Panel VI-A

Federal and State Programs to Support the Battery Industry

Moderator: Charles W. Wessner The National Academies

THE DEPARTMENT OF ENERGY BATTERY R&D PROGRAM AND GOALS

David Howell U.S. Department of Energy

A lot has happened in the Department of Energy recently in the energy-storage area, Mr. Howell said. “If you asked me to describe energy storage at the DOE two years ago, it pretty much would have focused on the vehicle-technology effort,” he said. Since then, significant funds have been allocated through a number of DOE offices and programs.

The DoE’s research for advanced vehicle batteries is run by the Office of Energy Efficiency and Renewable Energy Vehicle Technologies. The Office of Electricity already had been funding about $4 million in research for grid storage, Mr. Howell explained. President Obama has requested boosting that funding to $40 million in Fiscal Year 2011. The Advanced Research Projects Agency-Energy (ARPA-E), meanwhile, funds high-risk research seeking technology transformations in energy storage. The DoE’s Office of Science “has kind of re-entered the game” through chemical research projects relating to batteries.

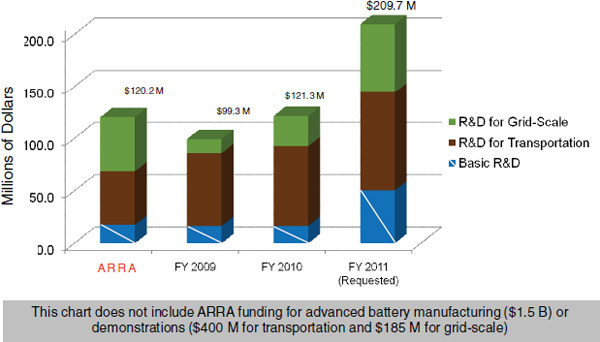

In 2009, the DoE’s R&D budget for energy storage research amounted to around $100 million. Of that, Mr. Howell noted, $76 million went to vehicle technologies. Funding for energy-storage research will grow to $209.7 million under the FY 2011 funding request, with greater portions set aside for areas like the grid. The transportation research budget will get a $20 million increase.

The Recovery Act infused another $120 million into storage-technology research. That sum does not include $1.5 billion in Recovery Act grants for battery manufacturing and $585 million for demonstrations of electrified transportation and grid projects, he noted.

FIGURE 14 Energy storage R&D funding from DOE and Recovery Act.

SOURCE: David Howell, Presentation at July 26-27, 2010 National Academies Symposium on “Building the U.S. Battery Industry for Electric Drive Vehicles: Progress, Challenges, and Opportunities.”

Vehicle-technology research funded by the DOE spans the entire development chain. It includes R&D for advanced materials such as high-energy cathodes and high-voltage electrolytes, high-energy and high-power cells, full system development and testing, and commercialization.

Of the $76 million FY 2010 vehicle-technology R&D budget, $44 million goes to plug-in hybrid electric vehicles, with $15.8 million going to conventional hybrids. The remainder is for “exploratory” research, Mr. Howell explained. Roughly half of funds go to national laboratories and universities for next-generation research. The rest goes to industry, he said.

The DOE has a “documented track record of success” in battery research going back to nickel metal hydride technologies, Mr. Howell said. The agency has worked with lithium-ion development since the late 1990s. Many recent lithium-ion commercialization successes have been supported by the DoE’s U.S. Advanced Battery Consortium program, which includes lab research, diagnostics, and modeling of new materials to help understand failure rates and the electrochemical phenomena of different chemistries, he said. “It’s a full-program effort,” Mr. Howell said. “It culminates, hopefully, in commercialized technology.”

Recent successes have included the high-power lithium-ion battery pack developed by Johnson Controls-Saft for BMW and Mercedes hybrids. Others are the lithium-ion cells that A123 is supplying to Hymotion’s Prius conversion

program and the battery pack Compact Power/LG Chem will supply to the GM Volt.

