3

Treaty and Regulatory Framework and Public Involvement Considerations

As mentioned in the introduction, the Army must clean up large quantities of buried chemical warfare materiel (CWM). Whether the cleanup involves containment on the one hand or the recovery and destruction of CWM on the other will impact the scope and costs of the program.

The first subsection of this chapter discusses the treaty and regulatory requirements that influence whether buried CWM that may exist in pits and trenches will be contained or destroyed.

The next subsection discusses the other federal and state environmental regulatory requirements that may be critical-path items in determining the ultimate total cost, the cost-effectiveness, and time frames for the remediation of buried CWM and the committee’s suggestions on how to address these requirements.

The last subsection discusses public involvement issues since, historically, public involvement has affected the remedial approaches selected by the Army and regulators.

This chapter provides only a very general overview of the environmental regulatory programs applicable to discarded chemical warfare materiel, with a focus on those legal and regulatory issues that have the most significant impact on implementation of the buried CWM remediation program. More detailed information on these regulatory programs and how they apply to the Army’s overall remediation responsibilities (i.e., the cleanup of munitions and industrial hazardous wastes) is provided in Appendix D.

TREATY AND REGULATORY REQUIREMENTS THAT DETERMINE SCOPE AND COST OF CLEANUP

The scope and costs of the CWM cleanup program are largely driven by (1) the Convention on the Prohibition of the Development, Production, Stockpiling and Use of Chemical Weapons and on their Destruction (CWC, or “the Treaty”);1 (2) the federal Comprehensive Environmental Response, Compensation and Liability Act of 1980 (CERCLA) hazardous substance cleanup program (EPA, 1980); and (3) the federal Resource Conservation and Recovery Act (RCRA) corrective action program (EPA, 1976).

The CWC and related U.S. enabling legislation require the destruction of recovered chemical warfare materiel (RCWM) (NRC, 2003). Nothing in the CWC requires the United States to recover buried CWM munitions. However, once removed and determined to fall into one of the categories of chemicals covered in the treaty, steps must be taken to declare and destroy the items in accordance with the requirements of the CWC.2

Overview

CERCLA is a federally implemented hazardous waste cleanup program and has been used to clean up hazardous waste sites all over the United States, including military sites that contain CWM. The Environmental Protection Agency (EPA) promulgates the regulations and has issued many guidances governing the investigation, remedy selection, and cleanup of CERCLA sites, whether the responsible entity is the government or a private company.

The decision to contain or recover and destroy buried CWM is made in the context of a complex set of laws, regulations, guidance, and implementing Department of Defense (DOD) cleanup programs. Under CERCLA, the Army performs the site investigations, evaluates the reme-

![]()

1Available at http://www.opcw.org/chemical-weapons-convention/. Last accessed March 15, 2012.

2Lynn M. Hoggins, Director, Chemical and Biological Weapons Treaty Management, Office of the Deputy Assistant Secretary of Defense, Nuclear, Chemical and Biological Defense, personal communication to Nancy Schulte, NRC study director, January 6, 2012.

dial alternatives, and proposes an action (Section 120 of CERCLA; EPA, 1988, 1990a, 1999). However, the process, program, and funding for DOD remediation differs from a nonfederal CERCLA cleanup and depends on the type of DOD cleanup site.

The precise oversight role at DOD sites depends somewhat upon the program: (1) sites no longer owned or controlled by DOD are handled by the formerly used defense sites (FUDS) program3 (U.S. Army, 2009b); (2) active bases are addressed by the Defense Environmental Restoration Program (DERP); and (3) sites on closing bases are addressed by the base realignment and closure (BRAC) program.

Some sites are placed on EPA’s National Priorities List (NPL), which means, as its name implies, that these cleanups generally receive a higher priority and a greater degree of EPA oversight. At NPL sites, EPA and DOD must negotiate a federal facility agreement (FFA), which provides a detailed agreement concerning the process and timing by which the site investigation is performed, the remedy selected, and the remedial action implemented, including the regulatory review (EPA, 1988, 1999.)

As of 2010, EPA and DOD had successfully negotiated FFAs at 136 out of 141 facilities (GAO, 2010), and additional agreements have been entered since 2010. However, at a small number of installations, disputes between EPA and DOD concerning implementation of FFAs have arisen (GAO, 2010). DOD has in rare cases failed to obtain EPA’s prior approval for key cleanup decisions, leading EPA not to recognize them and warn that additional work may be required (GAO, 2010; Ferrell and Prugh, 2011). According to GAO, “when an agency refuses to enter into an… [FFA] and cleanup progress lags because of statutory and other limitations, EPA cannot take steps—such as issuing and enforcing orders—to compel CERCLA cleanup as it would for a private party” (GAO, 2010). EPA may seek to have DOD perform additional work (EPA, 1988).4 Thus, disputes must be resolved through interagency discussions (GAO, 2010). Since Section 120 of CERCLA also contains a waiver of sovereign immunity, individuals and states may bring citizen suits if an agency is not adhering to a CERCLA mandate (EPA, 1999; GAO, 2010; EPA, 2011b).

At non-NPL sites, EPA’s role is less direct and the cleanup may be more flexible. For the most part, state agencies oversee DOD cleanup activities at non-NPL sites, which are the majority of DOD sites (U.S. Army, 2009b).

