3

Industrial Production and Use of

MIC at Bayer CropScience

The statement of task calls for an examination of the use and storage of methyl isocyanate (MIC) at the Bayer CropScience facility in Institute, West Virginia. This chapter provides an overview of the history of the plant, with a particular focus on processes relating to MIC and the pesticides it is used to synthesize. Alternative methods of producing these materials are presented in Chapter 5.

HISTORY AND CHARACTERISTICS OF THE SITE

The 460-acre, multitenant Institute Manufacturing Industrial Park is located 9 miles west of Charleston, West Virginia. The facility is on the Kanawha River to the south, abuts Route 25 and Interstate 64 to the north, and the West Virginia State University to the east. Transportation to and from the site is provided by barge, rail (located adjacent to the river), and truck.

West Virginia State University is the oldest extant institution in the immediate vicinity. Established in 1891 as a land grant college, the university enrolls 3,145 students on a 91-acre campus adjacent to the Institute industrial park (U.S. News, 2010). (See Figure 3.1)

Originally home to the Wertz Field Airport, the site was converted to a synthetic rubber production plant by the U.S. Government Defense Corporation during World War II. Originally designed, built, and managed by the Carbide and Carbon Chemicals Corporation (a subsidiary of Union Carbide) and the U.S. Rubber Company, the facility has had a number of owners. Union Carbide Corporation (UCC) purchased the chemical manufacturing operations plant in 1947, which it used to produce a variety of chemicals including butanol, olefins, plasticizers, and acetic acid. The plant also produced some fungicides, although

FIGURE 3.1 Google™ Earth satellite images of the facility at Institute, West Virginia and the surrounding area (accessed April 14, 2012). (a) The region around Institute, West Virginia (b) the Bayer CropScience facility and local area.

SOURCE: Google Earth satellite image: ©Google 2012.

this was initially a small portion of the plant’s operations. In the 1960s, UCC expanded operations, including construction of facilities to produce carbamates and to allow for production of new synthetic intermediates for other companies (Woomer, 2000). Rhône-Poulenc purchased UCC’s agricultural division, including the Institute site, in 1986. In 2000, Aventis (formed by a merger of Rhône-Poulenc and AgrEvo) took over management of the facility. Finally, Bayer CropScience acquired the facility in 2002 (CSB, 2011). Bayer CropScience is a global provider of insecticides, herbicides, and fungicides. Independently operated within Bayer, AG, Bayer CropScience is headquartered in Germany. The company employs about 20,700 workers in over 120 countries (Bayer CropScience, 2011c). The U.S. headquarters are in Research Triangle Park, North Carolina.

In 2008, the facility hosted seven tenants. Bayer CropScience owned and operated 9 of the 16 production units on the site. Two production units, owned by Adisseo and FMC Corporation, were also operated by Bayer. The remaining units were owned and operated by Dow Chemical, Catalyst Refiners, Reagent Chemical, and Praxair, respectively. Bayer employed approximately 85 percent of the 645 workers employed at the facility (CSB, 2011).

HISTORY OF CARBAMATE INSECTICIDE MANUFACTURING

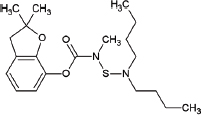

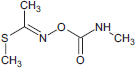

The focus of production at the Bayer plant in 2008 was on carbamate pesticides, which have been shown to be effective against a variety of pests. The general structure of carbamate pesticides is R1NHCOOR2, where R represents alkyl or aryl groups. The facility in Institute manufactured a number of different carbamates over the years. The processes for manufacturing these materials have changed over time, some of which have implications for process safety. What follows here is a description of some of the major changes at the facility, and Appendix B contains a detailed timeline of modifications. The major carbamate products are summarized in Table 3.1.

