The purpose of this overview is to provide a broad introduction to the nature of ceramic body armor plates and helmets as used by many U.S. servicemen and women; the medical basis for determining the relationships among body armor, blunt force trauma in humans and the testing of body armor; and techniques used by the U.S. Army to test the effectiveness of body armor.

The evolution of body armor in the United States dates from a series of inventions in 1861 when thin steel plates were enclosed in military jacket materials to protect against saber attacks and bullets (Peterson, 1950). Whether or not to use protective armor was a personal choice and depended on cost ($5-$7), weight (2 kg), and appearance (too unmanly). The use of vests ceased after the American Civil War and did not reappear in earnest until 100 years later, when the U.S. government began to supply law enforcement and public officials with protection from small-arms bullets. During the Vietnam War, U.S. military forces widely began wearing soft Kevlar-based protective vests. During the wars in the Middle East, U.S. personnel—both military and civilian—in the combat zone were required to wear protective vests containing hard body armor plates.

Currently, there are two major types of personal body armor, soft and hard. Soft armor vests are designed to protect against shrapnel resulting from explosions and against low-velocity, low-energy bullets (e.g., 9 mm, or .38 caliber). Hard armor and bullet-proof vests incorporate hard-plate inserts made of polyethylene or ceramic composite material in soft armor vests to defeat high-velocity threats such as 7.62 mm (.30 caliber) and 12.7 mm (.50 caliber) rifle bullets. The original work in standardizing body armor testing (discussed in Chapter 3) focused on soft armor, but the threats to both warfighters and law enforcement personnel are currently from shrapnel and projectiles of higher energy and higher velocity than anticipated 35 years ago. Therefore, much of the current research is on improving hard body armor.

Modern hard body armor can defeat incoming pistol and rifle rounds, trading energy and momentum deposition into the armor for deformation of the armor. This deformation includes direct deformation of the body armor in the case of soft body armors and deformation with fracture in hard body armors. A technical explanation of how ceramic body armor is able to defeat a threat

projectile and protect the wearer of body armor is contained in Appendix E. This deformation, however, has the potential for creating injuries in the thorax behind the armor that may generally be characterized as blunt trauma. These injuries are often termed “behind-armor blunt trauma.”

This study focuses on hard body armor (referred to as “body armor”) and helmets.

The Phase II report (NRC, 2010, p. 4) described the use of ceramic materials in body armor as follows:

Ceramic materials have been used successfully in personal armor systems to defeat small-arms threats. They are preferred for personal armor systems because they are lighter than more traditional armor made of metallic alloys. Properties that contribute to the performance of ceramic armor include superior hardness, low density, favorable elastic constants, and high compressive strength. However, as stand-alone items, ceramics would not be particularly good because of their low tensile strength, brittle response, and sensitivity to small mechanical defects such as pores and cracks. Hence, ceramics are used in combination with other materials, such as polymers and metals, to form laminar composites that provide excellent properties for body protection. A typical insert (also referred to as a “plate”) of body armor consists of a layer of dense boron carbide or silicon carbide backed by a layer of metal or polymer composite; the entire plate is wrapped in tightly woven ballistic fabric. The ceramic layer breaks up an incoming projectile and dissipates its kinetic energy. The layer of polymer composite and/or metallic alloy provides ductility and structural integrity and spreads the forces resulting from the impact of a projectile over a larger area.

The use of ceramic materials has been successful. The military collects data on casualties resulting from possible penetrations of body armor by enemy rounds, and there have been no known soldier deaths due to small arms that were attributable to a failure of issued ceramic body armor (NRC, 2010).

Fiber and Resin Composites in Helmets

Like body armor, current ballistic protective helmets employ a passive momentum defeat mechanism in which a bullet with a small mass and high velocity progressively engages a larger mass of high-performance fiber/resin composite, decreasing the bullet velocity and locally transferring momentum to the helmet. This process continues until all the momentum of the incoming round is deposited into the helmet or the helmet is defeated and penetrated by the incoming round. Even if the incoming round does not penetrate the helmet, there is still potential for substantial local head contact from sufficient helmet

“backface deformation” (BFD) into the head and resultant traumatic brain injuries.

All hard body armor systems currently add a significant burden of weight on the soldier. Armor testing therefore has implicit goals of ensuring that body armor meets survivability standards while allowing sufficient soldier mobility and flexibility. To provide soldiers with more weight than necessary to defeat a specified threat can lead to unintended consequences such as premature exhaustion and restricted ability to move rapidly and react appropriately in life-threatening situations (NRC, 2010).

