5

MIC and Pesticide Production

at the Institute Plant:

Alternatives Assessment

INTRODUCTION

In this chapter, possible alternative methods for production of methyl isocyanate (MIC) and carbamate pesticides at the Bayer CropScience facility are presented. This chapter directly addresses Tasks 2 and 3.1 of the committee’s statement of task. Before beginning, however, it is important to address two points.

First, when the committee began its work, there was an assumption that Bayer CropScience would be restarting production of MIC and the carbamate pesticides. Were that to be done, then a “[r]eview [of] current and emerging technologies for producing carbamate pesticides, including carbaryl, aldicarb, and related compounds.” (SOT, Task 2) would potentially have value for the company. During the course of the study, however, Bayer CropScience (Bayer) announced they would not be restarting production of MIC. This was based on a combination of the factors described in Chapters 1 and 3 including deregistration of aldicarb, carbosulfan, and carbofuran with the U.S. Environmental Protection Agency (EPA) and the continued economic viability of the other pesticides manufactured at the facility. In light of these changes, the committee determined that an in-depth review of the field as a whole would provide little value to the sponsor or the reader beyond what a targeted review of processes considered by Bayer and the legacy owners of the facility would provide. Thus, the analyses presented in this chapter focus on those processes identified by the current and former owners as most likely to meet the manufacturing needs of the Institute facility.

Second, the process assessments presented here may be incomplete because the analysis is based in large part on materials provided by Bayer CropScience that were generated by former site owners, primarily Rhône-Poulenc. At the first

meeting of the committee, Dr. Steven Smythe speaking on behalf of the company, stated that 29 routes to MIC production had been identified, and four had been evaluated in greater detail. Although the materials relating to the alternatives and their evaluation were provided to the committee for review in good faith, the documentation was rather disjointed and discontinuous, with documents ranging from undated handwritten notes without attribution to in-depth typewritten analyses of findings.

Therefore, the process assessments presented here are drawn from documents provided by Bayer and from the current academic and patent literature. Information gaps within the historic documents could result in gaps within these assessments.

ALTERNATIVES ASSESSMENT

In considering the adoption of a new or redesigned process, it is helpful to break down the impact that the proposed redesign would have on the elements outlined in Chapter 4, namely selection of basic technology, implementation of the selected technology, plant design, detailed equipment design, and impact on operations. The options facing the facility’s owners—Bayer CropScience today and the legacy companies in the past—were (1) continuing with the existing process, (2) adopting an alternative chemical process not involving MIC, (3) using an alternative process involving MIC production that would consume MIC immediately (just-in-time) and thus not require storage, and (4) reducing the volume of stored MIC and the risks of transporting MIC from one facility within the site to another by rearranging process equipment. Each of these has implications for the facility as a whole, and the technical considerations for them are presented below. However, a key motivation for this NRC study is to evaluate whether Bayer could have identified a superior process for manufacturing pesticides at the Institute facility that would have reduced risks to the surrounding communities.

Any potential changes proposed by Bayer CropScience were compared to the processes in place in 2008, referred to here as the “existing process,” for the chemistry and production methods in place at that time.

Production of MIC

There are a number of possible methods for production of MIC. This chemistry has been used for decades, and much has been written about the possible paths for production. In light of Bayer’s decision to no longer produce or store large quantities of MIC onsite, a full evaluation of every possible alternative method of production is not presented here. Rather, this section describes four methods evaluated by Bayer and previous owners of the facility. The evaluations of these processes and the role those evaluations played in Bayer’s decision making are described in Chapter 6.

In 2010, Bayer identified four alternative processes for generating MIC (referred to here as DuPont, cyanate, diphenylcarbonate, and Enichem) based in part on earlier evaluations conducted by prior owners of the Institute site. The company stated that data for their analyses were derived in part from the following sources (Smythe, 2011):

• The Union Carbide Corporation (UCC) process. Current operating data and cost

• DuPont. Stanford Research Institute Report and internal evaluation performed by Rhône-Poulenc

• Cyanate. Patent literature between 1973 and 1985

• Diphenykarbonate. Domagen operating costs and conditions between 1971 and 2002

• Enichim. Patent literature from 1975 and internal evaluation performed by Rhône-Poulenc

All four of the processes generate MIC in a gaseous form, rather than a liquid form, which would have necessitated some adjustments to the downstream production processes at Institute to be used directly or incorporation of a recovery step to condense or capture liquid-phase MIC. In addition, none of the processes had been run at a scale similar to the existing MIC process at Institute.

Note that all process flow diagrams below were provided by Bayer CropScience to the committee.

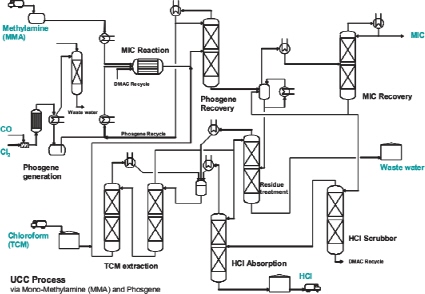

The Union Carbide Corporation (UCC) Process in Institute

The synthetic method for the production of MIC has remained largely unchanged since 1966, when production began in Institute. In this process, developed by Union Carbide, phosgene (Cl2CO) and methyl amine (CH3NH2, MMA) are combined to form N-methyl carbamoyl chloride (C2H4NClO, MCC), from which hydrogen chloride (HCl) is eliminated to generate MIC. See Figure 5.1.

The MCC generation takes place at high temperature and low pressure in a reactor with a specialized design that permits very fast reaction times and complete conversion of MMA to MCC, followed by a pyrolizer to split MCC into

FIGURE 5.1 Synthesis of MIC from N-methyl carbomoyl chloride, as used at the Bayer CropScience facility.

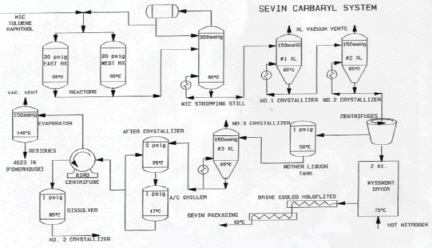

MIC and HCl. The pyrolizer has an inclined orientation to separate the HCl from the MIC, avoiding any re-formation of MCC. The process, as used at the Bayer CropScience facility, produced extremely pure MIC (99.9 percent), which was then stored in liquid form before being transferred for use in production of carbamate pesticides. A diagram of the process and the equipment used for production of MIC is shown in Figure 5.2.

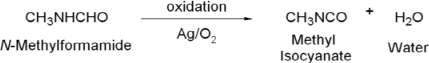

DuPont Process

In 1985, DuPont developed a methylformamide oxidation process to make its own MIC when the Union Carbide facility halted production following the Bhopal disaster (Carcia, 1984; Rao, 1985). The DuPont process combines monomethylamine and carbon monoxide to provide N-methylformamide (see Figure 5.3). The N-methylformamide is then oxidized with oxygen/palladium (through an air intake) at very high temperatures to generate gaseous MIC and water. To prevent the MIC from reacting with the water, it is almost immediately fed into a process to produce methomyl and oxamyl carbamate pesticides.

When Rhône-Poulenc considered the plausibility of developing this method for producing MIC at the Institute facility, concerns, such as whether downstream

FIGURE 5.2 Process flow diagram for production of MIC via mono-methylamine and phosgene (UCC process).

SOURCE: Smythe (2011).