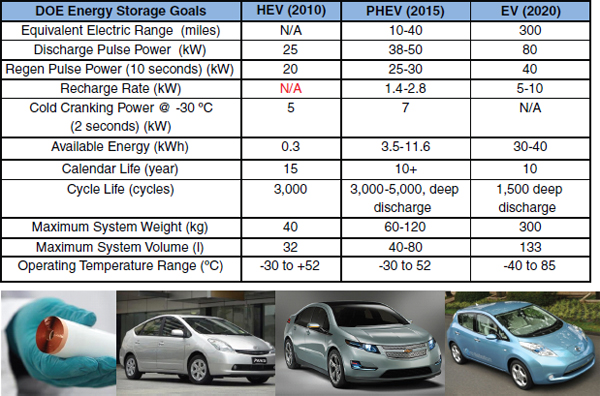

One reason behind this success is that the DOE develops detailed targets with its industry partners in the USABC, Mr. Howell said. “We don’t just suck these things out of our thumb,” he said. “We do a lot of analysis of how batteries operate in a vehicle. Then we come up with a set of performance goals that we manage our R&D projects toward.”

An example of such targets is to develop batteries for hybrids with 25 kilowatt discharge pulse power in 2010. “Auto companies may want 22, 30, or perhaps 40, but the point is this gets us into space of how a battery is supposed to operate in these types of vehicles,” Mr. Howell said. The goal is to push that power to 38 to 50 kilowatts by 2015 from plug-in hybrids and to 80 kilowatts for all-battery electric vehicles by 2020.

The DOE changed its focus in batteries to lithium in 2000 because nickel metal hydride technology was being commercialized, Mr. Howell explained. In particular, the DOE targeted lithium ion for conventional hybrids. “This was pretty much a success story for us,” he said. Most of the lithium ion chemistries that are now mature have been demonstrated to work for 300,000 cycles over a 10-year life, he noted.

FIGURE 15 DOE and USABC battery performance targets.

SOURCE: David Howell, Presentation at July 26-27, 2010 National Academies Symposium on “Building the U.S. Battery Industry for Electric Drive Vehicles: Progress, Challenges, and Opportunities.”

Cost reduction and improved tolerance are top priorities, Mr. Howell said. He said the record of USABC battery programs has been impressive. The cost of a 25 kilowatt hybrid battery pack has dropped by around two-thirds between 1997 and 2007, while densities and calendar lives have more than doubled. “We have increased energy density of these materials while at same time decreased their cost and increased their life,” he said. “One point we often make is that if you are going to reduce the cost of batteries you have to increase their performance at the same time so that you don’t divorce cost from performance.”

Work on plug-in hybrids through the USABC began around two years ago. The first projects are nearing completion, Mr. Howell said. A123 has a contract to develop batteries using nano-phase iron-phosphate, for example. Johnson Controls-Saft, EnerDel, 3M, Celgard, and Entek also have projects underway. The USABC has selected 12 new proposals to develop advanced high-performance storage systems.

Progress also is being made on batteries for plug-in hybrids. Batteries for a plug-in hybrid with a 10-mile range now cost about $2,500. That should drop to $1,700 in 2012. Improvements in cycle time, battery life, weight, and volume also seem to be on track. “But when you go to higher mileage plug-ins and electric vehicles, the targets get a lot tougher,” Mr. Howell said. “So we have to move beyond the next generation of lithium ion to meet the targets.”

The Vehicle Technologies Program does a lot of modeling to understand the main cost drivers for batteries, he said. Three cost models are used. The USABC model is a detailed hardware model to calculate costs for different designs with validated cell performance. “Typically, when I give cost numbers I am using USABC cost numbers,” he said.

Two others, the Argonne and TIAX cost models, assess what is technically feasible for a given chemistry with a given design. These models help researchers understand the impact of cell chemistry on cost, active material costs, and the effect of scale manufacturing.

Under current estimates, a plug-in hybrid battery pack produced at high volumes costs between $700 and $950 per kilowatt hour, Mr. Howell said. The Argonne and TIAX models project that reducing that cost to $300 per kilowatt hour is plausible, he said. Instead of being based on actual validated cell performance, Mr. Howell explained, these models estimate costs for certain technologies “if everything works right.”

