Appendix D

Assessments of Three Areas of Emerging S&T

The following three assessments, each written by a member of BGST, constitute an experimental qualitative, multi-dimensional view of the global landscape in three areas of emerging S&T—metamaterials, computing performance and synthetic biology, respectively. They are based on a template that was created by BGST. The template is intended to provide a multi-faceted yet brief snapshot of a particular subject area from several viewpoints: technology, international players, national security implications, future problems/avenues of exploration, and significant publications. The views expressed in these assessments belong exclusively to the authors and do not necessarily represent the views of the Committee on Going Global, the Board on Global Science and Technology, or the National Academies.

Appendix D.1

Metamaterials Nan Marie Jokerst Duke University

I. Keywords

Metamaterials (MMs), transformation optics, negative refractive index materials, engineered materials, cloaking, superlenses; Plasmonics and nanophotonics are related areas. Some types of metamaterials: photonic MMs, acoustic MMs, tunable MMs, switchable MMs, bi-isotropic and bianisotropic MMs, chiral MMs, resonator MMs.

II. Issue

Metamaterials are engineered materials designed to interact with and control waves (e.g., electromagnetic, acoustic waves). MMs are artificially structured materials that are periodic, with feature sizes that are less than or equal to 1/10 the size of the wavelength to be controlled. When the wave enters the metamaterial, it interacts with the structure, and the wave can be manipulated. MMs can be used to create materials with a designed permittivity (electrical) and/or permeability (magnetic), thus realizing material properties that do not occur in nature—such as negative index of refraction materials. Transformation optics has created a design toolset for wave media that can utilize MMs.

III. National Security Relevance/Importance

Metamaterials expand the design space for electromagnetic and acoustic materials, and enable far greater manipulation of waves. Areas of impact include: imaging (particularly infrared, visible in the longer term), tailored emissivity of surfaces, optical systems (e.g., superlenses), nonlinear optics (high EM fields in small volume), telecommunication photonics (e.g., 2D waveguide structures), antennas, sensors, power transmission, and solar cells. This is a field that is growing rapidly across the world. MMs have a potential impact on Engineered Resilient

Systems, Electronic Warfare/Electronic Protection, Counter WMD, Autonomy, and Human Systems.38

IV. “Metamaterials” Researchers with High Citation and Publication Counts

The following is a list of lead authors of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “metamaterials” in the title, abstract, or keywords, according to SciVerse Scopus.39

Pendry JB (Imperial College, U.K.); Schurig D (North Carolina State University, U.S.A.); Leonhardt U (University of Saint Andrews, Scotland); Shalaev VM (Purdue University, U.S.A.); Cai W (Geballe Laboratory for Advanced Materials, U.S.A.); Zhang SD (University of Birmingham, U.K.); Valentine J (Vanderbilt University, U.S.A.); Smith DR (Duke University, U.S.A.); and Soukoulis CM (Iowa State University).

The following is a list of the most highly published authors between 2005-2011 (October 2011) containing the terms “metamaterials” in the title, abstract, or keywords, according to SciVerse Scopus. 40 The number of citations is indicated in parentheses.

(81) Eleftheriades GV, University of Toronto, Canada; (63) Alu A, University of Texas at Austin, U.S.A.; (63) Ozbay E, Bilkent University, Turkey; (63) Bonache J, Universitat Autonoma de Barcelona, Spain; (61) Soukoulis CM, Iowa State University; (57) Martin F, Universitat Autonoma de Barcelona, Spain; (56) Kivshar YS, Australian National University, Australia; (56) Engheta N, University of Pennsylvania, U.S.A.; (56) Cui TJ, Southeast University, China; (56) Padilla WJ (Boston College, U.S.A.).

V. Background/Historical Synopsis

Sir John Pendry and David R. Smith are viewed as the early innovators in MMs. Victor Veselago predicted negative index of refraction in 1967; Pendry developed two structures, one that controlled microwave permeability, and one that controlled microwave permittivity, in the late 1990s; and Smith demonstrated negative refractive index in 2000. Cloaking was theorized by Pendry and Smith, and demonstrated by Smith in 2006. Transformation optics design tools for MMs were developed in 2006 by Pendry and Smith. MMs have expanded to THz, infrared, and visible wavelengths. As the wavelength decreases, the feature size of the artificial structures also decreases. Thus, for infrared and visible wavelengths, nanofeatures must be patterned to realize MMs. Losses for metals typically used in MMs at longer wavelengths are “lossy” in the visible. Thus, visible and shorter wavelength MMs are challenging to produce.

_______________________

38 Defense priorities as described in the S&T Priorities for FY 2013-2017 Planning Document, April 19, 2011.

39 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“metamaterials,” 2005-Oct 2011, sorted by citation count (excluded Shevchenko et al. Nature 439(7072):55-59, 2006). Lead authors from the top 10 most cited publications are listed. This list may include more than 10 people when publications have an equivalent number of citations. See references below.

40 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“metamaterials,” 2005-Oct 2011, sorted by publication count. The top 10 most published researchers are listed. This list may include more than 10 people when multiple researchers have equivalent numbers of publications.

VI. Future Options/Avenues of Exploration

Metamaterials can be considered generalized composite materials. The potential impact of MMs can be understood by considering glass or carbon fiber composites—artificially structured media that are often stronger and lighter weight than conventional materials—which have revolutionized structural and mechanical engineering. MMs have the potential to likewise impact waves such as electromagnetic and acoustic waves. MMs have an emerging suite of tools and techniques that provide guidance and precise design methods for electromagnetic, acoustic, and other types of materials that control wave phenomena. MMs are also currently demonstrating highly graded index of refraction materials. The impact and relevance to DoD and national security is not yet realized, but could be transformational. Areas to watch include:

Metamaterial Design – Design techniques for arriving at a homogenized description of an otherwise inhomogeneous collection of objects. The techniques for metamaterial design have been refined over the past decade, but techniques continue to evolve and should be monitored for emerging capabilities that will drive innovation and realization of practical structures.