Section 120 of CERCLA requires federal agencies, such as Army facilities containing CWM, to comply with CERCLA “in the same manner and to the same extent, both procedurally and substantively, as any nongovernmental entity, including liability” (EPA, 1980). The DERP statute requires that DOD “carry out a program of environmental restoration at facilities under the jurisdiction of the Secretary,” including response actions that are “subject to, and in a manner consistent with, section 120,” which in turn, requires compliance with CERCLA in the same manner as any nongovernmental entity. The Army final military munition guidance applies the CERCLA remedy selection process to munitions response sites, although explosive safety (which is generally not addressed at CERCLA sites) is the “paramount priority” during a munitions response (U.S. Army, 2009b). U.S. Army guidance, in effect, treats NPL and non-NPL sites the same with regard to coordination with regulators and meeting regulatory requirements.5 Thus, CERCLA remedy selection criteria apply to DOD sites and are discussed in detail below.

CERCLA Remedy Selection Factors

CERCLA remedial actions are selected using nine criteria. The mandatory threshold remedy selection criteria are “overall protection of human health and the environment” (EPA, 1980) and “compliance with federal and state regulatory requirements found to be applicable or relevant and appropriate” (EPA, 1990a). Protectiveness is essential. CWM responses address “the chemical safety; explosives safety, when applicable; human health; or environmental risks presented by chemical-agent-filled munitions or agents in other than munitions configurations” (U.S. Army, 2009b). Risks posed by agent-filled munitions are “assessed through a baseline risk assessment that adheres to the requirements of CERCLA and the National Oil and Hazardous Substances Pollution Contingency Plan (NCP) (U.S. Army, 2009b).

The final remedy is generally selected from protective and applicable, relevant, and appropriate requirement (ARAR)-compliant alternatives based on long-term effectiveness and permanence; the reduction of toxicity, mobility, or volume through treatment; short-term effectiveness; implementability; and cost (EPA, 1990a).

State and community “acceptance” must be considered, but it does not provide either the state or local citizens the right to veto a remedy (EPA, 1990a). U.S. Army guidance is clear that regulatory agencies and local governments must be part of the CERCLA planning process and must be consulted in key decisions (U.S. Army, 2005). However, as a practical matter, the exact process utilized and role of the state and community depends largely on whether the site is an NPL site or not.

![]()

3DOD, Environmental Restoration Program, web site. Available at https://www.denix.osd.mil/denix/Public/Library/Cleanup/CleanupOfic/derp/index.html. Last accessed March 16, 2012. See also Army Regulation 200-1, Envi ronmental rProtection and Enhancement (February 21, 1997); AR 200-1 (para 3-3b) requires facilities to include a contingency/response plan for hazardous substances as part of an SPCCP.

4Paragraph J Subsequent Modifications of Final Reports, subparagraph 3 of the 1988 Model Federal Facility Agreement.

5Deborah A. Morefield, Environmental Management, Office of the Deputy Under Secretary for Installations and Environment Department of Defense, “Remediation Operations from an OSD Installations and Environment Perspective,” presentation to the committee on November 2, 2011.

Balancing the Criteria Case by Case

On a case-by-case basis, the relevant criteria are “balanced in a risk management judgment as to which alternative provides the most appropriate solution for the site” (EPA, 1990a). Under CERCLA, EPA “expects to use treatment to address the principal threats posed by a site, wherever practicable” (EPA, 1996c, p. 2). Practicability, however, is “based on the balancing of trade-offs among alternatives that are conducted during the selection of remedy” (EPA, 2009b). In upholding the NCP against challenges seeking to require only permanent remedies, the Court of Appeals for the D.C. Circuit held that “nothing in CERCLA §121… suggest[s] that selecting permanent remedies is more important than selecting cost-effective remedies.”6 Rather, the emphasis on permanent solutions and treatment is balanced by the coequal mandate for remedies to be cost-effective (EPA, 1996c). As a result, 65 percent of EPA CERCLA source control records of decision published from FY 1998 to FY 2008 have included a containment component, and treatment was “not practical” at 56 percent of the Superfund sites in which the record of decision (ROD) was issued from 2005 to 2008 (EPA, 2010c).

The Resource Conservation and Recovery Act (RCRA) is primarily a statute regulating how wastes (solid and hazardous wastes) must be managed to avoid potential threats to human health and the environment, as opposed to CERCLA’s focus on the cleanup of contamination (EPA, 1976). However, the RCRA corrective action authority is a hazardous waste cleanup program analogous to CERCLA that applies to past disposal locations on RCRA-permitted facilities, and for facilities that are closing without obtaining permits (including DOD facilities). Although RCRA is a federal program, most states have been authorized by EPA to implement the program.