These analyses have produced other useful insights. While the costs of active cathode and anode materials are important, for example, they represent less than 15 percent of the total cost of a battery pack for plug-ins with 10- and 20-mile ranges, he said. As one goes up to higher driving ranges, however, the models show “we need to develop materials with higher specific energy,” he said. More materials in the pack remain active, reducing the number of cells required, packing costs, and other factors.

Manufacturing scale also matters. Boosting output from 10,000 batteries per year to 100,000 cuts cost by 30 percent to 40 percent, Mr. Howell said.

Consumer cells, he noted, now cost as low as $200 per kilowatt hour. “At the cell level, very high volume helps you drive down the cost,” he said.

The Vehicle Technology Program also works on materials and processing technologies through a program administered by Oak Ridge National Laboratories. Five contracts and cooperative agreements are underway with A123, Johnson Controls, Dow-Kokam, Planar, and Porous Power Technologies.

In 2009, the DOE began an effort to support suppliers of materials. Angstron Materials and 3M are developing advanced anode materials. Companies like TIAX, EnerDel, BASF, and A123 are working on safety improvements and high-volume, low-cost manufacturing techniques, Mr. Howell explained. The DOE and companies each contribute $17.8 million.

The Vehicles Technologies Program also funds extensive research into many areas of electrochemical cells, with $34 million a year going into 60 projects at 10 national laboratories and 12 universities. National labs include Lawrence Berkeley, Argonne, Sandia, and the National Renewable Energy Laboratory. Universities include MIT, the University of Texas at Austin, the University of Michigan, and the New York state universities at Binghamton and Stony Brook. Ten of those projects are devoted to analyzing and constructing cells. Twelve focus on electrolytes, 15 on advanced cathodes, and five on modeling.

These projects have produced a number of “success stories,” Mr. Howell said. “One of the ways you can gauge success from your universities and labs is whether industry really cares,” he said. Several technologies developed in the program have been licensed to industry, he noted. Toda and BASF licensed composite high-energy cathodes developed at Argonne, for example. Hydro Quebec licensed conductive electroactive polymers developed at the University of Texas, and EnerDel licensed nano-phase and lithium titanate chemistry developed at Argonne.

In future research, the program will concentrate on several key areas. One is high-capacity cathode materials, Mr. Howell said. A request for proposals will be issued in the fall of 2010. Other areas are new solvents and salts that allow for high-voltage electrolytes, high-capacity anode materials, and novel ideas to address problems with lithium metal.

Further funds from the Recovery Act enabled the DOE to beef up laboratory research. Some $20 million went into new facilities. Argonne, for example, got an $8.8 million grant to set up a facility to fabricate battery cell prototypes, scale-up materials production, and conduct post-test analyses. The Idaho National Laboratory, Sandia National Laboratories, and NREL set up testing facilities.

Another $100 million for energy-storage technology came from ARPA-E. Half of that sum went to “transformational” transportation technology research. Six ARPA-E energy storage projects were awarded in 2009. They went to Arizona State University, Envia Systems, FastCap Systems, Inorganic Specialists, Eagle Picher Technologies, and MIT. The Vehicle Technologies

Program and ARPA-E have “very well coordinated efforts” to figure out which space each agency should be in, Mr. Howell said.

For 2010, another 10 projects were selected for ARPA-E grants. They include projects in lithium-air batteries at the Missouri University of Science & Technology, an all-electron battery at Stanford, novel high-energy density lithium-ion cell designs and manufacturing modules at Applied Materials, and high-performance and ultra-low cost rechargeable batteries at MIT. “We’re very excited about this type of activity,” Mr. Howell said. “We do a lot of exploratory research, and we would touch on these areas. But this provides significant funds to increase the likelihood that we could pick up these kinds of technologies over two to three years and carry them into the vehicle technologies area.”

Even if half of these research projects are successful, “that would be a big win for us,” Mr. Howell said. Many of the projects related to technologies at the cell level that would yield more than 400 watt hours per kilogram of capacity. He said his programs tend to focus at the 300 watt-hour per kilogram level, “so it would be a great advance for us if some of these are successful.”

