6

A Framework to Assess Sustainable Development of Algal Biofuels

Although each process in the production pathway could present sustainability challenges or opportunities to reduce resource use or mitigate environmental effects (as discussed in Chapters 4 and 5), the effect from one part of the supply chain could be offset by another part of the supply chain. Therefore, all the sustainability challenges and opportunities have to be assessed from a systems perspective. Thus, the committee reviewed life-cycle assessments (LCAs) performed to estimate resource use and environmental effects from cradle to grave for those parameters where published studies were available—for example, water use, net energy return, and net greenhouse-gas (GHG) emissions. Each pathway for producing algal biofuels combines cultivation, harvesting or product recovery, dewatering, and processing into a system. The abilities of different pathways to meet different aspects of sustainability vary, but in all cases, improvement in productivity, for example, cell density in algae cultivation, algal product (oil or alcohol), or biomass yield, and processing yield of biomass to fuels, helps reduce resource use and environmental effects.

Given the multiple resource requirements and potential environmental effects, specific sustainability concerns cannot be viewed in isolation from others. Any one LCA for a single resource use or environmental effect is insufficient to determine the overall sustainability of an algal biofuel production system. Issues arise as to how to assess the overall environmental sustainability of algal biofuels and how to balance the environmental objectives against economic and social objectives of sustainable development. In that regard, the committee was asked to discuss whether there are preferred cost-benefit analyses that best aid in the decision-making process.

This chapter first summarizes the sustainability concerns that might arise in each of the pathways for algal biofuel production discussed in Chapter 3. The summary illustrates how various pathways differ in their ability to meet different and sometimes competing sustainability objectives. Then, the chapter discusses tools that could aid in decision-making processes and proposes a framework for assessing sustainability of algal biofuel as a developing industry.

6.1 SUMMARY OF RESOURCE USE AND ENVIRONMENTAL EFFECTS OF DIFFERENT ALGAL BIOFUEL PRODUCTION PATHWAYS

6.1.1 Reference Pathway–Raceway Pond Producing Drop-in Hydrocarbon

Most algae for commercial products have been cultivated in open-pond systems because of their low costs compared to photobioreactors (Earthrise Nutritional, 2009; Milledge, 2011). Ensuring a high level of productivity of the desired algal species also could improve economic viability and reduce resource use and environmental effects per unit of fuel produced. Some of the key concerns for resource use and environmental sustainability include:

Availability of suitable land for installing large ponds for algae cultivation.

• Evaporative loss of water from ponds, particularly in arid regions with low rainfall.

• Social perception and acceptance. They could be a key barrier if genetically modified organisms are to be cultivated in open ponds.

In the reference pathway, the nitrogen (N) and phosphorus (P) requirements are not a key sustainability concern because the lipid-extracted algae undergo anaerobic digestion to produce energy and these nutrients are returned to the algal culture. Energy generation from anaerobic digestion contributes to reducing energy input and hence GHG emissions. Other potential concerns that could be avoided if care is taken to maintain the algal cultures and the cultivation ponds include:

• Ground and surface water pollution.

• Presence of waterborne toxicants from contaminants.

• Potential for increasing mosquito-breeding grounds if ponds are not properly managed.

Some of the unknowns with respect to environmental sustainability include:

• Emissions of air pollutants from open ponds, which could be monitored to determine the extent of such emissions.

• Effects on terrestrial and aquatic biodiversity, but such effects could not be assessed unless the site of deployment for the algal biofuel production system and the cultivation system to be used are known.

• Site-dependent effect of open ponds on local climate.

The air quality emissions associated with drying, extraction, and processing to fuels could be mitigated by engineering solutions, particularly if most steps are performed indoors. Technology improvements in those steps and in harvesting could reduce energy use and hence reduce GHG emissions. The reference pathway produces a drop-in biofuel that can be used in the existing fuel distribution and vehicle infrastructure.

6.1.2 Alternative Pathway #1–Raceway Pond Producing Drop-in Hydrocarbon and Coproducts

The ability to meet various sustainability goals and the potential concerns for this pathway are similar to the reference case. The only difference lies in the production of coproducts other than energy from anaerobic digestion. That change could affect energy

requirements, GHG emissions, and nutrient requirements depending on what the highquality coproduct is. Coproducts also affect economic viability.

If the coproduct is an animal feedstuff, then a coproduct credit could be assigned to the LCA of nutrient and energy requirements, and to GHG emissions for the animal feedstuff that is substituted by the coproduct of algal biofuel. Safety would have to be considered if the coproduct is to be fed to animals or used to fertilize food crops. Algae potentially can accumulate toxic compounds (for example, mercury can accumulate in cultivated algal cells if unscrubbed flue gas is used as a source of supplemental carbon dioxide [CO2]). Toxicants accumulated in cultivated algae can be bioaccumulated if fed to animals or taken up by crop plants from fertilizers, or can inhibit anaerobic digestion if lipid-extracted algae are to be used for electricity generation. Other than safety, the nutritional quality of the feedstuff and the effect of the feedstuff on the quality of food animal (for example, meat quality) would have to be assessed to determine its suitability as a primary feedstuff or a supplement. A feedstuff coproduct can contribute to offsetting costs of algal biofuel production if there is a large enough market for the sale of the coproduct. If the feedstuff is only suitable for certain animals and has a limited market, then saturating the market with large quantities of the coproduct could lower its market price and utilization options.

