This chapter discusses the role of the backing material as a recording medium, the properties and use of Roma Plastilina #1 (RP #1) modeling clay in body armor testing, and potential alternative backing materials and systems. It concludes with a road map for the body armor testing community to achieve reductions in the variability of clay as backing material for testing processes.

USE OF BACKING MATERIAL AS A RECORDING MEDIUM

As introduced in Chapters 2 and 3, the RP #1 modeling clay backing material used in armor testing has two important purposes. The first is “to simulate [some aspects of] the tissue response appropriately beneath the point of impact so that … ballistic data generated in laboratory tests can be correlated to the effects seen on the human body” (Prather et al., 1977, p. 7). The second purpose of the backing material is to mark the extent of backface deformation (BFD) during ballistic testing. Multiple materials are available to simulate a body; in fact, at the time it was introduced, modeling clay was recognized to only approximate tissue response, and empirical correlations were needed to develop a probability for lethality or injury. The chief advantage of modeling clay over other materials available at the time was that it better served the function of recording the BFD, because when impacted, it deforms plastically and a permanent cavity (also termed indent, impression, or crater) is developed under the point of impact. Correlations were developed between the geometry of the cavity and the probability of lethal injury. These results, however, do not predict a strain-rate dependence for the mechanical response of RP #1 and therefore increase the committee’s sense that obtaining direct measurement of the mechanical response of RP #1 in the strain-rate regime, corresponding to the development of the cavity in live-fire testing, should be a high-priority task.

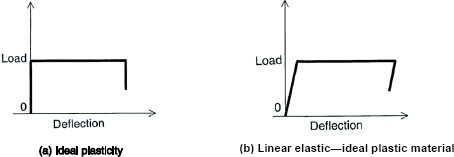

The role of a backing material such as RP #1 is to serve as a recording medium. That is, the backing material must exhibit plastic deformation. Ideal plasticity, illustrated in Figure 4-1a, exhibits no deformation until a critical stress is exceeded, at which point it deforms irreversibly (Fung and Tong, 2001). Thus, a backing made of such a material would serve as a “contour gauge” that would perfectly preserve the locus of points that corresponds to the maximum BFD.

FIGURE 4-1 A schematic illustration of the stress-strain curves for two idealized solids. The material corresponding to (a) exhibits ideal plasticity, in which there is no deformation until a critical stress (the yield point) is exceeded, at which point the material continues to deform at a constant rate until the stress is removed. The instant the stress falls below the critical value, such a material will stop deforming—that is, it exhibits no recovery. In contrast, linear elastic–ideal plastic material deforms elastically as the stress is applied before the plastic yield point. As before, the material deforms irreversibly when the yield point is exceeded. But in this case, upon removal of the stress, the elastic portion of the deformation is recovered as illustrated in (b). Real materials always exhibit some degree of elastic recovery. SOURCE: Fung and Tong, 2001, Copyright 2001, World Scientific Publishing Co.

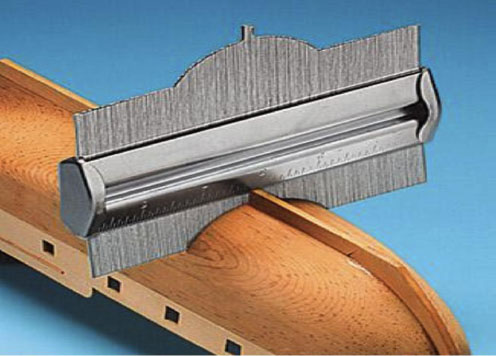

A contour gauge is a device familiar to craftsmen. It consists of a linear array of steel pins held parallel by a light clamping force. A typical device is illustrated in Figure 4-2. The pins are held in place with friction and therefore do not move until the application of stress. The relative motion in this case is caused by moving onto a shaped surface, but the principal is the same as in the armor test. In the latter case, the relative motion is the same, but it is the back face of the armor that moves into the backing material. If the backing material exhibited ideal plasticity, the resultant cavity would be a record of the maximum deflection of the BFD of the armor system, but this is manifestly not the case.

As illustrated in Figure 4-1b, the deformation of real materials differs in important ways from ideal plasticity. The first distinction is that all real materials have a finite elastic modulus. The consequence of this is that the material deforms reversibly prior to the onset of yielding and will exhibit elastic recovery when the load is removed. In the context of armor testing, this means that the cavity that remains in the backing material after the armor system has been struck by the projectile will be smaller than the maximum BFD.

FIGURE 4-2 A contour gauge in use. The parallel metal wires slide under the force that results from pressing the tool onto (or into) a shaped surface. The wires closely approximate plastic behavior in that they do not move until the applied force exceeds the frictional force produced by the clamping force. Given the high elastic modulus for the steel wires relative to the peak stress during sliding, there is effectively no elastic recovery when the tool and the surface separate. As discussed in the text, the backing material used in ballistic testing of armor is meant to serve an analogous role in that it should deform as the back face of the armor system moves and capture a permanent record of this transient event. SOURCE: Micromark, photo of a 5 in. metal contour gauge, found at: http://www.micromark.com/5-Inch-Metal-Contour-Gauge,9335.html.

In some materials elastic recovery is so large that they do not store any memory of the event. Prather et al. (1977) noted that ballistic gelatin, for example, is a highly elastic material and exhibits nearly total recovery. Constraining his choices to low-cost readily available materials, Prather et al. identified an oil-based modeling clay, RP #1, as a material that exhibited sufficient plasticity to evidence post-test cavities with geometries that correlated to lethality probabilities (Prather et al., 1977). It must be noted that in a presentation to the committee, Mr. Prather indicated that the study results should be considered provisional (i.e., not final or fully worked out or agreed upon at the

time). He also noted that RP #1 was “convenient,” and this attribute seems to have dominated as it rapidly became widely used.12

As time passed and a wide range of investigators used RP #1, two sources of confusion emerged. First, many assumed that it was a simulant when it was not. Second, the Prather report’s description of RP #1 has been misunderstood. It stated that RP #1 was “a highly plastic material which undergoes viscous flow when deformed and exhibits little recovery, thus providing a readily available cavity formed during impact from which measurements can be taken.”

The qualitative assertion that RP #1 exhibits little recovery has been interpreted to mean that the level of elastic recovery is small enough to be safely neglected. This led to the assumption that the shape of the cavity is a record to the BFD. It is not. As early as 1974, measurements of elastic springback were made using a modified Charpy impact tester (Aerospace Corporation, 1974). (A Charpy tester consists of a pendulum fitted with a weighted hammer that is allowed to swing into the sample material from a prescribed height, i.e., a given potential energy.) The difference in distance between the maximum point of the penetrator during its swing was compared to the size of the cavity in the RP #1, with this difference being the measure of displacement of the modeling clay during unloading. The results indicate that elastic recovery is in excess of 40 per cent and in some cases more than 70 per cent. That is, the differences are very large. Results from the Aerospace Corporation final report are shown in Table 4-1.

TABLE 4-1 Elastic Recovery in Modified Charpy Testing of Oil-Based Modeling Clay

| # of Plies of Kevlar-29 | Peak Load, N | Max. Depth of Indentor (mm) | Depth of Cavity (mm) | Difference (apparent recovery) (mm) | Difference (apparent recovery) | Expected* Elastic Recovery (mm) |

3 |

4671 |

37.34 |

18.54 |

18.8 |

50% |

12.45 |

| 3 | 5449 | 39.37 | 10.16 | 29.21 | 74% | 18.8 |

| 5 | 10453 | 41.66 | 24.13 | 17.53 | 42% | 20.07 |

| 5 | 10787 | 47.24 | 24.38 | 22.86 | 48% | 20.83 |

| * Calculated by Aerospace using “punch formula” de=[(1-v)Pia]/G. | ||||||

SOURCE: Committee-generated, derived from data in Table II, p. A38 (Aerospace, 1974).

________________________

12Russell Prather, Survice Engineering Co., “Prather Study Results” presentation to the committee on August 11, 2010.

Results of drop tests conducted by H.P. White Laboratory, Inc., also were consistent with significant elastic recovery.13 Furthermore, low-rate indentation experiments on plasticine, which is the same class of material as RP #1, indicate that recovery would be expected at high rates (Huang et al., 2002). Thus, the cavity in the RP #1 is not a record of the BFD. It is, as originally stated by Prather, “a readily available cavity formed during impact from which measurements can be taken” and to which correlations can be made (Prather et al., 1977). This is a critical point to recognize when considering either a replacement or the potential for improving the backing material performance by adjusting the formulation to produce a “ballistic grade.”

