3

Agent Monitoring Practices for Waste Generated at BGCAPP and PCAPP

In this chapter, the committee briefly describes plans for the overall monitoring of waste streams expected to be generated at the Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) and the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) and uses this as a basis for identifying opportunities to employ new ambient ionization surface-sensitive mass spectrometric techniques that offer potential benefits at these two Assembled Chemical Weapons Alternatives (ACWA) pilot plants. The committee recognizes that plans for operating these facilities are well under way and that any implementation of new technology may require time for adaptation and procedural vetting, etc. Given these considerations, surface measurement technologies may most likely be utilized during the later stages of operations, particularly during facility closure.

The committee wishes to point out that in examining the applicability of the new technologies discussed in this report, it is not calling into question the current monitoring protocols planned for these facilities. These have proven to be safe and effective during nearly two decades of chemical agent disposal campaigns at other chemical demilitarization facilities. Rather, the question is whether the new techniques could offer capabilities that beneficially augment the present techniques and perhaps lead to a reduction in the duration of the overall schedule.

This chapter is intended to identify monitoring opportunities and challenges. Chapters 4 and 5 address the suitability of the new ambient ionization mass spectrometric techniques to address those challenges. Several potential scenarios are presented in this chapter, where new measurement capabilities might facilitate faster, safer, or more efficient agent disposal and closure operations.

Chapter 2 presented an overview of the process flow plans for PCAPP and BGCAPP. This chapter addresses the plans for monitoring and analysis of those processes and the waste streams they will produce. This is not a comprehensive review because this subject was previously examined in the National Research Council (NRC) report Review of Secondary Waste Planning for the Blue Grass and Pueblo Chemical Agent Destruction Pilot Plants (2008a). Instead, the following sections are intended to provide a perspective on where additional monitoring tools might be useful. The ACWA

pilot plants are full-scale facilities that face all of the normal state permitting requirements that any industrial facility must comply with in terms of dealing with effluents and waste streams. Since these general requirements are reasonably standard, this report focuses on the unique aspects of monitoring for chemical agent contamination.

WASTE GENERATION AND MONITORING OVERVIEW

The various waste streams generated at BGCAPP and PCAPP can be classified as primary or secondary:

• Primary waste streams. Those encountered in conducting primary operations for disposal (e.g., explosives removed and agent drained from munitions) that are treated on-site, and

• Secondary waste streams. Those generated by activities either in support of or downstream of the primary processes for agent and energetics destruction—for example, activated carbon, used demilitarization protective ensemble (DPE) suits, dunnage, and so on that ultimately leave the facility. These wastes include additional materials produced during facility closure such as demolished concrete.

The characterization of the expected secondary wastes from the Pueblo and Blue Grass facilities and the planning for their disposal were described in detail in NRC, 2008a. The purpose of that study was to “provide PMACWA with a technical appraisal of its evolving plans to safely and efficiently handle, treat, and ultimately dispose of the waste materials that remain following the destruction of the assembled chemical weapons stored at PCD and BGAD” (p. 7). In the course of preparing the present report, the ACWA Monitoring Committee received additional information on this subject.1

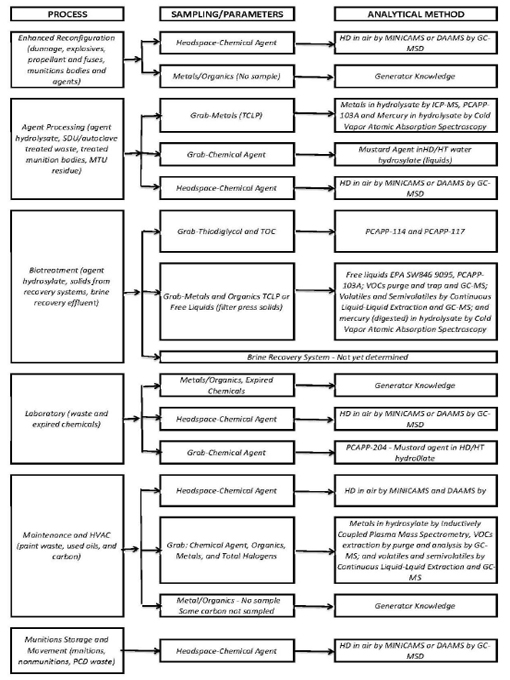

A general overview of the waste monitoring plan for PCAPP is shown in Figure 3-1, which itemizes the planned processes and corresponding analytical monitoring and sampling methods. A corresponding diagram for BGCAPP was unavailable to the committee, but the committee believes the PCAPP plan is reasonably illustrative and representative for the purpose of this report. The analytical methods are categorized by the primary process from which they originate and further identified by the type of sample and key measurement parameter.

In the case of generator knowledge, sampling is not needed if there was no opportunity for agent contamination to have occurred based on the Army’s criteria shown in Box 2-1. In other cases, headspace samples are taken after the waste is bagged or tented and allowed to equilibrate. The sample is then taken from the vapor space above the waste within the tented area, as described in the next section. In most cases, the methods are derived from standard EPA methods; however, some methods were

![]()

1This includes a presentation to the committee by Gary Groenewold, a member of the Committee to Review Secondary Waste Disposal and Regulatory Requirements for the Assembled Chemical Weapons Alternatives Program, “Sources and Amounts of Agent-Contaminated Wastes,” on February 23, 2011, and information provided by ACWA staff in response to committee questions or communications during site visits.

developed specifically for the chemical agent destruction program. These methods are indicated by the inclusion of the PCAPP method number (e.g., PCAPP-204).