Carbamate pesticide production in Institute began in the 1960s with carbaryl. Carbaryl is a broad-spectrum pesticide and is used in a variety of commercial and residential settings for control of pests such as beetles, crickets, fleas, ticks, and moths (U.S. EPA, 2004). Production of MIC also began during that decade, although at that time it was only manufactured for use at other facilities and for sale to other companies rather than for use onsite. That changed in 1976 with the production of aldicarb in Institute. Aldicarb had previously been produced in Woodbine, Georgia, and although final formulation and packaging of the material continued at that site, synthesis of the pesticide was moved to Institute. While sharing basic carbamate chemistry with carbaryl, for reasons that are discussed in Chapter 5, production of aldicarb was carried out by a chemical pathway using phosgene and MIC. Aldicarb is primarily used to control nematodes and sucking insects in crops such as cotton, beans, and peanuts (U.S. EPA, 2010). The method for production of carbaryl was changed in 1978 from one that used naphthyl-

TABLE 3.1 Trade Names and Structures of Pesticides Manufactured at the Bayer CropScience Facility

| Pesticide | Trade Name | Structure |

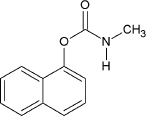

| Carbaryl | Sevin |  |

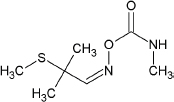

| Aldicarb | Temik |  |

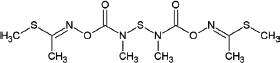

| Thiodicarb | Larvin, CropStar |  |

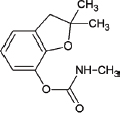

| Carbofuran | Furadan |  |

| Carbosulfan | Marshal |  |

| Methomyl |  |

chloroformate (NCF) as a starting material to one that used MIC. That year also saw the startup of a second, larger MIC unit to provide for the growing demand for aldicarb and changes to carbaryl production.1 In the early 1980s, carbamate

![]()

1 At that time, the facility shipped MIC around the world to customers in France, India, Brazil, and the United States, and to accommodate international demand, Union Carbide built a MIC unit in Bhopal in the late 1970s, with startup in 1980.

insecticide manufacturing was expanded to include methomyl (an intermediate feedstock sold internationally) and thiodicarb (an agricultural insecticide and ovicide used against cotton bollworms and budworms made from methomyl) (U.S. EPA, 1998), both of which required MIC for production.

The MIC and phosgene production units, along with the units that were used to manufacture aldicarb and carbaryl, were all co-located in the East Carbamoylation Complex (ECC). Production units for methomyl and thiodicarb were located in the West Carbamoylation Complex (WCC). The ECC and WCC are highlighted in Figure 3.2. Liquid MIC was stored in underground refrigerated pressure vessels in the ECC where it was manufactured. It was later used as a chemical feedstock there or at the WCC to which it was transferred at night and stored for later use.

On December 3, 1984, in response to the release in Bhopal, the MIC facility in Institute was shut down for several months while Union Carbide installed $5 million worth of safety equipment and enhancements (Los Angeles Times, 1985), which included increased MIC destruction capacity.

However, the Institute site itself suffered an accident on August 11, 1985,

FIGURE 3.2 The Bayer CropScience facility. The circle on the left marks the methomyl production unit, where the aboveground storage tank was located, in the West Carbamoylation Complex. The circle on the right marks the methyl isocyanate production unit in the East Carbamoylation Complex.

SOURCE: Smythe, 2011.

when 4,000 pounds of aldicarb oxime and methylene chloride were released, resulting in 136 people being sent to 5 local hospitals. No fatalities were reported, though 29 individuals were held for observation for one or more days (Houston Chronicle, 1985; Baron et al., 1988).

Following Bhopal, shipments of MIC from Institute to U.S. customers were curtailed. Two of these customers were FMC, a manufacturer of the carbamate pesticides carbofuran and carbosulfan and DuPont. In 1986, FMC built production units for carbosulfan and carbofuran in the WCC (Woomer, 2000). DuPont developed a process for manufacturing MIC as a feedstock that was almost instantaneously reacted into final product, thereby eliminating the need to purchase or store MIC. That same year, 1986, Rhône-Poulenc bought Union Carbide’s Agricultural Products Division.

In 1993 a $50 million Institute modification project carried out various changes to the facility related to MIC, phosgene, and chlorine safety (Ward, 1994). As part of that project, MIC capacity was reduced by more than 80 percent to 22 million pounds per year. This change was largely justified as a consequence of DuPont and other customers no longer requiring the product, which had previously been stored in batches of 240,000 pounds. Additional details about these changes can be found in Chapter 5.