MEDICAL STUDY BASIS FOR TESTING BODY ARMOR

In 1977 a study was performed to correlate the depth that a 200-g, 80-mm hemispherical missile impacting at approximately 55 m per second penetrated live animal tissue and other media (Prather et al., 1977). The goal of the study was to develop a simple, readily available backing material for characterizing both the penetration and deformation effects of ballistic impacts on soft body armor materials and to relate this information to the injury potential of nonpenetrating ballistic impacts. When there was no penetration of the armor the researchers noticed that dynamic ballistics forces caused a deformation in the recording material directly behind the point where the bullet struck the front side of the armor. This deformation in the backing material was the BFD mentioned above. The depth of penetration into various media such as modeling clay and ballistics gelatin as a function of time was compared to the probability of lethality for the same penetrator entering into a live animal model (goats were used as models) (Clare et al., 1975).

Prather et al. (1977) observed strong correlations between lethality probability and penetration into ballistic gelatin5 and also into the modeling clay Roma Plastilina (RP #1) . The ballistic gel required the use of high-speed photography to record BFDs because the gel was elastic and returned to its original shape after the projectile firing. To avoid the necessity of using expensive high-speed photography, an alternative material was sought that would retain its deformation and be easily measured using inexpensive manual calipers. The first conclusion of the Prather report had a profound effect on testing over the next 30 years. It reads as follows (Prather et al., 1977, p. 11):

A readily available, easy-to-use backing material, Roma Plastilina 1, has been found which can be correlated to tissue response for use in characterizing both the penetration and deformation effects of ballistic impacts on soft body armor materials.

________________________

5Ballistic gelatin is a clear or yellowish gelatin that is the standard medium for seeing and evaluating what happens to bullets on impact with soft tissue.

RP #1, a commercially available artists’ modeling clay, has since been adopted as a recording medium to assess the likelihood of injury or death from ballistics, and its use has been extended from assessing soft armor, such as Kevlar vests, to assessing hard armor plates and helmets, knife wounds, industrial injuries, such as one to a drop-forge operator, and nonlethal projectiles (Lyon, 1997; Chadwick et al., 1999; O’Callaghan et al., 2001; Vaughan, 2001; and Karahan, 2008). RP #1 appears to have become an industry standard despite being a questionable correlative of the human body. The deformation left in the modeling clay has until recently been measured using manual calipers. Over the past few years more technologically advanced laser profilimeters have been mandated for measuring the deformations made during Department of Defense body armor testing.

Since the original Prather effort, a number of studies and experiments have been conducted to better determine the relationships among blunt force trauma, human injury, and body armor testing processes. Even though there is no correlation between medical data and the BFD approach, the committee believes that the current methodology for testing body armor should be continued until it is replaced by a better methodology. As stated earlier, the current approach has allowed the Army to send body armor with adequate survivability characteristics (no known deaths due to penetrations of rounds the armor was designed to defeat) to soldiers in combat.

In this study the committee will offer ideas that may lead to a refinement or replacement of the original Prather methodology.

The Army’s procedures for testing hard body armor by measuring the deformations in clay backing from ballistic impacts are documented in “Test Operations Procedure (TOP) 10-2-210: Ballistic Testing of Hard Body Armor Using Clay Backing,” dated October 1, 2008 (ATC, 2008). As described in the Phase I report, the approach may be summarized as follows (NRC, 2009, p. 6):

A clay box 6 and a clay chest plate appliqué 7 [See Figure 2-1] are assembled, appropriately calibrated for part-to-part consistency using the column-drop performance test, and placed upright in the test holder.

… Independently, a “shoot pack” is prepared. …To create a shoot pack, the armor plate is placed in a fabric envelope together with multiple layers of Kevlar to replicate the vest worn by the soldier. The dimensions of the armor plate depend on the size of the vest … and can range from

________________________

6A plywood-backed aluminum frame (~61 × 61 × 14 cm) filled with modeling clay is subsequently referred to in this report as a “clay box” or as a “part” when discussing part-to-part variations. Since 1977 the modeling clay of choice for the testing community has been Roma Plastilina #1.

7As shown in Figure 2-1, the appliqué is an additional layer of clay that has been molded to the shape of the specific armor plate to be tested.