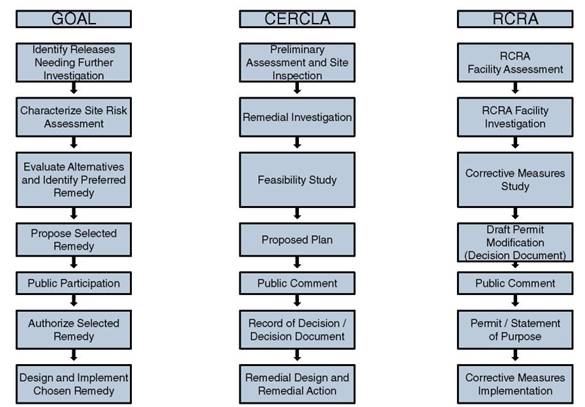

EPA’s written policy is that the “RCRA and CERCLA remedial programs should operate consistently and result in similar environmental solutions when faced with similar circumstances,” i.e., procedural differences between RCRA and CERCLA should not substantively affect the outcome of remediation (EPA, 1996b, 1997a, and 2011c).7 EPA uses essentially the same remedy selection criteria and the same expectations for RCRA remediation as for CERCLA, specifically including the preference for “treatment to address the principal threats posed by a site whenever practicable and cost-effective.” (EPA, 1996b).8 Substantively, cleanups required pursuant to CERCLA and RCRA corrective action are equivalent (see Figure 3-1,, which compares very generally the CERCLA and RCRA and remediation processes). (See Appendix D for details).

State Cleanup Programs

Because the RCRA cleanup process is driven primarily by guidance rather than regulation, states (and EPA in certain circumstances) have more flexibility in remedy selection and, in fact, some do not follow the EPA guidance (by definition, guidance is not legally binding). The process is described in Appendix D in more detail.

States implement RCRA programs within their boundaries and normally serve as lead regulator for non-NPL installations and are a “regulatory team member” at BRAC sites (U.S. Army, 2009b). Additionally, state requirements can be incorporated into CERCLA cleanups because ARARs may include state regulatory requirements (EPA, 1990a). CERCLA “specifies that state laws ‘concerning removal and remedial actions, including state laws regarding enforcement, shall apply to removal and remedial actions at facilities owned or operated by [the federal government] when such facilities are not included on the NPL.’”9 (U.S. Army, 2009b). Many of the state remediation regulations are similar to the federal approach, but states may adopt (and some have done so) their own cleanup policies or preferences.

Although there may be some states that set different cleanup goals than EPA for the same chemicals or situation, most states use EPA values and guidance and rely upon CERCLA and RCRA authorities for their legal framework. Most states have essentially adopted the federal RCRA corrective action program

Although there is no known large buried CWM site in New York, it is relevant in understanding the overarching state cleanup process to recognize that even the New York state statute (which requires sites to be restored “to predis-posal conditions, to the extent feasible”) has been interpreted by the highest court in the state to mean that remedies may “reduce rather than completely eliminate dangers” and that this statute “evinces a preference for the most thorough cleanup that makes sense in light of technical feasibility and cost-effectiveness.”10 The New York remediation “may encompass measures that run a gamut from removal of wastes to institutional controls… to address harms that

![]()

6Ohio v. EPA, 997 F.2d 1520, 1533, D.C. Cir. 1993.

7EPA uses the Corrective Action Advance Notice of Proposed Rule Making (ANPRM) as its corrective action guidance.

8CERCLA includes explicit statutory remedy selection criteria which express, among other things, a preference for treatment (see discussion above). This preference is also incorporated into the CERCLA cleanup regulations (EPA, 1990a). Although the RCRA statute does not contain a statutory preference, EPA directed its staff to use as “guidance” essentially the same remedy selection criteria as provided in CERCLA (EPA, 1997a). In particular, it specified “remedy expectations” that are intended to “guide development of remedial alternatives” (EPA, 1996b). These expectations are “not binding requirements,” but are often followed because they “reflect [EPA’s] collective experience” (EPA, 1996a). Specifically, “EPA expects to use treatment to address the principal threats posed by a site whenever practicable and cost-effective” (EPA, 1996b).

942U.S.C. § 9620(a)(4)(2001).

10New York State Superfund Coalition Inc. v. New York State DEC at 9-10 (N.Y., No. 189, 12/15/11). Available at http://www.courts.state.ny.us/CTAPPS/Decisions/2011/Dec11/189opn11.pdf.

Figure 3-1 Comparable CERCLA and RCRA remedial action processes. Final draft Army guidance for Military Munitions Response Program (MMRP) remedial investigation feasibility study (RI/FS). Available at http://www.milvet.state.pa.us/DMVA/Docs_PNG/Environmental/MRRI-FSGuidance.pdf, pp. 1-14 (U.S. Army, 2008c). Accessed April 10, 2012.

range from potential to actual hazards,” but the statute would not “compel a reversion to pristine environmental conditions.”11

Historic Examples of Cleanup of Buried CWM

Both RCRA and CERCLA have been or are planned to be used to address CWM, as summarized in Table 3-1.

A number of regulatory issues (particularly the remedy selection criteria) impact the investigation, remedy design, and remedy implementation of buried CWM. The committee’s review documented the reasons that the environmental regulatory programs may require very costly remedial actions and several other regulatory issues that may be obstacles or impact the cost of the remediation of buried CWM. Significant issues that are likely to impact most CWM cleanup operations are discussed below. Issues relevant to Redstone Arsenal are discussed in Chapter 5.