In 1999, Rhône-Poulenc purchased the carbofuran and carbosulfan manufacturing facilities owned by FMC and established the Carbamate Excellence Center at Institute, and a new carbamate process, the oxamyl process, was added. In December of that year, Rhône-Poulenc SA merged with Hoechst AG to form Aventis. The Institute site became the largest site in North America for Aventis CropScience (Woomer, 2000). In 2001, EPA performed a series of inspections at the facility and identified a set of violations of environmental laws (EPA, 2009). Also in 2001, the facility was purchased by Bayer, thus moving the Institute plant to its current ownership, Bayer CropScience. As the legal successor to Aventis, Bayer settled with EPA regarding the 2001 violations in February 2009 with an agreement to pay a $112,500 penalty and to spend over $900,000 on supplemental environmental projects. As part of the settlement, Bayer CropScience neither admitted nor denied the allegations.

By 2008 the Institute plant was the only facility in the United States that manufactured, stored, and consumed large quantities of MIC. Liquid MIC was stored in underground refrigerated pressure vessels in the ECC, where it was manufactured before being used—either as a chemical feedstock there or at the WCC to which it was transferred at night and additionally stored. Each pressure vessel was insulated and had double-wall construction, with leak detection in the annulus between the inner and outer wall. The transfer from the ECC to the WCC occurred through a 2,500-foot, insulated, aboveground piping system to an aboveground “day tank” located on the southwest corner of the WCC. The stainless steel tank, with a maximum capacity of 6,700 gallons, held approximately 37,000 pounds of MIC at its normal 75 percent operating capacity. A number of

safety features were incorporated into the day-tank design. The tank was filled once per day, and the pipes connecting the ECC to the WCC were purged after the transfer. The MIC was chilled, with methyl isobutyl ketone (MIBK) used as the chiller fluid because, unlike the water-ethylene glycol mixtures typically used in chillers, MIBK does not react with MIC and therefore poses less risk in case of a chiller leak. Fire suppressants were installed to prevent thermal reactions. Air monitors were in place to detect MIC leaks. Finally, the tank and top piping connections were surrounded with a blast blanket to prevent debris from striking the tank and to provide a thermal shield in case of fire (CSB, 2011).

Each of the pesticides being manufactured onsite at Institute used different production processes: aldicarb was produced in a batch reactor, carbaryl in a continuous fixed-bed reactor, methomyl in a continuous plug flow reactor, and carbofuran used a solventless process. All of these processes were designed to use liquid MIC. The pesticides had different seasonal patterns of production, and there was considerable variation in the facility’s MIC consumption over time—between 5,000 and 100,000 pounds per day over the course of their history. To regulate carbamate production and minimize startup/shutdown issues for MIC production, the facility maintained an inventory of up to 200,000 pounds of MIC— approximately 10 days of normal production or 3 days of high production (Martin, 2011).

On August 28, 2008, an uncontrolled chemical reaction inside a methomyl unit residue treater in the WCC caused the vessel to explode violently, causing the deaths of two employees. See the next chapter section (History of Emergency Preparedness and Accidents) for more information. As a result of the accident and the damage to the WCC, production of methomyl, MIC, and the carbamate-based pesticides ceased, pending investigation and evaluation of the production unit.

In March 2009, EPA made a decision to ban the use of carbofuran pesticides (74 Fed.Reg.11,551 [2009]) leading to the decision by Bayer CropScience to stop production at Institute of all but two of the carbamate pesticides: aldicarb and carbaryl. Dropping the other products led to substantial reductions in the need for MIC, and so 2009 MIC production was only 9 million pounds, with planned 2010 production of 11.5 million pounds (Martin, 2011).

In August 2009, Bayer announced a $25 million investment program “for further enhancing operational safety” (Bayer CropScience, 2009) at the facility, and as part of this program, the carbamate pesticide production would cease in the WCC approximately a year after the announcement. This would remove the need for the aboveground storage tank and for the transfer of MIC from the ECC to the WCC. Production would be limited to aldicarb and carbaryl, both of which were produced in the ECC.

As part of the modification plan the decision was made to reduce by 80 percent the maximum amount of MIC being kept in storage on the Institute site, with additional passive and active safety systems on MIC production to minimize risks. Additional details will be provided in Chapter 5, but briefly, the MIC-production changes included building a new storage unit for the MIC with

underground tanks; incorporation of a steam-ammonia curtain in the building’s perimeter to assist in controlling leaks, should they occur; and other passive and active safety controls.