The secondary waste streams anticipated during normal operations for PCAPP, which only has munitions containing mustard agent, are summarized in Table 3-1. Table 3-2 shows the anticipated secondary waste expected from closure of PCAPP. The corresponding secondary wastes expected from BGCAPP are presented in Tables 3-3, 3-4, and 3-5. The waste streams are divided into “agent contaminated” (>1 VSL) and “clean” (<1 VSL) based on the airborne exposure limits (AELs) and vapor screening levels (VSLs) detailed in Tables 2-1 and 2-2. The distinction between “agent- contaminated” and “clean” is important because it determines the type of handling required and the type of waste treatment, storage, and disposal facility (TSDF) to which the material can be sent.

At the time this report was prepared, PCAPP was further along on construction than BGCAPP and had an approved waste analysis plan (WAP) in place.2 A draft WAP submitted by BGCAPP as part of its Resource Conservation and Recovery Act (RCRA) permit application for BGCAPP had not been approved at the time of this writing. From a monitoring perspective, the only major difference between the two WAPs anticipated by the committee is that at BGCAPP, a sequence of agents needs to be monitored as the different agents are processed. The guiding principle for handling waste that may be agent-contaminated was summarized on page 34 in NRC, 2008a:

Under the WAP filed with the Colorado Department of Public Health and Environment (CDHPE), PCAPP will use generator knowledge as the primary means of characterization, with direct sampling and analysis used to verify process knowledge. Agent monitoring is conducted in accordance with the Army’s AEL guidance dated June 18, 2004). There are three approaches for classifying and disposing of secondary waste relative to its contamination by agent:

1. The waste is containerized and its headspace is monitored to determine the appropriate classification: or

2. The waste is assumed to be agent-contaminated and is decontaminated in accordance with the RCRA permit or regulations; adequate decontamination (<1.0 VSL) is verified via monitoring at the SDU [supplemental decontamination unit] or autoclave, whereupon it is reclassified as “clean and shipped offsite; or

3. The waste is assumed to be agent-contaminated and is shipped offsite to a facility permitted to receive such wastes.

For the purposes of this report, the committee again notes that the Army’s currently accepted means of characterizing agent-contaminated waste are generator knowledge or the AELs established by the Army as described in Chapter 2. The AELs are the basis for (1) quantifying the agent contamination measurements known as VSLs for wastes subjected to controlled air monitoring and for (2) the established waste control limits (WCLs) for wastes that must be analyzed by extractive procedures.

![]()

2For example, see http://www.cdhpe.state.co.us/hm/pcd/adminrecord.htm, accessed on September 12, 2011.

| TABLE 3-1 Projected Amounts of Mustard-Agent-Contaminated Secondary Waste from Normal Operations at PCAPP | ||

| Amount (lb) | ||

| Stream Description | <1 VSL | >1 VSL |

| Wood | 0 | 56,906 |

| Fiber tubes, additional packing material, metal strapping, miscellaneous metal | 0 | 0 |

| TAP gear | 9,639 | 6,709 |

| Steel | 0 | 0 |

| Lead alloy | 0 | 0 |

| Aluminum | 18 | 53 |

| Brine reduction | 0 | 0 |

| Water recovery thickener residue | 0 | 0 |

| Energetics | 0 | 0 |

| Brass and copper wire | 0 | 0 |

| Charcoal from PPE mask containers | 0 | 2,583 |

| Inert bulk solid waste | 15,421 | 35,790 |

| Halogenated waste | 3,153 | 2,661 |

| DPE suits | 121,514 | 81,010 |

| Waste oils and spent hydraulic fluid | 2,416 | 400 |

| Leather | 437 | 197 |

| Absorbents | 1,534 | 3,554 |

| Paper/fiberglass/rubber | 0 | 0 |

| Polystyrene and polyethylene | 669 | 2,318 |

| Combustible solid waste | 2,827 | 2,382 |

| Waste paint sludge | 915 | 455 |

| Dry cell batteries | 1,828 | 203 |

| Lead acid batteries | 1,219 | 135 |

| Mercury-containing lighting | 259 | 29 |

| Total | 161,849 | 195,385 |

SOURCE: PCAPP answers to Question Set 5 posed by the ACWA Secondary Waste Committee, March 11, 2008.

| TABLE 3-2 Projected Amounts of Mustard-Agent-Contaminated Secondary Waste from Closure at PCAPP | ||

| Amount (lb) | ||

| Stream Description | <1 VSL | >1 VSL |

| Wood | 0 | 0 |

| TAP gear | 3,704 | 412 |

| Steel | 0 | 0 |

| Aluminum | 21 | 7 |

| Brine reduction | 0 | 0 |

| Water recovery thickener residue | 0 | 0 |

| Propellant | 0 | 0 |

| Brass and copper wire | 0 | 0 |

| Charcoal | 0 | 1,000 |

| Inert bulk solid waste | 262,351 | 259,498 |

| Halogenated waste | 27,946 | 25,910 |

| DPE suits closure | 47,050 | 31,366 |

| Waste oils and spent hydraulic fluid | 927 | 164 |

| Leather | 147 | 98 |

| Absorbents | 350 | 3,153 |

| Paper/fiberglass/rubber | 0 | 0 |

| Polystyrene and polyethylene (poly drums and 5-mil poly bags) | 0 | 785 |

| HEPA/prefilters | 9,500 | 28,500 |

| HVAC | ||

| Filtration charcoal | 30,690 | 3,410 |

| Filter plenums | 15,300 | 1,700 |

| Filter ductwork | 9,000 | 1,000 |

| Concrete | 38,775 | 12,925 |

| Combustible solid waste | 26,359 | 26,503 |

| Waste paint sludges and other sludges | 0 | 531 |

| Dry cell batteries | 707 | 79 |

| Lead acid batteries | 472 | 52 |

| Mercury-containing lighting | 100 | 11 |

| Total | 473,399 | 397,102 |

SOURCE: PCAPP answers to Question Set 5 posed by the ACWA Secondary Waste Committee, March 11, 2008.

