Panel V

Building the Battery Workforce

Moderator: Bill Harris Science Foundation Arizona

The Michigan Economic Development Corp. deserves a lot of credit, said Mr. Harris, who prior to Science Foundation Arizona directed Science Foundation Ireland and served at the National Science Foundation for 18 years. “Looking at this from a distance, what you all are doing and what this state is doing is impressive,” Mr. Harris said. “What we have to figure out as a country is how to seriously work together to build these capacities and build this future. Otherwise, we will struggle going forward.”

Previous panels discussed political and industrial leadership, Mr. Harris noted. This panel addressed the workforce needed for an advanced battery industry. “One of the key aspects of the process is the 21st century workforce,” he said. “And I think everyone here knows the country is struggling with a K-12 education system that is weak.”

The U.S. used to lead the world in producing people with advanced degrees, Mr. Harris noted. It also “used to be thought of as the best engineering country in the world,” he said. “Now we wonder across the country whether our kids can add and subtract.”

This panel features a company that deals with workforce issues and a professor who deals with the production of students, Mr. Harris explained. “Hopefully, we can engage in a conversation about whether these things are matching up properly,” he said.

The first speaker was Robert Kamischke, the chief financial officer and chief information officer of lithium-ion battery storage systems manufacturer EnerDel. One thing he liked about Mr. Kamischke’s background, Mr. Harris said, is that he was an executive of General Motors’ EV1 electric car program in the 1990s. “Years ago, I had the privilege of driving that little car, liking it a lot, reading the book about it, and seeing it towed away,” Mr. Harris said. He said he hoped Mr. Kamishcke will be able to comment on whether the U.S. electric-vehicle program is now on the right track and about the workforce.

The next speaker, Simon Ng, “has a whole list of titles,” Mr. Harris said, “but I think the one he probably likes best is distinguished faculty fellow and professor of chemical engineering and material science.” At Wayne State University, Mr. Ng also is director of alternative energy technology, director of a national bio-fuels energy laboratory, and interim associate dean for research.

WORKFORCE NEEDS AND OPPORTUNITIES

Robert Kamischke EnerDel

Mr. Kamischke noted that this is his “second time around” in the movement to electrify the transportation sector. “When the opportunity came to join again, I asked myself why I would do that,” he said. “I felt it was compelling that we should work toward energy independence for our nation. Secondly, I was very interested in helping create a sustainable manufacturing base for our country.”

EnerDel is more than just an advanced battery manufacturer, Mr. Kamischke said. EnerDel is “a complete lithium-ion solutions provider,” he explained. The company is a fully owned subsidiary of Ener1. Its other subsidiaries are EnerFuel, a developer of low-temperature proton exchange membrane (PEM) fuel cells, and NanoEner, which develops processes for applying active materials on electrodes.

The company’s key partners include the Department of Defense, the Energy Systems Network based in Indianapolis, Argonne National Laboratory, Purdue University, Rose-Hulman Institute of Technology, the U.S. Advanced Battery Consortium, and Japan’s Itochu. EnerDel supplies customers in consumer electronics, transportation, industry, power-generation, and the military, he explained. They include Nissan, Volvo, TARDEC, AC Transit, Think Automotive, and Portland General Electric.

EnerDel has built the first commercial high-volume cell fabrication plant in the United States, Mr. Kamischke said, thanks in part to $118.5 million in federal money through the Recovery Act. The plant was set to open in the fourth quarter of 2010. In November 2009, it was awarded a contract by TARDEC to work on the Humvee. It began commercial production of battery-pack systems for Think Automotive in May 2010.

Success in vehicle electrification will have important benefits for the U.S., Mr. Kamischke said. He noted that the transportation sector accounts for 70 percent of the U.S. trade deficit. Light-duty vehicles represent 40 percent of annual U.S. oil consumption, which is about 25 percent of the U.S. trade deficit. “The U.S. is not the only country that imports more oil than it produces,” he pointed out. “China imports more than 52 percent of the oil it uses, and you can see the urgency with which they are moving toward electrification of their transportation sector to mitigate that.” Oil price volatility is another problem for the U.S. If one compares oil prices to electricity prices, oil is seven times more volatile, Mr. Kamischke noted.

