The net power output of a truck engine is consumed by numerous forces opposing the truck’s movement on the road. These forces in the case of a heavy-duty truck derive from a number of subsystems or components that consume energy by various forms of friction, by unfavorable pressure differentials, or by energy conversion to power a device. The 21st Century Truck Partnership (21CTP) has identified the areas of energy consumption for a typical Class 8 vehicle operating on a level road at a constant speed of 65 mph with a gross vehicle weight (GVW) of 80,000 lb. In this case, the engine losses are about 322 horsepower (hp), 60 percent of the fuel energy. The truck power demands consume the remaining 40 percent, as summarized in Table 5-1.

Under the described operating conditions, aerodynamic drag and tire rolling resistance are major contributors to energy loss. Although all trucks would benefit from aerodynamic drag reduction, those with high average speed and miles traveled would benefit most. Class 8, over-the-highway, tractor-trailer combination trucks best fit that operational description.

TABLE 5-1 Heavy-Duty Truck Power Consumption (each hour)

Operating Load |

Power Consumed (hp) |

Power Consumed (%) |

| Aerodynamic | 114 | 53 |

| Rolling resistance | 68 | 32 |

| Auxiliaries | 20 | 9 |

| Drivetrain | 12 | 6 |

| Total | 214 | 100 |

NOTE: Horsepower consumed each hour is an energy term (hp-h).

SOURCE: NRC, 2010, Table 5-4.

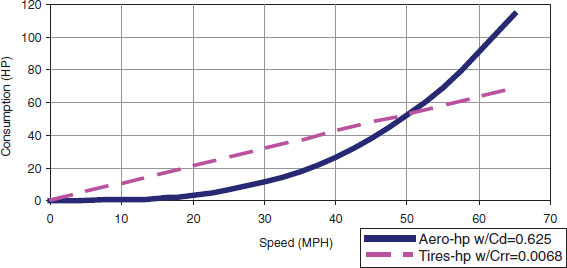

The resisting aerodynamic horsepower is proportional to

Cd × A × V3, where Cd = coefficient of drag, A = frontal area, and V = forward velocity (NRC, 2010, p. 28).1 This illustrates the important role of vehicle speed on aerodynamic horsepower consumption. The relationship is shown in Figure 5-1.

An analysis of the consumptions shown in Table 5-1 has illustrated that a 20 percent reduction in Cd results in about a 10.5 percent reduction in fuel consumption. This supports the industry’s rule of thumb that for high–road-speed tractor-trailers, the fuel consumption change is one-half of the drag change.

Although it is typical in truck aerodynamic improvement practice to report fuel consumption at 65 mph, rarely is an average speed of 65 mph achieved without frequently exceeding the common Interstate highway speed limit. In the case of many real-world trucks’ duty cycles with perhaps an average 55 mph, the aerodynamic fuel-consumption reduction is about 9 percent rather than the 10.5 percent associated with a 20 percent Cd reduction.

Also illustrated in Figure 5-1 is the tire-rolling-resistance power consumption.2Figure 5-1 indicates that these two sources of power consumption are equal at about 50 mph, while rolling resistance power consumption is about twice that because of aerodynamic drag at 37 mph, when the tractor-trailer is equipped as a 2008 model pre-SmartWay3 combination vehicle.

_____________________

1 Cd = coefficient of drag = Force/(1/2 ρ A V2), which is dimensionless; F = force the vehicle must overcome due to air, ρ = density of the air, A = projected area perpendicular to the direction of travel, and V = velocity of the vehicle relative to the fluid (air).

2 “Rolling resistance” is the force at the axle in the direction of travel required to make a loaded tire roll. The coefficient of rolling resistance (Crr) is the value of the rolling resistance force divided by the wheel load.

3 SmartWay is an Environmental Protection Agency (EPA) voluntary certification program for tractor-trailer combinations. The EPA notes that the

REDUCTION GOALS FROM THE PARTNERSHIP WHITE PAPERS

The goal of the 21CTP is to conduct research, provide hardware demonstrations, and validate and deploy cost-effective, reliable, and durable technologies that reduce vehicle power demands. The Partnership will continue to utilize a vehicle system approach to continually track the benefits of individual technologies on overall vehicle efficiency and performance. Five primary technology goals applicable to the target tractor-trailer truck are to be achieved over the next 10-year period (DOE, 2011).

1. Goal 1 (reference level of 53 percent aerodynamic power consumption): Reduce the aerodynamic drag coefficient by 20 percent (from a Cd of 0.69). Evaluate a stretch goal of 30 percent reduction in aerodynamic drag. (The baseline is from the Environmental Protection Agency/National Highway Traffic Safety Administration [EPA/NHTSA] final rule “Greenhouse Gas Emissions Standards and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles” for a conventional Class 8 tractor with high-roof sleeper. [EPA/NHTSA, 2011; NRC, 2010].) (Also, see footnote 3 in this chapter.)

2. Goal 2 (reference level of 32 percent rolling resistance power consumption): Reduce tire rolling resistance by 35 percent from tractors equipped with dual-tire drive wheels. (The baseline Crr is 0.0082 from the EPA/NHTSA rule for tires of the dual tire drive wheels, only, of a Class 8 tractor [EPA/NHTSA, 2011; NRC, 2010].) (Also, see footnote 3 in this chapter.)

3. Goal 3 (reference level of 9 percent auxiliaries’ power consumption): Reduce essential auxiliary loads by 50 percent. (The baseline for this goal is a Class 8 highway tractor-trailer with sleeper, operating 5 days in over-the-highway operations at 80,000 lb gross combined vehicle weight [GCVW].)

4. Goal 4: Reduce tare weight by 10 percent, and for the long-term stretch goal by 20 percent, from a 34,000 lb base tractor-trailer capable of an 80,000 lb GCVW operation, and comprised of a tractor (19,500 lb), trailer (13,500 lb), and fuel (1,500 lb).

5. Goal 5: Thermal Management, and Friction and Wear Reduction

a. Thermal Management Systems: Increase heat-load rejected by 20 percent without increasing radiator size.

b. Friction and Wear (reference level of 6 percent drivetrain power consumption): Reduce powertrain and drivetrain consumptions by 50 percent (NRC, 2010).4

The committee appreciates these carefully formulated goals statements. The committee believes that these goals are achievable within the 10-year period specified, but only if adequate research and development efforts are expended. Typically, achieving some goals will be found more problematic than achieving others. In the more problematic

_____________________

SmartWay brand identifies products and services that reduce emissions, such as greenhouse gas emissions. Certification using EPA test methods allows carriers, manufacturers, and shippers to apply the SmartWay logo. See the EPA website at http://www.epa.gov/smartwaylogistics/basic-information/index.htm and NRC (2010) for more detailed information.

4 Notes to Goals 1 and 2 were prepared to compare these current numerical goals to those stated in the DOE (2006) White Paper Roadmap, as well as to compare certain Cds and Crrs corresponding to other frequent descriptions (current available, SmartWay, Advanced SmartWay). See Appendix G in this report. The baseline for these goals is a Class 8 highway tractor-trailer with sleeper operating at a steady 65 mph at 80,000 lb GCVW.

areas, typically of higher technology risk and cost, 21CTP processes are very important. The ability of the Department of Energy (DOE) to assist in understanding how to achieve the goals through its Vehicle Technologies Program, including specifically the Vehicle Systems Simulation and Testing (VSST) protocols (DOE, 2010b), should be very beneficial and is particularly encouraged.