Metamaterials Fabrication – Once designed, physical metamaterial implementations must be found that enable the conceived designs. Not all metamaterial theoretical designs translate to practical implementation. There is a necessary step of coordinating theory and simulation of metamaterials with available dielectrics and metals, as well as fabrication and manufacturing techniques; realization of structures often requires innovation, experimentation, and iteration.

Metamaterial Integration into Devices – The successful development of devices requires an in-depth evaluation of existing technology. Entry points for metamaterial structures and components into existing technologies can be subtle, and require the fusion of traditional engineering methods with emerging metamaterial designs and structures. MMs face a number of technical challenges, including narrow band operation and polarization sensitivity (more complex designs may address these), as well as losses and small feature sizes (both particularly at optical and shorter wavelengths).

MMs also face a number of more non-technical issues: (1) A broadened definition of MMs by those in related fields who seek funding (e.g., photonic crystals and frequency selective surfaces); (2) Unrealistic short term expectations; (3) The potential to impair U.S. innovation and research through classification of MM research in the U.S.A.; (4) Highly competitive worldwide research, with heavy funding levels abroad.

At microwave and radio frequencies, MM manufacturing technologies are better understood, and the transition to applications is critical. The teaming of MM experts with industrial and DoD system designers is crucial, as the latter have knowledge of system needs and can help to identify areas where MM structures and devices can have an impact. In the THz, radar, infrared, and optical regimes, basic research is necessary into dielectric materials, conductors, structures, and manufacturing methods. Innovations in materials and structures will optimally be led by interactions between MM theorists, materials engineers, and fabrication researchers. Early interaction of these researchers with the component and systems communities will identify the critical aspects for MMs for each application (e.g., does loss matter?).

VII. Snapshot of Global Landscape

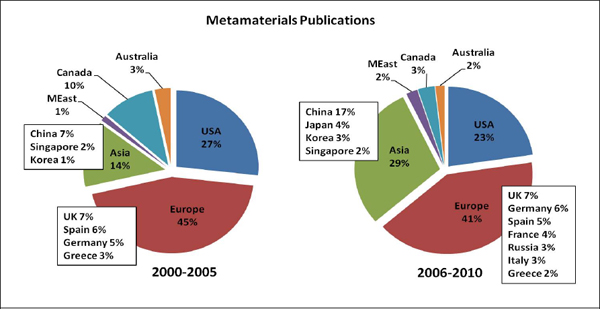

Metamaterials is a rapidly evolving, highly competitive field worldwide. This is demonstrated in the pie charts below, which show the distribution (by country) of the top 10% most cited “metamaterials” papers published between 2000-2005 (left) and 2006-2010 (right).41 While the U.S. and European share of metamaterials publications declined by 4% between the two time periods shown (2000-2005 and 2006-2010), Asia’s % of publications doubled. In particular, Japan, which was not even on the chart between 2000-2005, increased its % of publications to 4% and China’s percentage of publications dramatically increased from 7% to 17%.

VIII. References

The following is a list of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “metamaterials” in the title, abstract, or keywords. The number of citations is listed to the right.

- Pendry JB, Schurig D, and Smith DR. 2006. “Controlling electromagnetic fields.” Science 312(5718):1880-1782. 1530 citations.

- Schurig D, Mock JJ, Justice BJ, et al. 2006. “Metamaterial electromagnetic cloak at microwave frequencies.” Science 314(5801):977-980. 1261 citations.

- Leonhardt U. 2006. “Optical conformal mapping.” Science 312(5781):1777-1780. 857 citations.

- Shalaev VM, Cai WS, Chettiar UK, et al. 2005. “Negative index of refraction in optical metamaterials.” Optics Letters 30(24):3356-3358. 720 citations.

_______________________

41 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“metamaterials” for 2000-2005 (601 total publications) and 2006-2010 (6063 total publications), data by country.

- Shalaev VM. 2007. “Optical negative-index metamaterials.” Nature Photonics 1(1):41-48. 629 citations.

- Cai WS, Chettiar UK, Kildishev AV, et al. 2007. “Optical cloaking with metamaterials.” Nature Photonics 1(4):224-227. 461 citations.

- Zhang S, Fan W, Panoiu NC, et al. 2005. ”Experimental Demonstration of Near-Infrared Negative-Index Metamaterials.” Physical Review Letters 95(13):137404. 407 citations.

- Valentine J, Zhang S, Zentgraf T, et al. 2008. “Three-dimensional optical metamaterial with a negative refractive index.” Nature 455(7211):376-379. 365 citations.

- Soukoulis CM, S Linden. M Wegener. 2007. “Negative refractive index at optical wavelengths.” Science 315(5808):47-49. 318 citations.

- Chen HT, Padilla WJ, Zide JMO, et al. 2006. “Active terahertz metamaterials devices.” Nature 444:597-600. 308 citations.