| Projected Totals (lb)a | ||

| >1 VSL Waste | Operationsb | Closurec |

| Combustible solids | 5,242 | 30,879 |

| Metal | 24,737 | 449,457 |

| TAP gear/rubber | 555 | 390 |

| Halogenated plastic | 9,957 | 73,505 |

| Nonhalogenated plastic | 2,209 | 18,786 |

| Pre-HEPA filters | 1,044 | 13,140 |

| Agent collection system/spent decontamination solution sludge | 1,082 | 759 |

| Concrete | 0 | 50,053 |

| Foam wall panel | 0 | 31,371 |

| Special coatings | 0 | 4,052 |

| Aluminum | 0 | 2,149 |

| Overpack waste | 31,200 | 0 |

| Total | 76,068 | 674,540 |

NOTE: TAP, toxic agent protective; HEPA, high-efficiency particulate air; ACS, agent collection system; and SDS, spent decontamination solution.

aTotals calculated from estimated rate (lb/yr) data.

bBGCAPP operations are estimated to have a duration of 2.08 years.

cBGCAPP closure is estimated to have a duration of 1.46 years.

SOURCE: Adapted from PMACWA, 2006.

| Projected Totals (lb)a | ||

| <1 VSL Waste (Unless Otherwise Noted) | Operationsb | Closurec |

| Combustible solids | 2,623 | 22,014 |

| Metal | 22,087 | 571,717 |

| TAP gear/rubber | 1,066 | 1,066 |

| Halogenated plastic | 14,360 | 151,039 |

| Nonhalogenated plastic | 1,733 | 20,994 |

| 3X pre-HEPA filters | 82 | 5,084 |

| Sludge | 64 | 64 |

| 3X concrete | 0 | 79,993 |

| 3X foam wall panel | 0 | 50,136 |

| Special coatings | 0 | 6,475 |

| 3X aluminum | 48 | 3,435 |

| Total | 42,063 | 912,017 |

NOTE: 3X refers to a formerly used decontamination level that indicates that the item has been surface decontaminated by locally approved procedures, has been bagged or contained in an agent- tight container of sufficient volume to permit an air sample to be withdrawn while minimizing dilution with incoming air, and/or appropriate tests/monitoring have verified that concentrations are not above 0.0001 mg/m3 for agent GB, 0.00001 mg/m3 for agent VX, or 0.003 mg/m3 for H. Monitoring is not required for completely decontaminated and disassembled parts that are shaped simply (no crevices, threads, or the like) and are made of essentially impervious materials (such as simple lab glassware and steel gears) (NRC, 2007).

aTotals calculated from estimated rate (lb/yr) data

bBGCAPP operations are estimated to have a duration of 2.08 years.

cBGCAPP closure is estimated to have a duration of 1.46 years.

SOURCE: Adapted from PMACWA, 2006.

| TABLE 3-5 Estimated Agent-Contaminated Waste Stream Summary for Operations and Closure at BGCAPP | ||

| Waste Designation | Total Weight of the Waste (lb) | |

| Inert bulk solid waste | ||

| Metal | 1,243,545 | |

| Concrete | 152,369 | |

| Aluminum waste | 6,685 | |

| Foam core panels | 95,498 | |

| Special coatings | 12,333 | |

| Combustible bulk solid | ||

| Nonhalogenated plastics | 50,972 | |

| Tap gear | 4,555 | |

| HEPA filters and prefilters | 19,997 | |

| Adsorbents, cottons, rags, bulk | 4,477 | |

| Paper, wood, fiberglass, rubber | 63,794 | |

| Halogenated plastics | 308,404 | |

| Sludge | 1,997 | |

| RCRA toxic metal-bearing waste | ||

| Paint chips | 121 | |

| Leather gloves | 224 | |

| Other | 1,000 | |

| Waste oil and hydraulic fluids | 1,620 | |

| Agent-contaminated activated carbon | 103,488 | |

| Leaker campaign/overpack waste | 15,000 | |

| Total | 2,071,079 | |

SOURCE: Adapted from BPBGT, 2006.

MONITORING BASED ON VAPOR MEASUREMENTS

Air Monitoring Instrumentation and Methods

The predominant time-honored methods for agent monitoring of both plant areas and wastes depend on measuring airborne concentrations. The instrumentation and methods used were most recently examined in the NRC report Monitoring at Chemical Weapons Disposal Facilities (2005a). Other NRC reports over the last two decades have also discussed monitoring instrumentation and methods in the context of those reports’subject matter.3 The focus on disposal site monitoring and measuring airborne agent has been appropriate because vapor constitutes the most probable means of exposure for workers and is the only pathway by which the public could be exposed.

Miniature continuous air monitoring systems (MINICAMS) are the workhorse units chosen for airborne monitoring at PCAPP and BGCAPP; they provide near-realtime (NRT) data (5-15 min). Backup monitoring for confirmatory and historical purposes is provided by the depot area air monitoring system (DAAMS) collection tubes that adsorb and preconcentrate agent vapors from ambient air over a period of time. These collection tubes are transported to an on-site laboratory and their contents are regularly (daily or longer) flash-desorbed analyzed by gas chromatography/mass spectrometry (GC/MS). Results from the DAAMS tubes have a turnaround time of up to 72 hours and are thus not in real time or near real time, but do have the strength of providing a cumulative and historical record of agent vapor presence, even at very low concentrations.

