 78-98 |

| Kansas | 109 | 120,000 | 109 | 120,000 | No |

| Montana | 93 | 137,800 | 100 | 131,060 | 88-103 |

| Nebraska | 95 | 95,000 | 95 | See noteb | 68 |

| Nevada | 95 | 129,000 | 95 | 129,000 | 98 |

| North Dakota | 103 | 105,500 | 100 | 105,500 | 103 |

| Oklahoma | 110 | 90,000 | 95 | 90,000 | No |

| Oregon | 68 | 105,500 | 96 | 105,500 | 70 ft 5 in |

| South Dakota | 100 | 129,000 | 100 | 129,000 | 73-78 |

| Utah | 95 | 129,000 | 95 | 129,000 | 88-105 |

| Washington | 68 | 105,500 | No | -- | 68 |

| Wyoming | 81 | 117,000 | No | -- | 78-85 |

a A commercial motor vehicle combination with two or more cargo-carrying units not included in descriptions “truck tractor and two trailer units” or “truck tractor and three trailer units.”

b No maximum weight is established because this vehicle combination is not considered an “LCV” per the ISTEA definition because it is only allowed up to 80,000 lb.

SOURCE: FHWA (2010).

Board (TRB) in TRB Special Report 267 (TRB, 2002). The TRB proposed a way forward for high-productivity vehicles in the United States that would deal responsibly with the issues raised by different stakeholders. Fundamental to the TRB’s proposed process is the creation of a Commercial Traffic Effects Institute (CTEI) by Congress that would manage all issues related to high-productivity vehicles. Extensive pilot studies would be used to evaluate the consequences of increased truck size and weight, following accepted practices for test design and for analysis. In addition, all states would be authorized to begin permitting for heavier, 6-axle combination trucks and various other HPVs. Because having a range of permitted vehicle sizes and weights that varies from state to state effectively restricts the use of HPVs across state lines, the DOE and DOT should consider assigning high priority to further research and analysis on the potential for fuel savings from uniform, nation-wide size and weight regulations.

Trailers

The benefit of trailer aerodynamics is estimated NRC (2010, p. 100) as 9 percent today, growing to 12 percent by 2020. These savings were based on a baseline tractor-trailer coefficient of drag (Cd) of 0.625, which is lower than the baseline of 0.69 used in the EPA and NHTSA GHG and fuel-consumption regulations. As the earlier NRC (2010) report notes, there are also rolling resistance benefits that could be obtained if regulations were extended to cover trailer tires. For tractor-trailer combination vehicles, a significant potential fuel-savings has been neglected by leaving trailers out of the EPA and NHTSA regulations.

Summary of Fuel-Saving Opportunities

The values of the fuel saving opportunities discussed above are summarized in Table 9-2. Note that these fuel savings are often estimated for a specific operating condition of a specific vehicle type, not for the average operation of all trucks. Thus the fuel savings opportunities in the table are not valid for the entire truck population. There are many other fuel-saving opportunities not shown in Table 9-2, such as improved engine and driveline efficiency, reduced aerodynamic drag of the tractor, and others. This list only includes items related to efficient operations or to removal of regulatory barriers. The trucking industry normally operates on very narrow profit margins, so efficient operation is an area of intense interest and competition among trucking firms. Larger fleets invest significantly in finding ways to improve their operational efficiency. As a result, the industry can supply a wealth of ideas and data to help improve its own efficiency. The industry is also in a position to point out potential drawbacks and unintended consequences of regulatory changes that are intended to save fuel by improving the efficiency of trucking. The DOE, DOT, and other government