Appendix D.2

Computing Performance Bernard Meyerson IBM Corporation

I. Keywords

Semiconductors; power density; device scaling; 3D integration; multicore; parallel processing; compiler tuning; quantum computing; hybrid materials; autonomic dispatch; algorithmic workloads; generic accelerators; CMOS evolution; optical integration

II. Issue

A discontinuity of great significance is looming for the semiconductor industry. For the past five decades the United States—and ultimately the global semiconductor community—based much of its progress in information technology (IT) on a sustained evolution of silicon technology. There were countless predictions as to when silicon technology might “run out of gas,” but most such predictions were predicated on an inability to manufacture a given generation of devices due to a perceived, but incorrect, limitation in the ability to define the device lithographically. The impending discontinuity stems from true physical limitations. At the present rate, there are roughly three generations of silicon technology left before lateral dimensions on a silicon chip progress below the onset dimension for quantum mechanical behaviors in silicon itself, essentially terminating progress in silicon technology as we know it today.

III. National Security Relevance/Importance

Information technologies are integral to every aspect of national security, supporting both operational advantage and economic prosperity. The nation that leads in exploitation of IT to translate “data-to-decisions” will have a decisive advantage in operational agility.

IV. Researchers with High Citation and Publication Counts

“Semiconductors and 3D Integration” Researchers: High Citation Counts

The following is a list of lead authors of the most highly cited papers published between 2005-2011 (October 2011) containing the term “Semiconductors and 3D integration” in the title, abstract, or keywords, according to SciVerse Scopus.42

Kikuchi H (University of Tokyo, Japan); Beica R (Semitool Incorporated, U.S.A.); Gagnard X (STMicroelectronics SA, France); Ramm P (Fraunhofer Institute for Assembly and Packaging Technologies for Microsystems, Germany); Pozder S (Freescale Semiconductor, U.S.A.); Loh GH (Georgia Institute of Technology, U.S.A.); Zhang X (State Grid, China); Crnogorac F (Stanford University, U.S.A.); List S (The Research Triangle Park, U.S.A.); and Lee SW (Konkuk University, South Korea).

_______________________

42 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Semiconductors and 3D integration,” 2005-Oct 2011, sorted by citation count (excluded Kastalsky et al. Nuclear Instruments and Methods in Physics Research, Section A 565(2):650-656 and Suga T, ECS Transactions 3(6):155-163). See references, below. Lead authors from the top 10 most cited publications are listed. This list may include more than 10 people when publications have an equivalent number of citations.

“Multicore” Researchers: High Citation Counts

The following is a list of lead authors of the most highly cited papers published between 2005-2011 (October 2011) containing the term “Multicore” in the title, abstract, or keywords, according to SciVerse Scopus.43

Vlasov Y (IBM Corporation, U.S.A.); Kistler M (Pacific Northwest National Laboratory, U.S.A.); Gschwind M (IBM Corporation, U.S.A.); Hill MD (University of Illinois, U.S.A.); Hoskote Y (Intel, U.S.A.); Wentzlaff D (MIT, U.S.A.); Owens JD (University of California-Davis, U.S.A); Che S (University of Virginia, U.S.A.); Geer D (Freelance Technology, U.S.A.); and Donald J (Princeton University, U.S.A.).

“Power Density and Microprocessors” Researchers: High Citation Counts

The following is a list of lead authors of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “Power Density and Microprocessors” in the title, abstract, or keywords, according to SciVerse Scopus.44

Haensch W (IBM Corp., U.S.A.); Donald J (Princeton University, U.S.A.); Pop E (University of Illinois at Urbana-Champaign); Sankaranarayanan K (Ohio State University, U.S.A.); Mahajan R (Intel Corporation, U.S.A.); Schelling PK (University of Central Florida, U.S.A.); Zhou J (Third Military Medical University, China); Chaparro P (Intel Barcelona Research Center, Spain); Puttaswamy K (Intel, U.S.A.); and Colgan EG (Intel Corporation, U.S.A.).

“Semiconductors and 3D Integration” Researchers: High Publication Counts

The following is a list of the most highly published authors between 2005-2011 (October 2011) containing the terms “Semiconductors and 3D Integration” in the title, abstract, or keywords, according to SciVerse Scopus.45 The number of citations is indicated in parentheses.

(4) Beica R, Semitool Incorporated U.S.A.; (3) Kikuchi H, University of Tokyo, Japan; (3) Yamada Y, High Energy Accelerator Research Organization, Japan; (3) Fukushima T, Tohoku University, Japan; (3) Koyanagi M, Tohoku University, Japan; (3) Sharbono C, Semitool Incorporated, U.S.A.; (2) Ritzdorf T, Applied Materials Incorporated, U.S.A.; (2) La Manna A, Interuniversity Micro-Electronics Center at Leuven, Belgium; (2) Beyne E,

_______________________

43 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Multicore,” 2005-Oct 2011, sorted by citation count (excluded Kumacheva et al. Journal of the American Chemical Society. 127(22):8058-8063, 2005 and Olson et al. Journal of Computational Chemistry 31(2): 455-461, 2010). See references, below. Lead authors from the top 10 most cited publications are listed. This list may include more than 10 people when publications have an equivalent number of citations.

44 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Power Density and Microprocessors,” 2005-Oct 2011, sorted by citation count. See references, below. Lead authors from the top 10 most cited publications are listed. This list may include more than 10 people when publications have an equivalent number of citations.

45 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Semiconductors and 3D integration,” 2005-Oct 2011, sorted by publication count. The top 10 most published researchers are listed. This list may include more than 10 people when multiple researchers have equivalent numbers of publications.

Interuniversity Micro-Electronics Center at Leuven, Belgium; (2) Klumpp A, Fraunhofer EMFT, Germany; (2) Reichl H, Technical University of Berlin, Germany; (2) Tanaka T, Tohoku University, Japan; (2) Ruhmer K, SUSS MicroTec, U.S.A.; (2) Cassidy C, Queen’s University Belfast, U.K.; (2) Lu JQ, Rensselaer Polytechnic Institute, U.S.A.; (2) Siblerud P, Semitool Incorporated, U.S.A.; (2) Koppitsch G, Austriamicrosystems AG, Austria; (2) Clavelier L, CEA LETI, France; (2) Liang J, Ningxia University, China; and (2) Stucchi M, Interuniversity Micro-Electronics Center at Leuven, Belgium.