Another very important point is that the relative degree of elastic and plastic deformation will be expected to vary as a function of strain rate. That is, the material must be characterized under conditions that are relevant to those under which tests will be performed. To the knowledge of the committee this has never been done.

Although the properties of RP #1 have not been reported as a function of the strain rate, those of other candidate backing materials have been. For instance, the compressive properties of 20 per cent ballistic gelatin measured at 10°C using a modified split Hopkinson bar as a function of strain rate over a range comparable to the range of interest (hundreds to thousands of reciprocal seconds) (Salisbury and Cronin, 2009). The compliance is observed to change by a substantial amount, with the gel perhaps 10 times stiffer at the high strain rate. Also showing the dependence on strain rate is a study that compared ballistic gelatin with physically associated styrene-isoprene triblock copolymer gels (Juliano et al., 2006).

In sum, RP #1 was selected as a material of convenience rather than on the basis of well-determined engineering properties. It serves as a recording medium rather than a body simulant. The cavity that results from live-fire ballistic testing is related to the BFD of the armor, but it is not a true record of the maximum deflection. It remains unknown, therefore, how the dimensions of the cavity relate to the true BFD (and how such a relationship depends on the rate at which the cavity is formed).

________________________

13Don Dunn, H.P. White Laboratory, Inc., “Commercial Body Armor Testing Perspectives,” presentation to the committee, August 9, 2010.

CHARACTERISTICS AND PROPERTIES OF RP #1

Column-Drop Test

As standards have evolved, column-drop tests have been introduced to ensure that the modeling clay used for each test has well-defined behavior. The drop test consists of dropping a cylindrical steel mass with a hemispherical cap (44.5 mm in diameter) of defined mass (1 kg) from a height of 2 m. The mass is then removed, and penetration is quantified by measuring the distance between the original flat clay surface and the deepest point in the indent. As the deepest point lies on a highly regular hemisphere, it can be readily and reliably located by an operator using a digital caliper. The Phase I committee letter report (NRC, 2009) found that a digital caliper is adequate for this measurement because of the well-defined planar reference, the smooth and shallow indentation, and the ease of locating the center of the indentation.14,15

To assess the appropriate methodology for measuring the dimensions of deformed RP #1, it is useful to review the general characteristics of prior observations of its deformation, and this is best done by reviewing the results of so-called column-drop tests.

The introduction of the column drop test is another consequence of widespread adoption of Prather’s originally preliminary recommendation. “Roma Plastilina #1” is a trade name and as such does not embody a set of technical specifications. This was not an issue at the time as the recommendation was not expected to become a standard. However, it has been confirmed that the formulation of RP #1 has evolved over time. In part the evolution was in response to the primary customer base for clay (artists) making performance requests and in part it was due to the shifting availability of raw materials from different suppliers. While this may be commonplace for commercial products, it has had profound effects on the use of RP #1 as a backing material for live-fire testing of ceramic body armor. To quote Aberdeen Test Center (ATC) personnel, “The mechanical properties of Roma Plastilina #1 are dramatically different from the clay that was used in 1977.”16

________________________

14Finding 3 of the Phase 1 letter report stated that “the digital caliper is adequate for measurements of displacements created in clay by the column-drop performance test: there is a well-defined reference plane, and one can visually see the surface of the clay, given that the depression is relatively shallow (approximately 22 to 28 mm) and fairly smooth” (NRC, 2009).

15Finding 4 of the Phase 1 letter report stated that “The column-drop performance test (including the testing protocols, facilities, and instrumentation) is a valid method for assessing the part-to-part consistency of clay boxes used in body armor testing” (NRC, 2009).

16Scott Walton and Shane Esola, Aberdeen Test Center, “ATC Perspective on Clay used for Body Armor Testing,” presentation to the Body Armor Testing Phase II committee, March 10, 2010.

One consequence of shifting composition of the clay has been that a need was recognized to find a way to calibrate the modeling clay that was compatible with use on a ballistic firing range. This led to the development of the so-called column-drop test. Although it is not possible to trace the history of the test in published documents, it appears to have been developed in response to testers noting that newer versions of RP #1 were stiffer than older versions. Given that fact and the fact that oil-based modeling clay is readily softened by heating led to the use of ovens to warm the clay so that it behaved similarly to the older (de facto reference) formulation. The column-drop test developed to assess the similarity of clay behaviors.

Several variants of the drop test are currently employed. At ATC, the drop test consists of dropping a cylindrical steel mass with a hemispherical cap (44.5 mm in diameter) of defined mass (1 kg) from a height of 2 m onto RP #1 contained in a clay box. The mass is then removed, and penetration is defined by measuring the distance between the original flat clay surface and the deepest point in the indent. As the deepest point is determined by a highly regular hemisphere, it can be readily and reliably located by an operator using a digital caliper, and the depth at this point can be measured by any of a number of techniques. As noted earlier, the digital caliper is adequate for this because of the well-defined planar reference, the smooth shallow indentation, and the ease of locating the center of the indention.

The three photographs in Figure 4-3 illustrate the drop test. The cavity resulting from the drop test is of a volume and shape that is qualitatively similar to the cavity from an armor test. Both craters are tens of millimeters in depth and width, and both are smooth, regular shapes. However, the deformation rate experienced by the clay is markedly different. As demonstrated to the committee, the weight impacts the surface of the clay slightly faster than 6 m/sec, whereas the back face of the armor system moves at a velocity nearly an order of magnitude greater, just over 50 m/sec.17

________________________

17Ibid.

FIGURE 4-3 Column-drop test as performed at ATC. The overall setup is shown in (A). The weight, shown up close in (C), is held in place by an electromagnet at the top of the antiyaw tube. Upon release the weight accelerates under gravity and is implanted into the surface of the modeling clay. The weight is manually removed and the depth of the cavity (two are visible) is measured. Also visible are two thermometer probes used to track the temperature of the modeling clay. The results of a typical drop are shown in (B). Notable is the significant yaw (inclination with respect to the normal of the clay surface). SOURCE: ATC, 2008.

Nonetheless, the column-drop test is what is used to determine if the clay box is what is termed “within calibration” and therefore can be used to test the hard armor plates. The criterion for test/no test is that the cavity resulting in this test is 25 ± 3 mm (ATC, 2008).

Drop test results reviewed by the committee were all obtained using the standard clay box on which the clay appliqué is mounted for the live-fire testing of hard armor, as described in Chapter 2. Four characteristics typify the results:

- Drop test results exhibit scatter even under nominally identical conditions;

- The flow of RP #1 in response to load (rheology) depends on thermal history or heating;

- The rheology of RP #1 also depends on prior working (shear history); and

- Drop test results depend weakly on location in the clay box.

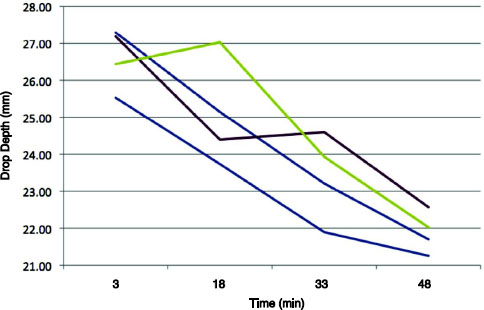

The effects of temperature have been systematically studied by both Army ATC personnel and an independent lab. The Army study employed the standard drop test. A clay box was thermally equilibrated at 40°C (104°F) and subjected to serial drop tests over time as the clay box was allowed to cool, approaching room temperature. Although temperature measurements were taken, they were not reported; instead, the variation with time was presented. These data (Figure 4-4) reveal two very important characteristics of the modeling clay with respect to this application: (1) there is substantial lot-to-lot variation (under nominally identical conditions different boxes yielded penetrations that varied systematically from 1 to 2 mm) and (2) the drift with time is significant compared to the allowed range for “calibration,” that is, ±3 mm. Over the 45 min of the test the average penetration in all cases was reduced by more than 4 mm. One implication of the latter characteristic is that the majority of clay boxes that are within calibration when removed from the oven can be predicted to fall out of calibration during the 45-min time window.