Budgets also have been increased for the Basic Energy Sciences project, which focuses on fundamental materials research and explores electrochemical processes and concepts. “We’re excited about this program too, because a lot of the fundamental knowledge feeding into our exploratory research program hopefully will be coming out of this activity,” Mr. Howell said.

The Basic Energy Sciences Program provides $300,000 for three years to individual investigators or teams. It also funds 46 Energy Frontier Research Centers. Five of those centers “are directly applicable to the work we are doing in the battery R&D area for vehicle technologies,” Mr. Howell noted. They include a project at Cornell to understand and control nano-structured interfaces for energy generation and storage and a center at Stony Brook to study fundamental chemical reactions in electrodes.

The DoE’s Office of Electricity “is really ramping up their energy-storage effort,” Mr. Howell said. Its budget for energy-storage for grid-scale projects shot up from $3.6 million in FY 2009 to $40 million in the requested FY 2011 budget. They include a $14 million project by Primus Power Corp., which is to deploy a wind farm in California’s Central Valley and a $22 million wind-storage project by Duke Energy Business Services. The projects are of “particular interest” to the vehicle technologies program, he said.

Although the DoE’s Vehicle Transportation Program “has a successful track record in developing technologies for commercialization,” Mr. Howell said, he cautioned that “this has taken us a long time.” The program has worked with lithium-ion for more than a decade. “It has taken a lot of effort to bring these technologies to the point where they are now commercially viable,” he said.

Until recently, though, this program operated on a “shoestring budget” of around $25 million a year, he said. With the Recovery Act funds to establish the industry in the U.S. and the increased budgets of different DOE offices, Mr.

Howell said, “we hope it doesn’t take us another decade to get the next generation of chemistries into commercialization.”

DEPARTMENT OF DEFENSE BATTERY R&D PROGRAMS AND GOALS

Sonya Zanardelli U.S. Army Tank Automotive Research, Development and Engineering Center

The U.S. Army is a demanding customer for advanced batteries. “Basically we want a battery that weighs nothing and is very small,” said Ms. Zanardelli, the energy-storage team leader at TARDEC. “We also are looking at reducing logistical and fuel burdens because sometimes those costs can equal the costs of the batteries themselves or more.” The Army wants longer calendar and cycle lives, Ms. Zanardelli explained. TARDEC is issuing new specification for combat vehicles that addresses battery management and performance and operation time.

The team’s mission is to “develop and mature advanced energy storage technologies and transfer them to our vehicle platforms,” she said. TARDEC has in-house testing and evaluation capabilities for various energy-storage technologies, she added, and is able to pre-qualify battery technology readiness levels.

TARDEC works with the Army Research Lab on proofs-of-concept and can take a technology all the way through to the systems level, Ms. Zanardelli said. It then gets technology ready to integrate into vehicles. TARDEC also provides “cradle to grave support” for all Army ground vehicles, she said. It supports all batteries used in the field and writes standardization specifications and maintenance procedures.

TARDEC collaborates with units across the Department of Defense and with other federal agencies. It works with the Communications-Electronics Research, Development, and Engineering Center (CERDEC), which handles all soldier applications. It also works with the Army Research Laboratory, which focuses on basic research, and research centers for the Navy, Air Force, and Marines. A “battery technology working group” comprised of experts in each service convenes four or five times each year “to look at programs across the board so that we don’t have redundancy,” Ms. Zanardelli said. Each service also has battery and material partners in industry.

The DOD and the DoE’s Vehicle Technology Program are developing a memorandum of understanding on vehicle energy efficiency, she pointed out. The MOU will establish a cooperative relationship to identify, develop, and test energy-saving technologies. It will enable TARDEC “to leverage some DOE funding for our applications,” she said.

The technology working group is developing a single rechargeable lithium-ion specification that will be applicable to all DOD components now being created, Ms. Zanardelli said. It will lead to standardization of tests and performance, reduce duplication, and cut the number of chemistries. This effort is to be completed in 2011.