FIGURE 5.3 Synthesis of MIC from N-methylformamide, used by DuPont.

pesticide production could continue with the vapor phase MIC or if recovery of liquid MIC was required, had to be considered. If the vapor phase could be used, then this process would have the advantage of using MIC as soon as it is produced (just-in-time production). DuPont’s production facility in LaPorte, Texas is able to use vapor phase MIC, so there is no MIC storage on site, and since it is produced as a gas rather than a liquid, only a small amount of MIC is in the system at any given time. However, according to Bayer’s analysis, the concentration of impurities in the MIC generated using the DuPont process is higher than with the UCC process.

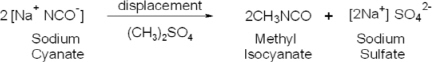

Cyanate Process

The cyanate process has been used in South Africa, and it is currently used as a method for making MIC in Asian countries. This method combines potassium or sodium cyanate and dimethyl sulfate in an aromatic solvent to generate MIC and potassium or sodium sulfate (See Figures 5.4 and 5.5). This is one of the earliest methods for synthesis of isocyanates reported in the literature, having been discovered by Alfred Wurtz in 1849.

In contrast to the DuPont process, but similar to the UCC process, the cyanate process is a batch process and requires some capacity for storing MIC. The yield of MIC was reported in a patent awarded in 1980 as on the order of 80-85 percent relative to added potassium cyanate (Giesselmann et al., 1980).

An important consideration any company contemplating adoption of this process is the amount of waste generated as a result of this reaction, which is roughly 1.5 kg of solid K2SO4or Na2SO4 waste per kg of MIC produced.

FIGURE 5.4 Synthesis of MIC from sodium cyanate, used in the cyanate process.

FIGURE 5.5 Process flow diagram for production of methyl isocyanate via dimethyl sulfate and sodium cyanate (cyanate process).

SOURCE: Smythe (2011).

Bayer Diphenylcarbonate and Dimethylurea Process

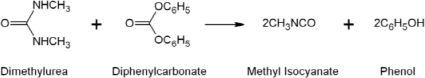

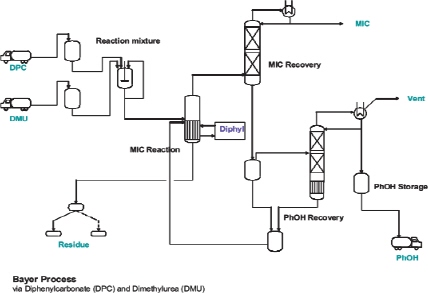

Bayer used a diphenylcarbonate process to make MIC at its Dormagen plant between 1971 and 2002, combining diphenylcarbonate with dimethylurea (Kober and Smith, 1968). In this method, the dimethylurea and diphenyl carbonate are heated to form MIC and phenol via an exchange-replacement-elimination sequence (See Figure 5.6).

The diphenylcarbonate process has the advantage of not requiring chlorine or phosgene as inputs, but it does generate large amounts of phenol, although this can be recovered by cooling the product mixture and recycling for use in the production of diphenylcarbonate. The diagram in Figure 5.7 shows the process.

Enichem Diphenylcarbonate Process

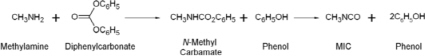

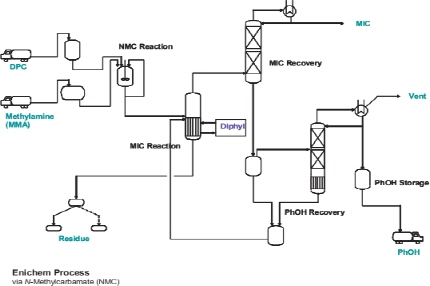

Enichem, a chemical company based in Europe, also had a process to make MIC that combined diphenylcarbonate with methylamine (Romano et al., 1984;

FIGURE 5.6 Synthesis of MIC from diphenylcarbonate and dimethylurea, used in the diphenylcarbonate process.

FIGURE 5.7 Process flow diagram for production of MIC via diphenylcarbonate and dimethylurea (Bayer diphenylcarbonate process).

SOURCE: Smythe (2011).

Rivetti et al., 1987) (see Figure 5.8). As with Bayer’s diphenylcarbonate process, the Enichem diphenylcarbonate process is essentially a replacement-elimination reaction. The two reactants are mixed and heated to form N-methylcarbamate, also known as phenyl-N-methylurethane, and phenol. Further heating leads to the elimination of MIC and additional phenol. The mixture is then cooled to remove the phenol and remaining N-methylcarbamate allowing MIC to undergo additional purification steps (see Figure 5.9). Because phenol is also a by-product of the Enichem reaction, manufacturers using this method must consider whether to dispose of or recycle this material.

FIGURE 5.8 Synthesis of MIC from diphenylcarbonate and methylamine, used in Enichem diphenylcarbonate process.

FIGURE 5.9 Process flow diagram for production of MIC via N-methylcarbamate (Enichem process).

SOURCE: Smythe (2011).

In the late 1980s, Rhône-Poulenc considered this option in great detail, including the manufacture of diphenylcarbonate onsite from dimethylcarbonate and phenol, which would negate the need for phosgene in the production of diphenylcarbonate. The company then engaged with Enichem to evaluate the feasibility of adopting and licensing this process from Enichem in Institute, West Virginia.

Carbamate Pesticide Production

MIC was produced at the Institute facility to act as a reactant in the synthesis of carbamate pesticides. In this section the focus is primarily on the possible tech-

nical alternatives for production of carbamate pesticides at the Institute facility. The assumption that carbamate production would continue was implicit in the Committee’s Statement of Task, which focused on identifying different technologies for producing carbamate pesticides and possible approaches for reducing or eliminating the use of MIC in their production. A broader range of alternatives could be considered, including not making any carbamate pesticides, or even not making any pesticides at all, which reduce safety risks. However, such alternatives could lead to a different set of risks to society—such as, losses of crop production, higher prices for food, possible starvation in developing countries unable to afford higher food costs, etc. Alternative processes that lead to lower quality and reduced effectiveness in the resulting pesticides, also relate to the overall benefits of the pesticide under consideration.

Consideration of the various nonprocess alternatives are discussed briefly in Chapter 6 when ways to quantify the benefits and costs from different production processes are described.

Alternative Production Methods for Carbamate Pesticides

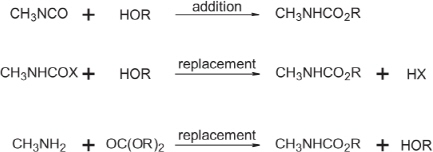

The carbamate pesticides in production in Institute in 2008 were all N-monomethyl carbamates, with carbaryl, aldicarb, and thiodicarb the primary pesticides produced onsite. The chemical reactions used to produce these pesticides are summarized in Figure 5.10. There are two reaction types available for the final step in synthesizing carbamate pesticides: additions to MIC and replacements in carbamates and carbonates (second and third equations of 5.10). The different pesticides are characterized by differences in the R group and physical formulations, but the underlying synthetic chemistry is similar. Specific applications of the carbamate synthesis equations are shown in Figure 5.11. An early

FIGURE 5.10 Possible methods for synthesis of N-monomethyl carbamate pesticides. These equations represent the generic forms of the possible synthetic pathways discussed later in this chapter.