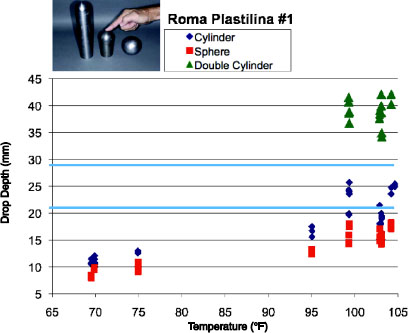

A second result from the same study is given in Figure 4-5. In this figure drop tests results using weights of different geometries are presented. The information implies that there is no particular advantage of any one shape. The three different geometries that are tested reveal equally useful information. However, the results do make startlingly evident the magnitude of the scatter associated with drop test results; it is disturbingly large compared to the allowed calibration range.

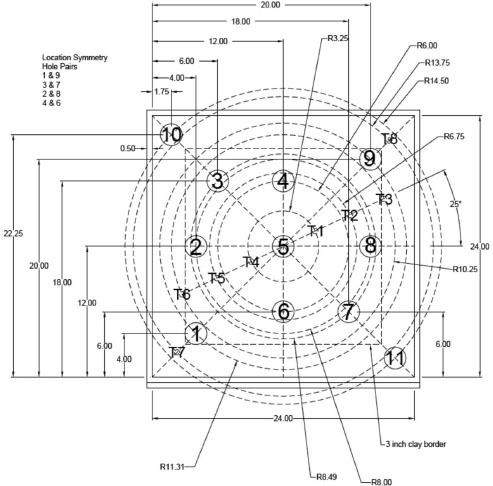

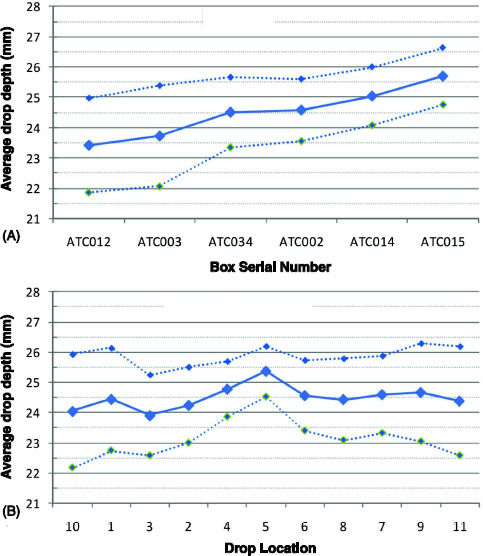

A qualitatively similar degree of scatter was observed in a study of drop test penetration as a function of radial position measured from the center of the box (see Figure 4-6) (Esola et al., 2010). In this study, there was a large box-to-box variation in drop-test penetration and substantial scatter under nominally identical conditions. Significantly, there was not a systematic trend with respect to radial distance from the center. In most boxes there was only a weak variation with distance, but there were some tests in which the edges were significantly less deeply penetrated and some in which the penetration was deeper near the extremities (see Figure 4-7). The results of this study can be summarized as follows:

- There was only weak correlation between radial position and average penetration depth;

- Variability of the average penetration depth under nominally identical conditions was significant;

- Variance increased as a function of distance from the center; and

- Well-used clay boxes exhibited behavior different from “dormant” boxes or from new boxes until they had been used for a while; however, the time constants for changes in behavior were not determined.

FIGURE 4-4 The results of drop tests on clay boxes allowed to naturally cool from 40°C to normal room temperature (roughly 23°C). Drops were made in a randomized 4 × 4 grid. The surface was not repaired between drops, and drops were intentionally separated to minimize potential interference. Four separate clay boxes were used, each represented by a different line on the graph. Each point on the graph is the average of two drops. Initial pairs of drops were made 3 min after removal from the oven, and subsequent data were taken in 15-min intervals. Although there is scatter, over the range investigated the slopes of the curves are all consistent with a decrease in average cavity depth of 1.5 mm every 15 min. The difference in the absolute values of the cavities resulting from the drop tests is attributed to lot-to-lot variation in the modeling clay and differing lengths of time in service. SOURCE: Scott Walton and Shane Esola, Aberdeen Test Center, “ATC Perspective on Clay used for Body Armor Testing,” presentation to the committee, March 10, 2010.

FIGURE 4-5 Drop test results using the standard Army right-circular cylinder with a solid hemispherical cap (44.5 mm [1.75 in.] in diameter with a mass of 1 kg [2.2 lb]), a similar non-standard double-length cylinder of the same diameter with the same type of hemispherical cap, and sphere with the diameter specified in the National Institute of Justice Standard (NIJ), 63.5 mm (2.5 in.) in diameter. The two horizontal blue lines represent the upper and lower limit of the calibration range. The most striking feature of the results is the observed scatter – which appears similar for all three classes of weight geometry. Under nominally identical conditions, the scatter is a substantial fraction of the allowable range! This is particularly so when the temperature is in the range of that seen in typical practice. SOURCE: Scott Walton and Shane Esola, Aberdeen Test Center, “ATC Perspective on Clay used for Body Armor Testing,” presentation to the committee, March 10, 2010.

FIGURE 4-6 Spatial pattern used in a series of experiments to determine the effect of position on the size of the cavity produced during a drop test. The positions of the drops are given by the circled numbers (all dimensions are in inches). Thermocouples were placed at the locations given by numbers preceded by the letter T. (Temperature data were tabulated but not used in the analysis.) SOURCE: Esola et al., 2010.

FIGURE 4-7 Illustrative results from a study on the effect of radial position on depth of penetration during a drop calibration test. The data presented in (A) represent the average and standard deviation for drops in different serial-numbered boxes. The ordering of the data is arbitrary—it is not intended to show a trend but rather the magnitude of the difference that can be expected from one clay box to another (a difference of 2 mm could be associated with a box switch). The scatter is very large: The upper and lower curves represent not the total observed range but the ± 1 standard deviation (about 68 per cent of observations fall within this interval when a data set is normal). The data presented in (B) show not only that the average penetration is shallower the farther from the center (the indexes are those from Figure 4-6), but also that the scatter was substantially greater

Similar results are found in a separate study conducted in an independent laboratory (Roberson et al., 2010). Some of the data in that study were obtained using a capillary rheometer. Such data are notoriously hard to interpret for systems such as this (a highly filled wax) owing to effects such as plug flow, wall slip, and flow instabilities associated with the axial migration of the low viscosity binder, and it does not appear that appropriate precautions were taken (Suwardie et al., 1998). Nonetheless, the study reported important results using calibration-drop tests (performed to the NIJ standard rather than the Army standard). In the NIJ-standard drop test, the weight is a sphere with a diameter of 63.5 mm (2.5 in.). The standards for penetration are 19 ± 3 mm for each drop, 19 ± 2 mm for the average of the prescribed five drops).

Roberson et al. (2010) reported similar results both with and without working the surface of the clay box through manual use of a rubber mallet to deliver repeated blows across a well-defined area. The calibration drop tests were performed to NIJ standards, which employ a sphere similar to that illustrated in the inset of Figure 4-5. Like the independent tests at the ATC, Roberson et al. observed substantial box-to-box variation that depends on shear history and temperature. There was significant scattering of penetration depths on the order of the range of allowed values ±2 mm. Under all conditions, the same temperature for the same box led to deeper penetrations after the modeling clay had been worked. The data from (Roberson et al., 2010) seems to support—at least in the case of the calibration drop test—the long-standing practice of correcting for box-to-box variation or differences in work history by changing temperature.

Another result in Roberson et al. is that the softening associated with mechanical working is reversible. That is, RP #1 is observed to stiffen when allowed to rest undisturbed for long periods of time. The results trace the behavior of oil-based modeling clay immediately after the requisite deformation to form the as-received 2-lb blocks into a clay box (soft); then after ageing undisturbed for 6 months (stiff); and, finally, after working the surface of the clay box (once again soft).

In sum, under all drop-testing conditions reported, RP #1 shows highly variable penetrations under nominally identical conditions. Typically, repeated drop tests show results covering a large fraction of the allowable (wide) range. This shows clearly that RP #1 is an inherently imprecise recording medium.