TABLE 9-2 Summary of Fuel Saving Opportunities

Source of Savings |

Fuel Savings Opportunity (%) |

Notes |

| Prevent tire underinflation | 2-3 | For a truck with 20% underinflation of all tires. |

| Prevention of axle misalignment | 0.1 to 0.4 | For 0.1 to 0.2 degree misalignment. |

| Packaging reduction | Unknown | Research needed. |

| Load management, routing optimization, and supply chain management | Unknown | Areas of competition among trucking companies. |

| Infrastructure improvements | Varies with severity of congestion | |

| Intelligent transportation systems | 8 to 15 | Primarily in urban conditions. |

| Driver training | 1.9 to 17 | Higher potential in urban driving. |

| Predictive cruise control | 1 to 5 | Useful only in rural driving. |

| Road-speed governors | 3.5 to 5 | For trucks slowed from 65 to 60 mph. Only effective where other factors do not limit speed. |

| Replacement mirrors with cameras | 1.5 to 3 | Only a factor at higher speeds. |

| Remove regulatory barriers to increased size and weight | 0 to 28 | Depends on what new configurations are allowed and where they can operate. |

| Trailer aerodynamic improvements | Up to 12 | Only effective at highway speeds. |

agencies interested in reducing fuel consumption by improving the efficiency of trucking will also need to work closely with members of the industry to gain the advantage of the ideas, data, and practical experience that are available. There may also be advantages in working with large customers of the trucking industry (shippers), to see if there is potential for shippers to make changes in their operations that would improve the overall freight system efficiency. The existing white paper (DOE-DOT, 2011) does not discuss industry involvement, and the committee would like to see this oversight remedied.

OPPORTUNITIES FOR COLLABORATION BY DEPARTMENTS OF ENERGY AND OF TRANSPORTATION

The DOE and DOT have opportunities to collaborate in facilitating the development and use of efficient operations for trucking. There are also some areas in which other agencies, such as the EPA and NHTSA (a part of DOT), need to be involved. This section considers some of the opportunities that are available.

Research and Development

One large set of opportunities for collaboration involves research, development, and information dissemination. In many cases, the potential benefits of fuel-saving technologies are not well understood across a wide range of operations. As noted at the beginning of the section above on “Fuel-Saving Opportunities from Efficient Operations,” for most of the technologies and approaches discussed above, the range of potential fuel savings possible in actual field use is very wide. It is very difficult to estimate even an approximate fuel savings for the implementation of a given technology across a wide range of truck applications, even in a relatively narrow segment such as long haul. There is considerable scope for further research to evaluate options under real-world operating conditions, to provide both regulators and the industry with data of better quality. In particular, research and development efforts are needed to identify, develop, and quantify the performance of items such as ITS features that can save fuel, and to assess the effects of removing regulatory barriers that prevent the application of some fuel-saving technology. Before new regulations are implemented, however, research is needed to help define potential benefits and avoid possible negative side effects, including effects on trucking company operations and on other concerns such as safety and road damage.

Based on the discussion above in the sections “Efficient-Operation Opportunities” and “Fuel-Saving Opportunities from Efficient Operations,” the committee believes that the DOE and DOT could usefully work together on research in the following areas:

1. Assessing the effects of vehicle maintenance practices on fuel consumption and the effects of potential maintenance standards aimed at reducing fuel consumption.

2. Evaluating the effects of infrastructure improvements (increased road capacity) on fuel consumption, traffic growth, and economic growth.

3. Analyzing the potential for ITSs to reduce fuel consumption and for the development of new ITS features specifically intended to save fuel.

4. Identifying what constitutes “best practice” driving techniques from the point of view of fuel consumption, as limited by other issues such as the possibility of delaying traffic. Developing driver-training curricula, allowing for flexibility to adapt to various technologies and the differing characteristics of vehicles in the field.

5. Determining the magnitude of fuel savings available from modifications to regulations, such as mirror requirements, size limitations that inhibit the use of aerodynamic features, and weight limits that prevent or constrain the use of features such as APUs or aerodynamic improvements that add weight to the vehicle.

Investigating potential concerns that could be raised by changes in regulations and ways of attaining the benefits of the modified regulations while minimizing negative effects.