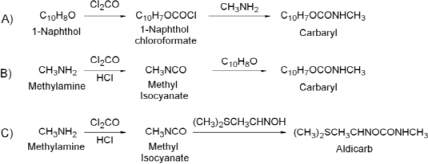

FIGURE 5.11 Synthesis routes for the production of carbaryl (without and with MIC) and aldicarb (with MIC). (A) A synthetic route for production of carbaryl without the use of MIC; (B) A synthetic route for production of carbaryl using MIC; and (C) A synthetic route for the production of aldicarb using MIC.

non-MIC process for carbaryl is shown in the first equation. The MIC-based syntheses of carbaryl and aldicarb are shown in the second and third equations. The most recent processes used by Bayer, DuPont, and Enichem to produce carbamate pesticides (described earlier) all use MIC.

Carbaryl

The first carbamate pesticide in production at the Institute plant was carbaryl. This broad-spectrum pesticide has relatively moderate toxicity to mammals, and it is commonly found in both agricultural and residential uses. It has a demonstrated toxicity for aquatic life (EPA, 2004), and environmental release is a concern for users of carbaryl. See Tables 5.1 and 5.2.

Carbaryl was originally produced with a non-MIC-based chloroformate process (see Figure 5.11) using intermediates produced elsewhere, and this process was used for many years (1961-1977). In this reaction, 1-naphthol is reacted with phosgene to create a chloroformate. Reaction of the chloroformate with methylamine results in the formation of carbaryl. In 1978, the production process for carbaryl was changed to use MIC. See Figure 5.12 for a flow diagram of this process. The reasons given for the change were that the chloroformate process was highly corrosive, had lower yield, and generated considerable waste products. One internal report stated that with the change in process, the yield of carbaryl went from 86 percent to 92 percent with respect to 1-naphthol with a purity of 99 percent (Peck, 1978). Production of carbaryl then became the largest volume consumer of MIC at the Institute plant. At one point, because of high demand for the product, 40 million pounds of MIC was produced annually. In 2008, the

TABLE 5.1 Acute Toxicity ategories for Carbaryl

| Guideline No. | Study | MRID No. | Results | Toxicity Categoryaa |

| 81-1 | Acute oral—rat (99% a.i.) | 00148500 | LD50 = 302.6 mg/k; for males = 311.5 mg/kg; combined = 307.0 mg/kg | II |

| 81-2 | Acute dermal—rabbit (99% a.i.) | 00148501 | LD50 > 2000 mg/kg | III |

| 81-3 | Acute inhalation—rat (99% a.i.) | 00148502 | LC50 > 3.4 mg/L | IV |

| 81-4 | Primary eye irritation—rabbit (99% a.i.) | 00148503 | Not a primary eye irritant | IV |

| 81-5 | Primary skin irritation—rabbit (99% a.i.) | 00148504 | Not a primary skin irritant | IV |

| 81-6 | Dermal sensitization—guinea pig (99% a.i.) | 00148505 | Negative | NA |

aI, highly toxic, everely irritating; II, moderately toxic, oderately irritating; III, slightly toxic, slightly irritating; IV, practically non-toxic, not an irritant.

SOURCE: EPA (2004).

process used a continuous fixed bed reactor run for 12 days followed by shutdown for 3 days to dissolve the accumulation of solids from the reactor (Martin, 2011).

Aldicarb

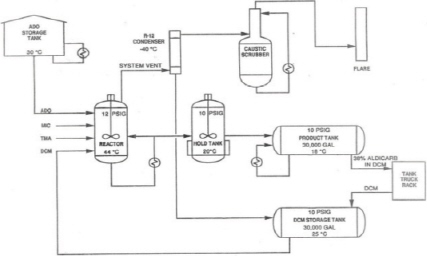

The Institute plant began producing aldicarb in 1976 (equation 5.11). Bayer personnel stated that of all the carbamates being produced at Institute, aldicarb was most clearly dependent on the use of the highly purified MIC generated from the existing Institute process. The primary uses of this pesticide are in early applications in commercial agriculture to control nematodes and sucking insects (U.S. EPA, 2010). In contrast to carbaryl, aldicarb and its metabolites are highly toxic through oral, dermal, and inhalational routes of exposure. Aldicarb is also toxic to fish and aquatic invertebrates. To render it safe to use, the aldicarb was processed into granules that reduced generation of dust and facilitated handling of the material, which in turn reduced exposure to the users.

The MIC-based aldicarb production process used a batch reactor, with an extended cook-out period that generated a complete reaction (see Figure 5.13). This material was then shipped to Woodbine, Georgia for binding onto particles of gypsum. This method necessitated a very clean coating of the pesticide being deposited on the particles of gypsum in the final formulation. Any impurities in the MIC could lead to imperfections in the coating, resulting in serious problems with clumping of the final product in the applicators. Such impurities could also

TABLE 5.2 Typical Human Hazard and Precautionary Statements

| Toxicity Category | Systemic effects (oral, dermal, inhalation toxicity) | Irritation effects (skin and eye) | Sensitizera |

| I | Fatal (poisonous) if swallowed [inhaled or absorbed through skin]. Do not breathe vapor [dust or spray mist]. Do not get in eyes, on skin, or on clothing. [Front panel first-aid statement required.] | Corrosive, causes eye and skin damage [or skin irritation]. Do not get in eyes on skin, or on clothing. Wear goggles or face shield and rubber gloves when handling. Harmful or fatal if swallowed. [Front panel first-aid statement required.] | If product is a sensitizer: Prolonged or frequently repeated skin contact may cause allergic reactions in some individuals. |

| II | May be fatal if swallowed, [inhaled or absorbed through the skin]. Do not breathe vapors [dust or spray mist]. Do not get in eyes, on skin, or on clothing. [Appropriate first-aid statement required.] | Causes eye [and skin] irritation. Do not get in eyes, on skin, or on clothing. Harmful if swallowed. [Appropriate first-aid statement required.] | |

| III | Harmful if swallowed [inhaled or absorbed through the skin]. Avoid breathing vapors [dust or spray mist]. Avoid contact with skin [eyes or clothing]. [Appropriate first-aid statement required.] | Avoid contact with skin, eyes, or clothing. | |

| IV | No precautionary statements required | No precautionary statements required. | |

aThere are no categories of sensitization.

SOURCE: 40 CFR § 156.62.

lead to greater formation of dust with correspondingly higher health risks. These issues were identified as a serious problem with most alternative sources of MIC, which tended to produce MIC of lower purity, which would in turn affect production of aldicarb. Figure 5.13 shows a simple process flow diagram for production of aldicarb.

Other Carbamates

Other carbamate pesticides (utilizing MIC) were also in production at Institute in 2008, but were not analyzed by the Committee for reasons described below. These pesticides include thiodicarb (Larvin), carbosulfan (Marshal), methomyl, which used a continuous plug flow reactor; and carbofuran (Furadan), which used a solventless process. The carbofuran unit was owned by FMC and operated by Bayer. When the Committee’s investigation began, Bayer had already decided to shut down production of methomyl and carbofuran after the 2008 accident. Pro-

FIGURE 5.12 Basic process flow diagram for production of carbaryl.

SOURCE: Martin (2011).

FIGURE 5.13 Basic process flow diagram for production of aldicarb.

SOURCE: Martin (2011).

duction of carbosulfan and thiodicarb continue using methomyl and carbofuran from an external source. The decision to close down those lines was apparently related to their location: those operations were in another part of the plant, requiring a separate MIC storage tank and a long pipe to transfer the MIC to that area.