EnerDel is “very appreciative” of what the U.S. and European governments have done to support vehicle electrification, he said. The company is selling the first auto applications of its batteries in Europe to Think Automotive. That Swedish company soon plans to assemble its electric vehicles in the U.S.

The workforce needs of the advanced battery industry vary across the supply chain. In electrode manufacturing, skilled workers are needed for the mixing, coating, calendaring, and slip-punch processes, Mr. Kamischke explained. To make cells, they are needed for the dry room, electrode-stacking, assembly, and formation processes. Skilled workers also are required for pack assembly and testing. The training and education requirements for manufacturing positions range “all the way from high-school degrees to Ph. Ds.,” he said.

Engineers will require four-year degrees, while some working in areas such as advanced materials, chemicals, modeling, and simulation will need advanced degrees, he said. The company also will need engineers to design electrical circuits, mechanical systems, and software to run the systems. The U.S. skills gap mainly is with advanced-material and chemical engineers, he said.

Most of EnerDel’s workforce, however, will be in “middle-skill” operations work, Mr. Kamischke said. The ratio of middle-skill to high-skill workers, in fact, is around five-to-one. In some of the more demanding manufacturing processes, such as with cell and electrode fabrication, EnerDel will look for workers with two-year applied sciences degrees. “They will be focused on the industrial technology path, advanced manufacturing, or engineering technology,” he said.

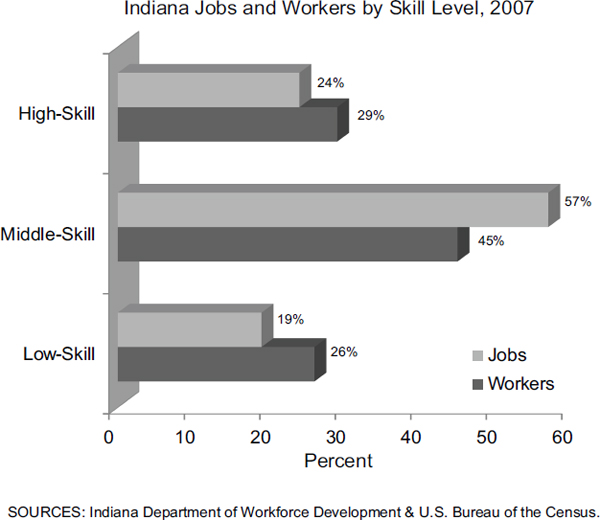

Demand for “middle skill” workers may exceed supply. Currently, 56 percent of demand for workers in Indiana falls in this category. This ratio is likely to remain stable through 2016, Mr. Kamischke said. However, only 45 percent of Indiana’s workforce qualifies as “middle skill.”33 “We have demand for those jobs outstripping the workers,” he said. “This is one area of concentration EnerDel is working to solve with the state of Indiana and our educational institutes.”

Compared to the rest of the nation, Indiana has a relatively low percentage—less than 40 percent--of adults aged 25 to 64 who have at least an associate’s degree, Mr. Kamischke said. Indiana ranks ahead of only West Virginia, Louisiana, Nevada, and Tennessee. 34

An innovative Indiana community college called Ivy Tech is working to resolve this gap. Ivy Tech has 23 campuses across the state and 130,000 students. “As we see it, Ivy Tech will be part of the backbone of building this emerging middle work force for the renewables age,” Mr. Kamischke said. “They are proactively teaming up with industry to create the workforce to meet this new demand.” The school offers an associate’s degree in applied science, for example, with focuses on industrial technology, advanced manufacturing, and engineering technology.

______________________

33 Data from Indiana Department of Workforce Development and U.S. Census Bureau.

34 Data from Indiana Cluster Skills Labor Market Monster Study.

FIGURE 13 Supply and demand for middle skill jobs.