Aerodynamic drag arises principally from the pressure differentials on fore and aft body surfaces. Surface friction is a much less significant issue if surfaces are substantially smooth, which is a common but not yet a universal design feature; a notable example is container boxes (DOE, 2010a). Full-truck on-road testing following Society of Automotive Engineers (SAE) protocols (e.g., SAE J1263 coast-down testing; SAE J1321, Type II over-the-road testing with control truck) is relatively imprecise for evaluating the aerodynamic effect of design changes. Wind tunnel tests, also following SAE protocols (e.g., SAE J1252), are an improvement in precision and, importantly, allow an evaluation of the effects of off-axis forces (yaw) due to prevailing wind. Computational fluid dynamics (CFD) is often useful for fine-tuning component design to take account of the aerodynamic contribution, but it is in limited use for full-truck behavior.

Historically, the truck manufacturers have not reported Cd values for tractors. This situation is likely due to the competitive nature of those values, especially in light of the imprecision of prevailing standard test procedures.

Four regions of the tractor-trailer combination truck are amenable to aerodynamic design improvements. These regions include (1) the various tractor-related “aero” details, (2) the tractor-trailer gap, (3) the trailer skirt (or underbody), and (4) the trailer “base” fairing, which are all illustrated in Figure 5-2, along with the approximate fuel-consumption reductions related to each region that are estimated to be achievable in the near term.

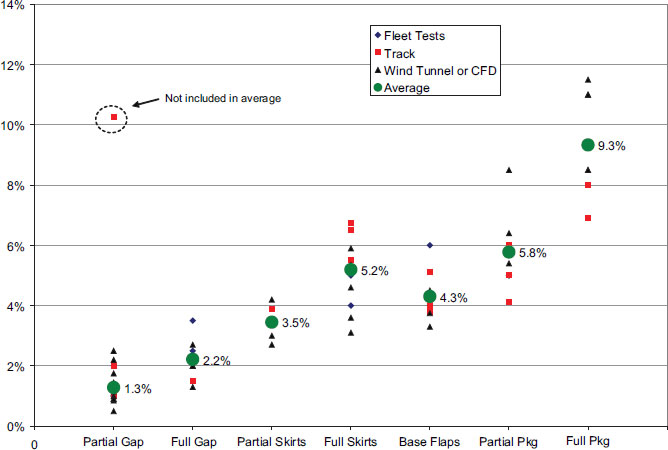

The DOE funded a $4.2 million study, initiated in 2007, on trailer aerodynamic improvements to reduce fuel consumption and presented a project status report to the committee (DOE, 2010a). The authors provided the committee a pre-publication draft of their results and analysis. The study combined CFD studies with a large battery of full-size tractor-trailer wind tunnel tests at 65 mph in the huge National Full-Scale Aerodynamics Complex (NFAC) at the National Aeronautics and Space Administration (NASA) Ames Research Center. This research was supported by numerous industrial partners. These data are reported as yaw-wind averaged drag, which is acquired only in a wind tunnel, and which most aerodynamicists agree represents the best on-road performance figure. The study clearly is an excellent one, with very thorough evaluation of numerous candidate design improvements for all three of the trailer regions in Figure 5-2. The analysis is quite insightful, providing very helpful commentary to clarify why certain design details yield the observed results. The best performance observed for the case of a 2008 long sleeper tractor and straight frame (LS/SF) tractor-trailer was a Cd reduction of 23 percent. The draft did not proffer a base case Cd for this LS/SF combination. However, if a Cd of 0.63—used in this chapter for a 2006-2008 pre-SmartWay tractor—is assumed, a fuel-consumption reduction of about 12 percent would be expected. This can be compared to the average fuel consumption of 9.3 percent for a full package described in the section below titled “TIAX Summary” and Figure 5-3.

EPA SmartWay Transport Program

In 2004 the EPA developed and implemented SmartWay, an organized effort to specify a collection of current and emerging technologies for creating fuel-efficient tractor-

trailer combinations with the best environmental performance in terms of both air pollution and emissions of greenhouse gases (GHGs) (EPA, 2011; NRC, 2010). SmartWay tractors must have an aerodynamic profile that includes a high-roof sleeper, integrated roof fairings, cab side extenders, fuel tank side fairings, and aerodynamic bumpers and mirrors. They must be powered by a 2007 or newer engine, with a SmartWay-approved option for idle reduction. The tires must be SmartWay-approved, low-rolling-resistance tires. All six major U.S. truck manufacturers have one or more complying tractors. Thousands of carriers, shippers, and manufacturers are SmartWay members or affiliates, attributing to the excellent success of this voluntary efficiency program.

SmartWay dry van trailers are 53 ft long and must have side skirt fairings, a front gap or rear fairing, and SmartWay-approved low-rolling-resistance tires. Trailer fairings and tires can be either provided by the original equipment manufacturer (OEM) on new trailers or retrofitted to older trailers by more than a dozen manufacturers that have developed these aerodynamic components.

The SmartWay program has provided an important visibility in the heavy-duty truck industry to the benefits of adapting manufacturer-developed aerodynamic trailer features and low-rolling-resistance tires. SmartWay combinations consume a minimum of 8 percent less fuel than pre-SmartWay specifications by virtue of their aerodynamic and tire-rolling-resistance changes alone.

California Regulation Based on SmartWay Program

One of the most significant consequences of the Smart-Way certification program is action taken by the California Air Resources Board (CARB) to reduce the state’s GHG emissions to 80 percent of 1990 levels by 2020 (ARB, 2008). In response to the California legislature’s Global Warming Solutions Act of 2006, the CARB required all tractor-trailers to implement SmartWay technologies.

Beginning in January 2010, with the 2011 model year, all sleeper cab tractors on California highways that pull 53-ft or longer box van trailers must be SmartWay-certified. Day cab tractors must have SmartWay-approved low-rolling-resistance tires. At the same time, in model year 2011 and beyond, all 53-ft van trailers must also be SmartWay-certified.

TIAX Summary

TIAX provided data on the performance of a collection of aerodynamic modifications to trailers, including packages of various combinations, using various testing methods.

These are reported in Figure 5-3. The full package includes the partial gap filler, full or partial trailer skirt, and base flaps (base fairings and boat tails). TIAX also reported that next-generation aerodynamic tractors would improve fuel consumption by 3 to 4 percent in the 2013-2015 time period (TIAX, 2009).

It might be helpful to note here that a 0.63 Cd base was used in several earlier documents, including the previous Partnership White Papers (DOE, 2006), the performance-improvement estimates in Figure 5-2, and the TIAX (2009) study. Further, the current Partnership white paper (DOE, 2011) adopted the proposed EPA/NHTSA GHG rule Cd base of 0.69 for application to the new goal. This difference in goal between the current and previous white papers represents a fuel consumption penalty increment of about 4 percent for the tractor-trailer operating condition described for Table 5-1.