Of the carbamate pesticides being produced at Institute in 2008, only carbaryl had been produced by a non-MIC process. At the time the present study was initiated, it appeared that a modified MIC process for the synthesis of carbaryl would be restarted at the Institute plant. In that case, a complete and critical review of the literature, patents, and worldwide practice for MIC-based and non-MIC-based N-monomethyl carbamate pesticide syntheses could have been appropriate, although such a review would have required considerable time and resources. Given the decision by Bayer to discontinue production of both MIC and N-monomethyl carbamate pesticides at the Institute plant, such a detailed review became unnecessary.

ALTERNATIVE ARRANGEMENTS OF PROCESSES

A key concern with the overall design of the production processes at the Institute plant was the need for storage of considerable amounts of MIC. This arose because of the characteristics of the production processes for MIC and the four carbamate pesticides. To account for the agricultural calendar, the production of MIC was ideally run on a continuous basis through most of the year, with only limited shutdowns (except for one long shutdown in July and August). The different carbamate processes had different schedules. The aldicarb and carbofuran processes ran all year long, whereas the carbaryl, oxamyl, and methamyl processes only required MIC during 4-5 months of the year. In addition, the Institute aldicarb and oxamyl processes ran in batch mode, and the carbaryl process was shut down for a few days every two weeks to dissolve solids from the reactor. Between the seasonal fluctuations and the short-run fluctuations in the carbamate processes, there was considerable variation in the need for MIC over time. The operators at the Institute plant had developed some degree of flexibility in the production rate for the MIC process, roughly a 3:1 (high:low) ratio, but they still relied upon a maximum MIC inventory level of 200,000 pounds to coordinate the MIC and carbamate production over time (Martin, 2011).

At various times the owners of the Institute site considered ways to reduce the amount of MIC being stored onsite. Reductions in MIC storage could offset impacts on the risk of the overall process. Smaller inventories of MIC would reduce the magnitude of damages from a potential accidental release of MIC from storage. However, holding smaller inventories would increase the number of times the MIC and carbamate processes had to be started or stopped, due to halting MIC production when the storage capacity was reached and stopping the carbamate process when the MIC in storage was used up. This could increase the overall risk of the process, because startup and shutdown periods have the

greatest potential for accidents (the 2008 methomyl accident happened during process startup) (CSB, 2011).

There were substantial reductions in the maximal MIC storage amounts at the Institute plant, from 1 million pounds at its peak to about 200,000 pounds more recently, as the scale of overall MIC production fell from over 40 million pounds annually in the late 1970s to around 10 million pounds by 2008 (Smythe, 2011). From 1989 to 1991 Rhône-Poulenc conducted an evaluation of alternative approaches to MIC production, including having separate MIC generators attached to each carbamate production line in order to reduce the need for MIC storage. This approach could have reduced the potential damage in the case of an accident because the amount of MIC being stored on each line would be smaller, but there would have been four times as many places for an accident to occur. In the end, the complications associated with having four separate MIC production units was considered to outweigh the benefits of reduced MIC storage, and the production process was not changed. In 1993, Rhône-Poulenc’s Institute Modification Project allowed the MIC production unit to operate at reduced rates, permitting a better match between MIC and carbamate production rates without increasing MIC storage. Most recently, in August 2009, Bayer announced plans to reduce the amount of MIC storage from 200,000 pounds to 40,000 pounds, as part of a $25 million investment project that also strengthened the layers of protection around the MIC production and storage units, and eliminated aboveground storage of MIC (Bayer CropScience, 2009).

Another important issue relates to the physical layout of the production process. In the case of the Institute plant, in 2008, the production of carbamate pesticides occurred in two separate areas of the plant, with the aldicarb and carbaryl processes located relatively close to the MIC production area, whereas the carbofuran and methomyl processes were located some distance away, in the West Carbamoylation Complex (WCC). Each night the MIC needed for the next day’s carbofuran and methomyl production was transferred to an aboveground holding tank. The proximity of that MIC tank to the explosion in the methomyl production unit in 2008 was a key concern in the investigation of the accident. Bayer’s 2009 decision to shut down the WCC helped reduce the risks associated with storing MIC in an aboveground tank and the overnight pumping of MIC to that tank (Bayer CropScience, 2009; Smythe, 2011).

Technical Considerations

A comparison of different production processes begins with consideration of the underlying chemical reaction. This determines the per-unit variable cost of production, along with energy and capital costs. There may be some uncertainty, especially on the capital costs, as well as a learning curve associated with operating a new production process. These uncertainties provide a substantial advantage for an incumbent production process, along with the cost

advantage that no additional capital costs are required to continue using the existing equipment.

Balanced against the costs of production is the revenue to be gained, which is likely to be influenced by the quality of the product. For the four alternative MIC production methods described above (DuPont, cyanate, diphenylcarbonate, and Enichem), purity of the MIC produced was an issue. According to the analysis provided by Bayer, the DuPont process generated considerable impurities at startup, which would have been unacceptable for the high-purity production requirements for the manufacture of aldicarb. Collection and purification of the gaseous MIC prior to use in the synthesis would require storage of a quantity of MIC on site and would, to some degree, reduce the benefit of just-in-time production of the chemical. Adoption of this process at the Institute site also presents additional technical challenges, since it would have required adapting the Institute aldicarb and carbaryl processes to work with gaseous MIC rather than liquid MIC. In addition, as production of aldicarb oxime ran as a batch process, onsite storage of MIC would still be required for at least short periods of time.

The cyanate method could match MIC production more closely to the batch versions of carbamate production. However, in order to accommodate the continuous production units of carbaryl and methomyl, onsite storage would again be required. In addition, the cyanate process is generally run on a much smaller scale than the UCC process; and adapting it to the Institute scale of production would require a very large number of reactors being built on site, which have an increased risk of leaks and equipment failures. Finally, as mentioned previously, the cyanate process generates significant quantities of hazardous waste that would need to be controlled and disposed of appropriately.

The diphenylcarbonate process for MIC production was used by Bayer in Germany until 2002. When that process was phased out, the company lost its in-house expertise. More importantly, however, this process depends on a supply of dimethylurea, which had been purchased from BASF in Germany but was not readily available in the United States. It is unclear whether onsite production of DMU was considered. There were also concerns about the quality of the MIC produced by the process, which could affect the final production of aldicarb. As with the DuPont process, an additional purification step might have resolved this issue, thought this would also have introduced a requirement for some onsite storage capacity. This process also requires the generation of phenol, which is also a hazardous material that must be managed, either by recycling of the material in the process or through treatment and disposal.

The Enichem process, although listed as potentially promising in the late 1980s, also presented some concerns. For example, the process had only been run on a very small scale (less than 5 percent of the level of production at Institute), and there were also concerns about the quality of the MIC that would be produced. The different MIC processes vary considerably in the purity of the

product MIC, with the Institute UCC process providing the highest MIC purity, which affects the quality of the resulting carbamate pesticides.

INFORMATION REQUIRED FOR SCREENING ALTERNATIVES

Performing a comprehensive inherently safer processes (ISP) analysis requires considerable information (see Chapter 4). There are multiple dimensions along which the processes can be compared, and many characteristics of each process need to be taken into account. These comparisons can then be incorporated into the process safety management (PSM) evaluations and, in turn, can affect business decisions. Indirectly, incorporating or developing systems that are “inherently safer” may reduce overall lifetime costs to a company by reducing the possibility of accidental release of hazardous materials from the process, with potential damages to personnel, the production facility, and the surrounding community.