In addition to their role in monitoring areas where agent contamination is expected, MINICAMS are also installed near to the areas where personnel might be exposed to agent. MINICAMS also are used for detection of leakers in storage igloos; in containers used to transport munitions from the igloos to the munitions storage magazine (MSM); and in transport vehicles from the MSM to the enhanced reconfiguration building. PCAPP anticipates that 132 MINICAMS will be required to support its operations.4

MINICAMS are also used for headspace monitoring of waste materials prior to shipment to an off-site TSDF, as mentioned above. The measurement cannot exceed the established WCLs, which are defined in terms of a VSL for each agent. As noted above, headspace monitoring of the waste involves placing it in an enclosure at a prescribed temperature for a sufficient amount of time to allow agent present on the solid to equilibrate with agent in the vapor. If the vapor-phase concentration is <1 VSL, the waste is deemed to be clean. Target release levels are generally somewhat lower than the WCLs to allow a margin for error and still be in compliance with the WCL values approved by state regulatory authorities.

One possible use of direct surface analysis using ambient ionization mass spectrometric technology could be to help resolve those instances where prior exposure

![]()

3Examples include NRC, 1994; 2002; 2005d; 2010.

4PCAPP Air Monitoring Strategies and Secondary Waste, discussion between Walter Waybright, PCAPP Laboratory Manager, and the committee, on June 28, 2011.

of materials to agent is in question. However, it should be noted that neither headspace concentrations (VSLs) nor concentrations determined from alternative extractive solvent analyses (discussed below) are directly and quantitatively derivable from surface concentrations. A first-order surface concentration measurement might entail obtaining a qualitative answer as to whether or not to analyze further. A conservative estimate of a corresponding gas-phase concentration could be made by assuming 100 percent desorption of the measured surface agent concentration multiplied by an estimated contaminated surface area to specify a total adsorbed agent mass, and then applying the ideal gas law to compute the potential gas phase agent concentration (mass per unit volume) in the headspace volume.

The immediate opportunities for ambient ionization monitoring techniques lie either in improving internal operation of the plant or in identifying materials with strongly absorbed agent that must be managed accordingly. By improving internal operations, the committee is referring to possible enhancements to worker safety and to potentially enabling the time needed for overall disposal and closure operations to be shortened.

Hazard analyses for work procedures conducted at chemical agent disposal facilities attempt to scrupulously avoid possibilities for dermal contact with chemical agent by workers. The use of appropriate-level personal protective equipment is among the prescribed means by which dermal contacts with agent are avoided. Consequently, the vapor-phase monitoring methods described above are aimed at controlling and providing valid measurements of the inhalation threat to workers posed by ambient airborne agent concentrations.

Meanwhile, certain waste materials (e.g., carbon and wood) are not amenable to accurately measuring the extent of agent contamination from headspace vapor monitoring owing to their physical properties (e.g., adsorptivity and absorptivity). The 2009 NRC report Disposal of Activated Carbon from Chemical Agent Disposal Facilities described the problem in using headspace vapor analysis for one such major waste stream (activated carbon) as follows (NRC, 2009b, p. 42):

… to use this method to accurately measure agent loading on carbon requires measurement of the gas-phase concentration in equilibrium with the carbon and also requires knowledge of the adsorption isotherm for that agent under relevant conditions. In principle, if the adsorption isotherm is known, then the adsorbed- phase concentration or loading can be determined from the gas-phase concentration. Three issues associated with the use of headspace analysis must be considered to achieve a reliable analysis of agent loading on carbon. First, the gas-phase concentration of agent that would be in equilibrium with an agent loading of 20 ppb at ambient and even moderately elevated temperatures could be undetectable by head space analysis. Second, the adsorption isotherm would be needed to correlate loadings with gas-phase concentrations at agent loadings near 20 ppb. Third, a pure-component adsorption isotherm would not even apply

to the real system, which would contain co-adsorbed amounts of other components, such as water and degradation products.

Given the issues and problems surrounding accurate determinations of the degree of agent contamination for materials such as activated carbon using vapor-phase methods, the Army and various regulatory authorities have instead turned to requiring characterization of agent concentrations by analytical extraction procedures. These are described in EPA publication SW-846, Test Methods for Evaluating Solid Waste, Physical/Chemical Methods—specifically, Method 3571, “Extraction of Solid and Aqueous Samples for Chemical Agents,” and Method 8271, “Assay of Chemical Agents in Solid and Aqueous Samples by Gas Chromatograph/Mass Spectrometry, Electron Impact (GC/MS/EI)” (EPA, 2007a, b).5

Several of the process monitoring methods summarized in Figure 3-1 involve extraction of a liquid sample aliquot containing potentially contaminated solid material, which would be subsequently analyzed in the laboratory by the techniques described in Methods 3571 and 8271 While they provide an alternative means to more accurately measure agent contamination, these methods involve time-consuming and difficult operations. That is, any method that requires taking an aliquot to a laboratory for analysis is far from real time, and it would seem desirable if it could be replaced with a real-time method. The new ambient ionization mass spectrometric methods offer the possibility of real-time agent contamination measurements of porous materials for the first time, giving the Army’s chemical demilitarization community the opportunity to consider their utility. In addition, as shown in subsequent chapters, ambient ionization mass spectrometry methods are capable of quantifying low levels of relevant agents in liquid solutions. Thus, it may be feasible to analyze liquid extraction samples where they are collected without transport for laboratory analysis. For the purposes of this report, the committee’s examination will focus on the most immediate and largest needs to characterize porous materials, activated carbon and concrete, which will be discussed in more detail in later sections of this chapter and in subsequent chapters.