Adjusting these TIAX data to the 0.69 new Cd base, the committee believes that in the 2013-2015 time frame, a 13 percent reduction in fuel consumption is achievable at 65 mph when utilizing the trailer “full package” average of 9.3 percent reduction. Note that this performance represents a Cd reduction of about 25 percent, compared to the expressed goal of 20 percent.

In the 2015 to 2020 time period, if it is assumed that the performance of the trailer individual devices at the 75th percentile would eventually be achieved, then the combined full package (of partial gap, full skirt, and base flaps) would be 16 percent (Cd base adjusted to 0.69). Combining that trailer performance with the forecast next-generation tractor performance would yield a 19 percent reduction in fuel consumption (a Cd reduction of about 38 percent) achievable at 65 mph, in the 2015-2020 time period. This result is derived through a method of multiplication of fuel-consumption reductions (DOE, 2010a). Take particular note that these packaged solutions include a boat tail or similar device that might interfere with trailer docks, and must be appropriately accommodated. At least one manufacturer of such devices reported that its boat tail folds flat onto the doors in 6 seconds (ATDynamics, 2010).

Navistar, with partners Kentucky Trailer and Freight Wing, initiated a Cooperative Research and Development Agreement (CRADA) with the DOE beginning in December 2008 to bring to market a tractor-trailer combination and tire package that can reduce the fuel consumption of a heavy-duty vehicle by at least 15 percent. After completion of the project, the team members will make this fuel-efficient technology package available for sale (Navistar, 2008).

All three of the SuperTruck projects will investigate tractor and trailer aerodynamic features (see Chapter 8 in this report). These projects will provide appropriate next steps under the 21CTP for many of the vehicle power demand topics.

Findings and Recommendations

Finding 5-1. Aerodynamic improvement studies need to become increasingly integrated, because individual component improvements are typically not additive. Appropriately, the perspective of the 21CTP for the SuperTruck projects is to utilize a vehicle systems approach for the validation of research and development results.

Finding 5-2. The aerodynamic test procedures may not be sufficiently precise, and only wind tunnel testing accounts for important yaw effects, so that competitive pressures discourage truck-tractor manufacturers from publishing Cd figures. Recommendation 5-15 from the National Research Council’s 2010 report titled Technologies and Approaches to Reducing the Fuel Consumption of Medium- and Heavy-Duty Vehicles provided good suggestions for standardizing Cd reporting.

Finding 5-3. The proposed EPA/NHTSA greenhouse gas emissions standards rule chose not to regulate trailer operational efficiency. Regardless of the reasons, this seems a significant omission, because both trailer aerodynamic devices and low-rolling-resistance tires that are currently production-available can provide an immediate, combined fuel consumption reduction of about 13 percent (compared to the rule’s baselines).

Finding 5-4. Aerodynamic design packages are expected to improve tractor-trailer fuel consumption by 19 percent at 65 mph when fully developed in the 2015-2020 time period. This reduction corresponds to a Cd reduction of nearly 40 percent (from the newly adopted 0.69 Cd baseline).

Recommendation 5-1. The Partnership should consider setting an aerodynamic drag stretch goal of 40 percent instead of 30 percent.

When tires roll under a truck’s weight, their shape changes cyclically, deforming and recovering with inherent hysteresis. That deformation energy is converted into heat and the tire’s environment dissipates the heat accumulation, and the heat dissipated is due to the tire’s rolling resistance. The power consumed by the tires is proportional to truck weight, speed, and the coefficient of rolling resistance (Crr) (NRC, 2010, p. 28). Rolling resistance is influenced by many factors, including design and construction features, materials, internal pressure, and tread design, which may be different according to intended tire use at steer, drive, or trailer locations. The change from bias to radial ply in the 1970s and 1980s reduced Crr by 25 percent.

A common 18-wheeler highway tire specification for today (pre-low rolling resistance) will have an average Crr

_____________________

5 “Regulators should require that aerodynamic features be evaluated on a wind-averaged basis that takes into account the effects of yaw. Tractor and trailer manufacturers should be required to certify their drag coefficient results using a common industry standard” (NRC, 2010).

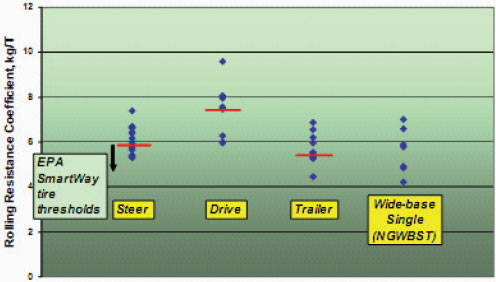

of about 0.0068. This results from the tire combination of 2 steers, 8 drives, and 8 trailers from a range represented by data such as in Figure 5-4. (See Appendix G of this report for the tire weighting values used in this averaging.) Similarly, the EPA SmartWay 18-wheeler average threshold Crr is 0.0063 based on the values from Figure 5-4, and might be achieved with low-rolling-resistance dual tires.

The tire industry has taken additional initiative, spurred by competitive market forces, to develop next-generation wide-base single tires (NGWBSTs), which have substantially reduced Crr and are becoming the current state of the art; some fleets are replacing dual tires with the NGWBST systems when new trucks are ordered. Figures for Crr in the low 0.004s are available for some tire positions (trailers). A currently available set of tractor-trailer tires, including wide-base low-rolling-resistance designs, provide a Crr of 0.0055.

As noted above in Goal 2, the 21CTP has recently adopted the Crr baseline used by the EPA for tractor tires on dual drive wheels, from the proposed truck GHG/fuel efficiency rule promulgated by the EPA and NHTSA (EPA/NHTSA, 2010). To put the Goal 2 drive tires’ Crr baseline of 0.0082 in perspective for an 18-wheeler, one must create a combination that includes the EPA/NHTSA rule’s selection for steer tires, 0.0078, along with a committee-assumed trailer tire value of 0.0072. That tractor-trailer combined weighted average Crr then is about 0.0077. Now, by comparison, the current NGWBST combined weighted average Crr is a reduction of nearly 30 percent, to 0.0055, and yields a fuel-consumption reduction of about 10.5 percent. (Note that 18-wheelers become 10-wheelers when their current 8 pairs of duals are replaced by single wide-base tires.)

This level of reduced fuel consumption has been validated in an extensive on-highway test series conducted by the Oak Ridge National Laboratory (ORNL) in cooperation with a carrier, Schrader Trucking, and using Michelin-supplied tires (ORNL, 2009). Six well-instrumented tractors and six trailers all with a mix of standard dual tires and NGWBSTs accumulated more than 688,000 miles at an aggregated average speed of 58 mph traveling through 39 eastern and midwestern states and Canada. Every combination of tires that included some mix of NGWBSTs provided statistically significant fuel-consumption reductions at all three of the selected gross weight groupings. Those applications that replaced both tractor and trailer duals with NGWBSTs achieved a 9.3 to 9.6 percent reduction in fuel consumed when carrying medium and high payloads.

A combined tractor-trailer Crr of 0.0045 is achievable in the next 5 years (TIAX, 2009, p. 4-53) and could yield a fuel-consumption reduction of about 15 percent. These reductions are compared to the supposed EPA non-low-rolling-resistance tractor-trailer 0.0077 Crr weighted baseline noted above, and result from the corresponding 40 percent reduction in Crr.