“Multicore” Researchers: High Publication Count

The following is a list of the most highly published authors between 2005-2011 (October 2011) containing the term “Multicore” in the title, abstract, or keywords, according to SciVerse Scopus.46 The number of citations is indicated in parentheses.

(29) Mahlke S, University of Michigan Ann Arbor, U.S.A.; (21) Ayguade E, Centro Nacional de Supercomputacion, Spain; (19) Bader DA, Georgia Institute of Technology, U.S.A.; (18) Fedorova A, Simon Fraser University, Canada; (18) Agarwal A, MIT, U.S.A.; (18) Kandemir M, Pennsylvania State University, U.S.A.; (17) Merritt R, EE Times, U.S.A.; (17) Benini L, Sveuciliste U Zagrebu, Croatia; (16) Dongarra J, University of Manchester, U.K.; and (16) Anderson JH, University of North Carolina at Chapel Hill, U.S.A.

“Power Density and Microprocessors” Researchers: High Publication Count

The following is a list of the most highly published authors between 2005-2011 (October 2011) containing the terms “Power Density and Microprocessors” in the title, abstract, or keywords, according to SciVerse Scopus.47 The number of citations is indicated in parentheses.

(6) Dick RP, University of Michigan Ann Arbor, U.S.A.; (5) Shang L, University of Colorado at Boulder, U.S.A.; (5) Atienza D, Universidad Complutense de Madrid, Spain; (4) Brunschwiler T, IBM Research, U.S.A.; (4) Chrysler GM, Intel Corporation, U.S.A.; (4) Ismail Y, Northwestern University, U.S.A.; (4) Garinto D, Indonesian Power Electronics Center, Indonesia; (4) Mahajan R, Intel Corporation, U.S.A.; (3) Chiu CP, IEEE, U.S.A.; (3) Liu P, Zhengzhou University, China; (3) Tan SXD, Chinese Academy of Sciences, China; (3) Bezama RJ, IBM, U.S.A.; (3) Skadron K, University of Virginia, U.S.A.; (3) Memik SO, Northwestern University, U.S.A.; (3) Ku JC, Samsung Electronics, U.S.A.; (3) Wu W, Capital Medical University, China; (3) Mukherjee R, IEEE, U.S.A.; (3) Jin L, NVIDIA, U.S.A.; (3) Goodson KE, Stanford University, U.S.A.; (3) Lee FC, Virginia Tech, U.S.A.; (3) Sauciuc I, Intel, U.S.A.; (3) Wakil J, IBM, U.S.A.; (3) Mahajan RV, Intel, U.S.A.; (3) Prasher R, Arizona State University, U.S.A.; (3) Yang J, Amgen Incorporated, U.S.A.; (3) Sun J, Virginia Tech, U.S.A.; (3) Gu Z, East China University of

_______________________

46 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Multicore,” 2005-October 2011, sorted by publication count. The top 10 most published researchers are listed. This list may include more than 10 people when multiple researchers have equivalent numbers of publications.

47 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“Power Density and Microprocessors,” 2005-October 2011, sorted by publication count. The top 10 most published researchers are listed. This list may include more than 10 people when multiple researchers have equivalent numbers of publications.

Science and Technology, China; (3) Zhu C, Queen’s University, Canada; (3) Li H, National University of Singapore, Singapore; and (3) Krishnan S, AT&T Laboratories, U.S.A.

V. Background/Historical Synopsis

The historical drivers of progress in the semiconductor industry were a combination of two fundamentals, Moore’s Law, and Classical Scaling. According to “Moore’s Law,”48 silicon technology density must double every 18 months in order to maintain technical and financial viability across the semiconductor industry. This anticipation has proved essentially correct over a six order magnitude range in device densities and a four decade long period of semiconductor achievements.

Additionally, it was understood that the power density of semiconductor technology must be maintained as approximately a constant. This requires halving the power of each component on the chip in exact synchrony with the halving of its area. For the better part of four decades, the entire industry has relied on R.H. Dennard’s49 formulaic approach to achieve constant power density while scaling (shrinking) silicon technology. However, this is only a temporary solution and is ultimately subject to the limits of physical laws.

From its inception, Information Technology was based upon high performance devices known as homo-junction bipolar transistors. While incremental shrinking, both laterally and vertically, of these devices resulted in enhanced performance, physical limitations—for example, increased device leakage due to band to band tunneling—eventually rendered them obsolete. In fact, no systems exist today, nor have there been for almost two decades, based upon bipolar transistors.

Approximately a decade ago, bipolar technology’s successor, CMOS, began to approach a similar set of physical limits. This heralded the end of classical device scaling after being practiced for many decades, ushering in an era of exponentially increasing device complexity as various material and structural “tricks” were implemented to address the inability to further shrink transistors without disastrous outcomes. Despite small gains, these “tricks” have only delayed the inevitable.

VI. Future Options/Avenues of Exploration

Summarized below are three potential areas of investment:

- 3D Integration: We must enable the tight coupling of logic, memory, and optical links in 3D “bricks” if we are to compensate for loss of ability to further conduct planar technology shrinks at the chip level. This may not drive cost down, but provides performance gains via minimized signal path dimensions. Dramatic improvements in optical link cost-performance and integration are required to fully execute this strategy.

