Medium- and Heavy-Duty Hybrid Vehicles

The 21st Century Truck Partnership (21CTP) focuses on “research and development of advanced heavy-duty hybrid propulsion systems that will reduce energy consumption and pollutant emissions” (DOE, 2011). A heavy-duty hybrid vehicle has an internal combustion engine, an energy storage system, and a means for absorbing or delivering torque from the drivetrain. Hybrid vehicles provide improvements in fuel consumption by several means, including the conversion of kinetic energy into a storable form of energy for later use, the downsizing of the internal combustion engine, engine shutoff, and accessory electrification. A mild hybrid provides idle-stop functionality and regenerative braking. Idle stop-start functionality is made possible by having the electric motor quickly restart the engine. A full hybrid design provides traction capability and higher rates of brake energy regeneration as well as idle-stop functionality.

The two major types of heavy-duty hybrid vehicles discussed in this chapter are hybrid electric vehicles (HEVs), which are the primary focus of the Department of Energy (DOE) in the 21CTP, and hydraulic hybrid vehicles, which are the focus of the Environmental Protection Agency (EPA). In addition to HEVs, similar technologies are being applied to plug-in hybrid electric vehicles (PHEVs) and battery electric vehicles (EVs). Hybrid electric vehicles are considered “a key technology that will help the 21CTP achieve its goals” by enabling manufacturers to achieve reduced fuel consumption and emissions (DOE, 2011). The various electric hybrid architectures have been well described elsewhere (NRC, 2010, 2011). Heavy-duty hybrid electric vehicles provide additional benefits from their unique capability to “creep” in queues and idle without operating the main engine. For Class 8 long-haul trucks, heavy-duty hybrid systems can recharge large-capacity batteries during daytime operation to provide for hotel loads (powering support services for the driver in the truck tractor), eliminating overnight idling of the main engine.

The 21CTP partners work together on technical and commercial programs related to the reduction of fuel consumption by heavy-duty hybrid trucks and the commercialization of these more-fuel-efficient vehicles. In addition to the DOE, the U.S. Department of Defense (DOD), the U.S. Department of Transportation (DOT), EPA, and several original equipment manufacturers (OEMs) and key suppliers, the 21CTP has strategic alliances with the Engine Manufacturers Association (EMA), the Truck Manufacturers Association (TMA), and the Hybrid Truck Users Forum (HTUF). The national laboratories assist the 21CTP in conducting research and development (R&D) involving hybrid technologies. Missing from these partnership alliances are companies in the electric machines, energy storage, and semiconductor-device industries. Such relationships should be fostered through 21CTP R&D programs with industry.

During the 2007-2010 period, the 21CTP project priorities in the area of medium- and heavy-duty hybrid vehicles have been the following:

• Simulation and modeling,

• Subsystem R&D, and

• Vehicle demonstrations.

Progress in addressing each of these priorities is discussed later in this chapter. Programs in these priority areas have been pursued by the DOE through the Argonne National Laboratory (ANL), the National Renewable Energy Laboratory (NREL), and DOE’s Office of Vehicle Technologies; by the DOD through the U.S. Army’s Tank-Automotive Research, Development and Engineering Center (TARDEC); by the DOT through its Federal Transit Agency’s National Fuel Cell Bus Program; and by the EPA through its National Vehicle and Fuel Emissions Laboratory.

Differences Between Heavy-Duty and Light-Duty Hybrids

Requirements for heavy-duty hybrid vehicles are significantly different from those of light-duty (LD) hybrid vehicles, and they necessitate unique solutions. In this chapter, the term heavy-duty vehicles refers to both medium heavy-duty trucks and heavy-duty trucks, as defined in Figure 1-3 in Chapter 1 of this report. Many technologies that apply to light-duty vehicles do not apply to heavy-duty vehicles. The heavy-duty truck and light-duty vehicle hybrid technologies leverage each other only at the most basic level. Consequently, the 21CTP hybrid program is needed to address the unique technology needs of heavy-duty vehicles.

Unlike LD hybrid vehicles, the broad class of vehicles comprising the heavy-duty fleet is very diverse and includes tractor-trailer, refuse, dump and utility trucks, package delivery vehicles, buses, and large pickups. These vehicles have highly differentiated mission profiles, which make it difficult to establish architectures or performance metrics that are commonly applicable to this broad range of heavy-duty vehicles. Key differences between heavy-duty trucks and light-duty vehicles (LDVs) include the following:

• Volume: Annual sales volume for heavy-duty trucks is about 5 percent of that for LDVs, and the former can be bought in a thousand times more configurations than the latter.

• Buying criteria: Heavy-duty truck buyers prioritize reliability and cost of ownership, whereas LDV buyers prioritize a variety of attributes including cost, functionality, reliability, performance, and styling.

• Weight: A heavy-duty truck can weigh up to a hundred times more than an LDV and has peak horsepower up to twice that of LDVs.

• Life expectancy and driving cycles: Heavy-duty vehicles have longer life expectancy and more demanding duty cycles than those for LDVs. Heavy-duty vehicles have expected lifetime mileages nearly 10 times greater than those of LDVs.

Driven by these vehicle differences, factors differentiating hybrid systems for heavy-duty vehicles and those for LDVs are power rating, energy storage capacity, number of relevant driving cycles, and economics. Unlike cars and light trucks, which are available in only a relatively restricted range of sizes and weights and whose missions have been characterized by a few standardized driving cycles, heavy-duty trucks span a size range from 8,500 lb (Class 2b) to greater than 33,000 lb (Class 8), with gross vehicle weights (GVWs) of up to 200,000 lb (DOE, 2011). As a result, heavy-duty hybrid vehicles require high energy storage density, much like an EV, as well as high power density for acceleration and deceleration, like light-duty hybrids.

Functional differences between hybrid systems for heavy-duty trucks and those for LDVs result in substantial economic differences. Light-duty vehicles are fundamentally similar. Their weight range is relatively limited (up to Class 2a, under 8,500 lbs GVW), and their driving schedules are characterized by a small number of driving cycles. They are manufactured in high volumes, and their expected lifetime mileage is up to 150,000 miles. Hybrid systems for these vehicles can be manufactured in volumes large enough to benefit from the economies of scale.

Heavy-duty trucks by contrast vary widely in both tare (empty) and gross weights. Their missions vary from daily runs with frequent stops (e.g., the work of a delivery van) to 24-hour-a-day, multiple-day long hauls of tractor-trailers up to 200,000 lb GVW. The total fleet of heavy-duty vehicles is 10.99 million, and the average life of a vehicle is up to 1 million miles, resulting in a small market with low turnover and a challenge to making an economic argument for hybrid systems generally applicable to the heavy-duty fleet. A conventional hybrid design applied to vehicles whose missions incorporate a lot of stop-and-go driving, such as delivery vans, urban transit buses, or refuse trucks, has the potential to be economically sound (i.e., to result in a favorable payback period) by providing substantial fuel economy benefits of 20 to 40 percent (17 to 29 percent reduction in fuel consumption) (Greszler, 2009).1 A further benefit of hybridization in these vehicles is the reduced brake wear and maintenance resulting from regenerative braking.

In contrast to medium-duty delivery vans, urban transit buses, and refuse trucks, a heavy-duty, Class 8 long-haul truck makes few stops, maintains a relatively constant speed, and requires high power for long periods of grade climbing. According to the 21CTP, there are three primary reasons to consider hybridizing a Class 8 long-haul powertrain (Greszler, 2009):

1. Reduced engine idle time, through the hybrid energy storage and use of electric auxiliaries;

2. Reduced fuel use, through the electrification of components, thereby improving efficiency; and

3. Reduced fuel usage during cruise, through energy management with traffic-induced speed variation and in rolling terrain.

An additional reason to consider hybridizing a long-haul truck is that, as mentioned above, the large-capacity batteries can be recharged during daytime operation to provide for hotel loads so that overnight idling of the main engine can be eliminated.

Hybrid Technology for the SuperTruck Program

In FY 2010, the DOE announced the establishment of the SuperTruck program, with an overall goal to develop and demonstrate a 50 percent improvement in freight efficiency

_____________________

1 Answers provided by Ken Howden, DOE Office of Vehicle Technologies, to committee questions 9(a) and 42.

expressed in ton-miles per gallon (33 percent reduction in the proposed fuel consumption standard expressed in gallons per 1,000 ton-miles) for Class 8 long-haul trucks (see Chapter 8). The three project teams selected for the SuperTruck program are Cummins-Peterbilt, Daimler Trucks North America, and Navistar, Inc. Two of the teams, Daimler and Navistar, are using hybrid technology, with Navistar specifying a dual-mode (series/parallel) electric hybrid. The Cummins-Peterbilt team is using waste heat recovery (WHR) and a solid oxide fuel cell auxiliary power unit (APU) for idle reduction. All three teams are planning to use some electrically driven accessories as part of their hybridization and idle-reduction systems.