Potential pavement damage due to changes in tire shape and load is a high concern for regulators. Road wear and damage are known to be directly controlled by contact (hertz) stress. This stress increases with the 4th power of unit load. As a result, vehicle weight and the distribution of that weight over the tire contact patches are critical factors in determining the durability of road surfaces. Studies show that NGWBSTs do not increase contact stress in the pavement compared to the stress generated by standard dual tires. As a

FIGURE 5-4 Example rolling resistance coefficients for heavy-duty truck tires. (Data in this figure are Crr × 1,000). Acronyms are defined in Appendix I. SOURCE: Courtesy of Michelin Tire North America. C. Bradley and S. Nelson, Michelin Tire North America, “Truck Tires and Rolling Resistance,” presentation to the National Research Council Committee to Assess Fuel Economy Technologies for Medium- and Heavy-Duty Vehicles, February 4, 2009, Washington, D.C.

result, pavement damage is expected to be similar for these two types of tires for primary roads.

Some of the concerns regarding pavement damage can be attributed to past experiences and studies of the original 65-series on-off-road and regional single tires (e.g., 385/65R22.5 and 425/65R22.5). These tires are normally operated at elevated service inflation pressures, with consequently reduced tire footprint size and peak tire-road contact stresses that surpass those of traditional dual tires. Studies of the original “65-series singles” concluded that increased road damage could be attributed to these tires, and this naturally generated concern for state and federal departments of transportation when NGWBSTs were developed and put in use (Al-Qadi, 2007a,b).

Other issues still concerning users of NGWBSTs are tread life, truck stability in blowout, running on a flat, availability of nearby repair facilities, and integrity of drive traction. Tire manufacturers believe that these issues have been resolved (Al-Qadi, 2007a,b). Many carriers have been replacing duals on existing equipment with NGWBSTs at an accelerated pace, seeking the anticipated fuel savings contribution of NGWBSTs. A recent trade press article identified eight medium and large carriers that have been converting, some beginning many years ago (TT, 2011). It has been observed that when replacement of dual with wide single tires are made to existing axles, manufacturers caution that improper wheel selection can reduce load-carrying capability (AM, 2010). Carriers need to be made aware of the importance of such caveats. Potential safety issues associated with blowouts of NGWBSTs do not appear to have become a remarkable problem. Nevertheless, the Department of Transportation (DOT) should thoroughly review the real-world ramifications of documented NGWBST blowouts. Many carriers are routinely using NGWBSTs because they are satisfied that these issues are minimal, but many other fleet owners will need to be convinced. Most Class 8 tractor-trailer combination trucks can benefit from the fuel-consumption reductions contained in NGWBSTs. There are some application issues that carriers must become aware of, such as trailer spread-axle configurations. In short, carriers must monitor the details of conversion as well as new purchases. Another benefit of using NGWBSTs is an 800 lb or greater weight reduction for an 18-wheeler, when used with aluminum wheels.

Maintenance of tire pressure is important both to tire life and rolling resistance. A 20 percent pressure reduction in all tires causes a fuel-consumption increase of 2 to 3 percent, associated with an increase in rolling resistance (NRC, 2010, p. 114). Tire pressure monitoring systems with in-wheel sensors have become available in recent years and are gaining acceptance in fleet application. As usual, the cost/benefit trade-off is an important element in the acceptance of such new technologies.

At least two standard laboratory test procedures are in common use for determining truck (and light-duty vehicle) rolling resistance characteristics: they are the SAE J1269 multi- and single-point, and the draft International Organization for Standardization (ISO) 28580 single-point with interlaboratory correlation procedure. Unfortunately, tire manufacturers have not voluntarily collaborated in efforts to facilitate the comparison of rolling resistance and other characteristics across company boundaries. Furthermore, given that Crr is not constant over the tread life of tires, it would be a great improvement toward tire selection if such laboratory procedures added a requirement to measure Crr at the tire mid-life (circa 150,000 miles). This is an area needing DOT or DOE attention, because fuel-consumption benefits are being lost because of limited carrier acceptance of the NGWBSTs.

Response to Recommendations from NRC Phase 1 Review

The 21CTP agreed that it is appropriate for the DOT, EPA, and DOE to report tire performance data to buyers and sellers. It noted that the EPA SmartWay Transport Partnership publicly reports the fuel-savings capability of low-rolling-resistance tires, including the wide-base single families of tires (see 21CTP response in Appendix C to Recommendations 5-9 on Parasitics from [NRC, 2008]). The DOE also recently reported the favorable results of its testing with NGWBSTs.

Findings and Recommendations

Finding 5-5. Next-generation wide-base single tires (NGWBSTs) can provide a combination tractor-trailer with an immediate 10.5 percent fuel-consumption reduction and up to a 15 percent reduction in the next 5 years, but many fleets do not yet embrace the technology.

Recommendation 5-2. The DOE should set the goal for reduced rolling resistance for the tires of the combination tractor-van trailer, rather than for the tractor drive wheels only, because improved-performance trailer tires are equally important to realizing the full benefit of reduced rolling resistance designs. This benefit can be achieved by combining the EPA base values for steer and drive tires in the EPA/NHTSA GHG rule, with an assumed trailer tire Crr value of about 0.0072. rr

Finding 5-6. Carriers need to follow carefully the recommendations of axle manufacturers for replacing dual tires with single-wide tires to ensure that the integrity of the load system is not compromised.

Recommendation 5-3. The 21CTP should consider producing a comprehensive summary that can be updated giving the prescriptions and precautions that carriers should consider when retrofitting NGWBSTs onto original equipment axles fitted with dual wheels and tires. This effect might best be

managed in conjunction with the American Trucking Association’s (ATA’s) Technology and Maintenance Council, which has drafted such a Recommended Practice and is a specialist in creating such directives for ATA membership (ATA, 2007).

Finding 5-7. There is no rolling resistance test procedure with interlaboratory correlation universally employed as an industry standard.

Recommendation 5-4. The 21CTP, strongly supported by DOT and EPA (the latter through its SmartWay program), should conduct an authoritative study of the several barriers (e.g., related to tread life, truck stability in blowouts, run-flat tires, and other topics) to the widespread carrier adoption of NGWBSTs. The DOT should specifically support reduction of barriers to NGWBST acceptance by requiring the universal use by tire manufacturers of a rolling resistance test procedure like that in ISO (International Organization for Standardization) 28580, to ensure that comparative inter-laboratory data exist.

Auxiliary loads are typically driven by a mechanical drive from the propulsion engine. Examples include compressed air for brake systems; air conditioning compressors; electrical energy for lighting, hotel loads, heating, ventilation, and air-conditioning (HVAC) fans and battery-charging systems; power-steering pumps; and power take-off (PTO) drives, where used. Trailer refrigeration loads are normally satisfied with a second, dedicated engine. Power demand on the propulsion engine for these functions might range up to 9 percent, depending on the truck duty cycle and environment.

Seemingly missing from this list of “auxiliaries” is the engine cooling fan. However, this is not a significant omission when the principal truck operation perspective is to be a line-haul tractor-trailer at high road speed. The line-haul fan power consumption has been summarized for a 1,800 engine rpm fan-on condition as 40 to 60 hp. However, for high road speed, the fan-on time was estimated at 5 percent (NRC, 2010, p. 110). Together these figures suggest a time average consumption of 2 to 3 hp, sufficiently small not to warrant attention. However, the committee notes that there are operating conditions, for example, at lower road speeds, climbing hills, and with the air conditioner on, when the fan on will be consuming 20 to 50 hp for appreciable periods. A variable-speed fan drive can reduce the necessary fan speed and accompanying power consumption to only that necessary to achieve both radiator and air-conditioner-condenser temperatures and pressure.