_______________________

48 Gordon Moore. 1965. “Cramming more components onto Integrated Circuits.” Electronics 38:114-117.

49 Robert H. Dennard, Fritz H. Gaensslen, Hwa-Nien Yu, V. Leo Rideout, Ernest Bassous, and Andre R. LeBlanc. 1974. “Design of Ion Implanted MOSFET’s with Very Small Dimensions,” IEEE Journal of Solid State Circuits 9:(5)256-268.

- Multi-Core Software Optimization: Current trends toward massive core counts are ineffectual as a long term strategy in the absence of software able to provide performance advantages linear in core count. This remains a fertile area for further research, as it is unclear to what extent one can further drive system throughput in this manner.

-

- Intelligent Software: To date, compiler tuning, as one example, is essentially a manual undertaking by our best and brightest computer science experts. An area of exploration is to exploit “intelligent” software, which upon analysis of a given application’s characteristics, halts and recompiles code to best match software to the available hardware. Autonomic real time tuning of operation, if rendered as effective as manual tuning, is a viable avenue to extract significant performance gains, and opens the door to countless other autonomic software functions.

Other relevant areas include quantum computing,50 hybrid materials, and autonomic dispatch mechanisms51 for algorithmic workloads to generic accelerators.

VII. Snapshot of Global Landscape

Homogeneous 3D integration is well known globally from broad use in flash memory designs to add density by stacking chips, but heterogeneous integration of computing “blocks” with logic, memory, and optical I/O is not practiced yet. A similar common global practice is the development of software to leverage multi-core chips and systems, with applications for systems aimed at High Performance Computing. China and Japan recently announced that software of this class was one enabler of performance records. There is little, if any, global work in the field of self-optimizing software, where “smart” compilation and recompilation, are leveraged to boost system capabilities in real time.

Abortive first attempts at semi-automatic variants have been made, providing software tools enabling the porting of algorithms from central processing units to highly parallel hardware accelerators such as FPGA’s and/or GPU’s, but overall this field is in its infancy. Future efforts will likely focus on finding new means to drive IT performance as classical means—such as raw technology performance—approach the end of their life.

There are many discussions regarding the use of silicon nano-wires, carbon based graphene devices, quantum computing, and all manner of alternatives, but the hard reality is that to compete with silicon, any new technology must achieve integration levels exceeding 10 billion devices. Since no such successor appears on the horizon at present, the question of how one must drive the performance of Information Technology going forward is paramount.

_______________________

50 Quantum computing is defined as utilizing quantum mechanical phenomena (e.g., superposition and entanglement) rather than traditional transistors and digital logic to perform operations on data.

51 Autonomic dispatch mechanisms are highly adaptable and dynamic processes that map messages to a specific sequence of code at runtime (as opposed to other phases of a program’s lifecycle such as compile, link, or lead time). They can similarly dispatch instructions to auxiliary capabilities within a system such as accelerators without need for human intervention/setup.

VIII. References

The following is a list of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “Semiconductor” and “3D Integration” in the title, abstract, or keywords. The number of citations of each article is listed to the right.

- Kikuchi H, Yamada Y, Ali AM, et al. 2008. “Tungsten through-silicon via technology for three-dimensional LSIs.” Japanese Journal of Applied Physics 47(4)Part 2:2801-2806. 18 citations.

- Beica R, Sharbono C, and Ritzdorf T. 2008. “Through silicon via copper electrodeposition for 3D integration.” Proceedings—Electronic Components and Technology Conference, art no. 4550031:577-583. 14 citations.

- Gagnard X and Mourier T. 2010. “Through silicon via: From the CMOS imager sensor wafer level package to the 3D integration.” Microelectronic Engineering 87(3):470-476. 11 citations.

- Ramm P, Wolf MJ, Klumpp A, et al. 2008. “Through silicon via technology –processes and reliability for wafer-level 3D system integration.” Proceedings—Electronic Components and Technology Conference, art no. 4550074:841-846. 10 citations.

- Pozder S, Chatterjee R, Jain R, et al. 2007. “Progress of 3D integration technologies and 3D interconnects.” Proceedings of the IEEE 2007 International Interconnect Technology Conference—Digest of Technical Papers, art no. 4263705:213-215. 9 citations.

- Loh GH. 2009. “Extending the effectiveness of 3D-stacked DRAM caches with an adaptive multi-queue policy.” Proceedings of the Annual International Symposium on Microarchitecture, MICRO pp 201-212. 7 citations.

- Zhang X, Kumar A, Zhang QX, et al. 2009. “Application of piezoresistive stress sensors in ultra thin device handling and characterization.” Sensors and Actuators, A: Physical 156(1):2-7. 6 citations.

- Beica R, Siblerud P, Sharbono C, et al. 2008. “Advanced metallization for 3D integration.” 10th Electronics Packaging Technology Conference, EPTC 2008, art no 4763436:212-218. 6 citations.

- Kikuchi H, Yamada Y, Kijima H, et al. 2006. “Deep-trench etching for chip-to-chip three-dimensional integration technology.” Japanese Journal of Applied Physics, Part 1: Regular Papers and Short Notes and Review Papers 45(4B):3024-3029. 6 citations.

- Cronogorac F, Witte DJ, Xia Q, et al. 2007. “Nano-graphoepitaxy of semiconductors for 3D integration.” Microelectronic Engineering 84(5-8):891-894. 5 citations.

- List S, Bamal M, Stucchi M, et al. 2006. “A global view of interconnects.” Microelectronic Engineering 83(11-12):2200-2207. 5 citations.

- Lee SW and Bashir R. 2005. “Dielectrophoresis and chemically mediated directed self-assembly of micrometer-scale three-terminal metal oxide semiconductor field-effect transistors.” Advanced Materials 17(22):2671-2677. 5 citations.