In 2010 Bayer reached an agreement with EPA to voluntarily cancel its registration of aldicarb, with production of the pesticide to end in 2014 and distribution and sales to end in 2016 (EPA, 2010; Ward, 2010). Citing this agreement and global restructuring of its parent company, on January 11, 2011 Bayer announced that “the production of certain carbamates is no longer economically viable.” (Bayer CropScience, 2011b) The company’s intention at that time was to continue to make modifications to the MIC plant at Institute; restart manufacturing of aldicarb, carbaryl, and the intermediate materials required for their production, including MIC; and continue manufacturing those materials until mid-2012.

In February 2011 a group of Kanawha Valley residents filed suit to stop Bayer CropScience from restarting its production of MIC at the Institute plant until EPA and OSHA completed comprehensive plant inspections. A preliminary injunction was granted, halting Bayer’s planned restart of MIC production (Ward, 2011). On March 18, 2011, Bayer CropScience announced that it would not restart the production of MIC. In a press release, the company stated that, “uncertainty over delays has led the company to the conclusion that a restart of production can no longer be expected in time for the 2011 growing season.” In light of this decision, the company said it would proceed with decommissioning the MIC and carbamate production units at Institute, as well as closing the Woodbine facility, which had continued to finalize the aldicarb formulation and packaging since 1976 (Bayer CropScience, 2011a).

HISTORY OF EMERGENCY PREPAREDNESS AND ACCIDENTS

The Kanawha River Valley is the home of an extensive network of chemical and other manufacturing facilities and represents one of the highest concentrations of such industries in the United States. In 1954, these industries established the Kanawha Valley Emergency Planning Committee (KVEPC) following an explosion of an acrolein tank car. An explosion of an ethylene oxide distillation column in 1955 damaged parts of the Institute facility and led to a major safety review by the management (Woomer, 2000). After that, such safety reviews were conducted internally to the plant and its management until the Bhopal accident. Following Bhopal, public concern in the Kanawha Valley about chemical accidents increased, and with passage of the Emergency Planning and Community Right-to-Know Act (EPCRA, see Chapter 2), the Kanawha/Putnam Local Emergency Planning Committee (KPEPC) was established in 1987 (KPEPC, 2011). At the same time, local public concern about MIC led to the establishment of the organization People Concerned About MIC (PCMIC, 2011).

In 1992, the KPEPC initiated the Kanawha Valley Hazard Assessment Project, which examined “worst-case” scenarios for all chemical plants in the valley. The

compilation of scenarios were presented during a June 3-4, 1994 workshop held in Charleston, West Virginia under the title “Safety Street: Managing Our Risk Together (Worst Case Scenario Presentations).” This was the first time such an activity had been held in the area, and according to the organizers, it was well received by the community (OECD, 1997). The materials identified a release from the MIC unit as one of worst-case scenarios associated with the Rhône-Poulenc-owned facility; the other two noted chemicals associated with the facility were phosgene and chlorine, the latter being used in the production of phosgene. The risk management plan from Rhône-Poulenc identified the worst case as the full release of 253,600 pounds of MIC from the ECC belowground storage tank. According to the analysis, such a release would exceed ERPG-2 (emergency response planning guidelines) levels out to a distance of 28 miles (at concentration of 0.5 ppm) and ERPG-3 levels out to a distance of 9 miles (5 ppm) (Fortun, 2001, pp. 66-67). ERPG-2 levels indicate the “maximum airborne concentration below which it is believed that nearly all individuals could be exposed for up to 1 hour without experiencing or developing irreversible or serious health effects or symptoms which could impair an individual’s ability to take protective action”2, while ERPG-3 levels indicate the “maximum airborne concentration below which it is believed that nearly all individuals could be exposed for up to 1 hour without experiencing or developing life-threatening health effects”.3 This constitutes the largest scenario vulnerability zone of any chemical used in the valley at the ERPG-2 level and nearly largest vulnerability zone at the ERPG-3 level.

At the time of the 1992 analysis, Rhône-Poulenc had just completed a 1.5-year study called Project Michelle (1989-1990) (as cited in Ward, 1994) which focused on improving the safety of thee MIC processes, including considering whether to put a “bubble” over the entire MIC unit to contain any leaks. Rhône-Poulenc had numerous active (and some passive) systems in place to reduce the risk associated with the MIC unit. These included:

1. Process design. An emergency dump tank for safe transfer of MIC from a leaking vessel, a scrubber to destroy MIC in the storage tank, a flare tower to destroy MIC from process vents, backup control room instruments, automatic MIC isolation valves to stop leaks, diking and spill collection sumps, a fire deluge system, MIC leak detection alarms, safety relief valves to protect vessels from overpressure, a diesel generator for backup power, sealless pumps for managing liquid MIC, fire protection for pipe rack transfer lines, and an independent nitrogen supply to prevent cross contamination.