The performance/power and energy requirements for Army vehicles are high. Ground combat vehicles require 45 kilowatts of quality, sustained electric power while they are stationary, Ms. Zanardelli said. Commercial hybrid vehicles require only 5 kilowatt hours and plug-in hybrids 16 kilowatt hours.

The combat vehicles must be able to conduct operations in silent mode while operating combat control systems, sensors, the integrated protection suite, and weapon fire controls for up to six hours or more with no transition delay. A battery-only solution, however, “is still very, very challenging to meet the high-power Silent Watch requirements given the practical battery state of the art and practical vehicle constraints,” she said.

For the Air Force, energy-storage systems are generally restricted by their mass, Ms. Zanardelli said. Its major applications are for aircraft emergency power, small unmanned aerial vehicles (UAVs), and long-endurance UAVs. Small UAVs, she explained, run for eight to 10 hours and use hundreds of watts of power. Long-endurance UAVs must operate 40 to 50 hours and need thousands of watts of power. The Air Force is looking at high-energy fuel cells, high-power batteries, and high power-management converters, she said. “They are looking at this approach to reduce the weight, total life-cycle cost, and to enhance their overall capability,” she said.

Naval vessels mainly have volume restrictions for batteries, Ms. Zanardelli said. The U.S. Navy is looking to use energy storage systems for unmanned underwater vehicles, shallow-water combat submersibles, submarine small distributed power systems, surface ship fuel economy, and surface ship pulsed and high power. Future surface ships will require 0.4 megawatts for active-denial weapons systems, 2 megawatts for laser weapons, and 30 megawatts for an electromagnetic rail gun planned for 2020, she said.

Soldiers also have special battery needs. Soldiers carry up to 100 pounds of gear and as much as 30 pounds of batteries to support mission-essential equipment, Ms. Zanardelli noted. “There is a real challenge to reduce the number of batteries a soldier carries,” she said. CERDEC is looking at fuel-cell batteries and hybrid power sources.

TARDEC sees numerous applications for advanced batteries in ground vehicles. Major applications range from robotics and weapons systems to electromagnetic armor, in addition to applications in vehicles themselves. Most of TARDEC’s advanced-battery resources are going into Silent Watch and starting, lighting, and ignition systems, Ms. Zanardelli said. For starting and lighting, “we basically need the battery to turn the engine on,” she said, so most vehicle platforms require two to four batteries. Up to six or twelve are needed for Silent Watch.

Silent Watch is “one of the most stringent requirements for the Army,” Ms. Zanardelli explained. Batteries supply the power for mission equipment when the main engine is off and the vehicle is stationary. The benefits of Silent Watch and Silent Mobility are that they emit a low thermal and acoustic signature and can provide a means to quickly generate power at peak electrical modes, better fuel economy, reserve power, and silent export power, she said.

TARDEC is looking at the business case for lithium ion in most vehicle platforms, Ms. Zanardelli said. It is looking at 12-volt drop-in replacement batteries compared to 28-volt replacements, for example. “How many pounds are shaved off a vehicle, and at what cost? What performance are we getting? Most of our programs focus on issues like that,” she said.

The challenges with energy-storage technologies receiving the most attention by TARDEC include cell and system safety and reliability, Ms. Zanardelli said. It has developed a process the government and industry can use to make quantifiable measurements for identifying the technical maturity of battery chemistries, she said.

TARDEC has been taking many steps to reduce the cost of batteries through the ManTech program,36 Ms. Zanardelli explained. One manufacturing technology project started in 2004 for Future Cat Systems focused on automating lithium-ion production processes and reducing the cost by half. Now TARDEC is transferring the knowhow to the Joint Light-Tactical Vehicle program, which is using lithium ion, she said.

The Integrated Target Acquisition System Program, which has 1,800 lithium-ion batteries in the field, is tapping this technology. The feedback is good. “The soldiers are happy because they are getting longer duration times,” Ms. Zanardelli said. The batteries are rugged. “They dropped one out of an airplane and it was still intact when it landed,” she said.