18 × 29 cm to 28 × 36 cm, with a thickness of approximately 2 cm. The vest has a significant nonconstant radius of curvature. Once assembled, the shoot pack is pressed firmly into the surface of the appliqué to ensure a conformal fit. The shoot pack is then removed and the laser scanning system is used to scan the surface of the appliqué in order to provide a reference surface relative to which subsequent deformations caused by the firing of the projectiles can be compared.

… The laser scanning system is moved out of the way and the shoot pack is repositioned onto the surface of the clay, with care taken not to disturb the reference surface, and the shoot pack is secured. … The selected projectile is then fired into the shoot pack, after which the shoot pack is removed from the clay and inspected for penetration …

FIGURE 2-1 The clay appliqué applied to the clay box. SOURCE: Richard Sayre, Deputy Director, Office of the Secretary of Defense, Director of Operational Test and Evaluation (OSD DOT&E) Live Fire Test and Evaluation, and Tracy Sheppard, Executive Officer and Staff Specialist, OSD DOT&E Live Fire Test and Evaluation, “DoD In-Brief to the National Research Council Study Team,” presentation to the Body Armor Testing Phase I committee, Aberdeen, Maryland, November 30, 2009.

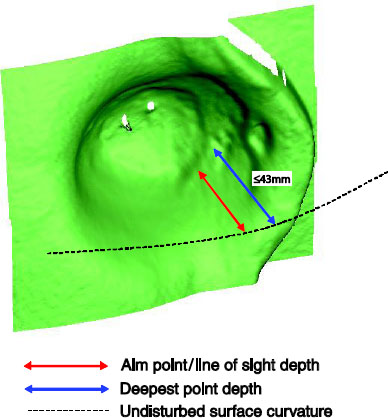

During the test, the velocity of the projectile is measured using Oehler Model 57 Ballistic Screens to verify that it was within the desired range. Any test round that penetrates the armor plate (a partial penetration) and continues on to completely break any Kevlar fiber on the back of the shoot pack is considered a complete penetration. A typical displacement or indent in the clay made by the deformation of the armor is shown in Figure 2-2. The nominal design specification is that the maximum depth in the clay relative to the original surface be less than 43 mm. That is, a BFD less than 43 mm deep is considered to indicate

FIGURE 2-2 Surface of the BFD as measured by a laser scanning system. SOURCE: Richard Sayre, Deputy Director, Office of the Secretary of Defense, Director of Operational Test and Evaluation (OSD DOT&E), Live Fire Test and Evaluation, and Tracy Sheppard, Executive Officer and Staff Specialist, OSD DOT&E Live Fire Test and Evaluation, “DoD In-Brief to the National Research Council Study Team,” presentation to the Body Armor Testing Phase I committee, Aberdeen, Maryland, November 30, 2009.

acceptable performance of body armor in service.8 Experimental data collected by the Army indicate that under nominally identical conditions the standard deviation for the maximum depth of the BFD (hard armor) is in the range of 2.5 to 4 mm.9 The BFD measurements in combination with the penetration data are used to evaluate the armor.

The deformation is measured with the laser scanning system. The data are collected and used to compute the profile (depth distribution) indent. The deformation is analyzed and serves as an indication of the survivability of a soldier subjected to a similar shot and protected by a similar plate in a protective vest.10

The testing of protective helmets also involves the measurement of clay deformation. In the helmet test methodology, a helmet is placed over a head form filled with modeling clay. A test round is fired against the helmet on the head form. The ballistic forces from the bullet cause an indent in the clay. The indents must not exceed the specifications for maximum acceptable indents on both the side and front for the helmet to pass the test. (A detailed discussion of the helmet test process with illustrations is contained in Chapter 7).

A typical firing range used to test body armor uses a rifle-like device to fire a projectile against an armor plate. An electronic instrument is used to measure the velocity of the projectile before impact. The armor plate being tested is affixed to an oil-based backing of modeling clay, which is left with a crater in its surface as a result of the impact. A laser system is used to measure the before and after surface geometry of the indentation in the clay. The indoor range set up for testing body armor at the Aberdeen Test Center (ATC) is shown in Figure 2-3.