2. Equipment design. A double-walled underground storage tank, special pressure vessels, blast material protection for the aboveground MIC storage

![]()

2 AIHA Definition

3 AIHA Definition

facilities, stainless steel construction, barriers to protect pipelines over roads, and double-walled pipelines with leak detection analyzers on critical transfer lines.

3. Safety reviews and procedures. Process hazard analysis completed every 5 years, ongoing safety reviews for design changes, operational reviews completed for all process changes, and safety review teams that included safety experts, engineers, union operators, and union maintenance personnel. It also established procedures and training inspection, emergency response and incident investigation systems (Fortun, 2001, p. 67).

Between 1989 and 1993, although the facility had no EPA-reportable releases (threshold of 10 pounds), it did report 13 leaks of between 1 and 10 pounds, and 30 leaks of less than 1 pound to the local emergency authorities. In 1993, Rhône-Poulenc was fined by OSHA for alleged safety violations that occurred during a non-MIC-related explosion and fire within the methomyl manufacturing unit, which was located near the aboveground MIC storage unit. The incident claimed the life of one plant worker and injured two others. OSHA investigators concluded that the company tried to boost pesticide production without regard for safety (Ward, 1994). The Institute Community Liaison Committee (CLC) commissioned a review of the incident investigation by PrimaTech, Inc. in 1993 (PrimaTech, Inc., 1993).

This incident caused considerable concern within the community, and the president of West Virginia State College,4 Hazo Carter, wrote to the plant manager stating,

As president of West Virginia State College, I am quite concerned about the safety of the more than 5,000 students, faculty, staff, and community residents due to recent accidents and frequent spills at the Institute Rhône-Poulenc plant. I was especially concerned to read that a tank holding 30,000 pounds of methyl isocyanate [MIC] gas was within 250 feet of the explosion and fire. The severity of this situation makes it imperative that every precaution be taken to prevent accidents from happening and that immediate notification be given to us if such accidents should occur in the future. (Carter, 1993)

In December 1994, following that explosion, Rhône-Poulenc completed the Institute Modification Project, involving $50 million in improvements. These improvements included: moving the phosgene unit closer to the MIC process to reduce the distance phosgene has to travel in pipes; adding a new cooling system for MIC tanks, using chloroform, rather than water-based brine; adding redundant warning systems to detect leaks and to monitor pressure,

![]()

4 West Virginia State College became West Virginia State University in 2004.

temperature, and possible water-contamination at concentrations as low as 2 ppm; upgrading the scrubber and flare systems; and adding another backup generator (Ward, 1994).

The U.S. Chemical Safety and Hazard Investigation Board (CSB) report on the 2008 incident states that,

[t]he five-year accident history for the RMP-regulated chemicals reports an accident that released approximately 15 pounds of phosgene (October 1999), another that released less than 1 pound of chlorine (May 2000), and a third that released approximately 3,000 pounds of liquid chloroform (August 2001). Each resulted in one or more worker exposures, and the phosgene release prompted a shelter-in place-alert. However, the company reports none of the releases involved offsite consequences (CSB, 2011).

Following its acquisition of the Institute facility from Aventis CropScience, Bayer CropScience completed 20 projects to enhance process safety and economic competitiveness, with particular attention paid to the phosgene and MIC units. These changes included a new, downsized phosgene unit, reductions in pipeline capacity in chlorine lines, downsizing the MIC unit to match lower demands (since inventory of MIC required for production was reduced by 80 percent since mid-1980s), modernizing equipment and instrumentation to safeguard the purity of the components used in the MIC process, additional emergency neutralization processes, and updated transfer processes.

2008 Accident in Methomyl Facility

As described in an earlier section, the production requirements and schedules varied for the different pesticides manufactured at the plant, and the methomyl process (located in the WCC) was only operated periodically in response to seasonal demand for the product. These gaps in the production schedule provided opportunities to perform repairs and system upgrades. In 2008, Bayer upgraded the methomyl control system and replaced the residue treater with a stainless steel tank during one of these downtimes. The process was restarted in August, with operations personnel, engineering staff, and contractors working around the clock to complete system upgrades. Dwindling supplies of methomyl and an increase in demand for thiodicarb created pressure to restart the operation (CSB, 2011). On August 28, 2008, amid startup procedures, an explosion occurred, resulting in the deaths of two plant operators and considerable damage to the WCC. A full investigation of the incident was performed by the CSB and the results of that investigation reported in 2011. An overview of key events and findings from that report is provided here.