6. Evaluating alternatives for modifying size and weight restrictions in ways that would allow for the use of high-productivity vehicles while improving safety and avoiding road-damage issues. For example, certain trailer and dolly configurations are inherently more stable than others, providing opportunities to upgrade braking and stability-control requirements. In addition, training requirements for drivers of high-productivity vehicles need to be addressed. This research could be done by the DOE and DOT or by the Commercial Traffic Effects Institute proposed by the TRB. The committee suggests that this research consider the Canadian experience with management of LCVs, where certain equipment requirements and restrictions in use result in major improvements in safety compared with more traditional tractor-trailer operations (NRC, 2010).2

Regulatory Matters

Another area for possible cooperation among the DOT and DOE is regulatory matters, as they are informed by the R&D described above. The committee believes that if the DOT and DOE decide to work on such regulatory matters, they should consider cooperating in the following areas:

• Vehicle maintenance practices that affect fuel consumption;

• Road design specifications that affect fuel consumption;

• Implementation of ITS features designed specifically to reduce fuel consumption (some features are likely to require changes in regulation);

• Driver-training requirements related to fuel consumption;

• Modification and standardization of regulations that constrain the use of fuel-saving features, such as regulations related to mirrors and limitations on maximum vehicle width and weight that inhibit the use of APUs and certain aerodynamic improvement features;

• Implementation of aerodynamic and rolling resistance requirements for trailers (requires the involvement of the NHTSA and EPA); and

• Modification of vehicle size and weight restrictions on a national basis, to allow for the use of high-productivity vehicle configurations on a national scale.

The draft white paper emphasizes the importance of implementing the systematic validation of technologies stating: “Developing drive cycles that are relevant for the many different types of trucks in use will allow much more accurate estimates of the fuel savings that are possible with specific technologies, and understanding the variations in drive cycles will allow an accurate assessment of how robust a technology will be in actual use” (DOE-DOT, 2011, p. 12). The paper also notes: “Component testing of heavy duty truck technologies is currently being performed in Canada under the EnergoTest campaign (McCormick, 2009), and experience from this testing could be used as guidance for similar testing in the U.S.” (DOE-DOT, 2011, p. 12). The committee notes that it agrees with these principles and believes that it would be helpful for all involved agencies to collaborate among themselves as well as with industry. Should the work in the draft (and later, modified) white paper go forward, an appropriate set of improvement targets (goals) should be set.

The committee believes that regulatory intervention in the following two areas could prove counterproductive: (1) Packaging—It is difficult to imagine how packaging regulations might work, or how they could properly cover the vast range of products that are shipped every day; and (2) Load management, routing optimization, and supply-chain management. These are areas of fierce competition among manufacturers, trucking companies, and their logistics solutions suppliers. Although there is a useful role for the DOT and DOE in doing research and development on driver-management features, the committee believes that the proposed regulation for road-speed governing will save fuel. There is substantial competition among engine and truck manufacturers on other driver-management features such as progressive shift, gear-down protection, and bonuses or power increases for fuel-sensitive driving. The situation today is that truck owners are free to select the features that work best for their operation and to adjust the parameters that these features use. Large fleets tend to be fairly sophisticated in terms of figuring out what features work in their operations and how to set the parameters. For any given driver-management feature there will be situations in which its use is not appropriate or in which a given set of parameters will lead to inefficient, or even unsafe, operation. There is an opportunity to provide training to small fleets and owner-operators so that they can see how using these features can make their operations more fuel-efficient and thus more profitable.

The following findings and recommendations are the result of the committee’s review of the draft DOE-DOT (2011) white paper on efficient operations. They describe what the committee believes should be added to or changed

_____________________

2 Government of British Columbia requirements for LCV operation are listed at http://www.th.gov.bc.ca/cvse/LCV/faqs.htm; Ontario requirements for operating 53-ft doubles are listed at http://www.mto.gov.on.ca/english/trucks/lcv/program-conditions/index.shtml.

in the white paper to help the 21CTP promote and enable more efficient trucking operations.

Finding 9-1. The DOE-DOT draft white paper proposes “efficient operations” as a new direction for the 21CTP. The committee agrees that this is an important area for R&D under the umbrella of the 21CTP. It also agrees that cooperation among the DOE and DOT and other agencies would be beneficial, particularly for assessing the possible effects of removing regulatory barriers to the use of fuel-saving measures.