________________________

8As described in the Phase II report, there has been variation over time about the allowable BFD depth (NRC, 2010). Traditionally, the Army has used 43 mm (with penalty points given for BFDs in the 44-47 mm range); the new DOT&E protocol requires that the 90 percent BFD upper tolerance limit be less than 44 mm with 90 percent confidence for the first shot and with 80 percent confidence for the second shot.

9James Zheng, Chief Scientist, PEO Soldier, “Ballistic Protection for Warfighters,” presentation to the Body Armor Testing Phase I committee, Aberdeen, Maryland, November 30, 2009.

10The Prather study showed that for various media, including the modeling clay Roma Plastilina #1, there is a correlation between the depth of penetration as a function of time and the probability of lethality for the same penetrator entering a human surrogate (goat) (Prather et al., 1977). The study addressed depth but did not address volume of the indentation.

FIGURE 2-3 The body armor test range at ATC. SOURCE: John Wallace, Technical Director, Aberdeen Test Center, “Body Armor Test Capabilities,” presentation to the Body Armor Testing Phase II committee, Aberdeen, Maryland, March 10, 2010.

GOVERNMENT ACCOUNTABILITY OFFICE REPORT

A primary motivation for the study was the Government Accountability Office (GAO) report GAO-10-119, “Report to Congressional Requesters, Warfighter Support, Independent Expert Assessment of Army Body Armor Test Results and Procedures Needed Before Fielding” (GAO, 2009). In the report, the GAO recommended that “the Army should provide for an independent ballistics evaluation of the First Article Testing results,” that “the Army should assess the need to change its procedures based on the outcome of the independent experts’ review and document these and all other key decisions made to clarify or change the testing protocols,” and that “the Army provide for an independent external peer review of ATC’s body armor testing protocol, facilities and instrumentation” (GAO, 2009, p. ii). The committee has addressed questions raised by the GAO throughout this report, and a summary of the committee’s responses to specific issues raised in the GAO report is contained in Appendix F.

While addressing the GAO concerns was of importance, the committee and sponsor have endeavored to focus the study on findings and recommendations that improve current testing processes. In turn, such improvements offer a way to field a lighter, more survivable body armor for our nation’s military forces.

ATC (U.S. Army Aberdeen Test Center). 2008. Test operations procedure (TOP) 10-2-210: Ballistic testing of hard body armor using clay backing. Aberdeen Proving Ground, Md.: Aberdeen Test Center.

Chadwick, E., A. Nicol, J. Lane, and T. Gray. 1999. Biomechanics of knife stab attacks. Forensic Science International 105(1): 35-44.

Clare, V., J. Lewis, A. Mickiewicz, and L. Sturdivan. 1975. Blunt trauma data correlation. EB-TR-75016. Aberdeen Proving Ground, Md.: Edgewood Arsenal.

GAO (Government Accountability Office). 2009. Independent expert assessment of army body armor test results and procedures needed before fielding. GAO-10-119. Washington, D.C.: Government Accountability Office.

Karahan, M. 2008. Comparison of ballistic performance and energy absorption capabilities of woven and unidirectional aramid fabrics. Textile Research Journal 78(8):718-730.

Lyon, D. 1997. Development of a 40mm nonlethal cartridge. ARL-TR-1465. Available online at http://www.defense-technology.com/pdfs/resources/development%20of%20a%2040mm%20nonlethal%20cartridge.pdf. Last accessed March 10, 2011.

NRC (National Research Council). 2009. Phase I Report on Review of the Testing of Body Armor Materials for Use by the U.S. Army: Letter Report. Washington, D.C.: National Academies Press.

NRC. 2010. Phase II Report on Review of the Testing of Body Armor Materials for Use by the U.S. Army. Washington, D.C.: National Academies Press.

O’Callaghan, P., M. Jones, D. James, S. Leadbeatter, S. Evans, and L. Nokes. 2001. A biomechanical reconstruction of a wound caused by a glass shard: A case report. Forensic Science International 117(3): 221-231.

Peterson, H. 1950. Body armor in the Civil War. Ordnance 34:432-433.

Prather, R., C. Swann, and C. Hawkins. 1977. Backface signatures of soft body armors and the associated trauma effects. ARCSL-TR-77055. Aberdeen Proving Ground, Md.: U.S. Army Armament Research and Development Command Technology Center.

Vaughan, N. 2001. Assessment of aprons for protection against drop forging projectiles. Contract Research Report 395/2001. Sheffield, U.K.: Health and Safety Laboratory.