Goal 3 above requires a reduction in essential auxiliary loads by 50 percent. In Table 5-1, auxiliary load is identified as 9 percent of the demand on the engine. A 50 percent reduction, to 4.5 percent of the demand, would provide a corresponding 4.5 percent reduction in fuel consumption on a level road at 65 mph, assuming unchanged brake thermal efficiency (BTE). Auxiliary power requirements are derived from many vehicle functions, as described above (DOE, 2011).

The most often imagined solution for removing these loads from their current drive is the electrification of the various drives, which was called the More Electric Truck project in the 21CTP. Electrically driving many of these systems can achieve power on demand, using energy only when and where it is needed. In that way, nonpropulsion energy like that from waste heat recovery (WHR) systems, hybrid system regenerative braking systems, or auxiliary idle reduction systems might supply the needed electricity. A 21CTP goal identified for hybrid drive units in Chapter 4 (see revised Goal 1) provides for “electrification of power accessories with goals of reduced weight and cost, operation in engine-off conditions and a service life of 1 million miles/15 years.” Truck electrification will have to be achieved without a degradation of current subsystem durability and reliability, and advanced electrical systems will have to be cost-effective. Multiple projects were initiated and successfully completed in the 21CTP program by the end of 2007. Average power savings of up to 2 percent of fuel are the largest estimated in the NRC Phase 1 report (NRC, 2008, p. 74).

Two of the SuperTruck platforms will investigate electrically driven auxiliaries, as those projects integrate WHR, hybrid-electric, and idle-reduction systems. It is expected that those projects may be better able to quantify the actual savings of electrically driven auxiliaries in real-world duty. Chapters 4 and 6 of this report are devoted to hybrid systems and idle reduction, respectively.

Response to Recommendations from NRC Phase 1 Review

The 21CTP reported that it is exploring the cost and benefits of continuing R&D in the auxiliaries area compared to the potential for efficiency improvements by other heavy-truck technologies (see Appendix C, response to Recommendation 5-1 on parasitics from NRC, 2008).

Finding and Recommendation

Finding 5-8. The More Electric Truck may achieve about one-third of the auxiliaries’ reduction goal for a loaded tractor-trailer. Better quantification is expected to result through two of the SuperTruck projects.

Recommendation 5-5. The Partnership should renew R&D efforts to further reduce fuel consumption related to auxiliary power demands.

Truck weight reduction affects fuel consumption by reducing tire rolling resistance and unrecovered energy used when accelerating or grade climbing. The energy required to

overcome resistances is approximately linearly dependent on the weight of the vehicles. Generally for Class 8 trucks, there is more incentive for reducing the vehicle weight for weight-limited trucks, which can replace the reduced tare weight with cargo. For a 35,000 lb tractor-trailer fully loaded with 45,000 lb of cargo, reducing weight by 1,000 lb increases load-carrying capacity by the same amount and therefore reduces payload-specific fuel consumption, expressed in gallons per 1,000 ton-miles, by a little more than 2 percent. Unfortunately, for a volume full (cubed-out) trailer application, the fuel-consumption reduction is only about 0.5 percent per 1,000 lb of tare weight reduction, because payload remains constant (NESCCAF/ICCT, 2009, p. 50). Approximately 60 percent of tractor-trailer loads are cubed-out before grossed out (weight full) (NRC, 2010). Opportunities for fuel efficiency impact vary considerably by truck type and class and duty cycle. Vehicle weight effects are more important for duty cycles with frequent starts and stops (NRC, 2010, Table 5-16). For urban delivery vehicles, a 10 percent reduction in weight can reduce fuel consumption by as much as 7 percent.

Because of budget reductions for the 21CTP, no funding was provided for lightweight materials (other than for propulsion materials) from FY 2007 through FY 2009. However, prior to the FY 2007 budget reduction, there had been numerous projects aimed at vehicle weight reduction. Several projects involving the national laboratories and industry led to useful examples of weight reduction. A complete list of 21CTP projects up to 2007 can be found in the 21CTP Quad Sheets (DOE, 2007).

New Incentives for Vehicle Weight Reduction

The incentive for reducing the weight of weight-limited Class 8 trucks has taken a new urgency as trucks have been adding weight particularly with emissions-compliance devices. Emissions control components have added as much as 400 lb to the typical tractor. Aerodynamic devices are slowly growing in popularity, adding several hundred pounds in some cases, especially trailer devices (the trade-off of adding weight to improve aerodynamics is a good one, because aerodynamic drag is a major contributor to fuel consumption at highway speeds). Weight reduction will be needed to offset other components such as auxiliary power units (~400 lb) added to reduce fuel consumption normally expended during idle. For city buses and urban delivery vehicles, weight reduction becomes important to offset the hybrid systems that many of these vehicles are adding.

Furthermore, the new EPA/NHTSA standards to reduce fuel consumption and greenhouse gas emissions from medium- and heavy-duty vehicles are expected to achieve reductions in CO2 and fuel-consumption from 7 to 20 percent reduction from current, 2010, baselines (EPA/NHTSA, 2011). As selected truck tractor technologies are expected to build on the EPA SmartWay configurations, some weight increase issues will be encountered—for example, with the use of tractor aerodynamic components and idle reduction components.

For these reasons, the 21CTP reinstated funding of the lightweight materials research beginning late in 2010 ($500,000) and into 2011 ($2.12 million) (see Chapter 1, Table 1-2). The FY 2011 budget of $2.12 million will be directed to lightweight materials initiatives for the Super-Truck projects. Several weight-reduction initiatives are funded under the SuperTruck projects themselves.

Weight-Reduction Goals

Weight-reduction goals vary by vehicle; the targets for all vehicle classes range from 10 to 33 percent. For Class 8 tractor-trailer combinations the goal had been from 15 to 20 percent, with the specific goal of 5,000 lb. Recently the goal has been modified. The new goal is a 10 percent reduction in weight for a baseline tractor-trailer tare weight of 34,000 lb (specific goal of 3,400 lb) along with a longer-term stretch goal of 20 percent reduction in weight.

Opportunities and New Initiatives

For a Class 8 truck there are numerous opportunities for reducing vehicle weight by introducing lighter-weight materials, albeit often at a cost premium. The more obvious opportunities lie in the body structure (~19 percent of total tractor weight), the chassis/frame components (~12 percent), and wheels and tires (~10 percent). Truck manufacturers have been substituting lightweight materials for a number of components in the cab, chassis, and wheels. Examples include composite structure in the cab, aluminum panels, aluminum wheels, and aluminum fuel tanks. There are also weight-reduction opportunities afforded by extensive use of aluminum for both tractor and trailer (NRC, 2010, see Figure 5-38).