Finding: Both the spatial and the temporal variations of the modeling clay are significant. The response of the clay depends on temperature, shear history, and, perhaps, proximity to the edge of the box in which it is contained. Column drop experiments can be conducted to determine the variation due to box geometry and location of the drop in relation to the side of the box. Analysis of these results

should lead to uniform and evidence-based procedures for use by the body armor community.

High-Velocity Tests

Although there is a paucity of high-velocity data on strain rates approaching those associated with the motion of the back face of an armor system, there are two sets of results that can be considered.

The first set is an extension of the study by Roberson et al. (2010) on the effects of ageing, heating, and working. In that study, soft armor rather than ceramic hard armor was tested, but a lower threat round was used so that penetration depths were comparable to what would be expected in a test of hard armor against a higher threat round. The work systematically compared the depth of penetration during live-fire testing of soft armor in worked and unworked clay. The interesting result is that working the clay surface typically resulted in penetration that was 4 mm deeper. This is very close to the results of the drop test after the modeling clay had been worked even though the penetrations in the ballistic tests were three to four times deeper. However, additional empirical data is needed as the existing data do not reveal an obvious scaling relationship.

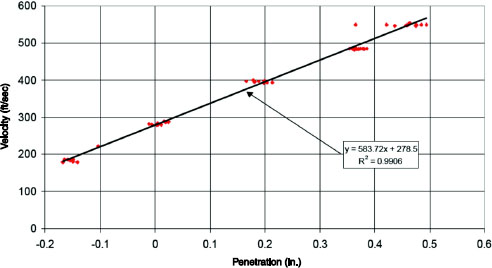

The second set of high-speed data comes from a nonlethal weapons development program (Weber, 2000). In this study, .32-cal (7.62-mm) rubber sting balls were shot from a high-velocity gas gun over a wide range of velocities into a clay box that was within calibration using the NIJ standard.18 The box was a square of the same edge length as a clay box used in the Army’s test operating procedure (TOP), but it was roughly one-third as deep—that is, 50 mm (2 in.) rather than 140 mm (5.5 in.). Figure 4-8 shows the configuration that was tested and the indentations from calibration drop tests and sting ball experiments. The results, presented in Figure 4-9, do not reveal any reason to expect a qualitative change in deformation behavior of modeling clay up to strain rates that approach those experienced in armor testing. Neither do they suggest that variance is lower at high velocities.

One point that is stressed by Weber is that the modeling clay is a relatively insensitive medium—that is, small differences in penetration depth correspond to large differences in sting ball velocity (and therefore energy). This means that accurate measurement of penetration depth is essential and that scatter in the data reflects a significant error in apparent projectile velocity.

Finding: Although the data are suggestive, the scaling relationship between drop tests and ballistic tests remains mostly unexplored.

________________________

18The sting ball hits the clay at a velocity three times that typical of the armor backface, but the diameter of a sting ball crater is less than a third as large as a typical BFD.

FIGURE 4-8 A clay box used for .32-cal rubber sting ball testing. The large diameter impressions represent NIJ standard calibration drops. SOURCE: Weber, 2000.

FIGURE 4-9 Results of sting ball experiments with projectiles ranging from 55 m/sec (180 ft/sec) to 168 m/sec (550 ft/sec). Penetration depths are measured from the aft end of the sting ball (they were not removed before measurements were taken). Converting to the tip of the sting ball (i.e., adding 0.32 in. to the recorded value and converting to mm) gives roughly 21 mm for the deepest penetration. Two observations may be made. The first is that there is no break in the curve. Over the wide range tested there is a linear relationship between the depth of penetration and the speed of the projectile at impact. This gives some measure of confidence in the drop test as a measure of consistency. The second observation is that a significant amount of scatter appears in the data; this is more true when penetration depths approach those that would be seen in ballistic testing. SOURCE: Daniel Weber, Edgewood Chemical Biological Center, “Measuring Impact Velocities of Non-Lethal Weapons,” presentation to NDIA - Non-Lethal Defense IV, March 21-22, 2000.

Taken as a whole, the work discussed above indicates that when considering the methodology, preparing and working the modeling clay, or interpreting the results of ballistic tests, the following points must be taken into account:

- As a recording medium RP #1 is inherently highly variable, giving noisy results;

- The response of the oil-based modeling clay RP #1 is dependent on both shear history (or working) and thermal history;

- There is a paucity of data at strain rates approaching those experienced in real armor test conditions; and

- Using thermal conditioning to correct for differences in shear history and ageing appears justified based on drop-test results.

Furthermore, when considering a road map for the development of an improved ballistics-grade clay or for the selection of an alternate backing material, the degree to which the first three points can be addressed must be rigorously evaluated.

Influence of Structure on Properties of Oil-Base Modeling Clay

Thixotropy as a Phenomenon

Understanding the behavior of an apparently complex material such as RP #1 or designing from scratch a backing material that offers desirable, predictable, and controllable properties will benefit from an understanding of microstructure. That is, if the phases present, their spatial distribution, and their relative amounts are known, the system has a much better chance of serving the intended function. Mechanical properties can be related to the structure, allowing a meaningful prediction of strain rate, shear history, and thermal history. Furthermore, properties such as thermal conductivity, diffusivity, and thermal expansion all can be deduced or modeled using appropriate mixing rules once the phase distribution has been well determined.

Although the specific formulation of RP #1 must, understandably, remain proprietary for commercial reasons, the general composition is understood. Combined with information in the open literature, this allows the relationship between internal structure (or microstructure) and properties to be anticipated to a degree that is helpful to understanding how they might be improved. The two properties of most interest are the shear- and temperature-dependence of the RP #1.

The RP #1 formulation is known to include several multicomponent organic phase(s), a kaolinite filler, and two other inorganic fillers, sulfur and zinc stearate; this places RP #1 in a family of well-known systems. For example, a published formulation in a patent assigned to 3M Corporation specifies 40 to 60 percent inorganics (by weight) in a plasticized wax medium. The inorganic phase contains 15-30 per cent powdered sulfur, 40-70 per cent clay, and 15-30 per cent zinc stearate.

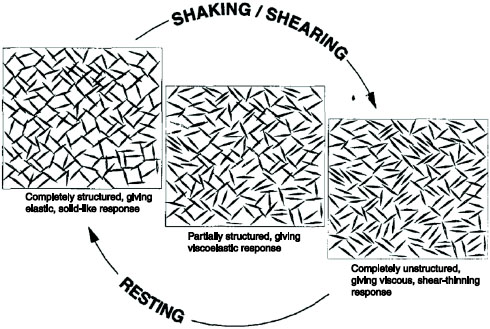

Such multiphase materials often exhibit a finite yield strength and thixotropy; that is, the material does not flow until it experiences a stress in excess of a critical value (the yield stress), and the material properties following the initiation of flow depend on time (thixotropy). Before they yield, the materials appear to respond as viscoelastic solids. The probable cause of shear sensitivity and thixotropy is shear-induced modification of the microstructure, which changes the modulus, yield stress, and viscosity among other things. Accordingly,

these materials can exhibit aging, shear conditioning, and even “avalanche” (runaway) behavior (Bonn and Denn, 2009).

Thixotropy can arise for a number of reasons and in a wide variety of materials. One classic example of such a system is a dilute suspension of clay minerals in a fluid such as water, but this is an illustrative system only. Indeed, quite varied and distinct systems exhibit thixotropy.

As outlined in the comprehensive review by Barnes (1997, p. 2) the term thixotropy was coined in the 1920s:

In 1923, Schalek and Szegvari found that aqueous iron oxide gels have the remarkable property of becoming completely liquid through gentle shaking alone, to such an extent that the liquified gel is hardly distinguishable from the original sol. These sols were liquified by shaking [and] solidified again after a period of time …. The change of state process could be repeated a number of times without any visible change in the system …. The term thixotropy was then coined by Peterfi in 1927 … in the first paper that properly described the phenomenon. The work combines the Greek words thixis (stirring or shaking) and trepo (turning or changing). (Barnes, 1997, p. 2)

Solid particles suspended in a liquid medium comprise one classic system that exhibits thixotropy when there is a driving force for the establishment of a space-filling agglomerate (a gel) due to net attractive interactions between particles. The attractive interaction has to be weak enough to be readily broken through the application of mechanical energy. If it is very weak the gel can be readily and reversibly reduced to a liquid state by heating as the thermal energy of the particles becomes greater than the interparticle bond strength. Such a system is perhaps the most intuitive class of thixotropic materials (see Figures 4-10 and 4-11).