Existing Army guidance for performing remedial investigations at munitions response sites, detailed in the Army’s Final Munitions Response Remedial Investigation/ Feasibility Study Guidance (MMRP RI/FS Guidance) (U.S. Army, 2009b) is both adequate and appropriate. This guidance recommends following the Technical Project Planning (TPP) process, which requires identifying and bringing decision makers and technical personnel together (TPP Phase I), determining data needs (TPP Phase II), developing data collection options (TPP Phase III), and finalizing the data collection program (TPP Phase IV). All of this planning activity is designed to be front-loaded to identify potential conflicts and decisionmaking before field activities begin. While the existence of this guidance is a significant positive step for expediting the buried CWM portion of the munition response mission, as a matter of law, guidance is not legally binding12 and, in the experience of many of the committee members, agencies do not always follow their own guidance. Moreover, some agency personnel may not be aware of all of the agency guidance.

![]()

11New York State Superfund Coalition Inc. v. New York State DEC at 9-10 (N.Y., No. 189, 12/15/11). Available at http://www.courts.state.ny.us/CTAPPS/Decisions/2011/Dec11/189opn11.pdf. Id. at 10-12.

12McLouth Steel Products Corp. v. Thomas, 838 F. 2d 1317 (DC Cir. 1988).

TABLE 3-1 Examples of CWM Cleanups

|

|

||||

|---|---|---|---|---|

| Site | Cleanup Program | Containment/Destruction | Technology | Other |

|

|

||||

| Rocky Mountain Arsenal (NRC, 2002) | CERCLA. Approved through a CERCLA record of decision and it met the requirements of the state's RCRA order because it was a CERCLA emergency removal action | Destruction selected | EDS | A large CERCLA cleanup has been under way since the 1980s. A small quantity of sarin bomblets in publicly accessed area Rocky Mountain Arsenal was already listed on the CERCLA NPL and had an ongoing remedial program for non-CWM; the sarin bombets are a small portion of overall cleanup. |

| Spring Valley, D.C. (EPA, 2011a) | CERCLA | Destruction selected to date. Future CWM remedy not decided. | EDS | Residential neighborhood, included soil Investigation is ongoing. |

| Camp Siebert | CERCLA | Destruction selected | EDS | Near a farm |

| Redstone Arsenala | State issued a RCRA permit requiring cleanup. EPA is negotiating a CERCLA FFA, which would result in an EPA lead. The Army prefers one regulatory decision maker. Who is the lead regulatory authority is not decided. | State policy: destroy. State has ordered destruction of all CWM. Final remedy not decided | Not determined | On a munitions range on an active base. Residential areas are encroaching on the base. Groundwater is shallow and contaminated groundwater is entering the Tennessee River. |

| Tooele, Utah | RCRA | Not decided. State prefers destroying CWM on surface, but contained buried | Not determined | These CWM are buried on an Army base that is remote from populated areas. |

| Dugway Proving Ground (RCRA Permit 2011)b | RCRA | While there were some removals, most sites involved containment remedies. | Covers with land use controls and continued monitoring. | Over 200 solid waste management units were identified at Dugway Proving Ground (DPG); corrective action was implemented at most units during the 1990s. There are no active RCRA corrective action activities at DPG except for postclosure care, including land use controls and continued monitoring. |

| Aberdeen, Md. (U.S. Army, 2008d) | CERCLA | Contained. Five-year reviews in 1999, 2002, and 2008. | A cover was placed on CWM in the O-field landfill using remote technology and ground water pumping | This was just one operable unit on a large active Army base. Munitions were unstable. For the remedy to be protective in the long-term, containment of the waste must continue and LTM and 5-year reviews conducted until site conditions allow for unlimited use and unrestricted exposure. |

|

|

||||

aPresentations to the committee and conference calls with EPA Enforcement (December 5, 2011).

bUtah, RCRA Permit Module VII, SMU 200 Post-Closure Plan. Available at http://www.hazardouswaste.utah.gov/HWF_Section/Docs/DPG/DPG7_Attach22_HWMU200.pdf.

Finding 3-1. The Army MMRP RI/FS Guidance document (U.S. Army, 2009b) describes how to implement a transparent and coordinated strategy for identifying stakeholders and including them in the MMRP decision-making process.

Recommendation 3-1. Army managers of CWM projects should fully implement the TPP process as described in the MMRP RI/FS Guidance as early as possible when planning and implementing CWM cleanups.

The exact amount of cleanup required and the time frame over which the remedy will be implemented cannot be predicted with accuracy because the ultimate scope can only be determined through the regulatory cleanup process; it is out of the Army’s complete control.

The Need for Flexibility in CWM Remediation

A “multitude of challenges make the RI/FS at CWM sites unique,” including the “potential for exposure to toxic chemical agents,” the presence of explosive material, and the co-location with nonchemical munitions or hazardous wastes (U.S. Army, 2009b). The presence of explosives requires

unique procedures to ensure safety. In addition, soil and other media may be contaminated.

Each site where CWM is buried may also be unique with respect to other factors. Factors include disposal conditions (e.g., depth of disposal, cover soil), location (e.g., floodplain, shallow groundwater, operational range), and exposure pathways (e.g., distance from installation boundary), in addition to other factors. The diversity of conditions at each facility, many with multiple CWM disposal areas, argues for a flexible approach toward site assessment, investigation, conduct of removals or interim actions, final remedy selection and remedy implementation. This is especially the case since it is often difficult to know exactly what is buried in disposal sites or the condition of the items in the burial site until the site is actually investigated.

The CERCLA and RCRA processes provide flexibility to conduct a tailored approach to assessment, investigation, and eventual cleanup that still meets the substantive requirements of both RCRA and CERCLA regulatory programs (i.e., discovery, adequate characterization of the scope of the problem, determination of the risk, and balancing of the remedy selection factors).