If the coproduct is electricity, then market saturation will not be a concern. The energy requirement and GHG emissions could be lower compared to the reference pathway, and the cost of energy input into the algal biofuel production pathway could be reduced.

6.1.3 Alternative Pathway #2–Raceway Pond Producing FAME

The key difference between this and the reference pathway is the fuel produced, with this scenario assuming the fuel product to be fatty-acid methyl esters (FAME). With most processes along the supply chain being equal, the ability to meet various sustainability goals and the potential concerns for this pathway are similar to the reference case. However, FAME’s poor cold-flow properties could affect their marketability and hence their economic viability. In northern-tier states, FAME might have to be stored in heated tanks in winter to keep the fuel fluid. In fact, many of the biodiesel refineries producing FAME from soybean in the United States are idle. In 2011, the production capacity of biodiesel in the United States was about 2 billion gallons per year, but only 1 million gallons were produced (EIA, 2010).

6.1.4 Alternative Pathway #3–Photobioreactors with Direct Synthesis of Ethanol

Growing microalgae in photobioreactors can avoid a number of the sustainability concerns associated with open-pond cultivation but may require substantial energy input for pumping and mixing water and for temperature control. Incidents of contamination by algae and other microorganisms and evaporative loss of water likely would be reduced. Other than using a different cultivation system from the other pathways discussed above, this pathway does not require harvesting, drying, and rupturing the algal cells to extract algal oil because the cyanobacteria secrete alcohol into the medium continuously. The direct synthesis of ethanol reduces downstream processing and could result in substantial energy savings and associated cost savings. In addition, some members of the public might find cultivation of genetically modified algae in enclosed reactors more acceptable than in open ponds.

A key barrier to sustainable development of algal biofuels using such systems is the potentially high capital cost (Tredici, 2007; Davis et al., 2011). Another disadvantage of this

pathway is that the fuel product, ethanol, is not compatible with the fuel distribution infrastructure for petroleum-based fuels. Although ethanol can be used in flex-fuel vehicles (FFV) that accommodate a blend of 85 percent ethanol and 15 percent gasoline (E85), most vehicles in the United States have internal combustion engines that use E10, which contains 90 percent gasoline and 10 percent ethanol. As of January 2011, the U.S. Environmental Protection Agency (EPA) allows the use of E15 in vehicle models of 2001 or newer. If every drop of the 520 billion liters of gasoline consumed in the United States in 2010 was blended with ethanol for E10, the maximum ethanol that could be used is 52 billion liters. The United States produced 50 billion liters of corn-grain ethanol that year. Therefore, the U.S. transportation sector would not be able to incorporate much more ethanol into the fuel system unless the market for flex-fuel vehicles expands.

6.1.5 Comparing the Sustainability of Different Pathways

The summaries of resource use and environmental effects of different pathways illustrate that each pathway has its strengths and weaknesses in meeting different sustainability goals. For example, the use of open ponds and closed photobioreactors illustrate tradeoffs between aspects of economic and environmental sustainability. Open-pond systems could raise more environmental concerns than closed-photobioreactor systems, but the cost differential between the two systems could be a key determinant of economic viability. The direct synthesis and secretion of ethanol by cyanobacteria without cell destruction would reduce nitrogen and phosphorus input during cultivation (particularly if nitrogen and phosphorus recycling are not fully implemented in algal biofuel production systems that require biomass harvesting) and energy use from downstream processing and could result in synergistic cost savings for a closed photobioreactor system. The question arises as to how to make a holistic assessment of the relative sustainability of different algal biofuel production systems, given the multiple indicators and LCAs that represent various sustainability goals and objectives. As discussed in Chapter 2, indicators and LCAs are tools that can be used to assess a particular aspect of sustainability. Other tools are needed to integrate across disciplines to assess overall sustainability, which includes energy security, and environmental, social, and economic sustainability. As outlined in the statement of task, the committee was not asked to perform any technoeconomic analyses. Environmental sustainability has been considered more extensively than social sustainability in the literature because some aspects of social sustainability will be local and social acceptability in part depends on public opinion, transparency, stakeholder participation, and risk of catastrophe, all of which are largely unexplored for algal biofuels. Therefore, this chapter focuses on environmental sustainability.

6.2 TOOLS FOR ASSESSING OVERALL SUSTAINABILITY

The holistic assessment of sustainability is complicated by the fact that some sustainability objectives can be assessed and compared across systems while others are region-specific and cannot be compared across systems. For example, resource use and environmental effects such as nutrient budgets, energy balances, and GHG emissions can be compared directly across systems. Methods for assessing these variables are strictly quantitative. Other environmental effects such as land-use change and biodiversity are region specific and scale specific.

Some resource use and environmental effects can be assessed quantitatively, but whether they contribute to moving toward or away from the sustainability objectives could

be region dependent. For example, consumptive water use and emissions of air pollutants can be quantified and compared across alternative algal biofuel production systems. However, a comparison without considering the regional context might not indicate whether the systems contribute to improved sustainability. One algal biofuel production system could be more sustainable with respect to consumptive water use than another even if both use the same quantity of fresh water over their life cycles because one system is situated in an area with high rainfall and near an aquifer that replenishes sufficiently every year, and another is situated in an arid area with a fossil aquifer. Similarly, two identical open-pond systems for algae cultivation in different locations could have different effects on biodiversity depending on the species present at each location. Systematically assessing the sustainability of algal biofuel production systems and comparing them to each other or with other transportation fuel systems presents distinct challenges to researchers and policy makers. As noted by Gasparatos et al. (2011), there is not a consistent language for putting “biofuels’ diverse trade-offs into perspective,” nor are there appropriate tools “for assessing the sustainability of different biofuel practices during their full life cycle.” Despite these challenges for assessing overall sustainability, different approaches have been proposed.