The upgrades on the methomyl control system were significant, and as a consequence, the restart procedures were not routine. At the time of the startup, criti-

cal procedures had not been completed. In particular, process computer system engineers had not verified the functionality of all process controls and instruments in the new control system, and changes to standard operating procedures that were needed because of changes to system controls had not yet been finalized. In addition, the staff struggled with significant problems as they attempted to bring each subsystem online, including a missing valve on a solvent line, non-operational heat tracing on a process line, a broken stem on a vapor condenser water cooling system valve, and many problems tuning control loops and calibrating instruments for the newly installed computer control system. These problems were further complicated by the operators’ lack of familiarity with new methomyl work station functions and changes to some process variables (CSB, 2011).

The explosion originated in the new residue treater in the methomyl production unit. The methomyl was synthesized in solvent through a series of steps. In the final stage, the solvated methomyl was transferred to a crystallizer, where an “anti-solvent” was added to cause the product to precipitate. The solid methomyl was then separated from the solvent via centrifugation. The remaining liquid, consisting of solvent, residual methomyl, and other compounds resulting from the synthesis, was transferred to a “flasher,” where the solvent was separated from the other materials and recycled in the production process. After separation of the solvent, the remaining material (residual solvent, up to 22 percent methomyl, and impurities) was transferred to the residue treater. The role of the residue treater was to decompose the remaining methomyl in this liquid to a concentration of no more than 0.5 percent. At that point, this flammable liquid could then be burned for fuel within the facility.

By August 28, methomyl production had begun, although the residue treater had not yet been brought online. There were multiple issues with the production startup that operators were endeavoring to fix, one of which was that the system was depleting solvent faster than expected. This created a need to get the solvent recovery system on line as quickly as possible to replenish the solvent. Because the last stage in the solvent recovery process was the residue treater, that system also needed to be brought online. When beginning the startup of the recovery system, operators failed to prefill the residue treater to the minimum operating level and to heat the liquid to the minimum operating temperature before adding the methomyl. Decomposition of methomyl is an exothermic reaction, therefore it was necessary for safe operation of the system to control of temperature and solvent levels. A control system was designed to prevent addition of methomyl until the solvent was at minimum volume and temperature, but the operators bypassed the safety devices during the startup. In addition, samples taken from the liquid coming from the crystallizer indicated that methomyl concentrations were as much as eight times greater than the specified operating limit, the staff did not have time to review the laboratory results and were unaware of the problem (CSB, 2011).

At 10:25 PM, the residue treater high-pressure alarm sounded, and in response, a control board operator directed two outside operators to check the vent system of the residue treater. Eight minutes later, the vessel exploded and initiated a fire that burned for 4 hours. The explosion killed both operators who were sent to inspect the unit; two other workers onsite and six firefighters were treated for possible toxic chemical exposure at a local hospital.

The Kanawha-Putnam County Emergency Management Director advised more than 40,000 residents, including the resident students at the West Virginia State University directly adjacent to the facility, to shelter-in-place for more than 3 hours (Huntington News Net., 2011). During the emergency, the Bayer CropScience emergency response organization failed to provide timely and accurate information about the incident. In part this was because, continuous air monitors located in and around the production units to detect MIC leaks had malfunctioned in May, causing spurious alarms. The system had not been repaired and restarted even though the MIC storage tank had been refilled. In addition, fence-line monitors were inadequately designed and located for detecting MIC releases (CSB, 2011).

Emergency Response After 2008

In the wake of the accident, the emergency response systems in place at the facility and in the surrounding area were examined, and a number of recommendations were made by CSB in the areas of communication and planning. The report also noted efforts by local emergency responders (Metro 9-1-1), KPEPC, and Bayer to improve communication between the three groups in the event of an emergency. These efforts included direct telephone lines installed from the facility to Metro 9-1-1 headquarters, development of a method for e-mailing residents in case of a release, increasing call center capacity, and introducing a 15-minute rule for calling an advisory shelter-in-place if an event has been reported but no additional information is available from the facility. Conversations with Matthew Blackwood and Larry Zuspan, representatives from KPEPC in 2011 and testimony provided by Chief Joseph Crawford before Congress in 2009 confirmed that changes to emergency response have been made since the 2008 explosion. CSB also advised modifying KPEPC’s Basic Plan and/or the Functional Annex 16, Chemical HazMat Response, to ensure clear delineation of onsite and offsite authority in case of an incident. The relevant changes within the two documents were adopted by KPEPC in May 2011.