With regard to CWM burial sites, and assuming that an exhumation and destruction approach is taken, test burial pits, for example, may be dug as a removal or interim action in a first attempt to start the cleanup process but also to better understand what may be present in the remainder of the disposal site and its condition. Once more is learned about specific disposal sites, additional removal or interim actions may be taken to further reduce risk and better understand the materials present and their condition. More definitive remedial actions (CERCLA) and corrective measures (RCRA) should only be taken once the site is fully understood with regard to nature and extent of contamination, exposure pathways, and risk to human health and the environment.

Specifically, the committee notes that in some cases, adequate data about some CWM burial sites may be available without having to perform a full-blown remedial investigation (CERCLA) or RCRA facility investigation (see Appendix D). They may come from historical information, geophysical investigations, limited test-pits, and some sampling to enable development of a combined investigative and cleanup approach. The conventional approach in cleanup programs would entail completion of a full-blown remedial investigation or RCRA facility investigation even if insufficient data are available to enable evaluation of cleanup options and a cleanup decision. An expedited approach would entail the evaluation of cleanup options and selection of a cleanup technology based on minimal but still sufficient data. The advantage of the expedited approach is that funding can be applied toward risk reduction even if not enough data are available to fully characterize the nature and extent of the source of the contamination and the release and migration pathways. Where a leave-in-place remedy is selected, available funds can be applied toward cap design and the design of a continued media monitoring program, and eventual emplacement of the cap and monitoring system. Where a remove-and-destroy remedy is selected, removal can be conducted in parallel with the remedial investigation so that as the site is characterized, identified surface and buried munitions are exhumed and treated. This is similar to what the Army did at the Spring Valley site, where it took a remove-and-destroy-as-you-characterize approach. Risk has been reduced as the investigation proceeds.

Finding 3-2. The CERCLA and RCRA processes are flexible enough to address the unique situations that buried CWM sites may represent.

Finding 3-3. In some cases, sufficient data are available for some CWM burial sites to be able to evaluate and select remedial approaches and technologies without having to fully investigate the nature of the source or the extent of releases and migration pathways.

Recommendation 3-2. DOD and the appropriate regulatory authorities, with opportunity for input of the interested public, should use the flexibility inherent in RCRA and CERCLA to tailor the overall response to address unique attributes of individual buried CWM sites.

Recommendation 3-3. The Army should consider emphasizing the implementation of risk reduction activities as early as possible, even if there are not enough data to fully characterize the nature of the source and the extent of the release and migration pathways.

During the investigative phase of RCRA and CERCLA munitions sites cleanups, field investigative teams may encounter surface-disposed munitions as well as munitions that were buried. Under RCRA’s waste management requirements, once a buried munition is uncovered, it is considered having been “actively managed” and becomes newly generated waste. Similarly, a surface-disposed munition that has been undisturbed for many years would also become waste once it is actively managed. If these munitions are determined to be hazardous waste, they are subject to RCRA’s waste management requirements.

In addition, and as indicated previously, should the munition be determined to be CWM, the CWC also comes into play. Once confirmed to be chemical warfare materiel, the CWC would require that munition to be destroyed, although there is no specific time limit for achievement of destruction. Considering both RCRA and CWC requirements, uncovered CWM may not be placed back onto or into the ground. The Army RI/FS guidance, EPA guidance, and Army practice are to develop and obtain approval of plans for such activities. The Army may wish to develop, after consultation with

federal and state regulators and other stakeholders, a consensus systematic approach for how to process items that may be CWM. The approach should be site-specific and might include specific steps for further evaluation to identify the type of munition and chemical content, interim storage, and eventual disposition, to include destruction either on-site or off-site, and management of secondary wastes and other residuals. Approval by the regulatory authority and involvement of the public is a regulatory requirement.

Clean Islands in the Middle of Contaminated Operational Ranges

Operational ranges at most of the Army’s installations have been in use for many years, most for decades. These operational ranges are used for multiple purposes, primarily training and research and development. Through use over many years, these operational ranges have become contaminated with munitions-related constituents, including munitions-related chemicals (e.g., trinitrotoluene, perchlo-rate) the breakdown products of munitions-related chemicals (e.g., dinitrotoluene, heavy metals), and unrelated chemicals, such as those used to decontaminate chemical munitions (e.g., bleach solutions, caustics, and organic solvents). These operational ranges have been determined by the Army as safe for soldiers and other personnel involved in intermittent training and research and development, but the contamination at these ranges is a concern nonetheless.

As indicated above, one of the options for cleaning up waste disposal or treatment units located on operational ranges is removal of exploded munition bodies and decontaminated chemical munitions and the removal and destruction of intact munitions, including both conventional and chemical munitions. Presumably, contaminated media may also be removed and either treated or disposed of.

The committee notes that while the removal and destruction of exploded munition bodies and decontaminated chemical munitions and the removal and treatment of intact munitions, including both conventional and chemical munitions, and the removal and treatment and/or disposal of contaminated media may be appropriate for FUDS and BRAC sites, the removal and treatment option should be carefully evaluated for operational ranges. The committee is concerned that the removal and treatment option for old disposal units located on operational ranges could result in cleaned-up islands in the middle of historically contaminated operational ranges that through continued use for training and other purposes into the future, would only become contaminated again.