However, many complex fluids exhibit thixotropic behavior—or, more generally, rheology that is dependent on thermal and shear history. All that is necessary is for a weakly bonded network of a relatively rigid dispersed phase to exist in a matrix of relatively flowable matter. Examples include many foods and (of direct relevance to the use of RP #1 for measuring BFD) ointments and cosmetics (Borwankar, 1992; Barnes, 1997; and Abu-Jdayil, 2003). In these all-organic systems, a three-dimensional network forms of a phase that is relatively rigid because, for example, it is crystalline or the intramolecular bonding is stronger due to polarity.

FIGURE 4-10 A schematic illustration of the “thixotropic cycle” of a two-phase system. The system at rest is a metastable structure that consists of a three-dimensional network of a rigid dispersed phase in a flowable matrix. In this schematic the dispersed phase is a nonspherical (platy) particle surrounded by a liquid. The interparticle potential is attractive between edges and faces, leading to the so-called “house of cards” structure as evidenced, for example, by the montmorillonite clays in Benna et al. (2001). It is significant that the schematics of structure are not dramatically different in the completely structured, partly structured, and completely unstructured states. This is consistent with the notion that the topological connectedness of the structure is critical, not the volumetric density of particles, which changes only at local levels. The upper arrow indicates the destruction of the network caused by the application of mechanical forces. This is generally considered an effectively instantaneous response. The lower arrow represents the reformation of the three-dimensional network when the forces are removed. Significantly, the regeneration of the structure takes significant time. The forces that drive the reformation are the interparticle forces (a combination of van der Waals, hydrogen, and weak electrostatic forces). The rate of reformation can be altered in some circumstances by heating or small-amplitude vibration, as these increase the mobility of the particles. If the structure does not reform, then the material is not thixotropic: It was in an unstable initial state. If the structure reforms so quickly that the lag is not observable, the material also is not thixotropic: Here, the term “structural viscosity” is used. SOURCE: Reprinted from Barnes, H., Thixotropy—A review, Journal of Non-Newtonian Fluid Mechanics, 70/1-2:1-33. Copyright 1997, with permission from Elsevier.

FIGURE 4-11 Optical micrographs of a three-dimensional network of spherical latex particles. The same colloidal gel is shown at rest (A) and just after flow (B). In (A), a clearly percolating structure (i.e., connected in three dimensions) can be observed. This material has a yield stress of ~5 Pa. In (B), the gel has broken into many smaller flocs. The material no longer has a measurable yield stress. Particle diameter, 1.3 µm. SOURCE: Bonn and Denn, 2009. Reprinted with permission from AAAS.

Phase Makeup

The manufacturer describes RP #1 as an oil-based, nonhardening modeling clay. In this context the word “clay” refers to a class of tactile and rheological behavior. That is, RP #1 looks and feels like a clay-water system. In this sense it is like a “polymer clay” such a Fimo or Sclupey. Polymer clay has been described as “a sculptable material based on the polymer polyvinyl chloride.”19 It usually contains no clay minerals, and is called “clay” only because its texture and working properties resemble those of mineral clay.

The following information about the composition and processing of RP #1 is available from the manufacturer’s Web site and may therefore be regarded as public:20

________________________

19Available online at ![]() http://en.wikipedia.org/wiki/Polymer_clay

http://en.wikipedia.org/wiki/Polymer_clay![]() . Last accessed December 21, 2010.

. Last accessed December 21, 2010.

20Available at ![]() http://www.sculpturehouse.com/plastilina_info.aspx

http://www.sculpturehouse.com/plastilina_info.aspx![]() . Last accessed December 21, 2010.

. Last accessed December 21, 2010.

The main ingredients are wax, oil, and clay flour that is used as a binder. All plastilina is produced hot, and then cooled and extruded into the shape that will eventually be available for sale in art supply stores. There are basically three groups of plastilina: professional grade, school grade and industrial grade.

The professional grade plastilina commonly contains sulfur, to make the smoother, more homogeneous texture required by professionals. ROMA Plastilina is an oil- and wax-base modeling material preferred by professional sculptors.

The following description is from a competitor:21

Plastilina (or plasticine) is an oil-based, nonhardening modeling compound. Because it contains wax instead of water, plastilina remains pliable and can be used over and over again. It is smooth and does not stick to the hands and fingers, unless it is very warm. [This] clay is made by combining various waxes with different properties—ranging from soft to hard and from plastic to brittle—and melting them until well blended in a steel vat. A powdered filler and pigments are added to the melted wax and then mixed together to form a finished product.

This is sufficient information when combined with information in the open literature to guide an engineering understanding of the material when used as a backing material. In the following discussion, attention is first focused on the behavior of the organic constituents and then on how two inorganic dispersed phases can be expected to modify that behavior.

Organic Phases. To begin with it is useful to consider the behavior of a mixture of microcrystalline wax, grease, and oil and in this context to make use of the structure-property discussion about the rheology of a model ointment that is a mixture of petrolatum, mineral oil, and microcrystalline wax (Pena et al., 1994). The first point to be made is that all three constituents are obtained from the distillation of petroleum. Therefore, it is correct to view the creation of the ointment, and most likely the plasticized wax base of modeling clay, as a selective reconstitution of mutually soluble fractions of petroleum to achieve a desired set of properties.

All of these materials are natural products comprising a mixture of straight-chain, branched-chain, and cyclic hydrocarbons. Yet, they are distinct classes of material. Mineral oil is composed mainly of liquid hydrocarbons at room temperature and is a distillation product, whereas both petrolatum and microcrystalline wax are derived from the residue of distillation. In fact, petrolatum is considered to be a soft microcrystalline wax with a high oil content (or, conversely, microcrystalline wax is a de-oiled petrolatum). Both petrolatum

________________________

21Available online at http://www.vanaken.com/howclay.htm. Last accessed December 21, 2010.

and microcrystalline wax contain small irregular crystals whose size is believed to be limited by the presence of oil.

Other work has determined that petrolatum is a two-phase colloidal gel of liquid, microcrystalline, and crystalline hydrocarbons. When cooled, the wax crystals form a three-dimensional network with the liquid present in the interstices of that network (Barry and Grace, 1971). Because the crystals have a relatively high coordination number, the system develops a finite yield point. The rheological properties are dependent, of course, on the relative fractions of crystalline solid and liquid elements of the microstructure.

Of particular note in the context of the observed shear history dependence of modeling clay, a model all-organic ointment exhibits rheology that is dependent on both thermal history and shear history. In particular, the effect of increasing the liquid fraction (by increasing the mineral oil content) and the microcrystalline fraction (by adding microcrystalline wax) has been demonstrated (Pena et al., 1994). Increasing the microcrystalline fraction builds up the three-dimension network and increases the static yield value. During shear the three-dimension network is broken down and the material shows a marked softening that is not recovered even after a week at rest.

The effect of temperature in this system is complex because there are qualitatively distinct phases that have distinct melting and softening points. Notably, multiple inflections and thermal arrests occur in the ranges associated with thermal treatment of RP #1: 37°C-39°C, 46°C-47°C, and 57 °C -58°C (98 °F-102°F, 115°F-117°F, and 135°F-136°F).

These observations are important as they bear directly on the presumption that shear history and thermal history produce comparable changes in the response of modeling clay. While the empirical data discussed in the previous section showed an apparent equivalence between heating and working, a study by the National Institute of Standards and Technology (NIST) on the rheological properties in torsional shear of an earlier formulation of RP #1 found that the material was highly nonlinear and time dependent and that the shear properties of kneaded and “melted” (raised to a temperature of 90°C) clay at a fixed test temperature were different (NIST, 1994).

In considering the development of material systems and associated testing protocols, potential backing materials are unlikely to be anisotropic on a macro scale, since any organic polymers that may be contained will not be of sufficiently high molecular weight to induce orientation. Plasticity is not dependent on the presence of polymers; it normally requires the presence of weak bonds, but these may be colloidal interactions.