SOURCE: Robert Kamischke, Presentation at July 26-27, 2010 National Academies Symposium on “Building the U.S. Battery Industry for Electric Drive Vehicles: Progress, Challenges, and Opportunities.”

Ivy Tech also is offers new degree concentrations for emerging industries. Indiana has one of the largest wind farms east of the Mississippi, for example, located off I-65 near Chicago, Mr. Kamischke noted. So Ivy Tech and the state are setting up degree programs in electric-line construction, power-plant technology, natural-gas technology, utility-scale wind turbines, and home-integration technology for auditing residences and tailoring solutions to save energy and reduce cost.

For the transportation sector, Ivy Tech is establishing curricula for electric vehicles, recycling, and first-responder training. A DOE grant helped fund this effort, he said. Ivy Tech also is working to develop a nationally recognized certificate for electric transportation technicians. There also will be a need for specialists in reusing and recycling batteries for other uses. Mr. Kamischke noted that there will be many more batteries than vehicles on the road as

electrification expands. “There is going to be a need to refurbish and rehab that battery pack for another vehicle or grid application,” he said.

Such training efforts are needed to keep America competitive, Mr. Kamischke said. “As other nations explore green-technology solutions, America must focus on broadening our education opportunities for young adults in science and manufacturing technology,” he said. Continued investment in advanced transportation technologies will create “a rare surplus of jobs in many regions,” Mr. Kamischke said. Therefore, state and federal governments should focus on middle-skill jobs.

TECHNICAL TRAINING AND WORKFORCE DEVELOPMENT

Simon Ng Wayne State University

Dr. Ng opened the session by stating that Michigan’s need to train a highly skilled workforce is obvious. When electric-drive vehicles reach 5 percent to 10 percent of the market, “just imagine the number of skilled workers we will need to fill those jobs,” he said. He also stated a need to re-train other workers in the auto industry so they will understand how to transition from an internal combustion engine to a battery and electric-motor system In addition to automakers, many battery manufacturers are coming to Michigan and they too will need many skilled workers to produce millions of battery packs.

Wayne State is developing a comprehensive set of degree programs aimed at filling anticipated needs for electric-drive technology and batteries. The collaboration with Macomb County Community College and NextEnergy35 is one of three funded by the DOE in Michigan. Guidance for this program is critical, and so the advisory board for Wayne State’s program includes executives from GM, Ford Motor, DTE, TARDEC, AVL, and Compact Power, among others.

The program’s mission is very straightforward. “We want to design a program so that we can prepare our current and future workforce with the education and skills necessary for the advancement and maintenance of electric-drive vehicles,” stated Dr. Ng. Wayne State dubs its program E3, which stands for electrification, economy, and education; it is about electrifying the economy and educating the workforce

Wayne State’s offerings include a master’s degree in electric-drive vehicle engineering and a bachelor’s in electric transportation, Dr. Ng explained. It also offers is an undergraduate concentration and graduate certificate in electric-

______________________

35 Next Energy, launched in 2002, is a nonprofit organization based in Detroit dedicated to bringing promising technologies to maturity accelerating commercialization and scale production. It manages research projects in power-generation, transportation, and fuel technologies.

vehicle engineering. Many technician-level operators also are needed and Wayne State’s partner, Macomb Community College, offers an associate degree program in automotive technology and electronic engineering technology.

To design the curriculum, Wayne State relied on input from the electric-vehicle industry and OEMs. It also studied best practices in electric vehicle-related curricula from around the world. Dr. Ng recently visited key Chinese universities and noted that China is putting a tremendous amount of investment in industry and universities. It became apparent that, in looking at their universities and infrastructure, China is determined to train and prepare their workforce for the electric-vehicle industry. Dr. Ng noted that the Obama administration recognized the importance of workforce development and invested in higher education in developing electric vehicle education programs. Without this investment, the U.S. might otherwise lose its leadership position in the critical electric vehicle industry.

After obtaining initial data, the next step was to design a cohesive set of graduate, undergraduate, and technician-level courses. Making sure all courses contain interactive laboratory modules was another priority. “After all,” Dr. Ng stated, “we are engineers. We learn by doing things.”