Finding 3-4. By their very nature, the Army’s operational ranges are contaminated from prior and ongoing training, research, development, and other uses. Continued use of the range will result in low-level or moderate contamination.

Recommendation 3-4. In assessing the appropriate remedy for buried CWM on operational ranges, the Army and the regulators who approve or concur in the remedy for such sites, should continue to consider the unique circumstances presented by operational ranges.

Corrective Action Management Units

Management of remediation waste is a highly complex subject. Also, because RCRA is largely state-implemented, the states often implement the requirements pertaining to the remediation of wastes differently. Very large amounts of remediation wastes may be generated from the active remediation of some CWM disposal sites. Such wastes include contaminated and uncontaminated empty munition bodies, intact chemical and conventional munitions, disposed manufacturing and processing equipment, and contaminated soil and debris. While, it is beyond the scope of this report to evaluate the intricacies of the regulations for the remediation of wastes that may come out of CWM sites, it is nevertheless important to mention the options for managing such waste.

Historically, EPA interpreted any movement of waste or contaminated soil at a site as the “generation of hazardous wastes,” which in turned triggered RCRA waste management requirements, including the requirement to treat the wastes and, if necessary, contaminated soil and debris to meet standards established under the RCRA land disposal restrictions (LDR) program. EPA established a number of different types of units to allow flexibility in the selection of the approach for managing remediation waste and contaminated soil, other media, and debris. As indicated in Appendix D, remediation wastes can be managed in corrective action management units (CAMUs), temporary units, and in designated “areas of contamination” without having to meet all the restrictive requirements for what is known as “as-generated waste,” including the requirement to treat remediation waste to meet the same LDR requirements as “as-generated” wastes.

CAMUs in particular are intended for situations where large amounts of remediation waste are expected to be generated from one or more units, and where the wastes can be safely and securely managed in the same on-site location or at an acceptable off-site location. CAMUs include units intended for storage and treatment of remediation waste as well as for disposal of these wastes. Whereas storage and treatment CAMUs are temporary facilities, CAMUs intended for disposal are permanent waste management units. Disposal CAMUs would therefore likely be limited to active installations where the Army is expected to maintain ownership into the future. They could also be employed at BRAC locations where a federal land manager becomes the new landowner for the facility.

Contaminated or decontaminated chemical and conventional munitions and other remediation wastes could be managed in a CAMU. Indeed, any kind of remediation waste can be managed in a CAMU, as long as it can be shown to

be protective of human health and the environment. The CAMU could also be used for treatment, storage, or disposal of contaminated debris and soil. Since the CWC would require the destruction of intact chemical weapons, these materials could not be managed in a CAMU. Secondary wastes remaining after such destruction, however, could be managed in a CAMU.

Similar to CAMUs, Areas of Contamination, as described in Appendix D, could also be used to manage remediation wastes. If the concept of an Area of Contamination can be shown to be protective of human health and the environment, and pending regulatory acceptance, remediation wastes, including contaminated soils, could also remain in such Areas. This would be the case, for example, if a decision is made to leave remediation waste in place, with appropriate engineering controls (e.g., landfill cap, leachate collection system), monitoring (e.g., groundwater monitoring), and land use controls. These types of remedies have been employed, for example, at Aberdeen Proving Ground (Edgewood Area) and at Rocky Mountain Arsenal. The review of regulatory programs in Appendix D provides information on the decision-making process for remedy selection under RCRA and CERCLA. In particular, the section in Appendix D on types of remedies addresses the choice of active removal/ destruction vs. leave-in-place or containment remedies.

Similarly, Temporary Units, as described in Appendix D, could also be used for the management of remediation wastes. Such units would be ideal for an interim holding facility (IHF), for example, but could also be used for treatment units like the Explosive Destruction System (EDS) or any of the explosive destruction technologies (EDTs).

Setting up such units for the many “empty” munition bodies and scrap metals and for contaminated soil and debris that may be present in large disposal pits would have many advantages over other RCRA or CERCLA remedies.

Finding 3-5. Corrective Action Management Units, Temporary Units, or the designation of Areas of Contamination for management of remediation wastes are possible solutions for management of the large amounts of remediation waste that will be generated at RCRA or CERCLA CWM disposal sites.

Recommendation 3-5. The Army should make increased use of Corrective Action Management Units in situations where large amounts of remediation waste are expected, although the committee recognizes the need to retain the flexibility to make determinations based on site-specific circumstances.

The Problem Posed by RCRA Storage Requirements

One complication that the Army could encounter during CWM investigations and also during large-scale removal operations might be the storage of the munition(s) awaiting evaluation or destruction. RCRA requires a hazardous waste storage permit for waste in storage for longer than 90 days. While a 90-day extension to this deadline might be issued by the regulatory authority, it is likely that RCWM would need to be stored for much longer. At Spring Valley, for example, RCWM were stored for approximately 2 years in an IHF before the EDS was brought on-site and operated.13 Similarly, at the Camp Sibert, Alabama, FUDS, RCWM have been in storage for over a year in an IHF awaiting eventual treatment in an EDS or EDT.14 RCRA corrective actions would be considered to be an ARAR under CERCLA, and only the substantive aspects of RCRA regulations would be considered applicable.15 Storage in excess of 90 days is typically not an issue at sites being addressed under CERCLA, because permitting would be considered an administrative (nonsubstantive) requirement. The more likely issue would be if the cleanup is being conducted pursuant to RCRA corrective action. In this case, the 90-day storage criterion would apply. The regulatory authority in this case could direct the installation to initiate action to permit the IHF as a RCRA storage facility.