Impact of Duty Cycle

Fuel consumption improvements in a heavy-duty hybrid vehicle are highly dependent on the duty cycle, because the duty cycle determines the amount of kinetic energy available to be recovered, the time available for engine shutoff at idle, and the benefit of the electrification of accessories operating on demand and at constant speed versus operating full time at speeds proportional to engine speeds. There are no industry standards yet for heavy-duty hybrid vehicle testing. The duty cycle used to measure fuel consumption is typically determined by the way that a certain type of vehicle is used in the targeted application and the creation or selection of an appropriate cycle based on measured data taken to characterize the vehicle usage.

The Argonne National Laboratory has conducted modeling studies of the effect of duty cycle on a Class 8 long-haul truck with a mild hybrid (50 kW motor and 5 kWh battery) and a full hybrid (200 kW motor, a 50 kW starter/generator, and a 25 kWh battery) (NRC, 2010). Both were pre-transmission hybrids, that is, hybrids in which the electric drive motor is located between the clutch and the transmission, allowing torque multiplication through the transmission and electric-mode-only operation during low power demand. Five drive cycles were evaluated; they included three highway cycles: HHDDT 65 (Heavy Heavy-Duty Diesel Truck), HHDDT Cruise, and HHDDT High Speed; and two transient/urban cycles: HHDDT Transient and UDDS (Urban Dynamic Driving Schedule) Truck (NRC, 2010). Key observations from this ANL analysis as described in the National Research Council (NRC) report were as follows:

• On the highway cycles, fuel savings were less than 10 percent for the full hybrid and less than 5 percent for the mild hybrid.

• Neither hybrid system had enough electrical storage to contribute to cruise power demand for any significant length of time.

• Fuel savings on the transient/urban cycles were greater, although the mild hybrid showed significantly lower savings than the full hybrid, peaking at 14 percent, while the full hybrid showed savings over 40 percent.

Other simulation studies of the fuel consumption benefit from a variety of hybrid truck configurations have been conducted and reported (NRC, 2010). The qualification for these studies is relevant and is repeated here. “While indicative of the range of potential benefits, it should be noted that simulations are carried out under ideal conditions—hence results typically represent best-case scenarios. Real-world savings in fuel consumption are likely to be lower, because of off-design duty cycles and practical production vehicle constraints” (NRC, 2010, p. 83).

Limited test results for different duty cycles are available for medium- and heavy-duty hybrid vehicles. Regarding one set of results, the EPA conducted tests on a series hydraulic hybrid delivery truck over a number of different test duty cycles. The results indicated that the fuel economy improvements ranged from negligible for the Highway Fuel Economy Test (HWFET) to more than 100 percent improvement (50 percent reduction in fuel consumption) on the Manhattan Bus Cycle.2

Commercialization

Hybrid truck technology is currently available in demonstration vehicles as well as commercial vehicles. heavy-duty hybrid electric trucks are commercially available from several manufacturers, including Freightliner/Daimler Trucks, International/Navistar, Kenworth, Peterbilt, Ford, and GMC. Details of the specific models of commercially available heavy-duty hybrid trucks are listed in Appendix E of this report. Commercially available battery electric trucks are also listed in Appendix E. Heavy-duty hydraulic hybrid trucks are becoming commercially available, with the hydraulic hybrid systems primarily supplied by Eaton, Parker Hannifin, and Bosch-Rexroth. A summary of the status as of 2009 of the wide variety of hybrid system architectures currently available in the market is provided in Table 4-1.

Hybrid Truck Users Forum (HTUF)

The HTUF, which was briefly described in the NRC Phase 1 report (NRC, 2008), is a North American, user-driven program to speed the commercialization of heavy-duty hybrid and high-efficiency technologies. It is operated by CALSTART, a member-supported organization with headquarters in California and dedicated to supporting a growing clean transportation industry, in partnership with the U.S. Army’s National Automotive Center (NAC), with project support from the Hewlett Foundation, which makes grants to solve social and environmental problems, and the DOE. The HTUF focuses on developing the commercial hybrid industry

_____________________

2 John Kargul, EPA, “Clean Automotive Technology, Cost Effective Solutions for a Petroleum and Carbon Constrained World,” presentation to a subgroup of the committee, October 26, 2010, Ann Arbor, Michigan.

TABLE 4-1 Hybrid Vehicle Architectures, Their Status as of 2009, and Primary Applications

| Architecture | Technology Status | Primary Applications |

| Medium-duty/heavy-duty parallel HEV | Available now: Eaton, Azure, Volvo | Refuse, urban pickup, and delivery (P&D) |

| Medium-duty/heavy-duty parallel HEV w/e PTO | Available now: Eaton, Volvo | Bucket truck |

| Parallel gasoline or diesel HEV bus | Available now: ISE, Enova, BAE | Transit bus |

| Two-mode diesel HEV bus | Allison | Transit bus |

| Series gasoline or diesel HEV bus | Available now: ISE | Transit bus |

| Parallel hydraulic hybrid | Introduced in 2009: Eaton, Parker Hannifin, Crane Carrier | Refuse, urban P&D |

| Series hydraulic hybrid | Demo vehicles | Refuse, urban P&D |

| Parallel Class 2b | Demo vehicles | Class 2b pickups and vans |

| Two-mode Class 2b | Demo vehicles | Class 2b pickups and vans |

| Line-haul dual-mode HEV | Demo vehicles | Line-haul tractor trailer. |

| Line-haul parallel HEV | Demo vehicles | Line-haul tractor trailer, motor coach |

NOTE: Acronyms are provied in Appendix I. See Appendix E, Table E-1 , for a list of medium- and heavy-duty vehicle models.

SOURCE: TIAX (2009).

through increasing user-driven volumes in key platforms to provide the benefits of reduced fuel use and lowered emissions. HTUF efforts have accelerated the market “pull” that assisted in helping to launch the first production of hybrid trucks.

Ten years ago, the U.S. Army and collaborative partner CALSTART launched an initiative to promote hybrid and high-efficiency dual-use technologies for the commercial trucking industry and military platforms. The HTUF held its first annual conference at that time. In September 2010, the 10th annual HTUF conference was held in Dearborn, Michigan, with 700 attendees. It was the largest national conference in the program’s history, signaling the expanding interest in hybrid trucks and their growing market. During a panel discussion at this conference, efforts to secure purchase incentives (through an expansion and extension of the hybrid truck tax credit) and R&D funding (through H.R. 3246, the Advanced Vehicle Technology Act) were discussed, but both of these efforts have stalled.

The prime role of the HTUF with its military partners was to help create the commercial industrial capability to support military hybrid advanced technology and vehicle needs. To date, commercial hybrid use has surpassed that in pure military applications. When HTUF user specifications were developed, they included functionality (stealth mode/silent watch, power generation) of importance to the military. Therefore, most commercial systems can be easily adapted to military needs. Military hybrid truck adoption has been slowed owing to the prolonged and deployed status of the military since September 11, 2001. The military has been in a replace-and-repair mode with its vehicles since that time. The Army has had to delay or halt new vehicle development efforts that included hybrid vehicles. The HTUF is focusing its near-term efforts on the following areas for the military: (1) increasing deployments of commercial hybrids on military bases, (2) identifying and demonstrating hybrid and advanced systems in off-road commercial construction equipment of use to the military, and (3) assisting with identifying and testing commercial-based systems in tactical vehicle applications.

The only heavy-duty hybrid truck funding available since 2007 has been used to conduct in-use and laboratory evaluations on hybrid vehicles, mostly delivery trucks and transit bus applications. None of this funding was for hybrid R&D. Since 2007, the $1 million to $1.5 million per year for heavy-duty R&D has been focused on aerodynamics, thermal management, and friction and wear reduction. Although there were no congressional requests for FY 2007 through FY 2010 that specifically targeted 21CTP heavy-duty hybrids, the work cited above was completed under the DOE’s Office of Vehicle Technologies, which has included both light-duty and heavy-duty advanced vehicle testing and R&D activities, with some of these being hybrid-specific. Project funding since 2007 is shown in Table 4-2.

The various electric hybrid architectures have been well described elsewhere (NRC, 2010, 2011). The three major components of a hybrid system are the electric machines (motor/generator), the electronic controller, and the electric energy storage system (typically a battery or battery/ultracapacitor combination). In addition, the hybrid powertain system includes an internal combustion engine, a transmission system linking the motor and engine, and electromechanical controls that determine the electrical and mechanical power directions and their paths. The electrical machine(s),

TABLE 4-2 Heavy-Duty Hybrid Funding for FY2007-FY2010

| FY 2007 | FY 2008 | FY 2009 | FY 2010 | |

| HD Simulation and Technology Focused HEV R&D | $200,000 | $250,000 | $200,000 | $350,000 |

| HD HEV Fleet Demonstrations | $400,000 | $450,000 | $300,000 | $1,500,000 |

| Subsystem R&D | $0 | $0 | $0 | $0 |

NOTE: Acronyms are defined in Appendix I.