USE OF DPE SUITS DURING PLANT OPERATIONS

The largest single secondary waste category generated during normal operations at PCAPP (Table 3-1) is expected to be nonporous DPE suits: over 200,000 lb, of which 81,000 lb are anticipated to be >1 VSL. This represents roughly 40 percent of all anticipated waste with >1 VSL. Much of the DPE waste originates from routine maintenance entries into Category A areas, where agent is expected to be encountered. Another 78,000 lb or so of DPE waste are anticipated to be generated during closure operations at PCAPP. Unfortunately, DPE suits are not specifically itemized in Tables 3-3, 3-4, and 3-5 from BGCAPP, but the committee presumes that DPE suits, constructed

![]()

5SW-846 is the EPA Office of Solid Waste’s (OSW’s) official compendium of analytical and sampling methods that have been evaluated and approved for use in complying with the RCRA regulations. SW-846 functions primarily as a guidance document setting forth acceptable methods for the regulated and regulatory communities to use in responding to RCRA-related sampling and analysis requirements. Additional information is available at www.epa.gov/osw/hazard/testmethods/sw846/.

FIGURE 3-1 An overview of the analysis plan for PCAPP. SOURCE: Adapted from Walter Waybright, PCAPP, “PCAPP Air Monitoring Strategies and Secondary Waste Discussion,” presentation to the committee on June 28, 2011.

from various thicknesses of PVC material, make up the bulk of the listed halogenated plastic waste.

Finding 3-1. The waste category designations used for tabulating waste streams at the Pueblo Chemical Agent Destruction Pilot Plant and the Blue Grass Chemical Agent Destruction Pilot Plant differ, thus making waste management comparisons between the two facilities difficult. For example, at one site the waste quantity estimates list waste demilitarization protective ensemble suits separately, but at the other such waste is included in halogenated plastic waste.

Recommendation 3-1. The Program Executive Officer for Assembled Chemical Weapons Alternatives should consider implementing a uniform set of waste category designations for use at both the Blue Grass Chemical Agent Destruction Pilot Plant and the Pueblo Chemical Agent Destruction Pilot Plant to facilitate the transfer of knowledge and lessons learned between sites.

A typical DPE-suited operation is shown in Figure 3-2. The use of DPE suits is slow (limited to two workers at a time and no more than 2 hr per entry), cumbersome, physically tiring for the workers, and a major limitation for process throughput since operations are halted during the entries. Because of the human involvement, proximity to agent, and the awkward working conditions, DPE entries present challenges to safe and speedy work. A backup team of two workers is always standing by to assist with the safe egress of the workers. Plans are developed at each site that categorize the egress contingencies as follows:6

• Normal cutout. Most DPE entries are normal and consist of two workers in DPE suits doing a planned sequence of operations lasting no more than 2 hr. Before leaving the work area, they apply decontamination solution to their boots, gloves, knee area, or anywhere else they think may have come in contact with agent and walk to the airlock, allowing contact time for the decontamination solution to work. Once in the airlock, the workers rinse the decontamination solution off themselves and proceed to do “quadrant monitoring.” One worker holds the sample point of a MINICAM near the other worker and moves it slowly over the other worker’s body in a prescribed way quadrant by quadrant. The workers then switch roles. If less than 1 VSL is measured, then a normal cutout ensues and assistance is needed only to remove (cut off) the suits as they pass from one airlock to another.

• Assisted cutout. As workers are scanned in the airlock, if the readings are greater than 1 VSL, then some type of assistance is dictated. An example would be a worker who tried to decontaminate a boot or glove without success. In this case, an assistant would come into the airlock with appropriate personal protective equipment (PPE) gear, such as an M40 mask, gloves, and apron, to help with the cutout so that the worker(s) doffing the suit would not

![]()

6Personal communication between Harrison Pannella, study director, Jeff Kiley, Chief, Quality Assurance, CMA, and C.T. Anderson, Safety and Surety Engineer, ACWA, on October 26, 2011.

FIGURE 3-2 Workers in personal protective equipment working at a chemical weapons disposal facility. SOURCE: CMA Fact Sheet on Safe Disposal of Secondary Waste. Available online at www.cma.army.mil.

touch the outside of the suit where agent might still be present. The assistant comes in solely to help the workers doff their suits, not to help decontaminate. The aim is to help a worker avoid contact with the outer surface of the suit, where contamination may be present.

• Hot cutout. This type of egress occurs when there is a high level of residual contamination that cannot be successfully decontaminated. (For example, the agent might be embedded in grease on the suit.) An assistant wearing a higher level of PPE gear, such as a self-contained breathing apparatus along with gloves, boots, and other dermal protection, would enter the airlock to help remove the worker’s suit.

• Emergency cutout. In an emergency cutout there is some medical urgency (e.g., heat stress) such that there is no time to decontaminate and verify. The cutting out in this fast-moving situation is done in an expedited way by a backup rescue team, which may consist of one worker in Level B PPE and another in Level C, or both workers in Level B. This team does not look for contamination; rather, they will do a gross decontamination with the emphasis on avoiding contact with the outside surface of the suit. When the call is made for the rescue team, the other DPE-suited worker will immediately hose down or start dropping buckets of decontamination solution on the DPE-casualty worker while in the work area to provide some benefit before the rescue team

gets there to extract the stricken worker. Typically, one member of the rescue team will enter the area and work with the other DPE-suited worker to extract the DPE-casualty worker while the other member of the rescue team prepares to receive the stricken worker. For example, one litter or sled might go into the work area with one of the rescue team members while the other member prepares another litter or sled to which the casualty worker will be transferred for handoff to a medical team. In an emergency egress (medical, fire, etc.) the DPE-suited workers will not necessarily leave through an airlock but may use an alternative emergency exit door.

Clearly, these classifications become more problematic going down the list from the normal cutout to the emergency cutout. Each of the egress categories could be expedited by having a quick-response, real-time monitoring device capable of pinpointing areas of agent contamination and/or by verifying the lack of agent. Such a capability would help ensure the safety of workers. Scenario 3A in Box 3-1 describes how the new monitoring techniques might be of value.

BOX 3-1

Scenario 3A: Improving Worker Safety During DPE Entries

Worker safety is of paramount concern, and knowing as rapidly as possible where agent is or is not would facilitate smarter and safer DPE activities.