The following is a list of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “Multicore” in the title, abstract, or keywords. The number of citations is listed to the right.

- Vlasov Y, Green W, and Xia F. 2008. “High-throughput silicon nanophotonic wavelength-insensitive switch for on-chip optical networks.” Nature Photonics 2(4):242-246. 141 citations.

- Kistler M, Perrone M, and Petrini F. 2006. “Cell multiprocessor communication network: Built for speed.” IEEE Micro 26(3):10-23. 139 citations.

- Gschwind M, Hofstee HP, Flachs B, et al. 2006. Synergistic processing in Cell's multicore architecture.” IEEE Micro 26(2):10-24. 137 citations.

- Hill MD and Marty MR. 2008. “Amdahl’s law in the multicore era.” Computer 41(7):33. 124 citations.

- Hoskote Y, Vangal S, Singh A, et al. 2007. “A 5-GHz mesh interconnect for a teraflop processor.” IEEE Micro 27(5):15-61. 120 citations.

- Wentzlaff D, Griffin P, Hoffman H, et al. 2007. “On-chip interconnection architecture of the tile processor.” IEEE Micro 27(5):15-31. 117 citations.

- Owens JD, Dally WJ, HO R, et al. 2007. “Research challenges for on-chip interconnection networks.” IEEE Micro 27(5):96-108. 116 citations.

- Che S, Boyer M, Meng J, et al. 2008. “A performance study of general-purpose applications on graphics processors using CUDA.” Journal of Parallel and Distributed Computing 68(10):1370-1380. 102 citations.

- Geer D. 2005. “Industry trends: Chip makers turn to multicore processors.” Computer 38(5):11-13. 97 citations.

- Donald J and Martonosi M. 2006. “Techniques for multicore thermal management: Classification and new exploration.” Proceedings—International Symposium on Computer Architecture 2006, art no. 1635942, pp. 78-88. 89 citations.

The following is a list of the most highly cited papers published between 2005-2011 (October 2011) containing the phrases “Power Density” and “Microprocessor” in the title, abstract, or keywords. The number of citations is listed to the right.

- Haensch W, Nowak EJ, Dennard RH, et al. 2006. “Silicon CMOS devices beyond scaling.” IBM Journal of Research and Development 50(4-5):339-361. 102 citations.

- Donald J and Martonosi M. 2006. “Techniques for multicore thermal management: Classification and new exploration.” Proceeding—International Symposium on Computer Architecture 2006, art no. 1635942, pp. 78-88. 89 citations.

- Pop E, Singha S, and Goodson KE. 2006. “Heat generation and transport in nanometer-scale transistors.” Proceedings of the IEEE 94(8):1587-1601. 78 citations.

- Sankaranarayanan K, Velusamy S, Stan M, et al. 2005. “A case for thermal-aware floorplanning at the microarchitectural level.” Journal of Instruction-Level Parallelism 7, 16p. 53 citations.

- Schelling PK, Shi L, and Goodson KE. 2005. “Managing heat for electronics.” Materials Today 8(6):30-35. 41 citations.

- Mahajan R, Chiu CP, and Chrysler G. 2006. “Cooling a microprocessor chip.” Proceedings of the IEEE 94(8):1476-1486. 41 citations.

- Zhou J, Xu M, Sun J, et al. 2005. “A self-driven soft-switching regulator for future microprocessors.” IEEE Transactions on Power Electronics 20(4):806-814. 40 citations.

- Chaparro P, Gonzales J, Magklis G, et al. 2007. “Understanding the thermal implications of multicore architectures.” IEEE Transactions on parallel and Distributed Systems 18(8):1055-1065. 35 citations.

- Puttaswamy K and Loh GH. 2007. “Thermal herding: Microarchitecture techniques for controlling hotspots in high-performance 3D-integrated processors.” Proceedings—International Symposium on High-Performance Computer Architecture, art no. 4147660: pp. 193-204. 34 citations.

- Colgan EG, Furman B, Gaynes M, et al. 2007. “A practical implementation of silicon microchannel coolers for high power chips.” IEEE Transactions on Components and Packaging Technologies 30(2):218-225. 31 citations.

Appendix D.3

Synthetic Biology Neela Patel Abbott Laboratories

I. Keywords

Synthetic biology, synthetic genomes, synthetic biology engineering, Do-It-Yourself (DIY) biology/biopunks, biohacking, genetic engineering

II. Issue

Synthetic biology, as defined within this document, ultimately aims to make a complete DNA blueprint for an organism de novo. Currently, our understanding of the biology prevents achievement of the goal e.g.,, control of gene expression and of protein synthesis are still being explored on a single gene basis and are poorly understood on a genome basis. However, major technical advances in the speed and associated cost of DNA synthesis and sequencing, and decreases in the cost of molecular biology equipment have resulted in two parallel and sometimes intertwined research communities manipulating genes in small numbers (genetic engineering) and attempting to do so on larger scales (synthetic biology). Scientists within the research institute community have promoted engagement by youth through iGEM and other means, and have indirectly enabled Do-It-Yourself communities by the publication of large numbers of gene sequences from a variety of organisms. Synthetic biology may be understood to encompass incorporation of non-canonical amino acids, or building completely abiotic systems; however, these variations all rest upon foundations of manipulating DNA as described throughout this document.