SOURCE: Lee Slezak and Kevin Walkowicz, NREL, “Hybrid Team Progress on Past Goals,” presentation to the committee, November 15, 2010, Washington, D.C.

its coupling to the driveline, and the necessary power and control electronics are generally referred to as the drive unit. Of all the components, the energy storage system presents the greatest economic challenge for the truck application. Trucks in stop-and-go driving and with long lives will require long-life energy storage systems, as identified in the goal for energy storage systems discussed in the next section.

Goals and Status

The overall goal of the 21CTP for the heavy-duty hybrid system is to develop and demonstrate system technologies that deliver substantial reductions in fuel consumption for both urban start-stop use and for higher mileage applications. The top-priority hybrid electric vehicle R&D areas requiring support are the following:

1. Drive-unit optimization,

2. Drive-unit cost,

3. Energy storage system reliability,

4. Energy storage system cost, and

5. The ability to attain fuel-consumption improvements.

Three hybrid technology goals for 2012 were established in 2006 by the 21CTP.3 The progress toward achieving each of these goals is discussed below. The revised, stretch goals for heavy-duty hybrids issued by the 21CTP in 2011 are summarized in the section below titled “Revised Goals Issued in 2011.”

21CTP Goal 1: Develop a new generation of drive unit systems that have higher specific power, lower cost, and durability matching the service life of the vehicle. Develop a drive unit that has 15 years of design life and costs no more than $50/kW by 2012.

The drive unit consists of the motor, controller, and packaging. No R&D work for drive-unit systems technology for heavy-duty hybrid vehicles was funded by the DOE for FY 2007 through FY 2010. The NRC Phase 1 report (NRC, 2008) stated that “very little evidence was presented to the committee to substantiate any significant progress made by 21CTP-funded researchers toward achieving the desired reliability target of 15 years design life for the hybrid propulsion equipment. In fairness, the number of prototype heavy-duty hybrid trucks currently in the field is very low, making it particularly difficult to gather any meaningful reliability data.”

The DOE did not discuss the status of costs of the drive-unit system with the present committee. The NRC Phase 1 Report (NRC, 2008) stated that “meeting the aggressive cost target of $50/kW is proving to be one of the most difficult challenges for the developers of heavy hybrid propulsion systems.”

The Advanced Power Electronics and Electric Motors (APEEM) program is one of the DOE’s Office of Vehicle Technologies’ two basic building blocks for electric propulsion drive vehicles; it includes power electronics, electric motors, thermal management, and packaging. The Office of Vehicle Technologies addresses the needs of both light- and heavy-duty vehicles. A principal objective of the APEEM R&D program is to reduce component and subsystem costs so that a customer can recover the additional cost for advanced electric vehicles in 3 years through fuel savings (DOE, 2010). In addition to cost, APEEM research focuses on components that are significantly smaller, lighter, and more reliable than those of existing systems. The American Recovery and Reinvestment Act of 2009 (ARRA) awarded $500 million in grants to U.S.-based manufacturers to accelerate the development of the U.S. manufacturing capacity for electric drive components. These R&D programs are described in the DOE’s “Multi-Year Program Plan 20112015” (DOE, 2010, pp. 2.1-20 to 2.1-25). The specific applicability of these projects to heavy-duty vehicles was not provided to the committee.

21 CTP Goal 2: Develop an energy storage system with 15 years of design life that prioritizes high power rather than high energy, and costs no more than $25/kW peak electric power rating by 2012.

The energy storage system consists of the battery, its thermal control system, and packaging. No R&D work for energy storage technology for heavy-duty hybrid vehicles was funded by the DOE for FY 2007 through FY 2010. The NRC Phase 1 report (NRC, 2008) provided the status of energy storage systems for the light-duty FreedomCAR program. As noted earlier, heavy-duty hybrids are significantly different from light-duty hybrids. The DOE indicated to the committee that the state-of-the-art energy storage systems are typically rated for 8 years of useful life.4 The DOE did

_____________________

3 Lee Slezak and Kevin Walkowicz, NREL, “Hybrid Team Progress on Past Goals,” presentation to the committee, November 15, 2010, Washington, D.C.

4 Answers provided by Ken Howden, DOE Office of Vehicle Technolo-

not discuss the status of costs of heavy-duty hybrid energy storage systems with the committee.

The DOE’s 2010 cost goal for light-duty hybrid energy storage systems is $750 to $900/kWh (nameplate capacity).5 However, the committee was informed by one manufacturer that the current cost for heavy-duty hybrid energy storage systems was approximately $2,000/kWh (nameplate capacity). Drivers of the increased cost relative to light-duty energy storage systems are the operating environment (e.g., vibration) in the truck and lower production volumes over which tooling, design, and validation costs can be amortized.

Electrical energy storage has improved in the past decade, but further gains are required for truck applications. The more promising technologies are the nickel metal-hydride battery, lithium technology batteries, and ultracapacitors. The EV requires a high-energy electrical storage capacity for a long driving range. Heavy-duty hybrid vehicles require high energy storage density, much like an EV, as well as high power density for acceleration and deceleration, like light-duty hybrids. In recent years batteries have been the major focus for electrical energy storage for LDVs, and results provide an opportunity for cross-application to medium-duty and heavy-duty hybrid development. Several companies (A123 Systems, Hitachi, and Valence Technologies, Inc.) are producing batteries for transit operations. Since 2007 the DOE has funded seven heavy-duty hybrid projects. These have all been vehicles with a high level of stop-and-go behavior in their mission profiles—for example, delivery vehicles and school and transit buses. Observed fuel economy improvements for hybrid electric vehicles ranged from 0 to 30 percent (0 to 23 percent reduction in fuel consumption), whereas a plug-in hybrid electric school bus exhibited an improvement up to 57 percent (36 percent reduction in fuel consumption), but results were inconsistent because of incomplete battery-charging data.6

Opportunity exists for further fuel consumption reductions and cost reductions with the development and application of components designed specifically for the heavy-duty hybrid vehicles. For example, a greater fraction of braking energy could be regenerated if the power electronic and energy storage systems were more efficient and able to transfer energy at higher powers. Other areas for improvement are implementing the system-wide electrification of accessories and increasing the temperature range of operation for lithium batteries. The key challenges identified by the DOE for the heavy-duty hybrid energy storage system are as follows:

• Both procurement costs and life-cycle costs,

• Weight and space claim,

• Life expectancy (in a heavy-duty drive cycle),

• Energy and power capacity for a heavy-duty hybrid application,

• Suitability for the heavy-duty vehicle environment and cooling techniques,

• Architecture and modularity,

• Safety and failure modes,

• Maintainability,

• Management and equalization electronics and algorithms, and

• Supplier base for the storage elements.

On March 19, 2009, the DOE launched a $2 billion competitive grant program under the ARRA to promote the manufacturing of the batteries and parts for electric vehicles. The objective of these grants is to establish a complete “value chain” for lithium battery manufacturing, from material supply, to cell production, to pack assembly. Twelve domestic manufacturers are developing battery materials, production and recycling capabilities, as shown in Table 4-3. DOE funding for each of the manufacturers is listed in the table. Nine domestic U.S. battery manufacturing facilities for cell production and for pack assembly, together with total investment in these facilities, are shown in Table 4-4. The committee was not provided with information on the applicability of the manufacturing facilities shown in Tables 4-3 and 4-4 to light-duty versus heavy-duty vehicles.7 However, the committee believes that these facilities would be capable of supplying batteries for medium- and heavy-duty trucks, although their shock and vibration requirements are more severe than for LDVs.

As with the APEEM program mentioned above, battery energy storage is one of the DOE’s Office of Vehicle Technologies’ two basic building blocks for electric propulsion drive vehicles; it includes a wide range of battery technology R&D under the U.S. Advanced Battery Consortium (USABC) that addresses the needs of both light- and heavy-duty vehicles. The battery R&D is engaged in topics ranging from fundamental materials research through battery development and testing and includes the following:8

• Seventy laboratory and university projects to address the cost, life, and safety of lithium-ion batteries and to develop next-generation materials; and

_____________________

gies, to committee question 42.

5 Patrick B. Davis, DOE, “U.S. Department of Energy Vehicle Technologies Program Overview,” presentation to the committee, September 8, 2010, Washington, D.C. Note that these cost goals for electric energy storage are different from the peak power cost goal in Goal 2 of $25/kW.

6 Answers provided by Ken Howden, DOE Office of Vehicle Technologies, to the committee’s written questions to 21CTP representatives, Question 9a.

7 James Miller, DOE, “Status/Prospects for Energy Storage Technology for Medium-Duty and Heavy-Duty Hybrids,” presentation to the committee, January 31, 2011, Washington, D.C.