6.2.1 Ecosystem Service Analysis

Analysis of ecosystem services provides a means to assess the overall effects and tradeoffs of algal biofuel production and use (Gasparatos et al., 2011). Ecosystem services are goods and services generated by ecosystem processes that benefit human well-being (NRC, 2011). Thus, the analysis of ecosystem services is a way to link environmental sustainability to social and economic sustainability.

Ecosystem services can be categorized as provisioning, regulating, and cultural services (MEA, 2003). Algal biofuel production is a provisioning ecosystem service. It provides liquid fuels to improve energy security, wastewater treatment if wastewater is to be used as a culture medium, animal feed if it is produced as a coproduct, and energy if lipid-extracted algal biomass is used to generate electricity via anaerobic digestion. Conversely, algal biofuel production systems could compete for resources with other systems that provide ecosystem services—for example fresh water, or land that could be used for food production or other human benefits. Biofuel production also could affect cultural services by changing relatively unmanaged landscapes to highly managed ponds and processing facilities. An adaptation of the Gasparatos et al. (2011) table “Key sustainability issues associated with biofuel production from an ecosystem services perspective” is summarized in Table 6-1.

Although Table 6-1 is focused on land-crop biofuels, the sustainability issues listed are not fundamentally different from those associated with algal biofuels. Energy security and climate regulation are among the primary factors in sustainability of biofuel production irrespective of the feedstock type. The availability of sufficient nutrients and land for production could be added to this list, although these are implicit in the listing for food production and ecosystem conservation. Each of the major resource use issues discussed in Chapter 4—land, water, and nutrients—thus can be viewed as elements in an ecosystem services framework. The analysis by Gasparatos et al. (2011) also makes clear the utility of ecosystem services for addressing social and economic considerations, which are not addressed in this report. Similarly, Tilman et al. (2009) highlight the importance of placing decisions about biofuels in the context of energy security, GHG emissions, biodiversity, and food supply sustainability.

The Ecological Society of America (2008) advocates conservation of ecosystem services as one of three principles for assessing the ecological sustainability of biofuels, and

TABLE 6-1 Key Sustainability Issues Associated with Biofuel Production, from an Ecosystem Services Perspective

|

|

||

|

Sustainability Issue |

Main Ecosystem Services |

Main Constituents of Well-Being |

|

|

||

|

Energy security |

Fuel (provisioning service) |

Access to fuel |

|

Climate change |

Climate change regulation (regulatory service) |

Access to basic materials, e.g., sufficient nutritious food |

|

Economic development (rural development) |

Fuel (provisioning service) |

Basic materials for a good life |

|

Food production |

Erosion regulation (regulatory service) |

Basic materials for a good life |

|

Ecosystem conservation |

Services from conserved ecosystems: • aesthetic value (cultural service) • climate change regulation (regulatory service) • pollination of crops and other vegetation (regulatory service) • timber and forest nontimber products (provisioning services) • recreation and cultural service |

Basic materials for a good life |

|

Water provision |

Steady and clean water supply (provisioning) |

Basic materials for a good life |

|

Health |

Clean air (regulatory service) |

Health |

|

Social cohesion |

Sufficient and equitable supply of ecosystem services (provisioning, regulatory, supporting, and cultural services) |

Good social relations |

|

Maintenance of biodiversity |

Biodiversity is not an ecosystem service per se but “the foundation of ecosystem services to which human well-being is intimately linked” (MA, 2005, p. 18). |

Basic materials for good life |

|

|

||

SOURCE: Adapted from Gasparatos et al., 2011. Reprinted with permission from Elsevier.

Robertson et al. (2008, p. 50) recommend focused research on ecosystem services “to provide the information necessary for the development and implementation of land-management approaches that meet multiple needs.” Translation of ecosystem services analyses into tools that can help make informed decisions is thus a key need (Daily et al., 2009; Gasparatos et al., 2011) and has great promise for contributing to the understanding of the sustainability of algal biofuel production. Although analyses of ecosystem services integrate the various aspects of resource use and environmental effects, their application to a developing industry such as algal biofuels could be difficult because some aspects of ecosystem services

(for example, potential effects on biodiversity) cannot be analyzed until the actual site of deployment is known.