The degree programs are being implemented with synchronous and asynchronous web-based distance-learning technology, with the anticipation that they will have a national impact on educational programs. The curriculum will be validated by industry, with the expectation that the degree programs will become accredited at some future date.

One objective of the program is that it be comprehensive. “As you all know,” stated Dr. Ng, “the electric-drive itself is not just electrical engineering. It is not just mechanical or chemical. We wanted to pull all of these resources together so we involved faculty from electrical, chemical, mechanical, industrial, and alternative-energy technology to make sure we have a comprehensive approach to the curriculum.”

A second objective is to be industry-oriented. The university hosted a workshop with a number of companies to learn what they need for their workforce. In addition, to make sure students have real-life laboratory experience, the program is working with companies to use their laboratories for practice and experiments.

Another objective is to have a broad impact. Therefore, it addresses every level, using a system known as “two plus two plus two.” That means a two-year associate’s degree, two years of engineering technology, and two years of master’s level curriculum, Dr. Ng explained.

Eventually, the program will be translated for distance learning. The school is considering several strategies so that distant-learning students can also gain lab experience. One strategy is to develop simulations that can run experiments. Remote control is another approach. “Online students can be in Texas,” he said. “But they can remotely control the instrumentation and actually run the experiment and analyze results.” Wayne State also may require distant students to come to campus one week per semester to focus on experimentation.

The master’s in electric-drive vehicle engineering program consists of 32 credit hours. There are thesis and non-thesis tracks. Some workers, however, may not have the time or energy to pursue a complete master’s degree. For them, Wayne States offers a graduate certificate program. The certificate requires 12 credit hours, which is equivalent to three courses. “Essentially, they can work and take courses at night so that after a year or so they can receive a graduate certificate,” he explained. The bachelor’s program has 64 credit hours for the third and fourth years.

The electric vehicle-engineering program was launched at the beginning of 2010. It formed an advisory board and launched a Web site in April 2010. All of the degree programs have now been approved by the university, so that the program can begin courses in the fall of 2010, Dr. Ng said.

The E3 workshop conducted by Wayne State drew about 120 attendees, with representatives from 12 universities and community colleges and some 30 companies, Dr. Ng noted. The workshop had three tracks—batteries, vehicle integration, and infrastructure. One clear message from industry for the battery curriculum was that it is necessary to have a fundamental course on electrochemistry. “The way they look at it, you really have to have a system engineering approach, but get down to the molecular level,” Dr. Ng said. “Then there is the cell level, the pack level, then the system level.” Battery recycling and manufacturing were other major needs cited by industry representatives.

A number of new laboratories are being developed for the electric-vehicle program. The energy-storage laboratory is separated into three levels, Dr. Ng explained. Cell fabrication is more at the molecular level. Students learn how to make new materials, as well as how to make cathodes and anodes and how to put a cell together. The next level is to learn to characterize cells and learn different techniques to study subjects like thermal management. Students also study characterization of battery packs and modules in order to prepare them for potentially working for Ford, General Motors, and Chrysler, having considerable experience in testing battery packs.

A second laboratory is dedicated to electric propulsion, where various vehicle drive cycles can be studied. Braking, acceleration, and electronic controls can be simulated for different kinds of hardware and systems. The lab will enable students to engage in hands-on learning and to understand different issues of integrating the vehicles. A third lab allows for experimentation with electronic controls and studying interactions between batteries and electric motors.

The fall 2010 curriculum includes courses on the fundamentals of electric-drive vehicles and battery and battery systems. In infrastructure, there are courses on power electronics and vehicle-charging infrastructure. There are modeling courses for electric vehicles and power trains, as well as courses on design, production, and infrastructure development. A course on energy economics and policy will provide students with a comprehensive understanding of the impact of energy and policy on the development of electric vehicles. An

advanced course on material sciences for batteries is being taught by an expert from General Motors. There also are advanced topics in electric vehicle-control optimization, embedded systems, thermal management, and hydrogen production and storage.