III. National Security Relevance/Importance

Genetic engineering and synthetic biology may pose threats and opportunities for national security. From a threat perspective, the DIY movement, while espousing ethical, curiosity-driven goals, has the potential to enable individuals interested in bioterrorism to make life-threatening toxins, viruses, and bacteria with relative ease. In the future, as synthetic biology matures, the permutations become greater and the risk higher. Vendors are currently self-regulating and screen requests for suspicious requests; in 2007, Blue Heron Biotech reportedly received and denied requests for synthesis of a toxin and part of the smallpox genome.52 Alternately, genetic engineering has already resulted in life-saving medications beginning with insulin production in E. coli through monoclonal antibodies, and biosensors for arsenic and other toxins. On the economic security side, synthesis of petrochemical replacements is proceeding via synthetic biology (energy security) and technology applications for synthetic biology may create new industries which cannot yet be specified.

_______________________

52 Bhattacharjee Y. 2007. DNA synthesis. Gene-synthesis companies join forces to self-regulate. Science 22(316):5832-1682.

IV. “Synthetic Biology” Researchers with High Citation and Publication Counts

“Synthetic Biology” Researchers: High Citation Count

The following is a list of lead authors of the most highly cited papers published between 2005-2011 (October 2011) containing the term “Synthetic Biology” in the title, abstract, or keywords, according to SciVerse Scopus.53

Glass JI (J Craig Venter Institute, U.S.A.); Benner SA (Foundation for Applied Molecular Evolution, U.S.A.); Andrianantoandro E (Princeton University, U.S.A.); Stricker J (University of California, San Diego, U.S.A.); Sprinzak D (California Institute of Technology, U.S.A.); Li JWH (University of Alberta, Canada); Bhattacharyya R (University of California, San Francisco, U.S.A.); Alper H (University of Texas at Austin, U.S.A.); Posfai G (Biological Research Center, Hungary); and Hung PJ (CellASIC Corporation, U.S.A.).

“Synthetic Biology” Researchers: High Publication Count

The following is a list of the most highly published authors between 2005-2011 (October 2011) containing the term “Synthetic Biology” in the title, abstract, or keywords, according to SciVerse Scopus.54 The number of citations is indicated in parentheses.

(23) Fussenegger M, University of Basel, Switzerland; (14) Weber W, Swiss Federal Institute of Technology Zurich, Switzerland; (14) Weiss R, Columbia University, U.S.A.; (14) Benner SA, Foundation for Applied Molecular Evolution, U.S.A.; (12) Collins JJ, Boston University, U.S.A.; (12) Jaramillo A, Ecole Polytechnique-Palaiseau, France; (11) Keasling JD, University of Missouri-Columbia, U.S.A.; (11) You L, Duke University, U.S.A.; (10) Zhang YHP, Virginia Tech, U.S.A.; and (10) Krasnogor N, Universita degli Studi di Catania, Italy.

V. Background/Historical Synopsis

Synthetic biology is a logical next step building on genetic engineering by attempting to make gene-encoding and gene-controlling DNA segments into building blocks to be used as a “parts” kit. The first example of commercially applied genetic engineering was the production of insulin by bacteria in 1979.55 Subsequently, the molecular biology tools of DNA synthesis, sequencing, and replication were used for a variety of purposes from the production of enzymes for dying and for softening blue jeans (Genencor), to medicines (biotech and most pharma companies),56 to bacteria for bioremediation. Beginning in 1989, the Human Genome Project spurred the

_______________________

53 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“synthetic biology,” 2005-October 2011, sorted by citation count. See references, below. Lead authors from the top 10 most cited publications are listed. This list may include more than 10 people when publications have an equivalent number of citations.

54 Methodology: SciVerse Scopus. Search term: TITLE-ABS-KEY=“synthetic biology,” 2005-October 2011, sorted by publication count. The top 10 most published researchers are listed. This list may include more than 10 people when multiple researchers have equivalent numbers of publications.

55 Goeddel DV, Kleid DG, Bolivar F, et al. 1979. Expression in Escherichia coli of chemically synthesized genes for human insulin. Proceedings of the National Academy of Sciences of the United States of America 76(1):106-110.

56 Lee SY, Kim HU, Park JH, et al. 2009. Metabolic engineering of microorganizsms: general strategies and drug production. Drug Discovery Today 14(1-2):78-88.

evolution of faster and cheaper sequencing technologies; DNA synthesis technologies followed a similar path. Today, relatively long (1 kilobase pair) DNA sequences can be ordered commercially for <$0.35/base pair, compared to short sequences (30-50 bp) sequences at a cost of $25/bp 10 years ago. Similarly, sequencing costs have dropped from ~$0.25/bp to $0.00000317/bp.57 Community labs and even garage labs are now relatively inexpensive to furnish with second-hand basic molecular biology equipment, thanks to the high level of churn within the biotech/pharma industry. In the late 1990s, scientists with engineering backgrounds such as Randy Rettberg began to view DNA segments as building blocks for making new things and have been pushing the field towards the goal with BioBricks and BioFab. Despite the hoopla surrounding the May 2010 publication by Gibson et al of an artificially synthesized 1.08 mbp M. mycoides genome,58 the absence of fundamental understanding of control of gene and protein expression on a genome/organismal level poses a key impediment to the development of synthetic biology. From the physical engineering side, challenges remain to accurately assemble large numbers of DNA segments in the desired order, and once assembled, to faithfully replicate them.