8 James Miller, DOE, “Status/Prospects for Energy Storage Technology for Medium-Duty and Heavy-Duty Hybrids,” presentation to the committee, January 31, 2011, Washington, D.C.

| Company | Location | Funding | Material | Description |

| Elyria, OH | $50 M | Cathode | Production of nickel-cobalt-metal cathode material for Li-ion batteries | |

| Midland, MI | $70 M | Cathode | Production of nickel-cobalt-metal cathode material for Li-ion batteries | |

| Sanborn, NY | $23 M | Anode | Production of carbon powder anode material for Li-ion batteries | |

| Batesville, AR | $25 M | Anode | Production of high-temp anode material for Li-ion batteries | |

| Zachary, LA | $41 M | Electrolyte | Production of electrolytes for Li-ion batteries | |

| Buffalo, NY & Metropolis, IL | $55 M | Electrolyte | Production of electrolyte salt for Li-ion batteries | |

| Charlotte, NC | $101 M | Separator | Production of polymer separator material for lithium-ion batteries | |

| Silverpeak, NV & Kings Mtn., NC | $60 M | Lithium | Production of battery-grade lithium carbonate and lithium hydroxide | |

| Albany, OR | $28 M | Carbon | Production of high-energy density nano-carbon for ultracapacitors | |

| Holland, MI | $10 M | Cell Casing | Manufacturing of precision aluminum casings for cylindrical cells | |

| Lancaster, OH | $19 M | Recycling | Hydrothermal recycling of Li-ion batteries | |

| Lebanon, OR | JCI Partner | Separator | Production of battery separators for HEVs and EVs |

SOURCE: James Miller, DOE, “Status/Prospects for Energy Storage Technology for Medium-Duty and Heavy-Duty Hybrids,” presentation to the committee, January 31, 2011, Washington, D.C.

• Thirty-five industry contracts to design, build, and test battery prototype hardware, to optimize materials and processing specifications, and to reduce cost.

Notable accomplishments made by the USABC battery development partners for light-duty vehicles include the following:

• Johnson Controls-SAFT (JCS) is supplying lithiumion batteries to BMW and Mercedes for hybrids;

• A123 Systems is supplying batteries to Ford EVs and hybrid buses; and

• Compact Power/LG Chem is supplying lithium-ion cells to GM for the Chevrolet Volt.

Progress in heavy-duty batteries is expected to benefit from the development of light-duty vehicle batteries.

Finding 4-1. Although 2012 has been established as the deadline for 21CTP Goals 1 and 2 for hybrid vehicle technology, it is unlikely that these will be met, because there has been no funding for either goal. However, with regard to Goal 2, the DOE’s Office of Vehicle Technologies’ battery R&D program is supporting a large number of programs addressing issues ranging from fundamental materials research through battery development and testing. Significant progress has been made in developing domestic manufacturing facilities for battery materials production and recycling, cell production, and pack assembly. Although the applicability of these programs to heavy-duty applications was not provided to the committee, the committee believes that these developments are supportive of the needs of medium- and heavy-duty hybrid applications.

21CTP Goal 3: Develop and demonstrate a heavy hybrid propulsion technology that achieves a 60% improvement in fuel economy (38% reduction in fuel consumption), on a representative urban driving cycle, while meeting regulated emissions levels for 2007 and thereafter.

No R&D work to reduce the fuel consumption of heavy-duty hybrid vehicles was funded by the DOE for FY 2007 through FY 2010. However, fleet testing sponsored by the DOE has shown that, for “urban-based, start and stop driving cycles” (e.g., FedEx route, transit bus, etc.), demonstrations in the 20 to 40 percent range (17 to 29 percent reduction in fuel consumption) have been achieved, based on measured

| Company | Location | Total Investment | Cell Manu. | Pack Assembly | Description |

| Holland, MI Lebanon, OR | $600 M | Li-Ion: Nickel Metal Cobalt | |||

| Romulus & Brownstown, MI | $500 M | Li-Ion: Iron Phosphate | |||

| St. Clair & Holland, MI | $302 M | Li-Ion: Mixed Manganese | |||

| Brownstown, MI | $236 M | Battery Pack Assembly | |||

| Jacksonville, FL | $191 M | Li-Ion: Nickel Metal Cobalt | |||

| Midland, MI | $320 M | Li-Ion: Manganese Spinel | |||

| Indianapolis, IN | $236 M | Li-Ion: Nickel Metal Cobalt | |||

| Lyon Station, PA | $98 M | Advanced VRLA and the Ultra Batteries | |||

| Bristol, TN & | $70 M | Spiral Wound AGM and Flat Plate | |||

| Columbus, GA | Batteries |

SOURCE: James Miller, DOE, “Status/Prospects for Energy Storage Technology for Medium-Duty and Heavy-Duty Hybrids,” presentation to the committee, January 31, 2011, Washington, D.C.

fuel usage in the field and testing in the laboratory.9 These data are typically determined by measuring how the particular type of vehicle is used in the specific application, and creating or selecting an existing heavy-duty cycle based on the measured data characterizing the vehicle usage. There are no industry standards yet for heavy-duty hybrid vehicle testing. The demonstrated fuel economy improvement of 20 to 40 percent is somewhat reduced from the finding of 35 to 47 percent improvement (26 to 32 percent reduction in fuel consumption) from the NRC Phase 1 report (NRC, 2008), perhaps because of the additional data that were obtained in the intervening time.

DOE vehicle simulation tools have been used to evaluate the fuel consumption benefits of advanced technologies to meet the goal of 60 percent improvement in fuel economy (38 percent reduction in fuel consumption). Specific advanced technologies and their capabilities of reducing fuel consumption were not discussed by the DOE, although the DOE’s modeling and simulation of heavy-duty hybrid vehicles, discussed in the next section, is focused on identifying technologies for improving the fuel consumption of heavy-duty hybrid vehicles.

Finding 4-2. The DOE did not receive any funding for heavy-duty hybrid R&D in FY 2007 through FY 2010. Consequently, no progress was reported toward the 21CTP’s three heavy-duty hybrid goals, primarily focused on R&D, for achieving 15 years of design life, achieving cost goals for drive-unit systems and energy storage systems, and achieving a 60 percent improvement in fuel economy (38 percent reduction in fuel consumption). During this period, the DOE made progress in developing heavy-duty hybrid simulations and models and conducting fleet testing and evaluations of heavy-duty hybrid vehicles.

Recommendation 4-1. The DOE should provide an up-to-date status with respect to the heavy-duty hybrid goals. The DOE should partition the available hybrid funds between heavy-duty and light-duty hybrid R&D technology to promote the R&D required for the development of heavy-duty hybrid technologies, because heavy-duty hybrid requirements are significantly different from light-duty requirements.

Simulation and Modeling

Modeling and simulation work was begun in 2007 at the Argonne National Laboratory and is currently ongoing using the ANL’s simulation tool, Autonomie, to support original

_____________________

9 Answers provided by Ken Howden, DOE Office of Vehicle Technologies, to committee’s written questions to 21CTP representatives, Question 42.

equipment manufacturer (OEM) hybrid activities as well as those of government agencies (EPA). State-of-the-art component data characterizing heavy-duty vehicle components (engine, transmission, and vehicle aerodynamics) and specific control strategies have been implemented in Autonomie. Several applications were validated using test data provided by the EPA. The close collaborations with OEMs allow the national laboratories and industry users to accelerate the development of heavy-duty hybrid vehicles.

Modeling and simulation work began in 2008 at the National Renewable Energy Laboratory and continues today with simulation and modeling techniques being used to analyze how medium-duty hybrid vehicles are used in a broad array of fleet applications. Measured fuel consumption results were used to validate fuel consumption values derived from dynamic models of the vehicles. A matrix of 120 component sizes, usages, and cost combinations were analyzed to minimize fuel consumption and vehicle cost. The results illustrated the dependency of component sizing on the drive cycle and daily distance driven.

Vehicle Development and Demonstrations

Hybrid electric drive systems are being tested in heavy-duty vehicles through the NREL’s fleet testing and evaluation team. The results provide unbiased, third-party assessment of real-world operation and are used to focus future efforts to improve performance and cost-competitiveness. heavy-duty hybrid testing and evaluation project results since 2007 include the following:

• GM Allison’s HEV transit bus in Seattle, Washington (2007)—Improved on-road fuel economy by 27 percent (21 percent reduction in fuel consumption) during a 12-month period.

• ISE’s series gasoline HEV transit bus in Long Beach, California (2008)—Improved on-road fuel economy (based on diesel-equivalent energy content per gallon) by 8 percent (7 percent reduction in fuel consumption) over a 24-month period.

• BAE’s HEV system in New York City, New York (2009)—Improved fuel economy by 28 percent (22 percent reduction in fuel consumption) over a 12-month period.