6.2.2 Cost-Benefit Analyses

Cost-benefit analysis is the comparison of the monetized costs of a proposed action compared to the benefits, usually with costs and benefits expressed in monetary terms and from a particular perspective (for example, those investing in the project, those regulating it, or society as a whole). An economic cost-benefit approach relies on an ideological framework that depends on the economic theory applied. An example of an economic costbenefit analysis is the technical analysis of projects such as federal spending for flood control in which the determination of whether the overall benefits exceed the estimated costs is used to evaluate proposed systems. Cost-benefit analyses can incorporate factors that are noneconomic. For example, Simpson and Walker (1987) proposed to include environmental, technical, and risk analyses, in addition to economic analyses in cost-benefit analyses for energy investments. Because many environmental benefits and effects or ecosystems goods and services lack markets or market prices, methods have been developed to estimate their valuation by individuals or society. For example, stated preference methods use carefully designed questionnaires to estimate how much individuals are willing to pay for an increase in quantity of a particular ecosystem service or environmental benefits and how much compensation individuals are willing to accept for the loss of an ecosystem service or a negative effect they endure. Those values form the bases of monetization of ecosystem goods and services and environmental benefits and effects (Hanley and Barbier, 2009).

Cost-benefit analysis is a useful tool for assessing sustainability for the following reasons:

• It can express most relevant benefits and effects in monetary values that can be aggregated into one value (Hanley and Barbier, 2009) and allows direct comparison across algal biofuel production systems if it is applied consistently across systems.

• It aids decision making by showing the tradeoffs among nonmonetized variables that express societal values.

• If the key parameters of cost-benefit analyses are standardized, the analyses allow comparison of sustainability of different biofuels and ensure consistency in decision making (Hanley and Barbier, 2009).

There are some challenges to applying a cost-benefit analysis to environmental sustainability. Some ecosystem goods and services are not readily quantifiable so they cannot be valued (NRC, 2005). Although there are approaches to nonmarket valuation of ecosystem services, those approaches rely on a great deal of professional judgment and depend on the ideological orientation of the individual or group conducting the valuation (NRC, 2005; Bebbington et al., 2007). A key challenge to applying a cost-benefit analysis to algal biofuel production relates to nonmarket valuation. Because algal biofuel production is developing with multiple pathways being pursued, the actual effects of algal biofuel production on ecosystems and the environment are largely uncertain (as discussed in Chapters 4 and 5). Because the changes to the environment or provision of ecosystem goods and services that people care about cannot be described in precise ways, it is difficult for surveyed individuals to place a value on potential changes (Hanley and Barbier, 2009). Different individuals and groups are likely to value different sustainability goals differently. Therefore, Bebbington et al. (2007) cautioned against the over-reliance on cost-benefit analysis and proposed

the use of “sustainability assessment models” that recognize the need for accountings and also include a participatory approach to decision making. Prioritization of the sustainability goals and decisions on the appropriate tradeoffs to be made that meet the core societal needs requires the development of a collective vision of the desired attributes of a sustainable fuel industry (NRC, 2010).

6.2.3 Cumulative Impacts

In addition to assessing the sustainability goals quantitatively when possible, balancing the sustainability objectives, and minimizing tradeoffs, developing algal biofuels sustainably also would require consideration of the cumulative impacts to the environment. Cumulative effects are defined as “the impact on the environment which results from the incremental impact of the action when added to other past, present, and reasonably foreseeable future actions regardless of what agency (federal or non-federal) or person undertakes such other actions” (43 CFR 1508.7). Environmental assessments or environmental impact statements for proposed biofuel refineries include an assessment of cumulative effects, though some of them are limited in scale. For example, the environmental assessments for Algenol’s facility in Fort Meyer (DOE, 2010) and Sapphire Energy’s facility in New Mexico (USDA-RD, 2009) include a section on cumulative impacts on land use, air quality, soil, ground and surface water, and socioeconomic factors specific to the site. However, the cumulative impacts of future large-scale deployments of multiple algal biofuel production systems across the country have not been assessed.

Parallel lessons can be drawn from environmental impact assessment for solar energy development (BLM and DOE, 2010). Many of the locations considered desirable for algal biofuel production may overlap with potential areas for development of other renewable energy projects such as solar- or wind-powered electricity generation as well as a broad range of other activities. For example, according to the Draft Solar Energy Programmatic Environmental Impact Statement (BLM and DOE, 2010), the BLM-administered land area considered potentially available for solar development in six western states is about 87,000 square kilometers, with approximately one percent (866 square kilometers) needed to produce the 24,000 megawatts of power that would be generated over the 20-year period of the study. Another 8,000 megawatts could be produced on approximately 287 square kilometers in these same six states. NREL (2004) estimated that approximately 40,470 square kilometers of land would be required to meet all U.S. electricity demand using photovoltaic solar technology.

These values can be compared with the 430,830 square kilometers that Wigmosta et al. (2011) estimated would be needed nationwide to produce 220 billion liters per year of algal biofuels. Some of the general characteristics that make land desirable for solar development (for example, slope less than 5 percent and high insolation) are similar to the characteristics that make land desirable for algal biofuel production systems. Although the total land requirements are different, the similarities in desirable site characteristics suggest the importance of considering the possibility of competing solar-power development when evaluating the potential cumulative effects of algal biofuel production.

The Solar PEIS also notes ongoing and reasonably foreseeable future activities in its six-state study area (Arizona, California, Colorado, Nevada, New Mexico, and Utah) that include energy production and distribution, recreation, mineral production, military operations, grazing and rangeland management, fire management, forestry, transportation, and industrial development. A similarly broad range of activities is likely in areas that could be developed for algal biofuel production in these and other states. Further, the Solar PEIS

describes renewable energy development as “by far the largest potential new future use of rural lands” in the six-state area analyzed. Given the increasing demands for production of biofuel feedstocks in other areas of the United States, this is likely at least partly true nationally, in addition to the conversion of rural lands to suburban developments near metropolitan areas.