Recommendation 9-1. As suggested in the draft white paper on efficient operations, the DOE and DOT, in cooperation with the EPA and other agencies, should conduct joint research on efficient operations and should cooperate as appropriate on any regulations that affect fuel use and safety.

Finding 9-2. Extensive information is available regarding the importance of trailer aerodynamics and rolling resistance. The data show that trailer aerodynamic-improvement features and rolling resistance contribute significantly to overall vehicle fuel consumption.

Recommendation 9-2. The available data show that trailer aerodynamic-improvement features and rolling resistance contribute significantly to overall vehicle fuel consumption. Therefore, the DOE and DOT should look in detail at options for trailer improvement.

Finding 9-3. The application of intelligent transportation systems has the potential to reduce fuel consumption substantially, particularly in urban areas. Certain elements of ITSs, such as adaptive traffic signals, do not require new vehicle technology, so they can be rolled out much faster than other elements.

Recommendation 9-3. Traditionally, ITSs have been viewed as a way of improving safety. As suggested in the draft white paper on efficient operations, the DOT and DOE should conduct additional research and development devoted to exploiting the potential for reduced fuel consumption.

Finding 9-4. Driver-management features must be carefully researched and developed in cooperation with vehicle manufacturers and operators. There are important concerns with driver-management features that need to be addressed, regarding unintended consequences stemming from allowing the vehicle (or its controller) to ignore or modify driver input. Consideration must also be given to identifying the types of intervention that drivers would accept.

Finding 9-5. Trucking companies already have very strong economic incentives to improve operational efficiency and average load factors. As a result, they are making significant investment in logistics technology. In addition, shippers have an economic incentive to reduce the size and weight of packaging materials. The trucking industry is a valuable source of ideas, data, and experience regarding efficiency, and the industry can help agencies avoid unintended negative consequences of efforts to improve efficiency. Recommendation 9-4. The DOE and DOT should work with the trucking industry to take advantage of the ideas, data, and experience that the industry can provide to accelerate efficiency improvements and to avoid unintended negative outcomes of efforts to improve trucking efficiency.

Finding 9-6. High-productivity vehicles, known as HPVs or LCVs, as currently configured and using current technology, can reduce fuel consumption by up to 28 percent. In addition, HPVs can reduce greenhouse gas emissions, truck vehicle miles traveled, congestion, shipper costs, truck highway accidents, road damage, and truck driver shortages.

Finding 9-7. High-productivity vehicles have proven to be a highly controversial and emotional topic. Some U.S. states, as well as countries including Canada, Australia, and the Scandinavian countries, have extensive experience with HPV operations and safety performance. Operational limitations and equipment policy used for decades in Canada have significantly increased safety for HPVs compared with that of more conventional tractor-trailers. In 2002, the NRC’s Transportation Research Board proposed a process, to be led by a congressionally chartered Commercial Traffic Effects Institute, to make decisions regarding a number of critical and historically controversial issues that effectively have prevented the growth of HPV use for nearly three decades. As far as the committee can determine, no action on the CTEI recommendation has been considered by Congress.

Finding 9-8. The draft white paper on efficient operations brings up the topic of high-productivity vehicles and the possibility of raising weight and size limits to accommodate them. However, the white paper focuses narrowly on 6-axle tractor-trailer combinations with weights up to 100,000 lb (45.5 metric tons) and does not address other options that increase volumetric freight capacity or that allow weights beyond 100,000 lb .

Finding 9-9. The committee finds the case for fuel savings of HPVs compelling, and the case for improved safety of HPVs compared to that of standard 5-axle semitractor trucks is also strong.

Recommendation 9-5. The DOT and DOE should look at the full range of high productivity vehicles in use in some U.S. states and around the world and review the literature available on the safety and fuel-saving performance of these vehicles. The assessment should take into consider-

ation that the higher productivity of these vehicles can also be used to justify the implementation of additional safety technologies.

Recommendation 9-6. The DOT and DOE, in discussion with the Congress, should consider the recommendations of the Transportation Research Board regarding the establishment of a Commercial Traffic Effects Institute or a similar approach.