The committee visited and examined an IHF at the Spring Valley site. In addition, the committee is aware of the regulatory requirements imposed by the U.S. Army Technical Center for Explosives Safety (USATCES) and the Department of Defense Explosives Safety Board (DDESB) on the management of munitions in such containers. The committee believes that establishing additional regulatory requirements through the RCRA permit is unnecessary to protect human health or the environment. The requirement to obtain a storage permit in this case is similar to a situation that emerged as the Military Munitions Rule was being developed by EPA, with input from DOD. Here, EPA and DOD realized that munitions, both conventional and chemical, might be in storage for an extended period of time prior to undergoing demilitarization. EPA agreed, after reviewing DOD regulatory requirements, that requiring DOD installations to obtain RCRA permits for such storage was unnecessary (EPA, 1997b). In recognizing that obtaining a storage permit in this case was unnecessary, the “igloo door” policy was established (DOD, 1998). In accordance with this policy, munitions destined for demilitarization did not become defined as waste subject to RCRA until they exited the igloo on their way to demilitarization. This same concept can be applied to RCWM in storage awaiting destruction. Another approach would be to approve the IHF as a Temporary Unit under RCRA (see Appendix D).

![]()

13Steven Hirsh, Remedial Project Manager, Region 3, Environmental Protection Agency, “Protecting the Public: An EPA Perspective,” presentation to the committee on November 1, 2011.

14Karl E. Blankenship, FUDS Project Manager, Mobile District U.S. Army Corps of Engineers, “Remediation of Contaminated Soil at Camp Sibert, Alabama: The Installation Manager’s Perspective,” presentation to the committee on November 3, 2011.

15The committee notes, however, that the definition of what is and what is not applicable and appropriate is subject to regulatory interpretation.

Regulatory Approval and Permitting of the EDS and EDTs

The EDS and two of the three types of explosive destruction technology (EDT) have now been deployed to a number of locations within the U.S. and have been operated successfully. At CERCLA sites, such as Schofield Barracks in Hawaii and Spring Valley in Washington, D.C., destruction technology was established as part of CERCLA documentation. Regulators were given the opportunity, through the CERCLA process, to review the technology documentation and to comment on operating conditions or controls for these containers. The process has worked very well. At some CERCLA locations, such as at the Rocky Mountain Arsenal in Colorado, the regulatory authority sought an additional level of control over operations to destroy recovered sarin bomblets, so it set its own conditions by formulating state versions of RCRA’s emergency order provisions.

In addition to CERCLA sites, the EDS and one of the EDTs have also been used at installations operating under a RCRA permit. Examples include the Pine Bluff Arsenal for the destruction of various types of chemical munitions, and Anniston Chemical Depot, Alabama, where a static detonation chamber (SDC) was used experimentally on waste chemical munitions in anticipation of its use at the Pueblo Chemical Depot. Regulatory approval in these cases was not through the conventional RCRA permitting process, but through alternative regulatory approval mechanisms available under RCRA, such as Research Development and Demonstration (RD&D) permits. The EDS or any of the EDTs may also be approved as a Temporary Unit, mentioned above for approval of the IHF. Use of these alternative regulatory approval mechanisms can work well as a means of allowing the regulatory authority to review documentation and approve use of the devices for RCWM in a timely manner. Another alternative for regulatory approval would be to pursue a conventional RCRA operating permit for a hazardous waste management unit or, in the case of the EDS or the EDTs, a permit for a miscellaneous unit under RCRA Subpart X. Obtaining such permits can be a very long and expensive process, however, taking one or more years and many dollars to finalize.

Finding 3-6. Some states may wish to employ the conventional RCRA permitting process as a means of approving use of the EDS or one of the EDTs at a RCRA CWM munitions response site (MRS). Alternative approaches for regulatory approval might save time and money.

Recommendation 3-6. The Army should urge the Environmental Protection Agency or the state regulatory authority, as applicable, to employ the existing alternative approval mechanisms and flexibility available under the Resource Conservation and Recovery Act in lieu of the typical permitting process for use of the explosive destruction system or explosive destruction technologies.

Recycling of Treated Munition Bodies, Fragments, and Other Metals

Recycling of metal fragments has been addressed in prior NRC reports (NRC, 2007, 2010a). However, the number of such metal parts will be much greater at buried CWM sites. For this reason, it would be appropriate to summarize lessons learned. All types of EDT and the EDS will produce a significant amount of metallic secondary waste, consisting of the treated munition body, fragments, and, in some cases, the explosive fragmentation protection system. Currently, the project manager for non-stockpile chemical materiel (PMNSCM) plans to landfill these metal materials as hazardous waste at a RCRA-permitted treatment, storage, and disposal facility (TSDF).16 They could also be managed in a CAMU, as described above. Such secondary wastes, however, could instead be recycled as scrap metal. Experience has shown that EDT and EDS treatment can produce scrap metal that is <1 vapor screening level (VSL) (NRC, 2009a). The Dynasafe unit produces metal that may be released to the private sector for recycling or other uses. However, all the units are expected to be capable of completely removing and destroying the chemical agent.