Large-scale production of algal biofuels in areas adjacent to land already developed for other energy sources could contribute to cumulative effects on land use, water supply, and biodiversity. Solar technologies in particular could place site-specific demands on these three factors that are similar in scale to those of algal biofuels: extensive land areas would be cleared of vegetation and maintained as such, with consequent impacts on biodiversity; solar thermal facilities require water for cooling; and all solar facilities require water for mirror or panel washing (BLM and DOE, 2010).

6.3 FRAMEWORK FOR INTEGRATED ASSESSMENT

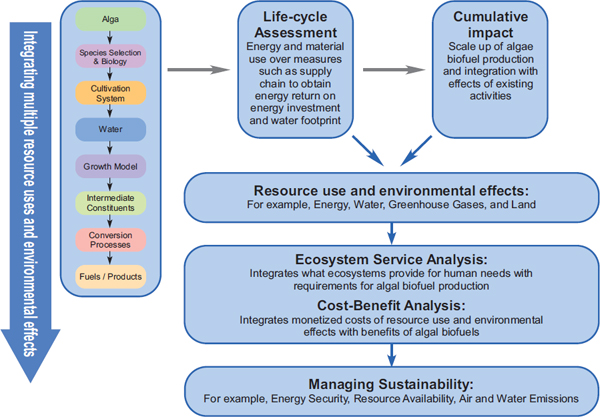

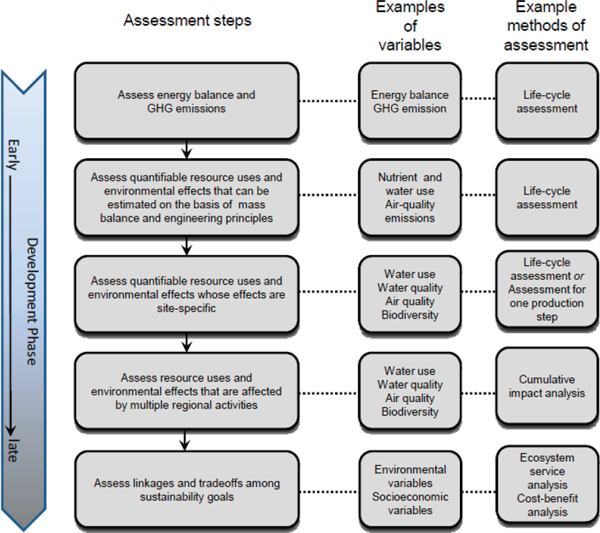

LCAs and cumulative-impact, ecosystem-service, and cost-benefit analyses each assess sustainability on a somewhat different scale and each has a role in assessing the overall sustainability of algal biofuel production systems (Figure 6-1). Therefore, the committee is not suggesting a specific cost-benefit analysis to aid decision-making processes. Instead, the committee proposes a stepwise framework that encompasses these tools at different stages of algal biofuel development (Figure 6-2) to aid the Department of Energy (DOE) in its decision-making process on sustainable development of algal biofuels. The framework

FIGURE 6-1 A diagram illustrating various tools for assessing sustainability at different scales.

FIGURE 6-2 A potential framework for assessing sustainability of algal biofuels during different stages of development.

for assessment starts with assessing two of the primary goals for developing alternative liquid fuels—improving energy security and reducing GHG emissions. Then, a few variables that reflect commonly agreed-upon sustainability objectives and that can be estimated from mass balance and engineering principles are assessed. When the industry is further along in its development, progressively comprehensive and regional assessments can be made. Data also could be collected to verify assumptions and estimates made earlier in the decision framework when the algal biofuel production systems are operating. The indicators for assessing each variable were discussed in Chapters 4 and 5.

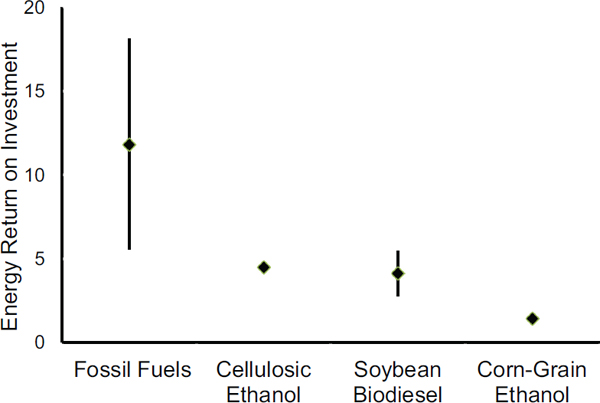

First, the energy return on investment (EROI) of less than 1 is definitely unsustainable; therefore, it is a logical first step for assessment. Specifically, a given algal biofuel production system would have to have or at least show progress toward EROI within the range of EROIs of other transportation fuels (Figure 6-3) because algal biofuels will be compared with other petroleum-based fuels and nonpetroleum-based alternatives. One of the most contentious issues associated with biofuels produced from land crops has been the level

FIGURE 6-3 Estimates of EROI for different fuels reported in the literature.

NOTE: Symbol denotes average of values reported in the literature. Line represents one standard deviation.