• Eaton Corporation’s HEV system in the UPS van fleet in Phoenix, Arizona (2009)—Improved fuel economy by 29 percent (22 percent reduction in fuel consumption) over a 12-month period.

• Enova’s Plug-In HEV system in IC Corporation’s school bus (2009)—Improved fuel economy up to 57 percent (36 percent reduction in fuel consumption) were observed, but results were inconsistent because of incomplete battery-charging data.

• Azure’s hybrid system in the FedEx Los Angeles delivery fleet (2010)—No statistically significant improvement in fuel economy was observed during a 12-month evaluation, although 21 percent improvement (17 percent reduction in fuel consumption) was measured on a dynamometer test cycle.

• Eaton Corporation’s HEV system in a Class 8 tractor in the Coca Cola Enterprise beverage delivery fleet in Miami, Florida (2010)—Chassis dynamometer testing showed 0 to 30 percent improvement in fuel economy (0 percent on mostly highway cycle, 30 percent on urban cycle; 0 to 23 percent reduction in fuel consumption).

The DOT has been involved in the funding of heavy-duty vehicle hybrids through support of hybrid buses for public transport. These programs include the following:

• National Fuel Cell Bus Program—$49 million over 4 years, starting in FY 2006;

• Transit Investments for Greenhouse Gas and Energy Reduction (TIGGER)—$100 million in ARRA funding in round 1 and $75 million of discretionary funds in round 2; and

• Emission Certification Support for Hybrid Buses—carried out at West Virginia University.

These DOT-supported programs have distinct goals and benefits that complement the work of other agencies.

From 2006 to 2010, the DOD has supported heavy-duty hybrid vehicle programs and has taken leadership in the areas of heavy-duty hybrids for combat vehicles and nontactical trucks. The U.S. Army, acting through TARDEC and its subordinate organization, the National Automotive Center, has sponsored heavy-duty hybrid programs. A current program is the Oshkosh ProPulse diesel electric drive system, which provides electric propulsion power as well as 100 kW of clean exportable alternating current (ac) power. This technology became part of the Heavy Expanded Mobility Tactical Truck (HEMTT) A3 platform from Oshkosh, which is a series-electric hybrid design. Recently, ADA Technologies announced a $70,000 contract from the U.S. Army for Phase I research into the development of advanced electrochemical ultracapacitor systems for use in hybrid electric vehicles for high-power military applications (Global and Refining Fuels Today, 2011).

Progress in Commercializing Hybrid ElectricVehicles

The committee obtained insight into industry’s progress in commercializing heavy-duty hybrid electric vehicles during a visit to the Eaton Corporation on January 14, 2011. Commercialization at Eaton is focused on developing flexible architectures to accommodate many diverse applications for hybrid systems and developing designs that can provide significant cost reductions through modularization and reusability.

Eaton has been developing hybrid power systems for more than a decade, having developed its first prototype in

2000. In 2002, Eaton began working with FedEx to develop a medium-duty hybrid system. Since that time, Eaton has sold more than 3,500 hybrid systems globally. Although Eaton’s largest application for hybrid systems has been for city buses in China, its largest application in the United States has been Class 4 and 5 FedEx delivery vans. Approximately 200 to 300 units have been sold for each class. Eaton’s second largest application for hybrid systems in the United States has been for Class 6 and 7 utility trucks. In these applications, Eaton has acted as the system integrator. One of Eaton’s challenges has been adapting its hybrid systems to many applications with diverse needs and many niche applications. In addition, there is increased emphasis on all-electric driving, especially in European cities and for port applications in the United States (see the following section, “Plug-in Hybrid and Battery Electric Vehicles”).

Eaton is developing two different parallel hybrid systems: (1) an in-line hybrid system with the engine, motor/generator, and transmission arranged in-line, and (2) a power take-off (PTO) input hybrid system for a utility truck, which has the hybrid drive system connected to the PTO of the transmission and located parallel to the driveshaft. To accommodate the proliferation of applications for hybrid systems, Eaton is developing a flexible hybrid system architecture. A base hybrid drive system common to all applications would be interfaced with a flexible architecture extension to provide an energy management system that could be adapted to individual, specialized needs. To facilitate this architecture, Eaton is developing scalable hybrid drive systems that would include scalable motors and batteries for specific applications. Power electronics are being integrated into a module to eliminate cables and simplify packaging in the vehicle (Eaton Corporation, 2009).

Eaton’s pursuit of hybrid vehicle cost reductions is focused on (1) smaller motors operating at higher speeds, (2) integration of the hybrid drive system with the transmission at the PTO, and (3) flexible architectures with standard interfaces. To realize standard interfaces, Eaton indicated that a committee of the Society of Automotive Engineers is needed to help drive a standard for this flexible architecture to accelerate the availability of compatible components.

PLUG-IN HYBRID AND BATTERY ELECTRIC VEHICLES

The 21CTP did not have any goals for plug-in hybrid electric vehicles or battery electric vehicles. However, much of the technology for HEVs, including electric machines and energy storage systems, is expected to be directly applicable, or nearly so, to the PHEVs and EVs.

Plug-in hybrids recharge their energy storage system through the electric grid, typically at night, when electricity prices and demand are low. The NRC reported in 2010 that commercial medium- and heavy-duty plug-in hybrid vehicles are being delivered in the United States to numerous companies (NRC, 2010, p. 74). The DOE, under ARRA Transportation Electrification, is funding the development of four additional PHEV and EV platforms. More than 1,800 commercial vehicles are being funded by the DOE to aid in the development and demonstration of PHEVs and full EVs in fleets around the United States. The objectives of these programs are (1) to accelerate the development of U.S. manufacturing capacity for batteries and electric drive components, to accelerate the deployment of electric drive vehicles, and to help reduce costs and meet the 21CTP goals set forth in 2006. Selected heavy-duty vehicle projects with energy storage being funded by the ARRA include the following:10

• Electric Vehicles:

—Smith Electric Vehicles—An all-electric Class 3 box truck is being developed with a 120 kW liquid-cooled motor and the option of either a 40 kWh, 80 kWh, or 120 kWh lithium battery pack. The battery packs are assembled in Kansas by Smith Electric Vehicles using modules assembled from Valence Technologies, Inc. cells manufactured in China. Smith Electric Vehicles received a $32 million award from the DOE to develop and deploy 100 of these vehicles.

— Navistar—A battery electric Class 2b/Class3 delivery truck is being developed. Navistar received a $39.2 million award to develop and deploy 400 of these vehicles. Battery packs will be supplied by A123 Systems.

• Plug-in Hybrid Electric Vehicles:

—Eaton Corporation and Azure Dynamics—The DOE awarded the South Coast Air Quality Management District $45.4 million, with an additional $45 million that will come from several sources, including $5.5 million from Eaton, to develop and deploy PHEV demonstration trucks and shuttle buses over a 3-year period, starting in August 2009. The 245 utility aerial trucks are based on the Ford F550 chassis equipped with an Eaton PHEV system. The 35 shuttle buses are based on the Ford E450 chassis equipped with an Azure Balance PHEV system. Battery packs will be supplied by Compact Power, Inc. Following the delivery of these vehicles in the summer of 2011, the demonstration period will run for at least 2 years. Additional details of the Eaton program are provided below.

—Ford Motor Company—The DOE awarded Ford $30 million to deploy 150 PHEVs, including 130 Ford Escape PHEVs and 20 E450 Van PHEVs in partnership with 15 utilities. The battery packs will be supplied by Johnson Controls.

Eaton provided the following overview of two heavy-duty PHEV programs that were under way during the committee’s January 2011 visit to Eaton:

_____________________

10 James Miller, DOE, “Status/Prospects for Energy Storage Technology for Medium-Duty and Heavy-Duty Hybrids,” presentation to the committee, January 31, 2011, Washington, D.C.

1. Ford F550 Diesel PHEV Utility Aerial Truck—Eaton has begun its program to develop a Ford F550 diesel PHEV utility aerial truck with a 15-mile EV range. Eaton is the system integrator, and Altec manufactures the utility aerial addition for the trucks and will be the manager of the vehicles. The drive unit has a specification of 65 kW and 620 Newton-meters (Nm). An electric air conditioning (A/C) compressor will be used. The control strategy will provide the following modes: (1) maximization of engine-off for job site operations, (2) range-extended EV mode, and (3) blended EV mode.

2. Class 8 PHEV Day Cab Tractor (for port operations)—This program is being conducted for the Texas Environmental Research Consortium, whose main interest is in reducing oxides of nitrogen (NOx) at shipping ports. The Class 8 tractor has a hybrid powertrain, electrified accessories, and engine stop-start management. The control strategy provides the following modes: (1) EV mode, (2) HEV with engine stop/start management, and (3) conventional HEV/engine-on operation. Preliminary results show 44 to 73 percent reduction in NOx emissions and 13 to 160 percent increase in fuel economy (12 to 62 percent reduction in fuel consumption) over two test routes—the Eaton Port Route with a maximum speed of 35 mph and the City Suburban Heavy Vehicle Route. An electric range of 10.6 miles was achieved at 25 mph and 9.7 miles at 33 mph for the 74,000 lb vehicle test weight. This program was completed in November 2010.