The Pacific Northwest National Laboratory (PNNL), in cooperation with PACCAR, Novelis, and Magna, is developing an aerodynamic lightweight cab structure.6 The objective is to develop a low-cost forming method using aluminum alloy that allows the use of aluminum instead of steel or other materials. A target of 40 percent weight savings is the objective. PNNL forming equipment will be used, and its impact on corrosion and ability to be painted will be evaluated. The forming technology will be transferred to Magna for the fabrication of a full-scale cab. The project will begin in FY 2011.

As part of the SuperTruck projects, additional lightweight materials initiatives are planned. For example, Navistar, which of the 21CTP industry partners provided the most

_____________________

6 Jerry Gibbs, DOE, “Materials Support for the 21st Century Truck: Lightweighting and Propulsion Materials,” presentation to the committee, November 15, 2010, Washington, D.C.

detail for its weight-reduction effort, plans to explore the following.7

• Use of composites in cab-in-white,

• Use of composites in trailer floor,

• Carbon composite drums,

• Lightweight rotors and aluminum calipers,

• Plastic fuel tanks,

• Single lightweight driveshaft, and

• Aluminum cross-members.

It may also be possible to transfer and expand technical work that had been carried out on light-duty vehicle activities to heavy-truck applications. Two examples were presented to the committee (see footnote 6). The first example involves the potential application of magnesium. Studies at the PNNL and ORNL will explore the possibility of improving the ductility of magnesium and its low-temperature formability. The researchers will also explore the development of new joining methods (magnesium to steel), as conventional automotive joining methods are not applicable to magnesium. Galvanic corrosion limits applications of magnesium currently—the team will explore the application of low-cost ceramic coatings as a solution to this problem.

The second example involves the processing of carbon fiber for composite applications. Although glass-reinforced composites, often in the form of sheet molding compound, have been used in high-volume automotive and in heavy-truck applications for years, higher-performance carbon-reinforced composites have not. The primary obstacle has been the cost of the carbon fiber itself. However, there are other issues associated with the application of high-performance carbon composites. The fabrication process is slow compared with steel stamping processes. Furthermore, assembly is complicated by the fact that joining methods typical of automotive assembly processes are not applicable. Other issues needing resolution include coloration, recycling methods, and the ability to repair damaged parts.

Progress is being made, however, in adapting carbon composites for automotive applications. Indeed, carbon composites have been used for years in the motor-sports industry, and they are more recently finding applications in low-volume specialty automotive products. And, in fact, certain characteristics of carbon composites are superior to conventional steel. Clearly the higher strength and stiffness of carbon composites enable part-to-part weight reduction. Composites offer opportunities for part consolidation as well as the ability to form complex shapes that could not be achieved by steel stamping. Composites are corrosion-resistant. For low volumes, tooling costs can be lower than those typical of metal stamping.

The DOE recently issued a Funding Opportunity Announcement (FOA) that includes opportunities for additional cost-shared research in the area of lightweight materials. It includes additional research in magnesium and carbon-fiber composites.8

Response to Recommendations from NRC Phase 1 Review

Because of severe reductions in the 21CTP budget, no budget was allocated to lightweight materials research from 2007 through 2009. In the NRC Phase 1 report (NRC, 2008), it was recommended (Recommendation 5-2) that scarce budget resources be allocated to projects with higher potential payoff for fuel-consumption reduction (e.g., engine efficiency) than payoff through the application of lightweight materials. Furthermore, the NRC Phase 1 report suggested that it should be the responsibility of the truck manufacturers to take the next steps of system integration, product validation, and production application of lightweight materials.

Finding

Finding 5-9. Several projects that were carried out prior to 2007 have shown the potential for the reduction in weight of individual components and subsystems. However, to date there has been no integrated full-vehicle project to show that the goal of reducing the weight of a Class 8 tractor-trailer by 3,400 lb can be achieved. Moreover, the NRC Phase 1 report had recommended that such a project, using prototype components, vehicle integration, and full-vehicle system analysis, should be carried out by industrial partners—led by original equipment manufacturers. The new SuperTruck program appears to be a response to this suggestion.

Thermal management projects have been coordinated with the DOE Heavy Vehicle Systems Optimization Program. The primary focus has been on increasing cooling radiator capacity without increasing size. Heat rejection and radiator size are issues that have several effects on truck design. Incurring higher heat rejection normally mandates a larger cooling package, which adds weight and cost. The larger cooling package also requires more airflow, and the air passes through the turbulent and restrictive areas under the hood, increasing the vehicle aerodynamic drag. A larger cooling package also requires changes to the shape of the truck’s front, which limits aerodynamic design options and results in increased drag. Because of these factors, lower heat rejection and/or a more efficient cooling system contribute to lower aerodynamic drag, lower truck weight, and potentially lower cost.

_____________________

7 Anthony Cook, Navistar, Inc., “Navistar’s SuperTruck Program,” presentation to the committee, September 8, 2010, Washington, D.C.

8 Financial Assistance Funding Opportunity Announcement, Number: DE_FOA-0000239, December 16, 2010.

Good progress has been achieved by the application of nanoparticle-containing coolants. Nanofluids contain highly conductive particles (1 to 100 nanometers) suspended in liquids to provide significantly increased heat transfer from cooled systems, compared to conventional glycol-water systems. These nanofluid coolant projects were planned for 7-year duration, with completion anticipated in 2012. The nanofluid cooling system work has been managed at the Argonne National Laboratory (ANL), evidently with limited trucking company involvement. Nevertheless, a heavy-duty truck demonstration is planned for the nanofluid coolant project(s). Research status forecasts a radiator size reduction of more than 10 percent (ANL, 2009a, 2010b).

Modeling of underhood cooling airflow has also been pursued. Both technologies were driven by the engine manufacturers’ addition of cooled exhaust gas recirculation (EGR) beginning in 2002 to lower NOx by combustion modification. EGR rates have continued to increase in some of those engines to enable compliance with the latest NOx standard reduction in calendar year 2010. The committee has not found that high-technology cooling radiator designs, coordinated with increased EGR, have been incorporated in heavy truck systems to date. It is noted that there is an ANL project associated with the nanofluid projects, called Efficient Cooling in Engines with Nucleated Boiling. This project is attempting to exploit the fact that the boiling heat-transfer coefficient is more than five times the liquid heat-transfer coefficient. A two-phase boiling heat-transfer regime is sought, then altering the cooling system to manage a continuous gas-liquid condition. Such a two-phase heat-transfer system with a net higher heat-transfer than a conventional nonboiling cooling system further supports the notion to reduce radiator size (ANL, 2009b).

The committee believes that the removal of barriers to production implementation is a key next-step action. The project leaders have listed barriers for nanofluids: adequate heat-transfer coefficient increase, high viscosity of nano-fluids, pumping power increase, and fluid production costs (ANL, 2009a); and for the nucleate boiling radiators: coolant boiling heat-transfer coefficients, coolant two-phase pressure-drop data, and acceptable boiling limits of both critical heat flux and flow instability (ANL, 2009b).