Inorganic Phases (Fillers). Turning to the role of the inorganic filler (“clay flour”), the first question is whether the presence of a particulate induces shear-dependent (thixotropic) behavior. The answer is clearly no. For example, in a study on the dispersion of the ferrofluid y-Fe2O3 in paraffin, no thixotropy is observed with or without a magnetic field (Hosseini et al., 2010). These results are in keeping with the more general observation that ceramic particles are readily dispersed in wax

matrices and form the basis of low-pressure injection molding of ceramics (Peltsman and Peltsman, 1984; Zorzi et al., 2003).

In such molding formulations it is important to have engineering control over the interparticle forces. Generally, it is desired to produce a stable dispersion in which the particles do not agglomerate. This is readily accomplished through the use of surfactants, including stearic and oleic acids for oxides and fatty amines for nonoxides (Peltsman and Peltsman, 1984; Lenk and Krivoshchepov, 2000; Zorzi et al., 2003).

The three filler components control the stiffness of the modeling clay and its surface finish. One material, clay mineral, is a low-cost platy particulate often used to stiffen thermoplastic organic systems (Rothon, 1999). Both zinc stearate and powdered sulfur are used as solid lubricants, the former in ceramic processing and the latter in powder metallurgy (Reed, 1988; Blagin, 1966). Presumably the main role of these agents is to modify the friction resulting from contact with the tool working the surface. (It is unclear that such surface properties affect the performance of the oil-based modeling clay used in ballistic testing.)

In sum, there is sufficient information in the engineering literature to provide a basis for the understanding the structure-property relationships of RP #1 oil-based modeling clay that pertain to mechanical working, thermal processing, and friction and how the various ingredients modify behavior. Furthermore, the principles of design are sufficiently clear that an alternative system with more favorable properties can be expected to be successfully developed.

SHORT-TERM DEVELOPMENT OF AN INTERIM STANDARD CLAY FORMULATION FOR BALLISTIC TESTING

The Army’s protocol for ballistic testing of soft and hard body armor specifies RP #1 as the backing material (DoD, 2008). Since the initial validation studies, the formulation of RP #1 has changed, and this has changed its properties. Whereas historically calibration and testing could be performed at room temperature, the clay must now be above 100°F to pass the column-drop test (described in the section on clay behavior). The committee was informed that the thermal conditioning temperature has increased about 1°F every year.

In response to these known deficiencies of the current backing material, the Director of Operational Test and Evaluation (DOT&E) established an ad hoc clay working group whose members are technical clay experts from the Department of Defense (DoD), NIST, NIJ, private laboratories certified for testing body armor, and others. The group’s purpose is to pursue short-term improvements in clay formulation and processing, and short- and long-term alternatives to clay. A short-term goal is to develop a replacement for RP #1.

Based on their experience, members of the clay working group have developed the following desirable characteristics of clays for ballistic testing:

- Known, controlled, and consistent change in properties as temperature is changed.

- A long useful life for repeated testing at room temperature.

- Known, controlled, and consistent change in properties due to cold working (thixotropic effect).

- Excellent dimensional stability.

- Minimal stickiness to the target (i.e., the clay must not peel away when the target is removed) but high stickiness of clay to clay.

- Easy moldability, so that clay blocks can be formed with no voids, air bubbles, or gaps.

- Long shelf life (more than 1 year).

- Nontoxic, minimum odor, and reasonable price.

- Specifiable and controllable mechanical properties: density, seismic velocity, elastic modulus, shear modulus, grain size, hardness, etc.

Because its properties depend on shear history, time, and temperature, RP #1 appears to meet only some of these criteria. For example, it is typically heated to over 100°F to meet the calibration specification, which limits its useful life for testing at room temperature to less than 45 minutes. The current formulation also requires a complex preparation and packing procedure to produce boxes with uniform, reproducible properties that can pass the calibration test described in MIL-STD-3027 (DoD, 2008). The goal of the clay working group is to develop a short-term replacement that can meet the calibration specification at ambient temperature and minimize the sensitivity of the properties of the clay in the box to cold working.

In addition to the criteria developed by the clay working group, two additional considerations could facilitate development of a clay replacement in the short term. First, the formulation could be simplified by minimizing the number of ingredients. For example, as previously noted, RP #1 contains sulfur, which has an unknown effect on its performance in ballistic testing. Minimizing the number of ingredients should reduce variability in performance over time and simplify attempts to characterize and model performance. Second, the current RP #1 formulation of microcrystalline wax, oil, and grease includes clay as an inorganic filler. The inherent anisotropic (i.e., platy) nature of the clay particles may complicate the behavior of the RP #1. Eliminating the clay particles or replacing them with an inorganic filler that has an equiaxed particle morphology may provide properties that are less dependent on work history and time.

Two approaches are possible for the procurement of a standard ballistic clay from an industrial supplier. One would be to develop a material specification that uses a precise composition formulated with particular raw materials that are called out in the specification. This approach would guarantee a consistent product as long as the raw materials do not change but would not allow the supplier to adjust the formula in the event that properties change because raw materials are no longer available or that the properties of the raw materials themselves change over time. This approach could cause the properties of the standard ballistic clay to evolve, as happened with RP #1. The second approach

would be to develop a performance specification. This approach would allow the supplier to continually evaluate and adjust the composition to produce a consistent product. It would put the burden on the Army to specify the properties that are most important to the application but would seem to be the best approach to meet the need for a consistent backing material.

The presence of an organic phase in a clay-like modeling material is important for two main reasons. First, it provides a continuous phase that is highly viscous and possesses a substantial modulus, which cannot be achieved with a water-based system. Second, the organic phase is not volatile, which gives the backing material a long usable lifetime with consistent performance.

Temperature sensitivity in the material is much less an issue than is the fact that the current RP #1 must be used at elevated temperature, which causes the temperature and temperature-dependent properties of the material to change substantially during testing. Such a problem would not arise with a temperature-sensitive material that could be used at room temperature, which is why the focus for a replacement modeling clay is to develop a room-temperature material.

Recommendation 4-1: The Office of the Director, Operational Test and Evaluation, and the Army should continue to expedite the development of a replacement for the current Roma Plastilina #1 oil-based modeling clay that can be used at room temperature.

Conditioning and Handling of Clay

The conditioning and handling procedures associated with the use of modeling clay in live-fire ballistic testing of body armor can be reviewed in light of the above information.

As described in the NIJ standard and the Army TOP, and as observed at ATC and during tours of three commercial testing laboratories, standard practices for conditioning and handling clay demonstrate operational awareness of the influence of both shear and thermal history on the rheology of modeling clay.

First, the modeling clay is heavily worked using mallets or tampers when the standard clay box is filled. The box surface is scraped before calibration to create a flat surface of precisely known elevation. The manner of preparing and working the clay is appropriate given the thixotropic nature of the clay composition. That is, the procedure described is consistent with standard practice to remove behavioral artifacts in the material that are due to the manufacturing process and to erase any differences that might be associated with the length of time the modeling clay has been stored. Thus, this procedure represents good practice.

The clay boxes are thermally equilibrated for at least 3 hr at 40°C (104°F) prior to use. During drop calibration testing, standard practice is to insert two thermometers into the clay mass. The thermometers are inserted at points approximately along the box face diagonal one-quarter of the way from the opposing corners. They are placed about halfway down through the clay. These measurements are used to confirm that thermal equilibrium has been established.

The personnel who repair and recondition clay boxes follow procedures that are consistent with standard practice by artists and others for filling space without entrapping air. That is, small additions are made sequentially and each is heavily sheared by hand to express any entrapped air. This procedure represents good practice. Army personnel related that periodic X-rays of clay boxes only very rarely indicate the presence of entrapped air. The same rebuilding procedure appears to be used both in rebuilding indentations produced during calibration and after an armor test to restore the box. However, at the conclusion, test clay containing any debris (such as fabric, fragments of body armor, or projectiles) is removed prior to rebuilding the surface.

Improvements to Mechanical Working

Given that mechanical working is known to break down the internal structure of the modeling clay, changing its flow behavior, and that mechanical working is routine and unavoidable given the need to assemble and rebuild the clay box, it is highly desirable to ensure that the entirety of the box can be worked in situ. It is standard practice in mechanical testing of thixotropic materials to establish a standard state, typically by preshearing.

A partial solution is to work the exposed surface of the clay box either manually or with a mechanism such as powered concrete tamper. This could be improved by removing the plywood backing and working both sides.