Faster quadrant scanning would speed normal DPE cutout time, and more accurate pinpointing of any residual agent on the DPE suit could guide workers to focus further decontamination on those spots. If further decontamination is not possible, the information could be used to avoid contaminated spots. Also, real-time monitoring of materials left in the wake of an extracted worker might help coworkers avoid contamination.

The use of portable ambient ionization instrumentation might allow faster assessment of agent presence for DPE activities and expedite safer worker egress.

DPE suits that have been exposed in Category A areas are assumed to be contaminated and require monitoring for agent contamination. That is typically accomplished by headspace analysis, as described in the ACWA Chemical Agent Monitoring Concept Plan (MCP) for personal protective clothing and equipment (PCE) (U.S. Army, 2011a, p. 59):

To monitor decontaminated PCE, the PCE will be placed in a container or room and held for at least 4 hours at a minimum temperature of 21o C (70o F). The atmosphere (i.e., headspace) inside the container or room will be monitored for contamination via a technique applicable to the monitoring level of interest (VSL or 8-hour WPL) to verify that agent concentrations are below the applicable AEL before the PCE may be sent to the laundry facility. If agent concentrations are

BOX 3-2

Scenario 3B: Enabling More Efficient DPE Entries

DPE entries into contaminated process areas place great physical strains on workers in DPE gear and also involve potential agent exposures. In addition, munitions processing must usually be suspended during entry operations. Opportunities to focus and expedite entry activities may lead to safer entries and shorter process interruptions and the generation of less DPE secondary waste.

Portable ambient ionization instrumentation may allow quick and reliable determination of agent contamination locations and levels during DPE entries—for example, by determining if observed liquid deposits are agent or nonagent (water, oil), by clearly defining contaminated areas to focus decontamination actions and confirm their effectiveness, and by generally expediting effective decontamination activities that in turn would allow workers to downgrade the level of personal protection necessary to work in contaminated areas when appropriate.

detected above the applicable AELs, the PCE will be further decontaminated and remonitored.

PCE includes DPE suits. While headspace analysis is a proven and effective method for verifying whether DPE suits are clean, it is also time consuming.

Scenario 3B in Box 3-2 provides a scenario for possibly reducing the number of DPE suits used during process maintenance, agent changeover, and closure activities.

Finding 3-2. Any new monitoring method that could efficiently and reliably locate and quantify agent contamination may make decontamination activities more efficient by:

• Enabling faster identification of leaking munitions and decontamination of machinery, potentially reducing the number and/or duration of DPE-suited entries during normal plant operations, agent changeover periods, and closure activities;

• Reducing the total amount of secondary waste;

• Speeding waste disposal; and

• Minimizing worker exposure.

CHANGEOVER OF AGENT DISPOSAL CAMPAIGNS AT BGCAPP

At BGCAPP, chemical agents will be destroyed in sequential campaigns beginning with GB, which due to its relative volatility presents the greatest risk, and then proceeding to VX. A decision is pending on whether all or only some of the mustard agent H projectiles should be destroyed by use of an explosive destruction technology

(EDT) instead of being processed through the main BGCAPP processes. During the changeover period from one agent to the next, the MINICAMS are reconfigured to monitor for the next agent to be destroyed. The facility and associated equipment and machinery must be completely decontaminated of the prior agent before operations can continue.

In preparation for changeover, occluded space teams (OSTs) are formed to identify occluded spaces that may harbor agent contamination. Common areas of occluded space include closed pipes, pump cavities, cracks in concrete, and caulking seals around equipment or concrete joints. Discussions and definitions of the types of occluded spaces that may occur in chemical weapons disposal facilities are presented in Box 3-3. Where possible, equipment having occluded spaces will be bagged for headspace analysis to verify contamination levels.7

If headspace analysis indicates contamination of a large piece of equipment, it might prove beneficial to have a more local, real-time probe (such as ambient ionization mass spectrometry for surface analysis) that could pinpoint the contaminated area for decontamination. Changeover operations typically take several months to complete and any reduction in the period of time necessary for changeovers would speed the overall disposal campaign. The committee believes it could be beneficial to identify situations in which bagging could safely be eliminated, or at least greatly reduced, by use of surface analysis by ambient ionization mass spectrometry. In this method, a wand would be waved over the surface of, for example, a contaminated machine or a cavity identified by an OST that would otherwise require bagging and headspace monitoring. Examples of how a real-time surface analysis instrument could speed changeover are given in Scenario 3C in Box 3-4 and Scenario 3D in Box 3-5.

Finding 3-3. A local, real-time agent monitoring system capable of monitoring surfaces might enhance the effectiveness of occluded space survey teams by identifying problematic occluded spaces and identifying other sources of contamination, possibly reducing the time necessary to conduct agent changeovers or facility closure.

Once a chemical agent disposal facility has completed the disposal campaign operations for all agents stored at the site, it transitions into closure operations. This involves the decontamination and removal of equipment and decontamination and demolition of any contaminated infrastructure and buildings areas. The objective of closure is to decontaminate and safely demolish to ground level, in a manner that provides for the safety and protection of the workers, the public, and the environment, all of the buildings that were exposed to agent contamination (NRC, 2010). Such closure activities must satisfy regulatory permit requirements and other applicable federal, state, and local stipulations whether or not the area is destined to be returned to the public

![]()

7Gary Groenewold, member of the Committee to Review Secondary Waste Disposal and Regulatory Requirements for the Assembled Chemical Weapons Alternatives Program, “Sources and Amounts of Agent-Contaminated Wastes,” presentation to the committee on February 23, 2011.