Furthermore, current efforts to achieve a major fuel-consumption reduction by means of the addition of WHR and hybrid electric systems will add yet higher cooling demands on the radiator system. Given the fuel-consumption reduction goal, aerodynamics needs to be improved substantially, and smaller radiators would facilitate changes to the frontal tractor shape for reduced air pressure and aero-friction. Cummins noted in its SuperTruck presentation to the committee that it would address this issue of tractor frontal shape as affected by cooling system capacity/efficiency needs. And the DOE has initiated a new CRADA with Cummins with this intention, reported at the June 2010 DOE Merit Review presentations. There is an associated CRADA with Peterbilt, to optimize coolant boiling to reduce coolant system size and power consumption (ANL, 2010a). This second project could support these same themes but was not reported by the SuperTruck participants. These projects are illustrative of areas in which technology development cost and risk can be managed under the DOE VSST protocol (DOE, 2010a). Further, the Partnership has identified a number of potential topics that might make a big contribution to the breakthrough sought, such as advanced window glazing, concepts for direct heating and cooling of the vehicle occupants, heat-generated cooling techniques, and thermoelectrics (DOE, 2011).

Other next steps appear to be to provide consistent funding to permit nanofluid performance-enhancing discoveries to be tested in truck-cooling demonstrations in aerodynamically efficient trucks, thereby integrating several technologies.

Response to Recommendations from NRC Phase 1 Review

The DOE has continued to emphasize the cooling system nanofluid developments through a series of ongoing projects at the ANL. It has also initiated the two CRADAs noted above: Cooling Boiling in Head Region-PACCAR, Integrated Underhood Thermal and External Aerodynamics-Cummins, VSS004 (ANL, 2010a). The Cummins Super-Truck project will evaluate tractor frontal shape as affected by cooling system capacity/efficiency needs.

The DOE also agreed to find methods to provide status reporting as part of its overall assessment of the Partnership’s processes and progress. The DOE believes that the SuperTruck projects provide a unique opportunity to bring together manufacturers and suppliers for coordinated systems R&D.

Finding and Recommendation

Finding 5-10. Heavy-duty truck thermal management objectives are growing in importance as new systems to improve both engine and truck efficiency, particularly waste heat recovery systems, become reality. These are accompanied by new heat management issues and are expected to be added to trucks in the current decade.

Recommendation 5-6. The Partnership should continue priority support of nanofluid and high-efficiency underhood cooling systems, as well as review other potential technical concepts, and validate them as an integrated system.

The DOE initiated a study focused on developing a comprehensive friction model for engine and drivetrain systems. The project purports to improve existing computational models, which are based only on fluid film lubrication. Noting that most engine and driveling components operate under both mixed and boundary lubrication regimes, a comprehen-

sive model that can adequately predict friction in both sliding and rolling contact regimes is the objective.

Completed work identified that friction at a lubricated interface (especially under the boundary regime) is a complex phenomenon involving the shearing of the lubricant fluid film, the tribochemical boundary films, and the near-surface material. Next steps will attempt to quantify and model all three regimes. The expected 6-year project was begun at the ANL in 2010 (ANL, 2010c). This project is also illustrative of one in which technology development cost and risk can be managed under the DOE VSST protocol. It is noted that no truck OEM companies are yet collaborating with the contractor in this project.

As described in the subsection titled “Lubricants” in Chapter 3, the Engine Manufacturers Association initiated a lubricant project beginning in April 2010 as the EPA/NHTSA GHG/fuel efficiency rule was anticipated. The primary objective is an improved fuel efficiency contribution through implementation of a High Temperature High Shear (HTHS) viscosity property. Early industry testing with HTHS controlled oils has shown promise for fuel-consumption reduction while other parameters continue to provide traditional performance. The notion of this HTHS property is believed to be applicable to drivetrain units as well as engines. This potential should be considered within the projects that the 21CTP considers for friction and wear reduction.

In addressing the committee, two of the SuperTruck presenters indicated that friction reduction was included in their projects. However, it is believed that these efforts are being directed toward engine friction specifically and not to driveline or auxiliaries.

The DOE presented fuel and lubricants development plans to the committee.9 The DOE suggested that it might play a valuable role in developing an understanding of microfluidic transport and tribological film formation. The first project noted above appears to be a good beginning. The DOE cited the long-standing engine and drivetrain friction-reduction needs, anticipating that half of the target improvement might be achieved with engine oil enhancements. The DOE surely can make a helpful contribution, but it will need to become engaged with driveline and auxiliary system developers and manufacturers as well as becoming involved in the heavy-duty-engine-industry oil development process. The 21CTP certainly provides an appropriate forum.

The DOE (2011) white paper identified a list of friction and wear activities that were proposed to begin in 2011 and to be completed in 2018. These activities may well make a needed contribution in this difficult area. A project plan needs to be developed within the Partnership to solidify this list (see below) and begin the work.

• Integration of friction and wear models to reduce powertrain loss,

• Development of advanced coatings for reduced friction and wear, and

• Down-selection and demonstration of engineered surface applications for reduced wear and friction.

Revision of Goal 5 within the new Vehicle Power Demand Orientation

The “friction and wear” component of Goal 5 requires the following: “Develop and demonstrate technologies that reduce powertrain and driveline losses” (DOE, 2011, p. 3). Note that this deals with both powertrain and drivetrain friction.

In Table 5-1, drivetrain load is identified as 6 percent of the demand (50 percent reduction of the load will reduce fuel consumption by 3 percent, assuming unchanged engine BTE). The drivetrain loads are those resulting from engine torque transmitted through units like a transmission(s) and rear axle(s) gearing, and not including auxiliaries or tires, as partitioned in the DOE (2011) white paper. Drivetrain loads derive from windage of gears running in lubricant and friction within components of the geared units.

Goal 5 has been carried over from the DOE (2006) white paper “Parasitics,” which included powertrain components, often referred to as engine accessories, that are needed to operate an engine on a dynamometer and on the EPA Federal Test Procedure (FTP). These are the oil pump, fuel pump, water pump, and any other engine fluid pump (like an EGR pump). Those loads are integral to engine operation contributing to the brake thermal efficiency and not to vehicle power demand. To represent only the power consumptions of vehicle power demand, it is appropriate that the term “powertrain” be removed from the Goal 5.b statement.

There is also a need for an updated study of the current driveline power demand of 12 hp. It is noted that this 12 hp, reported in the most recent white paper (DOE, 2011), is the same value as that in the previous white paper (DOE, 2006) which represented both powertrain and driveline “parasitic” (friction) losses together. The committee expects that the driveline-only power demand (friction) will be significantly revised downward.

Response to Recommendations from NRC Phase 1 Review

The NRC Phase 1 review report (NRC, 2008) estimated that a 50 percent reduction in drivetrain losses would reduce fuel consumption by 1.2 percent. Similarly, that review suggested that a 50 percent reduction in powertrain (engine) friction losses would reduce fuel consumption by 3.7 percent. The two losses sum to about 5 percent, somewhat lower than the stated goal. Further, Recommendation 5-8 from that review suggested that the DOE reassess the technical feasibility of these 50 percent reductions while retaining adequate durability and reliability (NRC, 2008, p. 80).

_____________________

9 Kevin Stork, DOE, “DOE Fuel & Lubricant Technology R&D,” presentation to the committee, November 15, 2010, Washington, D.C.

The Partnership responded that it agreed with the recommendation (see Appendix C), and that each of the three SuperTruck teams will continue the research in these areas of friction, wear, and lubrication in the engine and drivetrain. Both Daimler and Navistar have friction-reduction phases in their projects. The DOE believes that the 50 percent reduction goal feasibility (combined powertrain and driveline losses) will receive reasonably thorough evaluation through the SuperTruck projects. The committee suggests that the DOE will need to be proactive with the SuperTruck contractors to ensure that they allocate adequate resources in order to achieve the expected thorough evaluation.