SOURCES: Herweyer and Gupta (2008), Grandell et al. (2009), Hall and Day (2009), and Batan (2010) for petroleum-based fuels; Lynd and Wang (2004), Sheehan et al. (2004), and Farrell (2006) for cellulosic ethanol; Herweyer and Gupta (2008), Grandell et al. (2009), Hall and Day (2009), Batan et al. (2010), and Freise (2011) for biodiesel; Kim and Dale (2005), Farrell (2006), and Hill et al. (2006) for corn-grain ethanol; Clarens et al. (2010), Jorquera et al. (2010), Sander and Murthy (2010), Stephenson et al. (2010), Brentner et al. (2011), and Vasudevan et al. (2012) for algal biodiesel.

of EROI required for sustainable production of any fuel (Pimentel and Patzek, 2005). Algal biofuels would have to return more energy in use than was required in their production to be a sustainable source of transportation. Microalgal fuels use high-value energy inputs in the form of electricity and natural gas. If these high-quality energy sources are downgraded in the production of algal fuels, it is certainly a sustainability concern that can only be truly understood through careful life-cycle analysis. (See section Energy in Chapter 4.) EROI of 1, the breakeven point, is insufficient to be considered sustainable. However, the exact threshold for sustainability is not well defined. Hall (2011) proposed that EROI greater than 3 is needed for any fuels to be considered a sustainable source. EROI can be estimated with an LCA that tracks energy and material flow (Chapter 4).

Reducing GHG emissions is another key goal in developing alternative liquid transportation fuels, and GHG emissions are closely related to energy input and output of algal biofuel production systems (Chapter 5). GHG emissions have the same effect on global climate regardless of where the GHGs are emitted. The U.S. Congress enacted the Energy Independence and Security Act of 2007 (110 P.L. 140) to improve “energy independence and security” and “to increase the production of clean renewable fuels.” If reducing GHG emissions from the transportation sector is an important goal, then the fuels displacing

petroleum-based fuels would need to have lower net GHG emissions than the fuel that they are displacing.

In addition to energy balance and GHG emissions, nitrogen and phosphorus inputs are sustainability objectives that can be assessed using LCAs based on mass balance and engineering principles. Nitrogen and phosphorus consumption by algae cultivation could compete with food production. There are opportunities to mitigate the potential competition for nutrients with agriculture, including recycling nutrients from the lipid-extracted algae and using wastewater for algae cultivation. The feasibility of using wastewater for algae cultivation has to be assessed in at least a few dimensions:

• The number of locations that could accommodate the colocation of wastewater treatment and algae cultivation facilities.

• The potential for such systems to achieve both goals of wastewater treatment and algae cultivation for fuels without much compromise.

• The feasibility beyond the laboratory scale.

The estimated EROI, GHG emissions, and nutrient requirements would have to be reassessed once the likely locations of deployment are narrowed down. Then, the productivities and any potential land-use changes can be estimated with increased certainties, and the precision of the estimated resource requirements and GHG emissions can be improved. Those variables also can be measured after deployment to verify modeled estimates and to help improve future modeling efforts.

Though some resource uses or emissions can be estimated quantitatively, their effects on the environment are location specific. Requirements for land and water are two examples. Quantitative estimates of land requirements, though necessary, have to be considered in the context of the local climatic conditions, proximity to other resources, and land prices so as to achieve economically viable production of algal biofuels. Similarly, water use (saline, brackish, or fresh water) has to be assessed over the life cycle of fuel and in the context of regional availability. Thus, a national assessment of land requirements for algae cultivation that takes into account climatic conditions; brackish, fresh water, and wastewater resources; and sources of concentrated CO2, and land prices could inform the potential amount of algal biofuels that could be produced economically in the United States. Such assessment could be done at a county-by-county resolution as in the case of the U.S. Billion-Ton Update (DOE, 2011) for biofuel feedstock. The committee cautions that the realized amount of algal biofuels produced likely will be lower than the potential amount (as in the case with other biofuels) because of many other factors associated with deployment. However, algal strain development to enhance algae’s ability to scavenge CO2 could reduce the need for concentrated CO2 as a resource constraint. Once the potential locations for algal biofuel production are identified, existing uses of land and water, including neighboring and regional activities, have to be considered to assess the cumulative impacts.

Some environmental effects cannot be assessed unless the specific location of deployment is known. Some of these effects might be easily quantifiable. Others might require research and data collection before their effects can be understood and quantified. The resource and environmental effects also have to be assessed in the context of existing activities in the sites where algal biofuel production systems are to be developed (that is, a cumulative impact analysis). As the algal biofuel industry matures, the ability of different pathways for algal biofuel production to meet and balance yield with the other environmental, economic, and social sustainability goals has to be assessed in a holistic manner.

Ecosystem service analysis and cost-benefit analysis provide methods to examine tradeoffs among sustainability goals and an integrative perspective of sustainability.

Any given tool or framework for assessing sustainability for a given fuel does not determine whether the fuel contributes to improving sustainability of the transportation sector. In fact, the report Toward Sustainable Agricultural Systems in the 21st Century (NRC, 2010) suggests that sustainability is not a particular end state, but a trajectory toward achieving a set of environmental, economic, and social goals. In the context of this report, the question is whether substituting a portion of petroleum-based fuels with algal biofuels could move the transportation sector along a trajectory toward greater sustainability with respect to each of the four goals: contributing to energy security, maintaining and enhancing the natural resource base and environmental quality, producing fuels that are economically viable, and enhancing the quality of life for society as a whole. The environmental, economic, and social effects of algal biofuel production and use have to be compared with those of petroleumbased fuels and other fuel alternatives to determine whether algal biofuels contribute to improving sustainability.