In FY 2009, the Technology Acceleration and Deployment Activity in the DOE Office of Vehicle Technologies provided a $10 million grant to Navistar to fund the development and deployment of the next-generation PHEV school bus. Improvements from Navistar’s first-generation design include electric accessories to enable engine-off operation and improved strategies as well as improved energy storage approaches. This vehicle is expected to have a 30-mile range at 45 mph and will use an 80 kWh battery pack. Navistar is currently finalizing the design and build of two PHEV school bus designs. These vehicles will be evaluated, and one of the designs will be selected for the final build of the vehicles.

Finding 4-3. More than 1,800 commercial vehicles are being funded through the ARRA by the DOE to aid in the development and demonstration of plug-in hybrid electric vehicles and battery electric vehicles in fleets. One of the objectives of this program is to develop U.S. manufacturing capacity for all-electric drive components (energy storage, drive motors, power electronics, etc.). However, in at least one of these projects, the battery cells are being manufactured outside the United States.

Recommendation 4-2. The DOE should determine what is needed for the battery cells and other electric drive components in the ARRA-Transportation Electrification programs aimed at development and manufacturing in the United States, as specified in the objectives of these programs.

Although the 21CTP did not have any goals for heavy-duty hydraulic hybrid vehicles, the EPA has been conducting R&D of heavy-duty hydraulic hybrid vehicles since early in the 21CTP program. The EPA has supported Cooperative Research and Development Agreements (CRADAs) to help speed the commercialization of federally developed technology. Heavy-duty hydraulic hybrid vehicles were mentioned briefly in the NRC Phase 1 report (NRC, 2008). The NRC (2010) report reviewed the EPA’s hydraulic hybrid vehicle program in greater detail, indicating that the EPA had shifted its focus from parallel hydraulic hybrid technology to series hydraulic hybrid technology to realize further improvements in fuel efficiency.

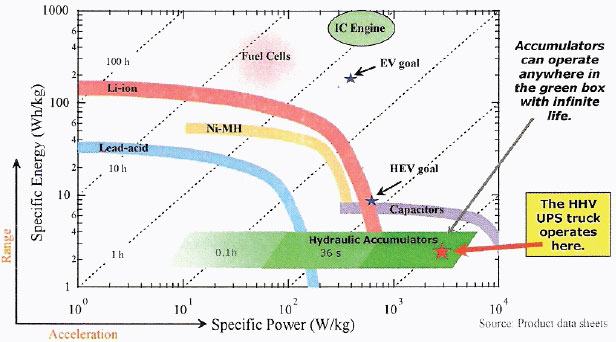

In contrast to an electric hybrid vehicle utilizing batteries for energy storage, a hydraulic hybrid vehicle provides high specific power, but low specific energy, as shown in Figure 4-1. As a result, hydraulic hybrids are effective in providing short-duration launch assist rather than extended-duration power assist for cruise conditions. Delivery trucks and refuse trucks with frequent starts and stops are potential applications for hydraulic hybrids.

Series Versus Parallel Hydraulic Hybrid

The NRC report on medium- and heavy-duty vehicles illustrates the differences between parallel and series hydraulic hybrid systems (NRC, 2010, Figures 4-13 and 4-8, respectively). In a parallel hydraulic hybrid system, the engine and transmission are connected to the differential and drive wheels as in a conventional vehicle. A hydraulic pump-motor unit is geared to the output shaft of the engine and transmission to assist in driving the wheels, or capturing braking energy to recharge the hydraulic accumulator tank. In contrast, in a series hydraulic hybrid system, there is no mechanical connection between the engine/transmission and the differential/drive wheels. A hydraulic pump-motor unit is mounted to the output of the engine, and another pump-motor unit is mounted on the input to the differential for the drive wheels. The respective pump-motor units acting as a pump can charge the hydraulic storage tanks using either engine power or deceleration energy from the wheels. The respective pump-motor units acting as a motor can be used to drive the differential for the drive wheels or to restart the engine. During cruise conditions, the engine-mounted pump-motor unit acting as a pump will provide hydraulic fluid with some buffering by the hydraulic accumulator system to the pump-motor unit acting as a motor mounted

FIGURE 4-1 Relative performance of energy-storage systems. Acronyms are defined in Appendix I. SOURCE: John Kargul, EPA, “Clean Automotive technology, Cost Effective Solutions for a Petroleum and Carbon Constrained World,” presentation to a subgroup of the committee, October 26, 2010, Ann Arbor, Michigan.

on the differential for the drive wheels. In a series hydraulic hybrid, the engine is decoupled from the wheels, enabling it to be operated at best-efficiency conditions. Buffering by the hydraulic hybrid accumulator system eliminates the need for quick engine transients. The EPA’s program began by investigating parallel hydraulic hybrid systems but switched to focus on series hydraulic hybrid systems.

System Components

One of the key components in the series hydraulic hybrid vehicle is the pump-motor unit. In the EPA’s program, a bent-axis pump-motor unit was developed. The bent-axis pump-motor unit is a barrel arrangement pump in which the head of the pump can be pivoted off the centerline of the driveshaft. As the yoke angle increases, the pumping or motoring power increases. A 110 cubic centimeter (cc) pump-motor assembly can provide 300 hp at a pressure of 5,000 pounds per square inch (psi). This pump-motor is small enough to be held in one’s hand.

Two hydraulic storage tanks are required. The high-pressure accumulator tank operates between 2,000 and 7,000 psi and the low-pressure accumulator tank operates between 50 and 200 psi. A Class 6 truck would use at least two 22-gallon carbon-fiber accumulator tanks, which are approximately 5 feet long and 12.5 inches in diameter. Hydraulic accumulator tanks can be either bladder or piston type. In the bladder type, adding hydraulic fluid to the accumulator compresses the nitrogen-filled bladder. In the piston type, adding hydraulic fluid to the accumulator compresses the piston into the nitrogen-filled shell.

Fuel Economy Improvements

The potential fuel economy improvements projected for parallel and series hydraulic hybrid trucks are shown in Table 4-5 (TIAX, 2009). Transient start-stop driving cycles, such as those of refuse trucks and delivery vans, are required to realize these potential improvements.

Eaton Corporation is working to improve the performance of parallel hydraulic hybrids in special applications such as refuse trucks. Eaton’s first-generation hydraulic hybrid, also referred to as a hydraulic launch assist (HLA) system, provided 10 to 30 percent improvement (9 to 23 percent reduction in fuel consumption) in fuel economy. The EPA showed similar results for its early experimental parallel

TABLE 4-5 Fuel Economy Improvements for Parallel and Series Hydraulic Hybrid Trucks

Type of Truck |

Fuel Economy Improvement % (mpg) Fuel Consumption (FC) Reduction (%) |

| Parallel hydraulic hybrid | 25 to 33% (mpg) 20 to 25% reduction in FC |

| Series hydraulic hybrid | 67 to 100% (mpg) 40 to 50% reduction in FC |

SOURCE: TIAX (2009).

hydraulic hybrid trucks. Eaton’s R&D shows that a parallel hydraulic hybrid with an efficient transmission can improve fuel economy by 35 to 45 percent (26 to 31 percent reduction in fuel consumption) in refuse trucks over the baseline. Eaton’s next-generation hydraulic hybrid, or HLA, is currently undergoing fleet testing in the refuse industry with about 50 systems.

EPA experiments with series hydraulic hybrid trucks have shown fuel economy improvements of 60 to 70 percent (38 to 41 percent reduction in fuel consumption) with proper matching of hydraulic components and driving the power steering and brake assist off the accumulator pressure. Although these improvements in fuel economy can be obtained with a system tuned for a particular drive cycle, these conditions generally do not exist in the real world. Such gains are feasible only when there are almost no electrical loads on the system at idle, very few engine starts, and no high-speed travel.11

Progress in Commercializing Hydraulic Hybrid Vehicles

The EPA initially partnered with Eaton Corporation to develop series hydraulic hybrid technology in a UPS delivery vehicle. Eaton, which developed a first-generation, parallel hydraulic hybrid refuse truck, or HLA, has more than 100 trucks in the field today. These first-generation vehicles provided a 10 percent improvement in fuel economy (9 percent reduction in fuel consumption) and four times longer brake life. Eaton’s next-generation HLAs will replace the Allison transmission with Eaton’s Ultra Shift Plus transmission with the hydraulic unit attached to the transmission’s PTO and will use hydraulic power to fill in torque during shifts. Eaton expects that this next-generation HLA will provide five times longer brake life and 30 percent better fuel economy (23 percent reduction in fuel consumption) than the baseline Peterbilt refuse truck. Eaton believes that a refuse truck provides an ideal duty cycle for the hydraulic hybrid vehicle and estimates that the North American refuse truck market is up to 10,000 vehicles per year.