The committee reiterates its prior view that the scrap metal produced from these devices should be cleared of chemical agent and should be recyclable as well. Recycling the metal from these other technologies might, however, involve demonstrating to federal and/or state regulatory authorities that the metals should no longer be classified as hazardous waste. While recycling from small and moderate MRSs will not result in the recycling of a significant amount of metal, the amount of metal that could be recycled from large MRSs (which are likely to involve hundreds or even thousands of munitions) could be substantial. The committee expects that the Army will continue to explore potential recycling of scrap metal resulting from RCWM treatment.

Extending the Pine Bluff Model

In the same fashion that NSCMP designated Pine Bluff Arsenal, Arkansas, as the location of its EDSs to destroy the non-stockpile inventory at Pine Bluff and to be available for emergency response, one or more of the large remediation sites could be used for this purpose in the future. Each of the large buried CWM sites will require investigation and some level of remediation (containment or treatment) of buried or recovered CWM and other related contaminated media. If a portion of the CWM emergency response team and equipment were located at one of these large sites, cost savings are likely to accrue because personnel could be engaged in remediation of buried CWM when they are not working on emergency responses, and their skills and training can be

![]()

16Franklin D. Hoffman, Chief, Operations Team, NSCMP, “Non-Stockpile Chemical Materiel Project Equipment and Capabilities Overview,” presentation to the committee on September 27, 2011.

maintained in between emergency responses. Indeed, the Army achieved just these benefits when it located several EDSs at Pine Bluff (NRC, 2004).

Finding 3-7. Potential cost savings are likely to be realized by co-locating resources on one of the large burial sites, so that emergency response functions can be deployed efficiently.

Recommendation 3-7. The Army should evaluate and select one of the buried CWM sites as the location/repository for its emergency response operations in order to increase the cost-effectiveness of the overall program and maintain flexibility (NRC, 2004).

THE IMPORTANCE OF PUBLIC INVOLVEMENT

The importance of constructive and open engagement of the public by the U.S. Army in its policy decisions regarding non-stockpile materiel has been emphasized in several earlier reports from the National Research Council (NRC, 1994, 1999, 2001a, 2001b, 2002) and other organizations (EPA, 2001, 2002b, 2009a, 2010b; U.S. Army, 2007d). Indeed, many of the alternative treatment technologies for chemical agents owe their existence to public concerns and the influence of the public on Congress and the states.

Munitions response actions are governed by a number of laws at the federal, state, tribal, and local levels. As noted above, public involvement is embedded in RCRA and CERCLA (U.S. Army, 2005; EPA, 2005). In addition, the Emergency Planning and Community Right-to-Know Act (EPCRA) requires military installations reporting releases of listed hazardous substances to complete and make public the Toxic Release Inventory annually if the quantities exceed the reporting threshold.17

These regulatory frameworks detail the community engagement and stakeholder participation activities to be followed by the lead agency at MRSs. Further, DOD and Department of the Army regulations and policies provide a framework to guide military decision makers—installation commanders as the executive agent on active DOD installations, and the U.S. Army Corp of Engineers (USACE) as executive agent at FUDS—on requirements for conducting public outreach and involvement activities (U.S. Army, 2004a, 2004c, 2005, 2009c, 2009d). The Non-Stockpile Chemical Materiel Program (NSCMP) never has primary responsibility,18 but it does play a support role—for example, by providing literature for distribution and meeting with residents of impacted neighborhoods.

Feedback from stakeholders, reported in an earlier committee report (NRC, 2002), indicates that the U.S. Army has made considerable progress in providing information to the public and improving communications with stakeholders. Stakeholder feedback has identified a number of issues that typically are of high concern to members of the community. For example, there has been widespread opposition to importing out-of-state wastes that could result in a site becoming a dumping ground, with a correspondingly high preference for mobile destruction technologies. In addition, nonincineration technologies have received broad acceptance as an advance over open detonation, but some community members have expressed concern about the costs associated with the new technologies (NRC, 2002).

The approach taken at different sites may vary, based on the level of public interest. For example, Spring Valley, in Washington, D.C., has a very active restoration advisory board (RAB), while at Camp Sibert, Alabama, the public has not shown any interest in having such a board. Both sites hold public meetings, offer literature to the public, and provide information to the media. The key issue facing the Army as it starts to remediate large buried CWM sites is whether to keep its public involvement program modest in size, in proportion to the limited public interest expressed, or to expand its efforts in case public concern materializes as the buried CWM remediation program grows.

Finding 3-8. The U.S. Army project managers at current CWM sites have recognized the importance of public engagement and are supported appropriately by NSCMP.

Recommendation 3-8. As the U.S. Army undertakes remediation at the larger CWM sites, project managers should anticipate that there will be more public concern and continue to seek proactive public engagement. They should take steps to ensure that communications from the different participating organizations are coordinated.

![]()

17David Lyon, Environmental Specialist, Environmental Division, Assistant Chief of Staff for Installation Management/Supply Directorate, personal communication to Derek Guest, committee member, on November 23, 2011.

18Laurence G. Gottschalk, PMNSCM, personal communication, to Richard Ayen, committee chair, November 29, 2011.