When a company faces a decision about whether or how to change a process, more than the safety elements are considered, although safety could be a deciding factor in whether to move ahead. Some process characteristics are obviously part of any business decision, including the costs of the chemicals, labor and energy requirements, and new capital expenditures, as well as the quality of the product and revenues expected from its production. There can also be environmental impacts anticipated from the process, depending on the nature of the inputs being used and any by-products being generated. Many of these characteristics involve a substantial degree of uncertainty. The underlying chemical reaction may support relatively straightforward calculations of the amounts of different chemical and energy inputs needed for the process, and hence the expected per-unit production costs. The costs of developing and installing new capital equipment for the process will be less certain, as will the steepness of the learning curve when starting a new process. On the other hand, the probability and consequences of a major accident are much less certain, making it difficult to quantify those risks and consider them along with the other characteristics in the final decision-making process.

Any firm approaching a redesign must consider the position of the product in the market and its expected life-cycle. At this point, carbamate pesticides are relatively mature products, with a limited remaining market life, and hence a less desirable focus for new investment. Of the pesticides made at Institute, aldicarb seemed to have fewer competing products, which may help explain why Bayer was initially willing to spend $25 million in 2010 to extend aldicarb production for a limited number of additional years (Bayer CropScience, 2009).

In addition to production costs, the reaction identifies the particular chemicals involved in the process, as either inputs or by-products, and hence the hazards associated with the process. In addition to MIC itself, phosgene and chlorine are commonly used as reactants in carbamate production, and generation

of unwanted by-products such as phenol also increases risks. Balanced against the hazards from the chemicals are the safety measures being employed in the process. These add to the costs of running the process, but reduce the risk of accidental exposures, both within the facility and in the surrounding community.

Regulatory Considerations

A company’s decisions about production processes are also strongly influenced by constraints imposed by other entities. For example, manufacturing carbamate pesticides for sale in the United States requires that the pesticide be approved by EPA. The pesticide approval process can take multiple years, and approval is needed when there is a substantial change in the production process for the pesticide. This gives a considerable advantage to an incumbent process that has already been approved by EPA. When Bayer evaluated several alternative methods for producing MIC in 2010, a major drawback of all the alternatives, as identified by the company, was that changing the MIC process would require an EPA review and reapproval of the “new” pesticide, because the purity of the MIC could change. The reregistration process can be lengthy, could result in significant periods of lost production… such a gap in production could risk permanent loss of customers (farmers), who would have to switch to alternative pest control measures for at least one growing season.

Government regulation of workplace and environmental hazards can also influence company decisions, given the hazardous nature of the chemicals involved. For example, the creation of EPA and the federal Clean Air Act and Clean Water Act legislation increased pressure to reduce air and water pollution in the 1970s. This pressure to limit pollution helped drive the decision by Carbide to switch away from a highly-polluting (non-MIC) process for carbaryl production to a MIC-based process that generated less pollution. This example highlights the complexities of regulating production processes—efforts to reduce exposures to one set of hazardous chemicals may lead to changes that increase the risks of exposure to other chemicals. For more information about policy initiatives relating to ISP, see Appendix D.

Company-Community Relationships

Government regulators are not the only source of external pressures on the company’s decisions. The local community can also influence the decisions, and the relationship between the company and the surrounding community can be very important in this process.

The relationship between a chemical company and the community that surrounds it is a complex one. Chemical companies manufacture useful products and provide employment for the local communities, but to create these products, most chemical manufacturing processes require use of hazardous materials

and/or processes of some form. These hazards are managed through, among other things, process controls, training and education, and management systems. Regulatory structures, professional standards, and other forms of required and voluntary guidance reinforce and encourage safe practices. In case of accidents or leaks, emergency response systems are in place to help minimize the adverse consequences and control the event. Ideally, these protective systems overlap and integrate in such a way that the risks posed by the chemical and physical hazards onsite are as low as possible.

Community perception and understanding of risk and safety are important. For example, when considering responses to accidents or leaks, if an incident large enough to require local emergency response services to respond is a possibility, then a thorough understanding of the potential risks posed is required for development of an appropriate response and training of emergency personnel and community members. At a basic level, a neutral or positive relationship between a facility and its community allows for open discussion about risks and responses. It allows for a sense of trust that the experts onsite are operating with care and consideration. A negative relationship can influence the community perception of risk, lead to distrust, and create an environment of defensiveness and lack of engagement on important issues relevant to everyone involved. This issue has been examined in the literature with respect to community risk perception of nuclear and chemical facilities among other hazards (Starr, 1969, 1981, 1985).

Community perception is built on so-called risk perception “frames,” which are closely linked with individual views about how societal decisions should be made (social control frames) and the way they think about a given problem (cognitive frames) (Wildavsky and Dake, 1990; Dake, 1991; Elliott and Hanke, 2003; Gray, 2003; Lewicki et al., 2003). In short, people use different frames, based on background, education, social norms, and the like, to define whether a problem exists and if so, what the problem is. People with different frames may disagree about the problem, its size and scope, and how to address it.

Relevant to chemical manufacturing, one area in which differences in framing exist is in how people view environmental hazards and whether they pose health risks for the community. Researchers working in the field of risk perception have shown that parties confronting environmental hazards develop considerably different frames about the characteristics and intensity of the hazard (Elliott, 1984). Conflicting differences in how technical and lay populations frame risks occur frequently: the former stress prediction and prevention of risks whereas the latter are concerned about risk detection and repairing damage from risks that have occurred. Community perceptions of risk stem from a diverse set of factors ranging from the psychological to social processes of framing, to cultural expectations, and these factors play themselves out within a context of a particular facility and the risks associated with that facility, the relationship between the facility and the surrounding community, and corresponding processes of communication, control, and conflict or collaboration.

With regards to consideration of ISP, discussions between a facility and the community regarding trade-offs between possible alternative manufacturing methods could help the two sides understand their respective risk perceptions and tolerances. These shared understandings could then be used to help develop reporting and emergency response systems, outreach and communication strategies, and other activities in support of maintaining a safe environment and positive relationship. Analysis and discussion of trade-offs is likely to be complex, and decision-aid methods, such as the example described in Chapter 6, could be useful for framing such a discussion by identifying points of disagreement and concurrence among stakeholder groups. The findings from these analyses can be used by companies to aid in decision making by helping to clarify the issues of concern to the members of the community.

A good example of the role communities can play in facility decision-making processes can be seen in a comparison of the community relations at the Institute plant with those at a DuPont plant in La Porte, Texas. DuPont had been producing their methomyl insecticide, Lannate, using MIC shipped from the Institute plant. In 1985, restrictions on transportation of MIC following the Bhopal accident led DuPont to modify their Lannate production process to generate its own MIC. DuPont’s good relationship with the surrounding community permitted an open exchange of information about the new process, so that the community was willing to allow DuPont to start producing MIC in the facility, albeit with a process that involved no storage of MIC and only a few pounds of MIC in the process at any one time (Carberry, 2011). In contrast, the poor relationship between Bayer and its surrounding community resulted in a court injunction filed by community members to stop Bayer from resuming MIC production at Institute. This contributed to a complete shutdown of MIC production, even though Bayer had been producing MIC there for many years, had recently spent $25 million installing additional safety features, had reduced MIC storage levels by 80 percent, and was planning to phase out MIC production altogether within a few years. Thus, good community relations are crucial to a facility’s gaining local acceptance of their decisions.