BOX 3-3

Definition and Classification of Occluded Spaces

The term “occluded space” is generally interpreted by the U.S. Army CMA as “a confined volume within a system, structure, or component that was exposed or potentially exposed to liquid agent and has the potential to contain any quantity of agent contaminated liquid.”1 Building on this definition, it is useful to classify occluded spaces into three broad types. Note that the following types do not reflect an official classification protocol by the U.S. Army but are presented for descriptive purposes in this report.

Occluded space, Type I. This category of occluded space is putatively the largest of the three categories. It represents areas that agent in liquid or vapor form could potentially penetrate and/or reside in that would hinder or preclude its detection by vapor screening methods (e.g., tenting). To avoid erroneous vapor screening measurements, systems, structures, and/or components are disassembled prior to VSL measurements to eliminate Type I occluded spaces before demonstrating that decontamination was successful. The derivative pieces following disassembly, for example, steel parts and laboratory glass, typically exhibit readily defined surfaces with smooth geometries.2 Examples of Type I occluded space include seams, crevices, cracks, fasteners, threads, tubing, valves, and unsealed joints.

Occluded space, Type II. This category of occluded space represents process system or structural components containing materials with properties of porosity, miscibility, and/or chemical affinity for the liquid agent. In these cases, there is a reasonable probability that any exposure to high levels of gaseous agent, liquid agent, or agent contaminated liquids may have resulted in significant quantities of agent being adsorbed, absorbed, and/or trapped within the matrix of the material. This may result in misleadingly low values of agent vapor concentration when VSL measurements are performed. Typically, such materials are either incinerated (at CMA demilitarization facilities equipped with suitable furnaces) or stored prior to chemical neutralization on-site. Examples of Type II occluded spaces include wooden pallets, spent activated carbon, polymer gaskets, pump oil, lubricating oil, porous materials (including spill pillows), and agent miscible liquids.

Occluded space, Type III. The third category of occluded space is challenging to anticipate, foresee, and detect, as it represents potential occluded spaces in the process system or structural components that may have been present upon initial fabrication or construction or that became occluded at a later time, either in use during agent destruction campaigns, or even following decommissioning and shipment of the material off-site. These occluded spaces may arise from nonideal construction of the individual process system or structural components that remain undetected or are thought to be impervious, or they may not exist during plant systemization but arise later—for example, through material degradation by geological, environmental, or chemical forces. Although it is difficult to assess the extent of Type III occluded spaces (if any), it is nevertheless important to recognize their potential to occur and become exposed—for example, during decommissioning or deconstruction campaigns and, longer term, as sequestered wastes age, such as those decontaminated to level 3X or 5X (NRC, 2007), that are shipped off-site for long-term disposal (e.g., in landfills).

![]()

1J.M. Kiley, 2011. “Closure Briefing,” presented to the committee on February 23, 2011.

2NRC. 2007. Review of Chemical Agent Secondary Waste Disposal and Regulatory Requirements, Box 3-1 “U.S. Army Decontamination Metrics for Potentially Exposed Materials,” p. 40.

Unventilated agent vapor monitoring shows that a process area is contaminated. A portable ambient ionization instrument might be able to quickly interrogate and survey identified occluded spaces or suspected absorbed agent-contaminated materials, machinery, equipment, and plant structures, including concrete walls, floors, seams, and interfaces, to determine if agent reservoirs might be present and, if they are, guide and confirm focused decontamination efforts, thus reducing changeover or closure time.

Bagging and monitoring headspace levels is not practical for some equipment, materials, and machinery and may not be the most cost-effective approach for others. A portable ambient ionization instrument might be able to quickly survey occluded spaces and/or absorptive material components and identify the contaminated parts to direct focused decontamination or component removal to expedite treatment.

domain. These operations produce large amounts of secondary waste, as summarized in Tables 3-2 through 3-4. To minimize decontamination and to protect workers, a well- defined process is followed based on established AELs for the agents (see Table 2-1). This process includes the following:

• Maintaining and reviewing documented agent history. Based on lessons learned at prior closure operations, a careful record of all contamination events, spills, leaks, and the like is maintained during plant operation and used to identify contaminated areas by what is termed “generator knowledge.”

• Selecting decontamination methods for each type of waste.

• Using OSTs to survey the facility and identify occluded spaces where agent may have accumulated. These include hidden spaces in piping, pumps, etc., that are not readily cleaned and decontaminated.

• Decontamination, monitoring, and dismantlement of equipment. Figure 3-3 shows tenting of a large piece of equipment in preparation for vapor monitoring.

FIGURE 3-3 An example of a large item tented for monitoring at closure. SOURCE: Jeff Kiley, Chief, Quality Assurance, CMA, “CWD Closure Briefing,” presentation to the committee on February 23, 2011.

• Decontamination and unventilated monitoring of the enclosed air space of building areas and rooms subject to having been contaminated by agent.

• Finally, razing buildings to the ground level.

Uncontaminated buildings may be retained based on agreement with the respective depot (Pueblo Chemical Depot or Blue Grass Army Depot) and any plans under base realignment and closure (BRAC) agreements. The criteria used to determine if an area is contaminated are contained in a U.S. Army review (2008a) and specified in the local environmental permits. Generally, the criteria areas are as follows:

• Any area or chamber exposed to liquid agent or aerosol is assumed to be contaminated.

• Any area or chamber exposed to agent vapor above the immediately dangerous to life or health (IDLH) level is considered to be contaminated.

• A decision on whether an area that has been exposed to agent vapor between IDLH and the short-term exposure limit (STEL) is contaminated is based on a risk assessment.

• Any area or chamber that has only been exposed to agent vapor below the STEL is assumed to not be contaminated.