VI. Future Options/Avenues of Exploration

While the full promise (and threat) of synthetic biology will require a deep understanding of networks, pathways, and chromatin structure and function, commercial applications will be enabled with intermediate stage tools such as the ability to co-express moderate numbers of proteins in bacteria. Today genetic engineering techniques are commonplace in the pharma/biotech and cleantech sectors which use individual gene scale approaches. Closer to synthetic biology, co-expression of multiple enzymes for production of biofuels, for example, is under way. Current levels of technology and equipment are also sufficient for biohackers and for potential bioterrorists to make bacteria that express particular proteins. Genome scale synthetic biology will require overcoming several barriers. While no single robust normative method has emerged for the concatenation and replication of large DNA segments, multiple techniques are being developed and tested.59 Genome scale experiments in bacteria lie in the distant future, with genome scale experiments in eukaryotes even farther off due to the complexity of gene regulation in higher organisms. Synthetic biology on a designed genome scale will require large scale experiments and analysis to build foundational knowledge of control of gene expression. Today experiments are conducted on single genes or small numbers; robotics and software to allow larger scale explorations are in development. Some of the more provocative methods to circumvent the issues facing de novo design are partially directed genome scale mutation and selection60 and the development of libraries of well-characterized DNA segments (so called BioBricks) to be used in the manner of Legos. The latter still suffers from the limitation of not knowing how multiple segments will interact both at the DNA level as well as protein expression levels. Research in the area of systems biology will eventually yield insights which may be

_______________________

57 Baker M. 2011. “Synthetic genomes: The next step for the synthetic genome.” Nature 473(7347):405-408.

58 Gibson DG, Glass JI, Lartigue C, et al. 2010. “Creation of a bacterial cell controlled by a chemically synthesized genome.” Science 329(5987):52-56.

59 Ellis T, Adie T, Baldwin. 2011. “GSDNA Assembly for synthetic biology: from parts to pathways and beyond.” Integrative Biology (Cambridge). February 8;3(2):109-118.

60 Wang HH, Isaacs FJ, Carr PA, Sun ZZ, Xu G, Forest CR, Church GM. 2009. “Programming cells by multiplex genome engineering and accelerated evolution.” Nature 460(7257):894-898.

applied to synthetic biology. However, systems biology is itself an emerging area and may lag behind our abilities in synthetic biology.

VII. Snapshot of Global Landscape

While true “synthetic biology” currently requires the scale and technical prowess embedded in conventional research labs (i.e., government funded), basic genetic engineering is rapidly becoming available to those outside the realm of large research labs via the DIY/ biohacker movement. For synthetic biology, while the United States (in particular MIT, Harvard, Stanford), is currently in a leadership position, ex-U.S. institutes are now on par with them (e.g., ICL, London), and the next generation of scientists is appearing throughout the world as evidenced by the origin of teams entering and winning the iGEM contest for undergraduates. From 2004-2010, countries of origin included Brazil, Peru, Columbia, Panama; Canada, the United States, and Mexico; China, Japan, Singapore, Australia, and New Zealand; South Africa, India; all Western European countries and some eastern European countries. The Grand Prize winning teams over the past five years have come from Slovenia (three times), Bejing, and Cambridge. To date, it appears that the DIY movement has nodes throughout North America and Europe, with a scattering of sites in Australia and New Zealand. It is unclear whether the movement will be able to spread into other parts of the world. Currently, the same infrastructure challenges that slow S&T generally in the developing world would also prevent the DIY movement from taking root there—poor roads, erratic mail delivery, limited electricity, access to the sequences available on the Internet, and so forth. Rather, scientists in those countries are likely to be working within universities where some of the challenges are addressed systemically. In countries where S&T are on the rise within political systems that tightly control access to information such as China, it would be surprising if a DIY movement could emerge as there would be significant impediments to self-organizing via the internet and to obtaining equipment and reagents without state detection. Both the evolution of synthetic biology worldwide and the promulgation of genetic engineering throughout western societies are worth monitoring. At the 5th annual Synthetic Biology conference held in June 2011 at Stanford (SB5.O, sponsored by the BioBricks Foundation), U.S. government representatives included Theresa Good (NSF), Alicia Jackson (DARPA), and Linda Chrisey (ONR). Previous meetings of SB were held in Berkeley (CA, U.S.A.), Hong Kong, and Zurich.

VIII. References

The following is a list of the most highly cited papers published between 2005-2011 (October 2011) containing the terms “Synthetic Biology” in the title, abstract, or keywords. The number of citations of each article is listed to the right.

- Glass JI, Assad-Garcia N, Alperovich N, et al. 2006. “Essential genes of a minimal bacterium.” Proceedings of the National Academy of Sciences of the United States of America 103(2):425-430. 234 citations.

- Benner SA and Sismour AM. 2005. “Synthetic biology.” Nature Reviews Genetics 6(7):533-543. 198 citations.

- Andrianantoandro E, Basu S, Karig DK, et al. 2006. “Synthetic biology: New engineering rules for an emerging discipline.” Molecular Systems Biology 2, art no. msb4100073:2006.0028. 175 citations.

- Sprinzak D and Elowitz MB. 2005. “Reconstruction of genetic circuits.” Nature 438(7067):443-448. 160 citations.

- Stricker J, Cookson S, Bennett MR, et al. 2008. “A fast, robust and tunable synthetic gene oscillator.” Nature 456(7221):516-519. 160 citations.

- Li JW-H and Vederas JC. 2009. “Drug discovery and natural products: End of an era or an endless frontier?” Science 325(5937):161-165. 147 citations.

- Bhattacharyya RP, Remenyi A, Yeh BJ, et al. 2006. “Domains, motifs, and scaffolds: The role of modular interactions in the evolution and wiring of cell signaling circuits.” Annual Review of Biochemistry 75:655-680. 136 citations.

- Alper H, Fischer C, Nevoigt E, et al. 2005. “Tuning genetic control through promoter engineering.” Proceedings of the National Academy of Sciences of the United States of America 102(36):12678-12683. 123 citations.

- Posfai G, Plunkett III G., Feher T, et al. 2006. “Emergent properties of reduced-genome Escherichia coli.” Science 312(5776):1044-1046. 121 citations.