Delivery trucks, refuse trucks, yard hustlers, and shuttle buses have been the focus of the EPA’s series hydraulic hybrid program over the past 5+ years. EPA technology transfer partners are moving to preproduction and/or full production of hydraulic hybrid vehicles in the 2010-2012 time frame. The following time lines for these programs was provided by the EPA:

• Refuse Vehicles:

—2008-2011: Fleet testing of 20 pilot vehicles.

—2010-2011: Purchases of 89 early/preproduction vehicles announced.

• Delivery Vehicles:

—2008-2011: Fleet testing of 6 pilot vehicles.

—2010-2012: Purchases of 46 early/preproduction vehicles announced.

The EPA has worked with Parker Hannifin Corporation, Freightliner, and FedEx in developing a hydraulic hybrid delivery vehicle. Currently, Parker Hannifin (in an Autocar refuse truck), Eaton (in a Peterbilt refuse truck), and Bosch-Rexroth (in an American LaFrance refuse truck) are progressing toward full production status with their hydraulic drive systems. Refuse trucks were a logical application, because they already utilize extensive hydraulic systems.

On November 23, 2010, Parker Hannifin Corporation announced that it had developed several hydraulic hybrid technologies that improve the performance of refuse and delivery vehicles to levels that exceed proposed new federal fuel-efficiency and criteria emission standards (Parker Hannifin, 2010). Parker Hannifin stated that its advanced hydraulic hybrid system is unique because it disconnects the engine from the rear wheels of the vehicles, indicating a series hybrid configuration. The hydraulic hybrid truck has the potential to reduce brake maintenance significantly owing to regenerative braking. Brake life can be extended two to eight times relative to the baseline vehicle, which requires three to four brake replacements per year, at approximately $2,000 each. This reduction in brake maintenance can assist in reducing the payback period. Parker Hannifin stated that the technology is already in use on 11 refuse vehicles in three South Florida communities. UPS and FedEx have become the first companies to order a variation of the technology for use in delivery vehicles, scheduled to be on the road in 2011. Parker Hannifin is currently developing further advancements in the technology for use on an advanced bus platform that is targeting a 45 percent reduction in fuel usage over average diesel powertrains.

Regulatory considerations for heavy-duty hybrid vehicles include hybrid truck tax credits, credits for fuel-efficiency standards, and emission certification. Each is discussed in the sections that follow.

Hybrid Truck Tax Credits

Tax credits, which are an important incentive for hybrid vehicles, have expired, but they are described below as background information for future consideration of credits (ACEEE, 2009). The Energy Policy Act of 2005 provided tax credits for heavy-duty hybrid vehicles in the period January 1, 2006, through December 31, 2009. The credit amount depended on the weight class of the vehicle, its fuel economy relative to a comparable conventional vehicle, and the incremental cost. By December 31, 2009, the following 10 manufacturers had certi-

_____________________

11 Information provided by Mihai Dorobantu, Eaton Corporation, to NRC staff, James Zucchetto, by e-mail, January 31, 2011.

fied tax credits through the Internal Revenue Service (IRS) for at least one heavy-duty hybrid truck or bus model:

Azure Dynamics

Freightliner (Daimler Trucks)

Freightliner/Eaton

International Truck/Eaton

Kenworth/Eaton

Navistar/Eaton

Navistar/IC Bus

Peterbilt/Eaton

Workhorse/Eaton

Odyne/Navistar

A hybrid vehicle’s incremental cost was defined in the Energy Policy Act of 2005 as the amount by which the manufacturer’s suggested retail price of the hybrid vehicle exceeded that of a “comparable” vehicle, but the incremental cost was capped by GVW class, as shown in Table 4-6.

The percentage of the incremental cost (up to the maximum allowed) that the credit covered was determined by the improvement in city fuel economy, as shown in Table 4-7. For example, the most efficient 20,000 lb hybrid truck could receive a credit of $6,000 ($15,000 maximum incremental cost × 40 percent [hybrid credit for improvement in city fuel economy of at least 50 percent]).

Also, under the Energy Policy Act of 2005, the vehicle had to meet a threshold value of “maximum available power,” a measure of the percentage of total vehicle power available from the rechargeable energy storage system of the vehicle. For a vehicle of 8,500 to 14,000 lb gross vehicle weight, the requirement was 10 percent of the maximum available power; over 14,000 lb, the requirement was 15 percent. This requirement was to ensure that a qualifying vehicle incorporated substantial hybrid technology. The language of the act did not specify the type of hybrid; both electric and hydraulic hybrids, for example, could qualify.

TABLE 4-6 Maximum Incremental Cost of a Hybrid Truck Qualifying for a Tax Credit

| Gross Vehicle Weight (GVW) Rating |

Maximum Qualified Incremental Cost |

| 8,501 to 14,000 lb | $7,500 |

| 14,001 to 26,000 lb | $15,000 |

| > 26,000 lb | $30,000 |

TABLE 4-7 Hybrid Truck Tax Credit as a Function of Fuel Economy

Improvement in City Fuel Economy |

Hybrid Credit as Percentage of Qualified Incremental Cost |

| At least 30% and under 40% (23 to 29% reduction in fuel consumption) |

20% |

| At least 40% and under 50% (29 to 33% reduction in fuel consumption) |

30% |

| At least 50% (At least 33% reduction in fuel consumption) |

40% |

In 2007, the IRS issued guidance setting out procedures for manufacturers to use in certifying a vehicle as an eligible heavy-duty hybrid, and the amount of the credit for that vehicle.12 The credit depended on the hybrid’s fuel economy relative to that of a comparable conventional vehicle, but there was no standard fuel economy test procedure in place for heavy-duty vehicles. Therefore, the IRS guidance directed manufacturers to assign fuel economies to their vehicles using an approach “substantially similar” to one used by the federal government or the state of California to measure fuel economy or emissions. Once the IRS acknowledged a vehicle credit, the manufacturer could certify it to purchasers. By the end of this program, 10 manufacturers were eligible for credits. Specific models for each manufacturer can be found on the IRS website.13

In February 2011, Senator Debbie Stabenow of Michigan introduced the Charging America Forward (S. 298) bill, which calls for an extension of the credits through December 31, 2014, and sets new qualifying incremental cost levels for which the purchaser can receive a portion as a tax credit. As of March 2011, this bill had been referred to the Senate Finance Committee.

Fuel Efficiency Standards

The EPA and the DOT/National Highway Traffic Safety Administration (NHTSA) introduced proposed standards for greenhouse gas (GHG) emissions standards and fuel efficiency standards for medium- and heavy-duty engines and vehicles on October 25, 2010 (EPA/NHTSA, 2010) and issued final standards on September 15, 2011 (EPA/NHTSA, 2011). The agencies (a term used throughout this section to indicate the EPA and DOT/NHTSA) noted that, although the standards are not premised on the use of hybrid powertrains, certain vocational vehicle applications may be suitable candidates for use of hybrids owing to the greater frequency of stop-and-go urban operation and their use of power take-off (PTO) systems. As an incentive, the agencies are providing credits for the use of hybrid powertrain technology. There is an important distinction between the two types of credits for hybrid vehicles discussed above. The credits provided by the fuel-efficiency standards could be used to meet any of the heavy-duty fuel-efficiency standards and are not restricted to the averaging set generating the credit. In contrast, the credits for hybrid vehicles, provided by the U.S. Energy Policy Act of 2005, were direct tax credits for the purchasers of hybrid

_____________________

12 See Internal Revenue Service Notice 2007-46. Available at http://www.irs.gov/irb/2007-23_IRB/ar08.html. Accessed December 3, 2010.

13 See http://www.irs.gov/businesses/article/0,,id=175456,00.html.

trucks that deliver improved fuel economy. Because the fuelefficiency standards provide procedures for defining the fuel economy improvements of hybrid vehicles, these procedures could provide a means, in lieu of the previously generated IRS guidance for truck purchasers, to obtain tax credits, if such credits are reinstated.

Two different classes of emissions, GHG emissions and “criteria pollutants,” are referred to in this section. The first class of emissions, GHG emissions (referring primarily to CO2), will be controlled by the new GHG emissions standards. The new GHG emissions standards also address hydrofluorocarbon emissions from air-conditioning systems and includes nitrous oxide (N2O) and methane (CH4) emissions standards. The second class of emissions, criteria pollutants, refer to hydrocarbons (HC), carbon monoxide (CO), NOx, and particulate matter (PM) exhaust emissions that have been regulated by the EPA for many years and require a certificate of conformity for engines based on tests conducted on heavy-duty transient engine dynamometers.