An alternative is to devise a means of working the entire volume of clay in place in the box. Examples of in situ mixing of soils exist in the open literature (Topolnicki, 2004). These might be adapted to the present purpose, but it is recognized that doing so would be a tough engineering challenge.

The committee was shown results of a preliminary experiment in which a clay box was placed on a vibration table and indentation experiments were carried out before starting the vibration and after 20, 30, and 40 min of vibration. The vibration frequency and amplitude, however, were not available. The average indentation increased monotonically from about 12 mm to just under 16 mm, with an approach to asymptotic behavior evident at 30 minutes. This result suggests that in situ mechanical working to obtain a uniform consistency should be feasible, and this work should be continued. The importance of such an effort is manifest in a statement by an ATC Protective Equipment Division science officer, who stated that in his opinion perhaps some of the most significant improvements to reduce variation in the testing process could come from the hand processing that goes into filling the clay boxes and working the clay before and after test firing.22

In-box mechanical conditioning alternatives were recommended in the Phase II report and offer the possibility of generating a mass that responds more predictably and uniformly (NRC, 2010). Further, such in-box conditioning might

________________________

22Shane Esola, Aberdeen Test Center, “Clay Calibration Study: Radial Dependence of Calibration Drop Depths,” presentation to the committee, October 13, 2010.

reduce the need for elevated temperature, with its concomitant need for precise control. Testing of such in-box mechanical working methods should continue.

Thermal Conditioning

Temperature changes affect the consistency, probably in large measure by changing the viscosity of the organic phase and, possibly, at sufficiently high temperatures, causing a phase change of one or more microstructural elements; the temperature must be maintained within a fixed interval for the clay to exhibit acceptable mechanical properties. Temperature drift with time has a measurable effect on drop test penetration, for example, and can move a block out of specification during the course of a test.

The current practice of elevating the temperature of the clay box and yet using it at room temperature means that an inescapable drift is superimposed on the experiment. This is a fundamentally flawed approach and leads to undesired laboratory practice. For example, when conforming to the NIJ standard, which requires a post-test calibration drop, operators will be predisposed to heating the clay to the highest temperature that yields drops that are within the permitted range, increasing the likelihood of satisfactory post-drops after the block has had some (perhaps variable) time to cool. This is contrary to the spirit of the 19 ± 3 mm NIJ standard even though it is formally compliant to the standard. The Army TOP does not require or allow a post-test drop but constrains the test time to 45 min in duration. However, it is known that the behavior of that clay is substantially modified over this period. Not permitting a post-test drop creates a situation in which the block is used under conditions when it will almost certainly be out of specification.

There appear to be only two plausible solutions to this dilemma. The first is to heat the clay throughout the test. However, there is no obvious engineering approach to this. The alternative is to reformulate the backing material to a ballistics grade so as to achieve a material that can be used at room temperature and does not require heating to calibrate.

Finding: In the short term, testing will continue to be conducted using the existing Roma Plastilina #1. As long as heating the clay is necessary, cooling will take place, and the post-test calibration drop test, as recommended in the Phase II Report (NRC, 2010), will continue to be an urgent requirement for the Army Test Operating Procedure.

Systematic Characterization

Fundamental thermomechanical information about the clay formulation appears to be lacking. Plasticine rheology has been widely studied over the decades due to the technical importance of modeling materials in a number of scientific and technical applications. It is a complex material with a response that has been shown to depend on strain, strain rate, and thermal and mechanical

history. The committee is unaware, however, of any linear viscoelastic measurements at low or high frequency for either worked or unworked RP #1 to determine the relative recoverable (elastic) and dissipative (viscous) fractions of the response; linear viscoelastic measurement, even at frequencies well below operational time scales, can be sensitive indicators of structural change. Nor have there been shear measurements at a range of temperatures to determine the viscoelastic solid response prior to yielding, the equilibrium yield stress, aging, the thixotropic response, or the apparent equilibrium viscosity and shear modulus as functions of shear rate. These are properties that are likely to affect (and hence correlate with) clay response during calibration and testing. Such measurements are standard practice in other industries that use similar materials, including oil well drilling, personal products, etc. These properties are also required for any simulation intended to relate indirect measurements to the mechanics of body armor deformation. In particular, viscoelastic recovery will give a measured BFD that is less than the maximum experienced dynamically during the test.

A priori calculation of temperature change and straightforward calculation of temperature variations within the box as a function of time require knowledge of the thermal diffusivity of the clay, which has also not been measured for the materials in use. Thermogravimetric measurements to measure weight loss and components that may be eluted over time at a fixed temperature have likewise not been carried out.

The committee notes that the Army has a contractual relationship with Rutgers University to carry out rheological and thermophysical measurements, but neither the scope of the effort nor the measurement data were available.

Finding: The comprehensive thermomechanical characterization of Roma Plastilina #1 that was recommended in the Phase II Report (NRC, 2010) will quantify the effect of shear history and thermal history on the storage and dissipative components of mechanical deformation. Such a characterization will also quantify the times associated with recovery of properties, as well as, the thermal properties, including thermal expansion, thermal conductivity, thermal diffusivity, heat capacity, and thermal arrests, associated with phase changes.

The current implementation of the column-drop test to calibrate RP #1 is clearly able to reveal changes in the resistance to penetration associated with box-to-box variation, heating or cooling, and working (or mechanical conditioning). It also has proved useful in quantitative assessment of the spatial variation in penetration resistance in the plane of the top surface of the box. As such, the column-drop performance test (including the testing protocols, facilities, and instrumentation) is a valid method for assessing the part-to-part consistency of the clay boxes used in body armor testing.

The noise inherent in the results of the drop test is also present in the results of other tests, including the Charpy impact test and high-speed ballistic

impacts of small-diameter sting balls, and is therefore inherent to the material and not a variance associated with the impactor.

The key limitation is that in the drop test the strain rate experienced by the clay is qualitatively lower than that experienced in the live-fire ballistic test of armor. However, very little information is available to unambiguously relate the behavior in these two domains.

Another discrepancy between the cavities formed in drop tests and those formed in live-fire testing is the volume of material deformed. The typical depth of penetration of the drop-test indenter, 25 mm, is roughly half the distance of a BFD that would pass under the Army’s previous protocol (43 mm). However, given the scaling results from using indenters of different size and scale (see Figure 4-5 inset), this is unlikely to be a big effect.

Several opportunities exist to improve the calibration drop test. These include establishing correlations to standard desktop laboratory instruments such as the penetrometer, which is used by soil scientists and food rheologists. The chief advantages here are the portability and convenience of the device. However, the greatest benefit would come from the creation and use of a high-velocity impactor such as a gas gun. As pointed out in the section “Characteristics of Clay Behavior Observed in Drop Tests,” at the time of impact, the velocity of the indenter used in the current calibration test is just over 6 m/sec. However, ATC personnel told the committee that the back face of the armor moves at ![]() 50 m/sec after being impacted by threat projectiles.23 That is, the current calibration occurs under significantly lower strain rates than those experienced in the armor test.

50 m/sec after being impacted by threat projectiles.23 That is, the current calibration occurs under significantly lower strain rates than those experienced in the armor test.

The Army is developing a gas gun capable of directing a penetrator onto the surface of a clay box at ballistic velocities. Although the gas gun is only one approach to achieving high velocities, it is the approach used in the following discussion for illustrative purposes.

The first advantage of employing high speeds is that impactors will penetrate to depths comparable to the BFD in ballistic tests. In addition, a gas gun will, at least in principle, be able to deliver penetrators ranging from spheres to other specialty shapes. It would allow choosing steel spheres to reproduce a cavity in the clay that approximates the dimensions associated with the BFD in a ballistic test. Then, too, it could reproduce the impacter of the original Prather study (1977), which will permit directly comparing the original work with work using modern oil-based modeling clay formulations and conditions.

Shaped impactors can be designed to reproduce the force distributions expected when a blunt trauma occurs as a projectile strikes hard armor. Such shaped impactors are commonly used in injury simulation to induce specific and reproducible forces over a well-defined area. This option is particularly appealing as work progresses to measure the force distribution associated with armor testing (Raftenberg, 2006). Shaped indentors of different radii at constant impact velocities might be used to probe the backing material at a variety of depths up to and perhaps exceeding the expected BFD. An additional appealing possibility is using small-diameter spheres because this allows a high-density matrix of small

________________________

23Scott Walton, and Shane Esola, Aberdeen Test Center, “ATC Perspective on Clay used for Body Armor Testing,” presentation to the Body Armor Phase II committee, March 10, 2010.

impacts that might permit direct measurement of clay homogeneity (Weber, 2000).