In February 2009, as part of a settlement with EPA to resolve issues identified in 2001 at the facility, Bayer agreed to support the following activities as part of supplemental environmental projects (CIC, 2009):

• Funding for a breathing air system for the Kanawha Valley Emergency Preparedness Training Center:

• Equipment for the St. Albans, Jefferson and Institute fire departments;

• Training courses for Kanawha Valley emergency responders; and

• Enhancements for emission dispersion modeling programs for the Metro 9-1-1 center.

Note that informal feedback was received after the public meeting in Institute, West Virginia from a local volunteer firefighter. He expressed concern about availability of emergency equipment in all jurisdictions in the Kanawha Valley. This question was later raised to KPEPC representatives, who stated that they had no knowledge of any particular concern but that efforts were underway to acquire equipment for local fire departments. It is beyond the scope of this study to look further into this question, but asking local personnel for additional input may aid in identification of any gaps in coverage or, if no such gaps are apparent, assist in dissemination of information about available resources.

REFERENCES

AAUP (American Association of University Professors). 2011 Black Colleges with Highest White Enrollments [online]. Available: http://www.aaup.org/AAUP/comm/rep/HBCUChart.htm. Accessed: Sept. 29, 2011.

Bayer CropScience. 2009. Bayer Crop Science Announces Investment of $25 Million for Institute Site. Bayer News Release: August 26 [online]. Available: http://www.bayerus.com/News/NewsDetail.aspx?ID=586330BF-C83B-4EF3-93DBFF791373C7D7. Accessed: Feb 14, 2012.

Bayer CropScience. 2011a. Bayer CropScience Announces Decision not to Resume. News: March, 18, 2011 [online]. Available: http://www.press.bayer.com/baynews/baynews.nsf/id/Bayer-Crop-Science-announces-decision-not-to-resume-MIC-production. Accessed: Sept. 29, 2011.

Bayer CropScience. 2011b. Bayer CropScience to Reduce Operations in Institute, West Virginia, and Close Woodbine, Georgia, Site. News: January 11, 2011 [online]. Available:http://www.bayercropscience.com/bcsweb/cropprotection.nsf/id/EN_20110111?open&l=EN&ccm=500020. Accessed: Sept. 29, 2011.

Bayer CropScience. 2011c. Overview [online]. Available: http://www.bayercropscience.com/bcsweb/cropprotection.nsf/id/AccessPlans. Accessed: Sept. 29, 2011.

Baron, R. C., R. A. Etzel, and L. M. Sanderson. 1988. Surveillance for adverse health effects following a chemical release in West Virginia. Disasters 12:356-365.

Blackwood, M. and Zuspan, L. 2011. Discussion with NRC Committee. Washington, DC.

Carter, H. W. 1993. Letter to Van Long, Plant Manager, Rhône-Poulenc, Charleston, W., from Hazo W. Carter, President, West Virginia State College. August 30, 1993 [online]. Available: http://library.wvstateu.edu/facultysenate/acadyear2008-2009/environmental-issues/Rhône-Polenc-PresCarter-Aug30-1993.pdf. Accessed: Feb. 16, 2012.

CIC (Community Improvement Committee). 2009. Community Minutes of March 25 meeting. CSB (U.S. Chemical Safety and Hazard Investigation Board). 2011. Investigation Report: Pesticide Chemical Runaway Reaction Pressure Vessel Explosion, Bayer CropScience, LP, Institute West Virginia, August 28, 2008. Washington, DC: CSB [online]. Available: http://www.csb.gov/assets/document/Bayer_Report_Final.pdf. Accessed: Sept. 29, 2011.

EPA (U.S. Environmental Protection Agency). 2004. Carbaryl IRED Facts, October 2004 [online]. Available: http://www.epa.gov/opp0001/reregistration/REDs/factsheets/carbaryl_factsheet.pdf. Accessed: May 1, 2012.