The DOD also is trying to improve the power and energy density of lithium-ion batteries by investing in alternative chemistries, new materials, and thermal management research. Ms. Zanardelli said the military has been investing in research and development programs over the past six years to improve Silent Watch, Silent Mobility, hybrid-electric boost power, power for soldier communications, and pulse power for armor, among other things. TARDEC is focusing on ultra high-power battery technology using thin electrodes, she said. It also is researching electromagnetic armor and high power density for survivability technologies.

In all, 60 TARDEC energy-storage R&D projects are underway, Ms. Zanardelli said. They are classified into basic research, applications, manufacturing processes, battery management and safety, and alternative systems. There are cooperative research agreements and SBIR programs.

______________________

36 The U.S. Army ManTech program funds “development of low-risk, affordable technologies for the military. The goal is to improve production cost through product flow improvements, simplifying product design, and reducing labor hours.” Source: http://www.armymantech.com/overview.html

One key basic research project studies the mechanism of “thermal runaway” in valve-regulated lead-acid batteries and is trying to find ways to suppress it. Thermal runaway can cause batteries to overheat and even explode. Currently, such lead-acid batteries are the most widely used in the field, and the Army wants to be able to keep them in vehicles longer, Ms. Zanardelli said.

Among the applied research projects are lithium-ion batteries for Silent Watch and starting, lighting, ignition systems that would replace lead acid batteries. TARDEC is looking at large-format lithium-ion phosphate and nickel cobalt oxide batteries that are lighter, run longer, and offer greater temperature range, she said.

Manufacturing research focuses on trying to improve domestic capability for lithium-ion cells and packs, Ms. Zanardelli said. These efforts concentrate on improving the cells for a 28-volt battery pack and the feasibility of module and pack manufacturing, she explained.

Numerous research projects for battery management and safety are funded in-house and through the SBIR program, she said. They evaluate systems from various manufacturers under cooperative research agreements. A heavy brigade combat team has released battery management specifications for lead-acid batteries in the field.

In terms of alternative systems, TARDEC is conducting research on lithium-titanate hybrid vehicle packs. It also is looking at ultra-capacitors as an option for starting vehicles in conjunction with a battery for Silent Watch, she said.

In summary, Ms. Zannardelli said TARDEC is working with a diversified base of customers and is “actively seeking collaboration” with other government agencies, military contractors, and battery partners.

THE KENTUCKY-ARGONNE NATIONAL BATTERY MANUFACTURING R&D CENTER

Ralph C. Brodd Kentucky-Argonne National Battery Manufacturing R&D Center

Establishment of the new Kentucky-Argonne Battery Manufacturing Research and Development Center is “a new activity that has been a challenging one and very important for the future of our country,” said Dr. Brodd, the center’s director and president of the consulting firm Broddarp.

The University of Kentucky has had a research center for around for 30 years that mainly focuses on carbon materials in coal, Dr. Brodd explained. The center already has been working on ultra-capacitors and been very successful at developing new carbon materials, he said. It also has recently been working with new materials such as grass.

The university recently received $10 million for the new center from the National Institute of Standards and Technology under the Recovery Act and $4 million from the Kentucky state government to build a 36,000-square-foot laboratory for advanced batteries. “We will have a reasonable size laboratory and staff,” he said. Partners are Argonne National Laboratory, the University of Kentucky, and the University of Louisville. “They have all agreed to work together, which is going to be a very interesting exercise,” Dr. Brodd said. “Each has a unique identity. But everyone I have been talking to has been very supportive and has been really interested in seeing the center come to fruition.”

The center’s initial role was to assist Argonne fabricate state-of-the-art lithium ion cells and to qualify the performance of new cell chemistries, Dr. Brodd explained. But the role broadened. It was determined the industry needed a facility to do more complete development work. “If you have a laboratory coin cell37 and try to tell somebody that you have a brand-new material that has these wonderful properties, they will say, ‘Yeah, sure,’” he said. “They know from experience that a coin cell is not always adequate to define a new material. They really want some real-life cells they can use to quantify their performance and see if these new materials will really measure up.”