Findings and Recommendation

Finding 5-11. There is a need for an updated study of the current driveline power demand of 12 hp. Furthermore, to represent vehicle power demand power consumptions only, it is appropriate that the term “powertrain” be removed from the 21CTP Goal 5.b. statement.

Recommendation 5-7. The term “powertrain” should be removed from the 21 CTP Goal 5.b statement. In addition, the Partnership should update its study on the driveline power demand of 12 hp.

Finding 5-12. There has been no apparent collaboration on lubricant projects between the DOE and OEM partners.

OVERALL FINDING AND RECOMMENDATION

Finding 5-13. Summarizing the committee’s findings on vehicle power demands: Project prioritization by the 21CTP roughly follows the consumption ranking of the several heavy-duty truck operating loads listed in Table 5-1 and technology risk. However, sometimes market forces provide considerable impetus for quite good development and implementation—for example, in tire rolling resistance and, to a lesser extent, trailer aerodynamic components. The DOE has identified a strong role in which technology development costs and risks are high, as in its vehicle systems simulation and testing activities for heavy-duty trucks. It has generally followed these principles, to address high cost and risk in the vehicle power demand projects. The SuperTruck projects will provide a unique Partnership opportunity to provide both further high-risk technology results for certain vehicle power demand reductions and real-world validation of numerous integrated systems.

Recommendation 5-8. Although it is tempting to assume that the SuperTruck projects will address all of the technologies required to reduce tractor-trailer fuel consumption, in practice many technologies may be left behind, particularly those that are not yet very mature. The Partnership should carefully review the technologies that have been identified and determine whether any technologies to reduce vehicle power demand are not being adequately addressed by the SuperTruck program. The DOE should define projects and find funding to support the development of technologies beyond the scope of SuperTruck.

Al-Qadi, I. 2007a. New Generation of Wide-Base Tire and Its Impact on Trucking Operations, Environment, and Pavements. Transportation Research Board 86th Annual Meeting. Paper No. 07-2432. January 21-25. Washington, D.C.

Al-Qadi, I. 2007b. Impact of Wide-Based Tires on Pavement and Trucking Operation. Presented at the International Workshop on the Use of Wide-Base Tires, Federal Highway Administration, Turner-Fairbank Highway Research Center. October 25-26. McLean, Virginia.

AM (ArvinMeritor, Inc.). 2010. Product Information Letter #515, Rear Drive Axle Application Guidance and Recommendations for Single Wide-Base Tires Mounted on Outset Wheels. January. Troy, Michigan.

ANL (Argonne National Laboratory). 2009a. Nanofluid Development for Engine Cooling Systems. Available at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2009/vehicles_and_systems_simulation/vssp_21_timofeeva.pdf.

ANL. 2009b. Efficient Cooling in Engines with Nucleated Boiling. Yu. Project VSSP_14_Yu. May 19.

ANL. 2010a. CRADAs: Cooling Boiling in Head Region—PACCAR, Integrated Underhood Thermal and External Aerodynamics-Cummins. Routbort. VSS004, June, 8.

ANL. 2010b. Erosion of Radiator Fluids by Nanofluids. Department of Energy. Available at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2010/propulsion_materials/pm008_routbort_2010_o.pdf. Accessed May 5, 2011.

ANL. 2010c. Friction Modeling for Lubricated Engine and Drivetrain Components. Ajayi. June. Available at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2010/propulsion_materials/pm026_ajayi_2010_p.pdf. Accessed June 1, 2010.

ARB (Air Resources Board). 2008. Final Regulation Order to Reduce Greenhouse Gas Emissions from Heavy-Duty Vehicles. Available at http://www.arb.ca.gov/regact/2008/ghghdv08/ghgfro.pdf. Accessed May 5, 2011.

ATA (American Trucking Association). 2007. New Generation Wide Based Single Tires. Position Paper, Brian Routhier, Revision 9, December 21.

ATDynamics. 2010. Four East Coast Trucking Fleets Put TrailerTails® on Tractor-Trailers to Reduce Fuel Consumption in Advance of the Holiday Season. Arlington, Virginia. Available at http://www.atdynamics.com/trailertail_faq.htm. Accessed January 1, 2011.

DOE (U.S. Department of Energy). 2006. 21st Century Truck Partnership Roadmap and Technical White Papers. Doc. No. 21CTP-003. December. Washington, D.C.

DOE. 2007. 21st Century Truck Partnership. Project Quad Sheets. Doc. No. 21CTP-004. February. Washington, D.C.

DOE. 2010a. Effort to Reduce Truck Aerodynamic Drag Through Joint Experiments and Computations. Project No. V5506 (K. Salari, Principal Investigator). November. Washington, D.C.

DOE. 2010b. Vehicle System Simulation and Testing. Multi-Year Program Plan, 2011-2015. December. Washington, D.C.: Vehicle Technologies Program.

DOE. 2011. White Paper Draft on Vehicle Power Demands. Washington, D.C.: Office of Vehicle Technologies.

EPA (Environmental Protection Agency). 2011. SmartWay Transport Verified Technologies. Available at http://www.epa.gov/smartwaylogistics/transport/what-smartway/verified-technologies.htm. Accessed April 20, 2011.

EPA/NHTSA (Environmental Protection Agency/National Highway Traffic Safety Administration). 2010. Greenhouse Gas Emissions Standards and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles. EPA-HQ-OAR-2010-0162. NHTSA-2010-0079. FRL-9219-4. November 30.

EPA/NHTSA. 2011. Greenhouse Gas Emissions Standards and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles. Federal Register, Vol. 76, No. 179, September 15. Available at http://www.nhtsa.gov/staticfiles/rulemaking/pdf/cafe/2011-20740.pdf.

Navistar. 2008. Navistar Awarded Department of Energy Funding to Develop Aerodynamic Trailers. Available at http://ir.navistar.com/release detail.cfm?ReleaseID=354505.

NESCCAF/ICCT (Northeastern States Center for a Clean Air Future/International Council on Clean Transportation). 2009. Reducing Heavy-Duty Long Haul Combination Truck Fuel Consumption and CO2 Emissions. Miller, ed. October.

NRC (National Research Council). 2008. Review of the 21st Century Truck Partnership. Washington, D.C.: The National Academies Press.

NRC. 2010. Technologies and Approaches to Reducing the Fuel Consumption of Medium- and Heavy-Duty Vehicles. Washington, D.C.: The National Academies Press.

ORNL (Oak Ridge National Laboratory). 2009. Effect of Wide-Based Single Tires on Class-8 Combination Fuel Efficiency, Oscar Franzese, Helmut Knee, and Lee Slezak. October 28.

TIAX. 2009. Assessment of Fuel Economy Technologies for Medium- and Heavy-Duty Vehicles. Report prepared for the National Academy of Sciences by TIAX LLC. July 31. Cupertino, Calif.

TT (Transport Topics). 2011. Low Rolling Resistance Tires Gain Traction with Carriers Seeking to Save Fuel, Money. S. Bennett. June 20.