The agencies’ new fuel consumption and CO2 emissions standards are to be tailored to each of three regulatory categories of heavy-duty vehicles:

1. Heavy-duty pickup trucks and vans,

2. Vocational vehicles, and

3. Combination tractors.

The new rules for the fuel consumption and CO2 standards contain provisions for obtaining credits as an incentive for applying hybrid powetrain technology. The approach to account for the use of a hybrid powertrain when evaluating compliance with the standards is described in Appendix F.

The procedure requires testing heavy-duty pickup trucks and van hybrids on the light-duty federal test procedure (FTP) and highway fuel economy test (HWFET) with suitable adjustments to the test procedures. For vocational vehicles and combination tractors incorporating hybrid powertrains, two methods are specified: chassis dynamometer or engine dynamometer. Each method requires a comparison test (hybrid versus baseline) of the actual physical product (engine, powertrain, or vehicle), because the agencies are not aware of analytical models that can assess the technology. The measured fuel consumption advantage of a hybrid vehicle versus the baseline is multiplied by the production volume and the useful life to provide the fuel consumption credits for the specific vehicle line that is applied to the manufacturer’s production volume-weighted annual fleet average standard.

Emission Certification

The NRC Phase 1 report noted the lack of an emissions test and certification procedure for heavy-duty hybrid trucks (NRC, 2008). The Phase 1 report noted that the EPA was developing a procedure to measure directly the emissions of complete heavy-duty vehicles, including hybrids. Unfortunately, no progress has been reported on this effort by the EPA. Even though the EPA and the NHTSA introduced their NPRM on October 25, 2010, providing test procedures for CO2 emissions and fuel consumption for hybrid heavy-duty trucks, a manufacturer still needs a certificate of conformity that the vehicle’s internal combustion engine meets the EPA criteria emissions standards for heavy-duty engines, a procedure that does not recognize hybrid heavy-duty trucks. Therefore, the potential reduction in emissions with a hybrid heavy-duty truck cannot be recognized, and so reductions in the size or simplification of the emission control system cannot be considered.

The California Air Resources Board (CARB) is currently drafting vehicle-level test procedures for heavy-duty hybrid vehicles. California is coordinating this effort with the EPA’s efforts to establish GHG standards for heavy-duty vehicles. The CARB’s work is aimed at quantifying the improvement in fuel consumption and emissions due to hybridization. However, at this time, procedures are in draft form, not finalized (DOE, 2011).

Finding 4-4. The EPA and the DOT’s National Highway Traffic Safety Administration (NHTSA) issued their final rules on September 25, 2011, for “Greenhouse Gas Emissions Standards and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles.” Although these standards contain test procedures for determining fuel consumption for heavy-duty hybrid trucks, a manufacturer still needs a certificate of conformity showing that a vehicle’s internal combustion engine meets the EPA criteria emission standards for heavy-duty engines (a procedure that does not recognize hybrid heavy-duty trucks). The CARB is currently drafting vehicle-level test procedures for heavy-duty hybrid vehicles.

Recommendation 4-3. As partners of the 21CTP, the EPA and DOT/NHTSA should work with the CARB to develop test procedures for the certification process for criteria emissions so that the emissions benefits of hybridization will be recognized, allowing the reduction in size or simplification of the emission control system of heavy-duty hybrid vehicles to be realized.

HYBRID COSTS AND PAYBACK PERIODS

The NRC report on medium- and heavy-duty vehicles (NRC, 2010) contains extensive information and projections on benefits and costs of hybrid truck systems. Because this information is contained in NRC (2010) in many tables with a variety of other information, a consolidated table presenting the information exclusively for hybrid truck systems is provided here. The fuel consumption benefit, capital cost, annual mileage, and typical fuel economy in miles per gallon for technologies projected to be available in the 2015-2020 time period are shown in Table 4-8. The capital costs are

TABLE 4-8 Hybrid Trucks—Break-even Cost Analysis (Future 2015-2020 Technology)

| Category | Description | Fuel Consumption Benefit (%) | Forecasted Capital Cost ($)a | Annual Mileageb | Typical MPGb | Payback Period to Breakeven Yearsc | Referencesd |

| Class 2b Pickups and Vans | Parallel electric hybrid | 18 | $9,000 | 27,500 | 12.5 | 7.6 | Table 6-9 |

| Class 3 to 6 Straight Box Truck | Parallel electric hybrid | 30 | $20,000 | 41,250 | 9.4 | 5.1 | Table 6-7 |

| Class 3 to 6 Bucket Truck | Parallel electric hybrid with | 40 | $30,000 | 13,300e | 9.4 | 17.7 | Table 6-8 |

| electric power takeoff | |||||||

| Class 8 Tractor Trailer Truck | Mild parallel electric hybrid with idle reduction | 10 | $25,000 | 137,500 | 5.75 | 3.5 | Table 6-5 |

| (not directly comparable because of inclusion of idle reduction feature) | |||||||

| Urban Transit Bus With federal subsidy of incremental cost | Series electric hybrid | 35 | $220,000 ($22,000) | 137,500 | 6.0 | 9.1 | Table 6-16 0.9 |

| Class 8 Refuse Hauler | Parallel hybrid electric | 30 | $39,000f | 50,000 | 4.25 | 3.7 | Table 4-9 |

| Class 8 Refuse Hauler | Parallel hydraulic hybrid | 25 | $30,000 | 50,000 | 4.25 | 3.4 | Table 6-10 |

| Class 8 Refuse Hauler | Series hydraulic hybrid | 50 | N/A | 50,000 | 4.25 | N/A Table 4-9 | |

NOTE: The break-even period is calculated on the basis of a fuel cost of $3.00/gal. For a fuel cost of $4.00/gal, the break-even period would be reduced by 25 percent.

aCosts for 2015-2020 are forecast to be reduced up to 47% from 2013 to 2015 costs.

bAverage values of ranges from NRC (2010), Table 2-1.

cbreakeven Time = Capital Cost/(Annual Mileage/MPG X % Improvement X $/gal).

dTables 6-5 through 6-16 provide future costs for 2015-2020. All tables are in NRC (2010).

eNRC (2010), page 138.

fNRC (2010), page 141.

projections for 2015-2020 contained in NRC (2010). Using this consolidated information, a simple calculation of the payback period to break even, defined as the time to achieve fuel cost savings equal to the initial capital cost of the hybrid system, was made assuming a $3.00/gal fuel cost.14 Maintenance costs and discount rates were not included. The results are also shown in Table 4-8. It is important to note that the capital costs listed in Table 4-8 are forecasted to be reduced by up to 47 percent from the 2013-2015 costs, which, in turn, are expected to be lower than current costs for hybrid systems. Thus, the capital costs shown are forecasts containing reductions of well over 47 percent from current costs.

The 21CTP acknowledges that current break-even times without subsidies, based on current costs and fuel consumption improvements, are typically twice as long as the 5 years that fleets normally require for a return on investment in new hardware for cost savings. The 21CTP stated that “heavyhybrid technology for commercial trucks and buses needs significant research and development (R&D) before it will be ready for widespread commercialization at prices that can be borne by the vehicles’ operators” (DOE, 2011). The 21CTP further stated, “HD [heavy duty] hybrid technology is far from mature…. Many of today’s HD hybrid vehicles have used components that are commercially available but were not designed or optimized for on-road HD hybrid vehicles. Some HD hybrid components cannot be found elsewhere and must be custom designed for the application. These will be costly due to low production volumes that have not justified the development of high volume manufacturing tools and processes to produce them economically.” A very large investment is needed by the developers of the heavy-duty hybrids, the engine manufacturers, and the truck manufacturers to fully develop and implement the technologies in commercial vehicles. The capital costs shown in Table 4-8 reflect the significant reductions that will be required for HEV systems to become commercially viable.

Fuel economy improvements of 20 to 40 percent (17 to 29 percent reduction in fuel consumption) have been achieved for hybrid trucks over urban-based, start-and-stop driving cycles. DOE vehicle simulation tools are currently being used to evaluate fuel consumption benefits of advanced technologies to meet the goal of 60 percent improvement in fuel economy (38 percent reduction in fuel consumption).

_____________________

14 For a fuel cost of $4.00/gal, the breakeven period would be reduced in length by 25 percent.

By using these forecasted capital costs, most of the technologies listed in Table 4-8 achieve payback, or break even, within approximately 5 years, except for the Class 2b pickups and vans, Class 3 to 6 bucket trucks, and transit buses without the 90 percent federal subsidy for the hybrid system incremental cost. The Class 2b pickups and vans need to achieve greater fuel consumption improvements and/or capital cost reductions to achieve payback in 5 years. The Class 3 to 6 bucket trucks have exceptionally low mileage that extends the payback period well beyond 5 years. No remedy for this shortfall appears to be available at this time. The continued application of hybrid technology to transit buses will require the continuation of federal subsidies.