It is important to stress there are two different functions of an improved calibration test. The first is to characterize the variability of clay within a given box at a given time in a manner that is directly relatable to the BFD. The second, equally important role is to use such a system to estimate the variation of BFD measurements both within a given box and between boxes, under realistic testing conditions using existing test protocols. The latter would help to provide information of use in the statistical analysis of armor testing results.

The Phase II study (NRC, 2010) recommended that the Army should quickly develop and experiment with a gas gun calibrator, or an equivalent device, capable of delivering impactors to the surface of clay boxes and determining the local variations within a clay box at speeds and depths corresponding to BFD (NRC, 2010). The experiments should be used to estimate as accurately as possible the variation of BFD measurements both within a given box and between boxes, under realistic testing conditions using the existing test protocols. Such experiments can form the basis for refinements in calibrating the clay for testing.

Finding: The testing community would benefit greatly from devising an alternative to the column drop test and certifying the validity of the current drop tests for calibration.

ALTERNATIVE BACKING MATERIALS AND SYSTEMS

As stated earlier, the committee strongly supports DOT&E and the Army in developing a standard ballistic backing material that would be an improvement on the current RP #1 for body armor testing. The Phase II study was interested in learning more about possible mid- and long-term replacements for modeling clay. Briefings from the Army and the personal knowledge of committee members led to suggestions of ballistic gelatin and microcrystalline waxes as possible alternatives.

Medium-Term and Long-Term Replacements for Modeling Clay

There are two broad classes of backing material for live-fire ballistic testing of armor when BFD is the quantity is of interest; both classes were considered in the original Prather study. The first is elastic materials that recover their original shape after unloading. In this case, the signal that is used to determine BFD is a set of images collected, for example, by high-speed video. The prototype for this type of material is ballistic gelatin. The second class of backing material is plastic material that preserves a permanent cavity whose dimensions can be correlated to lethality probability.

The issue with the first class of materials is the cost and complication of recording images. One such complication is devising and standardizing calibration procedures for the image gathering. The problem with the second class is assuring that the material is capable of quantifying elastic and plastic deformation as the recording medium, and then assuring minimal variability and reproducibility from test to test and box to box.

Ballistic Gelatin

At the time of the Prather study, the cost and availability of high-speed video were limiting factors, so the decision was made to recommend a plastic recording medium. In the modern era, video recording has become low cost and readily available. This might suggest a move to a transparent material such as ballistic gelatin in order to gain, for example, information about the dynamics of the event as armor deforms into a transparent body simulant such as ballistic gelatin. However, it is likely that the window for this strategy has both opened and closed, because advancements in sensor technology, discussed below, offer the benefit of time-resolved information in a solid-state reusable device. Such sensor systems typically incorporate a very tough transparent polymeric material behind the armor and in front of the sensor array.

While gelatin is the preferred material for penetrating injury studies, it cannot be shown that it offers qualitative advantages when the subject of interest is trauma associated with nonpenetrating injury (Harvey et al., 1962; Metker et al., 1975; Fackler and Malinkowski, 1985). Gelatin must be prepared as freestanding blocks, is labor intensive, typically is not reusable, has the potential for spoilage, is temperature sensitive, and requires specialized storage facilities. Nevertheless, it has been used in this application with appropriate imaging technology.

In addition to ballistic gelatin, other transparent elastically deforming materials are available (Uzar et al., 2003; Juliano et al., 2006; Moy et al., 2006). These materials are claimed to have advantages over ballistic gelatin because they are less sensitive to processing history, less affected by temperature, have a longer shelf life, and exhibit increased durability during repeated use. Moreover, because they are a synthetic rather than natural product, they are less variable in molecular structure.

In (NRC, 2010), the Phase II committee suggested in its Recommendations 11 and 12 (see Appendix L) that the Army should consider experimenting with ballistic gelatin and/or microcrystalline wax as a medium-term solution to the issues associated with the current recording medium, RP #1. However, the information detailed above, coupled with an improved understanding of the microstructure-property relationships in oil-based modeling-clay, calls for a general shift in emphasis.

If unlimited resources (time and money) were available, it would remain the case that there is potential benefit to exploring, through experiment, qualitatively different media with different means of recording BFD. However, such resources are limited, so, based on preliminary results—that is, small-batch

samples obtained by the clay working group—it appears that qualitatively new classes of materials are not an appropriate focus for development work.

Finding: There is no compelling rationale for expending resources to achieve an interim solution using an elastic material such as ballistic gelatin.

Ballistic-Grade Clay

In view of the finding above, attention must be directed at developing an improved ballistic-grade clay or an alternative plastic material to serve as a recording medium. As stated earlier the committee strongly supports DOT&E and the Army as they work to improve the current RP #1 modeling clay as a backing material to test body armor.

In fact, if it is understood that the term “modeling clay” is meant to broadly encompass materials that exhibit the working characteristics and feel of traditional clay- mineral formulations, then ballistic-grade modeling clay may meet two objectives. That is, it might serve as an incremental (or substantial) adjustment of the existing formulation (RP #1) or it might be based, for example, on an unfilled microcrystalline wax that is appropriately plasticized (with grease, oil, or a synthetic polymer). As a matter of course, but not as a research thrust, other materials (such as soap or paraffin) should be considered but investigated in any detail only if it can be determined that they offer the promise of dramatically reducing variability and dependence on shear and temperature history compared to modeling clay.

Finding: Plastically deforming recording media appear to be the proper choice of backing material for production testing of body armor for the foreseeable future.

A road map for improving the performance of a ballistic-grade modeling clay or other plastically deforming medium is presented in detail in the last section of this chapter.

As will be discussed in Chapter 8, a variety of electronic systems have been used by medical researchers to assess behind-armor blunt trauma (BABT) injuries. As a consequence, ATC has considered the possible use of electronic sensor-based systems in production testing of body armor in the medium or long term. Conceptually, having the same electronic sensor recording media used by medical researchers is intriguing since it could facilitate the correlation and interchange of data produced by the two communities.

Two examples of such systems are the anthropomoprhic test module (ATM) developed by the Army Medical Research and Materiel Command and the BABT Rig developed by the U.K. Defence Evaluation and Research Agency. The ATM and the BABT Rig are examples of electronic- sensor-based systems that

may ultimately help to synchronize research by the medical and armor testing communities. However, as is discussed in detail in Chapter 8, the transition to such a system presents a variety of scientific and logistic challenges, not to mention a significant increase in cost. Further, the discussion there calls into question the predictability of injuries from sensor data regardless of the fidelity of the data collection system. In considering the ATM and BABT Rig systems for the production testing of hard body armor, the committee drew two conclusions that are relevant to the potential future replacement of RP #1 for backing material:

Finding: The use of the anthropomorphic test module (ATM) represents a transition to a challenging methodology with only limited ability to extend results to injury prediction. Also, it is too costly to be used as a production testing alternative to Roma Plastilina #1 at this time. The ATM is judged a research tool that is not practical or appropriate for widespread deployment in ballistic testing ranges.

Finding: Overall, instrumented electronic sensor response elements are in a primitive state for the evaluation and assessment by medical researchers of ballistic behind-armor blunt trauma with rifle round threats. They also are too costly to be used in high-volume production testing. More research and detailed validation is necessary before electronic sensors can be considered as a practical medium or long-term alternative to use of Roma Plastilina #1.

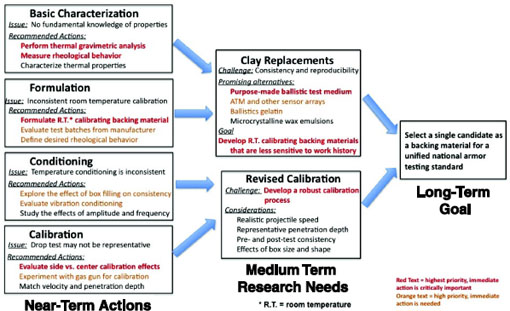

ROADMAP FOR IMPROVING THE TESTING PROCESS