EPA. 1998. R. E. D. Facts Thiodicarb [online]. Available:http://www.epa.gov/opp00001/chem_search/reg-actions/reregistration/fs_PC-114501_1-Dec-98.pdf. Accessed: May 1, 2012.

EPA. 2009. Bayer CropScience to Pay Penalty for Environmental Violations. U.S. Environmental Protection Agency, Region 3, News Release, February 27 [online]. Available http://yosemite.epa.gov/opa/admpress.nsf/90829d899627a1d98525735900400c2b/c0a0da8becf0bf6b8525756e004d6226!OpenDocument. Accessed: Feb. 2, 2012.

EPA. 2010. Agreement to Terminate All Uses of Aldicarb, October 2010 [online]. Available: http://www.epa.gov/oppsrrd1/REDs/factsheets/aldicarb_fs.html. Accessed: Sept. 29, 2011.

Fortun, K. 2001. Advocacy After Bhopal: Environmentalism, Disaster, New Global Orders. Chicago: University of Chicago Press.

Houston Chronicle. 1985. Nervous System Toxin Predominated in Carbide Leak Section 1, p. 2, August 16 [online]. Available: http://www.chron.com/CDA/archives/archive.mpl/1985_31269/nervous-system-toxin-predominated-in-carbide-leak.html. Accessed: Sept. 29, 2011.

Huntington News Net. 2011. Abbreviated Text of Citizens Complaint against Bayer to Prevent MIC Restart, February 9. Available: http://www.huntingtonnews.net/1563?format=print.

KPEPC (Kanawha/Putnam Emergency Planning Committee). 2011. History [online]. Available: https://www.kpepc.org/history/default.aspx. Accessed: Sept. 29, 2011.

Los Angeles Times. 1985. Union Carbide Delays Resuming Production of Chemical That Killed 2,000. May 4 [online]. Available: http://articles.latimes.com/1985-05-04/news/mn-20608_1_union-carbide-corp. Accessed Sept. 29, 2011.

Martin, W. 2011. ECC Presentation to NAS. Presentation at the Second Meeting on Inherently Safer Chemical Processes. March 21-22, 2011, West Virginia State University.

OECD (Organisation for Economic Co-operation and Development (OECD). 1997. OECD Environmental Health and Safety Publications Series on Chemical Accidents No. 1: Report of the OECD Workshop on Risk Assessment and Risk Communication in the Context of Chemical Accident Prevention, Preparedness and Response. Paris: OECD [online]. Available: http://www.oecd.org/officialdocuments/displaydocumentpdf/?cote=ocde/gd%2897%2931&doclanguage=en. Accessed: Feb. 2, 2012.

PCMIC (People Concerned About MIC). 2011. History [online]. Available: http://peopleconcernedaboutmic.com/history/. Accessed: Sept. 29, 2011.

PrimaTech, Inc. 1993. “Audit of Incident Investigation and Review of Emergency Response to August 18, 1993 Incident at Rhône-Poulenc AG Company Institute, West Virginia.” Princeton, NJ.

Smythe, S. 2011. An Evaluation of Alternate MIC Technologies. Presentation at the First Meeting on Inherently Safer Chemical Processes, February 9. Washington, DC.

U.S. News. 2010. College Ranking & Lists: West Virginia State University [online]. Available: http://colleges.usnews.rankingsandreviews.com/best-colleges/west-virginia-state-3826. Accessed:

Sept. 29, 2011.

Ward, K., Jr. 1994. Is MIC unit safe or a potential Bhopal? Sunday Gazette Mail, B-1, May 8 [online]. Available: http://wvgazette.com/static/watchdog/micstory.pdf. Accessed: Sept. 28, 2011.

Ward, K., Jr. 2010. Bayer to stop making one of its MIC pesticides. The Charleston Gazette, August 17 [online]. Available: http://blogs.wvgazette.com/watchdog/2010/08/17/bayer-to-stop-makingone-of-its-mic-pesticides/. Accessed: Sept. 29, 2011.

Ward, K., Jr. 2011. Residents Sue to Delay Start-Up of Bayer’s MIC Unit. The Charleston Gazette, February 9 [online]. Available: http://wvgazette.com/News/Bayerexplosion/201102081007?page=2&build=cache. Accessed: Sept. 29, 2011.

Woomer, W. J. 2000. The Institute Site: From George Washington to the World of Chemicals.. Charleston, WV: B. J. W Printing.

This page intentionally left blank.