The center also will develop manufacturing lines. “Up until now, we really have been relying on foreign sources for all of our production equipment,” Dr. Brodd said. “There need to be new concepts and new processes to produce batteries more efficiently and at lower cost. The interesting part for me is seeing an engineering center develop around making lithium ion cells, not just the cylindrical cells you have in your laptops today but things that can power vehicles around the country.”

Kentucky can be cost-competitive in manufacturing such cells for the world market, Dr. Brodd maintained. “In a sense, Kentucky is going to compete a little bit with Michigan,” he said. The space is large enough, however, that “there is no question we can both serve very effectively.”

Dr. Brodd said his personal goal is “to re-establish the United States as a world leader, not only in materials and development but in manufacturing technology and capability.” He said he has “spent a long time thinking about how to make sure we understand the cost structures and effectively manage the system.”

The first goal is to accelerate production of advanced systems and new technologies from national laboratories or universities. “We will be prepared to protect proprietary interests if you have a material you say is unique. We will hold that in strict confidence,” Mr. Broad said. “I think that is one of the key issues when you begin to be a service center.”

The Kentucky-Argonne center intends to generate new opportunities “not only for Kentucky but also for other local and national entities,” Mr. Broad said. It aims to help “close the gap in materials development and cell manufacturing,”

______________________

37 Coin cells refer to a small, round battery formats commonly found in consumer electronics.

he said. “The two need to be together in order for any production process to be successful.”

The center wants to facilitate interactions with industry, universities, and national laboratories to “optimize a good supply chain and develop a viable battery manufacturing industry here in the U.S,” Dr. Brodd said. “We are looking for competitiveness worldwide. I am convinced we can do it if we really want to do it. There is no question in my mind.”

The center will design new cell manufacturing concepts in both the cylindrical and prismatic formats, Dr. Brodd said. It also hopes to engage in new cell designs and fabrication processes that give more efficiency and higher performance in terms of speed, density, and cycle life.

Until now, cycle lives of lithium-ion batteries for notebooks have been very short. One thousand cycles has been deemed plenty. “That doesn’t measure up any more,” he said. “All of the auto companies are talking about 100,000 to 500,000 charge and discharge cycles. It is a new game. The designs of cells have to follow the requirements of the industry.”

The center would like to serve as a “focal point” for new battery development in Kentucky and on a national basis, he said. Construction of the building is expected to begin September 2010 and be ready for occupation in 2011.

A roadmap for advanced batteries also is being developed. The project looks at what technologies are available and industry demands for certain vehicles so that cells can be designed properly. “We are looking at the roadmap to be an ongoing situation, something we would renew every two or three years,” Dr. Brodd said. “As you all know, it has been a very dynamic market in these last several years.”

The roadmap also would identify the infrastructure and technology elements “that are required to develop and maintain a leadership position that we feel we absolutely must generate,” Dr. Brodd said. “We really have to re-establish the United States, not just as a technology interest but as a product interest. The country must have that to succeed.”

DISCUSSION

The moderator, Dr. Wessner, asked Mr. Howell to pretend he were in a Congressional hearing. He asked how Mr. Howell would respond if he were asked: “Isn’t this like picking winners and losers? Shouldn’t you let the market do this?” Dr. Wessner also asked what were the comparable international efforts and how “we stack up against our colleagues and competitors around the world.”

Regarding picking winners and losers, Mr. Howell responded that the Vehicle Technologies Program awards R&D grants in a competitive fashion. “It is the typical process,” he said. “Even with the USABC, we put out a request for initial proposals for a certain area, explain what our requirements are for

successful proposals, assemble a team to evaluate proposals, and make a selection.” Another factor is that the electric-vehicle battery community is fairly small, Mr. Howell said.

The DOE also is “trying open up opportunities for new ideas, even in the research area,” Mr. Howell said. The exploratory research program puts out requests for proposals in a new area each year. In 2009, the topic was electrolytes. In 2010, it was new anode materials. In 2011, the topic will be new cathode materials, he said. The program circulates funding announcements through the usual contracting agencies at the DoE, he said.