Finding 9-10. The DOE-DOT draft white paper on efficient operations in its current form does not include any goals that could be used to prioritize and drive R&D efforts on efficient operations.

Recommendation 9-7. Specific goals for efficient operations should be developed, with strong consideration given to exploiting the potential for intelligent transportation systems to reduce fuel consumption. In addition, priorities should be set for the R&D, testing, and data collection needed to analyze the benefits, drawbacks, and potential unintended consequences of removing barriers, including regulatory barriers, to the application of fuel-saving features. The draft white paper on efficient operations should be rewritten to take the findings and recommendations of the committee into account. The 21CTP partners, trucking fleets, and major suppliers should be involved in setting goals and research priorities.

Finding 9-11. There is a need for a more detailed evaluation of the large potential for fuel savings from efficient operations than is provided in the existing DOE-DOT draft white paper of February 25, 2011. This more detailed study can be used to set goals, targets, and timetables for fuel savings from efficient operations.

Recommendation 9-8. The DOE and DOT should study the potential fuel savings from efficient operations in more detail, including a review of cost-effectiveness and ease of implementation. Once this information is available, goals, targets, and timetables for fuel savings from efficient operations should be established. Programs should then be developed and implemented to realize the available fuel savings.

ATRI (American Transportation Research Institute). 2008. Energy and Emissions Impact of Operating Higher Productivity Vehicles. Revised Edition. American Transportation Research Institute.

CSC (Canada Safety Council). 2003. Literature Review of the Safety of Long Combination Vehicles and Their Operation in Canada. Available at http://archive.safety-council.org/info/traffic/LCVs.pdf. Accessed May 18, 2011.

Die Zeit. 2010. Die Giga-Brummis. Die Zeit Newspaper (Germany), No. 43, October 21, 2010, pp. 39-40.

DOE-DOT (Department of Energy and Department of Transportation). 2011. Reducing Fuel Consumption in U.S. Trucking—A DOE-DOT Joint Study and White Paper. 21st Century Truck Partnership Efficient Operations White Paper. Draft. February 15. Washington, D.C.

FHWA (Federal Highway Administration). 2010. Federal Size Regulations for Commercial Motor Vehicles. FHWA-MC-96-03.

FMCSA (Federal Motor Carrier Safety Administration). 2005. Motor Carrier Safety Progress Report. Available at http://www.fmcsa.dot.gov/facts-research/research-technology/tech/tired-pressure-sensors.htm. Accessed September 23, 2011.

McCormick, C. 2009. Proof Positive. Motortruck. September-October.

NETL (National Energy Technology Laboratory). 2007. Test, Evaluation, and Demonstration of Practical Devices/Systems to Reduce Aerodynamic Drag of Tractor/Semitrailer Combination Unit Trucks. Prepared for NETL by the Truck Manufacturers Association, Contract DE-FC26-04NT42117. April. Washington, D.C.

NRC (National Research Council). 2010. Technologies and Approaches to Reducing the Fuel Consumption of Medium- and Heavy-Duty Vehicles. Washington, D.C.: The National Academies Press.

OECD (Organization for Economic Cooperation and Development). 2011. Moving Freight with Better Trucks: Improving Safety, Productivity and Sustainability (Summary). Paris: International Transport Forum. Available at http://www.internationaltransportforum.org/jtrc/infrastructure/heavyveh/TrucksSum.pdf.

Regehr, J., J. Montufar, and G. Rempel. 2009. Safety Performance of Longer Combination Vehicles Relative to Other Articulated Trucks. Canadian Journal of Civil Engineering 36:40-49. Available at http://www.nrcresearchpress.com/doi/abs/10.1139/L08-109.

TRB (Transportation Research Board). 2002. Regulation of Weights, Lengths and Widths of Commercial Motor Vehicles. Special Report 267. Washington, D.C.

Walmart. 2010. Walmart 2010 Sustainability Report. Available at http://walmartstores.com/sites/sustainabilityreport/2010/environment_waste.aspx. Accessed April 10, 2011.