Today, decision making for the production, storage, and use of MIC and other hazardous chemicals is predominantly made by facility operators within the context of national, state, and local regulations and requirements. At the same time, the chemical industry has increasingly realized the importance of effective working relations with the communities in which plants are located. One example of this is the Responsible Care program described briefly in Chapter 2. This voluntary program seeks to improve health, safety, and environmental performance in the chemical industry. At the heart of the International Council of Chemical Associations program is an effort for “companies to be open and transparent with their stakeholders—from local communities to environmental lobby groups, from local authorities and government to the media, and of course the general public.” Community advisory panels, as well as a wide range of other outreach efforts, have followed.

These efforts by the chemical industry have increased transparency, outreach, and dialogue with stakeholders external to facilities. However, as is seen in the dynamics surrounding questions of safety associated with MIC production and use at Bayer in Institute, West Virginia, these efforts have sometimes failed to produce a convergence of perspectives as to what poses significant risks to the community or how best to manage those risks. Divergent perceptions of risk, a problem common to many facilities that pose some level of risk to the surrounding community, are particularly important when the risks are potentially as substantial as those for chemicals such as MIC or phosgene. In Institute, there are obviously divergent perceptions of the risk posed by large-scale manufacture and storage of MIC at the Bayer facility between individuals working at the facility and at least one subset of the community. The most prominent group advocating for the removal of MIC from the facility is People Concerned about MIC (PCMIC), a group formed after the Bhopal disaster and which has worked toward that goal since that time.

QUANTIFYING COSTS AND BENEFITS OF ALTERNATIVES

Corporate decision making, at least as modeled by economists, is fundamentally driven by the goal of profit maximization. Nicholson (2005) provides a standard textbook discussion of various terms used in this section, including profit-maximization, capital costs, expected value, and externalities. In terms of the technical considerations mentioned earlier, decision making involves a comparison of the revenues generated by a production process with the costs of that production. At its simplest level, per-unit revenues from the sale of a pesticide could be compared to the per-unit costs of the chemicals and energy needed to produce the pesticide, and so a firm choosing among alternative processes that produced exactly the same product should choose the lowest-cost alternative. This calculation could be complicated by consideration of the capital expenditures associated with the processes, which enter the calculations as a one-time cost rather than a per-unit cost. However, suitable tools are available to deal with that, such as the present discounted value of future costs and revenues, or the annual cost of renting the capital each year.

A profit-maximizing firm should also consider any risks involved in the production process. An accident causing a temporary shutdown in production and extensive repairs will represent a cost to the firm, but a cost with considerable uncertainty attached to it, both in terms of magnitude and probability. One approach would be to assign the “expected value” of the accident (accident cost*probability), and so an accident with $50 million of damages and a three percent chance of happening each year would be assigned an expected annual cost of $1.5 million. It would then be profitable for the firm to implement safety measures that could cut the damages (or the accident probability) in half, as long as those safety measures cost less than $750,000 per year. Firms are often assumed

to use expected values to make these calculations, although if the potential risks are extremely large (e.g., complete shutdown of the facility or bankruptcy of the firm), the firm might be “risk averse,” equivalent to being willing to pay more than the expected value of the risk for some sort of insurance policy to avoid the risk. In the case of production risk using ISP to avoid the risk entirely would be one way of “buying insurance” against an accident.

From the point of view of the broader society, a key problem with the profit-maximizing decision described above is that the firm would not include in its calculations all the costs borne by people who might be exposed as a result of an accident at the facility. This discrepancy between “private” and “social” costs has been a central topic in Benefit-Cost Analysis (BCA) for many years (see Pigou, 1952 for an early example and Boardman et al., 2010) for a modern textbook approach). BCA is commonly applied to government (and private) decisions to see whether they are in society’s best interest (benefits>costs), and is required for major federal regulations (e.g., under Executive Order 13563, January 18, 2011, regulations “must take into account benefits and costs, both quantitative and qualitative”).

A firm’s decisions about risks, even those involving risks to others, can sometimes coincide with the socially optimal decision. Risks to the facility’s workers could, at least in principle, be reflected in compensating differentials—higher wages needed to attract workers to those risky jobs (assuming they know about the risk)—and would be included as a cost in the firm’s profit calculations. However, risks affecting people outside the facility would not generally be connected to the firm’s costs. Ignoring these external costs, called externalities, can lead a profit-maximizing firm to choose a riskier production process than would be optimal for society as a whole (Nicholson, 2005). One way of forcing firms to “internalize” these external costs (recognize the costs in their decision making) is through legal liability—if those damaged by an accident can sue the firm and collect full compensation for their damages, it provides an incentive for firms to reduce risks.

The existence of externalities provides an economic justification for the activities of regulatory agencies (such as EPA or OSHA) that constrain firms’ decisions about utilizing hazardous production processes with high levels of external risks. The presence of regulators imposing penalties for violations of safety regulations can provide an incentive to firms to reduce the risks associated with their production processes. Community groups picketing the facility or organizing boycotts of the firm’s products can also impose direct costs on firms using risky production processes. Both types of external pressures, regulatory and community-based, can lead firms to reduce risks, in order to reduce their likelihood of being penalized for those risks.

Corporate Social Responsibility (CSR), whose history is discussed in Carroll (1999) and elsewhere, is another approach to firms’ decision making that emphasizes society’s role in permitting the firm to operate. CSR sees the firm as having

a responsibility to take into account the external effects of its decisions. From this perspective, firms should consider how their decisions could achieve socially-preferred outcomes, considering external costs and benefits even when there are no regulatory or community pressures to do so. Many discussions of CSR describe firms as accepting lower profits in return for social acceptance, but Porter and Kramer (2006) argue that socially responsible decisions can also benefit the firm’s long-run profitability, especially if the firm focuses on providing benefits to society using its areas of expertise.

Whatever decision-making process is being followed, one key element in the calculation of the optimal decision is the risk of an accident. This can be complicated, especially when the risk of a substantial release affecting the area outside the facility involves the simultaneous failure of multiple layers of protection. Calculations of such risks often assume that the probability of each layer’s failure is independent, so that three layers of protection, each with a 1-in-10,000 risk, would provide an overall risk of 1-in-a-trillion. One lesson from the Bhopal accident is that, at least in that institutional setting, failures to manage risk were correlated across the layers of protection, greatly increasing the risk of an accident. Regulatory decisions under BCA can depend heavily on the calculations of the risk of low-probability events, such as the probability of a large accident at a chemical plant, or the probability of a given person dying of lung cancer after being exposed to air pollutants. A key difference between these two examples lies in the frequency of their observations. Millions of people are exposed to air pollution every year, and the (very small) fraction of individuals who die after the exposure can be calculated, which allows one to determine reasonably precise estimates of the risk’s probability. For large industrial accidents, which fortunately rarely occur, calculations of the probabilities involved depend on engineering models of the effectiveness of the different layers of protection. It is not that such calculations cannot be made—they are done regularly as part of both applications of BCA and profit maximizing decisions by firms—but as noted in Box 4.1, there are inherent uncertainties and biases involved.