Table 3-2 summarizes secondary wastes expected from closure operations at PCAPP and Tables 3-2 and 3-4 provide similar expectations for BGCAPP. Although the two sites use different terminology to describe some of their waste, much of the waste from normal operations, including from DPE suits and other toxicological agent protective (TAP) gear, continue to be major contributors during closure. In addition, closure creates significant streams of concrete, metals, combustible solids, and other incombustible solids. Also, all the activated carbon from the heating, ventilation, and air conditioning (HVAC) filter system must be disposed of at closure.

Special challenges to agent contamination monitoring are presented by some of these materials. For example, activated carbon is a strong absorber of agent, and concrete can be porous and can have cracks that accumulate agent. Combustible wood and fabric materials are often fibrous or porous, and agent may strongly adhere or absorb. Porosity can effectively provide large volumes of occluded space that are highly agent-retentive. As a lesson learned from prior chemical demilitarization sites, concrete that could potentially become exposed to liquid agent is of a high density and coated with a special polymer intended to minimize agent access to any cracks or pores. At BGCAPP and PCAPP, it is anticipated that this will minimize the need for scrabbling to remove agent- contaminated layers of concrete.

The current method of monitoring for agent adsorbed on or absorbed in concrete is headspace monitoring of nonventilated tented walls; this procedure includes heating to aid in vaporizing absorbed agent.8 A previous NRC report questioned whether scrabbling would c`ause even more concrete to be classified as agent contaminated and recommended that ACWA investigate means for measuring residual agent on the concrete surfaces (NRC, 2008a, Recommendation 4-4). This committee concurs with that recommendation and suggests that ambient ionization mass spectrometry be investigated for that purpose. It now offers Scenario 3E (Box 3-6) as a possibility for further discussion in Chapters 4 and 5.

Finding 3-4. Materials with inherent porosity can readily adsorb or absorb agent and present a monitoring challenge for headspace vapor measurement methods.

![]()

8Personal communication from James Richmond, Director, ACWA Risk Management Directorate, to the committee, August 15, 2011.

BOX 3-6

Scenario 3E: Concrete Waste Contamination Evaluation

Concrete that will have to be disposed of at closure may have agent adsorbed to its surfaces or absorbed into its mass. A portable ambient ionization instrument might be able to quickly and reliably interrogate adsorbed agent on the concrete surfaces and/or absorbed agent in bulk concrete to identify contaminated areas, estimate contamination levels, and reduce the need for scrabbling.

Activated carbon (also referred to as charcoal in Tables 3-1 and 3-2) strongly absorbs agent and other organics and is thus used in protective masks for workers and the final filter banks before air is released from the plant. The bulk of the activated carbon must be disposed of at closure. Over 100,000 lb are expected to be disposed of at BGCAPP (Table 3-5) and about 35,000 lb at PCAPP (Table 3-2).

Activated carbon is a porous adsorbent that cannot be verified to be free of agent by headspace analysis because the agent is strongly adsorbed on or absorbed in the carbon. Shipment of agent-exposed activated carbon to off-site disposal or recycling facilities requires verifying the mass of agent on the carbon. The method currently being pursued is solvent extraction of the adsorbed/absorbed phase from the carbon sample followed by GC/MS analysis. Applying this method at the Anniston Chemical Agent Disposal Facility (ANCDF) in Alabama, Southwest Research Institute found that VX was below the WCL but GB was above it. The GB values were later ascribed to the reformation of GB from the hydrolysis products during extraction. A way was found to limit this re-formation, but if a real-time analysis technique were available that would not require extraction, it might prove to be a better alternative.

The NRC-recommended solution for the ultimate disposal of the activated carbon at ANCDF was to fill the polyethylene drums that held the carbon with caustic solution prior to transporting them to a treatment, storage, and disposal facility (TSDF) (NRC, 2009b). Scenario 3F in Box 3-7 asks whether surface ambient ionization mass spectrometry might be able to directly measure agent contamination on carbon, which might lead to more informed carbon disposal decisions.

BOX 3-7

Scenario 3F: Spent Activated Carbon Contamination Evaluation

Spent activated carbon is likely to have bulk absorbed agent. A portable ambient ionization instrument might be able to quickly and reliably interrogate adsorbed/absorbed agent in spent activated carbon to identify contaminated materials, estimate contamination levels, and thus inform and focus decontamination or disposal activities.

From a technical specifications perspective, the successful implementation of any new technologies to any of the scenarios presented in this chapter would represent a considerable departure from current agent monitoring practice, most noticeably in the detection of absorbed or chemisorbed materials on surfaces. In addition to directdetection on surfaces, a number of other analytical properties are critical to successful implementation for any particular application. These include purely analytical parameters such as sensitivity, dynamic range and selectivity as well as instrument factors such as reliability, portability, and ease of operation. Table 3-6 summarizes some of the criteria important to meeting the requirements of the different scenarios presented in this chapter. Chapters 4 and 5 will address the technical suitability of certain types of ambient ionization mass spectrometry for surface-adsorbed agent analysis.

TABLE 3-6 Critical Measurement Performance Criteria for Possible Scenarios

| Scenario | Critical Performance Criteria Categories for Measurements | ||||||||

| Detect on Surfaces | Dynamic Range | Portability | Precise Target Localization |

Rapid Reconfiguration |

Rapid Result | Scanning | Sensitivity | Short Duty Cycle | Specificity |

| 3A Improving worker safety during DPE entries | X | X | X | X | X | ||||

| 3B Enabling more efficient DPE entries | X | X | X | X | X | ||||

| 3C Process area occluded space surveys and/or absorbed agent surveys during changeover or closure activities | X | X | X | X | X | X | X | ||

| 3D Complex contaminated demilitarization machine needs decontamination at agent changeover or closure activities | X | X | X | ||||||

| 3E Concrete waste contamination evaluation | X | X | X | X | |||||

| 3F Spent activated carbon contamination evaluation | X | X | X | ||||||

This page is blank