Given the four aspects of sustainability and the multiple goals within each aspect, a participatory approach is necessary to develop a collective vision of the importance of various sustainability objectives relative to each other. Stakeholders would be involved from the beginning of a sustainability assessment. Such an approach that involves different stakeholders would help ensure that tradeoffs among sustainability goals would be acceptable to the various parties.

6.4 OPPORTUNITIES FOR ALGAL BIOFUELS TO IMPROVE SUSTAINABILITY

Algal biofuels have the potential to contribute to improving the sustainability of the transportation sector, but innovations and research and development (R&D) are needed to realize their full potential. Preliminary assessments in the literature suggest that several resource use and environmental challenges likely would have to be overcome for algal biofuel production to be scaled up in a sustainable way. Suitable locations for algal biofuels could be limited by the number and area of sites that are close to a source of CO2, fresh water, brackish water, wastewater, or combination thereof. Innovations and R&D in various aspects of the supply chain will help realize much of the potential for algal biofuels to improve energy security, reduce GHG emissions, and enhance environmental quality. Algal strain development to improve biomass or lipid productivity would clearly increase fuel production per unit resource use and improve the economics of fuel production. Engineering designs to enhance algae cultivation, facilitate biomass or product collection (for example, algal lipid), and reduce processing requirements have the potential to greatly improve the energy balance, reduce GHG emissions, and enhance the overall sustainability of algal biofuels.

SUMMARY FINDING FROM THIS CHAPTER

The environmental, economic, and social effects of algal biofuel production and use have to be compared with those of petroleum-based fuels and other fuel alternatives to determine whether algal biofuels contribute to improving sustainability. Such comparison will be possible only if thorough assessments of each step in the various pathways for algal biofuel production are conducted.

Batan, L., J. Quinn, B. Willson, and T. Bradley. 2010. Net energy and greenhouse gas emission evaluation of biodiesel derived from microalgae. Environmental Science and Technology 44(20):7975-7980.

Bebbington, J., J. Brown, and B. Frame. 2007. Accounting technologies and sustainability assessment models. Ecological Economics 61(2-3):224-236.

BLM (Bureau of Land Management) and DOE (U.S. Department of Energy). 2010. Solar Energy Development Draft Programmatic Environmental Impact Statement (Draft Solar PEIS). Washington, DC: Bureau of Land Management and U.S. Department of Energy.

Brentner, L.B., M.J. Eckelman, and J.B. Zimmerman. 2011. Combinatorial life cycle assessment to inform process design of industrial production of algal biodiesel. Environmental Science and Technology 45(16):7060-7067.

Clarens, A.F., E.P. Resurreccion, M.A. White, and L.M. Colosi. 2010. Environmental life cycle comparison of algae to other bioenergy feedstocks. Environmental Science and Technology 44(5):1813-1819.

Daily, G.C., S. Polasky, J. Goldstein, P.M. Kareiva, H.A. Mooney, L. Pejchar, T.H. Ricketts, J. Salzman, and R. Shallenberger. 2009. Ecosystem services in decision making: Time to deliver. Frontiers in Ecology and the Environment 7(1):21-28.

Davis, R., A. Aden, and P.T. Pienkos. 2011. Techno-economic analysis of autotrophic microalgae for fuel production. Applied Energy 88(10):3524-3531.

DOE (U.S. Department of Energy). 2010. Algenol Integrated Biorefinery for Producing Ethanol from Hybrid Algae. Washington, DC: U.S. Department of Energy.

____________. 2011. U.S. Billion-Ton Update. Biomass Supply for a Bioenergy and Bioproducts Industry. Oak Ridge, TN: Oak Ridge National Laboratory.

Earthrise Nutritional. 2009. Earthrise. Available online at http://www.earthrise.com/. Accessed February 9, 2012.

EIA (Energy Information Adminstration). 2010. Monthly biodiesel prodcution report. Available online at http://www.eia.gov/biofuels/biodiesel/production/. Accessed June 15, 2012.

ESA (Ecological Society of America). 2008. Biofuel sustainability. Available online at http://www.esa.org/pao/policyStatements/Statements/biofuel.php. Accessed February 27, 2012.

Farrell, A.E., R.J. Plevin, B.T. Turner, A.D. Jones, M. O’Hare, and D.M. Kammen. 2006. Ethanol can contribute to energy and environmental goals. Science 311:506-508.

Freise, J. 2011. The ROI of conventional Canadian natural gas production. Sustainability 3(11):2080-2104.

Gasparatos, A., P. Stromberg, and K. Takeuchi. 2011. Biofuels, ecosystem services and human wellbeing: Putting biofuels in the ecosystem services narrative. Agriculture, Ecosystems and Environment 142(3-4):111-128.

Grandell, L., C. Hall, and M. Hook. 2009. Energy return on investment for Norwegian oil and gas in 1991-2008. Presentation to the 9th Annual ASPO conference, Brussels, Belgium on April 27-29, 2009.

Hall, C.A.S. 2011. Sustainability: Special Issue on New Studies in EROI (Energy Return on Investment). Sustainability 3:1773-1777.