There is also the sensitive issue of assigning values to the illnesses or deaths of people that could result from a major accident. For profit-maximizing decisions by the firm, these values can be related back to the potential liability costs of an accident, as discussed earlier. For BCA applications, the most common tool is the “value of a statistical life” (VSL). Suppose that a typical worker requires $5,000 extra wages per year in order to accept a risky job that has a 1-in-1,000 chance of a fatal accident during the year. A group of 1,000 such workers would, on average, have suffered one extra death per year—and would have accepted a total of $5 million to bear the risk of that death—so the VSL would be $5 million. Considerable effort has been expended by both academics and regulatory agencies to refine their VSL estimates, as well as to consider whether and how VSL values might vary within the population (see Aldy and Viscusi, 2007 for a recent example). Despite the common use of VSL in these calculations, many

are uncomfortable about “putting a dollar value on a life”, and regulators face considerable controversy when making adjustments to VSL (see Nelson, 2011 for a discussion of such controversies at EPA).

IMPLEMENTING METRICS

A fully quantitative inherently safer process (ISP) analysis that assigns values to all the benefits and costs from alternative production processes, including risks of accidents and other uncertain outcomes, would require considerable resources and a level of detail about production costs and risks that were not made available for this study. The owners of the Institute plant have done some comparisons of alternative production processes, although these were not fully quantitative. The most recent example of this sort of analysis at Institute was an analysis of alternative methods of producing MIC, mentioned in above (Smythe, 2011). A summary of the results is shown in Table 5.3. The first thing to note is that the various dimensions in the analysis are described in qualitative terms (high, low, medium), which rules out any sort of fully quantitative analysis of trade-offs across dimensions. The underlying study did include dollar amounts for the per-unit cost of production (summarized here in low/high terms, to avoid revealing any confidential business information), but the other dimensions were qualitative.

This sort of qualitative information could still be valuable in conducting an ISP analysis of the processes and could be used in support of or as a starting point to quantitative analyses. One value would come in identifying cases where option A is “dominated” by option B, that is B performs better on every dimension. This would be unusual, given multiple dimensions, but it helps to rule out clearly unsatisfactory options. A second value comes in helping focus the discussion of trade-offs. Also indicated in Table 5.3 that the Bayer process has low process complexity, low waste generation, and low internal recycle streams. All of these characteristics would tend to make it an “inherently safer” process, relative to the other four. However, the need for a supply of dimethylurea (DMU) was a major obstacle, because it was not available in the United States, made this option unfeasible at the Institute plant. It is unclear whether onsite production of DMU was considered as part of the analysis.

When Bayer explained how this information was used in its decision making about the best MIC production process, major advantages were seen for the incumbent process. The “bottom line” yes/no questions— “adaptation of infrastructure,” “R&D required,” and “registration required” —played a crucial role in the decision. These all show “no” for the Institute process and “yes” for the four alternative processes. “Adaptation of infrastructure” refers to the potentially large capital costs that would be needed to install the equipment needed for a new process (while the equipment for the existing process is already in place). “R&D required” reflects the uncertainty and learning costs associated with beginning

TABLE 5.3 Comparison of Alternative MIC Production Processes from Bayer CropScience

| Process | UCC | DuPont | Cyanate | DPC/DMC | Enichem |

| Internal recycle streams | High | High | High, solvent reflux | Low | Very high |

| Per-unit operating cost | Low | Low | High | High | High |

| Waste and wastewater | Medium | Medium (cyanide) | High (cyanide?) | Low | Medium |

| License fee | No | Yes | Yes | No | Yes |

| Adaption of infrastructur | No | Yes | Yes | Yes | Yes |

| R&D required | No | Yes | Yes | Yes | Yes |

| Registration required | No | Yes | Yes | Yes | Yes |

| Other factors | Catalyst exchange every 2 weeks | Batch process | External intermediate (dimethylurea) | ||

| Raw material propertiesa | MMA (mono-methylamine) : F+, Xn CO:T Cl2: T; Phosgene: T+ | CO:T MMA: F+, Xn | NaNCO:Xn Dimethyl sulfate: T+ | Phenol: T, C | MMA: F+, Xn Phenol: T, C |

| Process complexity | Very High | High | Medium | Low | High |

| Experience | Mature | Mature | Mature | Mature | One Unit? |

SOURCE: Adapted from Smythe, 2011. a: F - Very Flammable, F+ - Extremely Flammable, T - Toxic, T+ - Very Toxic, Xn – Harmful, C - Corrosive.

any new production process. The final element, “registration required”, confers a unique advantage upon the incumbent process in the case of pesticide production. As noted earlier, the need for EPA to reapprove the “new” version of the pesticide (made using MIC generated by a new MIC production process with different impurities) would cause a delay of months to years (once the agricultural cycle is taken into account) in marketing the pesticide. Since carbamate pesticides are near the end of their marketing life anyway, such a delay could make the shift to a new process uneconomical. If it were possible to keep the old process operating during the EPA review of the new process, “registration required” might be less of an absolute barrier, but that was not the situation faced by Bayer in 2010, and few facilities would have the extra physical space needed to continue running the old process while constructing the new one.

Bayer eventually decided to continue the existing MIC production process, but with an 80 percent reduction in the maximum MIC storage levels (from 200,000 pounds to 40,000 pounds), and other safety enhancements, including the elimination of aboveground MIC storage and the closure of the methomyl facility. The August 26, 2009 news release announcing this decision identified “the concerns of public officials and the site’s neighbors” as an important factor and promised to “continue its dialogue and close cooperation with the community and governmental agencies involved” (Bayer CropScience, 2009). This highlights the importance of external pressures on the decision-making process. Bayer personnel indicated that the decision-making process was carried out at the corporate level, including the size of the reduction in MIC storage levels, and the facility’s involvement was limited to confirming that a reduction in MIC storage to 40,000 pounds was feasible. In particular, the size of the reduction in MIC storage did not seem to be based on a specific analysis of the potential trade-off between the risks of larger MIC storage capacity and the risks of more frequent startup/shutdown conditions (i.e., why was 40,000 pounds the optimal MIC storage capacity, rather than 30,000 or 60,000 pounds?).

As noted earlier, this study focuses on alternative processes for producing carbamate pesticides at the Institute plant. In these calculations, the relative costs (both production costs and potential accident risks) associated with different processes have been considered, but the decision whether to produce the pesticides at all, which would depend on the overall benefits and costs of pesticide production, was not. Expanding the analysis to include these decisions would require additional information, including the benefits of these particular pesticides to farmers, relative to using other pesticides or no pesticides at all. These benefits may be reflected (at least partially) in the price of the pesticide, and thus be included in the company’s decision. Many of the decisions by Bayer in recent years have been of this type: deciding first to shut down the methomyl and carbofuran production lines, then later to stop MIC production altogether, along with the production of additional carbamate pesticides.

Looking again at the four MIC manufacturing processes in light of consider-

ations such as those discussed above, Bayer’s predecessors developed a table to help evaluate the trade-offs among the alternatives. Although this table provides a very useful starting point for a comparison of technologies, it excludes factors that may be important in the decision-making process, from the perspective of both the company and the community. For example, it does not include the volume of onsite MIC storage required, the risk of an accidental release into the surrounding community (which is related to storage volumes), the purity of the resulting MIC, or the likelihood of facing a community lawsuit. The next chapter discusses one possible systematic framework for identifying the key attributes that must be included into this type of decision and for analyzing the trade-offs.