Mr. Howell said he plans to issue a major Funding Opportunity Announcement in 2010. “This will be a significant opportunity for industry,” he said. It will target three areas. One topic for batteries will be next-generation chemistries at the cell level approaching 300 kilowatt hours per kilogram, he said. Another will be for low-cost technologies, such as ultra-capacitors, “anything that can drive the cost down in these batteries,” he said. A third topic is design optimization, such as packaging or thermal management technologies that can cut packaging cost.

Over the next few years, Mr. Howell said he is looking to put $45 million of DOE funds into such research. “So there is quite a bit of opportunity for industry to participate in free and open competition.”

In terms of international competition, Mr. Howell noted that Japan obviously is putting a lot of R&D money into lithium-ion batteries for vehicles as well as the grid. The Chinese “are coming on strong, not necessarily with a lot of R&D, but with a lot of start-up companies and government support for commercialization of technologies,” he said.

The Koreans have “some major players” in the battery industry “and the government certainly puts in money to support that industry,” Mr. Howell said. In Europe, “there have been spots of money here and there for research” in electrochemistry, he said. “The Europeans are starting to come on strong in battery development, recognizing how competitive it’s going to be over the next decade.” The Germans and French in particular are investing aggressively.

Dr. Wessner commented that all of these issues should be explored further.

An audience member asked Mr. Howell if there is a timeline for releasing the $45 million funding announcement.

The Recovery Act “has kind of swamped our funding agents,” Mr. Howell replied. “If I don’t have Recovery Act on my first slide then they aren’t going to talk to me this fiscal year.” He said Recovery Act funds must be awarded by September 30, 2010. He said he hoped to publish the funding announcement in late September. “It is important to a lot more than just the battery program,” Mr. Howell said. “Other than that, I really can’t give you any concrete timeframe or date the announcement will be made. But be prepared. I already told you what is in it, and I’m not planning to change that.”

Larry Drzal of Michigan State asked Mr. Howell to explain the $34 million for FY 2011 for a “battery and energy storage hub.”

The project is under the DoE’s Office of Science, Mr. Howell explained, and is similar in concept to an Energy Frontier Research Center, “but obviously a lot larger than that.” He described it as a program “to develop a center or more than one center of R&D in the nation focused on basic electrochemical research.”

To get a better idea of the concept, Mr. Howell suggested looking at several hubs already awarded by the Office of Science. “I don’t expect the structure to be any different than what they’ve awarded in the past,” he said. The President requested that the center focus on energy storage, but he noted that “it is not obvious that this is going to happen at this point.”

Dr. Wessner asked Ms. Zarnadelli of TARDEC whether the Small Business Research Innovation program has been an effective tool for the U.S. Army and whether it provides enough money.

SBIR projects do have enough money, she responded. She said TARDEC has been very successful in getting grants in the battery area, with three topics funded in 2009 and another three approved in 2010. “So we are very successful in SBIR topics and getting Phase I and Phase II funds,” Ms. Zarnadelli said.

Dr. Wessner asked whether there was much pressure for the Army to reduce requirements of battery systems.

“No,” Ms. Zarndelli responded. Assessments are being done on the power of mission equipment, but “some are just necessary,” she said. There also is a new requirement for environmental control, which means air conditioning to keep crews cool. “That and the load needed to cool power electronics are what really are driving these power requirements up,” she said.

Dr. Wessner asked Dr. Brodd of the Kentucky-Argonne Battery Center whether there are “substantial industry partners willing to contribute” to the center. He also asked whether Kentucky would be able to maintain funding given the difficult economic climate and prevailing “short-termism” in the country.

The state of Kentucky can sustain the program, Dr. Brodd replied. The state has agreed to fund the center, and the deans of engineering of Kentucky and Louisville have strongly endorsed it and are enthusiastic about it. “But as things get going it will require help with equipment and things of that nature,” he said, adding that the center probably will be calling on the generosity of David Howell at the DoE.