Hall, C.A.S., and J.W. Day. 2009. Revisiting the limits to growth after peak oil. American Scientist 97(3):230-237.

Hanley, N., and E.B. Barbier. 2009. Pricing Nature: Cost-Benefit Analysis and Environmental Policy. Northhampton, MA: Edward Elgar Publishing Inc.

Herweyer, M.C., and A. Gupta. 2008. Unconventional Oil: Tar Sands and Shale Oil—EROI on the Web, Part 3 of 6: Appendix D Tar sands/oil sands. The Oil Drum: Net Energy. Available online at http://www.theoildrum.com/pdf/theoildrum_3839.pdf. Accessed February 15, 2012.

Hill, J., E. Nelson, D. Tilman, S. Polasky, and D. Tiffany. 2006. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proceedings of the National Academy of Sciences of the United States of America 103(30):11206-11210.

Jorquera, O., A. Kiperstok, E.A. Sales, M. Embiruçu, and M.L. Ghirardi. 2010. Comparative energy life-cycle analyses of microalgal biomass production in open ponds and photobioreactors. Bioresource Technology 101(4):1406-1413.

Kim, S., and B.E. Dale. 2005. Environmental aspects of ethanol derived from no-tilled corn grain: Nonrenewable energy consumption and greenhouse gas emissions. Biomass and Bioenergy 28(5):475-489.

Lynd, L.R., and M.Q. Wang. 2004. A product-nonspecific framework for evaluating the potential of biomass-based products to displace fossil fuels. Journal of Industrial Ecology 7(3-4):17-32.

MEA (Millennium Ecosystem Assessment). 2003. Ecosystems and Human Well-being. A Framework for Assessment. Washington, DC: World Resources Institute.

Milledge, J.J. 2011. Commercial application of microalgae other than as biofuels: A brief review. Reviews in Environmental Science and Biotechnology 10(1):31-41.

NRC (National Research Council). 2005. Valuing Ecosystem Services. Toward Better Environmental Decision-Making. Washington, DC: The National Academies Press.

____________. 2010. Toward Sustainable Agricultural Systems in the 21st Century. Washington, DC: The National Academies Press.

____________. 2011. Sustainability and the U.S. EPA. Washington, DC: The National Academies Press.

NREL (National Renewable Energy Laboratory). 2004. PV FAQs. Washington, DC: U.S. Department of Energy.

Pimentel, D., and T.W. Patzek. 2005. Ethanol production using corn, switchgrass, and wood; Biodiesel production using soybean and sunflower. Natural Resources Research 14(1):65-76.

Robertson, G.P., V.H. Dale, O.C. Doering, S.P. Hamburg, J.M. Melillo, M.M. Wander, W.J. Parton, P.R. Adler, J.N. Barney, R.M. Cruse, C.S. Duke, P.M. Fearnside, R.F. Follett, H.K. Gibbs, J. Goldemberg, D.J. Mladenoff, D. Ojima, M.W. Palmer, A. Sharpley, L. Wallace, K.C. Weathers, J.A. Wiens, and W.W. Wilhelm. 2008. Agriculture: Sustainable biofuels redux. Science 322(5898):49-50.

Sander, K., and G.S. Murthy. 2010. Life cycle analysis of algae biodiesel. International Journal of Life Cycle Assessment 15(7):704-714.

Sheehan, J., A. Aden, K. Paustian, K. Killian, J. Brenner, M. Walsh, and R. Nelson. 2004. Energy and environmental aspects of using corn stover for fuel ethanol. Journal of Industrial Ecology 7(3-4):117-146.

Simpson, D., and J. Walker. 1987. Extending cost-benefit analysis for energy investment choices. Energy Policy 15(3):217-227.

Stephenson, A.L., E. Kazamia, J.S. Dennis, C.J. Howe, S.A. Scott, and A.G. Smith. 2010. Life-cycle assessment of potential algal biodiesel production in the United Kingdom: A comparison of raceways and air-lift tubular bioreactors. Energy and Fuels 24(7):4062-4077.

Tilman, D., R. Socolow, J.A. Foley, J. Hill, E. Larson, L. Lynd, S. Pacala, J. Reilly, T. Searchinger, C. Somerville, and R. Williams. 2009. Beneficial biofuels—The food, energy, and environment trilemma. Science 325(5938):270-271.

Tredici, M.R. 2007. Mass production of microalgae: Photoreactors. Pp. 178-214 in Handbook of Microalgal Culture: Biotechnology and Applied Phycology, A. Richmond, ed. Ames, IA: Blackwell.

USDA-RD (U.S. Department of Agriculture Rural Development). 2009. Environmental Assessment for Sapphire Energy Inc.'s Integrated Algal Biorefinery (IBR) Facility in Columbus, New Mexico. Washington, DC: U.S. Department of Agriculture.

Vasudevan, V., R.W. Stratton, M.N. Pearlson, G.R. Jersey, A.G. Beyene, J.C. Weissman, M. Rubino, and J.I. Hileman. 2012. Environmental Performance of Algal Biofuel Technology Options. Environmental Science and Technology 46(4):2451-2459.

Wigmosta, M.S., A.M. Coleman, R.J. Skaggs, M.H. Huesemann, and L.J. Lane. 2011. National microalgae biofuel production potential and resource demand. Water Resources Research 47(4):W00H04.

This page intentionally left blank.