CONCLUSIONS

Several decisions regarding process safety were made over the years by the owners of the Institute, West Virginia plant. Most of these decisions involved adding safety protections to existing processes, rather than changes to the underlying process. Bayer and its predecessors evaluated trade-offs among the alternatives, but while analysis provides a very useful starting point for a comparison of technologies, it excludes factors that may be important in the decision, from the perspective of both the company and the community. The only major change in production process was in 1978 from chloroformate to isocyanate in the carbaryl production. For an ISP analysis that focused solely on MIC usage, this was going in the “wrong” direction, but increasing environmental concerns in the 1970s about the level of pollution by-products of the chloroformate process, relative to the isocyanate process, were the driving factor behind that decision. Depending on the extent of environmental damages caused by the pollution from the chloroformate process and the probability and magnitude of the damages from an accidental MIC release, the overall risks generated by carbaryl production at the Institute plant might well have been reduced by the change to using MIC.

Decisions about the production processes at the Institute plant appear to have been driven by business conditions and external pressures, rather than resulting from an application of ISP analysis to the processes. A timeline of these decisions is provided in Appendix B. The earliest example in the data was the establishment of the Union Carbide Reactive Chemicals employee awareness training program and the Kanawha Valley Emergency Planning Committee, following explosions at the site in 1954 and 1955. The 1984 Bhopal accident led to expansion of the MIC destruction capacity and other safety enhancements. Restrictions on the shipment of MIC following Bhopal also led FMC to shift its production of carbofuran to the Institute plant. The 2008 methomyl accident and EPA regulatory decisions led Bayer to not restart the methomyl and carbofuran production lines, and the court injunction and other delays in restarting production eventually led Bayer to close down MIC production at Institute.

The decisions at the Institute plant also demonstrate the importance of vari-

ous barriers to change in existing production processes. On the cost side, there are investment costs for installing new production equipment and the uncertainty and learning costs associated with beginning a new process. In addition to these cost factors, a key factor in recent decisions at the Institute plant about their carbamate pesticide production process was the requirement for EPA registration of pesticides. This gives a substantial advantage to incumbent production processes, since changing to a new production process for an existing product means a delay in production while the “new” version of the product is being approved by EPA—potentially losing customers as farmers switch to other products during one or more growing seasons.

REFERENCES

Aldy, J. E., and W. K. Viscusi. 2007. Age differences in the value of statistical life: Revealed preference evidence. Review of Environmental Economics and Policy. Vol. 1, Issue 2. Summer. Pp. 241-260.

Bayer CropScience. 2009. Bayer Crop Science Announces Investment of $25 Million for Institute Site. Bayer News Release: August 26 [online]. Available: http://www.bayerus.com/News/NewsDetail.aspx?ID=586330BF-C83B-4EF3-93DBFF791373C7D7. Accessed: Feb 14, 2012.

Boardman, A. E., D. H. Greenberg, A. R. Vining, and D. L. Weimer. 2010. Cost-Benefit Analysis: Concepts and Practice. 4th ed. Prentice-Hall.

Carberry, J. 2011. Transition to Just-in-time Production of MIC. Presentation to the committee in Washington, DC.

Carcia. P. F. et al. 1984. Catalytic Conversion of Formamides to Isocyanates. US Patent Number 4,469,640. Issued September 4.

Carroll, A. B. 1999. Corporate social responsibility: Evolution of a definitional construct. Business and Society.. Vol. 38. No. 3. September. Pp. 268-295.

CSB (U.S. Chemical Safety and Hazard Investigation Board). 2011. Investigation Report: January 2011 Pesticide Chemical Runaway Reaction Pressure Vessel Explosion. Report No. 2008-08-I-WV [online]. Available: http://www.csb.gov/assets/document/Bayer_Report_Final.pdf. Accessed: February 6, 2012.

Dake, K. 1991. Orienting Dispositions in the Perception of Risk: An Analysis of Contemporary Worldviews and Cultural Biases. J. Cross-Cultural Psychol.. 22:61-82.

Elliott, M. 1984. Improving community acceptance of hazardous waste facilities through alternative systems for mitifating and managing risk. Hazardous Waste: A Journal for Technology, Health Environmental and Policy Research 1(3):397-410.

Elliott, M., and R. Hanke. 2003. Framing effect in toxic disputes: Cross-case analysis. Pp. 333-354 in Making Sense of Intractable Environmental Conflicts: Concepts and Cases. R. Lewicki, B. Gray, and M. Elliott, eds. Washington, DC: Island Press.

EPA (U.S. Environmental Protection Agency). 2004. Carbaryl IRED Facts [online]. Available: http://www.epa.gov/oppsrrd1/REDs/carbaryl_ired.pdf. Accessed: February 6, 2012.

EPA. 2010. Agreement to Terminate All Uses of Aldicarb, October 2010 [online]. Available: http://www.epa.gov/oppsrrd1/REDs/factsheets/aldicarb_fs.html. Accessed: Sept. 29, 2011.

Giesselmann, G., K. Gunther, and W. aus der Funter. 1980. Process for the production of methyl isocyanate. U.S. Patent 4,206,136.

Gray, B. 2003. Framing of environmental disputes. Pp. 11-34 in R. Lewicki, B. Gray, and M. Elliott (Eds.), Making Sense of Intractable Environmental Conflicts: Concepts and Cases. Washington, DC: Island Press.

International Council of Chemical Associations [online]. Available: http://www.icca-chem.org/en/Home/Responsible-care/What-we-do/. Accessed: February 6, 2012.

Kober, E., and T. Smith. 1968. Process for preparing isocyanates. United States Patent 3,366,662.

Lewicki, R., B. Gray, and M. Elliott. 2003. Making Sense of Intractable Environmental Conflicts: Concepts and Cases. Washington, DC: Island Press.

Martin, W. 2011. ECC Presentation to NAS. Presentation at the Second Meeting on Inherently Safer Chemical Processes. March 21-22, 2011. West Virginia State University.

Peck, D. W. 1978. Technology Summary Report: Manufacture of Carbaryl. Memorandum.

Nelson, G., “EPA Plans to Revisit a Touchy Topic—the Value of Saved Lives”. Greenwire.com. January 18, 2011.

Nicholson, W. 2005. Microeconomic Theory: Basic Principles and Extensions. 9th Ed. South-Western. Pigou, A. C. 1948. The Economics of Welfare. 4th Ed. Macmillan and Co. Ltd.

Porter, M. E., and M. R. Kramer. 2006. Strategy and society: The link between competitive advantage and corporate social responsibility. Harvard Business Review.. December.

Rao, V. N. M. et al., 1985. Multi-Stage Process with Adiabatic Reactors for the Preparation of Isocyanates. U.S. Patent Number 4,537,726. Issued: August 27, 1985.

Rivetti, F., F. Mizia, G. Garone, and U. Romano. 1987. Process for the Production of N-Methylcarbamates. U.S. Patent Number: 4,659,845. Issued: April 21, 1987.

Romano, U., F. Rivetti, and G. Sasselli. 1984. Improved process for preparing alkyl isocyanates.

European Patent Number: EP 0 125 726 A1. Issued: November 21, 1984.

Smythe, S. 2011. An Evaluation of Alternate MIC Technologies. Presentation at the First Meeting on Inherently Safer Chemical Processes. February 9. Washington, DC.

Starr, C. 1969. Social benefit versus technological risk. Science 165:1232.

Starr, C. 1981. Risk criteria for nuclear power plants: A pragmatic proposal. Risk Anal. 1:113.

Starr, C. 1985. Risk management assessment and acceptability. Risk Anal. 5:97.

Wildavsky, A., and K. Dake. 1990. Theories of risk perception: Who fears what and why? Daedalus. 119:41-60.

This page intentionally left blank.